Everything You Need to Know About Conveyor Design Sourcing in 2025

Introduction: Navigating the Global Market for conveyor design

In today’s fast-paced global market, sourcing an efficient conveyor design can be a daunting challenge for international B2B buyers. As businesses expand and diversify, the need for tailored conveyor systems that not only transport but also sort, cool, and screen materials becomes increasingly critical. This guide offers a comprehensive exploration of various conveyor types, their applications across industries, and essential considerations for selecting the right system. From belt and vibratory conveyors to roller and magnetic systems, understanding each option’s functionality and suitability for specific environments—whether in bustling factories or remote warehouses—is crucial.

Navigating the complexities of supplier vetting, cost analysis, and maintenance requirements can significantly impact operational efficiency and profitability. This guide empowers buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Brazil—by providing actionable insights and best practices for informed purchasing decisions. By equipping decision-makers with the knowledge needed to evaluate their options critically, this resource aims to streamline the conveyor design selection process, ultimately enhancing productivity and safety in material handling operations. Whether you are looking to upgrade existing systems or implement new solutions, this guide serves as a vital tool in your journey toward optimizing conveyor systems for your specific needs.

Understanding conveyor design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Belt Conveyor | Continuous loop of flexible material; versatile | Manufacturing, warehousing | Pros: Simple design, good for various materials. Cons: Requires regular maintenance and can suffer from tracking issues. |

| Vibratory Conveyor | Utilizes vibrations for material movement; low maintenance | Recycling, bulk processing, food handling | Pros: Fewer moving parts, reduced downtime. Cons: May not be suitable for all material types. |

| Roller Conveyor | Composed of rollers; ideal for heavy loads | Distribution centers, assembly lines | Pros: High load capacity, efficient for packaged goods. Cons: Requires more space and may involve higher initial costs. |

| Magnetic Conveyor | Uses magnets to move ferrous materials; fixed path | Manufacturing, recycling | Pros: Effective for metal parts, minimal wear. Cons: Limited to magnetic materials only. |

| Bucket Conveyor | Uses buckets attached to a chain; vertical transport | Mining, agriculture, bulk materials | Pros: Efficient for transporting bulk materials vertically. Cons: Limited speed and may require more maintenance. |

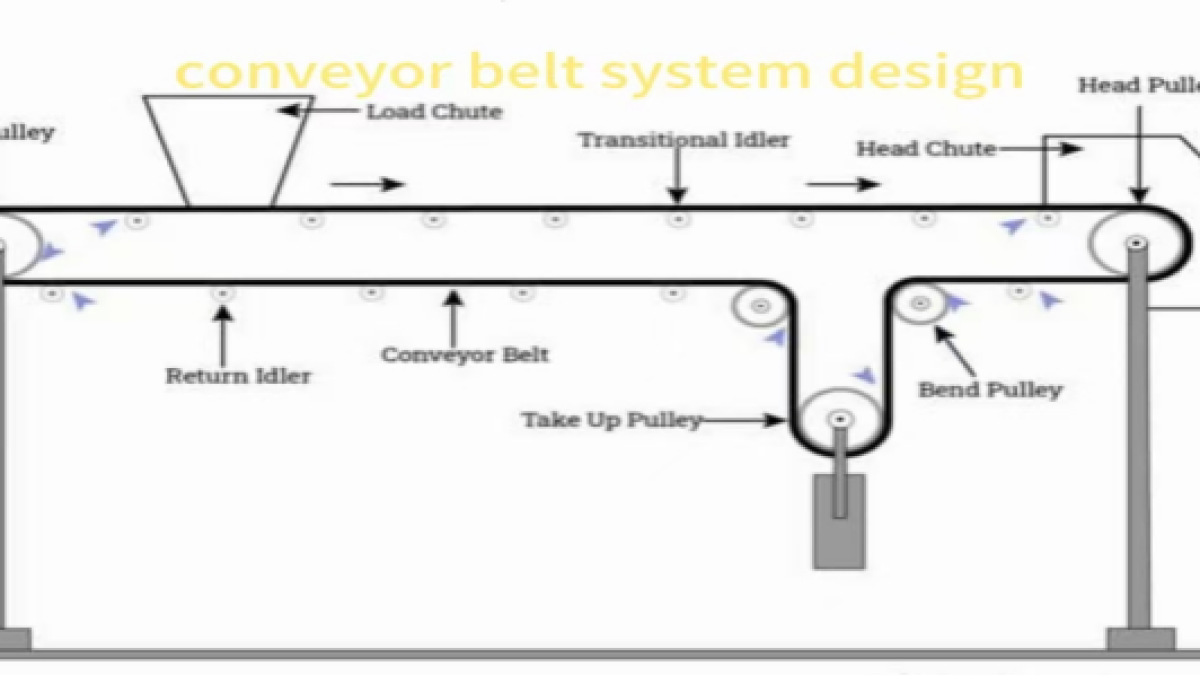

What are the Key Characteristics of Belt Conveyors?

Belt conveyors are one of the most common types of conveyor systems, featuring a continuous loop of flexible material, typically rubber or fabric, that moves goods from one point to another. They are highly versatile and can be configured for horizontal, inclined, or declined movement. When considering a belt conveyor, businesses should evaluate the weight and nature of the materials being transported, as well as the required speed and length of the conveyor. Regular maintenance is essential to avoid tracking issues and ensure optimal performance.

How Do Vibratory Conveyors Stand Out?

Vibratory conveyors utilize controlled vibrations to move materials along a smooth surface, making them particularly effective for transporting bulk materials. Their design allows for adjustable speeds and the ability to handle difficult-to-move items, which can be advantageous in recycling and food processing applications. Buyers should consider the specific material characteristics and whether the application requires additional processing, such as cooling or coating, as vibratory systems can often accommodate these functions. The low maintenance requirement is a significant benefit for many operations.

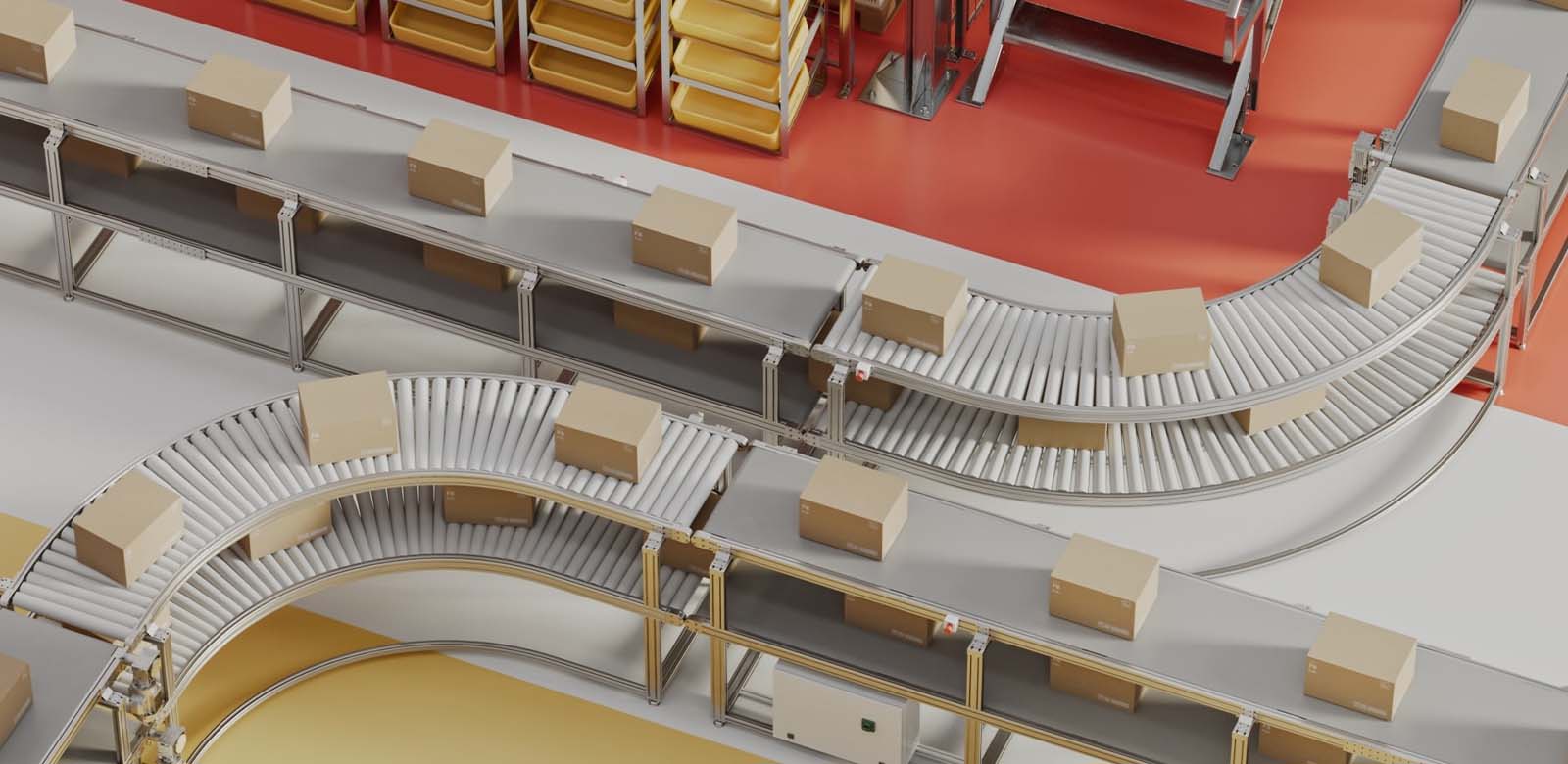

What Makes Roller Conveyors Suitable for Heavy Loads?

Roller conveyors consist of a series of rollers that facilitate the movement of goods, making them particularly suitable for heavy and bulky items. Commonly used in distribution centers and assembly lines, they enhance efficiency by allowing gravity or powered systems to move products. When selecting a roller conveyor, businesses should assess the load capacity, required space, and whether the products need to be sorted or accumulated. While they are effective, the initial investment and space requirements can be a consideration for budget-conscious buyers.

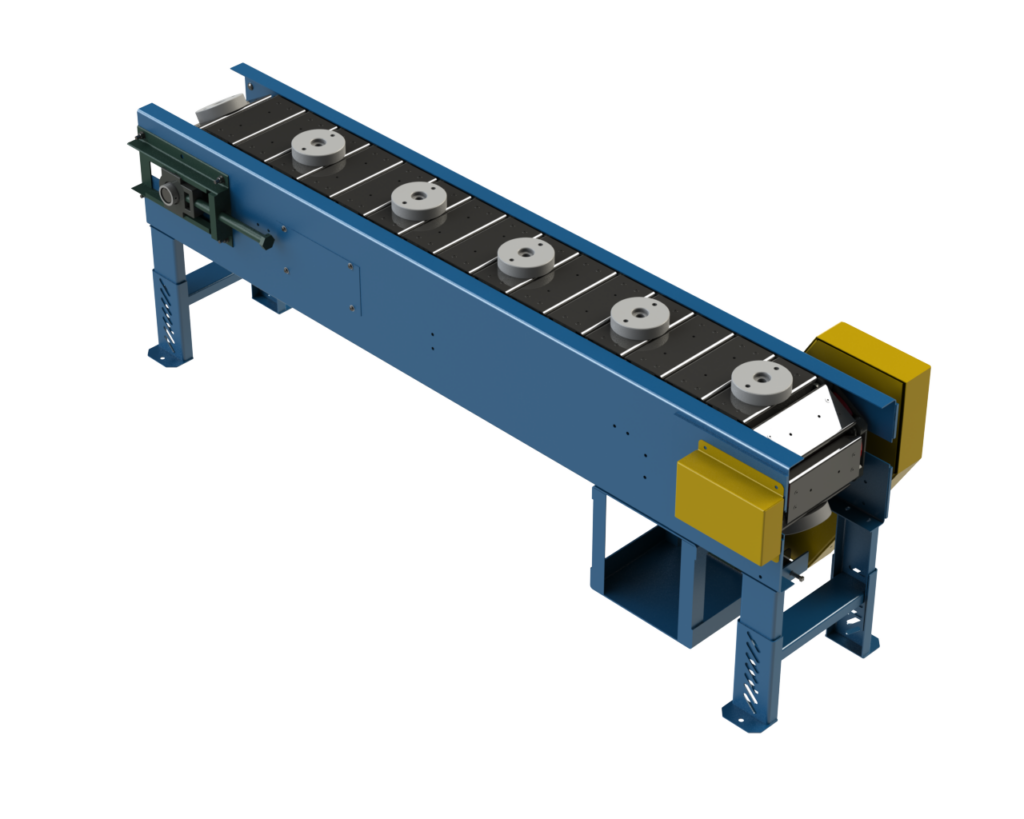

In What Situations Are Magnetic Conveyors Most Effective?

Magnetic conveyors leverage magnets to move ferrous materials along a fixed path, making them ideal for manufacturing and recycling environments. Their design minimizes wear and tear, as there are fewer moving parts involved. Companies looking to invest in a magnetic conveyor should consider the types of materials they will be handling, as these systems are limited to magnetic materials. The durability and efficiency of magnetic conveyors make them a compelling choice for specific applications, but their restricted use may limit flexibility in handling diverse product types.

Why Choose Bucket Conveyors for Vertical Transport?

Bucket conveyors are designed to transport bulk materials vertically, using buckets attached to a chain or belt. This type of conveyor is commonly used in mining, agriculture, and other industries that require efficient vertical movement of materials. When considering a bucket conveyor, businesses should evaluate the type of bulk material being moved, the required speed, and the potential for wear on the buckets. While they are effective for vertical transport, buyers should also weigh the limitations in speed and maintenance needs against their operational requirements.

Key Industrial Applications of conveyor design

| Industry/Sector | Specific Application of Conveyor Design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Automated sorting and packaging of products | Enhances productivity and reduces labor costs | Compliance with food safety regulations, hygienic design |

| Mining and Minerals | Bulk material handling and transportation | Improves efficiency in material movement, reduces downtime | Durability to withstand harsh conditions, high load capacity |

| Automotive Manufacturing | Assembly line integration for vehicle components | Streamlines production processes, minimizes manual handling | Customization for specific assembly tasks, safety features |

| Pharmaceuticals | Controlled environments for product transport | Ensures product integrity and compliance with regulations | Cleanroom compatibility, temperature control capabilities |

| Recycling and Waste Management | Sorting and processing of recyclable materials | Increases recycling efficiency, reduces waste management costs | Adaptability to different materials, low maintenance needs |

How is Conveyor Design Applied in the Food and Beverage Industry?

In the food and beverage sector, conveyor design plays a crucial role in the automated sorting, packaging, and transportation of products. This application streamlines operations by minimizing manual labor and enhancing productivity, which is vital in meeting high consumer demand. For international buyers, especially in regions like Nigeria and Brazil, sourcing conveyor systems that comply with stringent food safety regulations is essential. Additionally, these systems must be designed with hygienic materials that are easy to clean to prevent contamination.

What are the Key Applications in Mining and Minerals?

Conveyor systems are integral in the mining and minerals industry for the bulk handling and transportation of materials such as ores and aggregates. These systems enable efficient movement from extraction points to processing facilities, significantly reducing downtime and operational costs. Buyers in regions with challenging terrains, like parts of Africa, should consider sourcing conveyors that are durable and capable of handling high load capacities while withstanding harsh environmental conditions.

How is Conveyor Design Used in Automotive Manufacturing?

In automotive manufacturing, conveyor design facilitates the integration of assembly lines, allowing for the efficient movement of vehicle components through various stages of production. This application reduces manual handling and minimizes bottlenecks, thereby improving overall productivity. International buyers need to focus on sourcing customized conveyor solutions that cater to specific assembly tasks, ensuring they incorporate necessary safety features to protect workers in busy manufacturing environments.

What Role Does Conveyor Design Play in Pharmaceuticals?

Conveyor design is vital in the pharmaceutical industry, where it is used to transport products in controlled environments. This ensures that medications and other products maintain their integrity and comply with stringent regulatory requirements. Buyers, particularly from the Middle East and Europe, should prioritize systems that are compatible with cleanroom standards and have capabilities for temperature control to safeguard sensitive materials during transport.

How Does Conveyor Design Enhance Recycling and Waste Management?

In recycling and waste management, conveyor systems are employed for the sorting and processing of recyclable materials, significantly improving efficiency and reducing costs associated with waste management. These systems can be tailored to handle various materials, making them adaptable to different recycling processes. Buyers should consider sourcing conveyors that require low maintenance and can easily be adjusted for different types of waste, ensuring long-term operational efficiency.

3 Common User Pain Points for ‘conveyor design’ & Their Solutions

Scenario 1: Inefficient Material Flow in Manufacturing Processes

The Problem:

Many B2B buyers in the manufacturing sector face challenges with inefficient material flow due to poorly designed conveyor systems. For instance, a company might experience bottlenecks where materials get stuck or take too long to transfer from one station to another. This not only affects productivity but can also lead to increased labor costs and frustration among employees. In environments with high volumes of goods, such inefficiencies can severely impact overall operational performance and profitability.

The Solution:

To address this issue, it’s crucial to conduct a comprehensive analysis of the current workflow and identify specific pain points in the material transfer process. Collaborating with conveyor design experts can help you specify a custom solution that takes into account factors such as throughput, load capacity, and the nature of the materials being transported. Implementing a modular conveyor system can provide flexibility, allowing for easy adjustments and expansions as production needs change. Additionally, integrating smart technology for real-time monitoring can help identify potential bottlenecks before they escalate, ensuring a smoother operation.

Scenario 2: High Maintenance Costs and Downtime

The Problem:

Another common pain point for B2B buyers is the high maintenance costs and downtime associated with traditional conveyor systems. Many businesses operate with outdated equipment that requires frequent repairs or replacements, leading to extended periods where production is halted. This scenario can be particularly detrimental for companies in competitive markets, where every minute of downtime translates into lost revenue and a tarnished reputation.

The Solution:

Investing in modern conveyor design, such as vibratory or modular conveyor systems, can significantly reduce maintenance needs and operational downtime. These systems often feature fewer moving parts, which minimizes wear and tear. Additionally, engaging with manufacturers who provide robust warranties and post-installation support can safeguard against unexpected costs. It’s also beneficial to establish a proactive maintenance schedule, which includes regular inspections and upgrades to keep the conveyor system in peak condition. Adopting preventative measures can transform maintenance from a reactive to a proactive strategy, enhancing both reliability and performance.

Scenario 3: Inadequate System Customization for Unique Applications

The Problem:

B2B buyers often struggle with conveyor systems that are not tailored to their specific operational needs. For example, a business in the food processing sector may find that standard conveyor designs are not suitable for handling their products, which require specialized features like temperature control or hygiene compliance. This mismatch can lead to inefficiencies, product damage, and even regulatory issues, putting the entire operation at risk.

The Solution:

To mitigate these challenges, it’s essential to work closely with conveyor design specialists who can deliver customized solutions tailored to your unique application. Start by conducting a thorough assessment of your operational requirements, including the type of materials, handling conditions, and any regulatory standards that must be met. Collaborate with a design team that has experience in your industry to develop a conveyor system that incorporates necessary features such as adjustable speeds, temperature regulation, and easy cleaning mechanisms. This tailored approach not only improves efficiency but also enhances product safety and compliance, ultimately supporting your business’s growth and reputation in the market.

Strategic Material Selection Guide for conveyor design

When designing a conveyor system, the choice of materials is critical to the performance, durability, and efficiency of the operation. This guide analyzes four common materials used in conveyor design, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Conveyor Design?

Steel is a widely used material in conveyor systems due to its strength and durability. It typically has a high temperature and pressure rating, making it suitable for heavy-duty applications. Steel also offers excellent corrosion resistance when treated or coated, which is essential in environments exposed to moisture or chemicals.

Pros: Steel conveyors are robust, capable of handling heavy loads, and have a long lifespan. They are also relatively easy to manufacture and can be customized to meet specific operational needs.

Cons: The initial cost of steel can be high, and it may require additional treatments to prevent rust and corrosion. Steel conveyors can also be heavy, which may complicate installation and maintenance.

Impact on Application: Steel is ideal for industries such as mining, manufacturing, and heavy-duty material handling. Its compatibility with various media types makes it versatile for different applications.

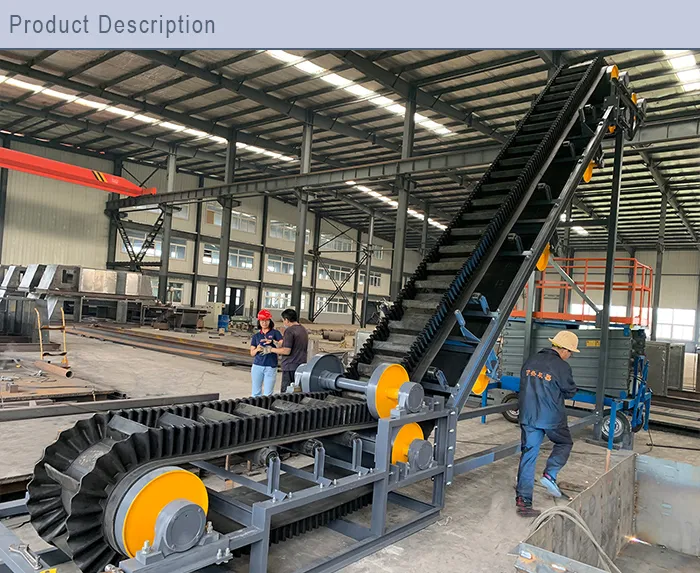

Illustrative image related to conveyor design

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN. In regions with high humidity, additional protective coatings may be necessary.

How Does Plastic Compare as a Conveyor Material?

Plastic, particularly in the form of polymer-based belts, is another popular choice for conveyor systems. It is lightweight and can handle a range of temperatures, though its pressure rating is generally lower than that of metal counterparts.

Pros: Plastic conveyors are resistant to corrosion and chemicals, making them suitable for food processing and pharmaceuticals. They are also quieter in operation and require less maintenance.

Cons: The main drawback is that plastic may not be suitable for heavy loads, and its lifespan can be shorter than that of metal conveyors. Additionally, the manufacturing process can be more complex and costly.

Illustrative image related to conveyor design

Impact on Application: Plastic is particularly effective in environments where hygiene is a concern, such as food and beverage industries. Its flexibility allows for various configurations, including curves and inclines.

Considerations for International Buyers: Buyers should verify that the plastic materials meet food safety standards and other local regulations, such as those set by the FDA or similar organizations.

What Are the Advantages of Using Rubber in Conveyor Systems?

Rubber is often used in conveyor belts due to its excellent grip and flexibility. It can handle a range of temperatures and is particularly effective in environments where materials are prone to sliding or shifting.

Illustrative image related to conveyor design

Pros: Rubber belts provide high friction, reducing the risk of slippage. They are also durable and can absorb impact, making them suitable for heavy loads and uneven surfaces.

Cons: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures. It may also require more frequent replacements compared to metal or plastic options.

Impact on Application: Rubber is ideal for bulk material handling in industries such as agriculture, mining, and recycling. Its ability to handle abrasive materials makes it a preferred choice in these sectors.

Considerations for International Buyers: Buyers should consider the climate of their operational areas, as extreme conditions can affect rubber longevity. Compliance with local standards regarding material safety and environmental impact is also crucial.

How Does Stainless Steel Enhance Conveyor Performance?

Stainless steel is a premium choice for conveyor systems, especially in industries that require high hygiene standards. It offers excellent corrosion resistance and can withstand high temperatures.

Pros: Stainless steel conveyors are durable, easy to clean, and resistant to rust and corrosion. They are ideal for environments where sanitation is critical, such as food processing or pharmaceuticals.

Cons: The main disadvantage is the higher cost compared to other materials. Additionally, stainless steel can be heavier, which may complicate installation.

Impact on Application: Stainless steel is particularly beneficial in food and beverage processing, pharmaceuticals, and any application where cleanliness is paramount.

Considerations for International Buyers: Buyers should ensure compliance with food safety standards and verify that the stainless steel used meets local regulations, such as those from the European Union or other relevant bodies.

Illustrative image related to conveyor design

Summary Table of Material Selection for Conveyor Design

| Material | Typical Use Case for conveyor design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty material handling | High strength and durability | High initial cost and weight | High |

| Plastic | Food processing, pharmaceuticals | Corrosion resistant and lightweight | Shorter lifespan and higher mfg cost | Medium |

| Rubber | Bulk material handling | High friction and impact absorption | Degrades over time | Medium |

| Stainless Steel | Food and beverage processing | Excellent hygiene and corrosion resistance | Higher cost and heavier | High |

In conclusion, selecting the right material for conveyor design is crucial for optimizing performance and ensuring operational efficiency. International buyers should consider local environmental conditions, compliance with regulations, and the specific needs of their applications when making their material choices.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor design

In the highly competitive landscape of conveyor system design, understanding the manufacturing processes and quality assurance measures is crucial for B2B buyers. This guide delves into the typical stages of manufacturing and the quality control practices that ensure reliability and performance, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Main Stages of Manufacturing Conveyor Systems?

The manufacturing process for conveyor systems involves several critical stages that ensure the final product meets operational requirements and quality standards.

How Is Material Prepared for Conveyor Systems?

The first step in conveyor manufacturing is material preparation. This involves selecting the right materials, such as steel, aluminum, plastic, or rubber, based on the application requirements. The chosen materials undergo cutting and surface treatment processes, including cleaning, coating, or galvanizing, to enhance their durability and resistance to wear and tear. Proper material preparation is essential as it sets the foundation for the conveyor’s performance and longevity.

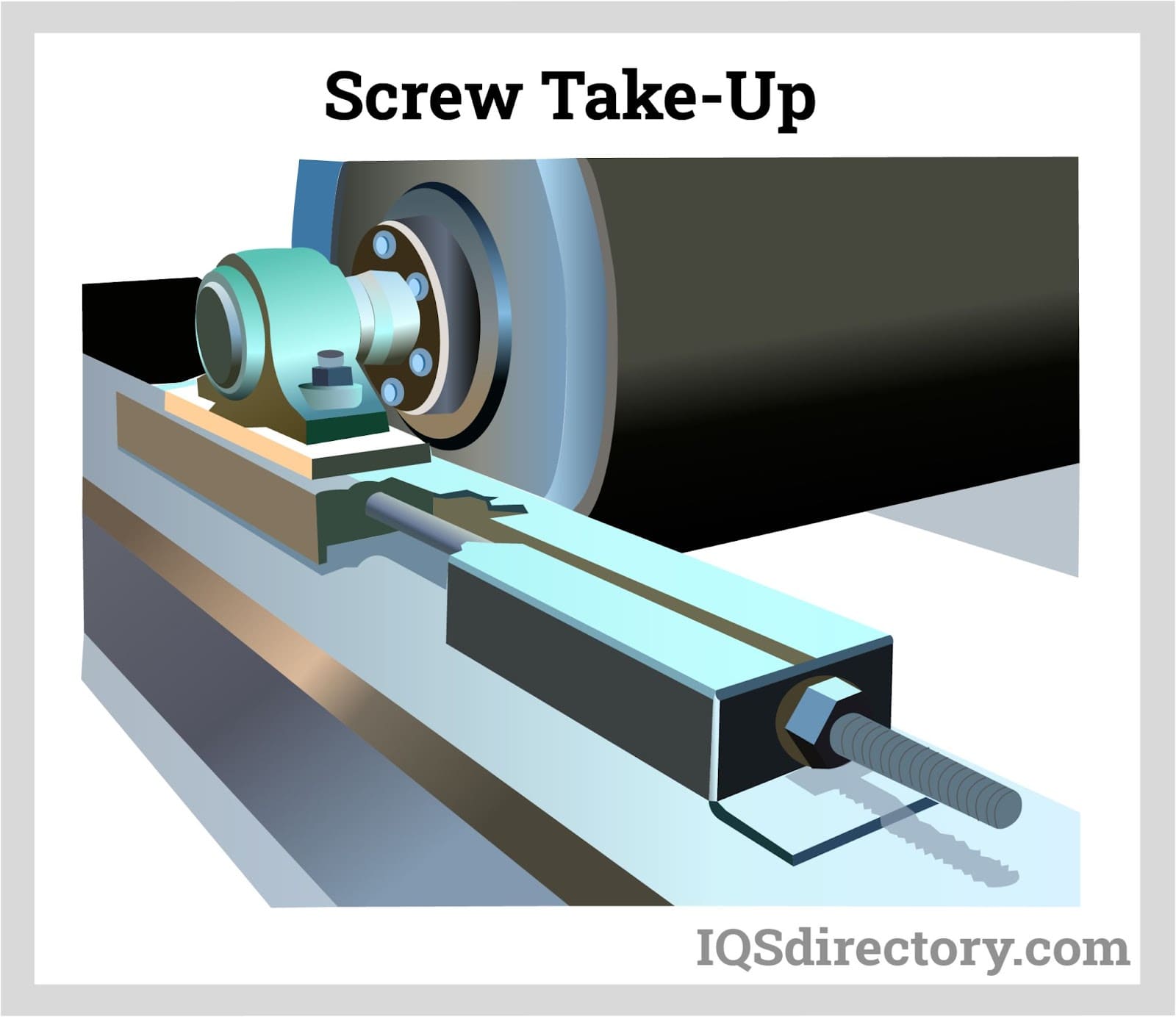

What Forming Techniques Are Used in Conveyor Manufacturing?

Once the materials are prepared, the next stage is forming. This can involve various techniques such as welding, bending, and machining to create the necessary components of the conveyor system. For instance, steel frames may be welded to create a robust structure, while pulleys and rollers might undergo precise machining to ensure smooth operation. The forming stage is critical as it directly impacts the alignment and functionality of the conveyor system.

How Are Conveyor Systems Assembled?

After forming, the assembly stage begins. This involves the integration of all components, including belts, motors, and sensors, into a cohesive system. During this stage, careful attention is paid to alignment and tensioning, particularly in belt conveyors where proper belt tension is crucial for operation. Automated assembly techniques can be employed to enhance efficiency and consistency, reducing the likelihood of human error.

What Finishing Processes Are Involved in Conveyor Production?

The final stage of manufacturing is finishing, which includes processes such as painting, coating, or applying protective finishes to enhance aesthetics and protect against environmental factors. This stage may also involve functional testing to ensure that all components operate correctly. A well-executed finishing process not only improves the appearance of the conveyor system but also increases its lifespan and reliability.

What Quality Assurance Standards Are Relevant for Conveyor Design?

Quality assurance is a vital aspect of conveyor design, ensuring that systems meet international standards and specific industry requirements.

Which International Standards Should Buyers Consider?

For B2B buyers, understanding international quality standards such as ISO 9001 is essential. This standard focuses on quality management systems and ensures that manufacturers adhere to consistent quality practices. Additionally, certifications like CE mark signify that the product meets European safety and health requirements, which is particularly relevant for buyers in Europe.

Illustrative image related to conveyor design

What Industry-Specific Certifications Are Important?

In addition to general standards, industry-specific certifications such as API (American Petroleum Institute) are important for conveyors used in sectors like oil and gas. These certifications ensure that products meet rigorous safety and performance criteria, which can be crucial for operational success in demanding environments.

What Are the Key Quality Control Checkpoints in Conveyor Manufacturing?

Quality control (QC) is integral throughout the manufacturing process, with several checkpoints established to ensure product integrity.

What Is Incoming Quality Control (IQC)?

Incoming Quality Control (IQC) involves inspecting raw materials upon arrival at the manufacturing facility. This step ensures that materials meet specified standards and are free from defects. For international buyers, it’s crucial to verify that suppliers conduct thorough IQC processes to prevent issues later in production.

How Is In-Process Quality Control (IPQC) Implemented?

In-Process Quality Control (IPQC) is conducted during the manufacturing stages. Regular inspections and measurements are performed to ensure components are being produced according to specifications. This proactive approach helps identify and rectify issues before they escalate, ultimately enhancing the quality of the final product.

What Is Final Quality Control (FQC) and Its Importance?

Final Quality Control (FQC) takes place after assembly and finishing. This stage involves comprehensive testing of the entire conveyor system, including functionality, safety, and performance evaluations. For B2B buyers, understanding the FQC process can provide insights into the reliability of the conveyor systems being purchased.

Illustrative image related to conveyor design

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying a supplier’s quality control practices is crucial for ensuring product reliability.

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one effective method for verifying quality control. Buyers should establish a clear audit process that evaluates the supplier’s manufacturing practices, quality management systems, and adherence to international standards. This can help identify potential risks and ensure that the supplier aligns with the buyer’s quality expectations.

How Can Buyers Request Quality Reports and Certifications?

Buyers should also request quality reports and certifications from suppliers. These documents provide evidence of compliance with international standards and industry-specific regulations. Reviewing these reports can help buyers assess the credibility of the supplier’s quality assurance processes.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can further enhance quality assurance. Independent inspectors can provide unbiased evaluations of the manufacturing process and product quality, ensuring that the conveyor systems meet the required specifications before shipment.

What Are the Quality Control Nuances for International Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, there are specific nuances to consider regarding quality control.

Illustrative image related to conveyor design

How Do Regional Standards Influence Quality Assurance?

Different regions may have varying standards and regulations that affect quality assurance practices. Buyers should familiarize themselves with local regulations and industry standards relevant to their region to ensure compliance and avoid potential issues during customs clearance.

What Are the Challenges of Sourcing Conveyor Systems Internationally?

Sourcing conveyor systems from international suppliers can present challenges such as language barriers, differing quality expectations, and logistical issues. It is essential for buyers to establish clear communication channels and set definitive quality expectations to mitigate these challenges effectively.

Conclusion

Understanding the manufacturing processes and quality assurance practices for conveyor systems is essential for B2B buyers looking to make informed purchasing decisions. By familiarizing themselves with the stages of manufacturing, relevant quality standards, and verification methods, buyers can ensure they select reliable and efficient conveyor systems that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor design’

Introduction

This practical sourcing guide serves as a step-by-step checklist for B2B buyers looking to procure effective conveyor design solutions. Given the diverse industrial applications and regional considerations, this guide aims to streamline your decision-making process, ensuring that you select a conveyor system that meets your operational needs while maximizing efficiency and safety.

Illustrative image related to conveyor design

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline your technical requirements. This includes throughput, load capacity, conveying speed, and material types. Defining these specifications helps suppliers tailor their solutions to fit your unique operational needs and minimizes the risk of costly adjustments later on.

- Throughput: Determine the volume of materials you need to move.

- Load Capacity: Ensure the system can handle the maximum weight of your products.

Step 2: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to ensure they can meet your requirements. Request detailed company profiles, case studies, and references from similar industries or regions. This step is crucial to gauge their experience and reliability in delivering conveyor systems.

- Industry Experience: Look for suppliers with a proven track record in your specific industry.

- Customer Testimonials: Seek feedback from past clients to understand their satisfaction levels.

Step 3: Assess Customization Capabilities

Not all conveyor systems are one-size-fits-all. Assess each supplier’s ability to customize solutions based on your defined specifications. Customization can significantly enhance the efficiency and effectiveness of your conveyor system.

- Modularity: Check if the supplier offers modular designs that can adapt to future changes.

- Integration: Ensure the system can seamlessly integrate with your existing processes and machinery.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers you are considering hold relevant industry certifications and comply with local and international standards. This step helps mitigate risks related to safety, quality, and operational reliability.

- ISO Certification: Look for ISO 9001 certification or other relevant quality management standards.

- Safety Standards: Confirm compliance with regional safety regulations, especially in high-risk environments.

Step 5: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals that include pricing, delivery timelines, and after-sales support. A comprehensive proposal allows you to compare offerings effectively and make an informed decision.

- Cost Breakdown: Ensure the proposal includes a transparent breakdown of costs, including installation and maintenance.

- Support Services: Inquire about warranty terms and ongoing support options.

Step 6: Conduct Site Visits or Virtual Demos

If possible, conduct site visits or request virtual demonstrations of the proposed conveyor systems. Observing the systems in action allows you to evaluate their performance and suitability for your operations firsthand.

- Operational Efficiency: Pay attention to how smoothly the conveyor operates under load.

- Space Utilization: Assess how well the system fits within your existing operational layout.

Step 7: Finalize Contracts with Clear Terms

Once you have selected a supplier, ensure that the contract outlines all critical terms, including delivery schedules, payment terms, and responsibilities for installation and training. Clear contractual terms help prevent misunderstandings and ensure accountability.

- Performance Metrics: Include performance metrics that the supplier must meet.

- Change Management: Outline procedures for handling potential changes or disputes.

By following these steps, B2B buyers can effectively navigate the complexities of conveyor design procurement, ensuring they make informed choices that align with their operational goals.

Illustrative image related to conveyor design

Comprehensive Cost and Pricing Analysis for conveyor design Sourcing

What Are the Key Cost Components in Conveyor Design Sourcing?

When sourcing conveyor design systems, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include steel, aluminum, and various polymers. Higher-quality materials may lead to increased initial costs but can result in lower maintenance and replacement costs over time.

-

Labor: Labor costs encompass both direct and indirect expenses. Skilled labor for assembly and installation can vary based on geographical location and market conditions. In regions like Africa and South America, labor costs may be lower, but expertise in conveyor technology can be limited, potentially leading to higher long-term costs.

-

Manufacturing Overhead: This includes costs related to the factory operation, such as utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help minimize these costs, which is crucial for competitive pricing.

-

Tooling: Custom conveyor designs may require specialized tooling, which can add to the initial investment. However, this cost can be amortized over larger production runs, so it’s important to consider volume when evaluating tooling expenses.

-

Quality Control (QC): Ensuring that the conveyor system meets industry standards and specifications is vital. QC processes can add to manufacturing costs but are essential for preventing defects and ensuring reliability.

-

Logistics: Transportation costs can vary widely based on distance, mode of transport, and local infrastructure. For international buyers, understanding shipping costs and potential tariffs is crucial for accurate budgeting.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and the supplier’s reputation.

How Do Price Influencers Affect Conveyor Design Costs?

Several factors can influence the pricing of conveyor systems, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on anticipated volume.

-

Specifications and Customization: Custom designs tailored to specific applications usually incur higher costs. Standardized solutions may offer cost savings, but they might not meet all operational needs.

-

Materials: The choice of materials can significantly affect the price. For instance, stainless steel conveyors are more expensive than their carbon steel counterparts but offer greater durability and corrosion resistance.

-

Quality and Certifications: Systems that meet higher quality standards or certifications may command a premium price. However, investing in certified products can lead to long-term cost savings through reduced downtime and increased reliability.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can impact pricing. Established suppliers may charge more for their expertise and support but can also provide better long-term value.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is critical for international buyers. These terms dictate who is responsible for shipping, insurance, and tariffs, which can affect the overall cost of the conveyor system.

What Buyer Tips Can Help Optimize Costs in Conveyor Design Sourcing?

-

Negotiate Pricing: Always engage in negotiations with suppliers. Request quotes from multiple vendors to leverage competitive pricing.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes initial purchase price, maintenance, and operational costs. A lower upfront price may not always equate to better value.

-

Consider Regional Suppliers: Local suppliers in regions such as Nigeria or Brazil may offer lower costs due to reduced shipping and import duties. However, ensure they meet the necessary quality standards.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import tariffs, and local regulations that can affect costs when purchasing from overseas suppliers.

-

Evaluate Long-Term Value: Invest in systems that may have a higher initial cost but provide durability and reduced maintenance over time. This approach can lead to significant savings in the long run.

In conclusion, a comprehensive understanding of cost components, pricing influencers, and strategic negotiation can empower B2B buyers to make informed decisions in conveyor design sourcing. This ensures not only cost-effectiveness but also enhances operational efficiency and reliability.

Alternatives Analysis: Comparing conveyor design With Other Solutions

Exploring Alternative Solutions to Conveyor Design

When evaluating material handling solutions, it’s essential to consider various alternatives to conveyor design. Each solution presents unique benefits and challenges depending on the specific requirements of a business. This section compares conveyor design with two viable alternatives: Automated Guided Vehicles (AGVs) and Robotic Arm Systems, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Conveyor Design | Automated Guided Vehicles (AGVs) | Robotic Arm Systems |

|---|---|---|---|

| Performance | High throughput; ideal for linear transport of materials. | Moderate to high; suitable for flexible routing and handling. | High precision; excellent for repetitive tasks and assembly. |

| Cost | Initial investment can be high, but long-term efficiency can offset costs. | Moderate to high; costs vary based on complexity and navigation systems. | High; significant investment in equipment and programming. |

| Ease of Implementation | Requires careful planning and integration; can be complex. | Generally easier to deploy; requires minimal infrastructure changes. | Complex installation; needs programming and calibration. |

| Maintenance | Regular maintenance needed; parts can wear over time. | Low maintenance; minimal moving parts reduce downtime. | Requires skilled personnel for maintenance and programming. |

| Best Use Case | Ideal for high-volume, repetitive tasks in manufacturing and distribution. | Best for dynamic environments requiring flexibility in routing. | Excellent for precision tasks like assembly and packaging. |

In-Depth Analysis of Alternatives

Automated Guided Vehicles (AGVs)

AGVs are mobile robots that transport materials throughout a facility without human intervention. They utilize various navigation technologies, such as lasers or magnetic strips, to move products efficiently. Pros include their flexibility in route adjustments, making them suitable for changing layouts and workflows. They can be integrated into existing systems with minimal disruption, offering a lower initial investment compared to extensive conveyor systems. However, cons include potential limitations in speed and capacity, particularly in high-volume scenarios where traditional conveyors might excel.

Robotic Arm Systems

Robotic arms provide automated handling of materials, capable of performing tasks ranging from assembly to packaging. Their advantages lie in their precision and versatility, allowing them to handle complex tasks that might require human dexterity. They can improve productivity and reduce labor costs over time. However, they come with disadvantages such as a high upfront investment and the need for skilled technicians to program and maintain the systems. Moreover, robotic arms are generally less effective for transporting large volumes of materials over long distances compared to conveyor systems.

Illustrative image related to conveyor design

Making the Right Choice for Your Business

Selecting the appropriate material handling solution depends on your specific operational needs and constraints. Businesses should evaluate the nature of their products, the layout of their facilities, and their production goals. For high-volume, repetitive tasks, conveyor design remains a robust choice. Alternatively, if flexibility and adaptability are paramount, AGVs may be more suitable. For precision tasks requiring advanced manipulation, robotic arms could be the ideal solution. Ultimately, a comprehensive understanding of each solution’s strengths and weaknesses will empower B2B buyers to make informed decisions that enhance operational efficiency and drive success.

Essential Technical Properties and Trade Terminology for conveyor design

What Are the Critical Technical Specifications for Conveyor Design?

When designing a conveyor system, several key technical properties must be considered to ensure optimal performance and reliability. Below are essential specifications that every B2B buyer should understand:

-

Throughput Capacity

Throughput capacity refers to the maximum amount of material that can be transported by the conveyor system within a specified timeframe, usually measured in tons per hour (TPH). Understanding throughput is crucial for businesses to ensure that the conveyor system can handle their production needs without bottlenecks. A system that cannot meet throughput demands may lead to increased operational costs and delays. -

Load Capacity

Load capacity is the maximum weight that a conveyor can safely carry at any given time. This specification is vital for preventing overloading, which can cause mechanical failure or reduce the lifespan of the equipment. Buyers must assess the weight of the materials being moved and choose a conveyor that can accommodate these loads to maintain efficiency and safety. -

Conveying Speed

Conveying speed is the rate at which materials move along the conveyor, typically measured in meters per minute (m/min). The right speed is essential for synchronization with other processes in a production line. Too fast may lead to spills or damage, while too slow can result in inefficiencies. Buyers should calculate the ideal speed based on their production cycle times. -

Material Grade

The grade of materials used in conveyor construction (such as stainless steel, plastic, or rubber) significantly impacts durability and maintenance. For instance, food-grade conveyors require materials that are resistant to corrosion and easy to clean. Understanding material grades helps buyers select a conveyor that meets industry standards and environmental conditions. -

Belt Width and Trough Size

Belt width and trough size are critical for accommodating different sizes of materials. A wider belt may be necessary for bulkier items, while the trough size must match the material’s dimensions to prevent spillage. Ensuring the right dimensions can optimize the conveyor’s performance and reduce maintenance issues.

What Are Common Trade Terms Used in Conveyor Design?

Familiarity with industry terminology is essential for effective communication and negotiation in the conveyor design and procurement process. Below are key trade terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers assess the quality and compatibility of components for their conveyor systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of goods that a supplier is willing to sell. This term is critical for budget planning, as it can affect the overall cost of procurement. Buyers should inquire about MOQs to ensure that they can meet purchasing requirements without incurring unnecessary expenses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This process allows buyers to compare costs and terms from multiple vendors, ensuring they get the best deal. Crafting a clear RFQ can facilitate smoother negotiations and faster procurement. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. They clarify the responsibilities of buyers and sellers in the shipping process, including who is responsible for shipping costs, insurance, and risk. Understanding Incoterms helps buyers manage logistics and avoid unexpected charges. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Knowing the lead time is crucial for production planning, as delays can disrupt operations. Buyers should discuss lead times with suppliers to align their procurement schedules with production needs.

By understanding these technical specifications and trade terms, B2B buyers can make informed decisions when designing or procuring conveyor systems, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the conveyor design Sector

What Are the Current Market Dynamics and Key Trends Influencing Conveyor Design?

The conveyor design sector is experiencing significant transformation driven by global industrialization, technological advancements, and evolving consumer expectations. As industries in Africa, South America, the Middle East, and Europe expand, there is an increased demand for efficient material handling solutions that enhance productivity and reduce operational costs. Key trends include the rise of automation and IoT technologies, which enable real-time monitoring and predictive maintenance, thus minimizing downtime and improving system reliability. Additionally, the integration of AI and machine learning in conveyor systems allows for smarter decision-making processes, optimizing the flow of materials based on real-time data analytics.

Illustrative image related to conveyor design

Furthermore, sustainability is emerging as a core consideration in conveyor design. International buyers are increasingly prioritizing suppliers who implement energy-efficient practices and environmentally friendly materials. This trend is particularly pronounced in regions facing stringent environmental regulations, such as Europe. In the context of sourcing, the demand for customizable and modular conveyor solutions is growing, allowing businesses to adapt their systems to changing operational needs without incurring significant costs.

Lastly, global supply chain disruptions have prompted B2B buyers to seek local suppliers and diversify their sourcing strategies to mitigate risks associated with long lead times and geopolitical uncertainties. This shift is particularly relevant for buyers in regions like Nigeria and Brazil, where local partnerships can enhance agility and responsiveness to market changes.

How Is Sustainability Shaping Sourcing Trends in Conveyor Design?

Sustainability is becoming a pivotal factor in the conveyor design sector, influencing not just product development but also sourcing strategies. The environmental impact of conveyor systems, particularly in terms of energy consumption and material waste, has led to a growing emphasis on eco-friendly design. For B2B buyers, investing in conveyor systems that utilize sustainable materials—such as recycled metals or biodegradable plastics—can significantly reduce the carbon footprint of their operations.

Illustrative image related to conveyor design

Moreover, ethical sourcing practices are gaining traction among international buyers who are increasingly concerned about the social responsibility of their supply chains. Companies are now more likely to partner with manufacturers that adhere to fair labor practices and contribute positively to their communities. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria for evaluating suppliers.

To further enhance sustainability, many manufacturers are adopting energy-efficient motors and incorporating smart technologies to monitor energy usage and optimize performance. This not only reduces operational costs but also aligns with the global push towards greener manufacturing practices. By prioritizing sustainability in their sourcing decisions, B2B buyers can enhance their brand reputation and meet the expectations of environmentally conscious consumers.

How Has Conveyor Design Evolved to Meet Modern Needs?

The evolution of conveyor design can be traced back to the industrial revolution, where simple belt systems were first employed to automate material handling processes. Over the decades, this foundational technology has undergone significant advancements, driven by the need for increased efficiency and the ability to handle diverse materials across various industries.

In recent years, the focus has shifted towards modular and flexible conveyor systems that can easily adapt to changing operational requirements. This evolution is largely attributed to the rise of automation and the integration of smart technologies, which allow for real-time monitoring and data-driven decision-making. Today’s conveyor systems are designed not only for functionality but also for ease of maintenance and energy efficiency, reflecting the dual priorities of performance and sustainability in modern manufacturing environments.

As the market continues to evolve, the emphasis on customization and integration with other automated systems will likely shape the future of conveyor design, ensuring that it meets the diverse needs of global B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor design

-

How do I solve challenges related to conveyor system efficiency?

To enhance conveyor system efficiency, start by conducting a thorough analysis of your operational workflow. Identify bottlenecks and assess the current throughput, load capacity, and speed of your existing system. Collaborate with conveyor design experts to customize solutions tailored to your specific needs, whether it’s upgrading components, optimizing layout, or integrating automation. Regular maintenance and monitoring can also help preemptively address issues, ensuring your system operates smoothly. -

What is the best conveyor type for bulk material handling?

The best conveyor type for bulk material handling often depends on the specific materials being transported. For heavy, abrasive materials, a belt conveyor is typically recommended due to its robustness and adaptability to various environments. Alternatively, vibratory conveyors are excellent for fragile materials, offering gentle handling and low maintenance. Assess your material’s characteristics, such as size, weight, and flow behavior, and consult with a supplier to determine the ideal conveyor system for your application. -

What factors should I consider when customizing a conveyor system?

Customization of a conveyor system requires careful consideration of several factors: the type of materials being handled, desired throughput, load capacity, and the operational environment. Additionally, think about space constraints, integration with existing machinery, and safety regulations. Collaborating with experienced suppliers can yield valuable insights into design options that maximize efficiency and minimize downtime, ensuring that the final solution meets all operational requirements. -

How do I vet suppliers for conveyor system design?

When vetting suppliers for conveyor system design, evaluate their industry experience, client testimonials, and portfolio of previous projects. Request references and inquire about their customization capabilities, lead times, and after-sales support. It’s also beneficial to assess their adherence to international quality standards, certifications, and compliance with local regulations in your region. Engaging in direct communication can help clarify any concerns and ensure alignment with your specific needs. -

What are the minimum order quantities (MOQs) for conveyor systems?

Minimum order quantities (MOQs) for conveyor systems vary significantly among suppliers and depend on factors such as the type of conveyor, customization level, and production capabilities. Some manufacturers may have flexible MOQs for standard systems, while custom designs might require higher quantities to justify production costs. It’s essential to discuss your requirements with suppliers upfront to understand their policies and negotiate terms that align with your operational needs. -

What payment terms should I expect when sourcing conveyor systems internationally?

Payment terms for international conveyor system purchases can vary widely based on supplier policies, the scale of the order, and the buyer’s creditworthiness. Common terms include upfront deposits (typically 30% to 50%), with the balance due upon completion or delivery. It’s advisable to clarify payment methods—such as letters of credit, wire transfers, or escrow services—to mitigate risks. Always ensure that terms are documented in the contract to avoid misunderstandings. -

How can I ensure quality assurance (QA) for my conveyor system?

To ensure quality assurance for your conveyor system, choose suppliers who implement rigorous QA processes throughout their manufacturing stages. Request documentation of quality certifications, such as ISO standards, and inquire about their testing protocols for components and systems. Establish clear acceptance criteria in your contract and consider scheduling factory visits or audits during production to verify compliance with your specifications before shipment. -

What logistics considerations are important for importing conveyor systems?

When importing conveyor systems, logistics considerations include shipping methods, lead times, customs regulations, and potential tariffs. Ensure that your supplier provides detailed shipping schedules and assist with necessary documentation for customs clearance. Additionally, evaluate the costs associated with transportation and delivery to your site, including the availability of local support for installation and maintenance. Collaborating with a logistics expert can streamline the process and minimize delays.

Top 5 Conveyor Design Manufacturers & Suppliers List

1. PPI – Precision Conveyor Design Tool

Domain: ppi-global.com

Registered: 2016 (9 years)

Introduction: PPI’s Precision Conveyor Design tool is a web-based application for conveyor horsepower calculation, selection of pulleys and idlers, and selection of take-up travel length for fixed take-up conveyors up to 1,000 feet long using Stretch-Rite calculations. It is limited to non-regenerative conveyors not exceeding 2,000 feet in length and fabric belts with ratings up to 1,000 PIW. Recommended for us…

2. Reddit – Conveyor System Design Resources

3. Rapid Industries – Overhead Conveyor Systems

Domain: rapidindustries.com

Registered: 1998 (27 years)

Introduction: Overhead Conveyor Systems: Rapid Flex (enclosed track), Rapid Flow Q (Power + Free), Rapid Flow 3×3 (Power + Free), Rapid Flow 4×4 (Power + Free). Additional offerings include System Integration, Floor Conveyors, and Conveyor Systems Components such as Take Ups, Drives, and Track IBeam. Design Guides available for system design and layout planning.

4. JH Foster – Automated Conveying Systems

Domain: jhfoster.com

Registered: 1998 (27 years)

Introduction: Automated conveying systems designed for material handling efficiency, available in various types including belt, roller, ball transfer, chute, drag/chain, overhead, screw, vertical, and vibrating. Key considerations for design include material type, conveyor speed, available space, safety mechanisms, and maintenance requirements. Benefits include streamlined productivity, reduced labor, improved …

5. Dorner – Industrial & Automation Conveyors

Domain: dornerconveyors.com

Registered: 2007 (18 years)

Introduction: INDUSTRIAL & AUTOMATION CONVEYORS: Fabric & Modular Belt, 1100 Miniature Conveyors, 2200 Low Profile Conveyors, 2700 Medium Duty Conveyors, 3200 Heavy Duty Conveyors, DCMove Heavy Duty Steel, Precision Move, Compact Curve Conveyor, Flexible Chain, FlexMove, FlexMove Helix, FlexMove Stainless, Pallet Systems, ERT 150, ERT 250, ERT 350, DualMove Pallet System, SANITARY, STAINLESS STEEL CONVEYORS: Aq…

Strategic Sourcing Conclusion and Outlook for conveyor design

In conclusion, effective conveyor design is crucial for optimizing material handling processes across various industries. By strategically sourcing conveyor systems tailored to specific operational needs, businesses can enhance productivity, reduce downtime, and improve overall efficiency. Key takeaways include understanding the importance of system customization, considering environmental factors, and prioritizing safety and maintenance in design.

Strategic sourcing not only ensures you select the right technology but also fosters partnerships with experts who can provide ongoing support and innovation. For international B2B buyers in Africa, South America, the Middle East, and Europe, this is a pivotal opportunity to leverage advanced conveyor solutions that can drive competitive advantage in increasingly dynamic markets.

As industries evolve and demand for efficient logistics grows, investing in high-quality conveyor systems will be essential. Engage with specialized manufacturers and engineers to explore customized solutions that align with your unique operational requirements. The future of your material handling efficiency starts today—take the next step and transform your conveyor design strategy into a robust asset for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.