Everything You Need to Know About Commercial Air Blower Sourcing in 2025

Introduction: Navigating the Global Market for commercial air blower

In today’s rapidly evolving global market, sourcing the right commercial air blower can pose significant challenges for international B2B buyers. Whether you’re in the manufacturing sector looking to enhance ventilation or in the construction industry needing efficient drying solutions, selecting the appropriate air blower is crucial for operational efficiency. This comprehensive guide delves into various types of commercial air blowers, their applications across industries, and essential considerations for supplier vetting.

Buyers from Africa, South America, the Middle East, and Europe—countries like Saudi Arabia and Germany—will find actionable insights tailored to their unique market conditions. Understanding the diverse range of blowers available, from high-pressure models to portable options, equips you with the knowledge to make informed purchasing decisions. Additionally, we will explore cost factors, performance metrics, and maintenance requirements, ensuring you can effectively evaluate your options.

By leveraging this guide, you will be empowered to navigate the complexities of sourcing commercial air blowers with confidence, ultimately enhancing productivity and ensuring the safety and comfort of your work environments. The information presented here not only helps in making better buying decisions but also aids in fostering long-term supplier relationships that can lead to sustained operational success.

Understanding commercial air blower Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Velocity Blowers | High airflow rates, portable, multiple speed settings | Construction, restoration, drying applications | Pros: Fast drying, versatile; Cons: Can be noisy, less effective in enclosed spaces. |

| Industrial Blowers | Designed for high pressure, durable materials | Manufacturing, ventilation, cooling | Pros: Strong performance, suitable for heavy-duty tasks; Cons: Higher initial investment, may require maintenance. |

| Axial Fans | Compact, lightweight, direct air movement | HVAC systems, cooling electronic equipment | Pros: Energy-efficient, easy to install; Cons: Limited airflow compared to larger models, less suitable for high-pressure needs. |

| Carpet Dryers | Specialized for drying carpets, adjustable angles | Janitorial services, flood restoration | Pros: Targeted drying, user-friendly; Cons: Limited to specific applications, may not be as powerful as general blowers. |

| Blower Fans | Versatile use, often feature wheels for mobility | Event setups, workshops, indoor air circulation | Pros: Portable, easy to use; Cons: Not suitable for high-pressure tasks, variable performance based on model. |

What Are High-Velocity Blowers and Where Are They Best Used?

High-velocity blowers are characterized by their ability to generate significant airflow, making them ideal for applications requiring rapid drying or cooling. These blowers are often portable and come with multiple speed settings, enhancing their versatility. They are commonly used in construction sites, water damage restoration, and carpet drying. B2B buyers should consider noise levels and effectiveness in enclosed spaces when selecting high-velocity blowers, as these factors can impact operational efficiency.

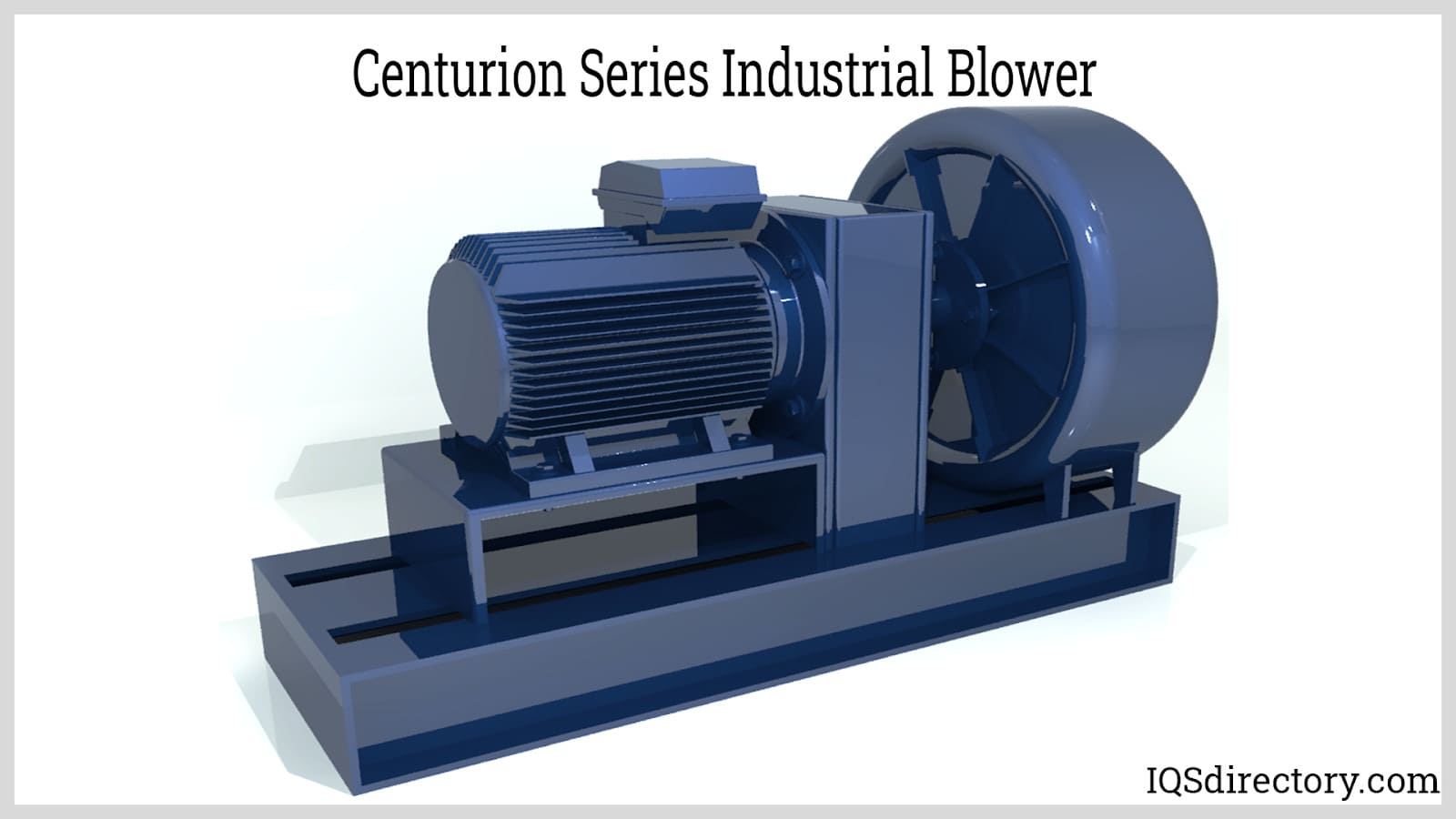

How Do Industrial Blowers Differ in Performance and Application?

Industrial blowers are designed for high-pressure environments and are typically constructed from durable materials like cast aluminum or steel. They are essential in manufacturing settings for ventilation and cooling, capable of handling both light and heavy materials. Buyers should evaluate the specific pressure requirements of their applications, as well as the potential need for ongoing maintenance. The initial investment may be higher, but the long-term performance can justify the cost.

What Are the Advantages of Using Axial Fans in Commercial Settings?

Axial fans are compact and lightweight, making them suitable for applications where space is a constraint. They are primarily used in HVAC systems and for cooling electronic equipment. Their energy-efficient design appeals to B2B buyers looking to reduce operational costs. However, axial fans may not provide the same airflow as larger blowers, limiting their effectiveness in high-pressure scenarios. Buyers should assess the airflow needs of their specific applications before making a selection.

Why Choose Carpet Dryers for Specialized Drying Needs?

Carpet dryers are specifically engineered for drying carpets and floors quickly, often featuring adjustable angles to direct airflow precisely where needed. They are commonly used in janitorial services and during flood restoration efforts. Their user-friendly design makes them accessible for various staff levels. However, their specialized nature limits their application scope, and they may not match the airflow capacity of more generalized blower types. Buyers should consider their specific drying requirements when investing in carpet dryers.

How Do Blower Fans Fit into General Air Movement Needs?

Blower fans are versatile tools that can be used across various settings, including event setups, workshops, and indoor air circulation. Many models come equipped with wheels for easy mobility, making them practical for temporary setups. While they are user-friendly and portable, they may not be suitable for high-pressure tasks or specialized applications. B2B buyers should weigh the flexibility of blower fans against their specific airflow requirements to ensure they make an informed purchase.

Key Industrial Applications of commercial air blower

| Industry/Sector | Specific Application of commercial air blower | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Dust and debris removal during construction and renovation | Improved air quality and worker safety | Durability, portability, and noise level |

| Food Processing | Cooling and drying of food products | Enhanced product quality and reduced spoilage | Compliance with food safety standards, energy efficiency |

| Water Damage Restoration | Rapid drying of carpets and structures post-flood | Faster restoration times, minimizing damage | Compact design, variable speed settings, and power output |

| Manufacturing | Ventilation in production facilities | Increased worker comfort and productivity | High air flow capacity, resistance to contaminants |

| Agriculture | Aeration in storage facilities for grains and produce | Prevention of spoilage and improved shelf life | Robust construction, energy efficiency, and adaptability |

How are Commercial Air Blowers Used in Construction?

In the construction sector, commercial air blowers are essential for maintaining a clean and safe work environment. They are used to remove dust and debris during construction and renovation projects, ensuring that air quality remains high and that workers can operate safely. For international buyers, especially in regions like Africa and the Middle East, sourcing blowers that are durable and portable is critical, as construction sites can be demanding environments. Additionally, noise levels must be considered to comply with local regulations and ensure worker comfort.

What Role Do Commercial Air Blowers Play in Food Processing?

In the food processing industry, commercial air blowers are employed for cooling and drying food products post-processing. This application is crucial for maintaining product quality and extending shelf life, thereby reducing spoilage rates. Buyers from South America and Europe should prioritize blowers that meet food safety standards, as compliance is vital in this sector. Energy efficiency is also a significant consideration, as it directly impacts operational costs and sustainability efforts.

How Are Commercial Air Blowers Essential in Water Damage Restoration?

Commercial air blowers are indispensable in the water damage restoration industry, where they facilitate the rapid drying of carpets and structures following flooding incidents. By accelerating the evaporation process, these blowers help minimize damage and reduce restoration times, which is critical for maintaining client satisfaction and profitability. For B2B buyers in regions prone to flooding, such as parts of Europe and the Middle East, factors like compact design, variable speed settings, and high power output are essential for effective operation in diverse environments.

What Benefits Do Commercial Air Blowers Provide in Manufacturing?

In manufacturing facilities, commercial air blowers are used for ventilation, helping to maintain a comfortable and safe working environment. By improving air circulation, they enhance worker comfort and productivity, which is vital for operational efficiency. Buyers from Africa and Europe should consider blowers with high airflow capacity and resistance to contaminants, as these features ensure long-term reliability and performance in demanding industrial settings.

How Do Commercial Air Blowers Assist in Agriculture?

In agriculture, commercial air blowers are utilized for aeration in storage facilities, ensuring that grains and produce remain fresh and free from spoilage. This application is particularly important for international buyers looking to enhance the shelf life of agricultural products. Robust construction and energy efficiency are key sourcing considerations, as they contribute to the blower’s longevity and operational cost-effectiveness, especially in regions with fluctuating energy prices.

3 Common User Pain Points for ‘commercial air blower’ & Their Solutions

Scenario 1: Inconsistent Airflow Leading to Inefficient Operations

The Problem: Many B2B buyers in sectors such as manufacturing or food processing face the challenge of inconsistent airflow from their commercial air blowers. This inconsistency can lead to inadequate ventilation, affecting both the comfort of workers and the efficiency of machinery. An air blower that fails to deliver a steady stream of air can cause overheating of equipment, leading to production delays and potential safety hazards. Buyers often struggle to pinpoint the source of airflow issues, whether it stems from improper blower specifications, insufficient maintenance, or environmental factors.

The Solution: To combat inconsistent airflow, it’s essential to accurately assess your operational needs before purchasing a commercial air blower. Begin by evaluating the specific airflow requirements of your facility, taking into account factors like the size of the area, the type of equipment used, and the presence of any obstructions that could impede airflow. Opt for blowers with adjustable speed settings and directional capabilities, as these features allow for customization based on real-time needs. Regular maintenance, including cleaning filters and inspecting ducts, is crucial to ensure optimal performance. Additionally, consider investing in smart blowers equipped with IoT technology that can monitor airflow and send alerts for any discrepancies, allowing for proactive adjustments.

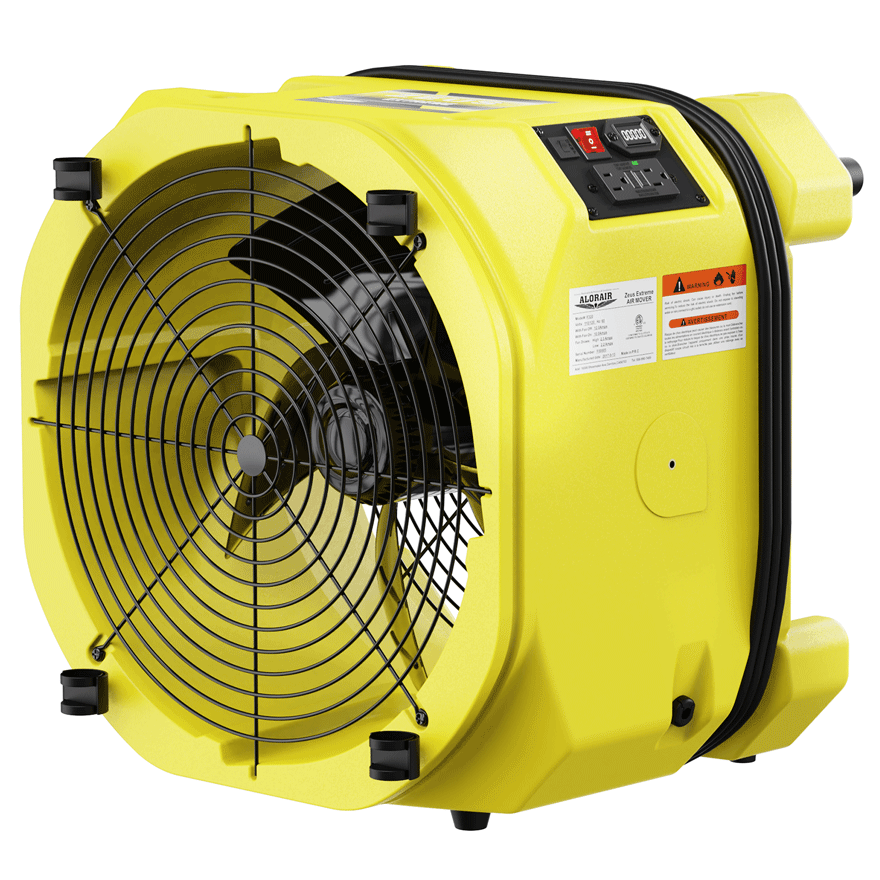

Illustrative image related to commercial air blower

Scenario 2: Noise Pollution Disrupting Workplace Environment

The Problem: In environments such as offices or educational institutions, excessive noise from commercial air blowers can become a significant pain point. High-decibel levels can distract employees, hinder communication, and even affect productivity. Buyers often overlook the importance of noise levels when selecting air blowers, leading to post-purchase regret as they discover the adverse effects on their work environment.

The Solution: When sourcing commercial air blowers, prioritize models designed with noise reduction features. Look for blowers specifically labeled as “quiet” or with sound-dampening technology. Manufacturers often provide decibel ratings that can guide you in selecting a blower that meets your noise tolerance requirements. Additionally, consider the placement of the blower; positioning it away from high-traffic areas can help mitigate noise disruption. For applications that require prolonged use, investing in blowers with variable speed settings can also be beneficial, as lower speeds typically generate less noise. Finally, implementing sound-absorbing materials in the surrounding area can further enhance workplace acoustics.

Scenario 3: High Energy Costs Due to Inefficient Equipment

The Problem: Many businesses are concerned about the rising energy costs associated with operating commercial air blowers. Inefficient blowers not only consume excessive energy but can also lead to an increase in operational costs, which impacts the bottom line. Buyers often find themselves stuck with outdated models that lack energy-efficient features, resulting in a costly cycle of high utility bills and inadequate performance.

The Solution: To reduce energy costs, invest in energy-efficient commercial air blowers that adhere to industry standards such as ENERGY STAR ratings. These blowers are designed to provide the same or improved airflow while consuming less energy. When selecting a blower, consider the power consumption specifications, and choose models that offer variable speed settings to match airflow needs without unnecessary energy expenditure. Additionally, implement regular maintenance schedules to keep your equipment running efficiently, as dirt and blockages can increase energy usage significantly. Exploring options for alternative energy sources, such as solar power, can also help mitigate costs over the long term. By prioritizing energy efficiency in your purchasing decisions, you can achieve substantial cost savings while also contributing to sustainability efforts.

Illustrative image related to commercial air blower

Strategic Material Selection Guide for commercial air blower

What Are the Key Materials Used in Commercial Air Blowers?

When selecting a commercial air blower, the choice of materials is crucial for ensuring optimal performance and longevity. Different materials offer varying properties that can significantly impact the blower’s efficiency, durability, and suitability for specific applications. Here, we analyze four common materials used in the construction of commercial air blowers: steel, aluminum, plastic, and composite materials.

How Does Steel Contribute to Commercial Air Blower Performance?

Steel is a widely used material in the manufacturing of commercial air blowers, particularly for components that require strength and durability. Key properties of steel include high tensile strength and excellent resistance to deformation under pressure, making it suitable for high-performance applications.

Pros: Steel blowers are highly durable, capable of withstanding harsh environments and high temperatures. They are also cost-effective in terms of manufacturing and have a long service life.

Cons: The primary drawback of steel is its susceptibility to corrosion, particularly in humid or chemically aggressive environments. This can lead to increased maintenance costs over time.

Impact on Application: Steel is particularly effective for applications involving heavy-duty air movement and environments where mechanical stress is prevalent.

Illustrative image related to commercial air blower

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and the Middle East, should ensure that steel components are treated or coated to prevent rusting. Compliance with international standards like ASTM for material specifications is also essential.

What Advantages Does Aluminum Offer for Air Blowers?

Aluminum is another popular choice for commercial air blowers, especially for applications requiring lightweight and corrosion-resistant materials. Aluminum has a good strength-to-weight ratio and excellent thermal conductivity.

Pros: The lightweight nature of aluminum makes it easier to transport and install. Additionally, aluminum’s natural corrosion resistance reduces maintenance needs.

Cons: While aluminum is durable, it is generally less robust than steel and can be more expensive. It may also be prone to denting or deformation under heavy impact.

Impact on Application: Aluminum blowers are ideal for portable applications and environments where weight is a critical factor, such as in temporary setups or event venues.

Considerations for International Buyers: Buyers in regions like Europe, where energy efficiency is prioritized, may prefer aluminum blowers for their lightweight properties. Compliance with EU standards for energy efficiency and material safety should be verified.

How Do Plastics Enhance Commercial Air Blower Functionality?

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are utilized in commercial air blowers for their lightweight and versatile properties. They offer good chemical resistance and can be molded into complex shapes.

Pros: Plastics are generally less expensive and can be manufactured in various colors and designs. They are also resistant to corrosion and can withstand a range of chemicals.

Illustrative image related to commercial air blower

Cons: The main limitation of plastic is its lower strength compared to metals, making it less suitable for high-pressure applications. Plastics can also degrade under UV exposure unless treated.

Impact on Application: Plastic blowers are often used in lighter-duty applications, such as residential settings or in environments where chemical exposure is a concern.

Considerations for International Buyers: Buyers in South America and Africa should consider the UV stability of plastic materials, especially for outdoor applications. Compliance with local environmental regulations regarding plastic use may also be necessary.

What Role Do Composite Materials Play in Air Blower Design?

Composite materials, often a blend of plastic and fiberglass, are increasingly used in commercial air blower manufacturing due to their unique properties. They offer a balance between strength and weight, making them suitable for various applications.

Pros: Composites are lightweight yet strong, providing excellent resistance to corrosion and chemicals. They can also be engineered for specific performance characteristics.

Cons: The manufacturing process for composites can be complex and more expensive, which may increase the overall cost of the blower.

Impact on Application: Composite blowers are ideal for specialized applications, such as in chemical processing facilities or environments where traditional materials may fail.

Considerations for International Buyers: Buyers should ensure that composite materials meet international standards for safety and performance. Understanding the specific applications and environments in which composites excel can guide purchasing decisions.

Summary Table of Material Selection for Commercial Air Blowers

| Material | Typical Use Case for commercial air blower | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | Highly durable and cost-effective | Susceptible to corrosion | Medium |

| Aluminum | Portable and lightweight applications | Lightweight and corrosion-resistant | Less robust than steel | High |

| Plastic | Residential and light-duty applications | Cost-effective and versatile | Lower strength, UV degradation | Low |

| Composite | Specialized industrial applications | Lightweight with excellent corrosion resistance | Complex manufacturing process | High |

This material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of each material used in commercial air blowers. Understanding these factors will aid in making informed purchasing decisions tailored to specific operational needs and environmental conditions.

Illustrative image related to commercial air blower

In-depth Look: Manufacturing Processes and Quality Assurance for commercial air blower

Manufacturing commercial air blowers involves several key stages, each critical to ensuring the final product meets performance and quality expectations. The manufacturing process typically encompasses material preparation, forming, assembly, and finishing, with each stage employing specific techniques to optimize efficiency and output.

What Are the Main Stages of Manufacturing Commercial Air Blowers?

Material Preparation: Ensuring Quality Starts Here

The manufacturing process begins with material selection, where high-quality raw materials such as cast aluminum, steel, and plastics are sourced. These materials are chosen for their durability, lightweight properties, and resistance to corrosion. Suppliers often utilize advanced logistics to ensure that materials meet industry standards, which is crucial for maintaining the integrity of the final product.

Once materials are sourced, they undergo quality checks to confirm compliance with specifications. This initial inspection, known as Incoming Quality Control (IQC), is vital for identifying defects early in the process. By ensuring that only high-quality materials proceed to the next stage, manufacturers can minimize waste and reduce costs.

How Are Commercial Air Blowers Formed?

The forming stage utilizes various techniques, including casting, machining, and molding. For metal components, processes like die casting and CNC machining are common. These methods allow for precise shaping of parts such as blower housings and impellers, which are critical for airflow efficiency.

For plastic components, injection molding is often employed. This technique allows for complex shapes and designs, ensuring that the blower can operate effectively in various applications, from industrial settings to commercial environments.

What Happens During the Assembly of Commercial Air Blowers?

Once components are formed, they move to the assembly stage. Here, skilled technicians or automated systems combine the parts, integrating motors, fans, and electrical components. Assembly lines are typically organized to maximize efficiency, often employing lean manufacturing principles to reduce downtime and streamline production.

During this phase, In-Process Quality Control (IPQC) checkpoints are established. These checkpoints verify that components fit correctly and function as intended. Any issues identified at this stage can be addressed before the product reaches the final quality check, reducing the risk of defects in the finished blower.

What Finishing Techniques Are Commonly Used?

After assembly, the blowers undergo finishing processes, which can include painting, coating, and surface treatments. These processes not only enhance the aesthetic appeal of the blowers but also improve durability, particularly in outdoor or high-humidity environments.

Finishing is also critical for meeting international standards such as CE marking, which indicates compliance with health, safety, and environmental protection standards. For B2B buyers, understanding the finishing processes can help gauge the expected lifespan and maintenance needs of the equipment.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is a cornerstone of manufacturing commercial air blowers. Compliance with international standards such as ISO 9001 ensures that manufacturers maintain a consistent quality management system. This certification is recognized globally and provides assurance to B2B buyers that the manufacturer adheres to best practices in quality control.

In addition to ISO standards, industry-specific certifications like API (American Petroleum Institute) and CE marking may also apply, depending on the intended application of the blowers. For example, blowers used in hazardous environments may require compliance with additional safety standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control in the manufacturing of commercial air blowers typically involves several checkpoints:

Illustrative image related to commercial air blower

-

Incoming Quality Control (IQC): This checkpoint assesses raw materials before they enter the production process.

-

In-Process Quality Control (IPQC): Conducted during assembly, this ensures that components meet specifications and function correctly.

-

Final Quality Control (FQC): The finished blowers undergo rigorous testing to verify that they meet performance standards. Common tests include airflow rate measurements, noise level assessments, and energy consumption evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality assurance measures firsthand. This can include reviewing production lines, quality control documentation, and employee training programs.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s quality management system, including historical performance data and any non-conformance issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s manufacturing processes and compliance with international standards.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding regional nuances in quality control is essential for B2B buyers. For instance, regulatory requirements may vary significantly between Europe and Africa. Buyers should be aware of local certifications and regulations that may impact the usability and safety of commercial air blowers in their specific markets.

Additionally, language barriers and cultural differences may affect communication with suppliers. Establishing clear expectations and maintaining open lines of communication can help mitigate these challenges.

Conclusion: Ensuring Quality in Commercial Air Blower Manufacturing

By comprehensively understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing commercial air blowers. From material selection to final testing, each stage plays a vital role in ensuring the reliability and performance of the product. Buyers are encouraged to leverage supplier audits, quality reports, and third-party inspections to validate the quality claims of manufacturers, ensuring that they receive equipment that meets their operational needs and adheres to international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘commercial air blower’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure commercial air blowers. Whether you are in the manufacturing sector, construction, or facilities management, selecting the right air blower is crucial for operational efficiency. This checklist will help you navigate the sourcing process, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for your commercial air blower. This includes airflow rate (measured in CFM), motor power (HP), and noise levels. Understanding these parameters will help you identify the right blower for your specific application, whether it’s for ventilation, cooling, or drying.

- Airflow Requirements: Consider the size of the area where the blower will be used. Larger spaces may require higher CFM ratings.

- Power Needs: Depending on the tasks, determine whether you need a high-pressure blower or a standard model.

Step 2: Identify Your Application Needs

Different applications may require different types of blowers. Identify whether your needs are for general ventilation, drying, or industrial cooling. This will help narrow down your options.

Illustrative image related to commercial air blower

- Ventilation: Look for blowers designed to move air efficiently in large spaces.

- Drying: Consider high-velocity blowers with adjustable speeds for effective drying of carpets or floors.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your quality and delivery requirements. Request detailed company profiles, including their experience in your industry.

- References: Ask for case studies or references from other buyers in similar sectors or regions.

- Certifications: Verify that suppliers hold necessary certifications, such as ISO or CE compliance, to ensure product quality and safety.

Step 4: Assess Quality and Durability

Quality is paramount when investing in commercial equipment. Assess the materials and construction of the blowers.

- Material Composition: Look for blowers made from durable materials like cast aluminum or steel, which are less prone to wear and tear.

- Warranty and Service: A robust warranty can indicate the manufacturer’s confidence in their product’s durability.

Step 5: Compare Pricing and Total Cost of Ownership

While initial pricing is important, consider the total cost of ownership, which includes maintenance, energy consumption, and replacement parts.

- Energy Efficiency: Select models with energy-efficient motors to reduce operational costs over time.

- Maintenance Costs: Investigate the ease of maintenance and availability of replacement parts to avoid unexpected expenses.

Step 6: Verify Compliance with Local Regulations

Ensure that the blowers you are considering comply with local regulations and standards, particularly regarding noise levels and emissions.

- Noise Regulations: Different regions have specific noise level regulations that may affect your choice of blower.

- Safety Standards: Confirm that the equipment meets safety standards relevant to your industry.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics of delivery and installation. Discuss lead times with your suppliers to ensure timely procurement.

- Shipping Arrangements: Understand shipping options available and any additional costs that may arise.

- Installation Support: Check if the supplier offers installation services or guidelines to facilitate a smooth setup process.

By following this checklist, B2B buyers can effectively navigate the procurement of commercial air blowers, ensuring they select the right equipment for their operational needs.

Comprehensive Cost and Pricing Analysis for commercial air blower Sourcing

What Are the Key Cost Components in Commercial Air Blower Manufacturing?

Understanding the cost structure of commercial air blowers is crucial for B2B buyers aiming to optimize their sourcing strategies. The primary components of the cost structure include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals, durable plastics, and advanced components (like motors and blades) contribute to both performance and longevity, which can justify higher upfront costs.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. Regions with higher labor costs may produce blowers that reflect those expenses, while countries with lower labor rates may offer more competitive pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Initial setup costs for molds, dies, and specialized machinery are significant, especially for custom designs. Buyers should factor in these costs when considering customized blowers.

-

Quality Control (QC): Rigorous testing and quality assurance processes are essential to ensure product reliability. The costs associated with QC can vary, influencing the final pricing of the blower.

-

Logistics: Shipping costs can fluctuate based on the distance, mode of transport, and current fuel prices. Buyers should be aware of these factors, especially when sourcing from international suppliers.

-

Margin: Suppliers typically include a margin to cover their costs and generate profit. Understanding the expected margins within the industry can help buyers negotiate better pricing.

How Do Price Influencers Affect Commercial Air Blower Costs?

Several factors influence the pricing of commercial air blowers, including:

-

Volume/MOQ: Purchasing in larger quantities often results in lower per-unit costs. Buyers should assess their needs and negotiate minimum order quantities (MOQs) that align with their purchasing power.

-

Specifications and Customization: Custom blowers designed to meet specific operational requirements may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or CE) often lead to increased costs but can provide long-term reliability and compliance assurance.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their experience and customer service, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of delivery (such as FOB or CIF) is crucial, as it affects the final cost. Buyers should clarify responsibilities for shipping, insurance, and customs duties to avoid unexpected expenses.

What Are Effective Buyer Tips for Sourcing Commercial Air Blowers?

B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for bulk orders. Highlighting long-term relationships can lead to better terms.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes initial purchase price, operational costs, and maintenance. A cheaper blower may have higher operational costs over time due to inefficiency or durability issues.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that could affect overall pricing. Understanding local market conditions can also provide leverage during negotiations.

-

Due Diligence on Suppliers: Conduct thorough research on potential suppliers, including reviews and case studies, to ensure they meet quality and reliability standards. This step can prevent costly issues in the supply chain.

Disclaimer on Pricing

The prices for commercial air blowers vary widely based on the factors discussed above. The figures can fluctuate significantly based on market conditions, supplier negotiations, and specific product features. It is advisable for buyers to conduct market research and consult multiple suppliers to obtain the most accurate pricing for their needs.

Alternatives Analysis: Comparing commercial air blower With Other Solutions

When considering commercial air blowers for industrial applications, it’s essential to evaluate alternative solutions that can achieve similar results. Different technologies can provide various benefits depending on the specific needs and operational conditions of a business. This analysis will compare commercial air blowers against two viable alternatives: industrial fans and air compressors.

| Comparison Aspect | Commercial Air Blower | Industrial Fan | Air Compressor |

|---|---|---|---|

| Performance | High airflow, effective for drying and cooling | Moderate airflow, generally less powerful | Variable airflow, pressure-dependent |

| Cost | Moderate initial investment, low operating costs | Lower initial investment, moderate operating costs | Higher initial investment, variable operating costs |

| Ease of Implementation | Simple setup and operation | Very easy to install and use | Requires professional installation and setup |

| Maintenance | Low maintenance, easy to clean | Minimal maintenance required | Regular maintenance needed, including oil changes |

| Best Use Case | Drying carpets, water damage restoration, ventilation | General cooling and ventilation in large spaces | Industrial applications requiring high pressure for tools and machinery |

What Are the Advantages and Disadvantages of Industrial Fans Compared to Commercial Air Blowers?

Industrial fans are designed to move large volumes of air and can be used for general cooling or ventilation purposes. Their ease of installation makes them appealing for large spaces that require constant airflow. However, they typically provide lower airflow rates than commercial air blowers and are less effective in applications requiring focused air delivery, such as drying wet surfaces or materials.

How Do Air Compressors Compare to Commercial Air Blowers?

Air compressors are versatile machines that supply high-pressure air for various applications, including powering pneumatic tools and equipment. While they can be effective for applications requiring pressurized air, they generally come with a higher initial investment and ongoing maintenance costs. Additionally, air compressors require professional installation and can be less efficient for tasks like drying carpets or surfaces compared to commercial air blowers, which are specifically designed for such tasks.

Conclusion: Which Solution Should B2B Buyers Choose for Their Needs?

When selecting the right solution, B2B buyers should consider the specific requirements of their operations. Commercial air blowers are optimal for applications that necessitate high airflow and targeted drying capabilities, such as in restoration or cleaning services. Industrial fans are suitable for general ventilation and cooling, particularly in larger spaces where high pressure isn’t a priority. Air compressors, while versatile, may be better suited for industries requiring pressurized air for tools or machinery. Ultimately, understanding the unique needs of your business and the environment in which these devices will operate is crucial for making an informed decision.

Essential Technical Properties and Trade Terminology for commercial air blower

What Are the Key Technical Properties of Commercial Air Blowers?

When selecting a commercial air blower, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

1. Airflow Capacity (CFM)

Airflow capacity, measured in Cubic Feet per Minute (CFM), indicates the volume of air that the blower can move in a minute. This specification is vital for determining whether the blower can meet the specific ventilation or drying needs of a facility. Higher CFM ratings are typically associated with more powerful blowers, making them suitable for large spaces or demanding applications.

2. Horsepower (HP)

Horsepower refers to the power output of the motor driving the blower. It influences both the efficiency and performance of the air blower. For commercial applications, blowers typically range from 1/8 HP to several HP. Selecting the appropriate horsepower ensures that the blower can handle the intended workload without overheating or failing.

3. Noise Level (dB)

Noise level, measured in decibels (dB), is an essential factor, especially for indoor use or in noise-sensitive environments. Lower dB ratings are preferable as they indicate quieter operation, which can enhance workplace comfort. Buyers should consider both the operational noise and any potential impact on surrounding areas.

4. Build Material and Durability

The material used in constructing the blower significantly affects its durability and application suitability. Common materials include high-grade plastic, aluminum, and steel. Each has its strengths; for example, aluminum offers corrosion resistance, while heavy-duty plastic can reduce weight. Understanding these materials helps buyers choose a blower that can withstand specific environmental conditions and usage scenarios.

5. Portability Features

Portability is a key consideration for commercial air blowers. Features such as built-in handles, wheels, and lightweight designs enhance ease of transport and setup. For businesses that require frequent repositioning of equipment, these features can streamline operations and improve efficiency.

What Are Common Trade Terms in the Commercial Air Blower Industry?

Navigating the commercial air blower market requires familiarity with industry terminology. Here are some common jargon and trade terms:

Illustrative image related to commercial air blower

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the air blower industry, buyers often seek OEM products for their reliability and quality assurance, as these products are typically designed to meet specific performance standards.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell in a single order. Understanding MOQ is essential for businesses, as it impacts inventory management and budget considerations. Buyers should negotiate MOQs that align with their operational needs and financial capacity.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit pricing and terms from suppliers. This process allows buyers to compare offers from different manufacturers and choose the best option based on price, specifications, and delivery terms. Crafting a clear RFQ can lead to more favorable purchasing outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Terms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) dictate who pays for shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international buyers to avoid unexpected costs and ensure smooth transactions.

Illustrative image related to commercial air blower

5. CFM (Cubic Feet per Minute)

CFM is often used in both technical specifications and trade discussions. It quantifies the airflow capacity of blowers, making it a critical term for buyers evaluating performance. Understanding CFM helps in selecting a blower that meets the specific airflow needs of an application.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing commercial air blowers, ensuring they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the commercial air blower Sector

What Are the Key Trends and Market Dynamics in the Commercial Air Blower Sector?

The commercial air blower market is witnessing significant growth driven by various global factors, including industrial expansion, increased focus on workplace safety, and the rising demand for energy-efficient solutions. Notably, sectors such as construction, manufacturing, and hospitality are major contributors to the demand for air blowers. In regions like Africa and South America, rapid urbanization and industrialization are creating new opportunities for B2B buyers looking to procure air blowers for diverse applications, from ventilation to drying processes.

Emerging technologies in the commercial air blower sector, such as IoT integration and automation, are reshaping sourcing strategies. B2B buyers can now benefit from advanced monitoring systems that enhance operational efficiency and maintenance scheduling. Furthermore, the shift towards portable and lightweight models is gaining traction, especially in markets with fluctuating demand patterns. Buyers from the Middle East and Europe, particularly in countries like Saudi Arabia and Germany, are increasingly prioritizing high-performance blowers that can handle specific environmental conditions, such as high humidity or dust-laden air.

Additionally, the competitive landscape is evolving with the entry of niche players focusing on custom solutions tailored to specific industry needs. As international B2B buyers navigate this dynamic market, they should prioritize suppliers who can offer a range of products, flexible pricing, and robust customer support to ensure a seamless procurement experience.

How Is Sustainability and Ethical Sourcing Affecting the Commercial Air Blower Market?

Sustainability has become a pivotal concern in the commercial air blower sector, influencing both product development and sourcing strategies. Environmental impacts of production processes, including energy consumption and waste generation, are at the forefront of buyer considerations. B2B buyers are increasingly seeking products that not only perform efficiently but also minimize their carbon footprint.

Ethical sourcing practices are essential for maintaining a positive brand image and meeting regulatory requirements. Buyers are encouraged to partner with manufacturers who adhere to sustainability certifications, such as ISO 14001, which ensures environmental management systems are in place. The use of recyclable materials in blower construction is another trend gaining momentum, appealing to buyers focused on reducing environmental impacts.

Furthermore, the demand for ‘green’ certifications is rising among consumers and businesses alike. B2B buyers should look for suppliers who can provide transparency in their supply chains, detailing the environmental and social impacts of their products. This not only fosters trust but also aligns with the growing consumer preference for eco-friendly solutions, creating a competitive advantage in the marketplace.

How Has the Commercial Air Blower Sector Evolved Over Time?

The commercial air blower sector has undergone significant evolution since its inception, driven by advancements in technology and changing market needs. Initially, air blowers were primarily mechanical devices used for basic ventilation and cooling. Over the decades, innovations in materials and engineering have transformed them into sophisticated machines capable of handling various industrial applications, from drying and cooling to contamination control.

The introduction of electric blowers marked a significant turning point, offering enhanced efficiency and reliability. As industries began to recognize the importance of air quality and ventilation, the demand for more advanced and specialized blowers surged. Today, commercial air blowers are equipped with features such as variable speed controls, energy-efficient motors, and smart technology integration, which cater to the diverse needs of B2B buyers across multiple sectors.

As the sector continues to evolve, staying informed about technological advancements and market shifts will be crucial for international buyers looking to optimize their procurement strategies. The focus on sustainability and ethical sourcing will likely shape the future landscape of the commercial air blower market, presenting both challenges and opportunities for B2B transactions.

Illustrative image related to commercial air blower

Frequently Asked Questions (FAQs) for B2B Buyers of commercial air blower

-

How do I choose the right commercial air blower for my business needs?

When selecting a commercial air blower, consider the specific application, such as drying, cooling, or ventilation. Assess the airflow requirements measured in CFM (cubic feet per minute) to ensure the blower meets your operational needs. Evaluate features like portability, noise levels, and power options (e.g., plug-in or hardwired) that suit your workspace. Additionally, consider the durability of materials, especially if the blower will be exposed to harsh environments. Consulting with suppliers can provide tailored recommendations based on your unique circumstances. -

What is the best air blower for industrial applications?

For industrial applications, high-capacity blowers with robust construction are ideal. Look for models with high CFM ratings, typically above 1,000 CFM, to ensure effective airflow in large spaces. Direct drive blowers are often preferred due to their efficiency and ability to handle high pressure. Additionally, consider blowers with features like adjustable speed settings and built-in power outlets for added versatility. Brands known for industrial reliability include RIDGID and B-Air, offering a range of products tailored for demanding environments. -

What are the typical payment terms for purchasing commercial air blowers internationally?

Payment terms can vary significantly depending on the supplier and the buyer’s negotiation. Common arrangements include 30% upfront payment with the balance due upon shipment or delivery. Letters of credit are often used for larger orders to provide security for both parties. It’s essential to discuss and confirm payment terms before finalizing any agreements, ensuring clarity on currency, transfer methods, and any potential fees associated with international transactions. -

What factors should I consider when vetting suppliers for commercial air blowers?

When vetting suppliers, prioritize their experience and reputation in the industry. Check for certifications and compliance with international standards, particularly those relevant to your region. Request references and reviews from other B2B clients to gauge reliability and service quality. Additionally, assess their production capabilities, lead times, and after-sales support. Engaging in direct communication can also provide insights into their responsiveness and willingness to accommodate your specific needs. -

Are customization options available for commercial air blowers?

Many manufacturers offer customization options to meet specific operational needs. Customization can include modifications to size, airflow capacity, and features like built-in sensors or specialized attachments. When seeking customization, provide detailed specifications and discuss your requirements with potential suppliers to understand their capabilities. Keep in mind that customized products may involve longer lead times and potentially higher costs, so plan accordingly to avoid project delays. -

What is the minimum order quantity (MOQ) for commercial air blowers?

Minimum order quantities (MOQ) can vary widely among suppliers, typically ranging from a single unit to several dozen, depending on the product and manufacturer. Large suppliers may have lower MOQs for standard models, while custom orders often require higher quantities. It’s advisable to discuss MOQs during initial negotiations to ensure they align with your purchasing strategy. If you anticipate needing ongoing supplies, consider establishing a long-term relationship with your supplier to negotiate better terms. -

How can I ensure quality assurance (QA) for my commercial air blower order?

To ensure quality assurance, request product samples before placing a bulk order, allowing you to assess performance and durability firsthand. Verify that the supplier follows quality control protocols and holds relevant certifications, such as ISO standards. Discuss the testing procedures for their products, including airflow efficiency and noise level assessments. Additionally, establish clear agreements regarding warranties and return policies to safeguard your investment. -

What logistics considerations should I keep in mind when importing air blowers?

When importing air blowers, consider shipping methods, costs, and delivery timelines. Choose between air freight for faster delivery or sea freight for cost-effectiveness, especially for large orders. Be aware of customs regulations and import duties that may apply to your products, as these can impact overall costs. Collaborating with a reliable logistics partner can help streamline the process, ensuring compliance with all regulations and timely delivery to your location.

Top 5 Commercial Air Blower Manufacturers & Suppliers List

1. Tennant – Air Mover Commercial Dryer

Domain: tennantco.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Air Mover Commercial Dryer’, ‘description’: ‘Dry surfaces faster with an air mover known for its durability and efficiency. Choose from three positions and three speeds to quickly dry carpet, hard floors, fresh paint, concrete sealer, and more. The innovative design allows for stacking multiple units, and an optional wheel cart provides effortless maneuverability.’, ‘features’: [‘Easily …

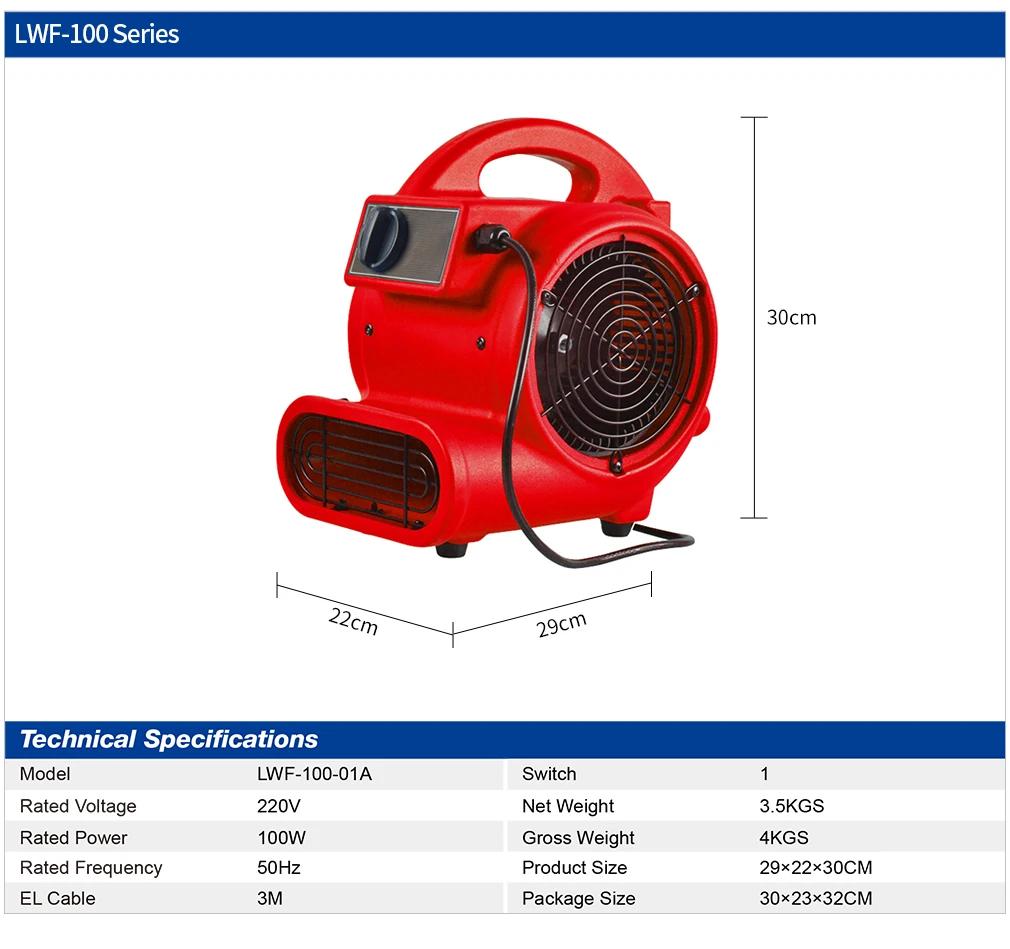

2. Lavex – 3-Speed Mini Air Mover

Domain: lavexproducts.com

Registered: 2023 (2 years)

Introduction: {“products”:[{“model”:”761LAVAM0125″,”type”:”3-Speed Mini Air Mover”,”horsepower”:”1/8 hp”,”flow_rate”:”500 CFM”,”features”:[“GFCI Power Outlets”]},{“model”:”761AMLV100″,”type”:”3-Speed Commercial Air Mover”,”horsepower”:”1 hp”,”flow_rate”:”1,500 CFM”,”features”:[“GFCI Power Outlets”]},{“model”:”761AMLV100WH”,”type”:”3-Speed Commercial Air Mover”,”features”:[“Telescoping Handle”,”Wheels”,”GFCI Pow…

3. B-Air – VP-50 Air Mover

Domain: b-air.com

Registered: 2003 (22 years)

Introduction: {“model”:”BA-VP-50H-GY”,”description”:”The B-Air Vent VP-50 Air Mover is designed for carpet cleaning and hospitality industries, featuring a compact and durable design. It has a powerful 2-speed, 1/2 HP sealed motor for efficient air circulation and drying of medium-to-large carpet cleaning jobs. The unit can be positioned at 0° and 90° angles for versatility in drying corners and stairs. It incl…

4. Recreonics – 1 HP Commercial Spa-Duty Air Blower

Domain: recreonics.com

Registered: 1996 (29 years)

Introduction: {“products”:[{“name”:”1 HP Commercial Spa-Duty Air Blower”,”sku”:”70-500″,”price”:”$2,934.43″,”description”:”Commercial spa air blowers features all the performance and quality of the standard air blower with added features for aggressive use.”},{“name”:”1.5 HP Commercial Spa-Duty Air Blower”,”sku”:”70-501″,”price”:”$3,142.50″,”description”:”Commercial spa air blowers features all the performance …

5. AirScape – CF Cabinet Fan with Filtration

Domain: hvacquick.com

Registered: 2000 (25 years)

Introduction: [{‘name’: ‘AirScape CF Cabinet Fan with Filtration’, ‘description’: ‘Air handler for general purpose filtration.’, ‘features’: ‘Aluminum with R-4 insulation, MERV-6, MERV-13, MERV-15 (near HEPA) filtration options.’, ‘CFM’: ‘1930 CFM at 0.5 inches W.C.’, ‘price’: ‘From $1049.00’}, {‘name’: ‘S&P SQB Belt Drive Square Inline Centrifugal Duct Fans – 1 Phase’, ‘description’: ‘Square inline duct mounte…

Strategic Sourcing Conclusion and Outlook for commercial air blower

In the competitive landscape of commercial air blowers, strategic sourcing emerges as a critical factor for success. By understanding the diverse applications and specifications of air blowers—from high-velocity models to specialized industrial blowers—international B2B buyers can make informed purchasing decisions that align with their operational needs. Key takeaways include the importance of evaluating product performance, energy efficiency, and versatility, which can significantly impact long-term operational costs and efficiency.

Investing in high-quality blowers not only enhances air circulation and cooling but also contributes to a healthier work environment by reducing airborne contaminants. Additionally, leveraging supplier partnerships can lead to better pricing, improved service, and enhanced product offerings tailored to specific market demands.

Looking ahead, as industries worldwide continue to evolve, the demand for efficient and reliable air-moving solutions will only grow. B2B buyers from Africa, South America, the Middle East, and Europe should prioritize strategic sourcing as a pathway to not only meet current operational challenges but also to position themselves advantageously for future developments. Embrace the opportunity to streamline your supply chain and elevate your business by investing in the right commercial air blowers today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.