Everything You Need to Know About Diaphragm Material Sourcing in 2025

Introduction: Navigating the Global Market for diaphragm material

Navigating the intricate landscape of diaphragm material sourcing can be daunting for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying high-quality diaphragm materials that meet specific operational needs but also in ensuring compliance with regional standards and regulations. This guide aims to alleviate those challenges by providing a comprehensive overview of diaphragm materials, including their types, applications, and the critical factors to consider when vetting suppliers.

Throughout this guide, international buyers will gain insights into various diaphragm materials—ranging from fabric-reinforced options to advanced polymers—tailored for applications in valves, pumps, and pressure control systems. We will delve into the nuances of each type, exploring their strengths and weaknesses, as well as their suitability for specific environments and operational conditions.

Moreover, we will outline essential criteria for supplier evaluation, helping you to select partners who not only deliver quality products but also align with your business values and standards. Cost considerations will also be addressed, equipping you with the knowledge to make informed purchasing decisions that balance quality and budget. By the end of this guide, B2B buyers will be empowered to navigate the global market confidently, ensuring they procure the right diaphragm materials for their unique applications.

Understanding diaphragm material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rubber Diaphragms | Flexible, cost-effective, good chemical resistance | Pumps, valves, automotive systems | Pros: Affordable, versatile; Cons: Limited temperature range. |

| Fabric Reinforced | High durability, flexibility, stable shape maintenance | High-pressure applications, sensors | Pros: Long-lasting, customizable; Cons: Higher cost, specific sourcing. |

| PTFE Diaphragms | Excellent chemical resistance, high-temperature tolerance | Chemical processing, food and pharma | Pros: Superior durability, non-stick; Cons: Expensive, may require special fittings. |

| Silicone Diaphragms | Broad temperature range, good flexibility | Medical devices, food processing | Pros: Biocompatible, versatile; Cons: Can degrade under certain conditions. |

| Metal Diaphragms | High strength, excellent for extreme environments | Aerospace, high-pressure systems | Pros: Very durable, precise control; Cons: Heavier, more expensive. |

What Are the Characteristics of Rubber Diaphragms?

Rubber diaphragms are widely used due to their cost-effectiveness and flexibility. They are suitable for a variety of applications, including pumps and automotive systems, where moderate chemical resistance is needed. Buyers should consider the specific rubber type (e.g., Nitrile, EPDM) based on the chemicals and temperatures involved. While they are generally affordable and versatile, their performance may be limited under extreme conditions.

How Do Fabric Reinforced Diaphragms Stand Out?

Fabric reinforced diaphragms offer superior strength and flexibility, making them ideal for high-pressure applications and sensors. The inclusion of materials like Nylon or Kevlar enhances their durability, ensuring they maintain shape and functionality over time. Customizable options are available, but buyers should be aware of the potentially higher costs and sourcing challenges. These diaphragms excel in demanding environments, providing reliability and longevity.

Why Choose PTFE Diaphragms for Specific Applications?

PTFE diaphragms are renowned for their exceptional chemical resistance and ability to withstand high temperatures, making them suitable for chemical processing and the pharmaceutical industry. Their non-stick properties enhance performance in applications where contamination is a concern. However, they tend to be more expensive than other materials, and special fittings may be required, which can increase overall system costs.

What Benefits Do Silicone Diaphragms Offer?

Silicone diaphragms are valued for their broad temperature range and biocompatibility, making them perfect for medical devices and food processing applications. Their flexibility allows for effective operation in various environments. However, buyers must be cautious as silicone can degrade when exposed to certain chemicals or conditions. Understanding the specific application requirements will help in selecting the right silicone formulation.

In What Situations Are Metal Diaphragms Preferred?

Metal diaphragms are ideal for applications requiring high strength and precise control, such as in aerospace and high-pressure systems. Their durability makes them suitable for extreme environments. However, they can be heavier and more expensive than other diaphragm types, which may limit their use in cost-sensitive applications. Buyers should weigh the benefits of precision against the potential for increased costs and weight.

Key Industrial Applications of diaphragm material

| Industry/Sector | Specific Application of diaphragm material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Processing | Diaphragms in pumps for handling corrosive fluids | Prevents leaks and ensures safe fluid transfer | Material compatibility with chemicals, pressure ratings |

| Oil and Gas | Diaphragms in pressure regulators and control valves | Enhances operational safety and efficiency | Temperature resistance, durability under high pressure |

| Food and Beverage | Diaphragms in sanitary pumps and valves | Ensures hygiene and compliance with regulations | FDA compliance, resistance to cleaning chemicals |

| Water and Wastewater | Diaphragms in wastewater treatment systems | Improves system reliability and reduces maintenance | UV resistance, ability to handle varying pH levels |

| Pharmaceutical | Diaphragms in dosing systems for accurate medication delivery | Ensures precision and safety in drug delivery | Biocompatibility, strict quality control standards |

How is diaphragm material utilized in the Chemical Processing sector?

In the chemical processing industry, diaphragm materials are integral to pumps that handle corrosive fluids. These diaphragms prevent leaks, ensuring safe fluid transfer and minimizing the risk of contamination or hazardous spills. Buyers in this sector must consider the diaphragm’s material compatibility with various chemicals, as well as pressure ratings to ensure reliability under operational conditions. Selecting the right diaphragm can lead to significant cost savings by reducing downtime and enhancing safety.

What role do diaphragm materials play in Oil and Gas applications?

Diaphragm materials are crucial in oil and gas applications, particularly in pressure regulators and control valves. They help maintain safe operating conditions by controlling fluid pressure and preventing leaks. The durability and temperature resistance of the diaphragm are critical, as they must withstand extreme conditions typical in this sector. Buyers should focus on sourcing diaphragms that can endure high pressure and temperature fluctuations to ensure long-term operational efficiency and safety.

Why are diaphragm materials important in the Food and Beverage industry?

In the food and beverage industry, diaphragm materials are used in sanitary pumps and valves to ensure hygiene and compliance with strict regulations. These diaphragms help maintain the integrity of products by preventing contamination during processing. Buyers need to ensure that the diaphragm materials are FDA compliant and resistant to various cleaning chemicals used in sanitation processes. This compliance is vital for maintaining product quality and meeting regulatory standards.

How do diaphragm materials enhance Water and Wastewater management?

In water and wastewater treatment systems, diaphragm materials are essential for ensuring system reliability and reducing maintenance needs. They are used in various applications, including pumps and valves, where they help manage the flow of wastewater effectively. Sourcing considerations include the diaphragm’s resistance to UV exposure and its ability to handle varying pH levels, which are common in wastewater environments. Selecting the right diaphragm material can significantly enhance operational efficiency and extend equipment lifespan.

What is the significance of diaphragm materials in the Pharmaceutical sector?

Diaphragm materials are critical in the pharmaceutical industry, particularly in dosing systems that require precise medication delivery. These materials ensure that drugs are administered accurately while maintaining safety and efficacy. Buyers must prioritize biocompatibility and rigorous quality control standards when sourcing diaphragms for pharmaceutical applications. Ensuring these materials meet stringent health regulations is paramount for maintaining the integrity of pharmaceutical products.

3 Common User Pain Points for ‘diaphragm material’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Diaphragm Material for Harsh Environments

The Problem: B2B buyers often struggle to choose the appropriate diaphragm material that can withstand extreme conditions such as high temperatures, corrosive chemicals, or high-pressure environments. This challenge is particularly pronounced in industries like oil and gas, chemical processing, and pharmaceuticals, where the failure of diaphragm materials can lead to operational downtime, safety hazards, and costly repairs. Buyers may be overwhelmed by the variety of options, each with different strengths, weaknesses, and application suitability.

The Solution: To effectively select the right diaphragm material, buyers should begin by conducting a thorough analysis of their specific application requirements. This includes understanding the operating environment, such as temperature ranges, chemical exposure, and pressure levels. For instance, materials like PTFE or FKM (Viton) are excellent for chemical resistance, while silicone may be preferred for high-temperature applications. Collaborating with suppliers who offer technical support can provide valuable insights into material specifications and performance data. Additionally, buyers should request samples for testing under actual operating conditions to ensure reliability before full-scale implementation.

Scenario 2: Issues with Diaphragm Longevity and Durability

The Problem: A common pain point for companies is the premature failure of diaphragm materials, leading to frequent replacements and increased maintenance costs. This issue often arises from using subpar materials or not accounting for the specific stresses and strains the diaphragm will encounter during operation. Industries such as water treatment or food processing are particularly affected, as diaphragm failure can lead to product contamination or system inefficiencies.

The Solution: To enhance diaphragm longevity, it is crucial to invest in high-quality, fabric-reinforced diaphragm materials that offer superior strength and flexibility. Buyers should look for suppliers that provide rigorous quality testing and performance guarantees. Additionally, specifying diaphragms that are custom-engineered to suit the operational demands can significantly mitigate wear and tear. Regularly scheduled maintenance and inspections can also help identify wear patterns early, allowing for timely replacements before catastrophic failures occur. Implementing a systematic review of diaphragm performance data can guide future material selections and improve overall operational efficiency.

Scenario 3: Sourcing Challenges for Custom Diaphragm Solutions

The Problem: Many B2B buyers face difficulties in sourcing customized diaphragm solutions tailored to their unique operational requirements. Off-the-shelf options may not meet specific dimensional, material, or performance needs, leading to compatibility issues that can disrupt production. This is particularly relevant in niche industries where standard solutions are insufficient, creating delays in project timelines and additional costs.

The Solution: To address sourcing challenges, buyers should establish partnerships with manufacturers who specialize in custom diaphragm solutions. This entails providing detailed specifications, including dimensions, material types, and intended applications, to ensure the manufacturer can deliver a product that meets exact requirements. Engaging in collaborative design processes can also lead to innovative solutions that enhance functionality and performance. It’s beneficial to request prototypes for testing, which can help refine the design before mass production. Furthermore, leveraging digital platforms for communication and project management can streamline the sourcing process, ensuring alignment between buyer expectations and manufacturer capabilities.

Strategic Material Selection Guide for diaphragm material

What are the Key Properties of Common Diaphragm Materials?

When selecting diaphragm materials for industrial applications, it is essential to consider their key properties, including temperature and pressure ratings, chemical resistance, and mechanical strength. The choice of material can significantly affect the performance and longevity of the diaphragm in various environments.

Silicone: Versatile and Temperature-Resistant

Silicone is a widely used diaphragm material known for its excellent temperature resistance, typically ranging from -60°C to 200°C. It exhibits good flexibility and maintains its properties over a wide temperature range, making it suitable for applications in both high and low-temperature environments.

Pros: Silicone is highly durable and resistant to UV light, ozone, and aging, which makes it ideal for outdoor and harsh conditions. Its non-toxic nature is a considerable advantage in food and medical applications.

Cons: The primary drawback of silicone is its lower mechanical strength compared to other elastomers, which may limit its use in high-pressure applications. Additionally, it can be more expensive than alternatives like nitrile.

Impact on Application: Silicone diaphragms are often used in medical devices, food processing, and automotive applications where temperature stability and chemical resistance are critical.

Illustrative image related to diaphragm material

Nitrile (Buna N): Cost-Effective and Strong

Nitrile, also known as Buna N, is a synthetic rubber that offers excellent resistance to oils and fuels. It typically operates effectively within a temperature range of -40°C to 100°C, making it suitable for various industrial applications.

Pros: Nitrile is cost-effective and provides good mechanical strength and durability, making it a popular choice in automotive and industrial settings. Its resistance to petroleum-based fluids is a significant advantage.

Cons: Nitrile is less resistant to extreme temperatures and ozone compared to silicone, which can limit its application in harsh environments.

Impact on Application: This material is commonly used in automotive fuel systems, hydraulic applications, and oil seals, where oil resistance is paramount.

EPDM: Chemical Resistance and Durability

Ethylene Propylene Diene Monomer (EPDM) is a type of synthetic rubber known for its excellent weather and ozone resistance. It can withstand temperatures from -50°C to 150°C and is particularly resistant to steam and a variety of chemicals.

Pros: EPDM’s durability and resistance to UV light and aging make it suitable for outdoor applications. Its flexibility at low temperatures is another advantage.

Cons: While EPDM is resistant to many chemicals, it is not suitable for applications involving petroleum-based products, which can limit its use in certain industries.

Impact on Application: EPDM diaphragms are ideal for use in water and wastewater applications, as well as in HVAC systems where chemical resistance is essential.

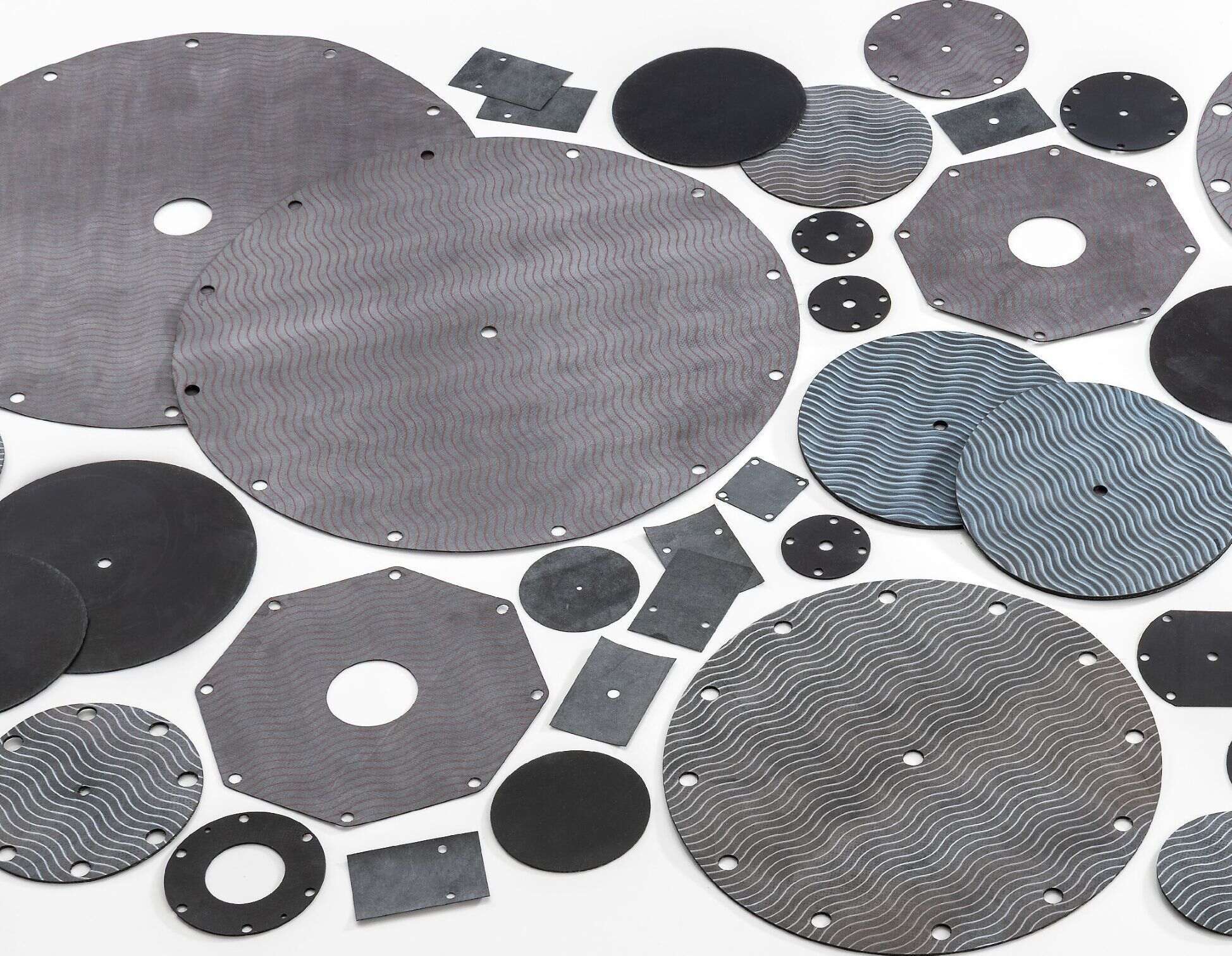

Fabric-Reinforced Diaphragms: Enhanced Strength and Stability

Fabric-reinforced diaphragms incorporate materials like nylon or Kevlar, providing enhanced strength and flexibility. These diaphragms are engineered to maintain their shape under high pressure, making them suitable for demanding applications.

Pros: The reinforcement allows for greater durability and longevity, particularly in high-pressure environments. They can be customized to meet specific application needs.

Cons: The complexity of manufacturing fabric-reinforced diaphragms can lead to higher costs and longer lead times compared to standard materials.

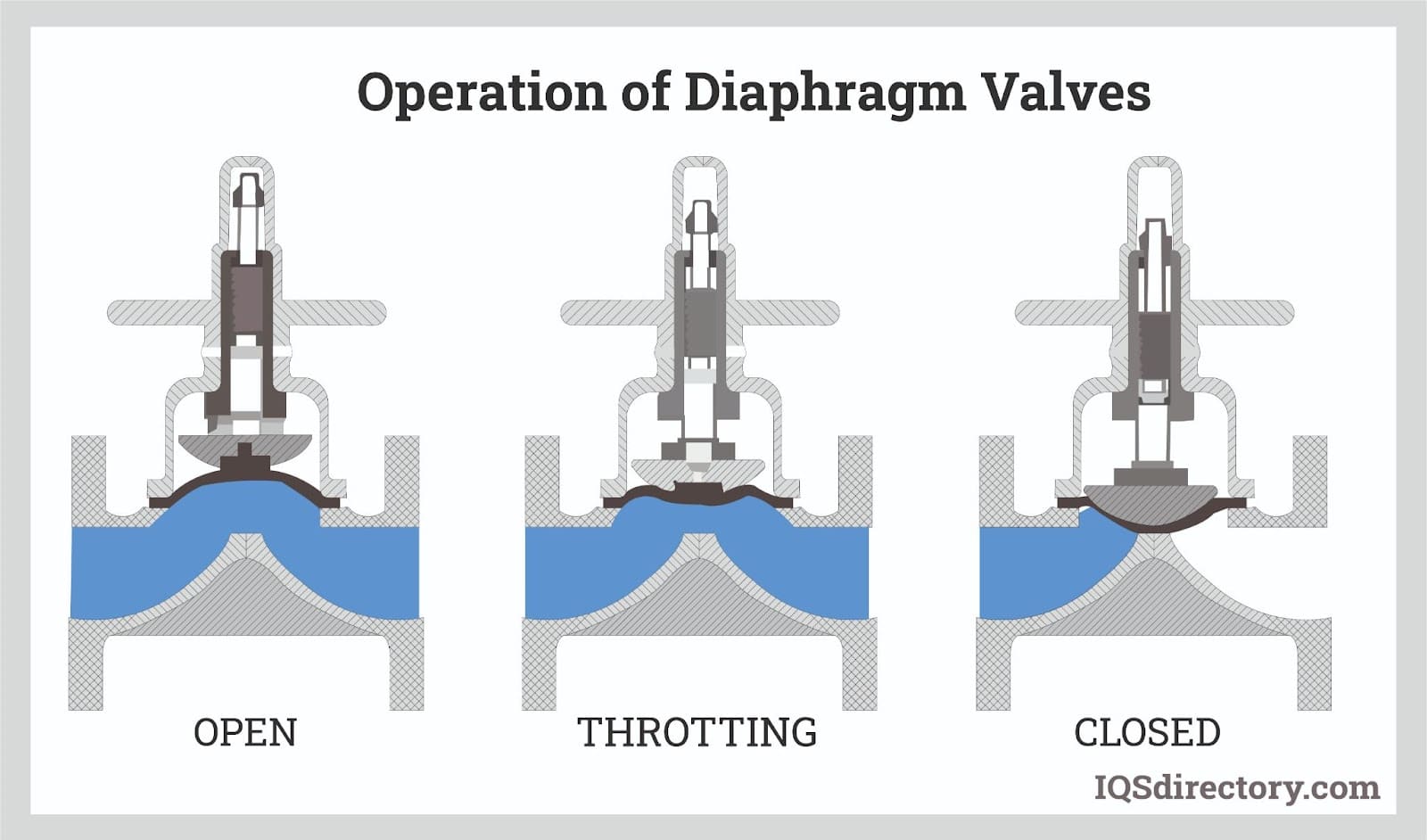

Impact on Application: These diaphragms are commonly used in valves, pumps, and pressure sensors, where reliable performance under pressure is critical.

Summary Table of Diaphragm Materials

| Material | Typical Use Case for diaphragm material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | Medical devices, food processing | Excellent temperature resistance | Lower mechanical strength | High |

| Nitrile (Buna N) | Automotive fuel systems | Cost-effective and strong | Limited temperature and ozone resistance | Low |

| EPDM | Water and wastewater applications | Excellent chemical and weather resistance | Not suitable for petroleum products | Medium |

| Fabric-Reinforced Diaphragms | Valves, pumps, pressure sensors | Enhanced strength and stability | Higher manufacturing complexity | Medium to High |

This guide provides a comprehensive overview of diaphragm materials, helping international B2B buyers make informed decisions based on their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for diaphragm material

What are the Main Stages of Diaphragm Material Manufacturing?

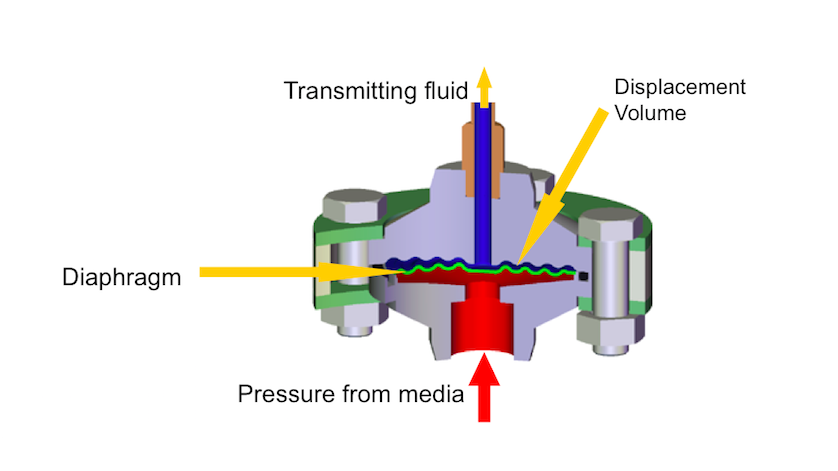

The manufacturing process of diaphragm materials is critical to ensuring their performance and reliability in various applications, such as valves, pumps, and pressure measurement devices. Here’s a breakdown of the main stages involved:

1. Material Preparation

The first stage involves selecting the appropriate materials based on the diaphragm’s intended application. Common materials include silicone, EPDM, nitrile (Buna N), and FKM (Viton), often reinforced with fabrics like nylon or Kevlar for added durability.

Illustrative image related to diaphragm material

Once the materials are selected, they are prepared for processing. This includes cutting sheets to size, blending rubber compounds with additives to enhance properties such as chemical resistance and flexibility, and pre-treating fabric reinforcements to ensure proper adhesion during subsequent stages.

2. Forming Techniques

The forming stage typically employs several techniques to shape the diaphragm material. Common methods include:

-

Compression Molding: This is a widely used technique where the prepared rubber compound is placed in a heated mold. The heat and pressure cause the material to conform to the mold’s shape, producing a diaphragm that meets precise specifications.

-

Transfer Molding: Similar to compression molding, this technique involves transferring the rubber compound from a separate chamber into the mold cavity, allowing for better control over the material flow and reducing waste.

-

Injection Molding: This method allows for greater precision and consistency, making it ideal for high-volume production. The rubber is injected into the mold under pressure, ensuring uniformity in thickness and shape.

3. Assembly Process

Once formed, diaphragms may require assembly with other components, especially if they are part of a more complex system. This could involve attaching reinforcing fabrics, integrating metal components, or bonding with other rubber parts.

Special attention is paid to ensure that the assembly is done under controlled conditions to prevent contamination and ensure the integrity of the seals.

4. Finishing Touches

The finishing stage involves several processes to enhance the diaphragm’s performance and aesthetic qualities. This can include surface treatments to improve adhesion, coatings for chemical resistance, and any necessary machining to achieve specific dimensions.

Finally, the diaphragms are cleaned and packaged to prevent contamination during storage and shipment.

What Quality Control Measures are Essential for Diaphragm Materials?

Quality control (QC) is a vital aspect of diaphragm manufacturing, ensuring that products meet both international standards and specific industry requirements. Here are key elements of the QC process:

1. Relevant International Standards

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications may include CE marking for products sold in Europe and API specifications for those used in oil and gas applications.

Illustrative image related to diaphragm material

2. QC Checkpoints in the Manufacturing Process

Quality control is integrated throughout the manufacturing process, involving several checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt to ensure they meet specified criteria. This may include testing for physical properties, chemical composition, and compliance with regulatory standards.

-

In-Process Quality Control (IPQC): Monitoring occurs at various stages of production to ensure that the manufacturing process adheres to quality standards. This may include checks during material preparation, forming, and assembly.

-

Final Quality Control (FQC): Once the diaphragms are completed, a thorough inspection is conducted. This includes visual inspections, dimensional checks, and performance testing to verify that the products meet all specifications before shipment.

3. Common Testing Methods for Diaphragm Materials

To ensure reliability, diaphragm materials undergo various testing methods, including:

- Tensile Testing: Evaluates the strength and elasticity of the diaphragm material.

- Burst Pressure Testing: Determines the maximum pressure the diaphragm can withstand before failure.

- Chemical Resistance Testing: Assesses how well the diaphragm material holds up against various chemicals it may encounter in its application.

- Thermal Stability Testing: Tests the material’s performance under extreme temperature conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control is crucial. Here are actionable steps to ensure quality assurance:

1. Conducting Supplier Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This includes reviewing their quality management systems, production facilities, and compliance with relevant standards.

2. Requesting Quality Reports

Buyers should request documentation related to quality control processes and testing results. This may include certificates of compliance, test reports, and records of previous audits.

3. Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an objective assessment of a supplier’s quality control practices. These services can conduct on-site inspections, perform testing, and verify compliance with international standards.

Illustrative image related to diaphragm material

What Are the QC/CERT Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances when it comes to quality control and certifications:

-

Understanding Regional Standards: Different regions may have specific standards that must be met. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Language Barriers: Communication can sometimes pose challenges. It’s essential for buyers to ensure that documentation and certifications are available in a language they understand.

-

Cultural Differences in Quality Expectations: Quality perceptions may vary by region, so establishing clear expectations and standards upfront is crucial for successful international transactions.

By understanding the manufacturing processes and quality assurance measures associated with diaphragm materials, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diaphragm material’

In the competitive landscape of B2B procurement, sourcing diaphragm materials effectively is crucial for ensuring the reliability and efficiency of your applications. This guide provides a structured checklist that will help international buyers navigate the complexities of selecting the right diaphragm materials for their needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your application is the first step in sourcing diaphragm materials. Consider factors such as pressure levels, temperature ranges, and chemical compatibility. Clearly defined specifications will guide you in selecting materials that meet your operational needs and prevent costly failures.

- Key Considerations:

- Pressure and temperature ratings of the diaphragm.

- Compatibility with fluids or gases involved in your processes.

Step 2: Identify Material Options

Different applications may require different diaphragm materials, such as silicone, EPDM, or fabric-reinforced options. Each material has unique properties that influence performance, durability, and resistance to environmental conditions.

- Popular Material Types:

- Silicone: Excellent for high-temperature applications.

- EPDM: Good for weather resistance and versatility.

- Fabric-Reinforced: Offers enhanced strength for high-pressure environments.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is essential. Assess their reputation, experience, and track record in producing diaphragm materials. Request case studies and references from clients in similar industries to gauge reliability.

- What to Look For:

- Supplier certifications (ISO, etc.) that ensure quality standards.

- Testimonials or reviews from previous customers.

Step 4: Request Samples for Testing

Obtaining samples allows you to test the diaphragm materials under real-world conditions. This is critical for validating that the material meets your technical specifications and performance expectations.

- Testing Criteria:

- Assess material flexibility and tensile strength.

- Evaluate chemical resistance and durability in your specific application.

Step 5: Check Compliance with Industry Standards

Ensure that the diaphragm materials comply with relevant industry standards and regulations, especially if they are used in sensitive sectors such as pharmaceuticals or food processing. Compliance not only ensures safety but also affects your company’s reputation.

Illustrative image related to diaphragm material

- Regulatory Considerations:

- FDA compliance for food-related applications.

- ATEX certification for explosive environments.

Step 6: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers and materials, it’s time to negotiate pricing and terms. Consider bulk purchasing options or long-term contracts that can lead to cost savings.

- Negotiation Tips:

- Be clear about your budget constraints.

- Discuss payment terms and delivery schedules upfront to avoid future misunderstandings.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the performance of the diaphragm materials post-purchase. Regular evaluations will help you identify any issues early and maintain operational efficiency.

- Quality Assurance Steps:

- Set up regular performance reviews.

- Maintain open communication with suppliers for feedback and support.

By following this checklist, international B2B buyers can streamline their sourcing process for diaphragm materials, ensuring they select the right products that meet their operational needs and uphold industry standards.

Comprehensive Cost and Pricing Analysis for diaphragm material Sourcing

What Are the Key Cost Components in Diaphragm Material Sourcing?

When sourcing diaphragm materials, understanding the cost structure is crucial for effective budgeting and negotiation. The primary components include:

-

Materials: The type of material significantly influences cost. Options like silicone, EPDM, and fabric-reinforced diaphragms vary in price based on their chemical resistance, temperature tolerance, and durability. High-performance materials tend to be more expensive but offer better longevity and reliability.

-

Labor: Labor costs encompass not only the manufacturing workforce but also skilled technicians involved in quality control and customization. In regions with higher labor costs, like Europe, the total expense may be elevated compared to manufacturing hubs in South America or Asia.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility management. Manufacturers with advanced technology might incur higher overheads, but they can also produce higher quality products efficiently.

-

Tooling: Custom tooling for specialized diaphragm shapes or sizes can add significant initial costs. However, these costs are often amortized over large production runs, making them more manageable for bulk orders.

-

Quality Control (QC): Rigorous QC processes ensure product reliability, especially for critical applications like valves and pumps. This adds to the overall cost but is essential for meeting industry standards and certifications.

-

Logistics: Shipping costs vary based on distance, mode of transport, and weight of the materials. International shipping can add complexity and expense, particularly with customs duties and tariffs.

-

Margin: Supplier margins will vary based on market demand, competition, and perceived value. Understanding the supplier’s cost structure can help buyers negotiate better pricing.

What Influences Prices for Diaphragm Materials?

Several factors can influence pricing in diaphragm material sourcing:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield better pricing due to economies of scale. Suppliers often have tiered pricing structures where costs decrease with increased volume.

-

Specifications and Customization: Customized diaphragms tailored to specific applications can incur additional costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Material Quality and Certifications: High-quality materials with certifications (e.g., FDA compliant for food applications) can command higher prices. Buyers should weigh the importance of certifications against cost.

-

Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers may charge more but often provide assurance of quality and service.

-

Incoterms: The terms of shipment, including who bears the cost and risk during transport, can significantly affect total costs. Understanding Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial for international transactions.

What Are Some Tips for Negotiating and Maximizing Cost Efficiency?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can benefit from several strategies:

-

Negotiate Effectively: Leverage your purchasing power by negotiating based on volume commitments. Suppliers may offer discounts for long-term contracts or larger orders.

-

Focus on Total Cost of Ownership (TCO): Consider the long-term costs associated with the diaphragm materials, including maintenance, replacement, and potential downtime. Sometimes, a higher upfront cost can lead to lower TCO through enhanced durability and performance.

-

Understand Pricing Nuances: Be aware that prices can fluctuate based on market conditions, material availability, and geopolitical factors. Keeping abreast of market trends can help in timing purchases effectively.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Comparing multiple suppliers can provide insights into market rates and help identify the best value proposition.

-

Be Clear About Requirements: To avoid miscommunication and unexpected costs, provide detailed specifications and application requirements upfront to potential suppliers. This clarity can lead to better quotes and fewer revisions.

Disclaimer

The prices mentioned in this analysis are indicative and can vary widely based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough market research and engage directly with suppliers for accurate pricing information.

Alternatives Analysis: Comparing diaphragm material With Other Solutions

Exploring Alternatives to Diaphragm Material in Industrial Applications

In the realm of industrial applications, selecting the right diaphragm material is crucial for ensuring optimal performance and reliability. However, there are alternative solutions available that may suit specific needs depending on factors such as application type, environmental conditions, and budget constraints. This section will compare diaphragm materials with two viable alternatives: membrane technology and piston seals.

Comparison Table

| Comparison Aspect | Diaphragm Material | Membrane Technology | Piston Seals |

|---|---|---|---|

| Performance | High flexibility and pressure resistance | Excellent for gases and liquids; can vary in flexibility | Strong sealing capability under high pressure |

| Cost | Moderate initial investment; long-term durability | Generally lower upfront costs; variable lifecycle costs | Higher initial investment but durable in demanding applications |

| Ease of Implementation | Requires precise installation and alignment | Typically easier to install; less technical expertise needed | Can be complex to install; requires skilled labor |

| Maintenance | Low maintenance if properly installed | Low maintenance; occasional checks needed | Moderate maintenance; seals may need replacement |

| Best Use Case | Fluid control in pumps and valves | Filtration and separation in chemical processes | Heavy-duty applications in hydraulic systems |

In-Depth Analysis of Alternatives

Membrane Technology

Membrane technology involves the use of thin films to separate substances, typically in applications like filtration or gas separation. One significant advantage of membrane technology is its efficiency in handling both gases and liquids, making it versatile across various industries. The initial investment is often lower compared to diaphragm materials, which can be appealing for cost-sensitive projects. However, the longevity and durability can vary greatly depending on the specific application and environmental factors. In settings where high pressure or extreme temperatures are involved, membrane technology may not perform as reliably as diaphragm materials.

Piston Seals

Piston seals are designed to provide a robust sealing solution in hydraulic and pneumatic systems. They are capable of withstanding high pressures, making them ideal for heavy-duty applications. While the initial investment in piston seals can be higher than that of diaphragm materials, they are known for their durability and longevity in demanding environments. However, installation can be complex and may require skilled labor, which can increase overall project costs. Regular maintenance is also necessary to ensure optimal performance, as seals may wear over time, necessitating replacement.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right solution for your industrial applications, it’s essential to consider the specific requirements of your operation. Diaphragm materials offer excellent performance in fluid control applications, providing flexibility and reliability. However, for applications focused on filtration or gas separation, membrane technology could be more cost-effective and easier to implement. Conversely, if your operations involve high pressures and require robust sealing, piston seals may be the best choice despite their higher initial costs and maintenance needs. By evaluating these factors—performance, cost, ease of implementation, and maintenance—B2B buyers can make informed decisions tailored to their unique operational needs.

Essential Technical Properties and Trade Terminology for diaphragm material

What Are the Key Technical Properties of Diaphragm Materials?

Understanding the technical properties of diaphragm materials is essential for B2B buyers to ensure compatibility with their specific applications. Here are some critical specifications that influence performance and durability:

Illustrative image related to diaphragm material

-

Material Composition

The type of material used in a diaphragm significantly affects its performance. Common materials include Silicone, EPDM, Nitrile (Buna N), FKM (Viton), and Neoprene. Each material has unique chemical resistance and temperature tolerance, making it crucial for buyers to select the right one based on their application requirements. -

Hardness (Shore A)

Measured on the Shore A scale, hardness indicates the flexibility and durability of the diaphragm. Softer materials (lower Shore A values) are typically more flexible but may have lower resistance to pressure, while harder materials (higher values) can withstand more stress but may be less flexible. Understanding hardness helps buyers gauge how a diaphragm will perform under their operational conditions. -

Tensile Strength

This property measures the maximum amount of tensile (stretching) stress a material can endure before failure. High tensile strength is essential for diaphragms used in high-pressure applications, as it indicates the material’s ability to maintain integrity under stress. Buyers should consider this property to ensure longevity and reliability. -

Elongation at Break

Elongation at break refers to the percentage increase in length a material can withstand before breaking. This property is vital for applications involving dynamic movement, as a higher elongation percentage means the diaphragm can flex and stretch without tearing. Buyers must assess this to prevent premature failure in their systems. -

Chemical Resistance

The ability of a diaphragm material to resist degradation when exposed to various chemicals is critical, especially in industries like oil and gas, pharmaceuticals, and food processing. Buyers should review compatibility charts provided by manufacturers to ensure the diaphragm will perform reliably in their specific chemical environments. -

Temperature Tolerance

Each diaphragm material has a specific temperature range within which it can operate effectively. Understanding the maximum and minimum temperatures a diaphragm can handle is crucial for applications in extreme environments. Selecting a diaphragm that meets these thermal requirements is essential for maintaining system performance.

What Common Trade Terms Should B2B Buyers Know About Diaphragm Materials?

Familiarity with industry jargon helps facilitate smoother transactions and clearer communications between buyers and suppliers. Here are some key terms to understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding whether a supplier is an OEM can provide assurance regarding the quality and compatibility of diaphragm materials with existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is essential for buyers, as it impacts inventory management and procurement strategies, particularly for smaller businesses or those testing new products. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process is crucial for buyers to compare costs, evaluate suppliers, and negotiate terms effectively. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms helps B2B buyers understand shipping terms, costs, and risks associated with international transactions. -

Lead Time

Lead time refers to the period from placing an order to receiving the product. Understanding lead time is crucial for supply chain management, as it affects production schedules and project timelines. -

Certification Standards

Many diaphragm materials come with certification standards (e.g., ISO, FDA) that assure quality and safety. Buyers should look for these certifications to ensure that the materials meet industry regulations and standards for their specific applications.

By mastering these technical properties and trade terms, B2B buyers can make more informed decisions, leading to enhanced operational efficiency and product performance in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the diaphragm material Sector

What Are the Current Market Dynamics and Key Trends in the Diaphragm Material Sector?

The diaphragm material sector is experiencing notable growth, driven by the increasing demand for high-performance components across various industries, including chemical processing, food and beverage, and pharmaceuticals. One of the primary global drivers is the need for reliable sealing solutions that can withstand extreme conditions, such as high temperatures and aggressive chemicals. Emerging technologies, such as advanced materials like fabric-reinforced diaphragms and new polymer formulations, are reshaping the market landscape. These innovations not only enhance durability but also improve flexibility and resistance to wear, making them ideal for high-pressure applications.

Illustrative image related to diaphragm material

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must stay informed about these trends to make strategic sourcing decisions. The increasing focus on customization is another significant trend; companies are now offering tailored diaphragm solutions to meet specific application requirements. Additionally, the digital transformation in supply chain management, including the use of blockchain for traceability and advanced analytics for demand forecasting, is becoming increasingly relevant. This shift enables buyers to make informed decisions and streamline their procurement processes, ensuring they source the most appropriate materials for their needs.

How Is Sustainability and Ethical Sourcing Shaping the Diaphragm Material Industry?

Sustainability has emerged as a critical concern in the diaphragm material sector, prompting B2B buyers to prioritize environmentally responsible sourcing practices. The production of diaphragm materials can have significant environmental impacts, including resource depletion and waste generation. Therefore, companies are increasingly seeking suppliers who adopt sustainable manufacturing processes and utilize eco-friendly materials.

Ethical supply chains are also gaining prominence, with businesses looking for partners who ensure fair labor practices and reduce their carbon footprint. Certifications such as ISO 14001 (Environmental Management) and materials that meet green standards, like those free from harmful chemicals, are becoming essential criteria in sourcing decisions. By choosing suppliers with recognized sustainability credentials, international buyers can enhance their brand reputation and meet regulatory requirements, making their operations more resilient in an increasingly eco-conscious market.

How Has the Diaphragm Material Sector Evolved Over Time?

The evolution of diaphragm materials can be traced back to the early 20th century when rubber and simple elastomers were primarily used for sealing applications. As industries advanced, the demand for more durable and chemically resistant materials led to the introduction of synthetic options, such as neoprene and EPDM. In recent decades, advancements in polymer technology have paved the way for high-performance materials like PTFE and fabric-reinforced composites, which offer superior strength and flexibility. This evolution reflects a broader trend toward customization and specialization, enabling manufacturers to meet the specific demands of diverse applications, from automotive to aerospace. Today, diaphragm materials continue to evolve, driven by technological innovation and the increasing emphasis on sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of diaphragm material

1. How do I select the right diaphragm material for my application?

Selecting the appropriate diaphragm material depends on factors such as the application’s temperature range, chemical exposure, and pressure requirements. Common materials include silicone, EPDM, Nitrile, and FKM, each offering distinct properties like chemical resistance and flexibility. It’s essential to assess the specific demands of your environment—such as whether it involves high temperatures or aggressive chemicals—and consult with suppliers who can recommend materials based on performance criteria. Additionally, consider the diaphragm’s mechanical properties, such as tensile strength and elasticity, to ensure optimal functionality.

Illustrative image related to diaphragm material

2. What are the benefits of custom diaphragm solutions for my business?

Custom diaphragm solutions offer tailored specifications that cater to unique operational needs, enhancing performance and reliability. By working with manufacturers to create bespoke designs, you can achieve optimal fit, function, and longevity, which can significantly reduce maintenance costs and downtime. Customization allows for the selection of materials that best resist the specific chemicals and temperatures in your application, leading to improved efficiency. Furthermore, customized diaphragms can be engineered to meet specific regulatory or industry standards, ensuring compliance and safety in your operations.

3. What is the minimum order quantity (MOQ) for diaphragm materials?

Minimum order quantities (MOQs) for diaphragm materials can vary widely based on the supplier and the complexity of the product. Typically, MOQs range from a few hundred to several thousand units, depending on factors such as material type, customization, and manufacturing processes. It’s advisable to inquire directly with potential suppliers about their MOQs, as some may offer flexibility for first-time orders or smaller businesses. Understanding the MOQ is crucial for budgeting and inventory planning, particularly for international buyers who may face additional logistics considerations.

4. How can I ensure the quality of diaphragm materials from suppliers?

To ensure the quality of diaphragm materials, conduct thorough supplier vetting by reviewing their certifications, production processes, and quality assurance protocols. Request samples to evaluate material properties such as durability, flexibility, and chemical resistance. Additionally, inquire about their testing methods and whether they adhere to international quality standards, such as ISO certifications. Establishing a robust relationship with suppliers that prioritize quality control will help mitigate risks associated with defective materials, ensuring reliability in your applications.

5. What payment terms should I expect when sourcing diaphragm materials internationally?

Payment terms for international sourcing of diaphragm materials often vary between suppliers and regions. Common terms include payment in advance, letters of credit, and net payment terms (e.g., 30, 60, or 90 days). It’s essential to negotiate terms that align with your cash flow and operational needs. Some suppliers may offer discounts for upfront payments, while others might require a deposit followed by payment upon delivery. Always clarify payment methods, currency, and any potential fees associated with international transactions to avoid misunderstandings.

Illustrative image related to diaphragm material

6. What logistics considerations should I keep in mind when importing diaphragm materials?

When importing diaphragm materials, consider factors such as shipping costs, customs duties, and delivery timelines. Engage with logistics providers who specialize in international shipping to navigate customs regulations and ensure compliance with local laws. Additionally, evaluate the reliability of your suppliers in meeting shipping deadlines, as delays can impact production schedules. It’s also beneficial to establish clear communication regarding shipment tracking and any potential issues that may arise during transit, allowing for timely resolutions.

7. How do I identify reliable suppliers for diaphragm materials in different regions?

Identifying reliable suppliers requires thorough research and due diligence. Start by exploring industry directories, trade shows, and online platforms that connect buyers with manufacturers. Assess suppliers based on their experience, customer reviews, and certifications. Engaging with industry peers for recommendations can also provide valuable insights. Once potential suppliers are identified, request quotes, inquire about their production capabilities, and conduct site visits if possible. Building a strong relationship with your supplier can lead to better service and collaboration.

8. What certifications should diaphragm materials have for international standards?

Diaphragm materials should comply with relevant international standards and certifications to ensure safety and performance. Common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific industry-related certifications such as FDA compliance for food-grade applications or ATEX certification for explosive atmospheres. When sourcing materials, confirm that suppliers can provide documentation for these certifications, as they reflect adherence to quality assurance practices and regulatory requirements essential for global trade.

Top 9 Diaphragm Material Manufacturers & Suppliers List

1. Garlock – Style 7992 Neoprene Rubber Sheet

Domain: garlock.com

Registered: 1995 (30 years)

Introduction: This company, Garlock – Style 7992 Neoprene Rubber Sheet, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. McMaster – Diaphragm Rubber Selection

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Diaphragm Rubber Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Exactseal – Fabric Reinforced Diaphragm

Domain: exactseal.com

Registered: 2016 (9 years)

Introduction: Fabric Reinforced Diaphragm – Exactseal Inc

4. Ashcroft – Diaphragm Seals

Domain: blog.ashcroft.com

Registered: 1995 (30 years)

Introduction: Diaphragm seals are used to protect pressure sensors from corrosive materials in industries such as oil & gas, water/wastewater, chemical, and petrochemical. Key components include a top housing, fill port, lower housing, and diaphragm. The wetted parts material is crucial for compatibility with the process media, and considerations include material corrosion resistance, galvanic series compatibil…

5. PSG Dover – Diaphragm Materials and Designs

Domain: psgdover.com

Registered: 2011 (14 years)

Introduction: Diaphragm Materials: Thermoplastic Elastomers (TPE), Polytetrafluoroethylene Elastomers (PTFE), Rubber Elastomers. Diaphragm Designs: Chem-Fuse IPD, Pure-Fuse IPD, EZ-Install Diaphragm, Full-Stroke PTFE Diaphragm, Reduced-Stroke PTFE Diaphragm, Ultra-Flex™ Diaphragm, Traditional AODD Diaphragm.

6. The Rubber Company – Diaphragm Sheeting

Domain: therubbercompany.com

Registered: 2013 (12 years)

Introduction: Diaphragm Sheeting is available in various types including Thin Nitrile Coated Nylon, Thin Gauge Nitrile Rubber, Nitrile Reinforced Nylon, EPDM, and Non Reinforced Neoprene. The stock range includes rubberized fabrics made from NBR Nitrile and CR Neoprene, both reinforced with high strength Polyamide Nylon fabric. These products are suitable for applications in automotive carburettors, LPG and Met…

7. Yamada – Diaphragm Pumps

Domain: yamadapump.com

Registered: 1996 (29 years)

Introduction: Yamada offers a variety of diaphragm pumps including: NDP-5 Series, DP-10/DP-15/G15 Series, NDP-15 Series, NDP-20 Series, NDP-25 Series/G25 Series, NDP-32 Series, NDP-40 Series, NDP-50/500/G50 Series, NDP-80 Series, Specialty Diaphragm Pumps, Diaphragm Drum Pumps, SolidPRO Solids Diaphragm Pump, High Pressure Diaphragm Pump, Split Manifold Diaphragm Pump, Powder Diaphragm Pumps, UL Listed Diaphrag…

8. GK Supply – Diaphragm Pumps

Domain: gk-supply.com

Registered: 2022 (3 years)

Introduction: Diaphragm pumps are essential for fluid transfer in various industries. Key materials used in their construction include: 1. Diaphragm: Typically made from rubber, thermoplastics, or metal, each offering unique advantages such as flexibility and chemical resistance. 2. Pump Casing and Valves: Commonly crafted from stainless steel, plastic, or aluminum for corrosion resistance and structural integr…

9. Zatkoff – Flat Elastomer Diaphragm Material

Domain: zatkoff.com

Registered: 1997 (28 years)

Introduction: Flat Elastomer Diaphragm Material includes tables illustrating standard construction, fabric characteristics, flammability, and properties. The product offering is part of Zatkoff’s standard products, which also includes O-Rings, adhesives, molded packings, and various gasket materials. Technical specifications are available in a downloadable PDF.

Strategic Sourcing Conclusion and Outlook for diaphragm material

In the evolving landscape of diaphragm materials, strategic sourcing emerges as a critical component for B2B buyers aiming to optimize performance while managing costs. Key takeaways highlight the importance of selecting high-quality materials such as silicone, EPDM, and fabric-reinforced options, which offer superior durability and resistance to extreme conditions. By prioritizing suppliers who adhere to rigorous quality testing and offer customizable solutions, buyers can ensure that their diaphragm applications—ranging from valves to pumps—operate reliably and efficiently.

Looking ahead, the demand for innovative diaphragm materials is expected to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As industries increasingly focus on sustainability and efficiency, suppliers that can provide tailored, high-performance diaphragm solutions will stand out.

International B2B buyers are encouraged to engage with manufacturers that not only meet current needs but also anticipate future challenges. By forging strategic partnerships and investing in quality diaphragm materials now, companies can position themselves for success in a competitive global market. Embrace the opportunity to enhance your operations with cutting-edge diaphragm technology and ensure your supply chain remains resilient and responsive.

Illustrative image related to diaphragm material

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.