Everything You Need to Know About Dreadlock Machine Sourcing in 2025

Introduction: Navigating the Global Market for dreadlock machine

Navigating the global market for dreadlock machines presents a unique challenge for B2B buyers, particularly when sourcing reliable equipment that minimizes physical strain while maximizing efficiency. As the demand for quality dreadlock services grows across regions like Africa, South America, the Middle East, and Europe, the need for a robust understanding of the available options becomes crucial. This guide serves as a comprehensive resource, covering various types of dreadlock machines, their applications in both professional and personal settings, and essential considerations for supplier vetting.

B2B buyers will benefit from insights into pricing structures, operational capabilities, and the latest technological advancements in dreadlock machinery. We delve into the nuances of different machine models, allowing buyers to identify which features align best with their business needs. Additionally, the guide offers strategies for evaluating potential suppliers, ensuring that purchasers can make informed decisions that not only meet their operational demands but also enhance customer satisfaction.

By equipping international buyers with the knowledge they need to navigate this specialized market, this guide aims to empower businesses to invest wisely in dreadlock machines. With the right information at their fingertips, buyers can streamline their purchasing processes, reduce overhead costs, and ultimately drive profitability in their operations.

Understanding dreadlock machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Dreadlock Machine | Operated by hand, typically portable and lightweight. | Small salons, mobile stylists | Pros: Affordable, easy to transport. Cons: Labor-intensive, slower process. |

| Electric Dreadlock Machine | Motorized, offers adjustable speed and settings. | Large salons, hair extension specialists | Pros: Faster results, less physical strain. Cons: Higher upfront cost, requires power source. |

| Combination Dreadlock Machine | Combines manual and electric features for versatility. | Versatile salons, mobile services | Pros: Flexible usage, caters to various styles. Cons: Can be complex to operate, more maintenance. |

| Professional Dreadlock Machine | Designed for high-volume use, robust construction. | High-demand salons, training centers | Pros: Durable, efficient for bulk styling. Cons: Expensive, may require training for optimal use. |

| Portable Dreadlock Machine | Compact design, battery-operated for on-the-go use. | Event stylists, traveling professionals | Pros: Convenient, ideal for remote work. Cons: Limited features, shorter battery life. |

What Are the Characteristics of Manual Dreadlock Machines?

Manual dreadlock machines are typically lightweight and portable, making them ideal for small salons and mobile stylists. These machines require manual operation, which can be labor-intensive but allows for a personal touch in styling. B2B buyers should consider the affordability and ease of transport, especially for businesses with limited budgets. However, the slower process may not suit high-demand environments where efficiency is crucial.

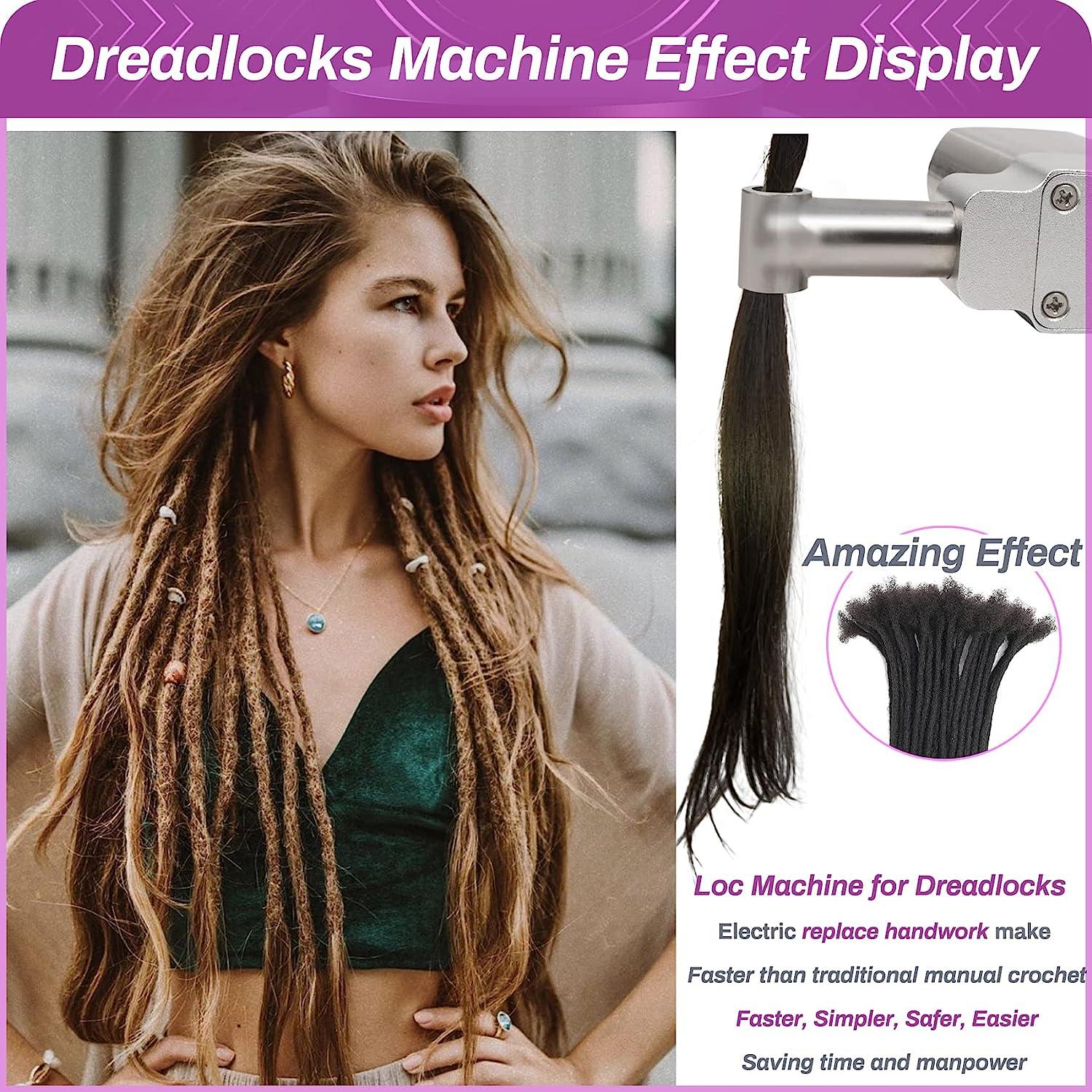

Illustrative image related to dreadlock machine

How Do Electric Dreadlock Machines Enhance Efficiency?

Electric dreadlock machines are motorized devices that offer adjustable speed settings, allowing for faster and more consistent results. These machines are particularly suited for larger salons and hair extension specialists who require efficiency without compromising quality. When purchasing, B2B buyers should weigh the initial investment against the potential for increased productivity and reduced physical strain on stylists. However, the need for a power source and higher upfront costs may be drawbacks for some businesses.

What Benefits Do Combination Dreadlock Machines Provide?

Combination dreadlock machines merge the benefits of manual and electric operation, offering versatility for various styling techniques. This type is particularly advantageous for versatile salons that cater to a diverse clientele. B2B buyers should consider how the machine’s flexibility can accommodate different styles and preferences. However, the complexity of operation and potential maintenance requirements may pose challenges for some users.

Why Choose Professional Dreadlock Machines for High-Demand Salons?

Professional dreadlock machines are designed for high-volume use, featuring robust construction to withstand the rigors of busy salons. These machines are ideal for high-demand settings and training centers, where efficiency and durability are paramount. B2B buyers should evaluate the long-term investment in terms of durability and efficiency for bulk styling. However, the higher price point and potential need for operator training may be considerations for budget-conscious businesses.

Illustrative image related to dreadlock machine

What Makes Portable Dreadlock Machines Ideal for Traveling Professionals?

Portable dreadlock machines are compact and often battery-operated, making them perfect for event stylists and traveling professionals. Their convenience allows for on-the-go styling, catering to clients in various settings. When considering a purchase, B2B buyers should assess the convenience versus the limitations in features and battery life. While these machines offer great flexibility, they may lack the power and capabilities of larger, stationary models.

Key Industrial Applications of dreadlock machine

| Industry/Sector | Specific Application of dreadlock machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hair and Beauty Salons | Creating and maintaining dreadlocks for clients | Increases service offerings and customer satisfaction | Quality of machine, ease of use, training support, and warranty |

| Textile Manufacturing | Producing synthetic dreadlocks for fashion and decor | Expands product range and meets diverse market demands | Material compatibility, machine versatility, and production speed |

| Health and Wellness | Offering dreadlock services in wellness centers | Enhances service portfolio, attracting a broader clientele | Ergonomics, training for staff, and maintenance requirements |

| Educational Institutions | Training future hairstylists in dreadlock techniques | Prepares students for a growing niche market | Availability of educational resources, machine accessibility |

| Cultural Festivals | Providing on-site dreadlock services during events | Generates additional revenue and promotes brand visibility | Portability, setup time, and adaptability to different hair types |

How is the Dreadlock Machine Used in Hair and Beauty Salons?

In hair and beauty salons, the dreadlock machine streamlines the process of creating, repairing, and thickening dreadlocks. It allows stylists to efficiently serve more clients while minimizing physical strain. This is particularly beneficial for salons in regions like Africa and the Middle East, where the demand for dreadlock styling is high. Buyers should consider the machine’s ease of use and the availability of training to ensure staff can operate it effectively and safely.

What Role Does the Dreadlock Machine Play in Textile Manufacturing?

Textile manufacturers utilize dreadlock machines to produce synthetic dreadlocks for fashion accessories and home décor. This application is crucial for businesses aiming to diversify their product lines and cater to various aesthetic preferences. When sourcing, companies should focus on the machine’s material compatibility and production speed to meet market demands efficiently, especially in competitive markets like South America and Europe.

Illustrative image related to dreadlock machine

How Can Health and Wellness Centers Benefit from Dreadlock Machines?

Health and wellness centers are increasingly incorporating dreadlock services into their offerings, utilizing dreadlock machines to provide these services efficiently. This not only enhances their service portfolio but also attracts a broader clientele interested in holistic beauty practices. Buyers in this sector should prioritize ergonomic designs to minimize strain on staff and assess training resources available to ensure quality service delivery.

Why Are Educational Institutions Investing in Dreadlock Machines?

Educational institutions, particularly those focused on cosmetology, are investing in dreadlock machines to train students in specialized hairstyling techniques. This investment helps prepare students for a growing niche market, particularly in regions with rich cultural ties to dreadlock hairstyles. Key considerations for these institutions include the availability of educational materials and the accessibility of the machines for hands-on training.

How Do Cultural Festivals Leverage Dreadlock Machines?

Cultural festivals often provide on-site dreadlock services, capitalizing on the popularity of dreadlock styles among attendees. Dreadlock machines enable quick service delivery, enhancing the festival experience and generating additional revenue for vendors. When sourcing machines for such events, portability and adaptability to different hair types are essential to meet the diverse needs of festival-goers from various backgrounds.

3 Common User Pain Points for ‘dreadlock machine’ & Their Solutions

Scenario 1: Overcoming High Operational Costs in Dreadlock Services

The Problem: Many B2B buyers in the beauty and haircare industry face significant operational costs when it comes to dreadlock services. Traditional methods can be time-consuming, requiring skilled labor that not only inflates labor costs but also limits the number of clients that can be serviced daily. This is particularly challenging for businesses in regions like Africa and South America, where margins can be tight and competition fierce. The result is often a struggle to maintain profitability while meeting client demand.

Illustrative image related to dreadlock machine

The Solution: Investing in a dreadlock machine can dramatically reduce operational costs by streamlining the dreadlock creation and maintenance process. When sourcing a dreadlock machine, buyers should prioritize models that offer versatility, allowing for various services such as creating, repairing, and thickening locs. Additionally, opting for machines that come with comprehensive training and support can ensure that staff are fully equipped to use the equipment efficiently. By calculating the return on investment (ROI) based on reduced labor hours and increased client throughput, businesses can make informed purchasing decisions that enhance profitability.

Scenario 2: Addressing Customer Satisfaction and Service Quality

The Problem: In the beauty industry, maintaining high customer satisfaction is critical. B2B buyers often encounter issues when clients are dissatisfied with the quality or speed of dreadlock services. Slow service or uneven results can lead to negative reviews, which can tarnish a salon’s reputation, especially in regions where word-of-mouth and online presence are vital for attracting new clients. As customer expectations rise, businesses must find ways to enhance service quality without sacrificing efficiency.

The Solution: Implementing a dreadlock machine can significantly improve service quality and customer satisfaction. By providing consistent results and faster service, the machine helps businesses meet and exceed client expectations. When selecting a machine, buyers should look for features that allow for customization based on hair types and styles, ensuring that each client receives a tailored experience. Additionally, investing in customer feedback mechanisms post-service can help businesses continuously refine their offerings and address any issues promptly, fostering a loyal client base.

Scenario 3: Managing Physical Strain on Stylists

The Problem: Many professionals in the beauty industry suffer from repetitive strain injuries due to the physical demands of styling hair, particularly with intricate techniques like dreadlocking. This is an acute problem for stylists who spend long hours working with their hands, leading to absenteeism and high turnover rates. For B2B buyers, the challenge lies in ensuring a healthy work environment that can retain skilled staff while providing high-quality services.

The Solution: A dreadlock machine can alleviate physical strain on stylists by automating many of the repetitive tasks involved in creating and maintaining dreadlocks. Buyers should consider machines designed ergonomically to minimize discomfort, as well as those that can handle multiple functions. Additionally, training sessions focused on best practices for using the machine can empower stylists, promoting a healthier work culture. By addressing the physical demands placed on employees, businesses not only improve retention rates but also enhance overall service quality, creating a win-win scenario for both staff and clients.

Illustrative image related to dreadlock machine

Strategic Material Selection Guide for dreadlock machine

When selecting materials for a dreadlock machine, it is crucial to consider properties that directly influence performance, durability, and suitability for various applications. Below, we analyze several common materials used in the construction of these machines, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Aluminum for Dreadlock Machines?

Aluminum is a popular choice for dreadlock machines due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating up to 400°F (204°C) and can withstand moderate pressures, making it suitable for various hair types and styling techniques.

Pros: Aluminum is durable yet lightweight, which enhances the machine’s portability. It is also relatively cost-effective, allowing manufacturers to keep production costs low.

Cons: While aluminum is strong, it can be prone to scratching and denting, potentially affecting the machine’s aesthetics over time. Additionally, its thermal conductivity may require careful handling to avoid overheating.

Impact on Application: Aluminum’s compatibility with various hair products and techniques is advantageous, as it does not react with most chemicals used in hair care.

Considerations for Buyers: International buyers should ensure that the aluminum used meets local standards, such as ASTM or DIN specifications, particularly regarding thickness and alloy composition to ensure durability and performance.

How Does Stainless Steel Compare in Terms of Durability for Dreadlock Machines?

Stainless steel is another common material, known for its exceptional strength and resistance to corrosion and rust. It can handle higher temperatures and pressures, typically rated up to 1500°F (815°C), making it suitable for intensive use in professional settings.

Pros: The durability of stainless steel means that machines made from this material have a longer lifespan, which can be a significant advantage for businesses looking to minimize replacement costs.

Cons: The primary drawback is the higher cost compared to aluminum, which may deter some buyers. Additionally, stainless steel is heavier, which can affect the machine’s portability.

Impact on Application: Its robustness allows for compatibility with high-performance hair products, ensuring that the machine can handle various styling techniques without degradation.

Considerations for Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should prioritize stainless steel options to avoid corrosion issues. Compliance with local standards for stainless steel grades is also crucial.

What Role Does Plastic Play in the Construction of Dreadlock Machines?

Plastic components are increasingly being utilized in dreadlock machines, especially in non-load-bearing parts. These plastics can be engineered for specific applications, offering flexibility and lightweight characteristics.

Pros: The main advantage of plastic is its low cost and ease of manufacturing, allowing for more complex designs without significant expense. It also provides insulation, reducing the risk of heat transfer.

Cons: However, plastics may not offer the same level of durability as metals, making them less suitable for high-stress applications. They can also degrade over time when exposed to certain chemicals.

Impact on Application: Plastic parts can be tailored to specific applications, such as ergonomic handles or lightweight covers, enhancing user experience.

Considerations for Buyers: Buyers should ensure that the plastics used comply with safety standards and are resistant to the chemicals commonly used in hair care products.

Why is Composite Material Gaining Popularity in Dreadlock Machine Design?

Composite materials, which combine multiple materials to enhance performance, are becoming increasingly popular in the design of dreadlock machines. These materials can offer the best of both worlds, combining the lightweight nature of plastics with the strength of metals.

Pros: Composites are highly durable and can be engineered to meet specific performance criteria, making them ideal for high-performance applications.

Cons: The manufacturing process for composites can be complex and costly, which may lead to higher prices for end users.

Impact on Application: Composites can be tailored to provide specific benefits, such as increased resistance to heat and chemicals, making them suitable for a wide range of hair types and products.

Considerations for Buyers: International buyers should be aware of the specific composite materials used and ensure they meet relevant international standards for safety and performance.

Illustrative image related to dreadlock machine

Summary Table of Material Selection for Dreadlock Machines

| Material | Typical Use Case for dreadlock machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame and casing components | Lightweight and cost-effective | Prone to scratching and denting | Medium |

| Stainless Steel | Structural components and tools | Exceptional durability and corrosion resistance | Higher cost and weight | High |

| Plastic | Non-load-bearing parts | Low cost and ease of manufacturing | Less durable and chemical sensitivity | Low |

| Composite | High-performance components | Tailored strength and lightweight design | Complex manufacturing process | High |

This strategic material selection guide is designed to assist international B2B buyers in making informed decisions when sourcing dreadlock machines, ensuring that they choose materials that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dreadlock machine

What Are the Key Stages in the Manufacturing Process of Dreadlock Machines?

The manufacturing of dreadlock machines involves several critical stages, each contributing to the overall performance and quality of the final product. Understanding these stages is essential for B2B buyers looking to ensure they select a reliable supplier.

Material Preparation: What Materials Are Used?

The first stage in the manufacturing process is material preparation, which typically involves selecting high-quality raw materials. Common materials used include durable plastics for the machine casing, stainless steel for internal components, and specialized wiring for electronic functions. Suppliers often source materials from reputable vendors to ensure they meet specific quality standards. For B2B buyers, it’s crucial to inquire about the origin and specifications of these materials to assess their durability and performance.

Forming: How Are Components Shaped and Crafted?

Once the materials are prepared, the next stage is forming, where raw materials are shaped into parts of the dreadlock machine. Techniques such as injection molding for plastic components and CNC machining for metal parts are commonly employed. These processes allow for precision in the manufacturing of intricate components that are essential for the machine’s functionality. Buyers should look for suppliers that utilize advanced manufacturing techniques, as these can significantly affect the machine’s reliability and efficiency.

Assembly: What Is the Assembly Process Like?

The assembly stage is critical as it involves putting together all the formed components into a fully functional machine. This stage often employs both manual and automated processes to ensure accuracy and efficiency. Skilled technicians carefully assemble the parts, ensuring that electrical connections are secure and mechanical components function smoothly. B2B buyers should inquire about the assembly practices of potential suppliers, including workforce training and the use of assembly jigs, to guarantee that the machines are built to high standards.

Finishing: What Final Touches Are Applied?

The final stage of manufacturing is finishing, which includes painting, polishing, and quality checks. This stage not only enhances the aesthetic appeal of the dreadlock machine but also adds protective coatings to increase durability. Finishing processes may also involve applying branding elements that are important for marketing. Buyers should assess whether the supplier offers customizable options in this stage, as branding can be vital for businesses looking to differentiate themselves in the market.

What Quality Control Measures Are Essential for Dreadlock Machines?

Quality control (QC) is a critical aspect of the manufacturing process that ensures the final product meets required standards and performs effectively. Understanding the QC measures in place can help B2B buyers make informed purchasing decisions.

What International Standards Should Buyers Look For?

International standards like ISO 9001 provide a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. For dreadlock machines, certifications such as CE mark (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) standards for mechanical devices may also be relevant. B2B buyers should verify that their suppliers hold these certifications, as they reflect a commitment to quality and compliance with international norms.

What Are the Key QC Checkpoints During Manufacturing?

Quality control occurs at various checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they are used in production. Effective IQC procedures can prevent defective materials from entering the production line.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC ensures that each stage meets predetermined quality criteria. This includes monitoring machinery performance and conducting regular inspections of components.

-

Final Quality Control (FQC): The last checkpoint before shipment, FQC involves comprehensive testing of the finished dreadlock machines. This may include functional testing, safety assessments, and performance evaluations to ensure compliance with specifications.

B2B buyers should inquire about the specific QC processes employed by suppliers to ensure that they are rigorous and effective.

What Testing Methods Are Commonly Used for Dreadlock Machines?

Common testing methods for dreadlock machines include:

-

Functional Testing: Verifying that the machine operates as intended, including checking the speed, effectiveness, and ease of use.

-

Durability Testing: Assessing the machine’s resilience under normal operating conditions to ensure it can withstand wear and tear over time.

-

Electrical Safety Testing: Ensuring that electrical components are safe and compliant with relevant standards, which is crucial for preventing hazards during use.

Buyers should request documentation of these tests to confirm that the machines meet safety and performance standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is paramount. Here are several strategies to ensure that potential partners maintain high standards:

What Role Do Audits and Reports Play?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. Audits can involve on-site visits to evaluate the manufacturing environment, equipment, and adherence to quality standards. Additionally, suppliers should be willing to provide quality control reports detailing their processes, test results, and any corrective actions taken.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These organizations can conduct inspections at various stages of the manufacturing process, offering detailed reports that highlight any concerns or areas for improvement. For B2B buyers, this adds an extra layer of assurance regarding the quality of the products being sourced.

What Are the Nuances in Quality Control for International Buyers?

When sourcing dreadlock machines from international suppliers, B2B buyers must be aware of potential nuances in quality control. Variations in regulatory requirements, cultural practices, and manufacturing capabilities can impact product quality. Buyers should familiarize themselves with local standards in the countries they are sourcing from and consider working with suppliers who have experience in international trade. Establishing clear communication channels and expectations regarding quality can also help mitigate risks associated with sourcing from diverse regions.

In conclusion, understanding the manufacturing processes and quality assurance measures for dreadlock machines is essential for B2B buyers. By focusing on the key stages of manufacturing, quality control checkpoints, and verification strategies, businesses can make informed decisions that lead to successful partnerships and high-quality products.

Illustrative image related to dreadlock machine

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dreadlock machine’

This guide serves as a comprehensive checklist for B2B buyers interested in sourcing a dreadlock machine. By following these steps, you can ensure a well-informed purchasing decision that aligns with your business needs and operational goals.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s essential to outline the specific requirements for the dreadlock machine. Consider factors such as the machine’s capacity, speed, and compatibility with different hair types. Knowing your specifications will help you narrow down suppliers and avoid unsuitable options.

- Capacity: How many locs can the machine create or repair in an hour?

- Compatibility: Is the machine suitable for various hair textures and types?

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Look for manufacturers and distributors with a strong reputation in the dreadlock industry. Utilize online platforms and industry directories to gather a list of candidates.

Illustrative image related to dreadlock machine

- Industry Reviews: Check online reviews and testimonials to gauge supplier reliability.

- Networking: Attend trade shows or industry events to connect with suppliers directly.

Step 3: Evaluate Supplier Certifications

Certifications can indicate a supplier’s commitment to quality and safety standards. Verify if the supplier holds relevant certifications such as ISO or compliance with local regulations. This step is crucial to ensure that the machine meets industry standards and can be trusted for professional use.

- Quality Assurance: Ask for documentation that demonstrates compliance with international manufacturing standards.

- Safety Standards: Ensure the machine adheres to safety regulations, especially if used in a salon environment.

Step 4: Request Product Samples

Before making a significant investment, request samples of the dreadlock machine or its components. Testing the machine can provide insights into its functionality, ease of use, and durability.

- Trial Period: Inquire if the supplier offers a trial period for you to assess the machine in a real-world setting.

- Demonstrations: Arrange for a live demonstration to see the machine in action.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure you understand all costs involved, including shipping and customs duties, particularly for international transactions.

- Bulk Discounts: Ask about pricing for bulk purchases to maximize savings.

- Warranty and Service: Clarify warranty terms and after-sales support to safeguard your investment.

Step 6: Assess After-Sales Support

After purchasing the machine, the relationship with your supplier should continue. Evaluate the supplier’s after-sales support, including maintenance, repairs, and availability of spare parts. A reliable support system can significantly impact your operational efficiency.

- Customer Service: Verify if the supplier offers prompt customer service for troubleshooting.

- Parts Availability: Ensure that spare parts are readily available to minimize downtime.

Step 7: Finalize Your Purchase

Once all evaluations are complete and negotiations are satisfactory, finalize your purchase. Ensure that all agreements are documented and signed to protect your interests.

- Purchase Agreement: Review the terms of sale carefully before signing.

- Shipping Arrangements: Confirm shipping details and estimated delivery times to plan your operations accordingly.

By following this practical sourcing checklist, you can make an informed decision when procuring a dreadlock machine, ensuring that it meets your business needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for dreadlock machine Sourcing

What Are the Key Cost Components in Dreadlock Machine Production?

When sourcing dreadlock machines, understanding the cost structure is crucial for B2B buyers. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials typically comprise the mechanical and electronic components required for the machine. High-quality materials may increase the initial cost but can enhance durability and performance, making them a worthwhile investment.

Illustrative image related to dreadlock machine

Labor costs encompass the wages paid to workers involved in manufacturing and assembling the machines. Regions with lower labor costs, such as parts of Africa and South America, may provide competitive advantages in pricing.

Manufacturing overhead includes indirect costs such as utilities, rent, and administrative expenses associated with the production facility. It is essential to evaluate how these costs are allocated when assessing the total price.

Tooling involves the initial setup costs for production, including molds and specialized equipment. These costs can vary significantly based on the complexity of the machine design.

Quality Control is vital for ensuring the machines meet industry standards and customer expectations. Investing in rigorous QC processes may increase upfront costs but can reduce long-term warranty claims and customer dissatisfaction.

Illustrative image related to dreadlock machine

Logistics costs involve transportation and handling fees associated with moving the machines from the manufacturer to the buyer. International shipping can add significant costs, especially if the machines are bulky or require special handling.

Lastly, the margin represents the profit the manufacturer aims to achieve. This can vary widely based on market demand, competition, and the perceived value of the machine.

How Do Price Influencers Affect Dreadlock Machine Sourcing?

Several factors can influence the pricing of dreadlock machines, particularly for international B2B buyers. Volume and Minimum Order Quantity (MOQ) play significant roles; larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating for better rates on larger quantities.

Specifications and customization can also impact pricing. Machines that are tailored to specific needs may require additional design and engineering work, thereby increasing costs.

Material quality and certifications are critical for ensuring the machines meet safety and performance standards. Machines with certifications may command higher prices but offer peace of mind regarding compliance with industry regulations.

Illustrative image related to dreadlock machine

Supplier factors such as reputation, reliability, and previous customer reviews can also influence pricing. Established suppliers may charge a premium for their products due to their proven track record.

Understanding Incoterms is essential for international transactions, as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms can help buyers avoid unexpected costs.

What Buyer Tips Can Enhance Cost-Efficiency in Dreadlock Machine Sourcing?

For B2B buyers, effective negotiation strategies can significantly impact the overall cost of sourcing dreadlock machines. Buyers should be prepared to discuss volume discounts, payment terms, and delivery schedules to achieve a favorable agreement.

Assessing the Total Cost of Ownership (TCO) is crucial. This includes not only the purchase price but also maintenance, operational costs, and potential downtime. Investing in higher-quality machines may lead to lower long-term costs, making them a better choice despite a higher initial price.

Buyers should be aware of pricing nuances specific to their regions. For instance, import duties and taxes can vary widely between Africa, South America, the Middle East, and Europe, affecting the final cost.

It’s important to note that while indicative prices can provide a starting point for negotiations, they can fluctuate based on market conditions, material availability, and currency exchange rates. Buyers should conduct thorough market research and maintain flexibility in their sourcing strategy to adapt to these changes.

Alternatives Analysis: Comparing dreadlock machine With Other Solutions

Understanding Alternatives for Dreadlock Solutions

In the diverse landscape of hair care, particularly within the context of dreadlock creation and maintenance, various methods and technologies exist. The dreadlock machine is a modern solution that has garnered attention for its efficiency and effectiveness. However, it’s essential for B2B buyers to explore alternative methods and products to determine the best fit for their business needs. This analysis will compare the dreadlock machine against two other viable solutions: manual dreadlock techniques and crochet hooks.

Comparison Table

| Comparison Aspect | Dreadlock Machine | Manual Dreadlock Techniques | Crochet Hooks |

|---|---|---|---|

| Performance | High; consistent results | Variable; skill-dependent | Moderate; technique-dependent |

| Cost | Medium; initial investment | Low; minimal investment | Low; affordable tools |

| Ease of Implementation | High; user-friendly | Low; requires training | Medium; requires practice |

| Maintenance | Low; minimal upkeep | Medium; depends on tools used | Low; minimal upkeep |

| Best Use Case | High-volume salons | Individual styling | DIY and small salons |

Detailed Breakdown of Alternatives

Manual Dreadlock Techniques

Manual techniques involve the traditional methods of creating dreadlocks, such as twisting and palm rolling. While this approach can yield beautiful and unique results, it heavily relies on the stylist’s skill level and experience. Pros include low initial costs and the ability to create customized looks tailored to individual clients. However, the cons include longer application times and potential variability in results, making it less suitable for high-volume settings.

Crochet Hooks

Using crochet hooks for dreadlock maintenance and creation is another popular method. This technique allows for the tightening and repair of existing locs and can also be used for initial dreadlock formation. The advantages of crochet hooks include their affordability and versatility, as they can be used for various hair types. Nonetheless, the technique can be challenging for novices and requires practice to achieve the desired results. While it is a viable option for smaller salons or DIY enthusiasts, it may not be the best choice for businesses looking to scale operations efficiently.

Conclusion: How to Choose the Right Dreadlock Solution

When selecting the appropriate dreadlock solution, B2B buyers should consider their specific business needs, including client volume, skill levels, and desired outcomes. The dreadlock machine stands out for its efficiency and user-friendliness, making it ideal for high-volume salons aiming to provide consistent results with minimal physical strain on stylists. In contrast, manual techniques and crochet hooks may cater to niche markets or smaller operations focused on personalized services. Ultimately, understanding the pros and cons of each solution will empower buyers to make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for dreadlock machine

What are the Essential Technical Properties of a Dreadlock Machine?

Understanding the technical specifications of a dreadlock machine is crucial for B2B buyers looking to invest in equipment that meets their operational needs. Here are some key properties to consider:

-

Material Grade

The material grade of a dreadlock machine often refers to the quality and durability of the components used in its construction. Common materials include stainless steel and high-grade plastics, which are resistant to wear and corrosion. A higher material grade typically indicates a longer lifespan and less maintenance, essential for businesses that rely on consistent performance. -

Motor Power

Motor power is a critical specification that impacts the machine’s efficiency and capability. Measured in watts or horsepower, a more powerful motor can handle thicker or more complex hair types without overheating. For B2B buyers, selecting a machine with adequate motor power ensures faster processing times and reduced operational delays, which is vital in high-demand environments. -

Speed Settings

Dreadlock machines often come with adjustable speed settings, allowing users to customize the operation based on hair texture and desired results. This flexibility is important for salons and barbershops that cater to diverse clientele. A machine with multiple speed settings can enhance service quality and customer satisfaction. -

Weight and Portability

The weight of the dreadlock machine is significant, especially for businesses that may need to move equipment between locations or for mobile services. A lightweight design can facilitate easier transport without compromising stability during use. For international buyers, considering the portability of the machine can also impact shipping costs and logistics. -

User Interface

An intuitive user interface is essential for ease of operation, especially for new users. Machines equipped with digital displays and straightforward controls can reduce training time and improve workflow efficiency. A user-friendly interface is particularly beneficial for businesses with high staff turnover or those training new employees frequently.

What Trade Terminology Should B2B Buyers of Dreadlock Machines Know?

Familiarity with industry-specific terminology can greatly enhance communication and negotiation processes. Here are some commonly used terms relevant to dreadlock machines:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality manufacturers and ensure they are sourcing reputable products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan inventory and manage cash flow effectively. It is particularly relevant for businesses looking to stock multiple machines or replacement parts. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and other details from suppliers. This term is important for B2B transactions, as it helps buyers compare offers and negotiate better terms before making a purchase. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international trade. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery timelines, which are crucial for cross-border transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses that rely on dreadlock machines for their operations, understanding lead times can help in planning and minimizing downtime. -

Warranty and Service Agreement

These terms refer to the commitments made by the manufacturer regarding the repair and maintenance of the machine. A solid warranty and service agreement can provide peace of mind for buyers, ensuring that they have support in case of equipment failure.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing dreadlock machines, ultimately improving their operational efficiency and service quality.

Illustrative image related to dreadlock machine

Navigating Market Dynamics and Sourcing Trends in the dreadlock machine Sector

What Are the Key Trends Shaping the Dreadlock Machine Market?

The dreadlock machine sector is experiencing notable growth driven by several global factors, particularly among international B2B buyers in regions such as Africa, South America, the Middle East, and Europe. The increasing popularity of dreadlocks and other natural hairstyles is pushing demand for efficient hair styling tools. As a result, manufacturers are innovating with advanced technologies to create machines that not only enhance productivity but also reduce physical strain on hair professionals.

Emerging trends include the integration of automation and AI in the dreadlock machine design, allowing for more precision and less manual effort. Additionally, the rise of e-commerce platforms is reshaping how businesses source these machines, providing easier access to suppliers and facilitating international trade. B2B buyers are now looking for suppliers who can offer not only competitive pricing but also robust after-sales support, warranty options, and comprehensive training on machine usage.

Furthermore, as consumer preferences shift towards sustainable practices, the demand for eco-friendly dreadlock machines is on the rise. This trend is prompting manufacturers to explore sustainable materials and production processes, which can significantly influence sourcing decisions for international buyers.

How Does Sustainability Impact Sourcing in the Dreadlock Machine Sector?

Sustainability is becoming an essential consideration in the dreadlock machine sector, particularly for B2B buyers who are increasingly aware of environmental impacts. The production of dreadlock machines can contribute to waste and pollution if not managed responsibly. Buyers are encouraged to seek suppliers who demonstrate commitment to ethical sourcing and sustainable practices.

Illustrative image related to dreadlock machine

Ethical supply chains not only enhance brand reputation but also mitigate risks associated with environmental regulations and consumer backlash. B2B buyers should look for manufacturers that utilize green certifications, which indicate adherence to sustainability standards, and those that employ recyclable or biodegradable materials in their products.

Moreover, the incorporation of sustainable practices in the supply chain can lead to cost savings in the long term. By minimizing waste and optimizing resource use, businesses can enhance their operational efficiency and reduce their carbon footprint. This trend not only aligns with global sustainability goals but also appeals to a growing segment of environmentally conscious consumers.

What Is the Evolution of the Dreadlock Machine and Its Significance for B2B Buyers?

The dreadlock machine has evolved significantly over the years, transitioning from manual tools to sophisticated, automated devices. Initially designed for basic styling, modern dreadlock machines now incorporate advanced technology that allows for the creation, maintenance, and repair of locs with minimal physical strain on hair professionals. This evolution has been driven by the increasing demand for high-quality and efficient hair care solutions.

For B2B buyers, understanding the historical context of dreadlock machines is crucial. It provides insights into the technological advancements that have shaped current products and informs sourcing decisions. Buyers can leverage this knowledge to assess which features and specifications align with their business needs, ensuring they invest in machines that enhance productivity and meet evolving market demands.

In summary, the dreadlock machine sector is poised for growth, influenced by market dynamics, sustainability considerations, and technological advancements. B2B buyers must navigate these trends to make informed sourcing decisions that align with their operational goals and customer expectations.

Illustrative image related to dreadlock machine

Frequently Asked Questions (FAQs) for B2B Buyers of dreadlock machine

-

1. How do I select the right dreadlock machine for my business needs?

Choosing the right dreadlock machine depends on your specific requirements, such as production volume, hair type, and desired features. Assess machines based on their ability to create, repair, and thicken locs effectively. Consider factors like ease of use, maintenance requirements, and ergonomic design to reduce physical strain on your staff. Additionally, seek machines that offer versatility, allowing for different techniques and styles, which can help cater to a wider clientele. -

2. What are the customization options available for dreadlock machines?

Many suppliers offer customization options to tailor dreadlock machines to your business’s unique needs. Customizations may include different attachments for various hair types, adjustable speed settings, and specific design features that enhance usability. Before finalizing a purchase, discuss your requirements with the manufacturer to explore available modifications. This ensures the machine aligns with your operational processes and meets customer expectations. -

3. What is the minimum order quantity (MOQ) for dreadlock machines?

The MOQ for dreadlock machines can vary significantly between manufacturers. Typically, MOQs can range from one unit for smaller suppliers to several units for larger manufacturers. It’s essential to clarify the MOQ before engaging in negotiations. Understanding this will help you gauge initial investment costs and assess whether the supplier can meet your scaling needs as your business grows. -

4. What payment terms should I expect when purchasing a dreadlock machine?

Payment terms for dreadlock machines can vary by supplier and region. Common arrangements include upfront payment, partial payment upon order confirmation, and the balance before shipment. Some suppliers may offer financing options or extended payment terms for bulk orders. Always clarify the payment structure in advance to avoid misunderstandings and ensure that it aligns with your cash flow management strategy. -

5. How can I ensure quality assurance for dreadlock machines?

To ensure quality assurance, request detailed product specifications and certifications from potential suppliers. Look for machines that have passed international quality standards, such as ISO certifications. Additionally, inquire about the supplier’s warranty and return policy, which can provide insights into their commitment to product quality. If possible, arrange for a product demonstration or trial period to assess performance before committing to a larger order. -

6. What logistics considerations should I keep in mind when importing dreadlock machines?

When importing dreadlock machines, consider shipping methods, customs duties, and delivery timelines. Determine whether the supplier handles logistics or if you will need to engage a freight forwarder. Ensure you have all necessary import permits and are aware of local regulations regarding machinery imports. Understanding these logistics will help you streamline the process and avoid unexpected delays or costs. -

7. Are there any specific certifications or regulations for dreadlock machines in my country?

Each country may have its own regulations and certifications regarding the import and use of machinery, including dreadlock machines. Research local compliance requirements, such as safety standards and electrical certifications. Engaging with a local import/export consultant can provide valuable insights into these regulations, ensuring that your equipment meets all necessary legal obligations and avoids any potential fines or delays. -

8. How can I effectively vet suppliers of dreadlock machines?

To effectively vet suppliers, start by researching their reputation through online reviews and industry forums. Request references from previous clients to gauge their experiences. Assess the supplier’s production capabilities, lead times, and customer service responsiveness. Additionally, consider visiting their facility if possible or conducting virtual meetings to establish a rapport. This thorough vetting process will help you select a reliable partner for your dreadlock machine needs.

A Look at Dreadlock Machine Manufacturers & Suppliers

Could not verify enough suppliers for dreadlock machine to create a list at this time.

Strategic Sourcing Conclusion and Outlook for dreadlock machine

In the evolving landscape of haircare technology, the dreadlock machine stands out as a vital asset for professionals aiming to enhance service efficiency and client satisfaction. By strategically sourcing these machines, businesses can address the growing demand for quick and effective dreadlock creation, maintenance, and extensions. The ergonomic design of these machines not only alleviates the physical strain on stylists but also allows them to offer a wider range of services, catering to diverse hair types and textures.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, embracing this technology can significantly improve operational workflows and customer retention. Investing in high-quality dreadlock machines will enable salons and barbershops to position themselves as leaders in the haircare industry, ultimately driving profitability and growth.

As the market for dreadlock services continues to expand, now is the time to evaluate your sourcing strategies. Engage with suppliers who understand the unique needs of your clientele and can provide tailored solutions. By prioritizing strategic sourcing, you can ensure your business remains competitive and responsive to the evolving demands of your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.