Everything You Need to Know About Comb Knife Sourcing in 2025

Introduction: Navigating the Global Market for comb knife

In today’s fast-paced global market, sourcing the right comb knife can pose significant challenges for B2B buyers, particularly when navigating varying regulations, quality standards, and supplier reliability across regions. This guide offers a comprehensive overview of the comb knife landscape, covering essential aspects such as types of comb knives, their diverse applications, effective supplier vetting processes, and cost considerations. As international buyers from Africa, South America, the Middle East, and Europe (including key markets like Saudi Arabia and Brazil) seek to make informed purchasing decisions, understanding these factors is crucial.

With the rise in demand for discreet self-defense tools, the comb knife has garnered attention not only for its practical applications but also for its unique design that caters to a variety of consumer needs. This guide aims to empower B2B buyers by providing actionable insights and data-driven strategies for successfully sourcing comb knives that meet both market expectations and regulatory requirements. By leveraging this resource, businesses can enhance their procurement processes, minimize risks, and ultimately gain a competitive edge in the evolving comb knife market.

Understanding comb knife Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Discrete Comb | Concealed blade within a standard comb design | Self-defense, personal security | Pros: Discreet, easy to carry; Cons: Limited blade length (3 inches). |

| Tactical Comb Knife | Robust design with tactical features and larger blade | Military, law enforcement, outdoor survival | Pros: Versatile, durable; Cons: Bulkier than other types. |

| Multi-Function Comb | Comb with additional tools (e.g., screwdriver) | Everyday carry, utility applications | Pros: Multifunctional; Cons: Can be heavier, more expensive. |

| Decorative Comb Knife | Stylish designs with artistic elements | Gift items, collector’s markets | Pros: Attractive, can be a conversation starter; Cons: May lack practicality. |

| Keychain Comb Knife | Compact design that attaches to keychains | Everyday carry, personal protection | Pros: Highly portable; Cons: Smaller blade may limit effectiveness. |

What Are the Characteristics of a Discrete Comb Knife?

The Discrete Comb is designed to look like an ordinary hair comb, featuring a hidden blade that typically measures around three inches. This type is primarily used for self-defense and personal security, making it appealing to individuals seeking discreet protection. When purchasing, B2B buyers should consider local regulations regarding concealed weapons, as these products often have specific legal restrictions.

How Does a Tactical Comb Knife Differ from Other Types?

Tactical Comb Knives are built with a focus on durability and functionality, often featuring larger blades and additional tactical enhancements such as grips and sheaths. These knives are commonly utilized by military personnel and law enforcement officers, as well as outdoor enthusiasts. Buyers should evaluate the intended application and ensure that the knife meets the necessary specifications for their operational needs.

Why Choose a Multi-Function Comb Knife?

Multi-Function Comb Knives combine the utility of a traditional comb with additional tools, such as screwdrivers or bottle openers. This versatility makes them suitable for everyday carry and utility applications. B2B purchasers should assess the quality of the additional tools and the overall build of the knife to ensure reliability and durability in various situations.

What Makes Decorative Comb Knives Unique?

Decorative Comb Knives feature artistic designs and are often sought after as gift items or collectibles. While they may not be as practical for self-defense or utility, their aesthetic appeal can attract buyers looking for unique items. B2B buyers should consider the target market’s preferences and the potential for resale value when investing in these products.

Illustrative image related to comb knife

What Are the Benefits of Keychain Comb Knives?

Keychain Comb Knives are compact and designed to attach easily to keychains, making them ideal for everyday carry and personal protection. Their portability is a significant advantage; however, the smaller blade size may limit their effectiveness in certain situations. Buyers should focus on the quality of the blade and the attachment mechanism to ensure reliability and ease of use.

Key Industrial Applications of comb knife

| Industry/Sector | Specific Application of comb knife | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Security & Defense | Personal defense tool for security personnel | Provides a discreet means of protection for employees, enhancing safety. | Compliance with local laws regarding self-defense tools. |

| Hospitality | Guest safety and security measures | Enhances guest safety perception, fostering trust in hospitality services. | Quality assurance and material durability for frequent use. |

| Outdoor Recreation | Camping and survival gear | Versatile tool for outdoor activities, appealing to adventure enthusiasts. | Weight, portability, and multi-functionality for outdoor use. |

| Retail | Novelty item for self-defense merchandise | Attracts customers interested in self-defense products, increasing sales. | Unique designs and compliance with marketing regulations. |

| Law Enforcement | Training and tactical exercises | Serves as a safe training tool for officers, reducing risk during drills. | Quality of materials to withstand rigorous training environments. |

How is a Comb Knife Used in Security & Defense Applications?

In the security and defense sector, comb knives serve as discreet personal defense tools for security personnel and individuals in high-risk environments. They provide an effective means of self-protection without drawing attention. Buyers in this sector must ensure compliance with local regulations regarding self-defense tools, as laws vary significantly across regions, especially in Africa, South America, the Middle East, and Europe. Quality and reliability are paramount, as these tools may be used in critical situations.

What Role Does a Comb Knife Play in the Hospitality Industry?

In the hospitality sector, comb knives can be utilized as part of guest safety measures. They can be included in staff training programs to prepare employees for potential emergencies, thereby enhancing guests’ safety perceptions. For international buyers, sourcing comb knives requires attention to quality assurance and material durability, ensuring they can withstand frequent use. Additionally, businesses must consider the design and branding potential when integrating these tools into their safety protocols.

How is a Comb Knife Integrated into Outdoor Recreation?

Comb knives are increasingly popular in outdoor recreation as versatile camping and survival tools. They provide users with a compact solution for various tasks, from cutting rope to food preparation, making them appealing to adventure enthusiasts. For buyers in this sector, key sourcing considerations include the weight and portability of the comb knife, as well as its multi-functionality to enhance user experience in outdoor settings. Ensuring the product meets durability standards is crucial for reliable performance in rugged environments.

Why Are Comb Knives Important in Retail?

In retail, comb knives can be marketed as novelty self-defense items, attracting customers interested in personal safety products. This application not only increases sales but also enhances the store’s reputation as a provider of unique and practical items. Retailers must consider the uniqueness of designs and ensure compliance with marketing regulations while sourcing these products. Understanding consumer preferences and trends in self-defense can further guide retailers in selecting the right comb knives for their inventory.

Illustrative image related to comb knife

How Do Comb Knives Benefit Law Enforcement Training?

For law enforcement agencies, comb knives can be utilized in training and tactical exercises. They serve as safe training tools, allowing officers to practice techniques without the risks associated with traditional weapons. Buyers in this sector should prioritize the quality of materials used in comb knives to ensure they can withstand rigorous training environments. Additionally, compliance with safety regulations and standards is essential to mitigate liability and enhance training effectiveness.

3 Common User Pain Points for ‘comb knife’ & Their Solutions

Scenario 1: Misleading Product Information Leading to Buyer Disappointment

The Problem: B2B buyers often face frustration when sourcing comb knives due to misleading product information or unclear specifications. For instance, a buyer might see a promotional deal for a bulk order of comb knives, only to receive a smaller quantity or a product that doesn’t meet their expectations. This not only wastes valuable time and resources but can also lead to customer dissatisfaction if the product is intended for resale. Such situations can severely damage supplier relationships and impact brand reputation.

The Solution: To mitigate this issue, it is crucial for buyers to conduct thorough research on potential suppliers before placing orders. Look for suppliers that provide transparent and detailed product descriptions, including dimensions, materials, and functionalities. Engage in direct communication with suppliers to clarify any uncertainties regarding product specifications and quantity. Additionally, consider requesting samples before committing to a larger order to assess quality and ensure that it aligns with your expectations. Establishing strong communication channels with suppliers can help set clear expectations and foster a reliable partnership.

Illustrative image related to comb knife

Scenario 2: Regulatory Compliance and Legal Concerns

The Problem: Navigating the regulatory landscape around comb knives can be particularly challenging for B2B buyers, especially in regions with stringent laws on self-defense weapons. Buyers may inadvertently procure products that do not comply with local regulations, resulting in legal repercussions and potential fines. This is particularly concerning in international markets like Europe and the Middle East, where laws can vary significantly from one country to another.

The Solution: To address regulatory compliance, B2B buyers should familiarize themselves with the laws and regulations governing comb knives in their target markets. This includes understanding blade lengths, types of use, and shipping restrictions. Partnering with suppliers who are knowledgeable about compliance issues can be highly beneficial. Suppliers should provide documentation proving that their products meet the necessary legal standards. Additionally, consider engaging legal counsel or compliance experts to review contracts and product details to ensure that all procurement activities are compliant with local laws.

Scenario 3: Quality Control and Product Reliability

The Problem: Quality inconsistency is a significant pain point for B2B buyers sourcing comb knives, especially when purchasing from multiple suppliers. Buyers may receive products that vary in quality, which can lead to dissatisfaction among end-users and tarnish the buyer’s brand image. This inconsistency can stem from various factors, including differences in manufacturing processes, materials used, or lack of quality assurance measures.

The Solution: To ensure high-quality and reliable products, B2B buyers should implement a robust quality control process. This could involve setting specific quality standards and conducting regular audits of suppliers’ manufacturing practices. Look for suppliers who can demonstrate their commitment to quality through certifications or third-party testing. Establishing a clear return policy for defective items can also protect buyers from losses related to low-quality products. Furthermore, building long-term relationships with trusted suppliers can help ensure consistency in product quality and reliability, ultimately enhancing the buyer’s reputation in the market.

Illustrative image related to comb knife

Strategic Material Selection Guide for comb knife

When selecting materials for comb knives, it is crucial for B2B buyers to consider the properties and suitability of various materials. This guide analyzes four common materials used in the production of comb knives, focusing on their key properties, advantages, disadvantages, and specific considerations for international markets.

What Are the Key Properties of Stainless Steel for Comb Knives?

Stainless steel is a popular choice for comb knives due to its excellent corrosion resistance and durability. Typically, grades such as 420 and 440C are used, which offer a good balance between hardness and toughness. Stainless steel can withstand a wide range of temperatures and pressures, making it suitable for various environments.

Pros: Its high resistance to rust and staining ensures longevity, while its strength allows for sharp, durable blades.

Cons: However, stainless steel can be more expensive than other materials and may require complex manufacturing processes, particularly when producing intricate designs.

Impact on Application: Stainless steel is compatible with various media, making it ideal for both personal and self-defense applications.

Illustrative image related to comb knife

Considerations for International Buyers: Buyers from regions such as Africa and the Middle East should ensure compliance with local regulations regarding blade materials and safety standards, such as ASTM or JIS.

How Does Aluminum Compare as a Material for Comb Knives?

Aluminum is lightweight and offers good corrosion resistance, making it a viable option for comb knives. It is often anodized to enhance its protective qualities and aesthetic appeal.

Pros: The low weight of aluminum makes it easy to carry, and its resistance to corrosion can be beneficial in humid environments.

Cons: Aluminum is generally less durable than stainless steel and can bend or deform under high stress, which may limit its suitability for heavy-duty use.

Impact on Application: While it is suitable for everyday carry, aluminum may not be the best choice for high-stress environments or applications requiring high durability.

Considerations for International Buyers: Buyers should be aware of the anodization processes and ensure that the aluminum meets local standards, particularly in regions with specific regulations regarding metal composition.

What Are the Benefits of Using Carbon Steel in Comb Knives?

Carbon steel is known for its exceptional hardness and edge retention, making it a favored material for high-performance knives. It is often used in professional-grade comb knives where cutting efficiency is paramount.

Pros: The ability to achieve a razor-sharp edge and its overall toughness are significant advantages.

Cons: However, carbon steel is prone to rust and requires regular maintenance to prevent corrosion, which may be a drawback for some users.

Impact on Application: Carbon steel is ideal for applications that prioritize sharpness and performance over corrosion resistance.

Illustrative image related to comb knife

Considerations for International Buyers: Buyers should consider the maintenance requirements and ensure that their market allows for carbon steel products, as some regions may have restrictions on materials used in self-defense items.

How Does Plastic Stand Up as a Material for Comb Knives?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is increasingly used in the production of comb knives, especially for budget-friendly options.

Pros: The lightweight nature and resistance to corrosion make plastic a practical choice for everyday use. It is often less expensive to manufacture and can be produced in various colors and designs.

Illustrative image related to comb knife

Cons: However, plastic lacks the durability and sharpness of metal options, which may limit its effectiveness in serious applications.

Impact on Application: Plastic comb knives are typically used for non-threatening situations or as novelty items rather than for self-defense.

Considerations for International Buyers: Buyers should ensure that the plastic used complies with safety standards and regulations in their region, particularly regarding safety and product durability.

Summary of Material Selection for Comb Knives

| Material | Typical Use Case for comb knife | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Self-defense and everyday carry | High corrosion resistance and durability | Higher cost and complex manufacturing | Medium |

| Aluminum | Everyday carry and light use | Lightweight and corrosion-resistant | Less durable under stress | Medium |

| Carbon Steel | Professional-grade performance | Exceptional sharpness and edge retention | Prone to rust, requiring maintenance | Medium |

| Plastic | Budget-friendly and novelty items | Lightweight and cost-effective | Lacks durability and sharpness | Low |

This analysis provides B2B buyers with insights into the material selection process for comb knives, enabling informed decisions that align with their specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for comb knife

What Are the Main Stages of Manufacturing a Comb Knife?

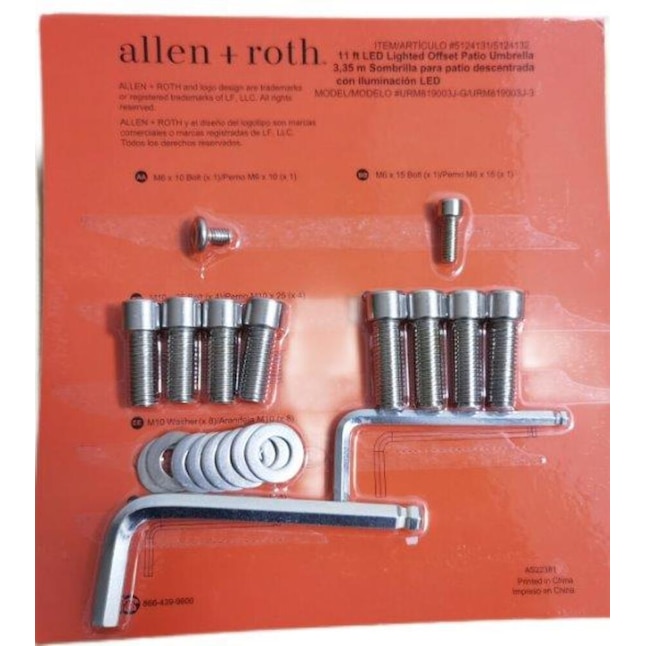

Manufacturing a comb knife involves a series of well-defined stages that ensure the final product is both functional and compliant with safety standards. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to comb knife

How Is Material Prepared for Comb Knife Production?

The manufacturing process begins with the selection of appropriate materials. Common materials for comb knives include high-carbon stainless steel for blades and durable plastic or metal for the comb structure. Material preparation involves sourcing raw materials that meet specific quality standards, such as ASTM or ISO certifications. This ensures that the materials are not only strong but also resistant to corrosion and wear.

Once the materials are sourced, they undergo inspection to confirm compliance with specified standards. This initial quality check, often referred to as Incoming Quality Control (IQC), is crucial for avoiding defects in later stages.

What Forming Techniques Are Used in Comb Knife Manufacturing?

The forming stage involves shaping the prepared materials into their final form. For comb knives, this typically includes processes such as stamping, forging, or laser cutting for the blade, and injection molding or CNC machining for the comb structure.

- Stamping is commonly used for creating the blade profile, where a die is used to cut the steel into the desired shape.

- Forging can enhance the strength of the blade, providing additional durability.

- Injection molding is used for producing the comb from plastic, ensuring consistent shape and quality.

Each of these processes requires specialized machinery and skilled labor, which can vary significantly between manufacturers.

How Are Comb Knives Assembled?

After the components are formed, they are brought together in the assembly stage. This involves attaching the blade to the comb securely. The assembly process may include:

- Mechanical fastening: Using screws or rivets to attach the blade to the comb.

- Adhesive bonding: For certain designs, strong adhesives may be used to ensure a seamless connection.

Quality checks during assembly, known as In-Process Quality Control (IPQC), help identify any issues early in the production line. This minimizes the risk of defects in the final product.

What Finishing Techniques Enhance the Quality of Comb Knives?

The finishing stage of manufacturing focuses on refining the product’s appearance and functionality. This includes processes like sharpening the blade, polishing the surfaces, and applying protective coatings.

- Sharpening: Ensures the blade edge is honed to the required sharpness for effective use.

- Polishing: Enhances the aesthetic appeal and can also help with corrosion resistance.

- Coating: Protective coatings, such as PVD (Physical Vapor Deposition) or anodizing, are applied to improve durability and aesthetic quality.

These finishing techniques not only enhance the product’s performance but also contribute to its marketability.

What Quality Assurance Measures Are Essential for Comb Knives?

Quality assurance (QA) is critical in the manufacturing of comb knives to meet international standards and customer expectations. A robust QA process includes adherence to relevant international standards, systematic quality checkpoints, and various testing methods.

Which International Standards Should B2B Buyers Consider?

For comb knife manufacturers, compliance with international standards such as ISO 9001 (Quality Management Systems) is essential. This certification demonstrates that a company consistently provides products that meet customer and regulatory requirements.

Additionally, industry-specific certifications like CE marking for products sold in the European Union or API standards for products used in specific industries may be relevant. Understanding these certifications helps B2B buyers ensure that the products meet safety and performance benchmarks.

Illustrative image related to comb knife

What Are the Key QC Checkpoints in Comb Knife Production?

Quality control checkpoints are essential for maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to detect any deviations from quality standards.

- Final Quality Control (FQC): Comprehensive testing of the finished product before it is shipped. This includes functional testing of the blade and comb assembly, as well as visual inspections for defects.

Implementing these checkpoints helps in identifying issues at various stages of production, thus reducing the risk of faulty products reaching the market.

What Testing Methods Are Commonly Used for Comb Knives?

Testing methods for comb knives can vary based on the intended use and market requirements. Common methods include:

- Sharpness Testing: Ensures the blade meets specified sharpness standards.

- Durability Testing: Involves subjecting the knife to stress tests to determine its resilience under various conditions.

- Corrosion Resistance Testing: Evaluates how well the materials withstand exposure to moisture and other corrosive elements.

These tests are essential for validating the quality and safety of the products being offered.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several methods to ensure that suppliers meet required standards:

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality control measures. This can also help identify areas for improvement.

-

Quality Assurance Reports: Requesting detailed QA reports can help buyers understand the supplier’s compliance with international standards and internal quality benchmarks.

-

Third-party Inspections: Engaging independent third-party organizations to conduct inspections can provide an unbiased assessment of the supplier’s quality assurance processes.

-

Certification Verification: Confirming that suppliers possess relevant certifications (e.g., ISO 9001, CE) can reassure buyers of their commitment to quality.

What Are the Nuances of Quality Control for International Buyers?

International buyers must be aware of specific nuances related to quality control. Regulatory requirements can differ significantly between regions. For instance, products sold in the European Union must comply with CE marking regulations, while those in the Middle East may have different safety standards.

Illustrative image related to comb knife

Additionally, cultural differences may influence manufacturing practices and quality expectations. It is crucial for B2B buyers to communicate clearly with suppliers about their specific requirements and ensure that both parties have a mutual understanding of quality standards.

By understanding the manufacturing processes and quality assurance measures involved in the production of comb knives, B2B buyers can make informed decisions and establish reliable partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘comb knife’

Introduction

This practical sourcing guide aims to equip B2B buyers with a comprehensive checklist for procuring comb knives. With the rising demand for self-defense products across diverse markets, understanding the nuances of sourcing comb knives effectively is crucial. This guide outlines essential steps to ensure that you partner with reliable suppliers while meeting legal and quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in the sourcing process. Identify the key features you require, such as blade length, material, and design. This clarity will help you communicate effectively with suppliers and ensure that the products meet your expectations.

- Considerations:

- Blade length (e.g., 3 inches, as noted in some offerings).

- Material durability (e.g., stainless steel versus other materials).

- Design preferences (e.g., discrete versus overt designs).

Step 2: Research Market Trends and Regulations

Understanding market trends and regional regulations is vital for successful procurement. Different regions may have varying laws governing the sale and ownership of self-defense tools, including comb knives. Researching these regulations will help you avoid legal pitfalls and identify opportunities in the market.

- Key Actions:

- Review local laws in your target markets, particularly in Africa, South America, the Middle East, and Europe.

- Stay updated on emerging trends in self-defense products to anticipate customer needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; conduct background checks to ensure they have a solid reputation.

- What to Look For:

- Supplier certifications and compliance with international quality standards.

- Customer testimonials and feedback from previous clients.

Step 4: Request Samples for Quality Assessment

Always request product samples before making bulk purchases. This allows you to assess the quality and functionality of the comb knives firsthand. Evaluating samples can help you avoid costly mistakes and ensure that the products align with your specifications.

- Considerations:

- Check the sharpness and durability of the blade.

- Assess the overall design and usability.

Step 5: Negotiate Terms and Pricing

Once you’ve identified potential suppliers and evaluated their products, it’s time to negotiate terms. Discuss pricing, minimum order quantities, payment terms, and delivery schedules. Effective negotiation can lead to better deals and build stronger supplier relationships.

- Tips:

- Be clear about your budget and expectations.

- Look for flexibility in terms of payment and shipping options.

Step 6: Verify Shipping and Compliance Requirements

Understanding shipping logistics and compliance is essential, especially for international orders. Confirm that your suppliers can meet shipping timelines and that their products comply with your country’s import regulations.

- Action Items:

- Inquire about shipping methods and costs.

- Ensure all products meet necessary import/export regulations.

Step 7: Establish a Communication Plan

Finally, setting up a robust communication plan with your suppliers is crucial for ongoing success. Regular updates and open lines of communication can help address issues promptly and maintain a strong business relationship.

Illustrative image related to comb knife

- Best Practices:

- Schedule regular check-ins to discuss order status and any concerns.

- Use project management tools for tracking communications and deliveries.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing comb knives, ensuring quality products while building strong supplier relationships.

Comprehensive Cost and Pricing Analysis for comb knife Sourcing

What Are the Key Cost Components in Comb Knife Manufacturing?

When analyzing the cost structure for sourcing comb knives, it’s essential to break down the individual components that contribute to the final price. The primary cost components include:

-

Materials: The type of materials used significantly affects the cost. High-quality stainless steel for blades and durable plastics for the comb casing are common choices. The cost fluctuates based on market demand and availability, with premium materials typically leading to higher prices.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality. Understanding the labor market in the supplier’s country is crucial for cost estimation.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and administrative expenses. Overhead costs can be higher in regions with stringent regulations and higher operational costs. Suppliers often factor these expenses into their pricing models.

-

Tooling: Tooling costs relate to the equipment required for production. Custom designs or unique features may necessitate specialized tooling, increasing initial costs but potentially reducing per-unit costs in larger orders.

-

Quality Control (QC): Ensuring the final product meets quality standards can incur additional costs. Suppliers with robust QC processes may charge more, but this investment often results in fewer defects and higher customer satisfaction.

-

Logistics: Transportation and shipping costs vary based on the distance from the manufacturer to the buyer’s location. Factors such as shipping methods, weight, and packaging requirements all contribute to logistics expenses.

-

Margin: Suppliers will add a profit margin on top of their costs, which varies based on the supplier’s business model and market positioning. Understanding the expected margin can aid in negotiations.

How Do Pricing Influencers Affect Comb Knife Costs?

Several factors influence the pricing of comb knives, particularly for international B2B buyers. Key influencers include:

-

Volume and Minimum Order Quantity (MOQ): Larger order quantities often lead to bulk discounts. Understanding the MOQ can help buyers negotiate better pricing terms and reduce overall costs.

-

Specifications and Customization: Custom designs or specific features (e.g., unique blade shapes or personalized engravings) can increase costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Materials and Quality Certifications: Premium materials and compliance with international quality certifications (like ISO or CE) can significantly impact price. Buyers should assess whether these certifications are necessary for their target markets.

-

Supplier Factors: Supplier reliability, reputation, and location play crucial roles in pricing. Established suppliers may charge higher rates due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the product, influencing the final price.

What Buyer Tips Can Enhance Cost-Efficiency in Comb Knife Sourcing?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency in sourcing comb knives:

-

Negotiation: Always approach negotiations with a clear understanding of market prices and your budget. Building a strong relationship with suppliers can lead to more favorable terms and pricing adjustments.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but all associated costs, including shipping, customs duties, and potential warranty claims. A lower upfront cost may lead to higher TCO if quality issues arise.

-

Understand Pricing Nuances: Different regions may have unique pricing structures due to local demand and supply chain conditions. Being aware of these nuances can provide leverage during negotiations.

-

Supplier Diversification: Consider sourcing from multiple suppliers to mitigate risks and ensure competitive pricing. This strategy can also provide alternatives in case of supply chain disruptions.

-

Market Research: Regularly conduct market research to stay informed about changes in material costs, labor rates, and manufacturing trends. This knowledge can help anticipate price fluctuations and adjust sourcing strategies accordingly.

By thoroughly understanding the cost structure, pricing influencers, and effective sourcing strategies, B2B buyers can make informed decisions that optimize their investments in comb knife products.

Alternatives Analysis: Comparing comb knife With Other Solutions

Exploring Alternatives to the Comb Knife: A Comparative Analysis

When considering the best self-defense tools for your business or personal safety needs, it’s crucial to evaluate the available options. The comb knife, which combines the functionality of a traditional comb with a concealed blade, is a popular choice for discreet self-defense. However, other viable alternatives exist that may better fit specific requirements or preferences. This analysis will compare the comb knife against two alternative solutions: tactical pens and self-defense keychains.

Comparison Table

| Comparison Aspect | ‘Comb Knife’ | Tactical Pen | Self-Defense Keychain |

|---|---|---|---|

| Performance | Good for discreet use; 3-inch blade | Durable, can be used for striking or writing | Effective for quick defense |

| Cost | Approximately $15 | Ranges from $10 to $50 | Typically $5 to $20 |

| Ease of Implementation | Easy to carry and conceal | Requires awareness of writing function | Simple to attach to keys |

| Maintenance | Minimal, occasional cleaning needed | Requires replacement if damaged | Very low, just keep clean |

| Best Use Case | Discreet self-defense | Multi-functional, everyday carry | Quick defense in emergencies |

Detailed Breakdown of Alternatives

Tactical Pen

Tactical pens are designed to function both as a writing instrument and a self-defense tool. Made from durable materials, they can withstand significant impact and are often equipped with features like glass breakers. Their versatility makes them suitable for everyday carry, combining practicality with self-defense capabilities. However, tactical pens can be more expensive and may require users to familiarize themselves with their self-defense applications, which could be a drawback for those seeking simplicity.

Self-Defense Keychain

Self-defense keychains are compact and easy to carry, making them an excellent option for individuals looking for a quick response tool. These keychains often come in various designs, such as kubotans or knuckle-style options, allowing for effective striking or pressure point techniques. Their affordability and low maintenance make them appealing to budget-conscious buyers. However, their effectiveness may depend on the user’s training and confidence in using them in high-stress situations, which could limit their appeal to some users.

Conclusion: How to Choose the Right Self-Defense Solution

In selecting the ideal self-defense solution, B2B buyers should consider their specific needs, including the context of use, desired functionality, and budget constraints. The comb knife provides a discreet option for those prioritizing concealment, while tactical pens offer versatility for users who value multifunctionality. On the other hand, self-defense keychains serve as affordable, easily accessible tools that can be employed in emergencies. Ultimately, understanding the strengths and weaknesses of each alternative will empower buyers to make informed decisions that align with their safety requirements and operational contexts.

Essential Technical Properties and Trade Terminology for comb knife

What Are the Essential Technical Properties of a Comb Knife?

When sourcing comb knives, understanding their technical properties is crucial for making informed purchasing decisions. Here are the key specifications that B2B buyers should consider:

1. Blade Material Grade

The material used for the blade significantly impacts its durability and functionality. Common materials include stainless steel, carbon steel, and high-carbon stainless steel. Stainless steel is corrosion-resistant, making it ideal for humid environments, while high-carbon steel offers excellent sharpness and edge retention. Knowing the material grade helps buyers assess the knife’s suitability for specific applications and its longevity.

2. Blade Length

Typically, comb knives feature blades ranging from 2 to 4 inches in length. The blade length can affect the knife’s usability and compliance with local regulations. Shorter blades may be more discreet and easier to conceal, making them preferable for personal safety applications. Understanding the optimal blade length for your target market is essential for meeting customer expectations.

3. Weight and Balance

The weight of a comb knife affects its handling and ease of use. A well-balanced knife provides better control, which is particularly important in self-defense scenarios. Buyers should evaluate the weight specifications to ensure that the product meets their customers’ preferences for portability and ease of use.

Illustrative image related to comb knife

4. Locking Mechanism

Some comb knives come equipped with a locking mechanism that secures the blade when deployed. This feature is vital for safety, especially when the knife is used by individuals with limited experience. Understanding the types of locking mechanisms available can help buyers select products that enhance user safety and confidence.

5. Finish and Coating

The finish of the blade can include options like satin, matte, or black oxide. Coatings can provide additional benefits such as reduced glare, corrosion resistance, and enhanced aesthetics. Buyers should consider how the finish aligns with customer preferences and the intended use of the comb knife.

6. Compliance with Regulations

Understanding the legal framework governing the sale and use of knives in various regions is crucial. Regulations may dictate blade length, locking mechanisms, and even the materials used. B2B buyers should ensure that the products they source comply with local laws to avoid legal complications and ensure marketability.

What Trade Terminology Should B2B Buyers Know When Purchasing Comb Knives?

Familiarity with industry jargon can streamline communication and enhance negotiations. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of comb knives, buyers may engage with OEMs to customize designs or branding, ensuring that the product aligns with their specific market needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to manage inventory and cash flow effectively. Suppliers often set MOQs based on production costs, so negotiating favorable terms can lead to better pricing.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This document typically outlines specifications, quantities, and delivery timelines. Crafting a clear RFQ helps ensure that suppliers provide accurate quotes, facilitating better decision-making.

Illustrative image related to comb knife

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms used in international transactions to clarify the responsibilities of buyers and sellers. Familiarity with terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers understand shipping costs and liabilities, thus avoiding unexpected expenses.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is essential for inventory management and meeting customer demands. Buyers should discuss lead times with suppliers to ensure timely delivery.

6. Quality Assurance (QA)

QA encompasses the processes and procedures that ensure products meet specific quality standards. For comb knives, QA is critical to maintain safety and reliability. Buyers should inquire about the supplier’s QA processes to ensure they deliver high-quality products consistently.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing comb knives, ensuring they meet their business needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the comb knife Sector

What Are the Key Trends and Market Dynamics in the Comb Knife Sector?

The comb knife sector is witnessing significant growth, driven by a combination of consumer demand for multifunctional tools and the increasing focus on personal safety. Key drivers include the rise in self-defense awareness and the popularity of discreet self-defense tools, especially in regions where personal security is a major concern. For international B2B buyers, understanding the market dynamics is essential; the comb knife market is increasingly influenced by technological advancements and shifting consumer preferences. Emerging trends in sourcing include the integration of smart technologies into traditional comb knives, offering features like GPS tracking or biometric locks. Additionally, the rise of e-commerce platforms facilitates easier access to global suppliers, allowing buyers from Africa, South America, the Middle East, and Europe to source products that meet their specific needs.

As market competition intensifies, manufacturers are focusing on product differentiation through innovative designs and features. For example, comb knives are now available in various materials, including stainless steel and high-grade plastics, which cater to both aesthetic preferences and functionality. Moreover, compliance with local regulations regarding the sale of self-defense items is becoming increasingly important. International buyers must navigate these regulations while sourcing products that are compliant with their local laws to avoid legal complications.

How Is Sustainability and Ethical Sourcing Being Addressed in the Comb Knife Sector?

Sustainability is emerging as a crucial consideration for B2B buyers in the comb knife market. The environmental impact of manufacturing processes, particularly the use of non-renewable materials and energy-intensive production methods, is under scrutiny. Ethical sourcing practices, including the use of recycled materials and sustainable manufacturing processes, are becoming a priority for many companies looking to appeal to environmentally conscious consumers.

Buyers should seek suppliers that demonstrate a commitment to sustainability through certifications such as ISO 14001 for environmental management systems or specific green certifications for materials. This includes sourcing blades made from recycled stainless steel or handles crafted from biodegradable materials. Implementing sustainable practices not only helps in reducing environmental impact but also enhances brand reputation, which is increasingly important in competitive markets.

Furthermore, transparent supply chains are crucial for ethical sourcing. Buyers should engage with suppliers who provide clear information about their sourcing practices and labor conditions to ensure compliance with ethical standards. This is particularly relevant for international buyers in regions like Africa and South America, where supply chain integrity can significantly influence purchasing decisions.

Illustrative image related to comb knife

What Is the Historical Evolution of the Comb Knife Market?

The comb knife has a rich history that reflects broader societal trends in personal safety and self-defense. Originating as a tool primarily for grooming, the comb knife evolved significantly in the late 20th century when it began to be recognized for its utility as a discreet self-defense weapon. This shift was largely influenced by changing perceptions of personal safety and the increasing prevalence of urban violence in various parts of the world.

As the demand for multifunctional tools grew, manufacturers began to innovate, integrating blades into everyday items like combs. This evolution not only expanded the market but also introduced new challenges regarding safety regulations and consumer awareness. Today, the comb knife is marketed not just as a grooming tool but as a practical self-defense option, appealing to a wide range of consumers, including travelers, outdoor enthusiasts, and those concerned about personal safety. Understanding this historical context can provide B2B buyers with insights into consumer behavior and preferences, enabling them to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of comb knife

-

How do I ensure the quality of comb knives when sourcing internationally?

To ensure quality when sourcing comb knives internationally, conduct thorough research on potential suppliers. Look for manufacturers with ISO certifications and positive reviews from previous clients. Request samples to evaluate the material and craftsmanship. Additionally, consider hiring third-party inspection services to assess the products before shipment. Establish clear quality assurance standards in your purchase agreement to ensure compliance with your expectations. -

What are the best practices for vetting suppliers of comb knives?

When vetting suppliers, prioritize transparency and communication. Start by checking their business licenses and certifications to confirm legitimacy. Request references from previous clients and assess their experience in the comb knife industry. Use platforms like Alibaba or Global Sources to find verified suppliers and read reviews. Conduct video calls or site visits to gauge their operational capabilities and reliability. -

What customization options are available for comb knives?

Customization options for comb knives can vary by supplier. Common options include blade length, material, handle design, and branding elements like logos or colors. Discuss your specific requirements with potential suppliers to determine their capabilities. Ensure that they can meet your design specifications while adhering to safety and regulatory standards in your target markets. -

What is the typical minimum order quantity (MOQ) for comb knives?

Minimum order quantities (MOQs) for comb knives can differ based on the supplier and the complexity of the product. Generally, MOQs can range from 100 to 1,000 units. It’s crucial to negotiate MOQs during your discussions with suppliers, especially if you are a smaller business. Some suppliers may be willing to accommodate lower quantities for first-time buyers or sample orders. -

What payment terms should I expect when sourcing comb knives?

Payment terms can vary widely among suppliers, but common practices include a deposit (typically 30%) upfront and the remainder upon shipment. Some suppliers may offer net payment terms, such as net 30 or net 60, for established buyers. Always clarify payment methods accepted (e.g., bank transfer, credit card, or PayPal) and ensure that terms are documented in your contract to avoid misunderstandings. -

How can I manage logistics when importing comb knives?

Managing logistics involves coordinating with your supplier and freight forwarder. Discuss shipping options, such as air freight or sea freight, depending on your budget and urgency. Ensure that all necessary import documentation, including customs declarations and invoices, is prepared to avoid delays. Familiarize yourself with local regulations regarding the importation of knives to ensure compliance and smooth customs clearance. -

What legal regulations should I consider when importing comb knives?

Legal regulations for importing comb knives can vary by country. It’s essential to research local laws regarding knife ownership and importation, as some regions may have restrictions. Ensure that your products comply with safety standards and labeling requirements. Consulting with a legal expert or customs broker can help navigate the complexities of international trade and compliance. -

What are the best ways to establish a long-term relationship with suppliers of comb knives?

Building a long-term relationship with suppliers requires effective communication and mutual trust. Regularly engage with your suppliers, providing feedback and discussing future orders. Demonstrating a commitment to their business by placing consistent orders can strengthen ties. Additionally, consider collaborating on product development or marketing strategies to foster a partnership that benefits both parties.

Top 6 Comb Knife Manufacturers & Suppliers List

1. Fabulyss Boutique – Discrete Comb

Domain: fabulyssboutique.com

Registered: 2020 (5 years)

Introduction: {“Product Name”: “Discrete Comb”, “Brand”: “Fabulyss Boutique”, “Price”: “$15.00”, “Blade Length”: “3 in”, “Colors Available”: [“Black”, “Teal”, “Dark Blue”, “Pink”, “Purple”], “Shipping Information”: “This product can ONLY be shipped within the US + Puerto Rico.”, “Category”: “Discrete Safety Items”, “Reviews”: {“Total”: 14, “Positive”: 9, “Negative”: 5}, “Shipping Policy”: “Free shipping on orde…

2. Wholesale Blades – Self Defense Brush Comb

Domain: wholesaleblades.com

Registered: 2013 (12 years)

Introduction: Comb Knives available at wholesale prices with a 20% discount on orders of 6 or more. Products include various designs of Self Defense Brush Comb with hidden knives, featuring a 3.5″ stainless steel blade. Prices range from $1.79 to $2.25. The combs are designed to look like standard plastic combs and are available in multiple prints such as Pink, Carbon Fiber, Leopard Skin, Purple Hearts, America…

3. J&L Self Defense Products – Comb Knife

Domain: selfdefenseproducts.com

Registered: 1997 (28 years)

Introduction: {“name”: “Comb Knife”, “brand”: “J&L Self Defense Products”, “msrp”: “14.95”, “sale_price”: “7.99”, “savings”: “6.96”, “sku”: “PK-107”, “upc”: “”, “shipping”: “Calculated at Checkout”, “stock”: “Current Stock”, “description”: “It looks like an ordinary comb, but the handle is actually a hidden dagger! As a comb its particularly appropriate when carried in a glove compartment, travel luggage, or a …

4. Reddit – Comb Switchblade

5. Snake Eye – Tactical Folding Knives

Domain: mastercutlery.com

Registered: 2000 (25 years)

Introduction: {“search_term”:”comb xx punch box pocket knives”,”total_items”:3685,”products”:[{“name”:”Snake Eye – Tactical 24Pcs Black Folding Knives”,”sku”:”SE-1005BK”,”price”:”$36.99″,”stock”:”31″,”status”:”In stock”},{“name”:”Snake Eye – Tactical 24Pcs Brown Camo Folding”,”sku”:”SE-1005BC”,”price”:”$36.99″,”stock”:”19″,”status”:”In stock”},{“name”:”Snake Eye – Tactical 24Pcs Green Camo Folding”,”sku”:”SE-10…

6. Faire – Key Knife Keychain

Domain: faire.com

Registered: 1998 (27 years)

Introduction: Wholesale comb knife available for purchase online from over 100,000 brands. Key products include: 1. Key Knife Keychain – Small Utility Pocketknife – 2” Blade (Rating: 5.0, Reviews: 233) 2. Fox Head Women Self Defense Safety Keychain (Rating: 4.1, Reviews: 2,438) 3. Switchblade Comb – Fun Novelty Pocket Knife Comb (Rating: 4.8, Reviews: 66) 4. Folding Pocket Comb – Switchblade Style (Rating: 5.0…

Strategic Sourcing Conclusion and Outlook for comb knife

In conclusion, strategic sourcing of comb knives presents a unique opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The demand for discreet self-defense tools is rising, driven by an increasing focus on personal safety and security. By leveraging effective sourcing strategies, businesses can access high-quality products that meet local regulations and consumer preferences, ensuring a competitive edge in the market.

Buyers should prioritize suppliers that demonstrate compliance with international safety standards, offer transparent pricing, and provide comprehensive customer support. Additionally, understanding regional market dynamics and consumer behavior will enhance sourcing decisions, allowing businesses to tailor their offerings effectively.

Looking ahead, the comb knife market is poised for growth as more consumers recognize the value of such multi-functional tools. B2B buyers are encouraged to engage with reputable suppliers and explore innovative products that cater to diverse needs. By fostering strong partnerships and embracing strategic sourcing, businesses can capitalize on this trend, securing a profitable future in the comb knife market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.