Everything You Need to Know About Chem Mill Sourcing in 2025

Introduction: Navigating the Global Market for chem mill

Navigating the intricate landscape of the global market for chemical milling (chem mill) can be daunting for B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. The challenge often lies in sourcing reliable suppliers who can deliver quality materials and services that meet specific industrial requirements. This comprehensive guide addresses these challenges head-on by providing in-depth insights into the various types of chem mill processes, their applications across different industries, and essential considerations for supplier vetting.

Throughout this guide, you will discover critical factors influencing the cost of chem milling services and how to effectively assess potential suppliers to ensure they align with your operational needs. Whether you are looking to etch intricate designs on aerospace components or require precise metal removal for automotive parts, this resource equips you with the knowledge necessary to make informed purchasing decisions.

By understanding the nuances of chem milling, buyers can enhance their procurement strategies, minimize risks, and ultimately streamline their production processes. This guide serves as a pivotal tool for international B2B buyers from Brazil to Germany, enabling them to navigate the complexities of sourcing chem mill solutions effectively and efficiently.

Understanding chem mill Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| All-Over Etching | Uniform removal of metal across the entire surface. | Aerospace components, automotive parts | Pros: Consistent results, simple process. Cons: Limited to uniform thickness applications. |

| Selective Etching | Targeted etching with masked areas for precision. | Electronics, medical devices | Pros: High precision, tailored designs. Cons: More complex setup, potential for longer lead times. |

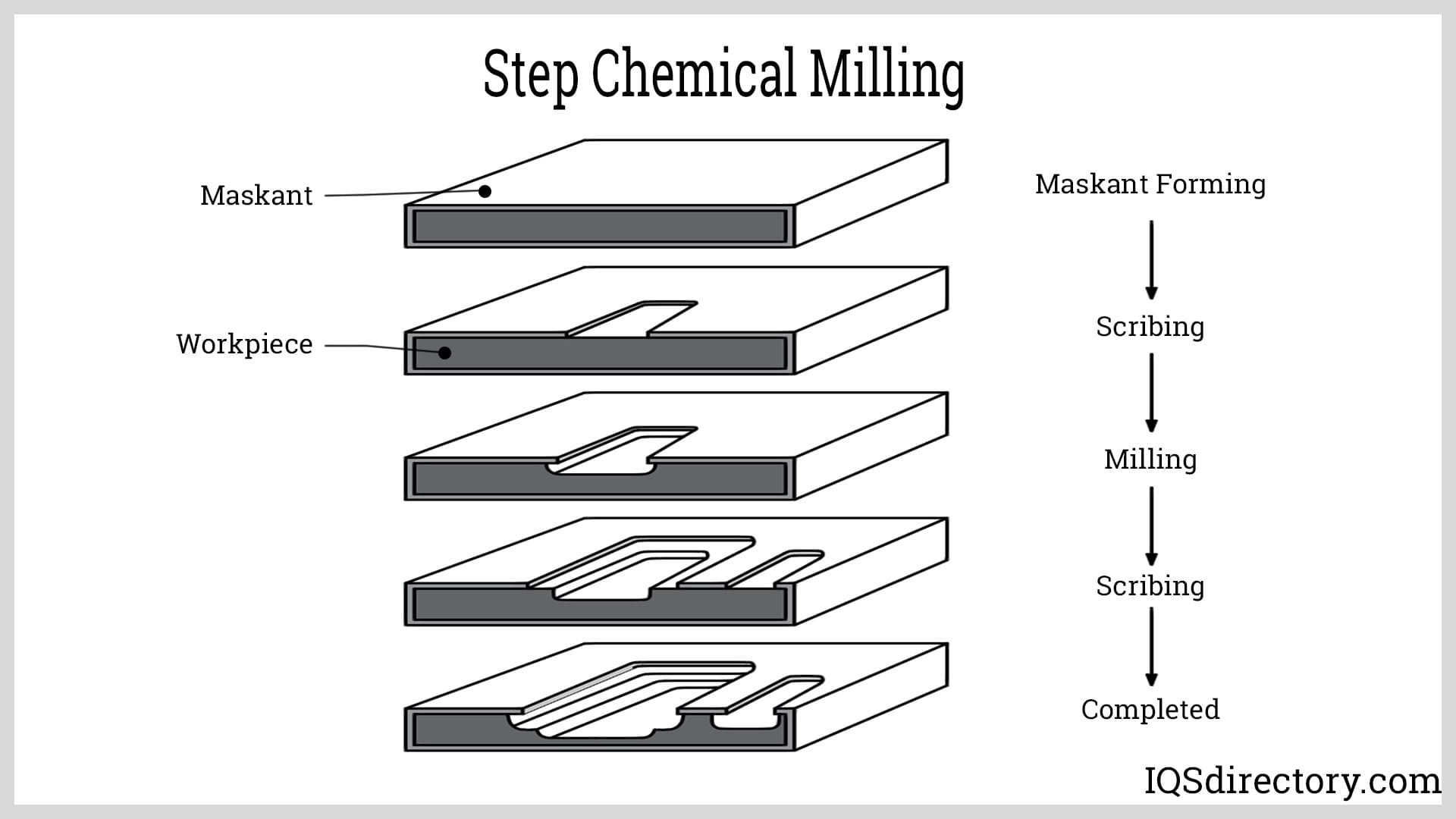

| Step Cut Etching | Progressive etching for varying depths in one part. | Tooling, molds, and dies | Pros: Versatile for complex geometries. Cons: Requires careful planning and execution. |

| Taper Etching | Controlled tapering of parts by adjusting immersion rates. | Aerospace, defense applications | Pros: Produces precise tapers, efficient. Cons: Specialized equipment needed for consistent results. |

| Combination Etching | Integrates multiple techniques for unique profiles. | Custom fabrication, prototyping | Pros: Highly customizable, innovative designs. Cons: Potentially higher costs and longer processing times. |

What are the Characteristics and Suitability of All-Over Etching?

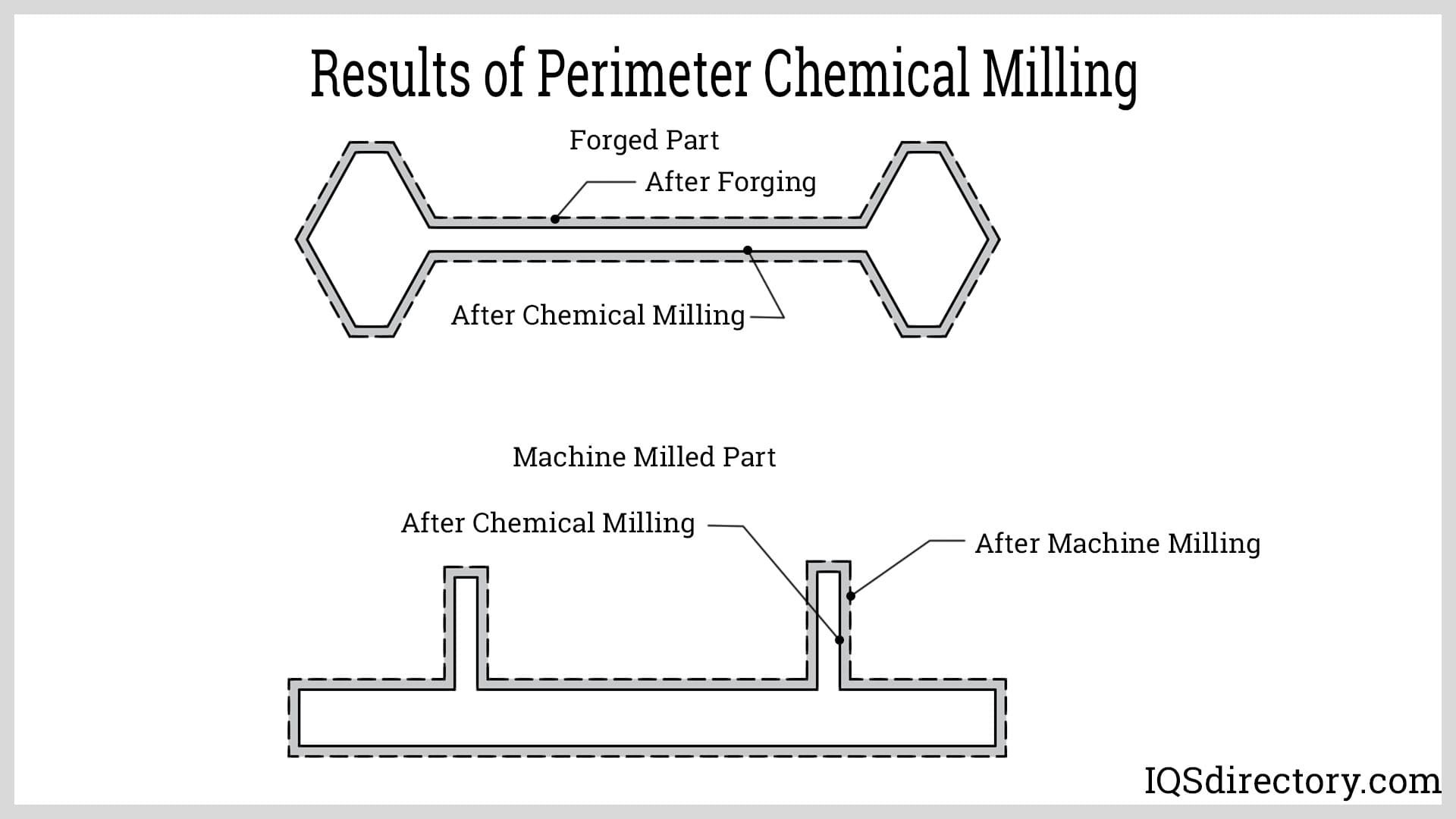

All-Over Etching is characterized by its straightforward approach of uniformly removing metal from the entire surface of a part. This technique is particularly suitable for applications where consistent thickness is essential, such as in aerospace and automotive components. Buyers should consider the simplicity of the process, which allows for rapid production cycles, but note that it may not be ideal for parts requiring varied thicknesses or complex geometries.

How Does Selective Etching Provide Precision?

Selective Etching distinguishes itself by allowing targeted etching of specific areas while masking others. This method is ideal for industries like electronics and medical devices, where precision is paramount. Buyers should weigh the benefits of high accuracy against the complexity of setup and potential lead time increases, as achieving the desired outcomes may require more rigorous quality control measures.

Why is Step Cut Etching Valuable for Complex Geometries?

Step Cut Etching enables the creation of parts with varying depths through a progressive exposure process. This technique is particularly valuable in tooling and mold-making, where intricate designs are common. B2B buyers should consider that while this method offers versatility for complex geometries, it demands meticulous planning and execution to ensure that the final product meets specifications.

Illustrative image related to chem mill

What Advantages Does Taper Etching Offer?

Taper Etching allows for the controlled tapering of parts by adjusting the rate of immersion and withdrawal from the etching solution. This method is especially useful in aerospace and defense applications, where precise tapers are critical for performance. Buyers should be aware that while taper etching yields precise results, it requires specialized equipment to maintain consistency, which can impact overall production costs.

How Does Combination Etching Enhance Custom Fabrication?

Combination Etching merges various etching techniques to achieve unique profiles and designs, making it an excellent choice for custom fabrication and prototyping. This approach provides buyers with the flexibility to create innovative designs tailored to specific needs. However, it is essential to consider that this method may incur higher costs and longer processing times due to its complexity and the need for specialized equipment and expertise.

Key Industrial Applications of chem mill

| Industry/Sector | Specific Application of chem mill | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight component fabrication | Reduces weight while maintaining structural integrity | Quality control of etching solutions and equipment durability |

| Automotive | Custom part design and manufacturing | Enhances performance through precise metal removal | Compliance with industry standards and specifications |

| Electronics | Circuit board and component etching | Improves conductivity and functionality of products | Precision in etch rates and surface finish quality |

| Medical Devices | Creation of specialized surgical instruments | Ensures safety and precision in medical applications | Material compatibility and biocompatibility testing |

| Defense | Production of intricate weapon components | Enhances operational efficiency and reliability | Adherence to strict regulatory requirements and quality assurance |

How is Chem Milling Applied in the Aerospace Sector?

In the aerospace industry, chem milling is utilized for fabricating lightweight components that require precise geometrical configurations. By selectively removing metal, manufacturers can achieve significant weight reductions without compromising structural integrity, which is crucial for aircraft performance and fuel efficiency. International buyers must ensure that the etching solutions used are compliant with aerospace standards and that the equipment can handle the specific alloys commonly used in this sector, such as titanium and aluminum.

What are the Benefits of Chem Milling in Automotive Manufacturing?

In automotive manufacturing, chem milling is applied to create custom parts with complex geometries, such as brackets and housings. This process allows manufacturers to enhance vehicle performance by optimizing weight and strength. Buyers should focus on suppliers that can provide consistent etch rates and surface finishes, as these factors directly impact part performance and longevity. Additionally, understanding the regulatory landscape in various regions, including emissions standards, can guide sourcing decisions.

How Does Chem Milling Improve Electronics Production?

Chem milling plays a vital role in the electronics sector by enabling the precise etching of circuit boards and components. This technique enhances electrical conductivity and minimizes material waste, leading to cost-effective production processes. For international buyers, it is essential to source suppliers who can guarantee high precision and quality control, particularly in terms of etch rates and surface finishes, as these attributes are critical for the functionality and reliability of electronic devices.

Why is Chem Milling Important for Medical Device Manufacturing?

In the medical device industry, chem milling is used to create specialized surgical instruments that require high precision and biocompatibility. The ability to selectively remove material ensures that instruments meet stringent safety standards while maintaining functionality. Buyers in this sector should prioritize sourcing from manufacturers who can demonstrate expertise in biocompatible materials and rigorous quality testing processes to ensure compliance with medical regulations.

How Does Chem Milling Contribute to Defense Manufacturing?

The defense industry employs chem milling to produce intricate components for weaponry and other military applications. This process allows for the creation of parts that enhance operational efficiency and reliability, which are critical in defense operations. Buyers must consider sourcing from suppliers that adhere to strict regulatory requirements and can provide comprehensive quality assurance documentation, as any failure in component performance can have significant implications.

3 Common User Pain Points for ‘chem mill’ & Their Solutions

Scenario 1: Inconsistent Etch Rates Leading to Quality Issues

The Problem:

One of the most pressing challenges B2B buyers face in the chemical milling process is achieving consistent etch rates across different batches. Variability in etch rates can lead to quality discrepancies in finished products, which is particularly detrimental for industries like aerospace and automotive, where precision is non-negotiable. Buyers may find that parts are either over-etched or under-etched due to fluctuations in chemical composition, temperature control, or even the age of the etching solutions. This inconsistency not only affects product quality but can also result in costly reworks and delays in production schedules.

The Solution:

To overcome this challenge, it is crucial to establish a robust quality control protocol that includes regular testing and monitoring of etch rates. B2B buyers should invest in advanced analytical tools to evaluate etch rates periodically and ensure that they remain within the desired range. This includes using test panels that correspond to the materials being processed, as outlined in industry best practices. Moreover, buyers should consider sourcing etching solutions from reputable suppliers who provide detailed specifications and guidance on maintaining optimal conditions. Implementing a systematic approach to documenting and analyzing etch rates over time will enable buyers to identify patterns and adjust the immersion time and chemical concentration accordingly, ensuring uniform quality across all batches.

Scenario 2: Equipment Downtime and Maintenance Challenges

The Problem:

Chemical milling operations often face unexpected equipment downtime due to maintenance issues, which can significantly disrupt production timelines and increase operational costs. B2B buyers may encounter challenges with the etching tanks and auxiliary systems, such as agitation mechanisms or heating elements, leading to suboptimal performance. This can be particularly frustrating when buyers rely on tight schedules to meet client demands, as delays can cascade throughout the supply chain.

The Solution:

To mitigate the risk of downtime, buyers should adopt a proactive maintenance strategy that includes regular inspections and scheduled servicing of all equipment involved in the chemical milling process. Establishing a partnership with equipment manufacturers or service providers can also facilitate timely access to replacement parts and expert support. Additionally, investing in modern monitoring systems that provide real-time data on equipment performance can help buyers identify potential issues before they escalate. Training staff on routine maintenance procedures and best practices will further enhance operational efficiency and reduce the likelihood of unexpected interruptions.

Scenario 3: Environmental Compliance and Chemical Disposal Issues

The Problem:

With increasing regulatory scrutiny regarding environmental impact, B2B buyers in the chemical milling sector often grapple with compliance challenges related to the use of hazardous chemicals and the disposal of waste products. Non-compliance can lead to hefty fines and damage to the company’s reputation, especially in regions with strict environmental laws, such as Europe. Buyers may struggle to understand the nuances of local regulations and the implications for their chemical milling processes.

The Solution:

To navigate these complexities, buyers should prioritize compliance by staying informed about local and international regulations governing chemical usage and waste disposal. Collaborating with environmental consultants can provide insights into best practices for chemical management and waste disposal. Buyers should also consider sourcing eco-friendly alternatives to traditional etching solutions that comply with environmental standards without compromising performance. Implementing a comprehensive waste management plan that includes recycling and safe disposal of chemicals will not only ensure compliance but can also enhance the company’s sustainability profile. Regular training for employees on environmental policies and procedures will further instill a culture of compliance and responsibility within the organization.

Strategic Material Selection Guide for chem mill

What Are the Key Properties of Aluminum in Chemical Milling Applications?

Aluminum is one of the most commonly used materials in chemical milling due to its favorable properties. It boasts excellent corrosion resistance, particularly when treated with appropriate coatings, and has a relatively low density, which makes it ideal for applications requiring lightweight components. Aluminum can withstand moderate temperatures and pressures, making it suitable for various chemical environments. However, its etch rate can vary significantly depending on the alloy and heat treatment, necessitating careful monitoring during the milling process.

Illustrative image related to chem mill

Pros and Cons: The primary advantage of aluminum is its lightweight nature combined with good strength-to-weight ratios, making it ideal for aerospace and automotive applications. On the downside, aluminum can be more expensive than other metals like steel and may require specialized handling to prevent oxidation and surface imperfections during the etching process.

Impact on Application: Aluminum’s compatibility with various etching solutions allows for precise control over the etching process, which is essential in applications requiring intricate designs. However, international buyers must be aware of specific alloy standards and certifications, such as ASTM B557 for aluminum alloys, to ensure compliance with local regulations.

How Does Stainless Steel Perform in Chemical Milling Processes?

Stainless steel is another popular choice for chemical milling, known for its exceptional corrosion resistance and mechanical strength. It can withstand higher temperatures and pressures compared to aluminum, making it suitable for more demanding applications. The most common grades used in chemical milling are 304 and 316, which offer different balances of corrosion resistance and strength.

Pros and Cons: The key advantage of stainless steel is its durability and resistance to pitting and crevice corrosion, making it ideal for harsh chemical environments. However, it is generally heavier and more expensive than aluminum, which may impact cost-effectiveness in large-scale applications.

Impact on Application: Stainless steel’s robust nature allows it to be used in a variety of chemical environments, including acidic and alkaline solutions. International buyers should consider compliance with standards such as ASTM A240 for stainless steel sheets and plates, which can vary significantly across regions like Europe and South America.

What Role Does Titanium Play in Chemical Milling?

Titanium is a high-performance material known for its superior strength-to-weight ratio and exceptional corrosion resistance, particularly in aggressive environments. It can handle extreme temperatures and pressures, making it suitable for specialized applications in aerospace and medical devices. However, titanium’s cost and manufacturing complexity can be significant drawbacks.

Pros and Cons: The primary advantage of titanium is its ability to withstand extreme conditions without degrading, which is crucial in high-stakes applications. The downside is its high cost and the complexity involved in machining and etching, which may deter some manufacturers from using it.

Impact on Application: Titanium is particularly effective for applications requiring biocompatibility and resistance to harsh chemicals. Buyers in international markets must be aware of compliance with standards such as ASTM B348 for titanium and titanium alloys, which can affect sourcing and pricing.

How Does Copper Compare in Chemical Milling Applications?

Copper is often used in chemical milling for its excellent thermal and electrical conductivity, making it ideal for applications in electronics and electrical components. It has good corrosion resistance, especially when alloyed with other metals, and can be easily etched to achieve precise designs.

Pros and Cons: The main advantage of copper is its cost-effectiveness and ease of machining, which makes it a popular choice for many applications. However, it is less durable than aluminum and stainless steel, and its susceptibility to oxidation can pose challenges during the etching process.

Impact on Application: Copper’s compatibility with various etching solutions allows for detailed work, but its oxidation can affect the final product’s quality. International buyers should consider compliance with standards like ASTM B152 for copper sheets, which can vary across regions.

Summary Table of Material Selection for Chemical Milling

| Material | Typical Use Case for chem mill | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components | Lightweight with good strength-to-weight ratio | Higher cost and requires careful handling | Medium |

| Stainless Steel | Chemical processing equipment | Exceptional corrosion resistance and durability | Heavier and more expensive than aluminum | High |

| Titanium | Aerospace and medical devices | Superior strength and corrosion resistance | High cost and complex machining | High |

| Copper | Electrical components | Excellent conductivity and cost-effective | Less durable and prone to oxidation | Low |

This guide provides a comprehensive overview of the strategic material selection for chemical milling, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for chem mill

What Are the Key Stages in the Manufacturing Process of Chemical Milling?

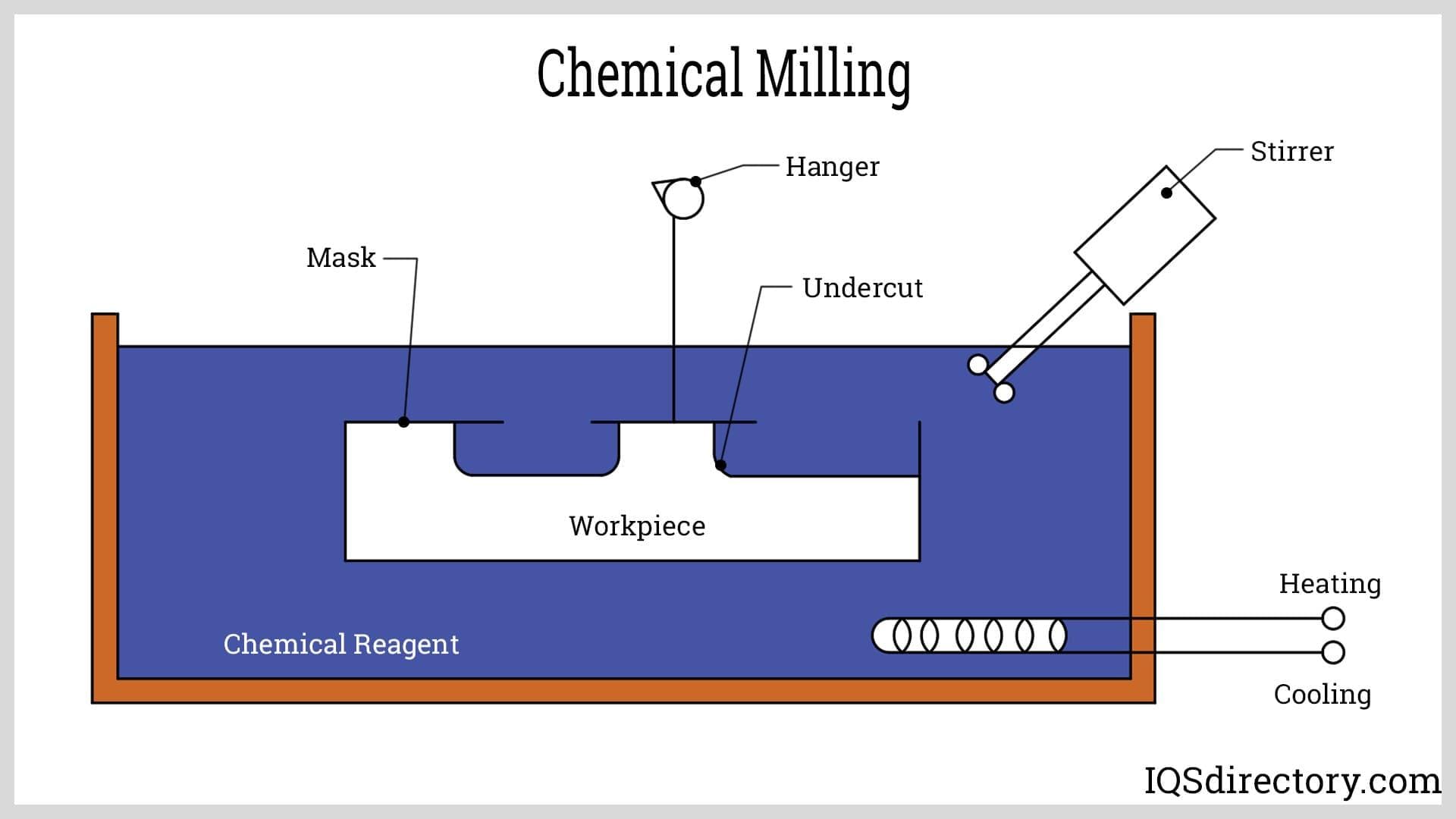

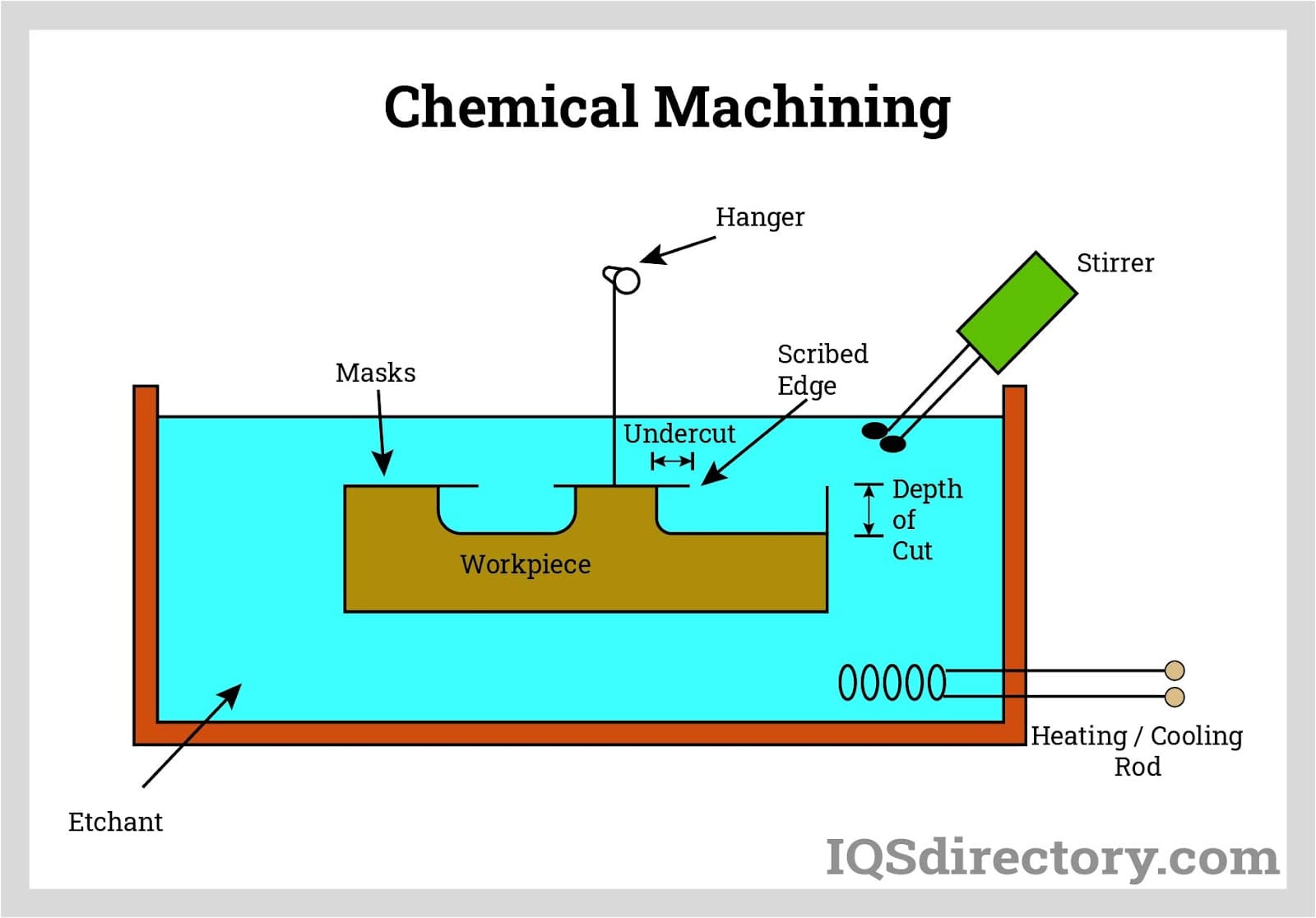

Chemical milling, or chem mill, is a sophisticated manufacturing process that involves the controlled removal of metal from a workpiece using chemical etchants. The manufacturing stages can be broadly categorized into material preparation, forming, assembly, and finishing.

How is Material Prepared for Chemical Milling?

The first step in the chem milling process is material preparation, which includes selecting the appropriate substrate and ensuring that it meets quality standards. Common materials used in chem milling include aluminum, titanium, and certain stainless steels. The selected material must be thoroughly cleaned to remove any surface contaminants, such as oils or dirt, that could interfere with the etching process. This cleaning is typically done through a combination of ultrasonic cleaning and chemical baths, ensuring a pristine surface for uniform etching.

Once cleaned, the material may undergo pre-treatment processes, such as anodizing or surface modification, depending on the final application requirements. This pre-treatment can enhance adhesion for subsequent coatings or improve resistance to corrosion.

What Techniques Are Used in the Forming Stage of Chemical Milling?

In the forming stage, the specific design of the part is established through a process of masking and etching. Parts are often masked using photoresist materials that define areas to be etched and those to remain intact. This masking is critical for achieving intricate designs and precise dimensions.

Once masked, the parts are submerged in etching solutions tailored to the specific material and desired etch depth. The etching solutions are formulated to ensure uniform metal removal, with careful control of concentration and temperature to optimize etch rates. The process may involve multiple immersion cycles to achieve the desired depth and detail.

How Does Assembly Fit into the Chemical Milling Process?

While chem milling typically focuses on the etching process, assembly may be required for complex components involving multiple parts. In such cases, chem-milled components may be joined using techniques such as welding or adhesive bonding. The assembly process must ensure that the integrity and specifications of the chem-milled parts are maintained.

Quality checks should be integrated into the assembly process to identify any potential issues early on, ensuring that the final product meets all design specifications.

What Finishing Techniques Are Applied After Chemical Milling?

The finishing stage in chemical milling is crucial for achieving the desired surface quality and functional properties. After etching, parts typically undergo rinsing to remove etchant residues. This is usually done in a series of rinse tanks, which may include both deep rinsing and low-pressure sprays to ensure thorough cleaning.

Depending on the application, additional finishing processes may include passivation, surface coating, or polishing to enhance corrosion resistance or aesthetic appeal. Each of these processes should be carefully controlled to ensure that they do not compromise the dimensions or integrity of the chem-milled features.

Illustrative image related to chem mill

How is Quality Assurance Implemented in Chemical Milling?

Quality assurance (QA) in chemical milling is critical for ensuring that the final products meet international standards and customer specifications. The QA process typically involves adherence to international standards such as ISO 9001, along with industry-specific certifications like CE or API.

What Are the Key Quality Control Checkpoints in Chemical Milling?

Quality control (QC) in chem milling is typically segmented into three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): During this stage, raw materials are inspected for compliance with specifications. This involves checking for material properties, dimensions, and cleanliness. Only materials that pass this initial inspection move forward in the production process.

-

In-Process Quality Control (IPQC): Throughout the chem milling process, regular checks are performed to monitor etch rates, solution concentrations, and surface finishes. This ensures that the process remains within defined tolerances and any deviations are corrected promptly.

-

Final Quality Control (FQC): Once the parts are completed, they undergo thorough inspections, which may include dimensional checks, visual inspections, and functional testing. This stage verifies that the finished products meet all requirements before shipping.

What Testing Methods Are Commonly Used in Chemical Milling Quality Assurance?

Common testing methods in the QC process for chemical milling include:

- Dimensional Inspection: Utilizing tools such as calipers, micrometers, and coordinate measuring machines (CMM) to confirm that the parts meet specified dimensions.

- Surface Finish Testing: Employing techniques like profilometry to assess the surface roughness and integrity.

- Metallurgical Testing: Conducting tests such as hardness testing or microstructure analysis to ensure material properties are within specified limits.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality assurance is essential. Here are actionable steps:

-

Supplier Audits: Conduct on-site audits of suppliers to assess their manufacturing capabilities, processes, and adherence to quality standards. This provides firsthand insight into their operations and quality management systems.

-

Review Quality Reports: Request quality assurance reports, including any certifications and compliance documents related to ISO standards or industry-specific requirements. These documents can offer valuable information about the supplier’s commitment to quality.

-

Third-Party Inspections: Engage third-party inspection agencies to perform independent assessments of the supplier’s processes and products. This adds an extra layer of assurance regarding quality and compliance.

-

Understanding Certification Nuances: Different regions may have unique certification requirements. Buyers should familiarize themselves with local standards to ensure that suppliers meet relevant regulations, especially in industries such as aerospace or automotive, where compliance is critical.

By following these steps and understanding the manufacturing and quality assurance processes involved in chemical milling, B2B buyers can make informed decisions when selecting suppliers and ensure that the products they procure meet their specific requirements and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chem mill’

Introduction

This guide is designed to assist B2B buyers in effectively sourcing chemical milling (chem mill) services. By following this step-by-step checklist, you will ensure that you select a supplier capable of meeting your specific requirements while maintaining quality and efficiency in the chem milling process.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical specifications. This includes the materials to be used, the dimensions of the parts, and the desired finish. Providing detailed specifications helps suppliers understand your needs and reduces the likelihood of miscommunication or errors during production.

- Material Types: Specify whether you need aluminum, titanium, or other metals.

- Dimensional Tolerances: Include precise measurements to avoid discrepancies.

- Surface Finish Requirements: Indicate if a particular finish is necessary for your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in chem milling. Look for companies with a proven track record in your industry, as well as positive reviews and testimonials from previous clients.

- Industry Experience: Focus on suppliers with experience in your specific sector.

- Geographic Considerations: Consider suppliers located in regions with favorable shipping options to your location.

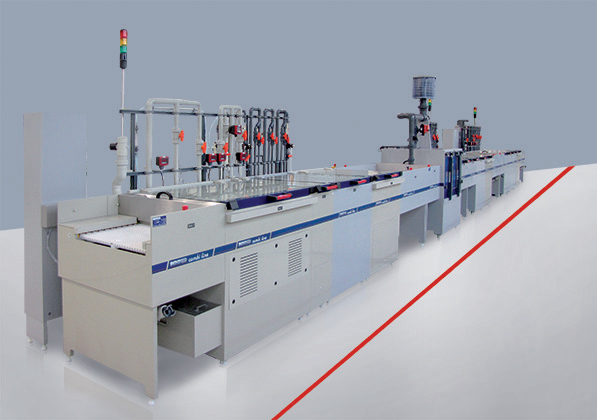

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each supplier to ensure they can meet your specific requirements. This includes examining their equipment, technology, and workforce expertise.

- Equipment and Technology: Confirm they have modern etching tanks and control systems.

- Workforce Skills: Ensure their team is skilled in handling the complexities of chem milling.

Step 4: Verify Certifications and Compliance

Check that potential suppliers hold relevant certifications and adhere to industry standards. This is crucial for ensuring quality and compliance with safety regulations.

Illustrative image related to chem mill

- ISO Certifications: Look for ISO 9001 or other relevant quality management certifications.

- Environmental Compliance: Ensure they follow local and international environmental regulations.

Step 5: Request Samples and Conduct Trials

Before making a long-term commitment, request samples or conduct trial runs. This allows you to evaluate the quality of their work and the effectiveness of their processes.

- Sample Parts: Ask for small-scale parts that reflect your specifications.

- Trial Runs: Consider running a small batch to assess turnaround times and quality.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms. Transparency in costs can help you budget appropriately and avoid unexpected expenses later on.

- Cost Breakdown: Request a detailed quote including all potential fees.

- Payment Options: Understand their payment terms, including deposits and credit options.

Step 7: Establish Communication and Support Channels

Ensure clear communication channels are established with your chosen supplier. Good communication is vital for addressing any issues that may arise during the production process.

- Dedicated Account Manager: Having a point of contact can streamline communication.

- Feedback Mechanism: Establish a process for providing and receiving feedback throughout the project.

Following this checklist will guide you in making informed decisions when sourcing chem milling services, ultimately leading to successful partnerships and high-quality outcomes.

Comprehensive Cost and Pricing Analysis for chem mill Sourcing

What Are the Key Cost Components in Chem Mill Sourcing?

When sourcing chem milling services, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of materials being processed significantly impacts costs. Metals like aluminum or titanium may have varying prices based on market conditions, alloy specifications, and availability. Buyers should consider the specific grades of materials required for their applications, as higher-grade materials typically come at a premium.

-

Labor: Skilled labor is crucial in the chem milling process, especially for managing the etching operation and ensuring quality control. Labor costs can vary by region; for example, labor in Europe may be more expensive than in South America or Africa. Understanding local wage rates and labor regulations can help buyers estimate labor-related expenses.

-

Manufacturing Overhead: This encompasses costs associated with running the facility, including utilities, rent, and equipment maintenance. Overhead rates can fluctuate based on the location of the supplier and the scale of their operations, impacting the overall cost of services.

-

Tooling: Specialized tooling and fixtures may be required for specific parts or designs. The initial investment in tooling can be significant but is often amortized over large production runs. Buyers should inquire about tooling costs, especially if they anticipate long-term contracts or repeat orders.

-

Quality Control (QC): Quality assurance processes are critical in chem milling to ensure that specifications are met. Costs associated with QC can include testing, inspections, and certifications. Buyers should factor in these costs to avoid potential rework or compliance issues.

-

Logistics: The transportation of raw materials to the facility and finished products to the buyer adds another layer of cost. Logistics expenses can vary significantly depending on the distance, mode of transport, and any tariffs or import duties applicable, especially for international shipments.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. Understanding the average industry margins can help buyers gauge whether they are receiving competitive pricing.

How Do Price Influencers Affect Chem Milling Costs?

Several factors can influence the pricing of chem milling services:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should assess their volume needs to negotiate better pricing.

-

Specifications and Customization: Custom parts often incur higher costs due to the need for specialized tooling and processes. Buyers should be clear about their requirements to receive accurate quotes.

-

Material Selection: The choice of material affects not only the base price but also the processing costs. Unique alloys or materials with specific certifications may command higher prices.

-

Quality and Certifications: Parts requiring specific industry certifications (e.g., aerospace, medical) may incur additional costs. Buyers should discuss these requirements upfront to avoid surprises in pricing.

-

Supplier Factors: The reputation and location of the supplier can influence pricing. Established suppliers with proven track records may charge a premium, while newer or less reputable suppliers may offer lower prices but come with higher risks.

-

Incoterms: Understanding the delivery terms is crucial. Incoterms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, all of which can affect the total cost.

What Buyer Tips Can Help Negotiate Better Chem Milling Prices?

To optimize sourcing strategies for chem milling, consider these tips:

-

Negotiate Based on Volume: Leverage potential order volumes to negotiate better pricing. Suppliers are often willing to offer discounts for larger commitments.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider long-term costs, including maintenance, downtime, and logistics, to determine the true cost of sourcing.

-

Understand Pricing Nuances: Be aware of regional pricing differences and how local economic conditions may affect supplier costs. For instance, suppliers in Brazil might offer different pricing strategies compared to those in Germany or the Middle East.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and service levels. Trust and communication can yield favorable terms over time.

-

Request Detailed Quotes: Ensure that quotes break down costs clearly, allowing for easier comparison between suppliers. This transparency can facilitate better negotiation.

Disclaimer

The prices discussed in this analysis are indicative and may vary based on specific project requirements, market conditions, and supplier negotiations. Always seek updated quotes and conduct due diligence when engaging suppliers.

Alternatives Analysis: Comparing chem mill With Other Solutions

Introduction: What Are the Alternatives to Chem Milling?

In the realm of metal processing, chem milling has established itself as a reliable method for achieving precise designs and shapes through controlled etching. However, several alternatives exist that can also fulfill similar objectives. Understanding these alternatives is crucial for B2B buyers looking to optimize their manufacturing processes. This analysis will compare chem milling with laser cutting and traditional machining, focusing on their performance, costs, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | ‘Chem Mill’ | Laser Cutting | Traditional Machining |

|---|---|---|---|

| Performance | High precision with complex shapes | Excellent for intricate designs | Good for standard shapes |

| Cost | Moderate, depending on setup | High initial investment, but low per unit cost | Variable; high tooling costs |

| Ease of Implementation | Requires specialized equipment | Requires specialized laser systems | Common, widely available tools |

| Maintenance | Regular maintenance of chemical baths | Minimal, but laser optics require care | High due to tool wear and tear |

| Best Use Case | Aerospace, automotive parts | Prototyping, signage, and intricate designs | Bulk production of simple parts |

Detailed Breakdown of Alternatives

Laser Cutting: Is It the Right Choice for You?

Laser cutting utilizes focused laser beams to melt or vaporize material, offering exceptional precision. This method excels in creating intricate designs and is particularly effective for thin materials. However, it comes with a high initial investment for the equipment and may not be cost-effective for high-volume production unless the unit costs are amortized over a large quantity. Additionally, while maintenance is generally minimal, the laser optics require regular cleaning and calibration to maintain performance.

Traditional Machining: When Should It Be Considered?

Traditional machining involves removing material through cutting tools and is suitable for creating a wide range of shapes. It is often the go-to method for high-volume production of simple parts due to its established processes and readily available machinery. However, it can incur significant tooling costs and longer lead times, especially for complex geometries. Maintenance is a critical factor, as tools wear out and require frequent replacements, increasing operational costs.

Conclusion: How to Choose the Right Solution for Your Needs?

Selecting the appropriate manufacturing method depends on several factors, including the complexity of the part, production volume, budget constraints, and material type. Chem milling is ideal for applications requiring high precision and complex shapes, particularly in industries like aerospace and automotive. Conversely, laser cutting may be more suitable for intricate designs and lower volume prototypes, while traditional machining can be the best option for high-volume production of simpler parts. B2B buyers should assess their specific requirements and consider not only the initial investment but also the long-term operational costs and maintenance needs associated with each method.

Essential Technical Properties and Trade Terminology for chem mill

What Are the Key Technical Properties of Chem Milling?

When engaging in the chem milling process, understanding the essential technical properties is crucial for ensuring precision, quality, and efficiency in production. Here are some critical specifications that international buyers should be aware of:

1. Material Grade

Material grade refers to the specific classification of metals or alloys used in chem milling, such as aluminum, titanium, or stainless steel. Each grade exhibits different etching characteristics and responses to chemical solutions. Understanding material grade is vital for achieving desired outcomes, as different materials may require unique etching times and solutions. For instance, aluminum alloys often demand specialized etchants to avoid surface irregularities.

2. Etch Rate

The etch rate is defined as the depth of metal removed per unit time, typically expressed in mils per surface per minute (M/S/M). This metric is essential for calculating immersion times to achieve specific design features. For B2B buyers, knowing the etch rate allows for better planning and scheduling of production runs, ensuring that timelines and quality standards are met.

3. Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of a part after chem milling. This specification is critical for parts that must fit within tight assembly constraints. Understanding tolerance levels helps manufacturers maintain quality control and avoid costly rework or scrappage, which can significantly impact overall project costs and timelines.

4. Surface Finish

Surface finish denotes the texture and smoothness of the etched surface. Different applications may require specific surface finishes to meet aesthetic or functional requirements. Buyers should consider the intended use of the components being produced, as varying surface finishes can affect adhesion, wear resistance, and overall performance.

5. Chemical Resistance

Chemical resistance is the ability of a material to withstand exposure to etching solutions without degrading. This property is particularly important for parts that will face harsh environments or require longevity in their applications. A thorough understanding of chemical resistance helps buyers select suitable materials and processes that align with their end-use conditions.

What Common Trade Terms Should B2B Buyers Know in Chem Milling?

Familiarity with industry jargon is essential for effective communication and negotiation in the chem milling sector. Here are some commonly used trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that are used in another company’s end products. In chem milling, understanding the OEM relationship is important for buyers looking to source components that meet specific quality and design standards required by their clients.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell in a single order. Knowing the MOQ is critical for buyers as it impacts inventory management and cash flow. Buyers must balance their needs against the supplier’s MOQ to ensure they are making cost-effective purchasing decisions.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of goods or services. For B2B buyers, issuing an RFQ is an essential step in the procurement process, enabling them to compare options and make informed purchasing decisions.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined rules that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to manage shipping, insurance, and risk effectively, ensuring that both parties have clear expectations regarding delivery and costs.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For buyers in the chem milling industry, understanding lead times is essential for project planning and scheduling, ensuring that production timelines align with operational needs.

By grasping these technical properties and trade terms, international B2B buyers can navigate the chem milling landscape more effectively, making informed decisions that align with their production goals and market demands.

Navigating Market Dynamics and Sourcing Trends in the chem mill Sector

What Are the Current Market Dynamics and Key Trends in the Chem Mill Sector?

The chemical milling (chem mill) sector is currently experiencing a transformative phase driven by several global factors. The rise of lightweight materials in industries such as aerospace and automotive is a significant driver, pushing manufacturers to adopt chem milling processes for precision and efficiency. This method allows for intricate designs and weight reductions, which are crucial for modern applications. Furthermore, technological advancements, including automation and digital monitoring, are enhancing production efficiency and quality control. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note that these regions are witnessing increased demand for chem milling services due to burgeoning manufacturing sectors.

Emerging trends also indicate a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers who implement eco-friendly processes, such as closed-loop systems that minimize waste and energy consumption. Additionally, the integration of Industry 4.0 technologies, including IoT and AI, is revolutionizing how chem mill operations are managed, offering real-time data analytics for better decision-making. This trend not only improves operational efficiency but also ensures compliance with international quality standards, making it vital for B2B buyers to align with suppliers who are at the forefront of these innovations.

How Does Sustainability and Ethical Sourcing Impact the Chem Mill Sector?

Sustainability is becoming a core focus for the chem mill sector, as environmental regulations tighten and consumers demand greener practices. The chemical milling process, by its nature, can have substantial environmental impacts, including chemical waste and energy usage. Therefore, companies that prioritize sustainability are not only protecting the environment but also enhancing their brand reputation and market competitiveness.

For B2B buyers, understanding the importance of ethical supply chains is crucial. Suppliers that can demonstrate their commitment to sustainability through certifications like ISO 14001 or adherence to green chemistry principles are increasingly preferred. Moreover, sourcing ‘green’ materials, such as biodegradable or recycled substances, is becoming a priority, aligning with global sustainability goals. Buyers should actively seek partnerships with chem mill manufacturers who integrate eco-friendly practices into their operations, ensuring that their supply chains are not only efficient but also responsible.

Illustrative image related to chem mill

What Is the Evolution of the Chem Mill Sector and Its Relevance Today?

The chem mill sector has evolved significantly since its inception in the mid-20th century, transitioning from manual processes to highly automated and precision-driven operations. Initially used primarily in the aerospace industry for lightweight components, chem milling has expanded its applications across various sectors, including automotive, electronics, and medical devices. This evolution has been marked by advancements in chemical formulations and technology that enhance etching processes and improve surface finishes.

Today, the relevance of chem milling is underscored by its ability to meet the demands for complex geometries and stringent tolerances required in modern manufacturing. As industries continue to innovate, the chem mill sector stands out as a critical enabler of progress, offering solutions that not only fulfill technical specifications but also align with sustainability goals. For international B2B buyers, understanding this evolution is key to making informed sourcing decisions that will impact their operational efficiency and market positioning.

Frequently Asked Questions (FAQs) for B2B Buyers of chem mill

-

How do I choose the right chemical milling supplier for my business?

Selecting a chemical milling supplier requires thorough research and evaluation. Start by assessing their experience and expertise in the specific materials and processes relevant to your needs. Check for certifications and compliance with international quality standards, such as ISO 9001. It’s essential to review customer testimonials and case studies to gauge their reliability. Additionally, inquire about their capacity to handle your expected order volume and turnaround times. Establishing clear communication channels and understanding their customer service approach can also help in building a long-term partnership. -

What are the advantages of chemical milling over traditional machining methods?

Chemical milling offers several advantages, including the ability to create complex geometries and intricate designs without the mechanical stress associated with traditional machining. This method minimizes material waste, as it removes only the necessary metal, leading to cost savings. Additionally, chemical milling can achieve uniform surface finishes and precise depth control, which may be challenging with conventional techniques. This process is also highly adaptable, allowing for the etching of various materials and alloys, making it suitable for diverse applications across industries. -

What customization options are available in chemical milling services?

Many chemical milling suppliers offer customization options to meet specific project requirements. This may include tailoring etching solutions to accommodate different materials or alloys, adjusting etch rates for precision, and creating bespoke designs as per your specifications. Additionally, suppliers may provide options for masking techniques to achieve selective etching or step cuts. Discussing your needs in detail with the supplier can help identify the best methods for customization, ensuring the final product aligns with your project objectives. -

What is the minimum order quantity (MOQ) for chemical milling services?

The minimum order quantity for chemical milling can vary significantly between suppliers. Some may accept small batches for prototyping or testing, while others may require larger orders to ensure cost-effectiveness. When sourcing suppliers, inquire about their MOQ policies and any associated pricing structures. Understanding these requirements upfront can help you plan your production schedules and budget accordingly, ensuring that you can meet your demand without incurring unnecessary costs. -

What payment terms should I expect when sourcing chemical milling services?

Payment terms for chemical milling services can differ based on the supplier and the scale of the order. Common arrangements include upfront payments, partial deposits, or payment upon delivery. It’s essential to negotiate terms that align with your cash flow and procurement processes. Additionally, clarify any implications for late payments or changes in order volume. Establishing clear payment terms in the contract can help avoid misunderstandings and ensure a smooth transaction. -

How can I ensure quality assurance in my chemical milling projects?

To ensure quality assurance in chemical milling projects, request detailed information about the supplier’s quality control processes. This should include testing methods for etch rates, surface finishes, and dimensional accuracy. Look for suppliers that follow established quality standards and have a robust inspection protocol in place. You can also consider requesting samples before committing to a large order to evaluate the quality of their work firsthand. Regular communication and feedback during the production process can further enhance quality assurance. -

What logistics considerations should I be aware of when sourcing chemical milling services internationally?

When sourcing chemical milling services internationally, logistics play a crucial role in ensuring timely delivery and cost efficiency. Consider factors such as shipping methods, customs regulations, and potential tariffs that may affect your overall costs. It’s important to choose suppliers that have experience with international shipping and can provide documentation to facilitate customs clearance. Additionally, assess the lead times involved in production and shipping to avoid delays in your supply chain. Collaborating with logistics partners familiar with international trade can also streamline the process. -

What are the environmental considerations in chemical milling processes?

Environmental considerations in chemical milling are increasingly important for sustainability and compliance with regulations. Suppliers should adhere to environmentally friendly practices, such as using less harmful etchants and proper waste disposal methods. Inquire about their environmental management systems and any certifications they hold, such as ISO 14001. Understanding how a supplier manages chemical waste and emissions can help ensure that your sourcing aligns with your corporate responsibility goals and regulatory requirements in your region.

Top 6 Chem Mill Manufacturers & Suppliers List

1. IQS Directory – Chemical Milling Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Chemical milling is a process used to selectively remove material from a workpiece through controlled exposure to a corrosive setting. It involves using chemicals, specifically formulated etching solutions, to erode targeted areas of metal. Key components include a protective coating (mask or maskant) to shield areas not meant for etching. The process is advantageous for altering surfaces, reducin…

2. Ducommun – Chem Milling Solutions

Domain: ducommun.com

Registered: 1996 (29 years)

Introduction: Chem Milling process selectively removes material while maintaining structural strength. Material weight reductions of 75% or more and thickness reductions down to .010″ or less. Capable of chemically milling a variety of materials including aluminums, titaniums, and steels. Suitable for rolled, cast, extruded, or formed materials. Provides close tolerance results that conventional machining metho…

3. ScienceDirect – Chemical Milling Process

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Chemical milling is a controlled dissolution process that removes material from a workpiece surface using strong inorganic acids or bases. It is a subtractive machining process that utilizes temperature-regulated etching chemicals to produce shapes, blind features like pockets and channels, and reduce weight. The process involves five steps: cleaning, masking, scribing, etching, and demasking. Key…

4. High Tech Etch – Chemical Milling Solutions

Domain: hightechetch.com

Registered: 2014 (11 years)

Introduction: Chem milling (Chemical Milling) involves immersing a part in an etching solution to remove metal and create a pre-determined design. The process can achieve various configurations such as tapers, selective reductions, or uniform reductions in dimensions. The main equipment consists of a series of tanks filled with special etching solutions, designed for rapid transfer of parts during etching, rins…

5. AAAIR Support – Chemical Milling Solutions

Domain: aaaairsupport.com

Registered: 2006 (19 years)

Introduction: Chemical milling, also known as industrial etching, is a manufacturing process that uses temperature-regulated etching chemicals to remove material and create desired shapes, primarily on metals like aluminum and steel. The process involves bathing metal parts in a corrosive chemical (etchant) while using maskants to protect areas not being milled. It is commonly used in the aerospace industry to …

6. SupraAlloys – Precision Chemical Milling Solutions

Domain: supraalloys.com

Registered: 1996 (29 years)

Introduction: Chemical milling on titanium, aluminum, nickel, and stainless steel. Key features include:

– Subtractive manufacturing method, particularly effective for titanium due to its strength-to-weight ratio and corrosion resistance.

– Achieves precise dimensions and thickness tolerances through selective material removal.

– Offers exceptional accuracy, tight tolerances, and repeatability, ensuring consist…

Strategic Sourcing Conclusion and Outlook for chem mill

As the global demand for precision-engineered components continues to rise, strategic sourcing in the chemical milling sector presents a significant opportunity for international buyers. By understanding the intricacies of the chem milling process—such as etch rates, immersion times, and the types of etching available—businesses can optimize their procurement strategies to ensure high-quality outputs while minimizing costs.

Investing in reliable suppliers that offer advanced etching solutions and robust equipment is crucial for maintaining competitive advantage. Buyers should prioritize partnerships that emphasize quality control, environmental compliance, and innovative techniques to enhance efficiency and reduce waste.

Illustrative image related to chem mill

Looking ahead, the chem milling market is poised for growth, driven by advancements in technology and increasing applications across various industries, including aerospace, automotive, and electronics. B2B buyers from regions like Africa, South America, the Middle East, and Europe must leverage these trends by aligning their sourcing strategies with suppliers that demonstrate a commitment to innovation and sustainability.

In conclusion, embracing a strategic sourcing approach will not only bolster operational efficiency but also pave the way for long-term partnerships that can adapt to evolving market needs. Engage with your suppliers today to explore tailored solutions that meet your unique requirements and position your business for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to chem mill

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.