Everything You Need to Know About Chicken Wire Types Sourcing in 2025

Introduction: Navigating the Global Market for chicken wire types

In an increasingly interconnected world, the challenge of sourcing the right chicken wire types for diverse applications has become paramount for international B2B buyers. Whether you are in agriculture, construction, or decorative arts, understanding the nuances of chicken wire—also known as poultry netting or hexagonal wire mesh—can significantly impact your project’s success. This comprehensive guide delves into the various types of chicken wire, including galvanized, PVC-coated, and stainless steel options, along with their specific applications, from poultry enclosures to garden protection and even artistic endeavors.

Navigating the complexities of supplier vetting, pricing structures, and material specifications can be daunting, especially for businesses operating in regions such as Africa, South America, the Middle East, and Europe, including nations like Saudi Arabia and Nigeria. This guide empowers you to make informed purchasing decisions by offering actionable insights and expert recommendations tailored to your unique market needs. By understanding the strengths and limitations of different chicken wire types, you can optimize your supply chain, ensure compliance with regional standards, and ultimately enhance the durability and effectiveness of your projects.

Join us as we explore the global market for chicken wire, equipping you with the knowledge to confidently select the best materials for your business endeavors.

Understanding chicken wire types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Chicken Wire | Coated with zinc for corrosion resistance | Poultry enclosures, garden fencing | Pros: Cost-effective, durable; Cons: Limited lifespan compared to PVC-coated options. |

| PVC Coated Chicken Wire | Galvanized wire coated with PVC for enhanced durability | Agricultural uses, garden borders | Pros: Longer lifespan, UV resistant; Cons: Higher initial cost than galvanized. |

| Stainless Steel Chicken Wire | Made from stainless steel, highly resistant to rust | High-end agricultural applications, industrial use | Pros: Extremely durable, aesthetically pleasing; Cons: More expensive than other types. |

| Rabbit Netting | Heavy-duty wire with smaller mesh openings | Protecting gardens from rabbits and small animals | Pros: Effective deterrent; Cons: Can be difficult to install. |

| Craft Chicken Wire | Thinner gauge wire available in various colors | Decorative applications, crafting | Pros: Versatile for crafts; Cons: Not suitable for structural uses. |

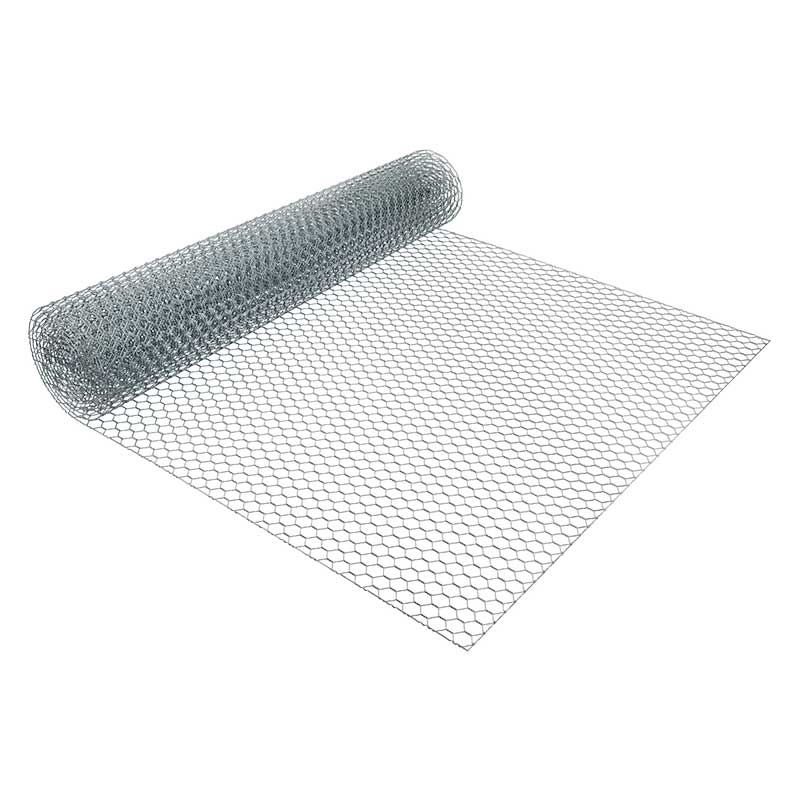

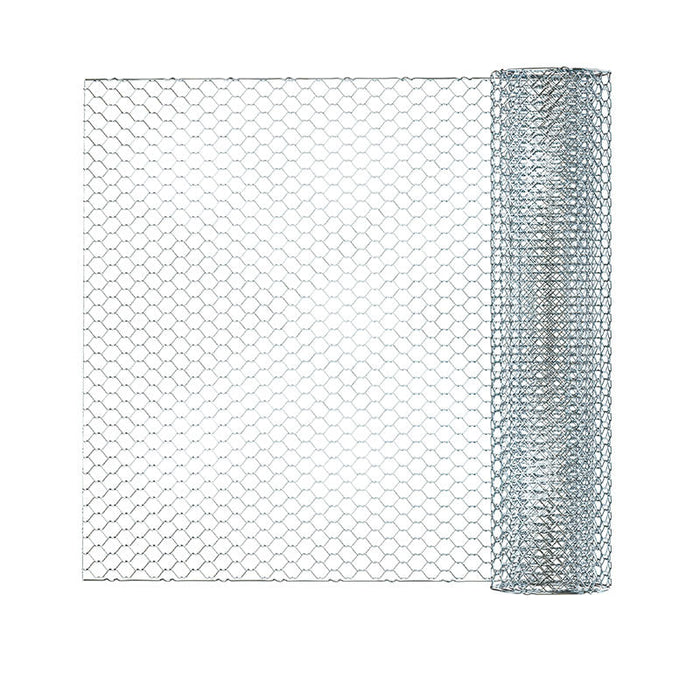

What Are the Characteristics of Galvanized Chicken Wire?

Galvanized chicken wire is coated with zinc to enhance its resistance to corrosion, making it a popular choice for outdoor applications. It is widely used for poultry enclosures and garden fencing due to its affordability and decent durability. However, its lifespan is generally shorter than that of PVC-coated wire, making it less suitable for long-term projects or areas with harsh weather conditions. B2B buyers should consider the specific environmental conditions and usage frequency when opting for galvanized wire.

How Does PVC Coated Chicken Wire Enhance Durability?

PVC coated chicken wire combines the rust-resistant properties of galvanized wire with an additional PVC layer, making it ideal for agricultural and garden applications. This type of wire is particularly effective in environments exposed to UV rays, as it significantly extends the product’s lifespan—often up to 20 years. While the initial investment is higher than that of galvanized options, the long-term savings due to reduced replacement costs can be beneficial for B2B buyers focused on sustainability and durability.

Why Choose Stainless Steel Chicken Wire for High-End Applications?

Stainless steel chicken wire is recognized for its exceptional durability and resistance to rust, making it ideal for high-end agricultural applications and industrial use. Its aesthetic appeal also makes it suitable for visible installations. Although it comes at a premium price, the longevity and low maintenance requirements can justify the cost for businesses looking for quality and performance. B2B buyers should weigh the initial investment against the potential for long-term savings in maintenance and replacement.

What Are the Benefits of Using Rabbit Netting in Agricultural Settings?

Rabbit netting is specifically designed with smaller mesh openings to protect gardens and crops from small animals such as rabbits. This heavy-duty wire is effective in deterring pests and is often used in conjunction with other fencing solutions. However, installation can be more complex due to its thicker gauge. B2B buyers should assess their specific needs and the types of pests they are targeting to determine the best fencing solution.

How Can Craft Chicken Wire Be Utilized in Decorative Applications?

Craft chicken wire is typically a thinner gauge wire available in various colors, making it suitable for decorative purposes and crafting projects. While it is versatile and can be used for a range of creative applications, it is not intended for structural uses or heavy-duty projects. B2B buyers interested in decorative solutions should consider the specific requirements of their projects to ensure they select the appropriate type of chicken wire.

Key Industrial Applications of chicken wire types

| Industry/Sector | Specific Application of chicken wire types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Poultry Enclosures and Livestock Fencing | Ensures animal safety and productivity | Gauge thickness, corrosion resistance, and mesh size |

| Landscaping and Gardening | Garden Protection and Soil Stabilization | Protects plants from pests and erosion | Material durability, UV resistance, and installation ease |

| Construction | Reinforcement in Civil Engineering Projects | Provides structural support and stability | Compliance with local regulations and project specifications |

| Arts and Crafts | Decorative and Functional Art Installations | Versatile material for creative projects | Availability in various colors and sizes |

| Wildlife Management | Habitat Protection and Pest Control | Safeguards native species and prevents crop damage | Material strength, environmental impact, and ethical sourcing |

How is Chicken Wire Used in Agriculture for Poultry Enclosures?

In the agriculture sector, chicken wire types are primarily used for poultry enclosures and livestock fencing. These structures protect animals from predators while allowing for ventilation and visibility. The durability of galvanized or PVC-coated wire ensures longevity, especially in harsh climates typical in regions like Africa and the Middle East. Buyers must consider gauge thickness and mesh size to ensure the safety of different livestock types, as well as corrosion resistance to withstand environmental conditions.

What Role Does Chicken Wire Play in Landscaping and Gardening?

In landscaping and gardening, chicken wire serves crucial roles in protecting plants from pests and stabilizing soil. It can be used to create protective barriers around gardens or as a support structure for climbing plants. This application is particularly beneficial in regions where wildlife poses a significant threat to crops, such as in South America. Buyers should look for UV-resistant materials to ensure longevity and evaluate ease of installation to facilitate quick setup in diverse terrains.

How is Chicken Wire Utilized in Construction Projects?

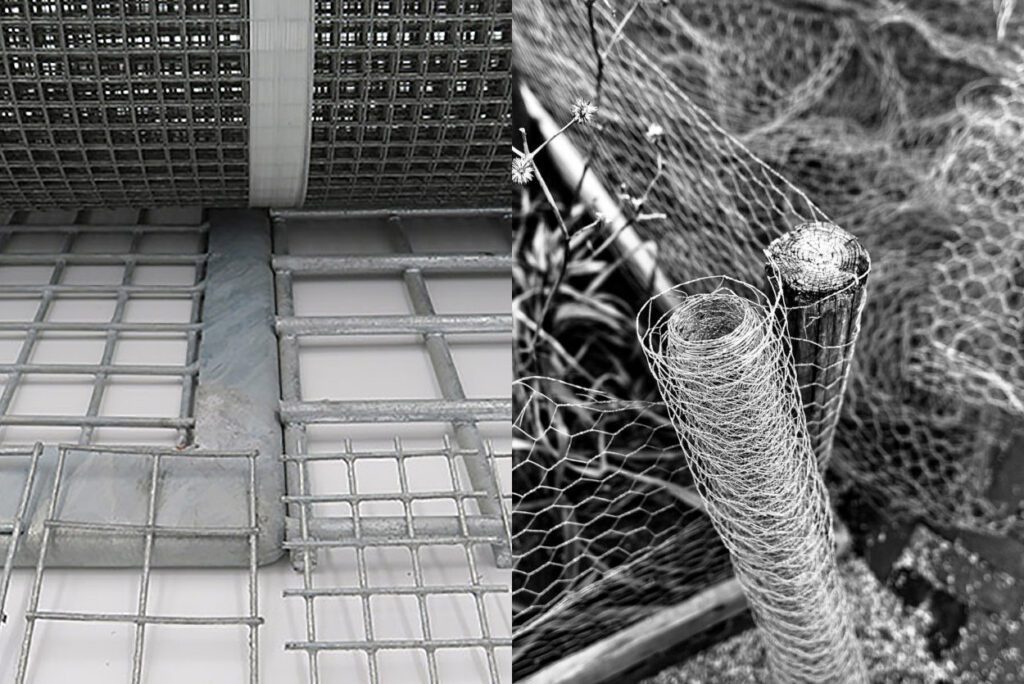

In construction, chicken wire is often employed as a reinforcement material in civil engineering projects. It provides additional structural support in concrete applications and can be used in creating barriers or fencing around construction sites. For international buyers, especially in Europe and the Middle East, compliance with local building regulations and standards is essential. The sourcing of high-quality, corrosion-resistant wire is critical to ensure safety and durability in long-term projects.

Why is Chicken Wire Important in Arts and Crafts?

In the arts and crafts sector, chicken wire is valued for its versatility in creating decorative and functional installations. Artists use it for sculptures, wall decor, and various craft projects, allowing for innovative designs and structures. Buyers should consider the availability of chicken wire in different colors and sizes to suit their creative needs. Additionally, sourcing from suppliers who prioritize sustainability can enhance the ethical appeal of art installations.

How Does Chicken Wire Assist in Wildlife Management?

In wildlife management, chicken wire is used to protect habitats and control pests that threaten agricultural productivity. It serves as a barrier to prevent animals from accessing crops, thereby safeguarding local ecosystems. For buyers in regions like Nigeria and Saudi Arabia, the material’s strength and environmental impact are crucial considerations. Ensuring the wire is ethically sourced and effective in deterring unwanted wildlife can significantly enhance agricultural sustainability.

3 Common User Pain Points for ‘chicken wire types’ & Their Solutions

Scenario 1: Sourcing Durable Chicken Wire for Agricultural Use

The Problem: B2B buyers in agriculture often encounter the challenge of sourcing chicken wire that withstands harsh environmental conditions. In regions like Africa and South America, the combination of high temperatures, humidity, and exposure to chemicals in fertilizers can lead to rapid deterioration of low-quality wire. Buyers may find themselves replacing fencing frequently, leading to increased costs and operational disruptions.

The Solution: To ensure longevity and durability, buyers should prioritize galvanized chicken wire with a heavier gauge, such as 14 or 16. This type of wire has a protective zinc coating that enhances its resistance to rust and corrosion. When sourcing, it is critical to verify the gauge and the quality of galvanization. Establishing relationships with reputable suppliers who provide detailed specifications and warranties can help mitigate risks. Additionally, consider investing in PVC-coated options, which not only offer added durability but also aesthetic benefits. When installing, ensure that the wire is properly tensioned and securely fastened to posts to prevent sagging and damage from animals or environmental factors.

Scenario 2: Ensuring Proper Mesh Size for Animal Protection

The Problem: A common issue for buyers, especially in the livestock and poultry sectors, is selecting the appropriate mesh size for chicken wire. Using a mesh that is too large can result in animals escaping or predators gaining access to livestock. Conversely, a mesh that is too small may lead to increased costs and unnecessary material usage. This balancing act can be particularly challenging for buyers in regions with diverse wildlife threats.

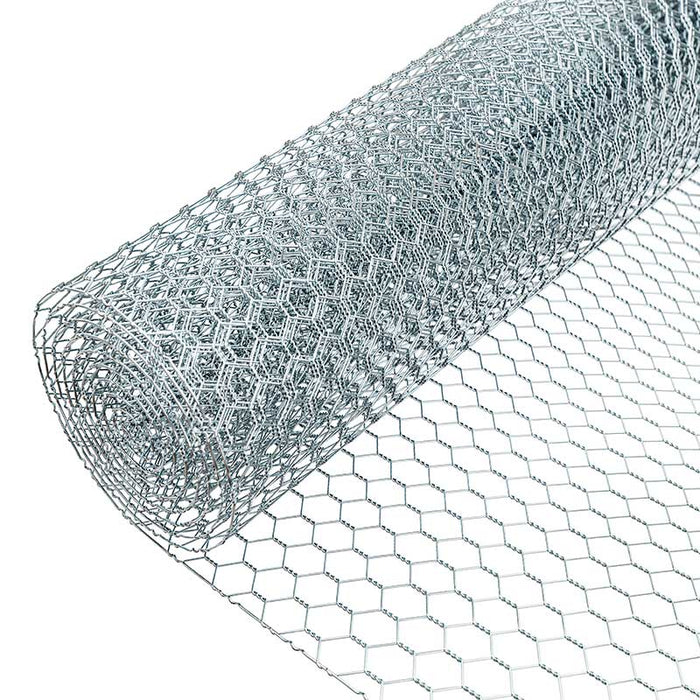

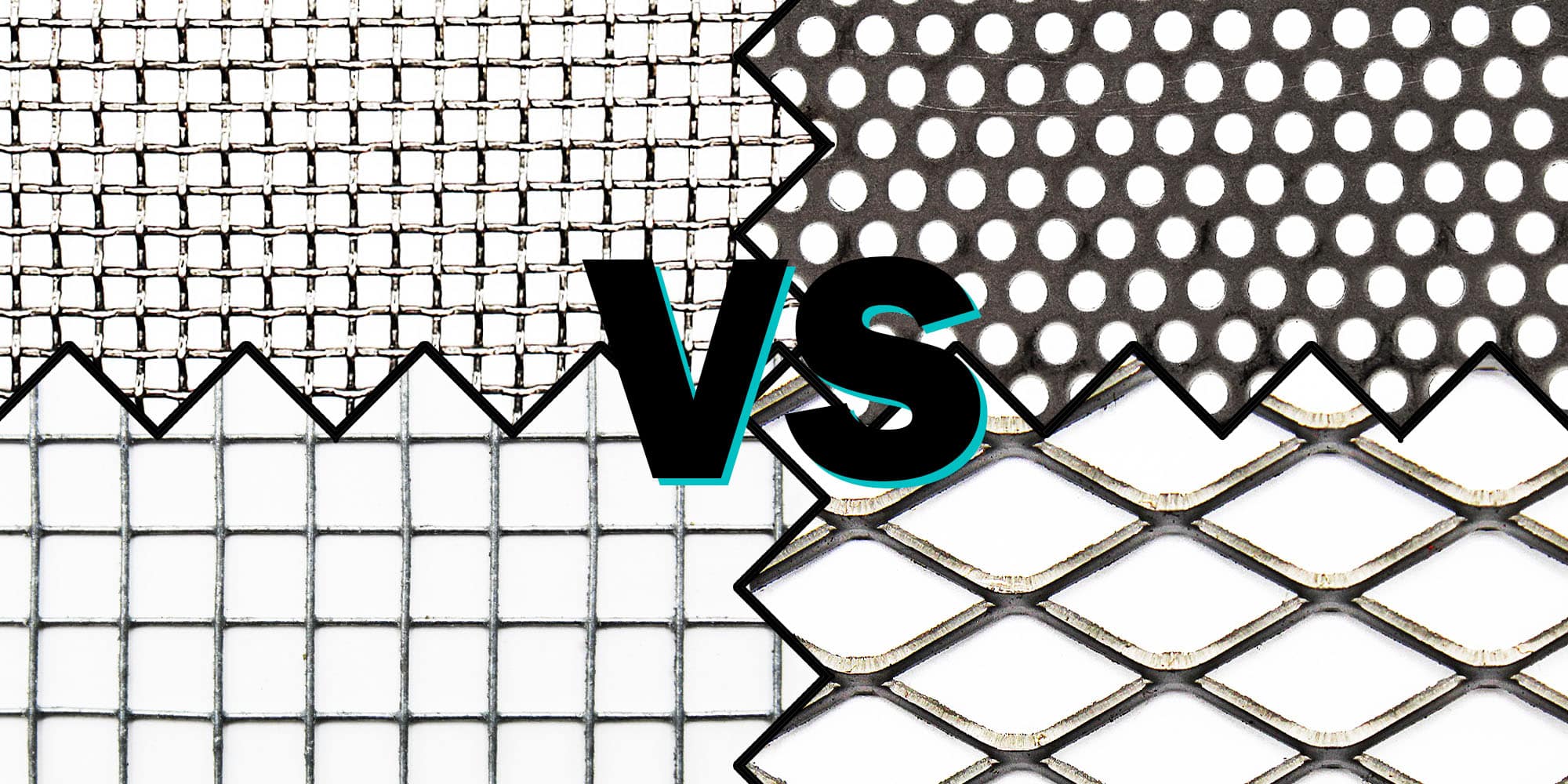

Illustrative image related to chicken wire types

The Solution: To avoid these pitfalls, it’s essential to assess the specific needs based on the type of animals being contained or protected. For poultry, a mesh size of 1 inch or smaller is typically recommended to prevent escapes and protect against predators. Buyers should conduct a thorough analysis of their specific use case—consider factors like the size of the animals and local wildlife threats. Additionally, purchasing sample rolls from suppliers can aid in making informed decisions. Collaborating with agricultural extension services or local agricultural experts can also provide insights tailored to regional challenges.

Scenario 3: Navigating Compliance and Regulatory Standards for Chicken Wire

The Problem: International buyers often face the challenge of navigating varying compliance and regulatory standards related to fencing materials. Different countries may have specific requirements regarding the materials used in agricultural applications, especially concerning food safety and environmental impact. This can lead to confusion and the potential for costly legal issues if the wrong type of chicken wire is used.

The Solution: To navigate these regulatory landscapes effectively, buyers should conduct comprehensive research into the local standards governing agricultural materials. Engaging with local agricultural or trade associations can provide valuable insights into compliance requirements. Additionally, consider working with suppliers who are knowledgeable about these regulations and can provide certification for their products. It is advisable to keep abreast of changes in legislation and ensure that all sourcing decisions align with both local and international standards. Regular audits of suppliers can also help maintain compliance and ensure that the materials used are safe and effective for their intended purpose.

Strategic Material Selection Guide for chicken wire types

What Are the Key Properties of Galvanized Steel Chicken Wire?

Galvanized steel chicken wire is one of the most common materials used in the production of chicken wire. It is coated with a layer of zinc to enhance its corrosion resistance, making it suitable for outdoor applications. This material can withstand a range of temperatures and pressures, which is critical in agricultural settings. Galvanized wire typically has a lifespan of around 10 years, depending on environmental conditions.

Pros and Cons: The primary advantage of galvanized steel is its durability and resistance to rust, which makes it ideal for long-term use in various climates. However, it can be more susceptible to damage from heavy impacts compared to other materials, and the initial cost may be higher due to the galvanization process.

Illustrative image related to chicken wire types

Impact on Application: Galvanized steel is widely used for poultry enclosures, garden fencing, and even erosion control. Its compatibility with various media, such as soil and water, makes it a versatile choice for agricultural applications.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, to guarantee product quality. In countries like Nigeria, where environmental conditions can be harsh, opting for a higher gauge of galvanized wire may be beneficial.

How Does PVC-Coated Wire Compare for Chicken Wire Applications?

PVC-coated chicken wire features a core of galvanized steel that is further coated with PVC for enhanced durability and aesthetic appeal. This type of wire is particularly resistant to UV rays and moisture, making it suitable for various outdoor applications.

Pros and Cons: The major advantage of PVC-coated wire is its extended lifespan, often exceeding 20 years, and its resistance to corrosion. However, the manufacturing process is more complex and can lead to a higher price point compared to standard galvanized wire.

Illustrative image related to chicken wire types

Impact on Application: PVC-coated wire is ideal for use in gardens and poultry enclosures where aesthetics and longevity are priorities. Its compatibility with various environmental conditions makes it a preferred choice for international buyers looking for quality and durability.

Considerations for International Buyers: When sourcing PVC-coated wire, buyers should verify compliance with international standards and consider local preferences for color and gauge. In Europe, for example, there may be specific regulations regarding the use of PVC in agricultural settings.

What Advantages Does Stainless Steel Offer for Chicken Wire?

Stainless steel chicken wire is known for its exceptional strength and resistance to corrosion, making it a premium choice for various applications. It can withstand extreme temperatures and is not prone to rust, ensuring longevity in harsh environments.

Illustrative image related to chicken wire types

Pros and Cons: The key advantage of stainless steel is its durability and low maintenance requirements. However, it is typically more expensive than other materials, which may be a consideration for budget-conscious buyers.

Impact on Application: Stainless steel wire is suitable for high-security applications, such as in zoos or for protecting valuable crops. Its compatibility with different media types makes it versatile for various agricultural uses.

Considerations for International Buyers: Buyers in regions like South America and Europe should be aware of the specific grades of stainless steel that meet local standards. Compliance with regulations such as JIS or ASTM is crucial for ensuring product quality and performance.

How Does Aluminum Wire Fit into the Chicken Wire Market?

Aluminum chicken wire is lightweight and resistant to rust, making it an attractive option for many applications. It is often used in areas where weight is a concern, such as temporary fencing or lightweight enclosures.

Illustrative image related to chicken wire types

Pros and Cons: The main advantage of aluminum wire is its ease of installation and handling due to its lightweight nature. However, it is generally less durable than steel options, making it less suitable for high-impact applications.

Impact on Application: Aluminum wire is often used for garden fencing and lightweight enclosures for small animals. Its compatibility with various environmental conditions makes it a viable option for international buyers looking for a cost-effective solution.

Considerations for International Buyers: When sourcing aluminum wire, buyers should consider the specific gauge and mesh size that meet local agricultural needs. Compliance with international standards is also essential to ensure quality and durability.

| Material | Typical Use Case for chicken wire types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Poultry enclosures, garden fencing | Durable, rust-resistant | Susceptible to heavy impacts | Medium |

| PVC-Coated Wire | Gardens, poultry enclosures | Extended lifespan, UV resistant | Higher cost due to manufacturing | High |

| Stainless Steel | High-security applications, zoos | Exceptional strength, low maintenance | Higher initial investment | High |

| Aluminum Wire | Lightweight enclosures, garden fencing | Lightweight, easy to handle | Less durable than steel options | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for chicken wire types

What Are the Key Stages in the Manufacturing Process of Chicken Wire?

The manufacturing process of chicken wire involves several critical stages, each designed to ensure that the final product meets specific quality standards and functional requirements. Understanding these stages can help B2B buyers make informed decisions when sourcing chicken wire from international suppliers.

Material Preparation: What Materials Are Used in Chicken Wire Production?

The primary materials used in chicken wire production are steel wires, which can be galvanized, stainless steel, or PVC coated. The selection of materials depends on the intended application and environmental conditions. For instance, galvanized steel offers a cost-effective option for general use, while stainless steel provides enhanced durability and corrosion resistance, making it suitable for more demanding environments.

Before manufacturing begins, raw materials are thoroughly inspected for quality. This includes checking for wire thickness, tensile strength, and coating integrity. Suppliers should provide detailed material certifications to ensure compliance with international standards.

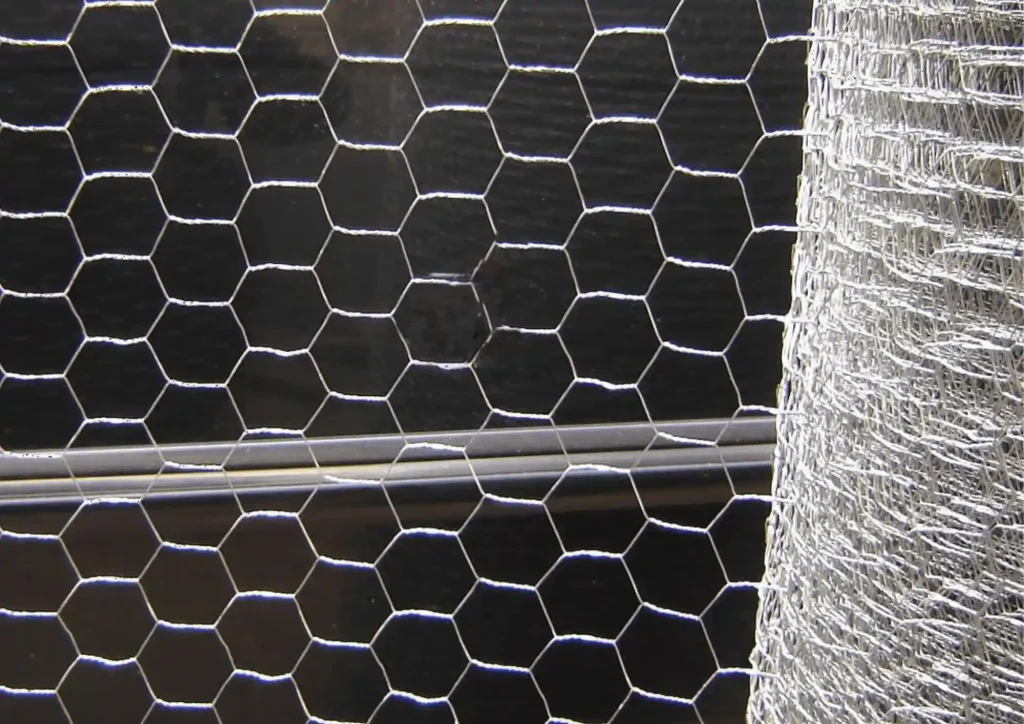

How Is the Wire Formed Into Mesh?

The forming stage involves several techniques to create the desired mesh pattern. The most common method is weaving, which can be done using either a machine or by hand. Machine weaving typically involves feeding the wire through a series of rollers that twist and shape the wire into a hexagonal mesh pattern.

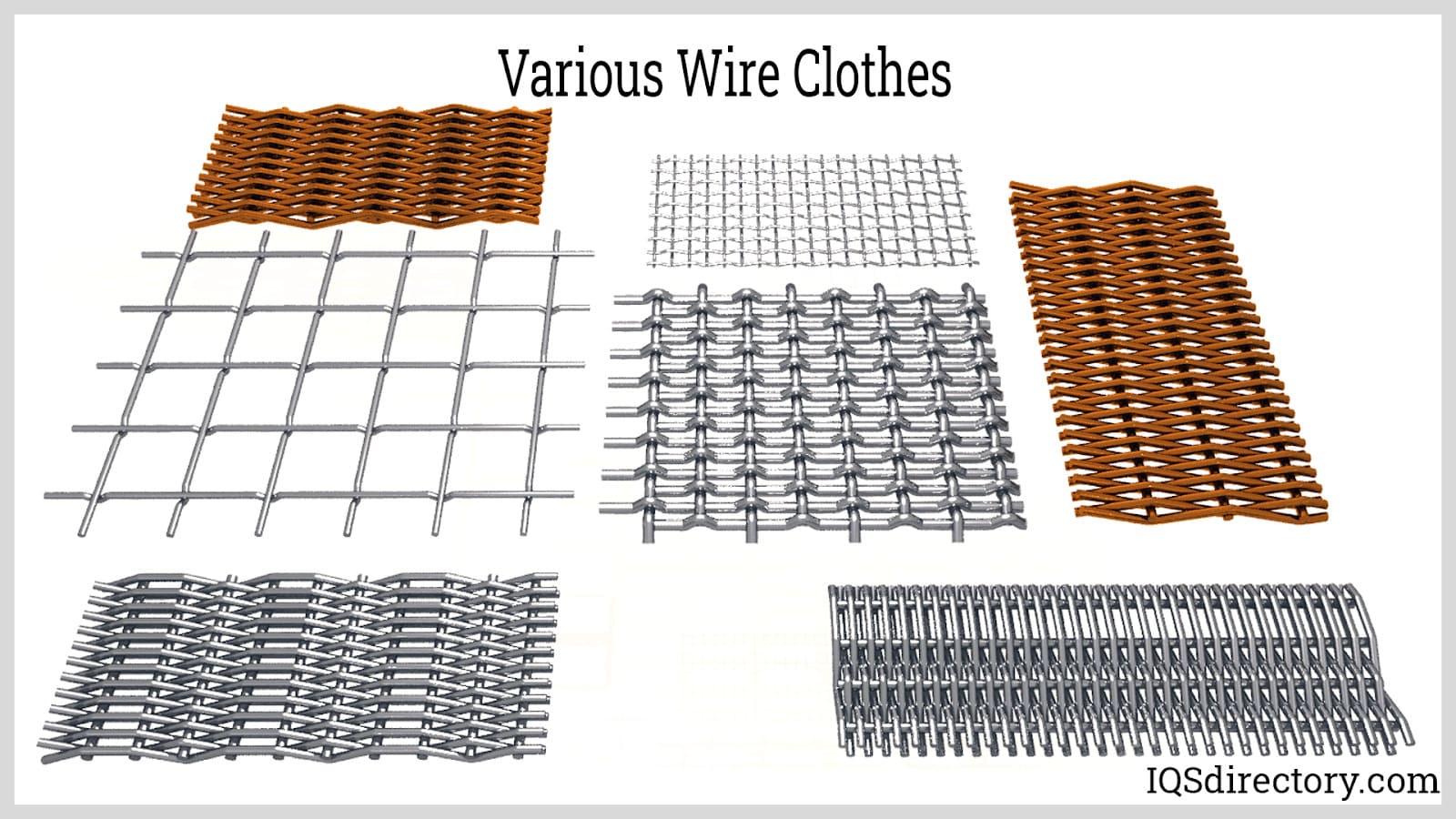

Illustrative image related to chicken wire types

Other techniques, such as welding or knotting, may also be employed depending on the type of chicken wire being produced. For example, welded wire mesh is often used for applications requiring additional strength, while knotted wire offers flexibility and ease of installation. B2B buyers should inquire about the specific forming techniques used by suppliers to ensure they align with their application needs.

What Are the Assembly and Finishing Processes?

Following the forming stage, the chicken wire undergoes assembly, where rolls or sheets are cut to specified lengths. This is often followed by a finishing process, which may involve additional treatments such as galvanization or PVC coating.

Galvanization is a critical step that enhances corrosion resistance, while PVC coating adds an extra layer of protection and aesthetic appeal. The coating process must be done carefully to ensure uniform coverage and adhesion. Buyers should seek information about the coating thickness and type to ascertain the product’s longevity.

What Quality Assurance Practices Are Essential for Chicken Wire Production?

Quality assurance is paramount in ensuring that chicken wire meets the necessary performance standards and regulatory requirements. Buyers need to understand the quality control measures in place at the manufacturing facilities they are considering.

Illustrative image related to chicken wire types

Which International Standards Apply to Chicken Wire Production?

International standards such as ISO 9001 are fundamental in establishing a quality management system for manufacturers. This certification indicates that the supplier follows systematic processes to ensure product quality and continuous improvement.

In addition to ISO standards, industry-specific certifications like CE marking (for European markets) and API specifications (for certain industrial applications) can provide additional assurance regarding product safety and compliance. Buyers should verify these certifications during the supplier selection process.

What Are the Key Quality Control Checkpoints?

Quality control in chicken wire manufacturing typically involves several checkpoints, including:

- Incoming Quality Control (IQC): This stage ensures that raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the production process and identify any deviations from quality standards.

- Final Quality Control (FQC): After production, finished products are inspected for defects, dimensions, and performance characteristics.

Each of these checkpoints plays a crucial role in maintaining product quality. B2B buyers should inquire about the specific QC processes employed by their suppliers.

Illustrative image related to chicken wire types

What Testing Methods Are Commonly Used for Chicken Wire?

Common testing methods for chicken wire include tensile strength tests, corrosion resistance tests, and mesh size verification. Tensile strength tests determine the wire’s ability to withstand pulling forces, while corrosion resistance tests evaluate the effectiveness of protective coatings. Mesh size verification ensures that the product meets specified dimensions, which is critical for applications like poultry enclosures.

B2B buyers can request test reports from suppliers to validate these testing methods and results. These reports provide transparency and build trust in the supplier’s commitment to quality.

How Can B2B Buyers Verify Supplier Quality Assurance?

Verifying a supplier’s quality assurance processes is essential for B2B buyers, especially when sourcing from international markets. Here are some strategies to ensure quality:

-

Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s quality control practices. This includes reviewing documentation, inspecting production lines, and assessing compliance with international standards.

-

Request Quality Control Reports: Suppliers should be able to provide detailed QC reports, including results from testing and inspections. These documents can serve as a benchmark for evaluating product quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can add an additional layer of assurance. These independent inspectors can verify compliance with quality standards and provide unbiased reports on product quality.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers operating in regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Different countries may have specific requirements for chicken wire products, affecting everything from material specifications to labeling.

Illustrative image related to chicken wire types

Additionally, language barriers and cultural differences can complicate communication with suppliers. Buyers should consider engaging local representatives or consultants who understand regional markets and can facilitate smoother transactions.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for chicken wire types enables B2B buyers to make informed decisions. By focusing on material quality, production techniques, and robust quality control measures, buyers can ensure they procure chicken wire that meets their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chicken wire types’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to source various types of chicken wire. Understanding the specifications and requirements of chicken wire is crucial for ensuring you select the right product for your needs, whether for agricultural, construction, or decorative purposes. This step-by-step approach will help you streamline your procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the chicken wire you need. Consider factors such as mesh size, gauge, and material type—galvanized, stainless steel, or PVC-coated.

– Mesh Size: Depending on your application, different mesh sizes (e.g., 1 inch or 2 inches) will be suitable for various uses, such as poultry enclosures or garden protection.

– Gauge: The wire gauge indicates the thickness of the wire, affecting strength and durability. Common gauges range from 14 to 20.

Illustrative image related to chicken wire types

Step 2: Identify Your Application Needs

Clearly identify the intended use of the chicken wire. This could range from agricultural applications, such as fencing for poultry or rabbits, to decorative uses in landscaping or arts and crafts.

– Poultry Protection: Ensure you select wire that can withstand environmental conditions and deter predators.

– Garden Use: If the wire is for garden protection, consider options that prevent small animals from accessing plants.

Step 3: Research Local Regulations and Standards

Understanding local regulations regarding fencing materials and agricultural practices is essential. Compliance with these regulations can impact your sourcing decisions.

– Material Standards: Verify that the materials meet safety and environmental standards in your region, especially when importing products.

– Building Codes: Check if there are specific codes governing the construction of enclosures for livestock.

Step 4: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Supplier Reputation: Research online reviews and testimonials to gauge reliability and product quality.

– Certifications: Ensure suppliers have necessary certifications, such as ISO, to indicate compliance with international standards.

Illustrative image related to chicken wire types

Step 5: Request Samples

Always request samples of the chicken wire before making a bulk order. This allows you to evaluate the quality, gauge, and durability of the product firsthand.

– Material Testing: Inspect the wire for rust resistance and strength.

– Compatibility Check: Ensure the mesh size and gauge align with your specifications for your intended application.

Step 6: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery timelines.

– Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

– Delivery Terms: Clarify shipping arrangements and lead times to ensure timely project completion.

Step 7: Finalize the Purchase Agreement

Carefully review and finalize the purchase agreement, ensuring that all specifications, terms, and conditions are clearly outlined.

– Legal Considerations: Consult with legal advisors to ensure the agreement protects your interests and complies with local laws.

– Contingency Plans: Include clauses for quality assurance and recourse in case of discrepancies in product delivery.

Following this checklist will help you effectively navigate the sourcing process for chicken wire types, ensuring you make informed and strategic purchasing decisions.

Comprehensive Cost and Pricing Analysis for chicken wire types Sourcing

What Are the Key Cost Components in Chicken Wire Types Sourcing?

When sourcing chicken wire, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The choice of material significantly impacts the cost. Common options include galvanized steel, stainless steel, and PVC-coated wire, with galvanized wire typically being the most economical. The gauge of the wire also plays a role—thicker wires generally cost more but offer enhanced durability.

Labor and Manufacturing Overhead: Labor costs can vary based on the region of production. For instance, manufacturers in developing countries may offer lower labor costs, which can be appealing for buyers. Overhead costs, such as utilities and facility maintenance, also contribute to the overall price.

Illustrative image related to chicken wire types

Tooling and Quality Control: Initial tooling costs can be substantial, especially for custom or specialized products. Quality control measures are essential to ensure the product meets specifications, which can add to the overall cost but is necessary for maintaining quality standards.

Logistics: Shipping costs are influenced by the distance from the manufacturing site to the buyer’s location, the mode of transport, and the volume of the order. International shipping can incur additional fees such as tariffs and customs duties, which should be factored into the total cost.

Margin: Suppliers typically apply a margin based on their operational costs and market demand. This margin can vary significantly depending on the supplier’s reputation, market position, and the complexity of the product.

How Do Price Influencers Affect Chicken Wire Costs?

Several factors can influence the pricing of chicken wire, particularly for international B2B buyers.

Illustrative image related to chicken wire types

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs with suppliers to maximize cost efficiency.

Specifications and Customization: Custom specifications, such as specific wire gauges, coatings, or mesh sizes, can lead to increased costs. Buyers should clearly define their needs to avoid unnecessary expenses.

Material Quality and Certifications: Higher quality materials or those with certifications (e.g., ISO, CE) can command higher prices. Buyers should weigh the benefits of investing in higher-quality products against their budget constraints.

Supplier Factors: Established suppliers with a solid reputation may charge a premium, but they often provide better reliability and service. Buyers should consider the trade-offs between cost and supplier reliability when making sourcing decisions.

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can significantly affect the overall cost structure. Buyers should be aware of who bears responsibility for shipping costs and risks, as this can impact the final price.

What Are the Best Practices for B2B Buyers in Chicken Wire Procurement?

To ensure a cost-effective procurement process, buyers should adopt several best practices.

Negotiation: Engage in open discussions with suppliers about pricing, particularly for larger orders. Suppliers may be willing to offer discounts for bulk purchases or long-term contracts.

Focus on Total Cost of Ownership (TCO): Instead of solely considering the initial purchase price, assess the long-term costs associated with maintenance, durability, and potential replacements. This broader perspective can lead to more informed purchasing decisions.

Understand Pricing Nuances for International Markets: Prices can vary significantly across regions due to factors like currency exchange rates, local demand, and supply chain dynamics. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to better understand these variations.

Illustrative image related to chicken wire types

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It’s essential for buyers to conduct their own due diligence when sourcing chicken wire products.

Alternatives Analysis: Comparing chicken wire types With Other Solutions

Introduction to Alternative Solutions for Chicken Wire Types

When it comes to securing poultry, gardens, or other small animals, chicken wire is a popular choice due to its versatility and cost-effectiveness. However, there are alternative solutions that can offer different benefits depending on the specific requirements of the application. This analysis compares various chicken wire types with alternative fencing solutions, providing B2B buyers with insights into their performance, costs, and suitability for different use cases.

Comparison Table of Chicken Wire Types and Alternatives

| Comparison Aspect | Chicken Wire Types | Welded Wire Fencing | Electric Fencing |

|---|---|---|---|

| Performance | Good for small animals; limited durability | Strong and durable; versatile | Highly effective for controlling animals |

| Cost | Low to moderate cost | Moderate to high cost | Higher initial cost, but long-term savings |

| Ease of Implementation | Easy to install; requires minimal tools | Requires more tools and effort | Requires installation of power source |

| Maintenance | Low maintenance; may require replacement | Low maintenance; long-lasting | Moderate maintenance; battery or power checks |

| Best Use Case | Poultry enclosures, garden protection | Livestock fencing, perimeter security | Controlling larger animals, rotational grazing |

Detailed Breakdown of Alternatives

1. Welded Wire Fencing

Welded wire fencing consists of horizontal and vertical wires that are welded together, creating a more robust structure than traditional chicken wire. It is highly durable and can withstand harsh weather conditions, making it suitable for long-term installations. While the initial investment is higher than chicken wire, it offers better protection against larger animals and can serve multiple purposes, including livestock fencing and perimeter security. However, the installation process is more labor-intensive, requiring additional tools and time.

2. Electric Fencing

Electric fencing uses a series of electrified wires to deter animals from crossing a designated boundary. This solution is particularly effective for controlling larger livestock or preventing wildlife incursions. Although the upfront costs are higher due to the need for a power source and additional equipment, electric fencing can be a cost-effective solution in the long run, especially for large areas. Maintenance involves checking the power source and ensuring the integrity of the wires, which can be a drawback for some users. However, its effectiveness in managing animal movement is unparalleled.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the appropriate fencing solution depends on various factors, including the type of animals being contained, the geographical location, and budget constraints. Chicken wire types are ideal for small animals and gardens due to their cost-effectiveness and ease of installation. However, for buyers looking for more robust solutions with greater durability and versatility, welded wire fencing or electric fencing may be preferable. Understanding the specific requirements of your application will guide you in making the best choice for your fencing needs, ensuring both efficiency and long-term value.

Illustrative image related to chicken wire types

Essential Technical Properties and Trade Terminology for chicken wire types

What Are the Key Technical Properties of Chicken Wire Types?

When selecting chicken wire, understanding its technical properties is crucial for ensuring it meets specific needs in various applications, from agricultural to decorative uses. Here are some key specifications that buyers should consider:

-

Material Grade

Chicken wire is typically made from materials such as galvanized steel, stainless steel, or PVC-coated wire. The grade of the material directly impacts durability, resistance to rust and corrosion, and overall lifespan. For example, galvanized wire is treated to resist rust, making it suitable for outdoor applications, while stainless steel offers superior strength and longevity, ideal for environments with harsh weather conditions. -

Wire Gauge

The gauge of wire refers to its thickness, which is critical for the strength and rigidity of the chicken wire. Common gauges range from 14 to 22, with lower numbers indicating thicker wire. Thicker wire (e.g., 14-gauge) is more robust and can withstand higher stress and impact, making it suitable for securing larger animals or heavy-duty fencing applications. -

Mesh Size

The size of the openings in the chicken wire, often measured in millimeters, affects what can be contained or protected. For instance, smaller mesh sizes (e.g., 13 mm) are used for smaller birds and animals, while larger openings (e.g., 25 mm) may be suitable for poultry. Understanding the required mesh size is essential for preventing unwanted intrusions and ensuring the safety of contained animals. -

Roll Length and Width

Chicken wire is available in various roll lengths and widths, typically ranging from 25 ft to 150 ft in length and widths from 2 ft to 6 ft. Choosing the right dimensions is vital for covering specific areas effectively without excessive waste. Buyers should assess their project requirements to select the most suitable dimensions. -

Coating Type

The type of coating on the wire, such as PVC or vinyl, enhances its resistance to environmental factors. PVC-coated wire not only provides a robust barrier against corrosion but also offers aesthetic advantages with color options. This is particularly important in decorative applications where visual appeal is as essential as functionality. -

Twist Type

Chicken wire can be manufactured with different twisting methods, such as single twist or double twist. The twist type affects the wire’s flexibility and strength. Double twist offers enhanced strength, making it ideal for applications requiring more durability, such as fencing for larger animals or in high-wind areas.

What Are Common Trade Terms in the Chicken Wire Industry?

Navigating the chicken wire market requires familiarity with specific trade terminology. Here are some essential terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces components or products that are then marketed by another company under its brand name. In the context of chicken wire, understanding OEM relationships can help buyers source products that meet specific quality standards and specifications. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers to ensure they can meet their project requirements without overcommitting to excess inventory, especially in markets with varying demand. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. It is essential for buyers to craft a detailed RFQ that includes specifications like material grade, mesh size, and quantity to receive accurate and competitive pricing. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for buyers to clarify shipping responsibilities, risks, and costs associated with the delivery of chicken wire. -

Lead Time

Lead time refers to the duration from placing an order to receiving the product. It is important for B2B buyers to understand lead times to effectively plan their projects and ensure timely delivery of materials. -

Certification Standards

Certification standards indicate that a product meets specific quality or safety benchmarks. Familiarity with relevant certifications for chicken wire can help buyers ensure they are sourcing high-quality materials that comply with regional regulations and industry standards.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and project requirements.

Navigating Market Dynamics and Sourcing Trends in the chicken wire types Sector

What Are the Current Market Dynamics and Key Trends Influencing Chicken Wire Types?

The chicken wire types market is witnessing significant growth driven by several global factors. Increasing agricultural activities and a rising demand for poultry farming, particularly in developing regions such as Africa and South America, are major contributors. Additionally, the construction sector’s expansion in the Middle East and Europe is driving the demand for chicken wire as a reliable fencing solution. Emerging technologies in manufacturing, such as automated weaving processes and advanced coating techniques, are enhancing product quality and durability, making chicken wire more appealing to B2B buyers.

Sourcing trends are also evolving, with a noticeable shift towards online procurement platforms. International buyers are leveraging e-commerce to access a broader range of products and suppliers, facilitating competitive pricing and faster delivery times. Additionally, the focus on customization is growing; B2B buyers are increasingly looking for specific mesh sizes and coatings that suit their unique operational needs. Companies that can offer tailored solutions and flexible sourcing options are likely to gain a competitive advantage in this dynamic market.

Illustrative image related to chicken wire types

How Can Sustainability and Ethical Sourcing Influence the Chicken Wire Types Sector?

Sustainability is becoming a critical factor in the chicken wire types sector, with environmental concerns prompting buyers to prioritize eco-friendly materials and ethical sourcing practices. The production of chicken wire, particularly galvanized and PVC-coated options, can have significant environmental impacts due to the use of chemicals and energy-intensive processes. Therefore, suppliers that adopt sustainable manufacturing practices and reduce their carbon footprint are gaining favor among international B2B buyers.

Ethical supply chains are also gaining importance, with many buyers looking for suppliers who adhere to labor rights and fair trade practices. Certifications such as ISO 14001 for environmental management and various green certifications for product materials are becoming essential for suppliers aiming to attract conscientious buyers. By sourcing chicken wire types that are produced sustainably, businesses not only enhance their corporate social responsibility (CSR) profile but also cater to a growing market segment that values environmental stewardship.

What Is the Historical Context of Chicken Wire Types in B2B Markets?

The evolution of chicken wire types can be traced back to its inception as a practical solution for poultry fencing in the early 19th century. Originally crafted from simple galvanized steel, its primary function was to protect livestock from predators while allowing for ventilation and sunlight. Over time, the product diversified into various forms, including PVC-coated and stainless steel options, catering to both agricultural and decorative uses.

As the market expanded, so did the applications of chicken wire. It is now utilized not only in farming but also in construction, art, and landscaping. The increase in urban gardening and DIY projects has further diversified its use, making chicken wire a versatile material in the modern B2B landscape. This historical context underscores the product’s adaptability and continued relevance, providing valuable insights for international buyers looking to source chicken wire types that meet contemporary needs.

Illustrative image related to chicken wire types

Frequently Asked Questions (FAQs) for B2B Buyers of chicken wire types

-

How do I choose the right chicken wire type for my needs?

Choosing the right chicken wire involves understanding your specific requirements. For general poultry enclosures, galvanized wire is cost-effective and durable. If you need a more aesthetic option, PVC-coated wire offers enhanced longevity and resistance to weather conditions. For high-security environments or areas with aggressive wildlife, stainless steel wire is ideal due to its strength and resistance to corrosion. Assess factors such as mesh size, wire gauge, and the intended use (e.g., livestock, gardening, or decorative purposes) to make an informed decision. -

What is the best mesh size for poultry enclosures?

The best mesh size for poultry enclosures typically ranges from 1 inch to 2 inches. A 1-inch mesh is suitable for smaller birds and provides adequate protection against predators, while a 2-inch mesh is often used for larger birds. For areas with specific wildlife threats, consider using finer mesh sizes to ensure maximum protection. Always evaluate the local wildlife and the size of the animals you intend to keep to select the appropriate mesh size that balances safety and practicality. -

What are the standard wire gauges used in chicken wire?

Wire gauges commonly range from 14 to 22. Thicker wires, such as 14-gauge, offer increased durability and strength, making them ideal for high-impact environments. Lighter gauges, like 20 or 22, are suitable for less demanding applications such as garden fencing. When sourcing chicken wire, consider the balance between strength, flexibility, and your specific application to select the appropriate gauge. -

What should I consider when vetting international suppliers for chicken wire?

When vetting international suppliers, prioritize their reputation, experience, and compliance with industry standards. Check for certifications such as ISO or local equivalents, which indicate quality management. Request samples to evaluate product quality and assess customer reviews or testimonials. Additionally, ensure they can meet your volume requirements and have a transparent supply chain to avoid potential issues with delivery and quality control. -

What are the common minimum order quantities (MOQs) for chicken wire?

Minimum order quantities (MOQs) for chicken wire can vary widely among suppliers, typically ranging from 100 to 1,000 meters, depending on the wire type and supplier policies. Larger orders often attract better pricing, while smaller orders may incur higher per-unit costs. Clarify MOQs during negotiations and consider consolidating orders with other buyers if you need smaller quantities to reduce costs. -

What payment terms are typically offered by chicken wire suppliers?

Payment terms vary, but many suppliers offer options such as 30% upfront deposit and 70% upon delivery. Some may accept letters of credit or payment upon shipment. It’s crucial to negotiate terms that align with your cash flow needs and ensure you understand the implications of each option. Always verify the supplier’s payment security measures to protect your financial interests. -

How can I ensure quality assurance (QA) for chicken wire purchases?

To ensure quality assurance, request detailed product specifications and compliance certifications from suppliers. Consider implementing a third-party inspection service to verify product quality before shipment. Establish clear communication regarding your quality expectations and conduct random checks upon delivery. Building a strong relationship with suppliers can also help facilitate better quality control practices. -

What logistics considerations should I keep in mind when importing chicken wire?

When importing chicken wire, consider shipping methods, customs regulations, and potential tariffs or duties. Choose a reliable freight forwarder experienced in handling similar goods to navigate logistics efficiently. Ensure that your documentation is complete, including invoices and certificates of origin, to prevent customs delays. Finally, factor in lead times to align delivery with your project schedules.

Top 3 Chicken Wire Types Manufacturers & Suppliers List

1. The Mesh Company – Chicken Wire Types

Domain: themeshcompany.com

Registered: 2007 (18 years)

Introduction: Chicken Wire Types: 13mm Galvanised Steel, 19mm Galvanised Steel, 25mm Galvanised Steel, 31mm Galvanised Steel, 50mm Galvanised Steel, 13mm Green PVC, 25mm Green PVC, 50mm Green PVC. Key Features: 13mm Galvanised Steel – enhanced security for smaller poultry; 19mm Galvanised Steel – bird deterrent for thatched roofs; 25mm Galvanised Steel – robust protection against larger predators; 31mm Galvanis…

2. Mainline Materials – Heavy-Duty Chicken Wire

Domain: mainlinematerials.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “Heavy-Duty Chicken Wire”, “Price”: “$307.09”, “SKU”: “MM-x5100”, “Material Options”: [{“Type”: “Double Galvanized Steel”, “Size”: “5′ x 100′ Roll”, “Estimated Lifespan”: “6-10 Years”}, {“Type”: “Stainless Steel”, “Size”: “4′ x 100′ Roll”, “Estimated Lifespan”: “25+ Years”}], “Wire Gauge”: “20”, “Mesh Opening”: “3/4″”, “Features”: [“High corrosion and rot resistance”, “Allows wate…

3. Gardeners – Chicken Wire Garden Products

Domain: gardeners.com

Registered: 1995 (30 years)

Introduction: Chicken Wire Garden Products: Sturdy barriers made from high-quality galvanized steel. Designed for durability and longevity. Provides secure protection for chickens from predators while allowing airflow and visibility. Available in various mesh sizes and wire gauges for different poultry types and enclosure sizes. Versatile applications include garden fencing, protecting plants from pests, and cr…

Strategic Sourcing Conclusion and Outlook for chicken wire types

In the rapidly evolving landscape of agricultural and construction materials, the strategic sourcing of chicken wire types presents a significant opportunity for international B2B buyers. Key considerations include understanding the diverse applications of chicken wire—ranging from poultry enclosures to garden protection—and selecting the appropriate material, whether galvanized, stainless steel, or PVC-coated options. Each type offers unique advantages, such as durability, corrosion resistance, and aesthetic appeal, catering to various regional needs and environmental conditions.

As buyers from Africa, South America, the Middle East, and Europe engage with suppliers, prioritizing quality and sustainability will be crucial. Establishing strong supplier relationships can enhance procurement efficiency, ensuring that businesses remain competitive and responsive to market demands.

Looking ahead, the market for chicken wire is expected to grow, driven by increased agricultural activities and construction projects. B2B buyers are encouraged to stay informed about industry trends and emerging technologies that can optimize their sourcing strategies. By aligning procurement practices with these insights, businesses can not only meet current demands but also position themselves for future growth and success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to chicken wire types

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.