Everything You Need to Know About Collier Metal Sourcing in 2025

Introduction: Navigating the Global Market for collier metal

In today’s competitive landscape, international B2B buyers face significant challenges when it comes to sourcing collier metal, particularly in regions such as Africa, South America, the Middle East, and Europe. With the growing demand for high-quality steel processing and fabrication, understanding the nuances of the global market is crucial. This guide serves as a comprehensive resource for navigating the complexities of collier metal, detailing various types, applications, and essential supplier vetting processes.

From hot-rolled and cold-rolled steel to galvanized options, each type of collier metal has specific uses across industries ranging from construction to automotive manufacturing. Additionally, this guide delves into cost considerations, providing insights into pricing structures that can impact your procurement strategy. By equipping B2B buyers with actionable knowledge about supplier reliability, quality assurance, and logistical coordination, this guide empowers informed purchasing decisions that align with operational goals.

Whether you’re based in Nigeria, Saudi Arabia, or anywhere in between, understanding the intricacies of collier metal sourcing can enhance your supply chain efficiency and product quality. This guide is designed to help you make strategic choices, ensuring that you partner with suppliers who meet your exact specifications and deliver on time, every time.

Understanding collier metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hot Rolled Steel | Produced at high temperatures, resulting in a rough surface | Structural components, automotive parts | Pros: Cost-effective, easy to shape. Cons: Lower precision, less surface finish quality. |

| Cold Rolled Steel | Processed at room temperature, offering better precision | Electrical enclosures, furniture manufacturing | Pros: Higher strength, better surface finish. Cons: More expensive, limited to thinner gauges. |

| Galvanized Steel | Coated with zinc for corrosion resistance | Outdoor structures, automotive parts | Pros: Excellent durability, low maintenance. Cons: Higher initial cost, coating may wear over time. |

| Pickled & Oiled Steel | Treated to remove oxides and oils, providing a clean surface | Appliances, metal fabrications | Pros: Enhanced surface quality, better weldability. Cons: Requires careful handling to maintain quality. |

| Edge Conditioned Steel | Edges are smoothed for better fit and function | Precision applications, custom fabrications | Pros: Improved performance, better fit. Cons: Additional processing time and cost. |

What Are the Characteristics of Hot Rolled Steel?

Hot rolled steel is formed by rolling the steel at high temperatures, which makes it malleable and easy to shape. This type of steel is often used in structural applications such as beams, channels, and automotive components due to its cost-effectiveness. Buyers should consider the trade-off between cost and precision, as hot rolled steel typically has a rougher surface finish and lower dimensional accuracy compared to cold rolled options.

How Does Cold Rolled Steel Differ from Other Types?

Cold rolled steel is manufactured at room temperature, resulting in a smoother surface and tighter tolerances. It is ideal for applications requiring enhanced strength and aesthetic appeal, such as electrical enclosures and furniture. When purchasing cold rolled steel, B2B buyers should weigh the higher costs against the benefits of improved durability and finish quality, particularly for visible components.

Why Choose Galvanized Steel for Your Projects?

Galvanized steel is coated with zinc to prevent corrosion, making it an excellent choice for outdoor applications like fences and automotive parts. Its durability reduces maintenance costs over time, which is a significant advantage for B2B buyers focused on long-term investments. However, the initial cost can be higher, and the zinc coating may degrade under certain conditions, requiring careful consideration of the application environment.

Illustrative image related to collier metal

What Are the Benefits of Pickled & Oiled Steel?

Pickled and oiled steel undergoes a treatment process that removes surface oxides and oils, resulting in a clean and smooth surface that is ideal for welding and further processing. It is commonly used in appliance manufacturing and metal fabrications. Buyers should keep in mind that while this type offers enhanced surface quality, it requires careful handling to maintain its properties, which can affect overall project timelines and costs.

How Does Edge Conditioned Steel Enhance Performance?

Edge conditioned steel features smoothed edges that facilitate better fitting and functionality in precision applications. This type is particularly beneficial for custom fabrications where tight tolerances are critical. While it improves performance and fit, B2B buyers should consider the additional processing time and costs associated with edge conditioning, ensuring that the benefits align with project requirements.

Key Industrial Applications of collier metal

| Industry/Sector | Specific Application of collier metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Custom metal fabrication for gates and railings | Enhances property security and aesthetic appeal | Quality of materials, precision in fabrication, lead times |

| Manufacturing | Precision steel slitting for automotive components | Reduces waste and ensures tight tolerances | Consistency in quality, turnaround times, logistics |

| Landscaping | Heavy gauge steel edging for landscape design | Long-lasting, stable solutions that withstand ground movement | Durability of materials, design flexibility, local regulations |

| Oil & Gas | Steel processing for pipeline construction | Ensures safety and reliability in harsh environments | Compliance with industry standards, material specifications, delivery schedules |

| HVAC | Custom ductwork fabrication using collier metal | Improves efficiency and effectiveness of HVAC systems | Precision engineering, material properties, installation support |

How Is Collier Metal Used in the Construction Industry?

In the construction sector, collier metal is prominently utilized for custom metal fabrication, particularly in the production of gates, railings, and other architectural features. These applications enhance both security and aesthetic appeal, making properties more attractive and functional. For international buyers, especially in regions like Africa and the Middle East, sourcing high-quality materials that can withstand local environmental conditions is crucial. Buyers should prioritize vendors that offer precision fabrication and reliable installation services to ensure long-term durability.

What Role Does Collier Metal Play in Manufacturing?

Collier metal serves a vital role in the manufacturing industry, particularly through precision steel slitting for automotive components. This process allows manufacturers to reduce waste while achieving tight tolerances, which are essential for the performance and safety of automotive parts. For B2B buyers from Europe and South America, it is important to consider suppliers that can guarantee consistent quality and rapid turnaround times, as these factors directly impact production efficiency and market responsiveness.

How Is Collier Metal Applied in Landscaping?

In landscaping, collier metal is used for heavy gauge steel edging, providing a robust solution for defining garden areas and preventing soil erosion. This durable product is designed to withstand ground movement, making it ideal for various climates, especially those prone to frost heave. Buyers in regions like Nigeria or Saudi Arabia should focus on sourcing from manufacturers who can customize designs and comply with local regulations regarding landscape materials, ensuring both functionality and aesthetic harmony.

Illustrative image related to collier metal

Why Is Collier Metal Important for the Oil & Gas Industry?

In the oil and gas sector, collier metal is essential for processing steel used in pipeline construction. The reliability and safety of these pipelines are paramount, as they must endure harsh environmental conditions. International buyers should ensure that their suppliers comply with industry standards and can provide materials that meet specific engineering requirements. Additionally, timely delivery is crucial to keep projects on schedule and avoid costly delays.

How Does Collier Metal Enhance HVAC Systems?

Collier metal is also utilized in the fabrication of custom ductwork for HVAC systems, contributing to improved efficiency and effectiveness. Properly designed and constructed ductwork ensures optimal airflow and energy savings. B2B buyers in regions with varying climate conditions should seek suppliers who offer precision engineering and can accommodate specific material properties to suit different environmental needs. Supporting installation services can also enhance the overall project success.

3 Common User Pain Points for ‘collier metal’ & Their Solutions

Scenario 1: Delays in Steel Processing Affecting Supply Chains

The Problem: B2B buyers often experience significant delays in steel processing, which can disrupt their supply chains and impact their ability to meet project deadlines. This is particularly challenging for businesses that rely on just-in-time inventory systems or have tight project timelines. Delays can arise from various factors, including equipment downtime, inefficient processing capabilities, or lack of communication from suppliers. Such interruptions can lead to increased costs, missed opportunities, and strained relationships with clients.

The Solution: To mitigate these delays, buyers should prioritize sourcing from suppliers like Collier Metals, who specialize in precision steel processing with a focus on fast turnaround times. When engaging with a supplier, it’s essential to clearly outline your processing needs, including specifications for toll slitting, cut-to-length, and edge conditioning. Establishing open lines of communication can also help ensure that your orders are processed efficiently and any potential issues are addressed proactively. Additionally, consider setting up a regular check-in schedule with your supplier to monitor the status of your orders, which can help you anticipate and manage any possible delays.

Scenario 2: Inconsistent Quality in Steel Products

The Problem: Another common pain point for B2B buyers is receiving steel products that do not meet the expected quality standards. Inconsistent quality can result in defects such as rough edges, improper dimensions, or material weaknesses, which can compromise the integrity of the final product. This issue can lead to costly rework, project delays, and even liability concerns if the final product fails.

The Solution: To ensure consistent quality, buyers should conduct thorough research when selecting a supplier. Look for companies like Collier Metals that emphasize precision and reliability in their processing operations. Request detailed specifications regarding their quality control processes and ask for samples to evaluate the consistency of their products before placing large orders. Implementing a robust quality assurance process on your end, including receiving inspections and performance testing, can help catch any issues early. Establishing a long-term partnership with a reliable supplier can also contribute to improved quality over time, as they will better understand your specific needs and expectations.

Scenario 3: Complicated Logistics and Delivery Coordination

The Problem: Logistics can pose a significant challenge for B2B buyers in the steel industry, particularly when it comes to coordinating deliveries across different regions. Buyers may face difficulties related to scheduling, transportation costs, or unexpected delays during transit. These logistical issues can hinder timely project execution and lead to increased operational costs.

The Solution: To streamline logistics, it’s crucial to work with a supplier that offers comprehensive delivery coordination, such as Collier Metals. When placing orders, discuss your specific logistics needs, including preferred delivery windows and packaging requirements. Leverage the supplier’s expertise in transloading and warehousing services to simplify the process. Additionally, consider using technology solutions, such as tracking systems, to monitor shipments in real-time. This proactive approach allows you to stay informed about delivery statuses and make necessary adjustments to your project timelines. By fostering a collaborative relationship with your supplier, you can enhance logistical efficiency and reduce the likelihood of complications.

Illustrative image related to collier metal

Strategic Material Selection Guide for collier metal

What Are the Key Properties of Common Materials Used in Collier Metal?

When selecting materials for collier metal applications, understanding the properties and performance characteristics of each option is crucial. Here, we analyze four common materials: hot-rolled steel, cold-rolled steel, galvanized steel, and stainless steel. Each material has distinct advantages and limitations that can significantly affect their suitability for various applications.

Hot-Rolled Steel: What Makes It a Popular Choice?

Hot-rolled steel is known for its high strength and durability, making it ideal for structural applications. It typically exhibits good weldability and is often used in heavy-duty applications. However, it has lower corrosion resistance compared to other materials, which can be a significant drawback in humid or corrosive environments.

- Pros: Cost-effective, strong, and easy to work with.

- Cons: Lower corrosion resistance and surface finish quality.

- Impact on Application: Best suited for internal structural components where exposure to elements is limited.

- Considerations for International Buyers: Compliance with standards such as ASTM A36 is crucial, especially in regions like Europe and the Middle East, where structural integrity is heavily regulated.

Cold-Rolled Steel: How Does It Compare?

Cold-rolled steel offers tighter tolerances and a better surface finish than hot-rolled steel. It is often used in applications requiring precision and aesthetic appeal, such as automotive components and appliances. However, it is generally more expensive and can be more challenging to weld due to its higher carbon content.

- Pros: Superior surface finish, tighter tolerances, and better mechanical properties.

- Cons: Higher cost and reduced ductility compared to hot-rolled steel.

- Impact on Application: Ideal for applications requiring precise dimensions and a smooth finish.

- Considerations for International Buyers: Ensure compliance with standards like JIS G3141, particularly for buyers in Asia and South America, where manufacturing standards may vary.

Galvanized Steel: Why Is It Essential for Corrosion Resistance?

Galvanized steel is hot-rolled or cold-rolled steel coated with zinc to enhance its corrosion resistance. This makes it suitable for outdoor applications, such as fencing and roofing. While it provides excellent protection against rust, the coating can be damaged during fabrication, which may expose the underlying steel.

- Pros: Excellent corrosion resistance and longevity in outdoor applications.

- Cons: Potential for coating damage during fabrication and higher initial costs.

- Impact on Application: Best for applications exposed to moisture and harsh environments.

- Considerations for International Buyers: Compliance with ASTM A123 is vital, especially for projects in humid climates like Nigeria or coastal areas in the Middle East.

Stainless Steel: When Is It the Right Choice?

Stainless steel is renowned for its exceptional corrosion resistance and aesthetic appeal. It is often used in high-end applications, including architectural features and food processing equipment. However, it is more expensive than other steel types and can be more challenging to work with due to its hardness.

- Pros: Outstanding corrosion resistance and durability.

- Cons: Higher cost and more complex manufacturing processes.

- Impact on Application: Ideal for environments where hygiene and corrosion are critical, such as food and medical applications.

- Considerations for International Buyers: Adherence to standards like ASTM A240 is essential, particularly for buyers in Europe and the Middle East, where quality and safety regulations are stringent.

Summary Table of Material Selection for Collier Metal

| Material | Typical Use Case for collier metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Hot-Rolled Steel | Structural components in construction | Cost-effective and strong | Lower corrosion resistance | Low |

| Cold-Rolled Steel | Precision components in automotive | Superior surface finish | Higher cost and less ductility | Med |

| Galvanized Steel | Outdoor applications like fencing | Excellent corrosion resistance | Coating can be damaged | Med |

| Stainless Steel | High-end architectural features | Outstanding corrosion resistance | Higher cost and complex fabrication | High |

This guide serves as a valuable resource for international B2B buyers, helping them make informed decisions based on material properties, application suitability, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for collier metal

What Are the Main Stages of Manufacturing Collier Metal?

The manufacturing process for collier metal involves several key stages, each crucial for ensuring the final product meets the specific needs of B2B buyers. Understanding these stages can help buyers assess potential suppliers and their capabilities.

Material Preparation: How Is Raw Steel Processed?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw steel, including hot rolled black, pickled and oiled, galvanized, and cold-rolled varieties. Once received, the steel coils undergo inspection to ensure they meet specified standards. Any defects are noted, and only materials that pass initial quality checks are moved to the next stage.

During this phase, suppliers may employ techniques such as chemical analysis and surface inspection to verify the integrity of the materials. Proper documentation is essential here, as it lays the groundwork for traceability and accountability throughout the manufacturing process.

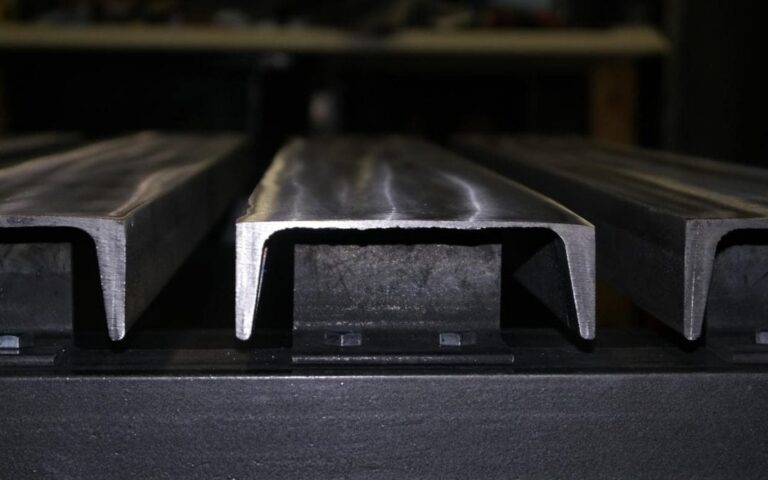

Forming: What Techniques Are Used to Shape Collier Metal?

Forming is a critical stage that involves transforming raw materials into usable products. Techniques commonly used include:

- Toll Slitting: This process cuts large coils of steel into narrower strips. Precision is key, as the dimensions must meet strict tolerances specified by the customer.

- Cut to Length (CTL): After slitting, steel strips are cut to precise lengths, ready for further processing or direct shipment.

- Edge Conditioning: This technique ensures that the edges of the metal strips are smooth and clean, which is essential for further processing and end-use applications.

Advanced machinery, including high-speed slitting lines and precision cutting equipment, is used to maintain consistency and accuracy throughout this stage.

Assembly: How Are Different Components Joined?

In some cases, assembly may be required, especially when manufacturing complex components that consist of multiple parts. This stage often employs welding, bolting, or riveting techniques, depending on the product specifications and end-use requirements. For collier metal products, welding is commonly used due to its strength and durability.

Illustrative image related to collier metal

Quality assurance at this stage is paramount. Each joint or connection must be inspected to ensure it meets engineering specifications and safety standards. This is particularly important for products intended for critical applications, such as construction and automotive sectors.

Finishing: What Is Involved in the Final Touches?

The finishing stage adds the final touches to collier metal products. This may involve surface treatments such as painting, galvanizing, or applying protective coatings to enhance corrosion resistance and aesthetic appeal.

Finishing processes are tailored to meet specific customer requirements, and rigorous quality checks are conducted to ensure that the finished products adhere to both aesthetic and functional standards.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is a vital aspect of the manufacturing process for collier metal, especially for international B2B transactions. Buyers should look for compliance with relevant international standards and industry-specific certifications.

What Are the Relevant International Standards?

- ISO 9001: This is a widely recognized quality management standard that ensures organizations consistently provide products and services that meet customer and regulatory requirements.

- CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For buyers in the oil and gas industry, the American Petroleum Institute (API) standards ensure that metal products meet specific performance criteria.

Adherence to these standards is not just a box-ticking exercise; it indicates a supplier’s commitment to quality and reliability.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process to ensure that products meet predefined specifications.

Incoming Quality Control (IQC)

IQC is the first line of defense against defects. During this phase, raw materials are inspected upon arrival to verify that they meet quality standards. This may involve physical inspections, chemical tests, and dimensional checks.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC involves continuous monitoring of production activities. Operators conduct regular inspections and tests to ensure that the manufacturing process adheres to established protocols. This includes checking tolerances, surface finishes, and the integrity of welds.

Final Quality Control (FQC)

FQC is the last checkpoint before products are shipped to customers. Here, finished products undergo comprehensive inspections to ensure they meet all specifications. Common testing methods include:

- Visual Inspections: Checking for surface defects, finish quality, and overall appearance.

- Dimensional Testing: Verifying that products meet specified measurements.

- Destructive and Non-Destructive Testing: Depending on the application, these tests assess the structural integrity of the metal.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are some actionable steps:

Conducting Audits

Regular audits of suppliers can reveal their quality control practices and compliance with industry standards. Buyers should request access to audit reports and documentation that showcases the supplier’s adherence to quality protocols.

Requesting Quality Reports

Buyers can request detailed quality reports from suppliers that outline the results of inspections and tests conducted at various stages of production. This transparency fosters trust and ensures accountability.

Illustrative image related to collier metal

Utilizing Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can conduct on-site inspections and testing, offering additional reassurance regarding product quality.

What Are the Nuances for International B2B Buyers in Quality Assurance?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate various complexities in quality assurance.

- Cultural Differences: Understand that quality expectations and interpretations may vary across cultures. Clear communication about quality standards is essential.

- Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers must ensure that their suppliers comply with both local and international regulations.

- Logistical Challenges: Transporting collier metal products internationally may introduce risks. Buyers should work with suppliers who have robust logistics capabilities and quality assurance processes to mitigate these risks.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting collier metal suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘collier metal’

In the competitive landscape of metal procurement, ensuring the right sourcing strategy is essential for B2B buyers. This guide offers a structured approach to sourcing ‘collier metal’ effectively, helping you navigate the complexities involved in selecting the right suppliers and products.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of your sourcing process. This includes understanding the specific types of collier metal required, such as hot rolled, pickled & oiled, galvanized, or cold-rolled steel. Knowing your dimensions, tolerances, and surface treatments will enable you to communicate effectively with potential suppliers and ensure that the products meet your operational needs.

Step 2: Identify Potential Suppliers

Conduct thorough market research to identify suppliers who specialize in collier metal. Look for companies with a proven track record in steel processing and a solid reputation in the industry. Utilize platforms like trade shows, industry directories, and online reviews to gather a list of candidates.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Assess their processing capabilities, including toll slitting, edge conditioning, and cut-to-length services. Inquire about their equipment and technology to ensure they can meet your volume and quality requirements.

- Ask for Production Samples: Request samples to evaluate the quality and precision of their work.

- Review Case Studies: Look for case studies or examples of similar projects they have successfully completed.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers adhere to industry standards and possess the necessary certifications. This is particularly important for B2B transactions, where compliance with local and international regulations can affect your business operations.

- Check ISO Certifications: Certifications such as ISO 9001 indicate a commitment to quality management.

- Review Material Certifications: Ask for mill certificates to verify the chemical and mechanical properties of the metal.

Step 5: Assess Logistics and Delivery Options

Understanding a supplier’s logistics capabilities is essential for ensuring a smooth supply chain. Evaluate their delivery schedules, transloading options, and packaging methods. Suppliers who offer customizable logistics solutions can provide significant advantages in terms of cost and efficiency.

- Consider Proximity: Suppliers located near major markets can reduce shipping times and costs.

- Inquire About Lead Times: Confirm lead times for production and delivery to align with your project timelines.

Step 6: Request Quotes and Negotiate Terms

Once you’ve narrowed down your list of suppliers, request detailed quotes. Ensure that the quotes include all relevant costs such as processing, shipping, and any additional services. Use this opportunity to negotiate terms that align with your budget and project needs.

Step 7: Establish a Relationship for Ongoing Collaboration

Building a strong relationship with your supplier can lead to better pricing, priority service, and collaborative problem-solving in the future. Open communication channels will foster trust and ensure that both parties are aligned on expectations.

By following this practical sourcing checklist, B2B buyers can streamline their procurement process for collier metal, ultimately enhancing their supply chain efficiency and product quality.

Comprehensive Cost and Pricing Analysis for collier metal Sourcing

What are the Key Cost Components in Collier Metal Sourcing?

When sourcing collier metal, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to collier metal

-

Materials: The type of metal, such as hot rolled, galvanized, or cold-rolled steel, significantly impacts costs. Prices can fluctuate based on market demand and availability, so buyers should keep abreast of current metal pricing trends.

-

Labor: Labor costs encompass skilled and unskilled workers involved in the processing and fabrication stages. Higher labor costs may correlate with increased quality, precision, and customization.

-

Manufacturing Overhead: This includes facility costs, utilities, and equipment maintenance. Efficient operations can help minimize these overheads, which can be a significant portion of the total cost.

-

Tooling: Tooling costs are incurred for the machines and tools necessary for processing the metal. Custom tooling for specific projects can lead to higher upfront costs but may reduce the per-unit cost for large volumes.

-

Quality Control (QC): Investing in quality assurance processes ensures that the final product meets specifications and certifications. While this may increase initial costs, it can lead to cost savings by reducing returns and enhancing customer satisfaction.

-

Logistics: Transportation and warehousing costs are critical, particularly for international shipments. Factors such as distance, mode of transport, and delivery timelines will influence logistics costs.

-

Margin: Suppliers will add a margin to cover their costs and generate profit. Understanding industry standards for margins can aid buyers in negotiating better pricing.

How Do Pricing Influencers Impact Collier Metal Costs?

Several factors influence the pricing of collier metal:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes typically lead to lower per-unit costs. Suppliers may offer tiered pricing based on order size, making it beneficial for buyers to consolidate orders when possible.

-

Specifications and Customization: Custom orders often incur additional costs due to specialized tooling and processing requirements. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: High-quality materials that meet specific certifications (e.g., ISO, ASTM) may command higher prices. However, these materials often provide better performance and durability, influencing the Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge a premium, but their reliability can mitigate risks in the supply chain.

-

Incoterms: The chosen Incoterms (International Commercial Terms) determine the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can help buyers manage costs effectively.

What Negotiation and Cost-Efficiency Strategies Should Buyers Consider?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Terms: Engage in discussions about pricing, payment terms, and delivery schedules. Flexibility in these areas can lead to significant savings.

-

Consider Total Cost of Ownership: Evaluate not only the purchase price but also costs related to quality, maintenance, and logistics. A lower initial price may not always equate to long-term savings.

-

Assess Market Conditions: Stay informed about market trends and fluctuations in metal prices. Timing purchases based on market conditions can yield better pricing.

-

Build Relationships: Developing strong relationships with suppliers can lead to better service, priority during shortages, and potentially lower prices through loyalty.

-

Leverage Technology: Utilize digital tools and platforms for sourcing and supplier management, which can streamline processes and reduce costs.

Disclaimer on Indicative Prices

Prices for collier metal are subject to fluctuations based on market conditions, material availability, and supplier pricing strategies. It is essential for buyers to conduct due diligence and obtain quotes tailored to their specific needs and project requirements.

Alternatives Analysis: Comparing collier metal With Other Solutions

Understanding Alternative Solutions for Collier Metal

When evaluating B2B solutions in metal processing and fabrication, it’s essential to consider various alternatives to ensure the best fit for your operational needs. While Collier Metal offers precision steel processing through toll slitting and custom fabrication, buyers should also explore other viable technologies and methods that may align with their specific requirements. This analysis presents a comparison of Collier Metal against two alternative solutions: traditional metal fabrication and automated laser cutting technologies.

Comparison Table

| Comparison Aspect | Collier Metal | Traditional Metal Fabrication | Automated Laser Cutting |

|---|---|---|---|

| Performance | High precision with tight tolerances | Variable precision, dependent on skill | Exceptional precision and speed |

| Cost | Competitive pricing for bulk orders | Generally higher due to labor costs | Higher initial investment but lower long-term costs |

| Ease of Implementation | Straightforward with dedicated support | Complex, requiring skilled labor | Requires specialized equipment and training |

| Maintenance | Low maintenance with regular checks | Moderate maintenance, skilled labor needed | High maintenance due to complex machinery |

| Best Use Case | Custom orders for service centers | General fabrication for various industries | High-volume production with intricate designs |

Pros and Cons of Each Alternative

Traditional Metal Fabrication

Traditional metal fabrication involves manual processes such as cutting, welding, and assembling metal parts.

Illustrative image related to collier metal

Pros:

– Flexibility in producing one-off or custom designs.

– Lower initial investment in tools and machinery compared to advanced technologies.

Cons:

– Labor-intensive, which can lead to higher operational costs and variability in quality.

– Dependence on skilled labor can limit scalability and efficiency.

Automated Laser Cutting

Automated laser cutting utilizes computer-controlled lasers to cut materials with high precision.

Pros:

– Offers exceptional speed and precision, allowing for intricate designs and high-volume production.

– Reduces waste due to accurate cutting and can handle various materials beyond metal.

Cons:

– High upfront costs for equipment and training can be a barrier for smaller businesses.

– Requires ongoing maintenance and technical expertise to operate effectively.

Choosing the Right Solution for Your Needs

When selecting the most suitable metal processing solution, B2B buyers should assess their specific requirements in terms of performance, cost, and operational capacity. Collier Metal is an excellent choice for companies needing reliable and precise steel processing with a focus on customer service and timely deliveries. In contrast, traditional metal fabrication may be suitable for businesses requiring flexibility and custom solutions, albeit at potentially higher costs. Automated laser cutting is ideal for those looking to maximize efficiency and precision, especially in high-volume production scenarios.

Illustrative image related to collier metal

Ultimately, the decision should align with your operational goals, budget constraints, and the specific demands of your projects. A thorough evaluation of these alternatives will empower you to make an informed choice that enhances your supply chain and meets your production needs.

Essential Technical Properties and Trade Terminology for collier metal

What Are the Key Technical Properties of Collier Metal?

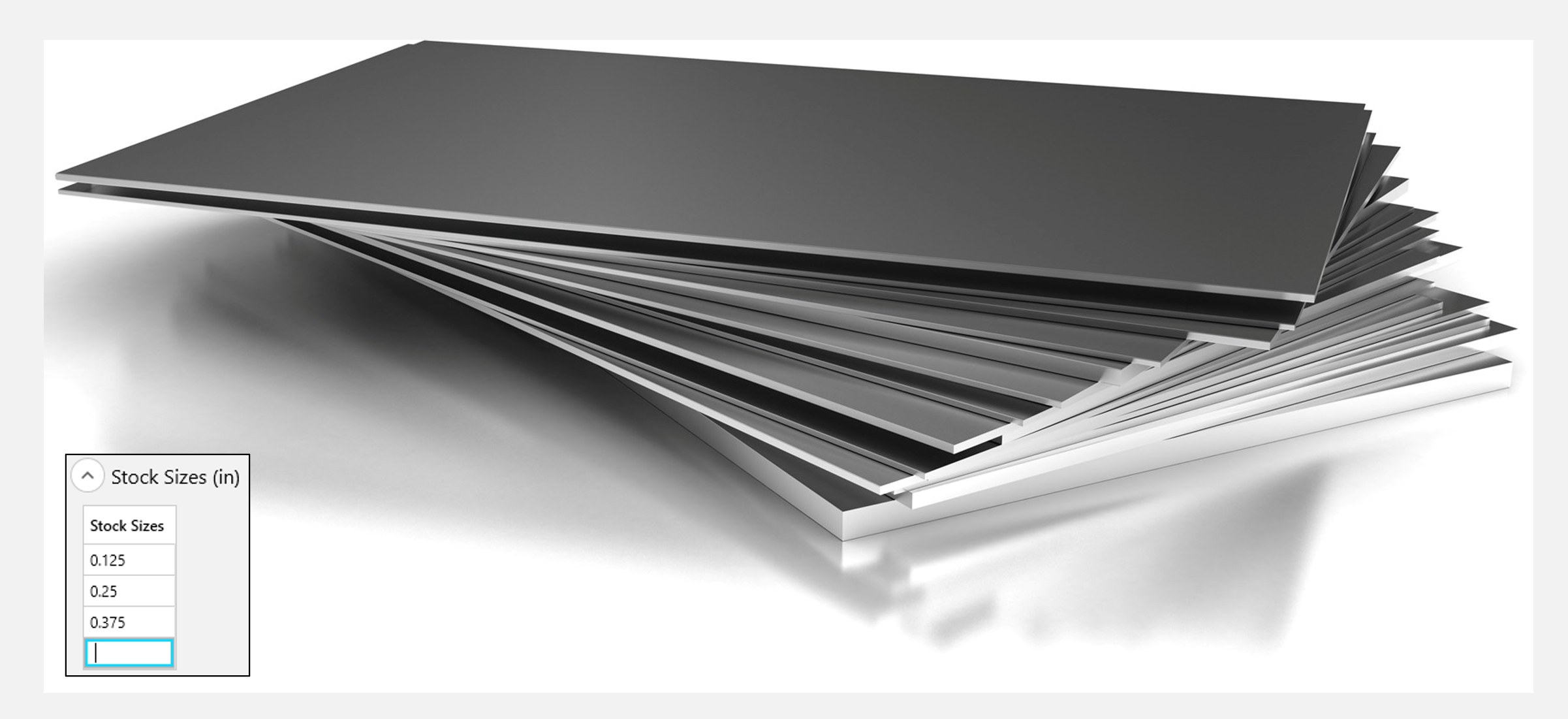

Understanding the technical properties of collier metal is crucial for B2B buyers, especially those involved in steel distribution, fabrication, and manufacturing. Here are several key specifications that should be considered:

-

Material Grade: Collier metals are typically available in various grades, including hot rolled (HR), cold rolled (CR), and galvanized steel. Each grade has different mechanical properties and applications. For example, HR steel is often used for structural applications, while galvanized steel is preferred for corrosion resistance. Selecting the right material grade ensures durability and performance in specific applications.

-

Tolerance: Tolerance refers to the allowable variation in dimensions and properties of the metal. In B2B operations, tight tolerances (e.g., ±0.005 inches) are essential for maintaining quality and compatibility in assembly processes. High-precision tolerance ensures that components fit together correctly, minimizing waste and reducing production costs.

-

Coating Type: The type of coating on collier metal, such as zinc for galvanized steel or oil for hot rolled pickled and oiled (HRPO) steel, significantly affects its performance. Coatings provide protection against rust and corrosion, which is particularly important for materials exposed to harsh environments. Buyers must consider the coating type based on the end-use application to ensure longevity.

-

Yield Strength: This property indicates the maximum stress that a material can withstand while still maintaining its shape. Yield strength is critical for structural applications where metals are subjected to heavy loads. Knowing the yield strength helps B2B buyers select materials that will not fail under operational stress, enhancing safety and reliability.

-

Thickness: The thickness of the metal can vary based on the specific requirements of a project. Standard thicknesses often range from 0.018 inches to 0.5 inches, and choosing the right thickness is vital for ensuring the structural integrity and performance of the final product. Buyers should assess the thickness based on the intended application and load-bearing needs.

-

Finish: The finish of collier metal can impact both aesthetic and functional aspects. Options include mill finish, polished, or painted surfaces. A proper finish can enhance corrosion resistance and improve the visual appeal of the final product. Buyers should consider the finish based on the application and customer preferences.

What Are Common Trade Terms Related to Collier Metal?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B marketplace. Here are several essential trade terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships helps buyers navigate supply chains and identify reliable sources for specific components.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers, as it impacts inventory management and cost-effectiveness. Knowing the MOQ helps buyers plan their purchases and negotiate better terms.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. This term is essential for procurement professionals looking to compare options and make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers engaged in cross-border trade, as they clarify risk and responsibility.

-

Lead Time: This refers to the time it takes from placing an order to receiving the goods. In industries where timing is critical, understanding lead times can help buyers manage their supply chain effectively and meet project deadlines.

-

Transloading: This term describes the transfer of goods from one mode of transportation to another. For buyers, understanding transloading logistics is crucial for optimizing shipping costs and ensuring timely delivery of collier metal products.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline procurement processes, and enhance their operational efficiency in the collier metal industry.

Navigating Market Dynamics and Sourcing Trends in the collier metal Sector

What Are the Key Market Dynamics and Sourcing Trends in the Collier Metal Sector?

The collier metal sector is experiencing significant evolution driven by globalization and technological advancements. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are witnessing increased demand for customized and precision-engineered metal products. This demand is fueled by various factors, including the rise of infrastructure projects, urbanization, and a growing emphasis on energy-efficient solutions. Buyers are increasingly seeking suppliers who can offer not only quality products but also reliable service, quick turnaround times, and competitive pricing.

Emerging B2B technologies are reshaping sourcing processes. The integration of digital platforms for supply chain management and communication enhances transparency and efficiency. For example, data analytics tools are being utilized to forecast demand accurately, allowing suppliers to optimize inventory and reduce lead times. Additionally, automation in manufacturing processes ensures higher precision and consistency in product quality, meeting the stringent requirements of global standards.

Moreover, the market is witnessing a shift towards local sourcing to mitigate risks associated with long supply chains. Buyers are increasingly favoring suppliers who can provide proximity advantages, such as reduced shipping times and lower transportation costs. This trend is particularly pronounced in regions like Nigeria and Saudi Arabia, where local infrastructure investments are accelerating.

How Does Sustainability and Ethical Sourcing Impact the Collier Metal Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the collier metal sector. Environmental considerations are paramount, as the production and processing of metals can have significant ecological impacts. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing waste, minimizing energy consumption, and utilizing recycled materials.

The importance of ethical supply chains cannot be overstated. Buyers are not only interested in the end product but also in the methods of production. Suppliers who can provide certifications for environmentally friendly materials and practices, such as ISO 14001 or LEED certification, gain a competitive edge. This focus on sustainability is particularly relevant in regions like Europe, where regulatory frameworks are tightening around environmental standards.

Furthermore, the adoption of green materials in collier metal production is gaining traction. Innovations in eco-friendly coatings and finishes, along with the use of low-impact processing methods, are appealing to buyers who seek to align their purchasing decisions with corporate social responsibility goals. As a result, suppliers who embrace sustainability not only enhance their brand reputation but also open doors to new markets and customers.

What Is the Historical Context of the Collier Metal Sector?

The collier metal sector has evolved significantly over the past few decades. Initially focused on traditional metalworking techniques, the industry has transitioned towards a more technology-driven landscape. The advent of precision steel processing and advanced manufacturing technologies has redefined production capabilities, allowing for the customization and scalability that today’s B2B buyers demand.

Historically, collier metals have been utilized in various applications, from construction to automotive manufacturing. As global trade expanded, so did the complexity of supply chains, leading to a need for reliable processing partners. This evolution has paved the way for specialized companies, like those focused on toll slitting and precision steel processing, to emerge as key players in meeting the intricate needs of international buyers.

Understanding this historical context helps B2B buyers appreciate the advancements in quality and service that characterize the modern collier metal sector. As the industry continues to adapt to changing market dynamics, buyers can leverage this knowledge to make informed sourcing decisions that align with their operational goals.

Frequently Asked Questions (FAQs) for B2B Buyers of collier metal

-

How do I choose the right supplier for collier metal?

Selecting the right supplier for collier metal involves evaluating their experience, reputation, and product quality. Look for suppliers that specialize in toll slitting and processing, as they will have the expertise to meet your specific requirements. Check customer testimonials and case studies to gauge reliability and service levels. Additionally, consider their geographical location to minimize shipping costs and time, especially if you are sourcing from regions like Africa or South America. A good supplier should also provide transparent communication and responsive customer service. -

What are the key considerations when sourcing collier metal internationally?

When sourcing collier metal internationally, consider factors such as tariffs, trade regulations, and import duties that may apply to your country. Ensure the supplier complies with international quality standards and certifications. It’s also vital to understand the logistics involved, including shipping times, costs, and customs clearance processes. Establish clear payment terms and ensure that the supplier can accommodate your specific needs, including minimum order quantities (MOQ) and customization options. -

What customization options are available for collier metal products?

Most suppliers offer customization options such as different thicknesses, widths, and finishes for collier metal products. Depending on your requirements, you can request specific edge conditioning or packaging that suits your logistics needs. It’s essential to communicate your specifications clearly to the supplier to ensure that the final product meets your expectations. Some suppliers may also provide design services to help you visualize the final product before fabrication. -

What is the typical minimum order quantity (MOQ) for collier metal?

The minimum order quantity (MOQ) for collier metal can vary significantly among suppliers. Generally, MOQs may range from a few tons to larger quantities depending on the type of processing and customization required. It’s advisable to discuss your specific needs with potential suppliers to determine if they can accommodate smaller orders or if they have flexibility in their MOQ policies. This is particularly important for international buyers who may have different volume requirements. -

What are the common payment terms for international purchases of collier metal?

Payment terms can vary by supplier but typically include options such as advance payments, letters of credit, or payment upon delivery. For international transactions, consider using secure payment methods to protect your investment. Discussing payment terms upfront can help avoid misunderstandings later. Ensure that the supplier is transparent about their payment policies and any additional costs, such as shipping or customs fees, that may affect the total price. -

How do I ensure quality assurance when sourcing collier metal?

To ensure quality assurance when sourcing collier metal, request certifications and quality control processes from your supplier. Many reputable suppliers will provide information on their quality management systems and any relevant industry certifications. You may also consider conducting audits or inspections, either in-person or through third-party services, to verify compliance with your specifications. Establishing clear quality expectations in your contract can also help safeguard against receiving subpar products. -

What logistics considerations should I keep in mind when importing collier metal?

Logistics plays a crucial role in importing collier metal. Consider shipping options, delivery timelines, and costs. Work closely with your supplier to coordinate delivery schedules that align with your production needs. It’s also important to be aware of customs regulations and ensure all necessary documentation is in order to avoid delays. Engaging with a logistics partner experienced in international trade can streamline the process and help manage any potential challenges. -

How can I build a long-term partnership with my collier metal supplier?

Building a long-term partnership with your collier metal supplier involves establishing open lines of communication and mutual trust. Regularly provide feedback on product quality and service, and be transparent about your needs and expectations. Consider collaborating on joint projects or sharing forecasts to help your supplier plan better. A strong partnership can lead to improved pricing, priority service, and better responsiveness to your changing demands.

Top 6 Collier Metal Manufacturers & Suppliers List

1. Collier Metal Works – Custom Metal Fabrication

Domain: colliermetalworks.com

Registered: 2020 (5 years)

Introduction: Collier Metal Works offers a variety of custom metal products including gates, fences, architectural metals, custom metal signs, and railings. They emphasize high-quality fabrication using solid materials designed to withstand the elements. Each project is customized to fit the client’s personal style and home design, with digital renderings provided before fabrication. The company also offers pro…

2. Hummert – Steel Edging 12 Gauge Green W/stakes

Domain: hummert.com

Registered: 1996 (29 years)

Introduction: [{‘item_no’: ‘55008000’, ‘title’: ‘Steel Edging 12 Gauge Green W/stakes’, ‘size’: ‘4″ X 10\”, ‘price’: ‘$61.04’, ‘suggested_retail_price’: ‘$64.25’, ‘retail_discount’: ‘5%’, ‘stock_status’: ‘Low stock’}, {‘item_no’: ‘55008100’, ‘title’: ‘Steel Edging 14Ga Green W/stakes’, ‘size’: ‘4″ X 10\”, ‘price’: ‘$45.22’, ‘suggested_retail_price’: ‘$47.60’, ‘retail_discount’: ‘5%’, ‘stock_status’: ‘Low stoc…

3. Colmet – Steel Edging Solutions

Domain: colmet.com

Registered: 1996 (29 years)

Introduction: Edging: QuickLock® Steel Edging, Classic Steel Edging, Attached-Stake Steel Edging, Classic Roll-Top Steel Edging, Place-and-Pin™ Steel Edging, Steel Tree Rings, Steel Edging Accessories; Planters; Yard Armor™ Sign Holders, Standard Sign Holders, Bedding Plant Sign Holders, Special-Purpose Sign Holders, Sign Holder Accessories; Custom Products: Custom Edging, Custom Planters, Custom Tree Rings, Cu…

4. Chris Collier – F.F.W.A.S. Feature

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Chris Collier – F.F.W.A.S. Feature, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Collier Metals – Coil Metal Processing

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Collier Metals – Coil Metal Processing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Design Guide – Commercial Grade Steel Edging

Domain: designguide.com

Registered: 1999 (26 years)

Introduction: This company, Design Guide – Commercial Grade Steel Edging, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for collier metal

In today’s competitive landscape, strategic sourcing of collier metal is paramount for international buyers seeking reliability and quality. Collier Metals stands out as a trusted partner, specializing in precision steel processing that guarantees fast turnarounds and tight tolerances, making it ideal for service centers and steel distributors. By leveraging their capabilities in toll slitting, edging, and custom packaging, businesses can ensure their supply chains are efficient and responsive.

Illustrative image related to collier metal

For buyers in Africa, South America, the Middle East, and Europe, choosing Collier Metals means accessing a strategic location in Atlanta, which facilitates timely deliveries to major markets. This advantage is crucial for maintaining project timelines and minimizing disruptions. Furthermore, the commitment to clear communication ensures that there are no surprises throughout the sourcing process, enhancing overall partnership satisfaction.

Looking ahead, the demand for high-quality collier metal will continue to rise as industries evolve. Now is the time for B2B buyers to engage with Collier Metals to secure a reliable supply chain that meets their specific needs. Connect with their team today to explore how they can support your projects with precision and dependability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.