Everything You Need to Know About Concealed Hinges Types Sourcing in 2025

Introduction: Navigating the Global Market for concealed hinges types

In today’s competitive global market, sourcing the right concealed hinges can pose significant challenges for B2B buyers, especially when navigating diverse regional standards and specifications. As these hardware components play a crucial role in the functionality and aesthetics of cabinetry, understanding the various types of concealed hinges is essential for making informed purchasing decisions. This comprehensive guide delves into the diverse types of concealed hinges available, including European, semi-concealed, and mortise hinges, along with their specific applications in different cabinetry styles.

Beyond just types, this guide also addresses key considerations such as supplier vetting, cost analysis, and installation requirements, ensuring that buyers from regions like Africa, South America, the Middle East, and Europe—including major markets like Germany and Brazil—are well-equipped to make strategic choices. By providing insights into industry best practices and trends, this resource empowers international buyers to enhance their procurement processes, streamline their supply chains, and ultimately improve their product offerings. With this guide, you will not only gain clarity on concealed hinge options but also uncover valuable strategies to optimize your sourcing efforts in a complex marketplace.

Understanding concealed hinges types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| European Two-Piece Hinges | Requires a hole in the door back, attaches to a mounting plate | Cabinet manufacturing, furniture | Pros: Easy to adjust and install; suitable for various cabinet styles. Cons: Requires precise drilling. |

| European One-Piece Hinges | Compact design, attaches directly to the face frame | Residential and commercial cabinetry | Pros: Space-saving; simpler installation. Cons: Limited adjustability compared to two-piece options. |

| Semi-Concealed Hinges | Small visible knuckle; cut slot in door edge | Specialty furniture, cabinetry | Pros: Aesthetic appeal; minimal visibility. Cons: Not suitable for all door types; requires precise cuts. |

| Mortise Hinges | Installed in a mortised opening, completely concealed when closed | High-end cabinetry, custom furniture | Pros: Strong and durable; offers a seamless look. Cons: More complex installation; requires skilled labor. |

| Soft-Close Hinges | Equipped with dampeners to prevent slamming | Residential cabinets, high-traffic areas | Pros: Reduces noise; enhances user experience. Cons: Slightly higher cost; may require additional space. |

What are the characteristics of European Two-Piece Hinges?

European Two-Piece Hinges are characterized by their design that necessitates a hole drilled into the back of the cabinet door. This hinge attaches to a mounting plate, which can be affixed to either a face frame or the side of a frameless cabinet. They are highly adjustable, making them suitable for various cabinet styles, which is a critical consideration for manufacturers aiming for flexibility in production. When purchasing, B2B buyers should ensure compatibility with their cabinet designs and consider the precision required for installation.

How do European One-Piece Hinges differ from their counterparts?

European One-Piece Hinges, often referred to as compact hinges, feature a more streamlined design that attaches directly to the face frame of the cabinet. This design simplifies installation and is particularly beneficial for space-constrained environments. While they offer ease of use, buyers should note that they may lack the same level of adjustability as two-piece hinges. B2B buyers focusing on residential and commercial cabinetry will find these hinges advantageous for their straightforward application.

What are the advantages of Semi-Concealed Hinges?

Semi-Concealed Hinges, also known as knife hinges, are notable for their minimal visibility, with only a small knuckle exposed on the edge of the door. This type of hinge is particularly suited for specialty furniture and cabinetry where aesthetics are paramount. However, they require precise cuts in the door, making them less versatile for all applications. B2B buyers should weigh the aesthetic benefits against the installation complexity when considering this option.

Why choose Mortise Hinges for high-end cabinetry?

Mortise Hinges are designed to be installed in a mortised opening, allowing them to remain completely concealed when the door is closed. This design provides a sleek and professional finish, making them ideal for high-end cabinetry and custom furniture. While they offer superior strength and durability, the installation process is more complex and may require skilled labor. B2B buyers should consider the long-term benefits of aesthetics and durability versus the initial installation costs.

What makes Soft-Close Hinges a popular choice?

Soft-Close Hinges are equipped with dampeners that slow down the door as it closes, preventing slamming and minimizing noise. These hinges are particularly beneficial in residential settings and high-traffic areas, enhancing the overall user experience. While they may come at a slightly higher cost and require additional space for installation, their advantages in terms of functionality and comfort make them a worthwhile investment for B2B buyers in the cabinetry market.

Key Industrial Applications of concealed hinges types

| Industry/Sector | Specific Application of concealed hinges types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Cabinet doors for kitchens and living spaces | Enhances aesthetics and functionality | Material durability, adjustability, and design compatibility |

| Hospitality | Hotel room doors and cabinetry | Improves guest experience and design appeal | Compliance with safety standards and ease of installation |

| Retail Displays | Store fixtures and display cabinets | Maximizes product visibility and accessibility | Customization options and load-bearing capacity |

| Automotive | Interior storage compartments and access panels | Increases space efficiency and user convenience | Resistance to wear and tear in high-use environments |

| Architectural Design | Concealed doors in commercial buildings | Provides a sleek, modern look | Precision in measurements and compatibility with architectural plans |

How Are Concealed Hinges Used in Furniture Manufacturing?

In the furniture manufacturing sector, concealed hinges are integral for cabinet doors in kitchens and living spaces. These hinges provide a clean aesthetic by hiding the hardware, thereby enhancing the overall design. They solve common issues such as misalignment and noise during operation, thanks to adjustable features. Buyers should prioritize durability and compatibility with various cabinet styles, ensuring the hinges meet the specific overlay requirements and load capacities of the furniture pieces.

What Role Do Concealed Hinges Play in the Hospitality Industry?

In the hospitality industry, concealed hinges are commonly used for hotel room doors and cabinetry. Their discreet design contributes to a modern and upscale appearance, which is vital for guest satisfaction. These hinges help prevent slamming, reducing noise disturbances. When sourcing, businesses need to ensure that the hinges comply with local safety standards and are easy to install, facilitating quick maintenance and upgrades in hotel environments.

How Are Concealed Hinges Beneficial for Retail Displays?

Retail displays utilize concealed hinges for store fixtures and display cabinets, allowing for a seamless design that draws attention to the products rather than the hardware. This application maximizes product visibility and accessibility, enhancing the shopping experience. Retailers should consider customization options to match their branding and ensure that the hinges can support the weight of display items without compromising functionality.

In What Ways Are Concealed Hinges Applied in the Automotive Sector?

In the automotive sector, concealed hinges are used in interior storage compartments and access panels. Their ability to provide a clean look while maximizing space efficiency is crucial in vehicle design. These hinges must be durable and resistant to wear, as they are subject to frequent use. Buyers should focus on sourcing hinges that can withstand the rigors of automotive environments, ensuring long-lasting performance and user convenience.

Why Are Concealed Hinges Important in Architectural Design?

Architectural design benefits from concealed hinges in commercial buildings, where they are used in concealed doors to create a sleek, modern look. This application enhances the aesthetic appeal of spaces while providing functional access. Buyers in this sector need to ensure precision in measurements and compatibility with architectural plans, as well as the ability to accommodate various door sizes and weights, ensuring seamless integration into the overall design.

3 Common User Pain Points for ‘concealed hinges types’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Concealed Hinge Type

The Problem: B2B buyers often struggle to identify which type of concealed hinge is suitable for their specific cabinet designs. With various options like European two-piece hinges, one-piece compact hinges, and mortise hinges, selecting the right one can be overwhelming. This confusion can lead to purchasing errors, resulting in increased costs and project delays.

The Solution: To effectively choose the correct concealed hinge type, it’s essential to assess the cabinet construction style first. For frameless cabinets, European two-piece hinges are typically recommended as they offer adjustable mounting plates that provide flexibility during installation. Buyers should also consider the overlay measurements—this ensures that the hinges will properly align with the cabinet doors. Utilizing detailed product specifications from suppliers can help confirm compatibility with existing designs. Additionally, engaging with a hinge expert during the selection process can provide valuable insights and recommendations tailored to specific needs, thus preventing costly mistakes.

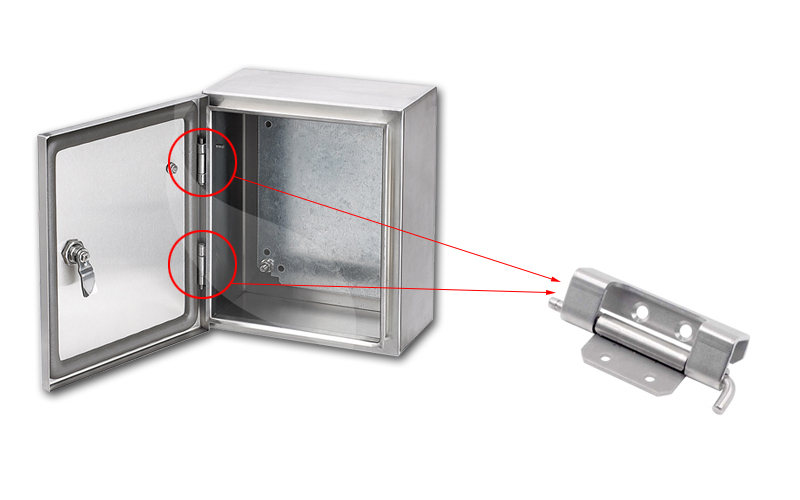

Illustrative image related to concealed hinges types

Scenario 2: Installation Challenges Leading to Misalignment

The Problem: Installation of concealed hinges can often lead to misalignment of cabinet doors, causing aesthetic issues and functional problems, such as doors not closing properly. This is particularly problematic in B2B environments where precision and quality are paramount, resulting in dissatisfaction from clients or end-users.

The Solution: To mitigate installation challenges, it is crucial to follow a systematic approach. Begin by using a hinge jig to ensure consistent placement of the hinges across all doors. This tool allows for precise drilling of the required holes, reducing the likelihood of misalignment. Furthermore, opting for hinges that offer adjustment features can make a significant difference. For instance, many modern concealed hinges come with built-in adjustability that allows for fine-tuning after installation. Providing your installation team with thorough training or instructional materials can also enhance their skills and confidence, leading to improved outcomes.

Scenario 3: Budget Constraints Affecting Quality Choices

The Problem: Budget limitations often force B2B buyers to compromise on quality when sourcing concealed hinges. This can lead to the selection of lower-quality hinges that may not perform well over time, resulting in increased maintenance costs and a negative impact on overall project quality.

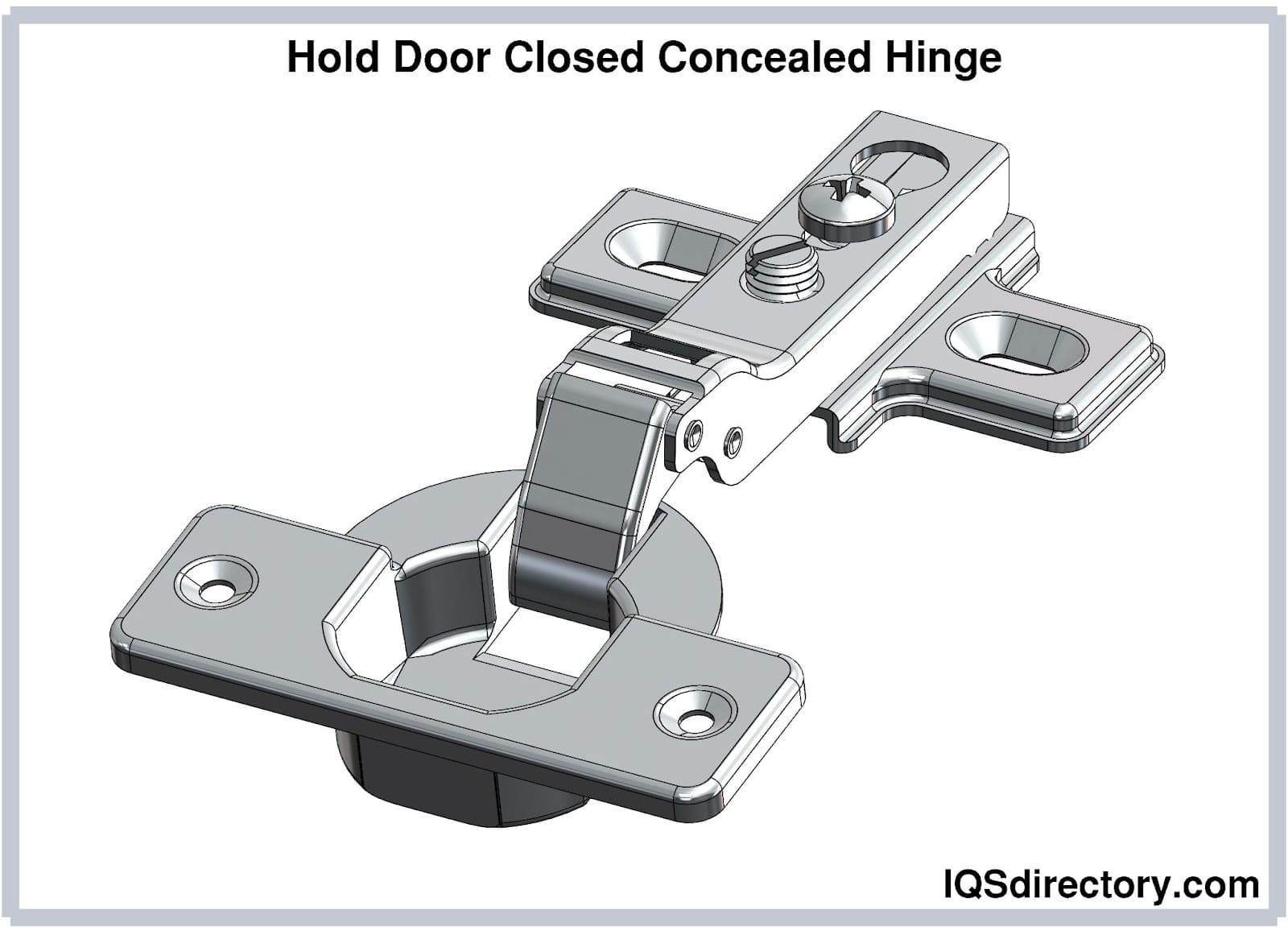

Illustrative image related to concealed hinges types

The Solution: To navigate budget constraints while ensuring high-quality choices, buyers should focus on value engineering rather than simply opting for the cheapest option. This means considering the long-term benefits and durability of concealed hinges. Investing in reputable brands known for their reliability can pay off in the long run by minimizing the need for replacements. Additionally, exploring bulk purchasing options or establishing relationships with manufacturers can yield discounts and cost savings. It’s also advisable to conduct thorough market research to compare prices and quality across different suppliers, ensuring that the chosen hinges meet both budgetary and performance standards. Leveraging supplier expertise can also provide insights into cost-effective alternatives that do not compromise on quality.

Strategic Material Selection Guide for concealed hinges types

What Are the Key Materials Used in Concealed Hinges?

When selecting concealed hinges, the choice of material plays a crucial role in determining the performance, durability, and suitability for specific applications. This analysis focuses on four common materials used in the manufacturing of concealed hinges: stainless steel, brass, zinc alloy, and plastic.

How Does Stainless Steel Perform in Concealed Hinges?

Stainless steel is one of the most popular materials for concealed hinges due to its exceptional corrosion resistance and durability. It can withstand high temperatures and is suitable for environments exposed to moisture, making it ideal for kitchen and bathroom applications. The key advantage of stainless steel hinges is their longevity, as they do not rust or corrode over time.

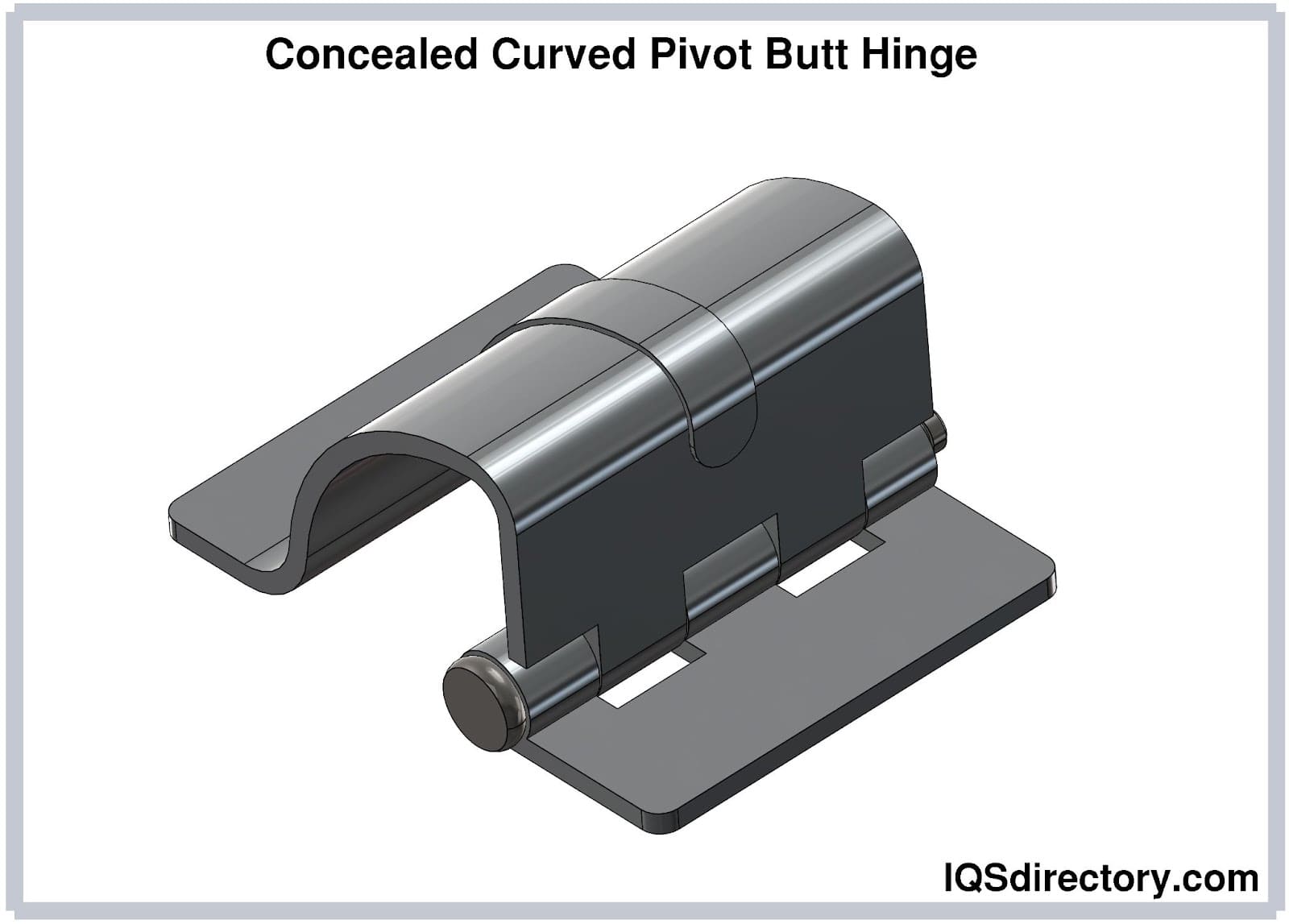

Illustrative image related to concealed hinges types

However, the manufacturing complexity of stainless steel hinges can lead to a higher cost compared to other materials. Additionally, while they are robust, they may not be suitable for extremely lightweight applications where cost-saving is a priority. For international buyers, especially in humid regions like parts of Africa and South America, stainless steel hinges comply with various standards, including ASTM and DIN, ensuring reliability and quality.

What Are the Benefits of Brass in Concealed Hinges?

Brass is another commonly used material for concealed hinges, known for its aesthetic appeal and good corrosion resistance. It is often chosen for decorative applications where appearance is a priority. Brass hinges can be easily machined, allowing for intricate designs and finishing options.

On the downside, brass is generally softer than stainless steel, which can lead to wear and deformation under heavy loads. Additionally, while brass can resist corrosion, it is not as effective as stainless steel in harsh environments. For buyers in Europe, particularly in Germany, brass hinges must meet specific standards like DIN 7337 to ensure quality and performance.

How Do Zinc Alloys Compare in Concealed Hinges?

Zinc alloys are often used in concealed hinges due to their cost-effectiveness and versatility. They can be easily cast into complex shapes, making them suitable for a variety of designs. Zinc alloy hinges are lightweight and provide decent corrosion resistance, making them appropriate for indoor applications.

However, zinc alloys may not perform well in extreme conditions, such as high humidity or exposure to chemicals, which can lead to corrosion over time. For international buyers, particularly in the Middle East where temperatures can soar, it is crucial to consider the environmental conditions when opting for zinc alloy hinges. Compliance with local standards, such as JIS in Japan or ASTM in the U.S., is also essential to ensure product reliability.

What Role Does Plastic Play in Concealed Hinges?

Plastic hinges are becoming increasingly popular for lightweight applications due to their low cost and resistance to corrosion. They are ideal for environments where moisture is a concern, such as in bathrooms or outdoor settings. Additionally, plastic hinges can be manufactured in various colors, allowing for design flexibility.

Despite their advantages, plastic hinges have limitations in terms of load-bearing capacity and durability compared to metal options. They may not withstand heavy use or extreme temperatures, making them less suitable for high-traffic areas. For buyers in South America, where diverse climates exist, understanding the specific application requirements is crucial when considering plastic hinges.

Summary Table of Material Properties for Concealed Hinges

| Material | Typical Use Case for concealed hinges types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Kitchen and bathroom cabinets | Exceptional corrosion resistance | Higher manufacturing complexity | High |

| Brass | Decorative cabinetry | Aesthetic appeal and machinability | Softer, less durable under load | Medium |

| Zinc Alloy | Indoor applications | Cost-effective and versatile | Poor performance in extreme conditions | Low |

| Plastic | Lightweight and moisture-prone environments | Low cost and corrosion resistance | Limited load-bearing capacity | Low |

This strategic material selection guide equips B2B buyers with critical insights into the properties, advantages, and limitations of various materials used in concealed hinges, helping them make informed purchasing decisions tailored to their specific needs and regional standards.

Illustrative image related to concealed hinges types

In-depth Look: Manufacturing Processes and Quality Assurance for concealed hinges types

What Are the Key Stages in the Manufacturing Process of Concealed Hinges?

The manufacturing process for concealed hinges involves several critical stages that ensure both functionality and quality. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

Material Preparation: What Raw Materials Are Used?

The initial stage of hinge manufacturing involves selecting high-quality raw materials. Most concealed hinges are made from durable metals such as stainless steel, brass, or zinc alloys, chosen for their strength and resistance to corrosion. Depending on the hinge type, additional materials like nylon or plastic may also be incorporated for specific applications, such as soft-close mechanisms. Once the materials are selected, they undergo a rigorous inspection to ensure they meet industry standards, which is crucial for maintaining the integrity of the final product.

How Are Concealed Hinges Formed?

The forming stage utilizes advanced techniques such as stamping, forging, or CNC machining. Each method is chosen based on the hinge design and the required precision.

- Stamping is often used for producing flat parts, where sheets of metal are cut and shaped into the desired profile using a die.

- Forging provides enhanced strength by shaping heated metal under pressure, which is particularly beneficial for heavy-duty hinges.

- CNC Machining allows for precise and intricate designs, essential for features like adjustable mounting plates or soft-close mechanisms.

After forming, the parts are often deburred and polished to remove any sharp edges and prepare them for assembly.

What Does the Assembly Process Involve?

During the assembly stage, individual components are brought together to create a complete hinge. This may involve welding, riveting, or using screws and fasteners. For more complex hinge types, such as those with adjustable features, additional precision is required to ensure smooth operation.

Quality assurance checks are integrated into this stage, ensuring that each hinge functions correctly before moving on to the finishing process. This can include testing for opening angles, resistance to wear, and alignment, which is particularly important for concealed hinges that must fit seamlessly within cabinetry.

How Are Concealed Hinges Finished?

Finishing is the final stage of the manufacturing process and is critical for both aesthetics and durability. Common finishing techniques include:

- Electroplating for corrosion resistance and to achieve a desirable surface finish, such as satin chrome or matte black.

- Powder Coating for a durable and colorful finish that can enhance the hinge’s appearance while providing additional protection against wear and tear.

- Anodizing for aluminum components to increase corrosion resistance and surface hardness.

These finishing processes not only enhance the visual appeal but also extend the lifespan of the hinge, making them suitable for a variety of applications in different environments.

What Quality Assurance Measures Are Important for Concealed Hinges?

Quality assurance (QA) is paramount in hinge manufacturing, particularly for B2B buyers who demand reliability and performance. Various international and industry-specific standards govern the QA processes that manufacturers must adhere to.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is one of the most recognized quality management system standards globally. It ensures that companies consistently meet customer and regulatory requirements, which is particularly relevant for international buyers seeking reliable suppliers. Compliance with ISO 9001 indicates that the manufacturer has implemented effective quality management processes.

Additionally, certain products may require compliance with CE marking standards in Europe, indicating that they meet health, safety, and environmental protection requirements. Buyers from regions like Africa and South America should also be aware of local regulations and standards that may apply to imported hardware.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) in the manufacturing of concealed hinges typically involves several checkpoints:

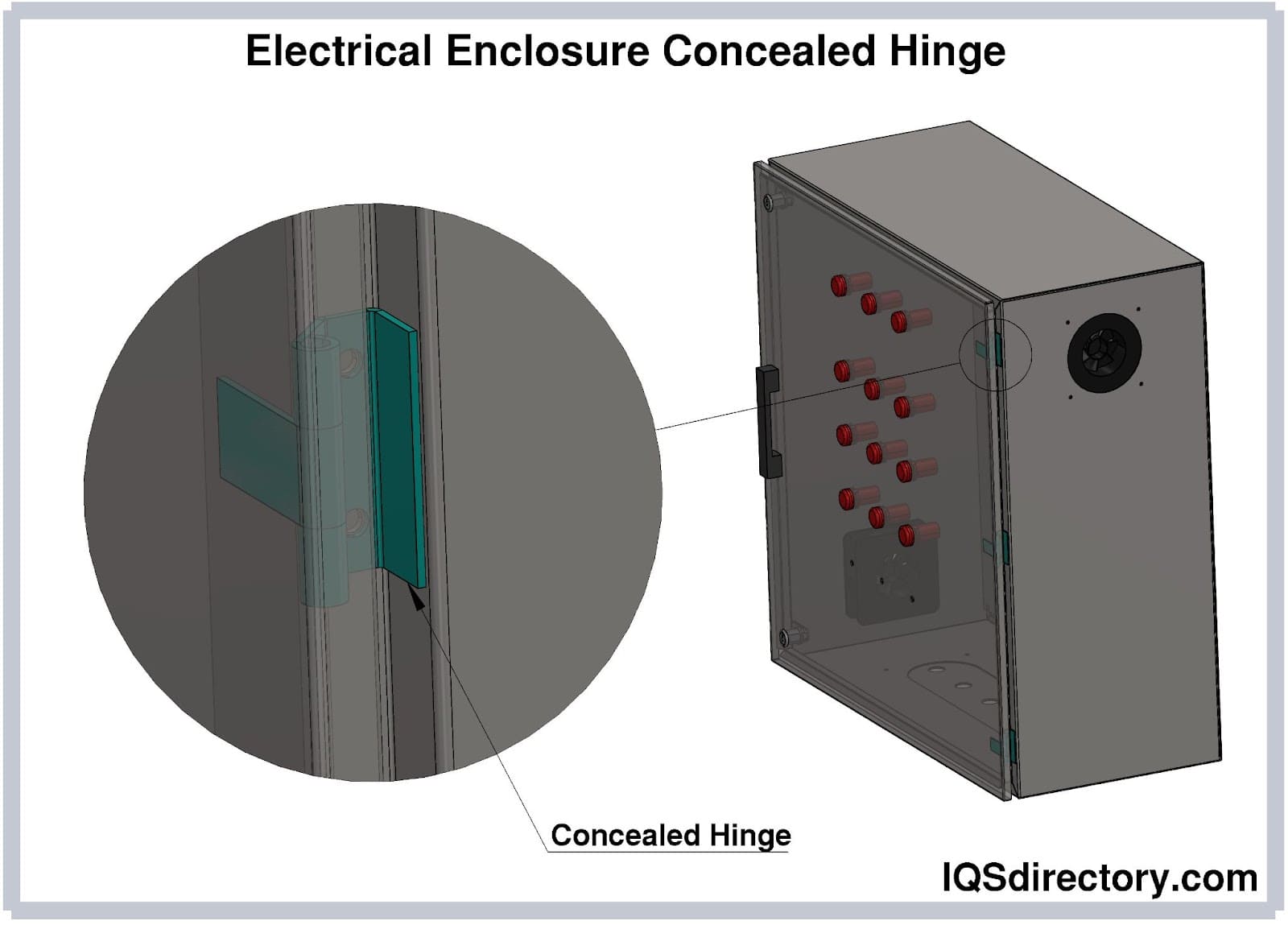

Illustrative image related to concealed hinges types

-

Incoming Quality Control (IQC): This initial check assesses the quality of raw materials before they are used in production. Suppliers should provide certificates of compliance for materials, ensuring they meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and tests are conducted to identify defects early. This might include dimensional checks and functional tests on assembled parts.

-

Final Quality Control (FQC): Before the hinges are packaged and shipped, a final inspection ensures that the products meet all specifications and quality standards. This may include testing for durability, functionality, and finish quality.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and QA systems in place. This can help identify whether a supplier adheres to international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC metrics and testing results. This transparency is crucial for building trust.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of product quality before shipment. This is particularly important for international transactions where language and cultural barriers may exist.

What Testing Methods Are Commonly Used for Concealed Hinges?

Testing methods for concealed hinges vary based on the application and intended use. Common testing procedures include:

- Load Testing: Assessing the hinge’s ability to support weight and withstand stresses during operation.

- Cycle Testing: Evaluating the durability of the hinge through repeated opening and closing to simulate long-term use.

- Corrosion Testing: Exposing hinges to saline or acidic environments to ensure they can withstand corrosion, particularly for outdoor or high-humidity applications.

By understanding these processes and standards, B2B buyers can make informed decisions when selecting suppliers for concealed hinges, ensuring they procure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘concealed hinges types’

Introduction

This practical sourcing guide provides a comprehensive checklist for B2B buyers seeking to procure concealed hinges. As concealed hinges are essential components in cabinetry and furniture design, understanding the various types and specifications is vital for making informed purchasing decisions. This guide will help you navigate the complexities of sourcing concealed hinges effectively.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. Consider factors such as the type of cabinetry (face-frame or frameless), door thickness, and desired opening angles.

Illustrative image related to concealed hinges types

- Overlay Measurements: Ensure you understand how the cabinet door overlays the frame, as this affects hinge selection.

- Weight Capacity: Assess the weight of the doors to determine the necessary hinge strength.

Step 2: Research Different Types of Concealed Hinges

Familiarize yourself with the various types of concealed hinges available on the market. Each type serves different functionalities and aesthetics.

- European Hinges: Commonly used in frameless cabinets, requiring a hole bored into the door.

- Mortise Hinges: Installed within a mortised cut, providing a clean look when doors are closed.

Step 3: Evaluate Supplier Capabilities

Thoroughly assess potential suppliers to ensure they can meet your specific needs. Look for suppliers that specialize in concealed hinges and have experience in your industry.

- Request Documentation: Ask for product catalogs, installation guides, and case studies.

- Certifications: Verify that suppliers adhere to international standards and quality certifications relevant to your region.

Step 4: Compare Pricing and Terms

Once you have a shortlist of suppliers, compare their pricing structures and terms of sale. Understanding the cost implications helps you stay within budget while ensuring quality.

- Bulk Discounts: Inquire about pricing tiers for larger orders to optimize costs.

- Shipping Terms: Review shipping costs and delivery timelines, especially for international sourcing.

Step 5: Assess Product Quality and Durability

Quality is paramount when it comes to hinges, as they directly affect the functionality and longevity of cabinetry. Evaluate the material and construction of the hinges.

- Material Composition: Look for hinges made from high-grade stainless steel or durable finishes to prevent rust and wear.

- User Reviews: Seek feedback from other buyers regarding the performance and durability of the hinges.

Step 6: Confirm After-Sales Support and Warranty

Reliable after-sales support can be crucial, especially for installation and maintenance. Ensure your supplier offers adequate support.

Illustrative image related to concealed hinges types

- Technical Assistance: Check if the supplier provides installation guidance or troubleshooting help.

- Warranty Policies: Review the warranty terms to understand the coverage in case of defects or issues.

Step 7: Finalize Your Order and Monitor Delivery

After selecting your preferred supplier and product, finalize your order while keeping an eye on delivery timelines.

- Order Confirmation: Ensure that all specifications are correct in the order confirmation.

- Track Shipping: Use tracking services to monitor the shipment, ensuring timely delivery for your project needs.

By following this checklist, B2B buyers can confidently navigate the sourcing process for concealed hinges, ensuring they select the right products for their specific requirements.

Comprehensive Cost and Pricing Analysis for concealed hinges types Sourcing

What Are the Key Cost Components for Concealed Hinges in B2B Sourcing?

When sourcing concealed hinges, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The choice of materials significantly impacts the cost. Stainless steel, for example, offers durability and corrosion resistance but can be more expensive than plastic or lower-grade metals. Custom finishes (e.g., satin nickel, matte black) also add to the material costs.

-

Labor: Labor costs encompass both manufacturing and assembly. Regions with lower labor costs may provide more competitive pricing, but this often correlates with quality variations.

-

Manufacturing Overhead: This includes expenses related to factory operation, equipment maintenance, and production efficiency. High-volume manufacturers can spread these costs over a larger output, resulting in lower per-unit costs.

-

Tooling: Initial tooling costs for specialized hinges can be significant, particularly for custom designs. Buyers should consider these as part of the overall investment, especially for low-volume orders.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. While this adds to the cost, it ultimately reduces the risk of returns or failures in the field.

-

Logistics: Shipping costs vary based on distance, shipping method, and packaging. International buyers must also factor in customs duties and taxes, which can significantly affect total costs.

-

Margin: Suppliers typically include a profit margin, which can vary based on brand reputation, product uniqueness, and market demand.

How Do Price Influencers Affect Concealed Hinge Sourcing?

Several factors can influence the pricing of concealed hinges:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing tiers. Larger orders typically yield better pricing due to economies of scale.

-

Specifications and Customization: Custom specifications, such as unique sizes or features, can lead to higher costs. Standardized products usually have lower prices due to established production processes.

-

Materials and Quality Certifications: Products made from high-grade materials or those that meet specific certifications (like ISO standards) may command premium pricing. Buyers must assess whether the additional cost aligns with their quality requirements.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiency can all impact pricing. Established suppliers with robust logistics may offer better reliability, justifying higher prices.

-

Incoterms: Understanding the terms of sale (Incoterms) is vital for international transactions. They determine who bears the risk and cost during shipping, affecting the overall cost structure.

What Are the Best Negotiation Tips for B2B Buyers Sourcing Concealed Hinges?

To optimize purchasing costs, buyers should consider the following strategies:

-

Leverage Volume: Buyers should negotiate based on volume commitments. Suppliers are often willing to provide discounts for larger orders, which can significantly reduce costs.

-

Explore Long-Term Relationships: Establishing long-term partnerships with suppliers can lead to better pricing and terms over time. Consistent orders may make suppliers more willing to negotiate favorable rates.

-

Understand Total Cost of Ownership (TCO): TCO includes not only the purchase price but also costs related to installation, maintenance, and potential failures. Focusing on TCO can lead buyers to choose higher-quality hinges that may be more cost-effective in the long run.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, regional market conditions, and geopolitical factors that may influence pricing. Understanding these nuances can aid in making informed purchasing decisions.

What Should International B2B Buyers Consider When Sourcing Concealed Hinges?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should keep in mind:

Illustrative image related to concealed hinges types

-

Regulatory Compliance: Ensure that products meet local regulations and standards to avoid issues during customs clearance.

-

Shipping Logistics: Factor in shipping times and costs, including potential delays due to customs. It’s beneficial to work with suppliers who have experience in international shipping.

-

Market Research: Conduct thorough research on local market prices and competitor offerings to avoid overpaying.

-

Communication: Clear communication with suppliers can prevent misunderstandings related to specifications, delivery timelines, and payment terms.

Disclaimer on Pricing

Prices for concealed hinges can fluctuate based on market demand, material availability, and other external factors. Buyers are encouraged to obtain multiple quotes and conduct due diligence to ensure they receive the best value for their investment.

Alternatives Analysis: Comparing concealed hinges types With Other Solutions

Exploring Alternatives to Concealed Hinges: What Should B2B Buyers Consider?

In the realm of cabinetry and furniture manufacturing, concealed hinges have gained popularity for their aesthetic appeal and functionality. However, various alternative solutions exist, each with distinct advantages and disadvantages. This section will compare concealed hinges against two other viable options: traditional exposed hinges and pivot hinges. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs.

Comparison Table

| Comparison Aspect | Concealed Hinges Types | Traditional Exposed Hinges | Pivot Hinges |

|---|---|---|---|

| Performance | Excellent for smooth operation and concealed appearance | Reliable but less visually appealing | Allows for 180-degree opening, suitable for heavy doors |

| Cost | Moderate to high, depending on quality | Generally low-cost | Higher initial investment, but durable |

| Ease of Implementation | Requires precise installation with pre-drilled holes | Easy installation, minimal tools needed | Requires precise alignment, can be complex |

| Maintenance | Low maintenance; durable and easy to adjust | Moderate; visible wear and rust can occur | Low maintenance; usually robust |

| Best Use Case | Modern cabinetry, high-end furniture | Budget-friendly projects, vintage styles | Heavy doors, special applications like foldable panels |

What Are the Pros and Cons of Traditional Exposed Hinges?

Traditional exposed hinges are commonly used in various applications due to their straightforward design and ease of installation. The primary advantage of these hinges is their affordability, making them an attractive option for budget-conscious projects. They are also easier to replace or adjust, as they do not require specialized tools or techniques. However, the downside is their visibility, which can detract from the overall aesthetic of modern cabinetry. Furthermore, these hinges are prone to wear and rust over time, particularly in high-moisture environments, which can necessitate more frequent maintenance.

How Do Pivot Hinges Compare to Concealed Hinges?

Pivot hinges offer unique functionality, particularly for heavy doors or applications requiring a full swing. These hinges allow doors to pivot from a single point rather than a side, enabling a wider opening angle—often up to 180 degrees. This feature is particularly beneficial in spaces where accessibility is essential. However, pivot hinges tend to require a more complex installation process and may incur higher upfront costs compared to concealed hinges. While they are durable and require minimal maintenance, their specific use cases may not suit all design preferences, especially in modern cabinetry where a seamless look is desired.

Making the Right Choice: How Should B2B Buyers Decide?

When evaluating hinge options, B2B buyers should consider their specific project requirements, budget constraints, and aesthetic goals. Concealed hinges are ideal for modern designs that prioritize a clean, unobtrusive look, while traditional exposed hinges may be more suitable for cost-effective solutions. Pivot hinges excel in applications requiring high functionality but come at a higher cost and complexity. By analyzing these factors, buyers can make a well-informed decision that aligns with their operational needs and design aspirations, ensuring they select the best hinge solution for their projects.

Illustrative image related to concealed hinges types

Essential Technical Properties and Trade Terminology for concealed hinges types

What Are the Critical Technical Properties of Concealed Hinges?

When selecting concealed hinges for various applications, understanding their technical specifications is essential. Here are some key properties that B2B buyers should consider:

1. Material Grade

Concealed hinges are typically made from materials like stainless steel, brass, or zinc alloy. The choice of material affects durability, corrosion resistance, and overall performance. For instance, stainless steel hinges are ideal for humid environments, while brass offers aesthetic appeal and resistance to tarnishing. Selecting the right material ensures longevity and reliability, which is crucial for reducing maintenance costs and enhancing product lifespan.

2. Load Capacity

The load capacity of a concealed hinge refers to the maximum weight it can support without compromising functionality. This specification is vital for applications ranging from residential cabinetry to commercial installations. Understanding the load capacity helps buyers select hinges that will adequately support their doors or panels, preventing premature failure and enhancing safety.

3. Opening Angle

Concealed hinges come with various opening angles, typically ranging from 90 to 180 degrees. The opening angle determines how far the door can swing open, which is essential for both accessibility and functionality. Buyers should consider the intended use of the hinge to choose one that aligns with their space requirements and design preferences.

4. Tolerance

Tolerance in hinge manufacturing refers to the permissible limit of variation in the dimensions of the hinge components. High tolerance levels ensure that the hinge operates smoothly and aligns perfectly with the cabinet or door. For B2B buyers, selecting hinges with tight tolerances can minimize installation errors, reduce the need for adjustments, and enhance the overall user experience.

5. Finish

The finish of a concealed hinge affects both aesthetics and functionality. Common finishes include satin chrome, matte black, and brushed nickel. The chosen finish not only impacts the visual appeal of the installation but also contributes to corrosion resistance and ease of maintenance. Buyers should select finishes that complement their design while ensuring durability in their specific environments.

6. Adjustment Mechanism

Many concealed hinges feature built-in adjustment mechanisms that allow for easy alignment and positioning after installation. This is particularly important for ensuring that cabinet doors close properly and align with adjacent surfaces. Buyers should prioritize hinges with user-friendly adjustment features to facilitate maintenance and enhance the longevity of their cabinetry.

What Are Common Trade Terminology Terms Related to Concealed Hinges?

Familiarity with industry jargon can streamline communication and purchasing processes. Here are some essential terms for B2B buyers:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of concealed hinges, understanding whether a product is OEM can assure buyers of its quality and compatibility with their existing systems.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for buyers as it can impact inventory management and budgeting. It helps businesses plan their purchases according to demand and storage capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. It typically outlines the specifications, quantities, and delivery requirements for products like concealed hinges. Submitting an RFQ enables buyers to compare prices and terms, ensuring they receive the best value.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with these terms is crucial for B2B buyers engaged in international trade, as they clarify shipping costs, risks, and responsibilities.

5. Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. For concealed hinges, understanding lead times is essential for project planning and ensuring timely installation. It helps buyers manage expectations and coordinate schedules effectively.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting concealed hinges that meet their specific needs and enhance their overall product offerings.

Navigating Market Dynamics and Sourcing Trends in the concealed hinges types Sector

What Are the Key Market Dynamics and Trends Impacting the Concealed Hinges Sector?

The concealed hinges market is experiencing robust growth, driven by the increasing demand for aesthetically pleasing and functional cabinetry solutions across various sectors. Global drivers include the rise of modern interior design trends, which favor minimalistic styles that concealed hinges facilitate. In regions such as Africa and South America, the construction and renovation boom is leading to heightened demand for innovative hardware solutions, while in Europe, particularly Germany, the focus is on high-quality, durable products that meet stringent design standards.

Emerging B2B technologies, such as advanced manufacturing processes and digital platforms for sourcing and logistics, are reshaping how buyers engage with suppliers. Buyers now prioritize suppliers that offer comprehensive catalogs online, enabling them to compare different hinge types—such as European one-piece and two-piece hinges—efficiently. Additionally, the use of augmented reality tools to visualize product applications in real-time is gaining traction, enhancing decision-making processes for international buyers.

Current sourcing trends show a shift towards suppliers that can provide customized solutions tailored to specific architectural requirements. This is particularly relevant for buyers in the Middle East, where bespoke designs are often necessary for luxury projects. Furthermore, the integration of smart technology into concealed hinges, such as soft-close mechanisms, is becoming more prevalent, reflecting a growing consumer preference for user-friendly products.

How Are Sustainability and Ethical Sourcing Practices Shaping the Concealed Hinges Market?

Sustainability is increasingly becoming a priority in the concealed hinges sector, influencing purchasing decisions among B2B buyers. The environmental impact of manufacturing processes, particularly in metal production, has led to a demand for eco-friendly practices. Suppliers that utilize recycled materials or sustainable manufacturing processes are becoming more attractive to buyers who aim to reduce their ecological footprint.

Ethical sourcing is equally important, with many buyers seeking suppliers that adhere to fair labor practices and transparency in their supply chains. Certifications such as Forest Stewardship Council (FSC) and ISO 14001 for environmental management can significantly enhance a supplier’s credibility. Buyers in Europe and North America, in particular, are more likely to favor suppliers with such certifications, as they align with the growing consumer expectation for sustainable practices.

Additionally, the development of “green” materials for concealed hinges, such as those utilizing bio-based plastics or non-toxic finishes, is emerging as a competitive differentiator. This trend is expected to gain momentum, particularly as regulations around sustainability tighten globally.

What Is the Historical Context of Concealed Hinges in the B2B Sector?

The evolution of concealed hinges can be traced back to the early 20th century, initially developed in Europe for frameless cabinetry. This design innovation allowed for a seamless look in modern kitchens and furniture, appealing to architects and designers who valued aesthetics alongside functionality. Over the decades, concealed hinges have gained popularity worldwide, adapting to various styles and needs, such as the introduction of soft-close technology in the late 20th century, which further enhanced user experience.

As the market continues to evolve, understanding the historical context of concealed hinges aids B2B buyers in recognizing the importance of quality and innovation in their sourcing decisions, ensuring they select products that not only meet current standards but also reflect the advancements in design and technology.

Frequently Asked Questions (FAQs) for B2B Buyers of concealed hinges types

-

How do I choose the right type of concealed hinge for my cabinetry?

Choosing the right concealed hinge depends on the cabinet style and the desired functionality. For frameless cabinets, European two-piece or one-piece hinges are often ideal. If you require soft-close features to enhance user experience and reduce noise, opt for self-closing or soft-close variants. Additionally, consider the overlay of your cabinet doors—this is the amount of the cabinet frame that the door covers. Measuring correctly ensures proper installation and functionality. Consulting with a hinge expert can also provide tailored recommendations based on your specific needs. -

What is the best concealed hinge for high-traffic environments?

For high-traffic environments, look for heavy-duty concealed hinges made from high-grade materials like stainless steel. These hinges are designed to withstand frequent use without compromising performance. Additionally, self-closing or soft-close options are recommended to ensure doors close securely, reducing the risk of damage. Brands like SOSS and Sugatsune offer reliable solutions that balance aesthetics and durability. Always verify the weight capacity of the hinge to ensure it meets the demands of your specific application. -

What are the minimum order quantities (MOQs) for concealed hinges?

Minimum order quantities can vary significantly between suppliers, typically ranging from 50 to 500 units per order. It’s essential to communicate your needs directly with the supplier to understand their MOQ policies. Some manufacturers may offer flexibility, particularly for established B2B relationships or bulk orders. If you’re sourcing from international suppliers, consider shipping costs and timeframes, as larger orders may provide better cost efficiency. -

How can I ensure the quality of concealed hinges when sourcing internationally?

To ensure quality when sourcing concealed hinges internationally, conduct thorough supplier vetting. Request samples before placing bulk orders to assess materials, finish, and functionality. Check for certifications and compliance with international quality standards, such as ISO or CE markings. Establish clear quality assurance processes, including inspections at various production stages. Additionally, consider working with a local representative or quality control service to oversee the manufacturing and shipment process. -

What payment terms should I negotiate when sourcing concealed hinges?

Payment terms can vary widely depending on the supplier and order size. Common terms include upfront payment, partial payment upon order confirmation, and balance before shipment. For larger orders, negotiating favorable terms such as net 30 or net 60 days can improve cash flow. Always ensure that the payment terms are clearly outlined in a formal contract to avoid any misunderstandings. Using secure payment methods, such as letters of credit or escrow services, can also provide additional protection against fraud. -

What are the logistics considerations when importing concealed hinges?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder with experience in handling hardware products. Understand the import regulations and tariffs applicable to concealed hinges in your destination country, as these can significantly impact costs. Additionally, consider the lead time from order placement to delivery, ensuring that it aligns with your project timelines. Proper documentation, including invoices and certificates of origin, is essential for smooth customs clearance. -

Can concealed hinges be customized for specific applications?

Yes, many manufacturers offer customization options for concealed hinges. This can include variations in size, finish, and functionalities, such as special closing mechanisms or unique mounting solutions. When discussing customization, provide detailed specifications and requirements to the supplier. Be aware that custom orders may have longer lead times and potentially higher costs. It’s advisable to confirm the feasibility of the customization before finalizing your order. -

What are the common challenges faced when sourcing concealed hinges and how can they be mitigated?

Common challenges include quality inconsistencies, lead time delays, and communication barriers with international suppliers. To mitigate these issues, establish a clear and detailed specification document for your requirements. Maintain open lines of communication throughout the sourcing process, utilizing tools like video calls or shared project management platforms to ensure alignment. Building strong relationships with suppliers can also lead to more reliable service and better problem resolution when challenges arise.

Top 5 Concealed Hinges Types Manufacturers & Suppliers List

1. HingeOutlet – Concealed Hinges

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Concealed Hinges available at HingeOutlet. Free shipping on orders over $160. Wide variety of concealed hinges for both commercial and residential applications. Expert support available at 888-250-8133. Additional resources include guides on installation and selection of hinges.

2. IQS Directory – Concealed Hinges

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Concealed hinges, also known as hidden or European hinges, are designed to sit flush on the inside of a cabinet door, providing a sleek exterior look. They support door weights ranging from 50 lbs to 90 lbs and are available in various styles with features such as soft-close functions, adjustable arms, and quick-detach options. Common materials include steel, zinc, stainless steel, and aluminum, w…

3. Hardwaresource – Hinge Solutions

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: This company, Hardwaresource – Hinge Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Sugatsune – Concealed Hinges

Domain: global.sugatsune.com

Registered: 1996 (29 years)

Introduction: Concealed hinges (hidden hinges) are designed to be invisible when a door or lid is closed, providing a seamless and aesthetically pleasing appearance. They come in various types, including those that integrate with thin door frames (8 mm), surface mount types, and options with features like separable and temporary holding for easier assembly. The product range includes the HES Series, which featu…

5. Maxave Group – Concealed Cabinet Hinges

Domain: maxavegroup.com

Registered: 2021 (4 years)

Introduction: Concealed cabinet hinges, also known as European hinges, are designed to be invisible when cabinet doors are closed, enhancing aesthetics. They are durable, provide smooth functioning, and are easy to install and detach. Types include full overlay, half overlay, inset, soft-close, and self-closing. Benefits include improved aesthetics, enhanced safety, adjustable door hanging, easy dismantling, hi…

Strategic Sourcing Conclusion and Outlook for concealed hinges types

In summary, the strategic sourcing of concealed hinges offers significant advantages for businesses across diverse markets. Understanding the various types—such as European two-piece, one-piece, semi-concealed, and mortise hinges—allows B2B buyers to select the most suitable options for their specific applications. The shift towards concealed hinges is driven by their aesthetic appeal, ease of installation, and ability to enhance cabinet functionality.

Moreover, leveraging strategic sourcing can lead to cost savings, improved supplier relationships, and access to innovative products tailored to regional preferences. International buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with reputable manufacturers who can provide high-quality, durable hinges that meet global standards.

Looking ahead, as the demand for modern cabinetry solutions continues to grow, businesses are encouraged to stay informed about emerging trends and technologies in hinge design. Embracing these advancements will not only enhance product offerings but also position companies as leaders in their respective markets. For those ready to optimize their hinge sourcing strategy, now is the time to explore new suppliers and innovative products that can elevate both functionality and design.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.