Everything You Need to Know About Coletor De Po Sourcing in 2025

Introduction: Navigating the Global Market for coletor de po

In today’s competitive business landscape, sourcing a reliable coletor de po (dust collector) can pose significant challenges for international B2B buyers. With varying standards and product availability across regions, finding the right solution that meets both operational efficiency and regulatory compliance can feel overwhelming. This guide aims to demystify the global market for dust collectors, offering insights into diverse product types, their applications across various industries, and effective strategies for supplier vetting.

As we delve into the intricacies of selecting the ideal dust collection system, this comprehensive resource will cover essential factors such as cost considerations, performance metrics, and logistical challenges faced by businesses in Africa, South America, the Middle East, and Europe. By providing a clear framework for evaluating potential suppliers, this guide empowers B2B buyers to make informed purchasing decisions that enhance workplace safety and productivity.

Whether you are involved in construction, manufacturing, or any sector where dust control is critical, understanding the nuances of the coletor de po market will equip you with the knowledge needed to navigate sourcing complexities. Ultimately, this guide serves as a valuable tool to ensure you choose a dust collection solution that aligns with your operational goals and enhances your business’s bottom line.

Understanding coletor de po Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Universal Dust Collector | Compatible with a variety of electric tools; flexible design for easy installation. | Construction sites, HVAC installations, general drilling tasks. | Pros: Versatile; Cons: May require additional adapters for some tools. |

| Heavy-Duty Dust Collector | Built for industrial applications; robust construction for high-volume dust capture. | Factories, woodworking shops, large-scale construction projects. | Pros: High efficiency; Cons: Higher initial investment. |

| Portable Dust Collector | Lightweight and mobile; often battery-operated for flexibility on-site. | Small job sites, maintenance tasks, DIY projects. | Pros: Easy to transport; Cons: Limited dust capacity compared to larger models. |

| Centralized Dust Collection System | Fixed installation with extensive ductwork; designed for large facilities. | Manufacturing plants, large workshops, and commercial spaces. | Pros: Continuous operation; Cons: High installation cost and complexity. |

| Cyclone Dust Collector | Utilizes centrifugal force to separate dust; effective for fine particles. | Woodworking, metalworking, and other precision industries. | Pros: Efficient for fine dust; Cons: Requires regular maintenance. |

What are the Characteristics of a Universal Dust Collector?

Universal dust collectors are designed to work with a wide range of electric tools, making them ideal for diverse applications such as construction, HVAC installations, and general drilling tasks. Their flexible design allows for easy installation and adaptability to various tool sizes and types. When purchasing, consider compatibility with existing equipment, as some models may require additional adapters. This type is perfect for businesses looking for versatility without compromising on performance.

How Does a Heavy-Duty Dust Collector Benefit Large Operations?

Heavy-duty dust collectors are engineered for industrial environments, capable of handling high volumes of dust and debris generated by manufacturing processes or large-scale construction projects. These systems often feature robust construction materials to withstand rigorous use. While they offer high efficiency and superior performance, the initial investment can be significant. B2B buyers should evaluate their dust management needs and budget to determine if the long-term benefits justify the upfront costs.

Why Choose a Portable Dust Collector for Smaller Jobs?

Portable dust collectors are lightweight and designed for mobility, often featuring battery-operated options for flexibility. They are particularly useful for small job sites, maintenance tasks, and DIY projects where space and power supply may be limited. While their dust capacity is smaller compared to larger models, they provide a convenient solution for quick clean-ups. Buyers should assess the trade-off between portability and dust collection efficiency based on their specific project requirements.

What are the Advantages of a Centralized Dust Collection System?

Centralized dust collection systems are ideal for large facilities, utilizing extensive ductwork to provide continuous dust management across various workstations. This type of system is beneficial for manufacturing plants and large workshops where dust generation is constant. However, the complexity and high installation costs can be a barrier for some businesses. B2B buyers need to consider their facility layout and dust generation levels to determine if this long-term investment aligns with their operational needs.

How Effective is a Cyclone Dust Collector for Fine Particles?

Cyclone dust collectors are designed to efficiently separate dust using centrifugal force, making them particularly effective for capturing fine particles in industries like woodworking and metalworking. They can significantly improve air quality and workplace safety. However, regular maintenance is required to ensure optimal performance and prevent clogs. Businesses should evaluate their specific dust types and volumes to decide if a cyclone system is the right fit for their operations, balancing efficiency with maintenance needs.

Key Industrial Applications of coletor de po

| Industry/Sector | Specific Application of coletor de po | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Dust collection during drilling and demolition | Enhances worker safety and compliance with regulations | Ensure compatibility with various drilling tools and angles |

| HVAC Installation | Dust capture during air conditioning installation | Improves air quality and reduces post-installation cleanup | Look for flexible designs that fit different installation scenarios |

| Manufacturing | Dust management in machining and assembly processes | Increases productivity and minimizes equipment wear | Assess durability and ease of maintenance in high-use environments |

| Renovation and Remodeling | Dust control during interior renovations | Protects surrounding areas and minimizes health risks | Evaluate the ease of installation and removal for various tools |

| Electrical Installations | Capture dust from drilling for wiring and fixtures | Creates a cleaner work environment and boosts efficiency | Consider lightweight options that do not impede tool operation |

How is ‘coletor de po’ Used in the Construction Industry?

In the construction sector, ‘coletor de po’ is essential for managing dust during drilling and demolition tasks. By effectively capturing dust particles, it enhances worker safety and ensures compliance with health regulations. This is particularly critical in regions with strict occupational safety standards. Buyers should prioritize models that are compatible with a range of drilling tools and can adapt to various working angles, ensuring maximum efficiency and safety on-site.

What Role Does ‘coletor de po’ Play in HVAC Installation?

During HVAC installations, the ‘coletor de po’ serves to capture dust generated from drilling and cutting, significantly improving air quality. This is vital for maintaining a healthy environment for both workers and clients. Effective dust management reduces the need for extensive post-installation cleaning, saving time and resources. International buyers should seek flexible designs that accommodate different installation scenarios, ensuring they can meet diverse project needs.

How is ‘coletor de po’ Beneficial in Manufacturing?

In manufacturing, particularly in machining and assembly processes, the ‘coletor de po’ is crucial for dust management. It helps maintain a clean workspace, which increases productivity and reduces wear on machinery. This is especially important in high-use environments where downtime can be costly. Buyers in this sector should assess the durability of the product and its ease of maintenance to ensure long-term value and efficiency.

Why is Dust Control Important in Renovation and Remodeling?

Renovation and remodeling projects generate significant dust, which can affect both the work environment and adjacent areas. The ‘coletor de po’ effectively captures this dust, protecting surrounding spaces and minimizing health risks for workers and occupants. Buyers should evaluate the ease of installation and removal features to ensure that these tools can be utilized efficiently across different tasks and settings, enhancing overall project productivity.

How Does ‘coletor de po’ Enhance Electrical Installations?

In electrical installations, capturing dust from drilling operations is essential for maintaining a clean work area. The ‘coletor de po’ not only protects the workspace but also contributes to improved efficiency by reducing interruptions caused by dust cleanup. Buyers should consider lightweight options that do not hinder tool operation, allowing for seamless integration into various electrical tasks and ensuring a smoother workflow.

3 Common User Pain Points for ‘coletor de po’ & Their Solutions

Scenario 1: Navigating Dust Management in Diverse Work Environments

The Problem: B2B buyers often face the challenge of maintaining a clean and safe work environment when using power tools, particularly in construction or manufacturing settings. Dust generated from drilling, cutting, or grinding can not only compromise air quality but also lead to compliance issues with health and safety regulations. Buyers may struggle to find a dust collector that is versatile enough to work effectively across various tools and job sites, leading to inconsistencies in performance and potential health hazards for employees.

The Solution: To address this issue, buyers should consider investing in a universal dust collector like the Nuevo Coletor De Pó, which is designed for compatibility with multiple electric hammers and drills. When sourcing this equipment, ensure that it features a flexible design that allows for easy installation at different angles and depths. This adaptability enables workers to maintain productivity while minimizing dust dispersion. Additionally, look for models that offer superior dust capture efficiency to enhance workspace cleanliness. Implementing a standardized dust collection system across all work sites will not only improve air quality but also bolster compliance with occupational health standards.

Scenario 2: Overcoming Installation Challenges for Dust Collectors

The Problem: Many B2B buyers encounter difficulties when it comes to installing dust collection systems, especially in complex working environments. Misalignment or improper attachment of dust collectors can lead to ineffective performance, resulting in increased dust levels and potential operational disruptions. Buyers may also feel overwhelmed by the variety of options available, leading to uncertainty about the best fit for their specific needs.

The Solution: To streamline the installation process, buyers should prioritize dust collectors with user-friendly designs that allow for quick and intuitive setup. For instance, the Nuevo Coletor De Pó’s elastic material ensures a snug fit on various tools, making it easier for workers to attach and detach as needed. Consider providing training sessions for employees on how to properly install and utilize the dust collector, emphasizing the importance of correct alignment for optimal dust capture. This proactive approach not only enhances operational efficiency but also empowers employees, reducing the likelihood of installation errors.

Scenario 3: Addressing Cost Concerns with Efficient Dust Collection Solutions

The Problem: Budget constraints are a common concern for B2B buyers looking to implement effective dust collection solutions. While investing in quality dust collectors is essential for maintaining a safe work environment, the initial costs can be daunting. Buyers may hesitate to commit to a purchase due to fears of hidden fees or ongoing maintenance expenses, which can complicate budgeting and financial planning.

The Solution: To alleviate cost concerns, buyers should seek dust collectors that offer transparency in pricing and long-term value. The Nuevo Coletor De Pó, for example, comes with a clear breakdown of pricing, including any handling fees and shipping costs, eliminating surprises during the purchasing process. Additionally, consider the durability and effectiveness of the dust collector; investing in a high-quality product may lead to reduced maintenance and replacement costs over time. Conducting a cost-benefit analysis that weighs the initial investment against potential savings from improved health compliance and reduced cleanup efforts will help justify the expenditure. By strategically planning and choosing equipment that maximizes value, buyers can enhance their operations without exceeding budget limitations.

Strategic Material Selection Guide for coletor de po

What Are the Key Materials Used in Coletor de Po Manufacturing?

When selecting materials for a coletor de po (dust collector), several factors must be considered to ensure optimal performance and compliance with international standards. Here, we analyze four common materials used in the construction of dust collectors, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Plastic Perform in Coletor de Po Applications?

Key Properties: Plastic dust collectors are typically made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC). These materials offer excellent corrosion resistance and can handle a wide range of temperatures, generally up to about 60°C (140°F).

Pros & Cons: The primary advantage of plastic is its lightweight nature, making installation and handling easier. Additionally, plastic is cost-effective, which is appealing for large-scale operations. However, it may not withstand high-pressure applications as effectively as metal options, and its durability may be compromised in extreme conditions.

Impact on Application: Plastic is suitable for general dust collection in environments with low to moderate temperatures and pressures. It is also compatible with a variety of non-corrosive materials, making it a versatile choice.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that the plastic meets local environmental standards and regulations. Compliance with standards such as ASTM D638 for tensile properties is crucial for maintaining quality.

What Advantages Do Metal Materials Offer for Coletor de Po?

Key Properties: Metal dust collectors, particularly those made from stainless steel or aluminum, boast high strength and temperature resistance, often rated for temperatures exceeding 200°C (392°F). Stainless steel is particularly resistant to corrosion, while aluminum is lightweight yet robust.

Pros & Cons: The durability of metal materials makes them ideal for heavy-duty applications, providing long service life. However, they are generally more expensive than plastic and may require more complex manufacturing processes. Additionally, they can be heavier, which may complicate installation.

Impact on Application: Metal dust collectors are suitable for high-temperature or high-pressure environments, such as industrial manufacturing or construction sites. Their robustness allows them to handle abrasive materials effectively.

Considerations for International Buyers: Buyers from Europe and the Middle East should ensure compliance with standards such as EN 10088 for stainless steel and ISO 9001 for quality management systems. These standards are crucial for ensuring product reliability and safety.

How Do Composite Materials Enhance Coletor de Po Functionality?

Key Properties: Composite materials, often a blend of plastic and metal, provide a balance of strength and weight. They can be engineered to resist specific chemicals and temperatures, depending on the application.

Pros & Cons: The main advantage of composites is their tailored properties, allowing for enhanced performance in specific environments. However, they can be more expensive to manufacture and may require specialized suppliers for sourcing.

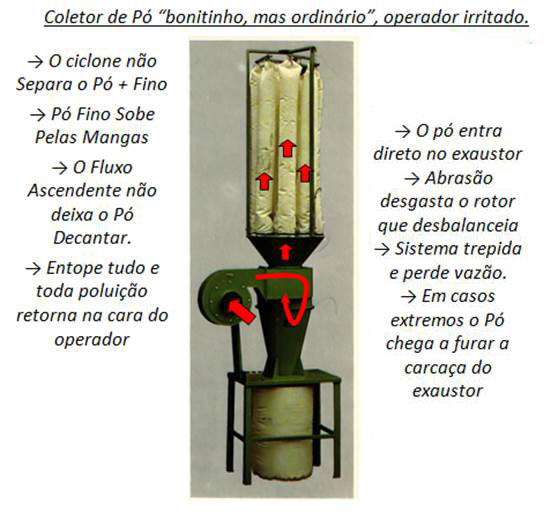

Illustrative image related to coletor de po

Impact on Application: Composites are particularly effective in environments where both weight and durability are concerns, such as in portable dust collectors used in construction or maintenance tasks.

Considerations for International Buyers: Buyers should verify that composite materials meet relevant standards, such as ASTM D3039 for tensile properties, to ensure they meet application requirements.

What Role Does Rubber Play in Coletor de Po Design?

Key Properties: Rubber components, often used in seals and gaskets, provide excellent flexibility and shock absorption. They can typically withstand temperatures up to 100°C (212°F) and offer good resistance to wear.

Pros & Cons: The flexibility of rubber allows for easy installation and maintenance, enhancing the overall efficiency of dust collection systems. However, rubber can degrade over time when exposed to certain chemicals or extreme temperatures, which may limit its lifespan.

Impact on Application: Rubber is particularly useful in applications requiring a tight seal to prevent dust leakage, making it essential for maintaining a clean work environment.

Considerations for International Buyers: Buyers should ensure that rubber materials comply with standards such as ASTM D2000 for rubber products, especially in regions with stringent environmental regulations.

Summary Table of Material Selection for Coletor de Po

| Material | Typical Use Case for coletor de po | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | General dust collection | Lightweight and cost-effective | Limited high-pressure capability | Low |

| Metal | Heavy-duty industrial applications | High durability and temperature resistance | Higher cost and complex manufacturing | High |

| Composite | Portable dust collectors | Tailored properties for specific applications | More expensive to manufacture | Medium |

| Rubber | Seals and gaskets | Excellent flexibility and shock absorption | Degradation over time under certain conditions | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in dust collector manufacturing, enabling informed purchasing decisions tailored to specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for coletor de po

What Are the Key Manufacturing Processes for Coletor de Po?

The production of a coletor de po (dust collector) involves several critical stages, each essential for creating a high-quality product that meets the demands of various industries, including construction and manufacturing. Understanding these processes can help B2B buyers make informed purchasing decisions.

How Is Material Prepared for Coletor de Po Manufacturing?

The first stage in the manufacturing process is material preparation. High-grade materials such as durable plastics or metal alloys are typically chosen for their strength and resistance to wear. These materials undergo a thorough inspection to ensure they meet specified standards, including tensile strength and flexibility.

Material preparation often includes cutting raw materials into specific dimensions. Advanced techniques like CNC (Computer Numerical Control) machining may be used to ensure precision in the cut and shape. This precision is crucial, as it directly affects the performance and efficiency of the dust collector.

What Forming Techniques Are Utilized in Coletor de Po Production?

Once the materials are prepared, the next stage involves forming. This may include various methods such as injection molding for plastic components or stamping for metal parts.

-

Injection Molding: This is a common technique for producing intricate designs and shapes in plastic. The process involves heating plastic until it melts and then injecting it into a mold. This allows for the creation of complex geometries that enhance the dust collector’s efficiency.

-

Metal Stamping: For metal components, stamping is often employed to create parts with high precision. This process involves using a die to shape metal sheets into desired forms.

These forming techniques not only ensure that components fit together perfectly but also contribute to the overall durability of the dust collector.

How Does Assembly Take Place in Coletor de Po Manufacturing?

The assembly stage is where all the individual components come together. This process typically involves:

-

Component Integration: Different parts, such as the dust collection chamber, connectors, and hoses, are assembled into a complete unit.

-

Use of Adhesives and Fasteners: High-quality adhesives or mechanical fasteners are used to ensure that components are securely attached, which is crucial for maintaining the integrity of the dust collector under operational stress.

-

Final Adjustments: During assembly, technicians may make adjustments to ensure that all moving parts operate smoothly. This includes checking for proper alignment and function of any mechanical components.

What Finishing Processes Are Important for Coletor de Po Products?

The finishing stage is vital for enhancing the dust collector’s aesthetic appeal and functional performance. Common finishing processes include:

-

Surface Treatment: Processes such as powder coating or galvanizing are applied to improve corrosion resistance and enhance durability. This is particularly important in environments where dust and moisture may be prevalent.

-

Quality Checks: After finishing, products undergo a series of quality checks to ensure that they meet industry standards. This is often the last chance to catch defects before the product is shipped to buyers.

What Quality Assurance Measures Are Essential for Coletor de Po?

Quality assurance (QA) is critical in ensuring that the dust collectors produced meet international standards and customer expectations. Here’s how it typically unfolds:

Illustrative image related to coletor de po

What International Standards Should B2B Buyers Consider?

For B2B buyers, understanding the relevant international standards is crucial. Some of the key certifications include:

-

ISO 9001: This standard focuses on quality management systems and is essential for manufacturers to demonstrate their commitment to quality and customer satisfaction.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: For dust collectors used in certain industrial applications, adherence to API (American Petroleum Institute) standards may be necessary.

These certifications help B2B buyers ensure that the products they purchase are safe, reliable, and of high quality.

What Are the Key QC Checkpoints in Coletor de Po Production?

Quality control checkpoints are integrated throughout the manufacturing process to ensure product integrity. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Materials that do not meet quality standards are rejected.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples may be taken for testing. This ensures that any deviations from quality standards are identified and corrected in real-time.

-

Final Quality Control (FQC): Before shipping, final inspections are conducted. This includes functionality tests and visual inspections to check for any defects.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is essential. Here are actionable steps to ensure that the manufacturers meet your quality expectations:

-

Request Documentation: Ask for quality assurance documentation, including certificates of compliance with international standards like ISO 9001 and CE.

-

Supplier Audits: Conduct on-site audits of the manufacturing facilities. This allows buyers to assess the quality control processes firsthand and verify compliance with industry standards.

-

Third-Party Inspections: Engage third-party inspection services to conduct independent quality assessments. This provides an unbiased view of the manufacturer’s capabilities and adherence to quality standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Regulatory Compliance: Different regions may have unique regulations that affect product compliance. Understanding these regulations can help avoid costly delays in customs or legal issues.

-

Documentation Requirements: Ensure that all required documentation is provided, including customs paperwork, quality certifications, and safety data sheets. This is particularly important for cross-border transactions.

-

Communication with Suppliers: Establish clear lines of communication with suppliers regarding quality expectations. This can help mitigate misunderstandings and ensure that products meet your specific needs.

By understanding the manufacturing processes and quality assurance measures for coletor de po, B2B buyers can make more informed decisions, ensuring they source reliable and efficient dust collection solutions tailored to their operational requirements.

Illustrative image related to coletor de po

Practical Sourcing Guide: A Step-by-Step Checklist for ‘coletor de po’

To successfully source a ‘coletor de po’ (dust collector), it is essential to follow a structured approach that ensures you meet your operational needs while minimizing risks. This checklist is designed to guide B2B buyers through the procurement process, ensuring that you select the right product and supplier.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing a dust collector. Consider factors such as the type of electric tools you will be using, the volume of dust generated, and the specific applications (e.g., wall drilling, air conditioning installation). This clarity will help you identify a product that effectively meets your operational demands.

Step 2: Research Market Options

Investigate various models and brands available in the market. Look for dust collectors with features such as high dust capture efficiency, compatibility with different tools, and ease of installation. Pay attention to user reviews and product ratings to gauge performance and reliability.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Ensure that the suppliers have a solid reputation for quality and service, as this can significantly impact your operational efficiency.

Illustrative image related to coletor de po

Step 4: Verify Supplier Certifications

Check that your chosen supplier possesses relevant certifications and complies with international quality standards. Certifications such as ISO 9001 or industry-specific standards can provide assurance of product quality and manufacturing processes. This step is vital for minimizing risks associated with substandard products.

Step 5: Assess Pricing and Payment Terms

Compare pricing structures among different suppliers, but be cautious of unusually low prices that may indicate inferior quality. Understand the payment terms, including any upfront costs, shipping fees, and potential import duties. Transparent pricing helps you calculate the total landed cost, enabling you to make an informed decision.

Step 6: Request Product Samples

Whenever possible, request samples of the dust collector to evaluate their quality and performance. Testing the product can provide insight into its durability and effectiveness in real-world applications. This step is particularly important for ensuring that the product meets your specific needs before making a bulk purchase.

Step 7: Understand Warranty and Return Policies

Finally, review the warranty and return policies provided by the supplier. A robust warranty indicates the supplier’s confidence in their product, while a clear return policy can protect your investment should the product fail to meet expectations. Knowing these terms in advance can help you avoid potential complications in the future.

By following this checklist, you can ensure a well-informed sourcing process for ‘coletor de po’, aligning your procurement strategy with your business needs while minimizing risks associated with international purchasing.

Comprehensive Cost and Pricing Analysis for coletor de po Sourcing

What Are the Key Cost Components in Coletor de Po Sourcing?

When sourcing a coletor de po (dust collector), understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. High-quality plastics and metals that withstand wear and tear will increase production costs but lead to greater durability and efficiency.

-

Labor: Labor costs vary widely based on the region of production. Countries with lower labor costs may offer more competitive pricing, but this can affect the quality of craftsmanship.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, equipment depreciation, and factory rent. Efficient manufacturing processes can help mitigate these overhead costs.

-

Tooling: Custom tooling for specific designs can be a significant upfront investment, impacting the overall price. Standardized designs often reduce tooling costs, making them more attractive for buyers.

-

Quality Control (QC): Implementing strict QC measures ensures that products meet specified standards. This can add to the cost but is essential for maintaining quality, especially for buyers requiring certifications.

-

Logistics: Shipping and handling costs are critical for international buyers. Factors such as distance, shipping method, and Incoterms can greatly influence the final price.

-

Margin: Suppliers typically apply a margin that reflects their operational costs and desired profit. Understanding this margin can help buyers negotiate better prices.

How Do Price Influencers Affect Coletor de Po Costs?

Several factors can influence the pricing of coletor de po, making it essential for buyers to consider the following:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and potential for bulk purchasing to maximize savings.

-

Specifications and Customization: Custom features or specifications can drive up costs. Buyers should evaluate whether standard models meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or CE) can justify a higher price but may also ensure better performance and longevity, offering better value over time.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven track record, while newer suppliers might offer lower prices to attract business.

-

Incoterms: Understanding shipping terms is critical for cost management. Incoterms define the responsibilities of buyers and sellers in international shipping, affecting who pays for shipping, insurance, and duties.

What Are the Best Buyer Tips for Cost-Efficient Coletor de Po Sourcing?

To navigate the complexities of sourcing coletor de po, international buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders. Many suppliers are open to negotiations, particularly if they see potential for long-term business relationships.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the purchase price. This includes evaluating maintenance, operational costs, and potential downtime associated with lower-quality products.

-

Pricing Nuances for International Buyers: Be aware of hidden costs such as import duties, taxes, and local regulations that can affect the final landed cost of products. Always request a breakdown of costs from suppliers.

-

Supplier Research: Conduct thorough research on potential suppliers, including reviews and ratings, to ensure reliability and quality. Utilize platforms like Trustpilot or industry-specific forums to gauge supplier performance.

-

Product Testing: Whenever possible, request samples or conduct tests before committing to larger orders. This can help confirm that the product meets your specifications and quality standards.

Disclaimer

Prices and cost structures are subject to change based on market conditions, supplier pricing strategies, and regional economic factors. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing coletor de po With Other Solutions

Understanding Alternatives to Coletor de Po

When evaluating dust collection solutions, it’s essential for B2B buyers to consider various alternatives to the coletor de po. The right choice can significantly impact operational efficiency, workplace safety, and overall project costs. Below, we compare the coletor de po against two viable alternatives: centralized dust collection systems and portable vacuum cleaners.

Illustrative image related to coletor de po

| Comparison Aspect | Coletor De Po | Centralized Dust Collection System | Portable Vacuum Cleaner |

|---|---|---|---|

| Performance | High dust capture efficiency; works with various tools | Excellent for large operations; consistent performance | Good for small jobs; less efficient for large debris |

| Cost | Moderate initial investment; low ongoing costs | High upfront cost; long-term savings on labor and maintenance | Low initial cost; higher ongoing costs for filters and bags |

| Ease of Implementation | Simple installation; compatible with various tools | Complex setup; requires professional installation | Easy to set up and use; minimal training needed |

| Maintenance | Low maintenance; occasional cleaning required | Requires regular maintenance; can be costly | Frequent filter changes; moderate maintenance |

| Best Use Case | Ideal for construction sites and small workshops | Best for large manufacturing facilities | Suitable for light-duty cleaning tasks and smaller areas |

Exploring Centralized Dust Collection Systems

Centralized dust collection systems are designed for larger operations, providing a centralized solution for dust management. They connect to multiple workstations through ductwork, effectively capturing dust at the source.

Pros: Their performance is unmatched in large facilities, offering consistent suction and filtration over extensive areas. Additionally, they contribute to a cleaner work environment, reducing airborne particles significantly.

Cons: However, the initial investment is substantial, and the installation process can be complicated, often requiring professional services. Regular maintenance is necessary to ensure optimal performance, which can lead to higher operational costs over time.

Evaluating Portable Vacuum Cleaners

Portable vacuum cleaners are a common alternative, especially for smaller jobs or projects requiring mobility. These devices are versatile and can be easily transported to various locations.

Pros: They are cost-effective with low initial prices, and setup is straightforward, making them accessible for many users. Their lightweight design allows for easy maneuverability, making them suitable for quick clean-ups.

Cons: Despite their convenience, portable vacuums often lack the power needed for larger debris or extensive dust collection. They may require frequent filter changes and maintenance, leading to higher ongoing costs compared to other solutions.

Making the Right Choice for Your Business Needs

When selecting the appropriate dust collection solution, B2B buyers should assess their specific operational needs, including the scale of their projects and budget constraints. The coletor de po offers a balanced approach for medium-sized operations, combining efficiency and ease of use. In contrast, centralized systems are best for large facilities with high dust output, while portable vacuums suit smaller tasks. Analyzing the trade-offs between performance, cost, implementation, and maintenance will help ensure that the chosen solution aligns with the buyer’s long-term operational goals and workplace safety standards.

Essential Technical Properties and Trade Terminology for coletor de po

What Are the Essential Technical Properties of a Coletor de Pó?

When considering the purchase of a coletor de pó (dust collector), understanding its technical properties is crucial for making an informed decision. Here are some key specifications that buyers should evaluate:

1. Material Grade

The material used in the construction of a dust collector significantly impacts its durability and performance. Common materials include high-density polyethylene (HDPE) and polyvinyl chloride (PVC). HDPE is known for its strength and resistance to impact, while PVC is lightweight and cost-effective. Selecting the right material is essential for ensuring longevity and effectiveness in various working environments.

2. Capture Efficiency

Capture efficiency refers to the percentage of dust particles that the coletor de pó can effectively collect during operation. A high capture efficiency is critical in maintaining a clean and safe workspace, as it minimizes dust dispersion. Buyers should look for products with a capture efficiency rating of 90% or higher, particularly in heavy-duty applications.

Illustrative image related to coletor de po

3. Compatibility with Tools

A versatile coletor de pó should be compatible with a range of electric tools, such as drills and hammers. This compatibility ensures that the dust collector can be used across different projects without the need for multiple devices. Check for specifications that indicate the range of tools with which the dust collector can operate effectively.

4. Installation Flexibility

The ease of installation is a vital property that affects operational efficiency. A dust collector designed with flexible materials allows for quick setup and removal, adapting to various drilling angles and depths. This feature is particularly important for contractors who frequently switch between tasks and require equipment that can keep pace with their workflow.

5. Shock Absorption Capability

In addition to dust collection, some coletor de pó units offer shock absorption features. This property protects the tools from potential damage during operation, enhancing their lifespan. For B2B buyers, investing in equipment that safeguards tools can lead to long-term cost savings by reducing the frequency of replacements.

6. Weight and Portability

The weight of the dust collector affects its portability and ease of use. A lightweight design ensures that workers can move the equipment easily from one job site to another, improving productivity. Consider the weight specifications when evaluating options to ensure that the dust collector aligns with your operational needs.

What Are Common Trade Terms Related to Coletor de Pó?

Understanding trade terminology is essential for effective communication and negotiation in the B2B sector. Here are several common terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another company. In the context of coletor de pó, buyers may want to ensure that they are sourcing from reputable OEMs to guarantee quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ can help businesses plan their purchases effectively, ensuring that they meet supplier requirements while also managing inventory levels.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details on specific products. This process is vital for comparing options and negotiating favorable terms before making a purchase.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms can help mitigate risks associated with international shipping, ensuring clarity on who is responsible for costs and risks at each stage of transport.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For dust collectors, shorter lead times can enhance operational efficiency, allowing businesses to respond quickly to project demands.

Illustrative image related to coletor de po

6. Warranty

A warranty is a guarantee provided by the manufacturer that the product will perform as promised for a specified period. Understanding warranty terms is critical for B2B buyers, as it can influence purchasing decisions and ensure protection against defects or failures.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing coletor de pó, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the coletor de po Sector

What Are the Current Market Dynamics and Key Trends in the Coletor de Po Sector?

The global market for dust collectors, particularly the coletor de po, is experiencing significant growth due to increasing industrialization and heightened awareness of occupational health and safety standards. As industries expand in regions like Africa, South America, and the Middle East, the demand for effective dust collection solutions has surged. Key drivers include stringent regulations aimed at minimizing workplace dust exposure, which not only protects workers but also enhances overall operational efficiency.

In recent years, there has been a noticeable shift towards digital sourcing technologies. B2B buyers are increasingly leveraging e-commerce platforms and marketplaces to streamline procurement processes and reduce lead times. For instance, international platforms allow buyers to access products that may not be readily available in their local markets, facilitating cross-border trade. Additionally, the integration of AI and data analytics into supply chain management is enabling companies to optimize their sourcing strategies, ensuring they can respond swiftly to fluctuating market demands.

Emerging trends include the adoption of multi-functional dust collectors, which cater to diverse applications across construction, manufacturing, and DIY projects. These innovations are designed to improve capture efficiency and reduce environmental impact. Furthermore, buyers are seeking customized solutions that can be tailored to specific operational needs, reflecting a broader trend towards personalization in B2B purchasing.

How Is Sustainability and Ethical Sourcing Shaping the Coletor de Po Market?

Sustainability has become a cornerstone of procurement strategies in the coletor de po sector. B2B buyers are increasingly prioritizing products that are manufactured using eco-friendly materials and processes. This shift is driven by both regulatory pressures and consumer demand for environmentally responsible practices. Buyers are urged to consider the environmental impact of their sourcing decisions, as products that contribute to pollution or waste can tarnish a brand’s reputation and customer loyalty.

Ethical supply chains are also gaining traction, with companies seeking to partner with suppliers who adhere to fair labor practices and transparency. Certifications such as ISO 14001 for environmental management and other green certifications are becoming essential credentials for manufacturers. These certifications not only validate a company’s commitment to sustainability but also serve as a competitive differentiator in a crowded marketplace.

Moreover, many organizations are integrating sustainability metrics into their procurement processes, assessing the carbon footprint and lifecycle impact of their products. By sourcing dust collectors that utilize recyclable materials or promote energy efficiency, businesses can reduce their overall environmental impact while enhancing their corporate social responsibility initiatives.

What Is the Brief Evolution of the Coletor de Po Sector?

The evolution of the coletor de po sector can be traced back to the early industrial era when dust management was primarily a manual process. As industries grew, the need for effective dust collection systems became apparent, leading to the development of primitive dust collectors. These early systems were often inefficient and cumbersome, prompting continuous innovation.

With advancements in technology, the 20th century saw the introduction of more sophisticated dust collection systems, including baghouses and cyclonic separators. The focus shifted towards improving efficiency and reducing energy consumption. Today, the sector is characterized by the integration of smart technologies, enabling real-time monitoring and data-driven decision-making.

The current landscape is defined by a commitment to sustainability and operational excellence, with manufacturers continuously innovating to meet the evolving needs of B2B buyers. As industries worldwide recognize the importance of maintaining a clean and safe working environment, the demand for advanced dust collection solutions like the coletor de po is expected to grow, paving the way for further advancements in this essential sector.

Frequently Asked Questions (FAQs) for B2B Buyers of coletor de po

-

How do I solve dust contamination issues in my workspace?

To effectively mitigate dust contamination, investing in a high-quality coletor de po is crucial. These dust collectors are designed to efficiently capture and contain dust produced during drilling or construction activities. Opt for models that offer superior capture efficiency, flexible installation, and compatibility with various electric tools. Regular maintenance and timely replacement of dust collection components will also help maintain a clean and safe working environment, protecting both your team and equipment from dust-related issues. -

What is the best dust collector for construction projects?

The ideal dust collector for construction projects is one that combines efficiency with versatility. Look for a coletor de po that is compatible with both light and heavy electric tools, ensuring it can handle a range of tasks from wall drilling to air conditioning installations. Features such as a flexible design for easy installation and a high dust capture rate are essential. Additionally, ensure that the product is made from durable materials that can withstand the rigors of a construction site. -

What should I consider when sourcing a coletor de po supplier?

When sourcing a supplier for coletor de po, consider their reputation, product quality, and service reliability. Look for suppliers with positive customer reviews and certifications that indicate adherence to safety and quality standards. It is also important to verify their ability to handle international shipments, including customs and duties. Establish communication to assess their responsiveness and willingness to provide support throughout the procurement process. -

Are there minimum order quantities (MOQ) for coletor de po?

Minimum order quantities can vary significantly among suppliers. Some may offer flexible MOQ options, while others might require bulk orders to ensure cost-effectiveness. It’s essential to clarify these details upfront to align with your purchasing needs. If your project requires a smaller quantity, look for suppliers who specialize in smaller batch orders or those willing to negotiate terms that suit your requirements. -

What are the payment terms typically offered by suppliers?

Payment terms can differ based on the supplier’s policies and your business relationship. Common arrangements include upfront payments, partial payments upon order confirmation, and net payment terms (e.g., net 30 or net 60 days). For international transactions, ensure that the payment method is secure and offers buyer protection. Discussing these terms during negotiations can help establish a mutually beneficial agreement that supports your cash flow management. -

How do I ensure quality assurance for my coletor de po orders?

To ensure quality assurance, request samples before placing a bulk order. This allows you to assess the product’s performance and compatibility with your tools. Additionally, inquire about the supplier’s quality control processes, such as inspections and testing protocols. Establishing clear quality standards in your purchase agreement will also help mitigate risks associated with product defects or inconsistencies. -

What logistics considerations should I keep in mind when importing coletor de po?

Logistics considerations include shipping methods, transit times, and customs clearance processes. Choose a supplier experienced in international shipping to streamline these aspects. Confirm that the supplier handles all necessary documentation and pre-pays any applicable duties and taxes to avoid unexpected costs upon delivery. Additionally, consider the reliability of shipping carriers used and the estimated delivery times to ensure timely receipt of your order. -

How can I customize my coletor de po to meet specific needs?

Customization options depend on the supplier’s capabilities. Discuss your specific requirements, such as size, design, or material modifications, during the initial inquiry. Many manufacturers are open to creating tailored solutions to meet unique project demands. Be prepared to provide detailed specifications and, if possible, collaborate on prototypes to ensure the final product aligns with your expectations and operational needs.

Top 5 Coletor De Po Manufacturers & Suppliers List

1. Latinafy – Nuevo Coletor De Pó

Domain: latinafy.com

Registered: 2020 (5 years)

Introduction: This company, Latinafy – Nuevo Coletor De Pó, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Loja do Mecânico – Coletor de Pó para Máquinas Elétricas

Domain: lojadomecanico.com.br

Registered: 2005 (20 years)

Introduction: This company, Loja do Mecânico – Coletor de Pó para Máquinas Elétricas, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Leo Madeiras – Coletor de Pó Monofásico e Trifásico

Domain: leomadeiras.com.br

Registered: 1996 (29 years)

Introduction: Coletor de Pó: Monofásico e Trifásico – Modelos disponíveis: CP/1.C, CP/2.C, CP1S, CP2S BLACK, CP5, CPB/1.S, CPD/3.C, CPD/5.C, CPD3S BLACK, CPD5S Black, CPL2 LEO, CPP/1.C, EXB23, EXB45. Potências variando de 1CV a 7,5CV. Entradas: 1 a 5. Reservatórios: 1 a 2.

4. Pinterest – Coletor de Pó

Domain: br.pinterest.com

Registered: 2009 (16 years)

Introduction: This company, Pinterest – Coletor de Pó, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Ferrari – Coletor de Pó CP-470

Domain: ferrarinet.com.br

Registered: 2001 (24 years)

Introduction: {“name”: “Coletor de Pó CP-470″,”power”: “550W (3/4 cv)”,”voltage”: “127V”,”rotation”: “3400 rpm”,”maximum_flow”: “800 m³/hora”,”suction_inlet”: “100 mm”,”collector_capacity”: “80 litros”,”application”: “Ideal para uso em marcenarias e pequenas indústrias de móveis, na aspiração e coleta de pó e serragem.”,”benefits”: [“Ambiente de trabalho sempre limpo – Evita prejudicar o funcionamento de máquin…

Strategic Sourcing Conclusion and Outlook for coletor de po

In conclusion, the strategic sourcing of the coletor de po presents an invaluable opportunity for B2B buyers looking to enhance operational efficiency and workplace safety. By investing in high-quality dust collection solutions like the Nuevo Coletor De Pó, businesses can significantly reduce airborne contaminants, thereby improving worker health and productivity. The versatility and ease of installation of these dust collectors make them suitable for various applications, from construction to light installations, ensuring that they meet diverse industry needs.

As international markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable and efficient dust collection systems will only grow. By leveraging strategic sourcing practices, businesses can not only secure the best products at competitive prices but also foster relationships with trusted suppliers who understand local market nuances.

Looking ahead, it is crucial for B2B buyers to embrace these innovations in dust collection technology. Doing so will not only enhance their operational capabilities but also position them as leaders in workplace safety and environmental responsibility. Engage with trusted suppliers today to explore the best options for your business needs and elevate your work environment for a brighter, cleaner future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.