Everything You Need to Know About Door Latches With Locks Sourcing in 2025

Introduction: Navigating the Global Market for door latches with locks

In an increasingly interconnected global market, sourcing high-quality door latches with locks presents a significant challenge for B2B buyers. As security concerns rise alongside the demand for durable and reliable hardware, understanding the nuances of this product category becomes essential. This guide serves as a comprehensive resource, detailing various types of door latches, their applications in residential and commercial settings, and the critical aspects of supplier vetting. Buyers will gain insights into cost considerations, compliance with international standards, and the latest trends in design and functionality.

With a focus on international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—this guide aims to empower purchasing decisions through informed analysis. By exploring the diverse options available, from electronic keyless systems to traditional deadbolts, businesses can identify solutions that meet their specific security needs and aesthetic preferences. Additionally, the guide emphasizes best practices in supplier selection, ensuring that buyers align with manufacturers who prioritize quality, sustainability, and innovation.

As the landscape of door hardware continues to evolve, understanding these elements will enable buyers to navigate the complexities of the global market effectively. Equip yourself with the knowledge necessary to make strategic purchasing decisions that enhance security and drive business success.

Understanding door latches with locks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Deadbolt Latch | High security, requires a key for locking | Commercial buildings, residential properties | Pros: Enhanced security; Cons: More expensive than standard latches. |

| Electronic Keyless Latch | Keyless entry, programmable codes | Hotels, office buildings | Pros: Convenience and flexibility; Cons: Requires power source and maintenance. |

| Privacy Latch | Allows locking from the inside only | Residential bathrooms, offices | Pros: Simple to use; Cons: Limited security from outside access. |

| Surface-Mounted Latch | Easy installation, visible hardware | Industrial applications, temporary setups | Pros: Quick installation; Cons: Less secure than mortised options. |

| Drive-In Latch | No faceplate required, adjustable backset | Residential doors without mortised edges | Pros: Versatile for various door types; Cons: May not fit all door styles. |

What Are the Key Characteristics of Deadbolt Latches for B2B Buyers?

Deadbolt latches are renowned for their robust security features, making them a preferred choice for commercial buildings and residential properties. They operate by extending a metal bolt into the door frame, which can only be retracted with a key or thumb turn. B2B buyers should consider the grade of the deadbolt, as higher grades indicate better resistance to forced entry. While they offer superior protection, the cost may be higher compared to standard latches, which is a crucial factor for budget-conscious buyers.

How Do Electronic Keyless Latches Enhance Security and Convenience?

Electronic keyless latches provide a modern solution for access control, allowing users to enter via a keypad or mobile app. These latches are ideal for hotels and office buildings, where ease of use and security are paramount. B2B buyers should evaluate the technology behind these systems, such as battery life and programming capabilities. While they offer significant convenience and can reduce the need for physical keys, the reliance on power sources and potential for technical issues may deter some buyers.

In What Situations Are Privacy Latches Most Suitable?

Privacy latches are designed for interior use, allowing users to lock doors from the inside without external access. Commonly used in residential bathrooms and offices, these latches provide a balance between privacy and ease of use. B2B buyers should consider the latch’s durability and ease of installation. While they are cost-effective, privacy latches do not offer the same level of security as deadbolts, which may be a consideration for high-security environments.

What Advantages Do Surface-Mounted Latches Offer for Temporary Installations?

Surface-mounted latches are straightforward to install and are visible on the door’s surface. They are often used in industrial applications or temporary setups where quick access is needed. B2B buyers should assess the latch’s material and build quality, as these factors influence longevity and security. Although they are easy to install, surface-mounted latches may not provide the same level of security as mortised options, which can be a drawback for some applications.

How Do Drive-In Latches Provide Versatility for Different Door Types?

Drive-in latches are designed for doors that do not have mortised edges, making them versatile for various residential applications. They feature an adjustable backset, allowing for installation on different door types without extensive modifications. B2B buyers should consider the compatibility with their door styles and the latch’s material for durability. While they are adaptable, drive-in latches may not fit all door styles, which could limit their applicability in certain projects.

Key Industrial Applications of door latches with locks

| Industry/Sector | Specific Application of door latches with locks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Securing factory entrances and sensitive areas | Enhances security, prevents unauthorized access | Compliance with local regulations, durability, and fire ratings |

| Healthcare | Locking access to patient rooms and medication storage | Protects patient privacy and medication integrity | Must meet health and safety standards, ease of use for staff |

| Hospitality | Controlling access to guest rooms and service areas | Improves guest security and enhances customer experience | Aesthetic appeal, keyless options, and durability |

| Logistics and Warehousing | Securing storage facilities and delivery areas | Reduces theft and ensures inventory security | Weather resistance, ease of installation, and maintenance needs |

| Education | Locking classrooms and administrative offices | Protects student safety and sensitive information | Compliance with safety codes, user-friendly mechanisms |

How Are Door Latches with Locks Utilized in Manufacturing?

In the manufacturing sector, door latches with locks are critical for securing factory entrances and sensitive areas, such as control rooms or equipment storage. These latches not only deter unauthorized access but also enhance the overall security of valuable assets. Businesses must consider local regulations regarding safety and security, ensuring that the latches are durable enough to withstand industrial wear and tear, and may also require fire-rated options for compliance.

What Role Do Door Latches with Locks Play in Healthcare Settings?

In healthcare facilities, door latches with locks are essential for locking patient rooms and medication storage areas. They help maintain patient privacy and protect sensitive medical supplies from unauthorized access. Buyers in this sector need to ensure that the latches comply with health and safety standards, are easy for staff to operate, and provide reliable security without compromising patient care. The ability to integrate keyless entry systems is increasingly beneficial for managing access efficiently.

How Do Door Latches with Locks Enhance Security in Hospitality?

The hospitality industry utilizes door latches with locks to control access to guest rooms and service areas, significantly improving guest security and enhancing the overall customer experience. These latches need to be aesthetically pleasing while also providing robust security features. Buyers should consider options that include keyless entry systems for convenience, durability to withstand frequent use, and designs that complement the hotel’s décor.

Why Are Door Latches with Locks Important in Logistics and Warehousing?

In logistics and warehousing, door latches with locks are vital for securing storage facilities and delivery areas, thus reducing the risk of theft and ensuring the safety of inventory. Businesses in this sector should prioritize latches that are weather-resistant and easy to install, as well as those that require minimal maintenance. Additionally, understanding the specific security needs of different storage environments can guide buyers in selecting the most suitable latch solutions.

What Are the Key Considerations for Door Latches with Locks in Educational Institutions?

Educational institutions use door latches with locks to secure classrooms and administrative offices, thereby protecting student safety and sensitive information. It is crucial for these latches to comply with safety codes and be user-friendly, allowing for quick access in emergencies. Buyers should focus on latches that offer a balance between security and ease of use, ensuring that they can be operated effectively by both staff and students in various situations.

3 Common User Pain Points for ‘door latches with locks’ & Their Solutions

Scenario 1: Difficulty in Meeting Local Security Standards

The Problem: B2B buyers, particularly those supplying commercial properties in regions like the Middle East and Africa, often face stringent local security regulations. These regulations might specify particular grades of locks or require that latches meet certain fire safety standards. For instance, a company might discover that the door latches with locks they initially selected do not comply with local laws, leading to costly delays, reordering, or even legal repercussions. This situation is further complicated when suppliers lack clear documentation or certifications to prove compliance, leaving buyers frustrated and at risk.

The Solution: To navigate these challenges, B2B buyers should prioritize sourcing door latches with locks from reputable manufacturers who provide comprehensive documentation regarding compliance with local standards. Before making a purchase, conduct thorough research on the security regulations specific to the country or region you are operating in. It’s also advisable to engage with local experts or consultants who can provide insights into the requirements. When evaluating suppliers, ask for certifications like UL ratings for fire resistance or ANSI grades for security assurance. This proactive approach will not only save time and money but also ensure that your projects meet the necessary legal and safety requirements.

Scenario 2: Incompatibility with Existing Door Hardware

The Problem: Many B2B buyers encounter compatibility issues when sourcing door latches with locks that need to work seamlessly with existing door hardware. This is particularly prevalent in older buildings or when retrofitting new systems onto existing structures. For example, a contractor may purchase a batch of latches only to find that they do not fit the pre-drilled holes or the latch types already in place, leading to delays and increased labor costs as adjustments are required.

The Solution: To mitigate this risk, buyers should conduct a thorough assessment of the existing door hardware before sourcing new latches. Measurements should be taken, including the backset (the distance from the edge of the door to the center of the lock) and the thickness of the doors. Buyers should also consider adjustable latches, which can fit a range of door thicknesses and configurations. When dealing with older buildings, it may be beneficial to consult with manufacturers that offer customizable solutions or have a wide range of products that can accommodate various existing setups. This way, you ensure that the new latches will integrate smoothly, minimizing installation issues.

Scenario 3: Lack of Durability in Extreme Conditions

The Problem: Buyers operating in regions with extreme weather conditions—such as high humidity in South America or sand and dust in the Middle East—often find that standard door latches with locks fail to perform adequately. This can lead to rust, malfunction, or overall degradation of the hardware, resulting in increased maintenance costs and security vulnerabilities. For example, a retailer in a humid coastal area might discover that their chosen latch has corroded within months of installation, jeopardizing the safety of their inventory.

The Solution: To address durability concerns, it is essential to select door latches with locks that are specifically designed for extreme environmental conditions. Stainless steel or marine-grade materials are often more resistant to corrosion and wear. When sourcing, buyers should inquire about the finish and materials used in the construction of the latches. Additionally, consider latches with protective coatings that resist moisture and dust infiltration. Engaging with suppliers who specialize in hardware for specific environmental conditions will provide access to products that offer enhanced durability, ensuring long-term performance and reliability. This foresight can significantly reduce the total cost of ownership by minimizing replacement frequency and maintenance efforts.

Strategic Material Selection Guide for door latches with locks

What Are the Key Materials Used in Door Latches with Locks?

When selecting materials for door latches with locks, it’s essential to consider the specific properties and performance characteristics of each material. This guide analyzes four common materials used in the manufacturing of door latches, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform as a Material for Door Latches?

Steel, particularly stainless steel, is a prevalent choice for door latches due to its strength and durability. Key properties include high tensile strength, excellent corrosion resistance, and the ability to withstand significant pressure and temperature variations.

Pros: Steel latches are robust, making them suitable for high-traffic areas and environments where security is paramount. They also have a relatively low manufacturing complexity, allowing for efficient production.

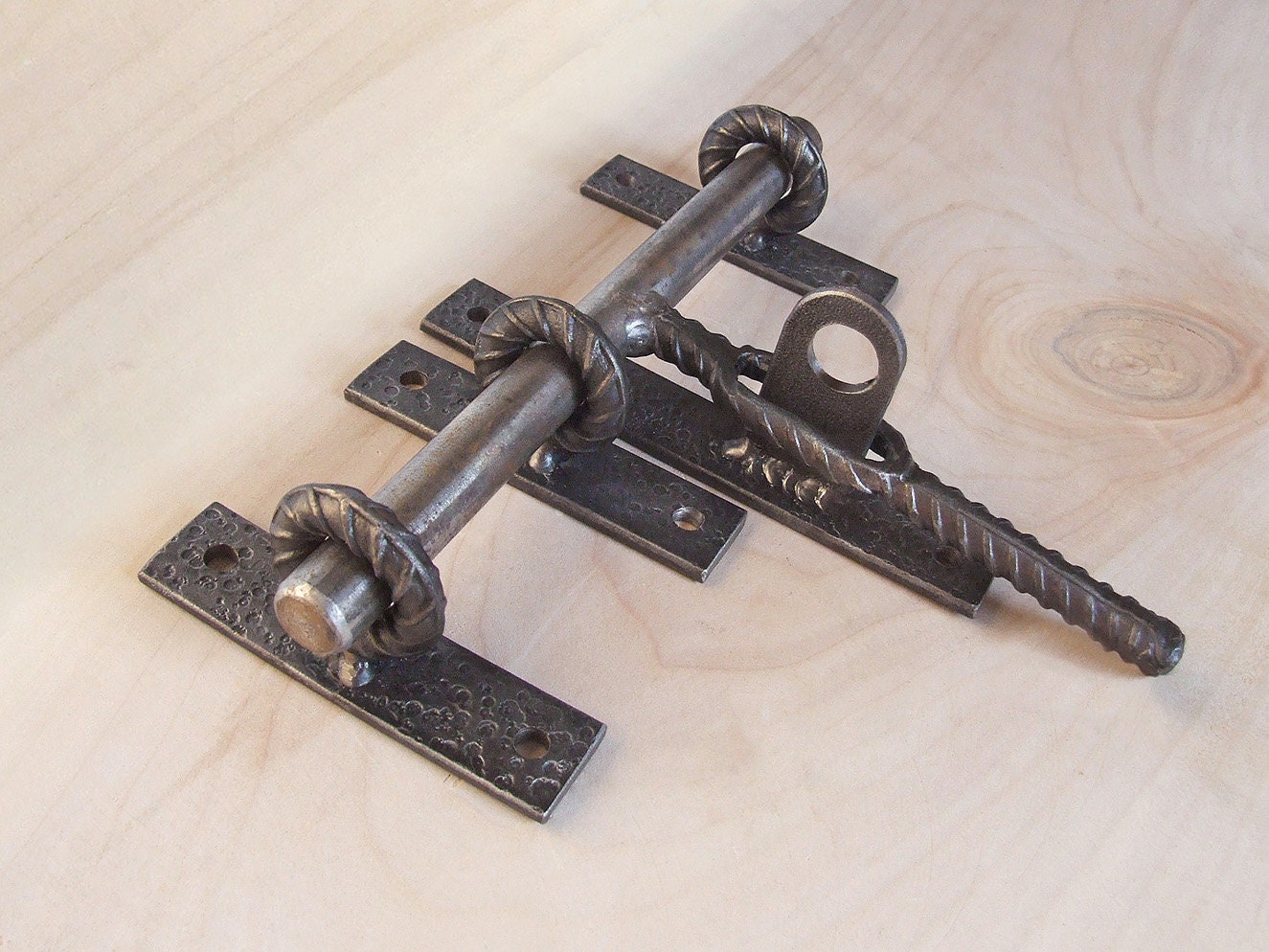

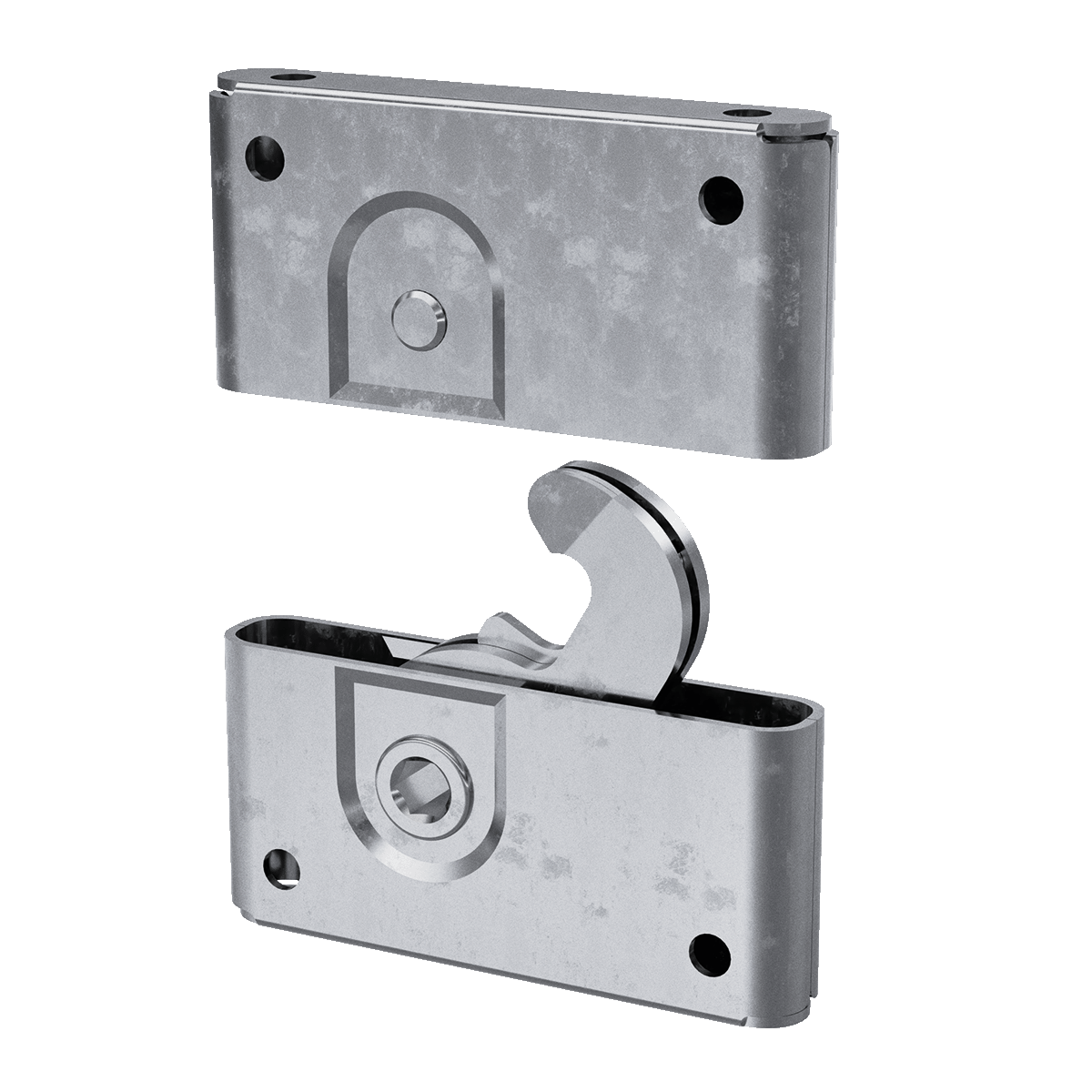

Illustrative image related to door latches with locks

Cons: However, steel can be heavier than other materials, which may not be suitable for all applications. Additionally, while stainless steel is corrosion-resistant, it can still rust if not properly maintained, especially in humid climates.

Impact on Application: Steel latches are ideal for commercial settings where durability is essential, but they may not be the best choice for coastal areas without proper treatment due to potential corrosion.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as EN 1670 for corrosion resistance. In Africa and South America, local environmental conditions may necessitate additional protective coatings.

Illustrative image related to door latches with locks

What Advantages Does Zinc Alloy Offer for Door Latches?

Zinc alloy is another common material used for door latches, known for its good balance of strength and weight. The alloy typically includes aluminum, copper, and magnesium, enhancing its mechanical properties.

Pros: Zinc alloy latches are lightweight yet strong, making them easy to install and handle. They also offer good corrosion resistance and can be easily cast into complex shapes, allowing for innovative designs.

Cons: The main limitation of zinc alloy is its lower strength compared to steel, which may not be suitable for high-security applications. Additionally, zinc alloys can be more expensive than basic steel options.

Impact on Application: These latches are often used in residential applications or light commercial use where aesthetic design is a priority over maximum security.

Considerations for International Buyers: Compliance with ASTM standards is crucial, especially for buyers in the U.S. and Europe. In regions like the Middle East, consideration of local climatic conditions is essential to ensure long-term performance.

Why is Plastic a Viable Option for Door Latches?

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is increasingly used in door latch applications, especially in environments where weight and corrosion resistance are critical.

Pros: Plastic latches are lightweight, resistant to corrosion, and can be produced at a lower cost. They are also non-conductive, making them suitable for electronic locking mechanisms.

Illustrative image related to door latches with locks

Cons: However, plastic may not provide the same level of security as metal options, making them less suitable for high-security applications. They can also be less durable under extreme temperatures.

Impact on Application: Plastic latches are ideal for interior doors or applications where aesthetics and weight are more critical than security.

Considerations for International Buyers: Buyers should be aware of compliance with international material safety standards, especially in Europe. In regions like Africa, the suitability of plastic for local climates should be assessed.

How Does Brass Compare as a Material for Door Latches?

Brass is a traditional material for door latches and locks, known for its attractive finish and good corrosion resistance.

Pros: Brass latches offer a classic aesthetic appeal and are resistant to tarnishing, making them suitable for decorative applications. They also have good machinability, which simplifies manufacturing.

Cons: The primary disadvantage of brass is its susceptibility to wear and tear over time, particularly in high-traffic areas. Additionally, brass can be more expensive than other materials like steel.

Impact on Application: Brass is often used in residential settings where aesthetics are important, but it may not be the best choice for commercial applications requiring high durability.

Considerations for International Buyers: Compliance with standards such as ASTM B453 for brass alloys is essential, particularly for buyers in Europe and North America. Buyers in South America and Africa should also consider local preferences for aesthetics and durability.

Summary Table of Material Selection for Door Latches with Locks

| Material | Typical Use Case for door latches with locks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-security commercial applications | Excellent strength and durability | Heavier and can rust if not maintained | Medium |

| Zinc Alloy | Residential and light commercial applications | Lightweight and good corrosion resistance | Lower strength compared to steel | Medium |

| Plastic | Interior doors and electronic locks | Lightweight and cost-effective | Less secure and less durable under extremes | Low |

| Brass | Decorative residential applications | Aesthetic appeal and tarnish resistance | Susceptible to wear in high-traffic areas | High |

This guide provides a comprehensive overview of the materials commonly used in door latches with locks, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for door latches with locks

What Are the Key Stages in the Manufacturing Process of Door Latches with Locks?

The manufacturing process of door latches with locks is intricate and involves several key stages to ensure high-quality products. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with the selection of raw materials, typically metals such as stainless steel, brass, or zinc alloys. These materials are chosen for their durability and resistance to corrosion. The raw materials undergo treatment to remove impurities and prepare them for shaping.

Forming: This stage involves shaping the prepared materials into the desired components of the latch and lock. Techniques like stamping, forging, and machining are commonly used. Stamping is often employed for mass production, allowing for precise shapes and sizes, while forging enhances the strength of the components. CNC machining is utilized for intricate designs and tight tolerances, ensuring that each piece fits perfectly.

Illustrative image related to door latches with locks

Assembly: Once the individual components are formed, they are assembled into the final product. This can include the integration of additional features such as key mechanisms, levers, and electronic components for smart locks. Automated assembly lines are increasingly common, but manual assembly is still prevalent for complex or custom designs, ensuring attention to detail and quality.

Finishing: The final stage focuses on enhancing the product’s aesthetics and durability. This can involve processes such as plating, painting, or coating to provide a protective layer against wear and environmental factors. Surface treatments like anodizing or powder coating not only improve appearance but also enhance corrosion resistance, which is critical for products used in various climates.

How Is Quality Assurance Implemented in the Manufacturing of Door Latches?

Quality assurance (QA) is a crucial component of the manufacturing process, ensuring that door latches with locks meet international standards and customer expectations. The QA process involves several checkpoints and testing methods to guarantee product reliability and safety.

Relevant International Standards: Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. For products sold in the European market, CE marking may be required, indicating compliance with health, safety, and environmental protection standards. In regions like the Middle East, local regulations may also dictate specific quality benchmarks.

Illustrative image related to door latches with locks

Quality Control Checkpoints: The quality control process typically consists of three main checkpoints:

1. Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers must provide certificates of compliance, and materials are tested for specifications before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to ensure that components are being produced within specified tolerances. This may include monitoring machining processes and assembly techniques to identify and rectify any issues in real-time.

-

Final Quality Control (FQC): Once the door latches are fully assembled, a thorough inspection is performed. This includes functional testing, durability testing, and aesthetic checks. Common testing methods include pull tests for strength, cycle tests for mechanical function, and environmental tests to simulate real-world conditions.

What Testing Methods Are Commonly Used to Ensure Quality?

Various testing methods are employed to validate the quality and reliability of door latches with locks. These methods can vary based on the specific product and market requirements.

Mechanical Testing: This includes tensile strength tests, fatigue tests, and impact resistance tests to evaluate how the latch performs under stress. For instance, a tensile test measures the maximum amount of tensile stress that a material can withstand before failure, which is critical for ensuring that the latch will not break under pressure.

Environmental Testing: Products are subjected to corrosion tests, temperature tests, and humidity tests to ensure they can withstand different environmental conditions. This is especially important for door latches used in outdoor applications or in regions with extreme weather.

Functional Testing: This verifies that the latch operates as intended, including ease of use and locking mechanisms. Testing might involve repeated cycles of locking and unlocking to ensure long-term reliability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure consistent product quality. Here are some actionable steps to consider:

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance measures. During an audit, buyers can assess the factory’s compliance with international standards and evaluate the effectiveness of their quality control systems.

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that outline their testing methods, results, and any certifications obtained. This documentation can provide a clear picture of the supplier’s commitment to quality.

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of verification. These organizations conduct independent assessments of the manufacturing process and product quality, providing unbiased reports that can help buyers make informed decisions.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers must navigate various quality control and certification nuances when sourcing door latches with locks. Different regions may have specific requirements, and being aware of these can streamline the procurement process.

Regional Certifications: For example, products intended for the European market may require CE marking, while those sold in the Middle East may need to comply with local standards. Understanding these requirements is crucial for avoiding compliance issues that could lead to delays or additional costs.

Documentation and Traceability: Buyers should ensure that suppliers maintain proper documentation and traceability for all materials and components used in production. This not only aids in compliance with international standards but also facilitates recall procedures in case of defects.

Cultural and Market Differences: Buyers from different regions may have varying expectations regarding quality and performance. Understanding these cultural nuances can help in selecting suppliers who align with specific market needs and customer preferences.

In summary, the manufacturing processes and quality assurance protocols for door latches with locks are vital components that B2B buyers must consider. By understanding these aspects, buyers can make informed decisions, ensuring they source high-quality products that meet their operational needs and comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door latches with locks’

The procurement of door latches with locks is a crucial component of ensuring security and functionality in various applications, ranging from residential buildings to commercial establishments. This guide aims to assist B2B buyers in navigating the sourcing process effectively, ensuring they select the right products and suppliers.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for the door latches you require. Consider factors such as size, latch type (e.g., deadbolt, lever, or electronic), and material preferences (like stainless steel or bronze). Defining these specifications will help streamline your search and ensure compatibility with existing door systems.

Step 2: Assess Security Features

Evaluate the security features of the door latches you are considering. Look for products that meet industry standards, such as ANSI grades, which indicate their durability and resistance to forced entry. Prioritize features like tamper resistance, electronic keypads, or smart lock capabilities, especially for commercial applications where security is paramount.

Illustrative image related to door latches with locks

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their experience with international shipping and compliance with local regulations, particularly if you are sourcing from regions such as Africa, South America, or the Middle East.

Step 4: Verify Certifications and Compliance

Ensure that the door latches comply with relevant safety and quality certifications. Look for UL ratings for fire resistance, especially if the latches will be used on fire-rated doors. Confirm that suppliers can provide documentation for any certifications, as this can significantly impact the reliability and safety of the products.

Step 5: Request Samples for Testing

Before placing a bulk order, request samples of the door latches. Testing samples allows you to assess the quality, durability, and ease of installation firsthand. It’s also an opportunity to ensure that the latches meet your specifications and security requirements.

Step 6: Consider After-Sales Support and Warranty

Investigate the after-sales support offered by potential suppliers. A reliable supplier should provide warranties on their products and have a clear return policy. This is crucial for addressing any issues that may arise post-purchase, ensuring that you have recourse in case of defective items.

Step 7: Negotiate Pricing and Payment Terms

Once you have selected a supplier, engage in negotiations regarding pricing and payment terms. Discuss bulk order discounts and payment flexibility, as these can significantly affect your overall procurement costs. Ensure that the payment terms align with your budget and cash flow requirements.

Illustrative image related to door latches with locks

By following this checklist, B2B buyers can approach the procurement of door latches with locks systematically, ensuring a successful sourcing experience that meets both security and operational needs.

Comprehensive Cost and Pricing Analysis for door latches with locks Sourcing

What Are the Key Cost Components for Door Latches with Locks?

When sourcing door latches with locks, understanding the cost structure is vital for informed decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The choice of materials significantly influences costs. Common materials include stainless steel, brass, and zinc die-cast, each offering varying durability and corrosion resistance. Higher-quality materials typically lead to increased costs but can enhance product longevity.

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing and assembly. These costs can vary greatly depending on the region. For instance, labor in Europe may be more expensive compared to regions in Africa or South America.

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these costs, making it crucial to evaluate suppliers’ operational efficiencies.

Tooling: The initial investment in tooling for production can be substantial, especially for custom designs. These costs are often amortized over the production volume, making them a significant factor in pricing.

Quality Control (QC): Implementing rigorous QC measures ensures product reliability and compliance with certifications. While this adds to the overall cost, it can prevent costly returns and enhance customer satisfaction.

Logistics: Shipping and handling costs are critical, particularly for international transactions. Factors such as distance, shipping method, and customs duties can all impact the final landed cost of the product.

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. Understanding the typical margins in the industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of door latches with locks, particularly for international buyers.

Volume/MOQ: Manufacturers often have minimum order quantities (MOQs). Larger orders can lead to discounts, making it essential for buyers to assess their needs against potential savings.

Specifications/Customization: Custom designs or specific features can drive up costs. Buyers should weigh the benefits of customization against their budget constraints.

Materials: As mentioned, the quality of materials directly affects pricing. Buyers must balance cost and quality, ensuring that the selected latch meets their performance requirements.

Quality/Certifications: Compliance with international standards and certifications (such as UL or ANSI) can impact pricing. Certifications often signify higher quality, justifying a higher price point.

Supplier Factors: The reputation and reliability of suppliers can influence costs. Established suppliers may charge more for their products, but they often provide better service and quality assurance.

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and liability, impacting the overall cost structure.

What Tips Can Help Buyers Optimize Cost-Efficiency?

To maximize value when sourcing door latches with locks, buyers should consider the following strategies:

Negotiation: Engage in open discussions with suppliers about pricing. Understanding their cost structure can provide leverage in negotiations, especially when discussing bulk orders or long-term partnerships.

Total Cost of Ownership (TCO): Evaluate the total cost of ownership, not just the purchase price. Consider factors such as maintenance, durability, and potential replacement costs over the product’s lifespan.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and trade regulations that can affect pricing. Building relationships with local suppliers may also reduce logistics costs.

Market Research: Conduct thorough market research to understand current pricing trends in different regions. This knowledge can help buyers identify competitive pricing and make informed decisions.

Illustrative image related to door latches with locks

Supplier Diversity: Consider sourcing from multiple suppliers to mitigate risks and leverage competitive pricing. A diverse supplier base can enhance negotiation power and provide options for different quality levels.

In summary, a comprehensive understanding of cost components, pricing influencers, and strategic sourcing tips can empower international B2B buyers to make informed decisions regarding door latches with locks. Always keep in mind that prices may vary widely based on region, supplier, and market conditions, so ongoing evaluation and negotiation are key to achieving the best value.

Alternatives Analysis: Comparing door latches with locks With Other Solutions

Exploring Alternatives to Door Latches with Locks

When evaluating security solutions for doors, businesses must consider various options beyond traditional door latches with locks. This analysis examines two viable alternatives: smart locks and mechanical deadbolts. Understanding the strengths and weaknesses of each solution is essential for making informed purchasing decisions that align with specific operational needs.

| Comparison Aspect | Door Latches With Locks | Smart Locks | Mechanical Deadbolts |

|---|---|---|---|

| Performance | Reliable for basic security; easy to use | Offers advanced features like remote access and monitoring | High security with robust construction |

| Cost | Generally low-cost, typically $5-$15 | Higher initial investment, ranging from $100-$300 | Moderate cost, typically $20-$50 |

| Ease of Implementation | Simple installation; minimal tools required | May require professional installation for network setup | Easy to install; compatible with standard doors |

| Maintenance | Low maintenance; occasional lubrication needed | Requires battery changes and firmware updates | Minimal maintenance; durable and long-lasting |

| Best Use Case | Ideal for residential and light commercial use | Best for tech-savvy environments needing remote access | Suitable for high-security applications in commercial settings |

What Are the Pros and Cons of Smart Locks?

Smart locks represent a significant advancement in door security technology. They provide features such as remote locking and unlocking via smartphones, integration with home automation systems, and activity logs that track entry and exit. However, the initial investment can be substantial, and they require a reliable power source, usually batteries or a hardwired connection. Additionally, smart locks may be vulnerable to hacking if not properly secured, making them less suitable for sensitive environments.

Illustrative image related to door latches with locks

How Do Mechanical Deadbolts Compare?

Mechanical deadbolts are a time-tested solution for securing doors. They offer robust security due to their solid construction and resistance to forced entry. Installation is straightforward, and they typically fit standard door frames without the need for extensive modifications. However, they lack the technological conveniences of smart locks, such as remote access and monitoring capabilities. While they require minimal maintenance, users must remember to manually lock and unlock the door, which can be a drawback in high-traffic areas.

How Can B2B Buyers Make the Right Choice?

Choosing the right door security solution depends on the specific needs of your business environment. For organizations prioritizing cost-effectiveness and simplicity, traditional door latches with locks may suffice. However, if advanced features and remote access are essential, investing in smart locks could enhance security and operational efficiency. Conversely, businesses that require high-security measures in demanding environments may find mechanical deadbolts to be the most reliable option. Evaluating the balance between cost, performance, and ease of use will lead to the most suitable choice for any organization.

Essential Technical Properties and Trade Terminology for door latches with locks

What Are the Essential Technical Properties of Door Latches with Locks?

In the realm of door hardware, understanding the technical properties of door latches with locks is crucial for B2B buyers. These specifications not only influence product performance but also affect compliance with safety standards and customer satisfaction. Here are some key properties to consider:

-

Material Grade

The material used in door latches often determines durability and performance. Common materials include stainless steel, brass, and zinc alloys. Stainless steel, for instance, offers corrosion resistance, making it suitable for both indoor and outdoor applications. Buyers should evaluate the material grade to ensure it meets environmental conditions and usage requirements. -

Locking Mechanism Type

Door latches can feature various locking mechanisms, such as deadbolts, electronic locks, and mortise locks. Each type offers different security levels and ease of use. For example, deadbolts provide enhanced security against forced entry, while electronic locks offer keyless convenience. Understanding these mechanisms helps buyers select products that align with their security needs. -

ANSI/BHMA Grade

The American National Standards Institute (ANSI) and Builders Hardware Manufacturers Association (BHMA) provide grading for locks and latches based on their durability and security features. Grades range from 1 to 3, with Grade 1 being the highest, indicating superior quality. This grading system helps buyers assess product reliability and compliance with industry standards. -

Adjustability Features

Many door latches are designed with adjustable backsets (the distance from the edge of the door to the center of the lock). This feature allows for compatibility with various door thicknesses and configurations. Adjustable latches can reduce installation time and costs, making them a preferred choice for contractors and builders. -

Fire Rating

Fire-rated door latches are essential for applications where fire safety is a concern. These products are tested and certified to withstand high temperatures, providing critical protection in commercial and residential settings. Buyers must ensure that the latches they select meet local fire safety regulations. -

Finish Options

The finish of a door latch can influence both aesthetics and corrosion resistance. Common finishes include satin nickel, oil-rubbed bronze, and polished brass. Selecting the right finish ensures that the latch complements the door design while providing necessary protection against wear and environmental factors.

What Are Common Trade Terms Related to Door Latches with Locks?

Understanding industry jargon is vital for effective communication and negotiation in the B2B landscape. Here are several key terms relevant to door latches:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of door latches, an OEM might supply components that are then branded and sold by larger hardware companies. Familiarity with OEM products can help buyers identify quality sources for their hardware needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is important for B2B buyers as it affects purchasing strategies and inventory management. Understanding the MOQ can help businesses plan their orders to avoid excess inventory or stock shortages. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for a specific quantity of products. This process is essential for buyers looking to compare prices and terms from multiple suppliers, ensuring they secure the best deal for door latches with locks. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is critical for B2B buyers importing door latches from overseas manufacturers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For door latches, understanding lead times is crucial for project planning and ensuring timely completion of installations. -

Certification Standards

Various certification standards, such as UL (Underwriters Laboratories) and CE (Conformité Européenne), indicate that products have been tested for safety and performance. Buyers should look for these certifications to ensure compliance with safety regulations and industry standards.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline procurement processes, and enhance the overall quality of their door hardware solutions.

Navigating Market Dynamics and Sourcing Trends in the door latches with locks Sector

What Are the Current Market Dynamics and Key Trends in the Door Latches with Locks Sector?

The global market for door latches with locks is experiencing robust growth, driven by several key factors. The surge in construction activities, particularly in emerging markets across Africa and South America, is a significant driver, as new residential and commercial buildings require reliable locking mechanisms. Furthermore, the increasing focus on security due to rising crime rates has prompted a shift towards more sophisticated locking solutions, including electronic and smart locks.

In terms of sourcing trends, international B2B buyers are increasingly leveraging technology to streamline procurement processes. Platforms that offer real-time inventory management and direct supplier engagement are becoming more popular. Additionally, the integration of Artificial Intelligence (AI) in supply chain management is enabling better demand forecasting and inventory control, which is particularly beneficial for buyers in regions like Europe and the Middle East, where efficiency is paramount.

Emerging technologies such as biometric locks and mobile access systems are also gaining traction, particularly in urban settings where convenience and security are critical. As buyers explore these innovations, they are advised to stay informed about regulatory standards, especially in the European market, where compliance with security certifications is essential.

How Is Sustainability Influencing the Sourcing of Door Latches with Locks?

Sustainability is becoming a vital consideration in the sourcing of door latches with locks. Buyers are increasingly aware of the environmental impact associated with manufacturing processes and the materials used. This awareness is prompting a shift towards products that utilize recycled materials or sustainably sourced metals.

Furthermore, ethical supply chains are gaining importance, as businesses strive to align with corporate social responsibility (CSR) goals. Buyers are encouraged to seek suppliers who adhere to recognized sustainability certifications, such as LEED or ISO 14001, which indicate a commitment to minimizing environmental impact. The use of green materials not only enhances brand reputation but also meets the growing consumer demand for environmentally friendly products.

In addition to environmental concerns, there is a significant push for transparency in the supply chain. Buyers should prioritize partnerships with manufacturers who can provide clear information about their sourcing practices, labor conditions, and environmental policies. This commitment to ethical sourcing not only mitigates risks but also fosters trust with end consumers.

What Are the Historical Developments That Have Shaped the Door Latches with Locks Industry?

The door latches with locks industry has evolved significantly over the past century. Initially, locking mechanisms were rudimentary and primarily made from wood and basic metal components. With the industrial revolution and the advent of mass production, locking systems became more sophisticated and widely available.

The introduction of standardized sizes and designs in the mid-20th century allowed for greater compatibility across various door types, facilitating easier installation and replacement. The late 20th century saw the emergence of electronic locks, which began to change the landscape of security solutions, paving the way for smart technology that integrates with home automation systems.

Today, the market continues to innovate, driven by advancements in technology and growing consumer demands for security, convenience, and sustainability. As the industry progresses, it remains crucial for B2B buyers to keep abreast of these developments to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of door latches with locks

-

1. How do I select the right door latches with locks for my business needs?

Choosing the right door latches with locks involves assessing the specific requirements of your application. Consider factors such as the type of doors you have (interior vs. exterior), the level of security needed, and whether the latch will be used in a commercial or residential setting. Additionally, check for features like fire ratings and weather resistance, especially if your projects are in diverse climates. Consulting with suppliers about product specifications and compatibility with existing door hardware can also provide clarity. -

2. What is the best locking mechanism for high-security applications?

For high-security applications, deadbolts are generally considered the most secure option due to their robust construction and resistance to forced entry. Electronic keyless deadbolts are also gaining popularity for added convenience and security. When sourcing, ensure the locking mechanism complies with relevant security standards and certifications, such as ANSI or UL ratings. Discussing these standards with suppliers can help you identify the best products for your needs. -

3. How can I ensure the quality of door latches and locks from international suppliers?

To ensure product quality from international suppliers, start by verifying their certifications and compliance with industry standards. Request samples before placing bulk orders to assess material quality and functionality. Additionally, consider suppliers with a strong track record and positive customer reviews. Establishing clear quality assurance protocols in your purchase agreement, including inspections and testing, can further safeguard against defects. -

4. What are common payment terms for international B2B transactions involving door latches?

Payment terms can vary widely among suppliers, but common practices include letters of credit, advance payments, or net 30-60 days after delivery. It’s crucial to negotiate terms that align with your cash flow while ensuring supplier confidence. Always clarify the terms in your purchase contract, and consider using escrow services for large transactions to mitigate risk. Familiarize yourself with the payment regulations in the supplier’s country to avoid complications. -

5. What is the minimum order quantity (MOQ) for door latches with locks?

MOQs can differ significantly based on the manufacturer and the type of product. Typically, for bulk orders, MOQs may range from 100 to 1,000 units. Some suppliers may offer flexibility for smaller orders, especially for new customers or custom products. When negotiating, clearly communicate your needs and explore potential alternatives like consolidated shipments with other buyers to meet MOQ requirements. -

6. How can I customize door latches and locks for my specific applications?

Customization options often include altering dimensions, finishes, or adding branding elements. Many suppliers offer a range of customizable features, so it’s essential to discuss your specific requirements upfront. Provide detailed specifications and design preferences to the supplier, and inquire about any additional costs or lead times associated with customization. Consider creating a prototype for testing before finalizing your order. -

7. What logistics considerations should I keep in mind when importing door latches?

When importing door latches, consider shipping methods, customs regulations, and import duties. Choose a logistics partner experienced in handling hardware imports to navigate these complexities smoothly. Be aware of potential delays in customs clearance and plan your inventory management accordingly. It’s also wise to confirm that your supplier is familiar with export regulations to ensure compliance and avoid penalties. -

8. How do I evaluate suppliers for door latches with locks?

Evaluating suppliers involves reviewing their experience, product quality, and customer service reputation. Request references from previous clients and check for industry certifications. Conduct site visits, if possible, to assess manufacturing capabilities and quality control processes. Additionally, consider their responsiveness to inquiries and willingness to provide support, as these factors can significantly impact your long-term partnership and satisfaction.

Top 5 Door Latches With Locks Manufacturers & Suppliers List

1. Harney Hardware – Residential Keyed / Entry Latch

Domain: harneyhardware.com

Registered: 2004 (21 years)

Introduction: [{‘product_name’: ‘Residential Keyed / Entry Latch’, ‘fire_rating’: ‘UL Fire Rated’, ‘adjustable_size’: ‘2 3/8 In. To 2 3/4 In.’, ‘product_number’: ‘87371’, ‘finish’: ‘Venetian Bronze’, ‘price’: ‘$6.47’}, {‘product_name’: ‘Residential Keyed / Entry Latch’, ‘fire_rating’: ‘UL Fire Rated’, ‘adjustable_size’: ‘2 3/8 In. To 2 3/4 In.’, ‘product_number’: ‘87370’, ‘finish’: ‘Satin Stainless Steel’, ‘pri…

2. Yale – High-Quality Door Hardware

Domain: shopyalehome.com

Registered: 2016 (9 years)

Introduction: This company, Yale – High-Quality Door Hardware, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Signature Hardware – Door Latches and Hasps

Domain: signaturehardware.com

Registered: 2004 (21 years)

Introduction: Door Latches and Hasps from Signature Hardware include various styles and finishes. Key features include options in Antique Brass, Black, Brushed Nickel, Champagne Brass, Dark Bronze, Matte Black, Oil Rubbed Bronze, Satin Brass, and Stainless Steel. Materials used are Brass, Iron, and Steel. The designs range from Modern to Rustic and Traditional. The product category includes 5 results, with opti…

4. Hartville Hardware – Door Latches

Domain: hartvillehardware.com

Registered: 2000 (25 years)

Introduction: This company, Hartville Hardware – Door Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Hardwaresource – Door Latches and Bolts

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Door Latches and Bolts:

1. Invisible Touch Latch for Full Size Doors – Price: $50.62, Available Finishes: Satin Brass, Satin Bronze, Satin Chrome

2. Concealed Magnetic Door Catch, Regular Duty – Price: $15.16, Rating: ★★★★★ (5), Available Colors: Black, Silver

3. Concealed Magnetic Door Catch, Heavy Duty – Price: $52.95, Rating: ★★★★★ (1), Available Colors: Black, Silver

4. Auxiliary Pusher for To…

Strategic Sourcing Conclusion and Outlook for door latches with locks

In summary, the strategic sourcing of door latches with locks is a critical component for international B2B buyers aiming to enhance their product offerings and meet diverse market demands. Key takeaways include the importance of selecting high-quality materials that comply with regional safety standards, such as UL fire ratings, particularly in sectors that prioritize security and durability. Buyers should also consider the versatility of adjustable latches and various finishes that cater to both aesthetic preferences and functional requirements across different markets.

As the global demand for reliable door hardware continues to rise, fostering strong relationships with manufacturers can lead to better pricing, superior product quality, and innovative solutions tailored to specific regional needs. International buyers from Africa, South America, the Middle East, and Europe should actively engage with suppliers who demonstrate a commitment to quality and sustainability in their manufacturing processes.

Looking ahead, the door latch market presents abundant opportunities for growth and collaboration. By leveraging strategic sourcing practices, buyers can position themselves advantageously within their respective markets. Now is the time to explore partnerships that will not only elevate your product line but also enhance your competitive edge in an increasingly interconnected global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.