Everything You Need to Know About Centrifugal Pump Parts Sourcing in 2025

Introduction: Navigating the Global Market for centrifugal pump parts

In the dynamic landscape of global industrial operations, sourcing high-quality centrifugal pump parts can be a daunting challenge for B2B buyers. With diverse applications across sectors such as oil and gas, manufacturing, and wastewater treatment, the demand for reliable components is paramount. This guide delves into the intricacies of centrifugal pump parts, providing a thorough overview of the various types, their applications, and critical considerations for procurement.

Understanding the nuances of centrifugal pump components—from impellers and casings to bearings and seals—is essential for making informed purchasing decisions. This comprehensive resource will empower international buyers, particularly those in Africa, South America, the Middle East, and Europe, to navigate the complexities of the market with confidence. Additionally, we will explore supplier vetting strategies, cost implications, and best practices for ensuring quality and efficiency in pump operations.

By equipping yourself with the knowledge presented in this guide, you can streamline your sourcing process, mitigate risks, and enhance operational efficiency. Whether you are looking to optimize existing systems or invest in new technologies, this guide serves as your roadmap to successfully navigating the global market for centrifugal pump parts.

Understanding centrifugal pump parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Impeller | Varies in design (open, semi-open, closed) to suit different fluids | Wastewater management, chemical processing | Pros: Enhances fluid velocity; Cons: Selection affects efficiency. |

| Casing | Can be volute or diffuser type, single or multi-stage | Oil & gas, nuclear, desalination | Pros: Optimizes flow; Cons: Complex designs may increase costs. |

| Shaft Seal | Prevents leaks, includes mechanical seals and packing seals | Pulp and paper, chemical manufacturing | Pros: Essential for containment; Cons: Maintenance can be challenging. |

| Bearings | Types include ball, roller, and sleeve bearings | Heavy-duty applications, manufacturing | Pros: Supports shaft alignment; Cons: Wear can lead to increased maintenance. |

| Diffuser | Converts velocity to pressure, enhances efficiency | Water treatment, industrial pumping systems | Pros: Improves pressure output; Cons: Requires careful design to avoid cavitation. |

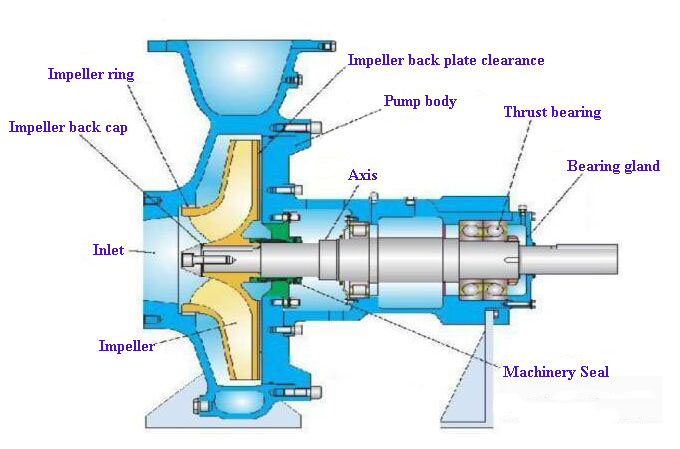

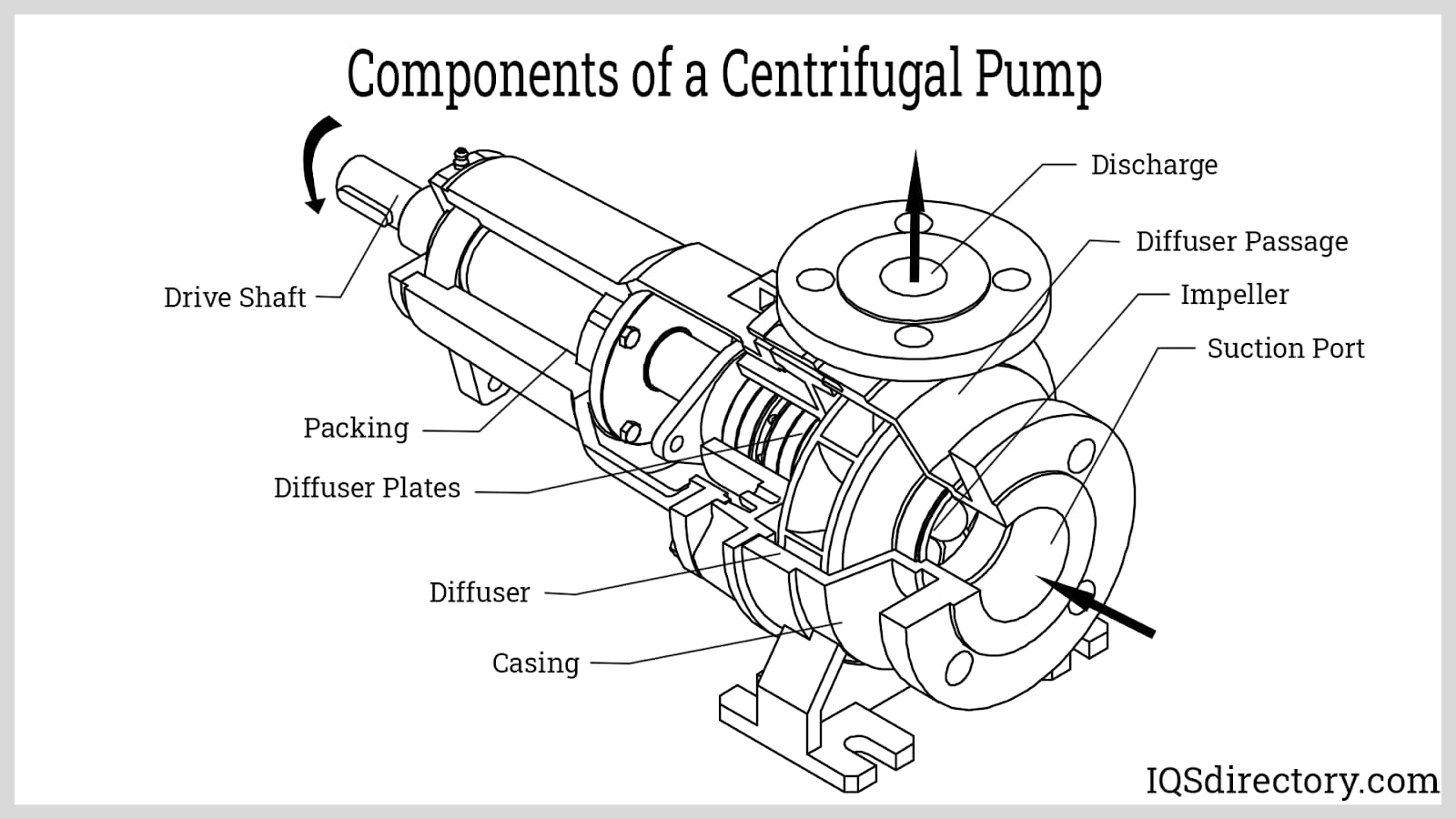

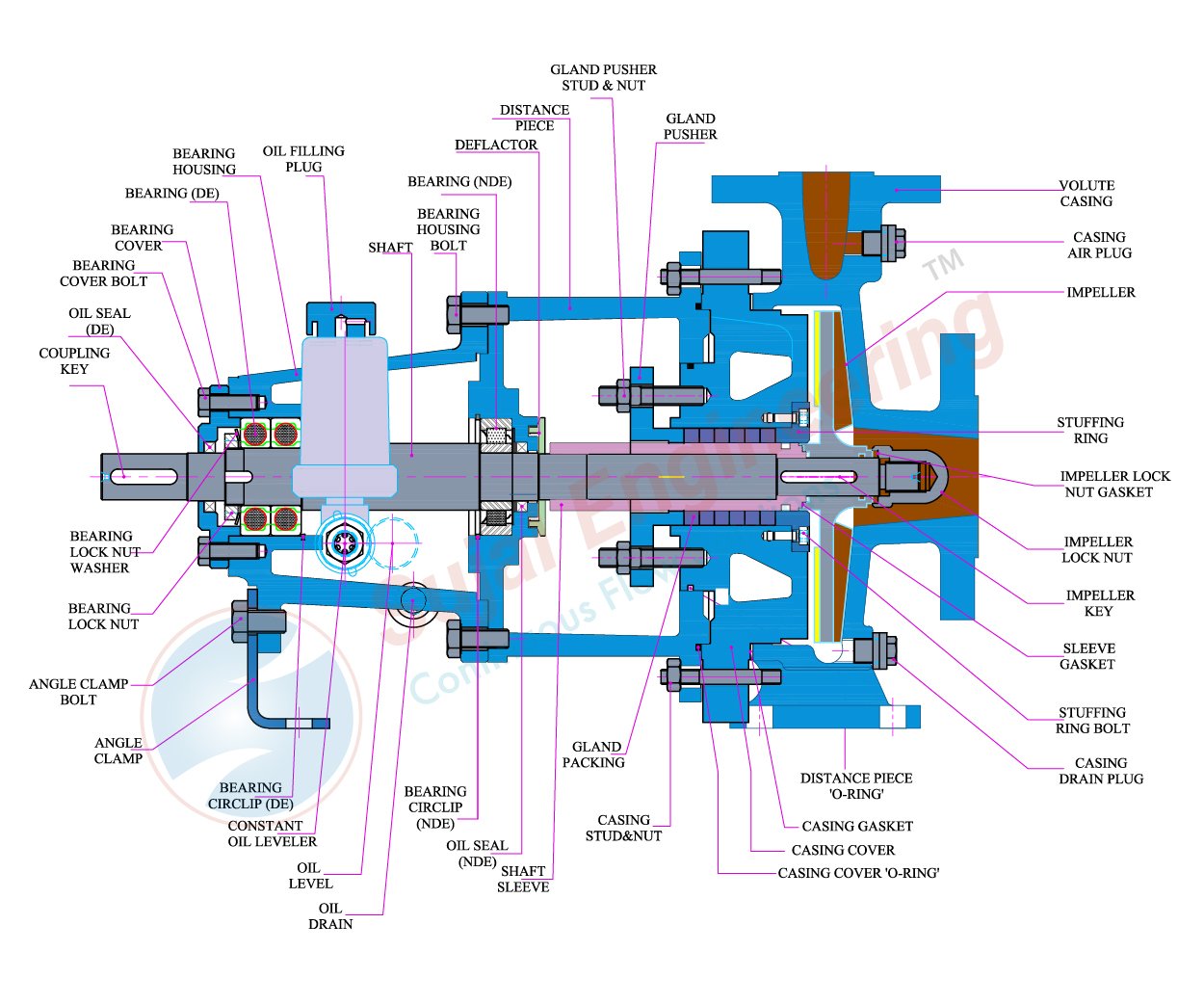

What Are the Key Characteristics of Impellers in Centrifugal Pumps?

Impellers are fundamental components of centrifugal pumps, responsible for increasing the velocity of liquids through centrifugal force. Available in various designs, including open, semi-open, and closed, each type is tailored to specific applications. Open impellers are ideal for handling liquids with solids, while closed impellers are better suited for clean liquids. When purchasing, consider the fluid type and operational conditions, as the impeller design significantly influences pump efficiency and performance.

How Does Casing Type Impact Centrifugal Pump Functionality?

The casing of a centrifugal pump is crucial for guiding fluid flow and maintaining pressure. It can be designed as either a volute or diffuser type and may be single or multi-stage, depending on the required pressure increase. Multi-stage casings are beneficial for applications that demand significant pressure boosts, such as in oil and gas industries. Buyers should evaluate the casing design relative to their specific application needs, as an improper choice can lead to inefficiencies and increased operational costs.

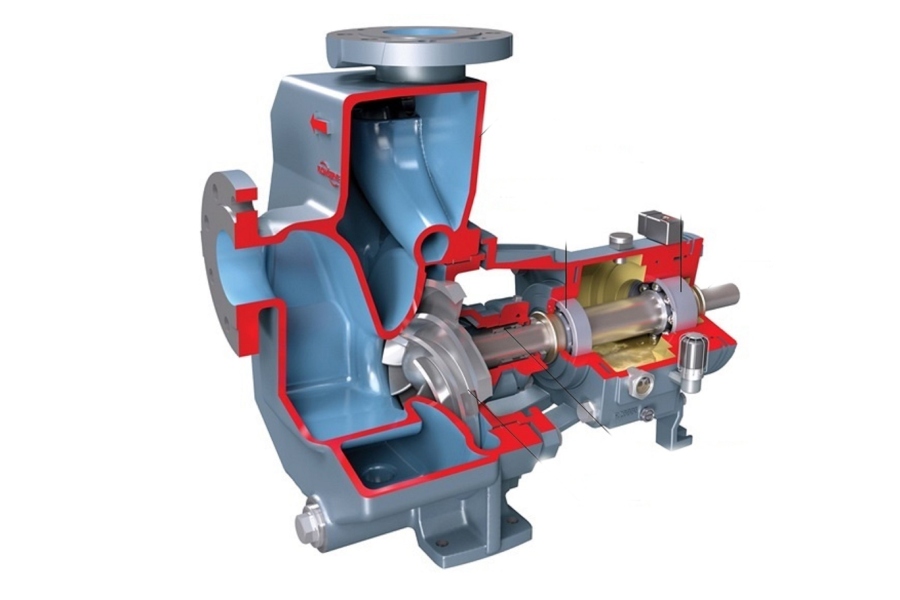

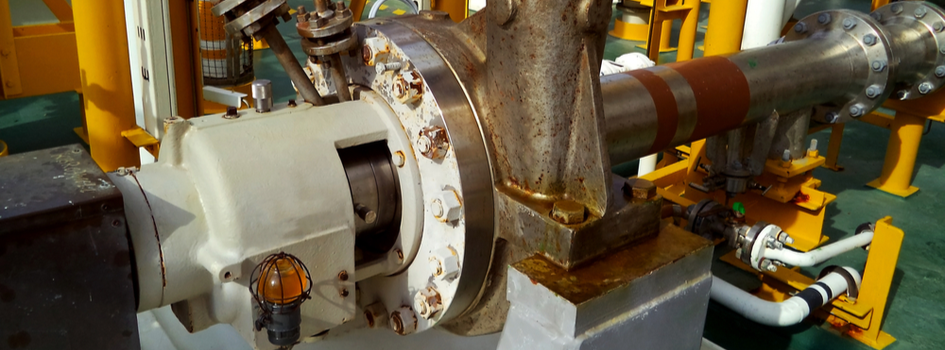

Illustrative image related to centrifugal pump parts

Why Are Shaft Seals Important in Centrifugal Pumps?

Shaft seals are critical components that prevent fluid leakage from the pump, ensuring operational integrity. They can be mechanical seals or gland packing seals, with the choice depending on the application and the type of fluid being handled. Industries such as pulp and paper and chemical manufacturing rely heavily on effective sealing solutions to maintain system efficiency. Buyers must consider the seal type based on temperature, pressure, and fluid characteristics to avoid leaks and reduce maintenance costs.

What Role Do Bearings Play in Centrifugal Pumps?

Bearings support the shaft and are vital for the smooth operation of centrifugal pumps. They come in various types, including ball, roller, and sleeve bearings, each suited for different applications. Properly selected bearings can minimize friction and enhance pump efficiency, particularly in heavy-duty environments. However, buyers should be aware that bearings can wear over time, leading to increased maintenance and replacement costs. The choice of bearing type should align with the operational demands of the specific application.

How Does the Diffuser Enhance Pump Efficiency?

The diffuser in a centrifugal pump plays a crucial role in converting the velocity of the fluid exiting the impeller into pressure. This component is essential for achieving optimal pump efficiency and is particularly relevant in water treatment and industrial pumping systems. Buyers should ensure that the diffuser design is compatible with their specific application to avoid issues like cavitation, which can severely impact performance. The right diffuser can significantly improve overall system efficiency and reduce energy consumption.

Key Industrial Applications of centrifugal pump parts

| Industry/Sector | Specific Application of centrifugal pump parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Crude oil extraction and transportation | Efficient fluid transfer reduces operational costs | Compliance with API standards and material durability |

| Water Treatment | Wastewater management systems | Enhanced flow rates improve treatment efficiency | Resistance to corrosion and compatibility with chemicals |

| Chemical Manufacturing | Chemical mixing and processing | Precise control over fluid dynamics ensures product quality | Customization options for impeller and casing designs |

| Food & Beverage | Beverage production and bottling | Maintains hygiene and product integrity | Compliance with food safety regulations and ease of cleaning |

| Agriculture | Irrigation systems | Reliable water supply boosts crop yield | Energy efficiency and adaptability to varying fluid types |

How Are Centrifugal Pump Parts Utilized in the Oil & Gas Industry?

In the oil and gas sector, centrifugal pump parts are crucial for the extraction and transportation of crude oil. These pumps handle high-viscosity fluids and operate under extreme conditions. The efficient transfer of oil not only minimizes operational costs but also ensures timely delivery to processing facilities. For international buyers, it is essential to source pumps that comply with API standards and are constructed from materials that can withstand corrosive environments typical in this industry.

What Role Do Centrifugal Pump Parts Play in Water Treatment?

Centrifugal pumps are vital in wastewater management systems, where they facilitate the movement of water through various treatment stages. By enhancing flow rates, these pumps significantly improve the efficiency of treatment processes, leading to better water quality. Buyers in this sector must prioritize sourcing pumps that resist corrosion and are compatible with the diverse chemicals used in water treatment, ensuring longevity and reliability.

How Are Centrifugal Pump Parts Applied in Chemical Manufacturing?

In chemical manufacturing, centrifugal pump parts are employed for mixing and processing various chemicals. The design of impellers and casings can be customized to meet specific operational requirements, allowing for precise control over fluid dynamics. This precision is crucial for maintaining product quality and safety. B2B buyers should consider sourcing options that allow for tailored configurations while ensuring compliance with relevant industry standards.

Why Are Centrifugal Pump Parts Important in Food & Beverage Production?

Centrifugal pumps are extensively used in the food and beverage industry for production and bottling processes. These pumps help maintain hygiene standards and product integrity by ensuring that fluids are transferred without contamination. For international buyers, it is vital to source pumps that comply with food safety regulations and offer ease of cleaning, as these factors directly impact product quality and compliance with health standards.

How Do Centrifugal Pump Parts Benefit Agricultural Irrigation Systems?

In agriculture, centrifugal pump parts are integral to irrigation systems, providing a reliable water supply to enhance crop yield. The efficiency of these pumps ensures that water is delivered consistently, even in varying conditions. Buyers in this sector should focus on sourcing energy-efficient pumps that can adapt to different fluid types and flow rates, supporting sustainable agricultural practices.

3 Common User Pain Points for ‘centrifugal pump parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Components

The Problem: Many B2B buyers face the challenge of sourcing high-quality centrifugal pump parts that meet specific industry standards. In regions like Africa and South America, where supply chains may be less developed, buyers often encounter inconsistent quality, leading to performance issues or premature failure of pumps. This can result in costly downtime and repair expenses, particularly in industries reliant on continuous operations, such as oil and gas or water treatment.

The Solution: To mitigate these challenges, buyers should establish relationships with reputable suppliers who specialize in centrifugal pump components. Conduct thorough research to identify suppliers with a proven track record in quality assurance and compliance with international standards, such as ANSI or API. Additionally, consider utilizing third-party inspection services to verify the quality of components before purchase. This proactive approach not only ensures the reliability of the parts but also builds trust with suppliers, enabling better negotiation on price and terms in the future.

Scenario 2: Inefficiencies Caused by Incorrect Specifications

The Problem: Specifying the correct parts for centrifugal pumps can be daunting, particularly for buyers who may not have in-depth technical knowledge. Incorrect specifications can lead to inefficiencies, such as inadequate flow rates or excessive energy consumption, ultimately impacting the operational costs of the entire system. This is especially critical in regions where energy costs are high, and every efficiency gain can significantly affect the bottom line.

The Solution: To overcome this issue, buyers should invest time in understanding the operational parameters of their systems. Collaborate closely with engineers or pump specialists to define the required specifications, including flow rates, pressure requirements, and compatibility with the fluids being pumped. Furthermore, utilizing advanced simulation tools can help visualize how different components will perform in real-world conditions. This strategic approach enables buyers to make informed decisions, ensuring the selected centrifugal pump parts enhance overall system efficiency.

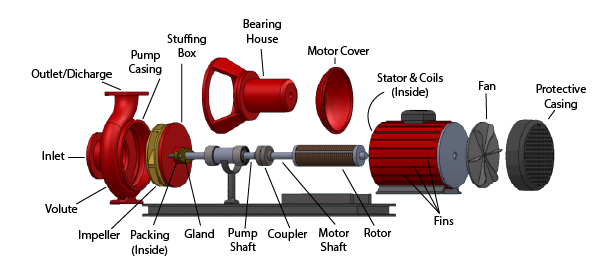

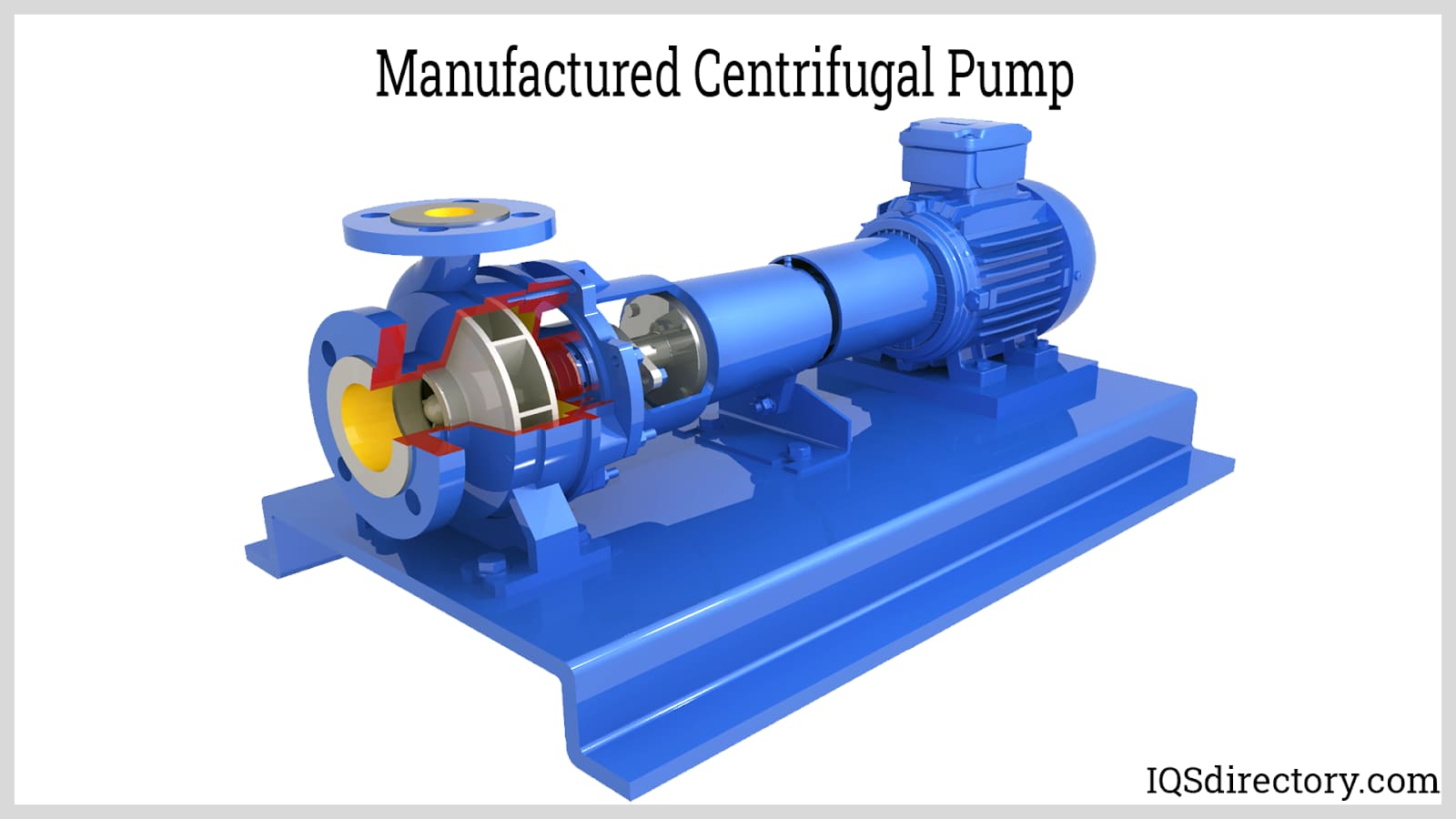

Illustrative image related to centrifugal pump parts

Scenario 3: Challenges with Maintenance and Downtime

The Problem: Maintenance of centrifugal pump parts is often overlooked, leading to unexpected failures and significant downtime. In industries such as mining or manufacturing, where pumps operate continuously, even minor issues can escalate quickly into major disruptions. Buyers frequently find themselves unprepared for maintenance needs, facing delays in obtaining replacement parts or technical support, which can severely impact productivity.

The Solution: To address maintenance challenges, buyers should implement a structured maintenance program that includes regular inspections and a schedule for replacing wear components like bearings and seals. Establishing a partnership with a reliable service provider can facilitate timely access to spare parts and technical expertise. Additionally, consider investing in predictive maintenance technology that utilizes IoT sensors to monitor pump performance in real-time. This proactive strategy not only minimizes unplanned downtime but also allows for more efficient use of resources, ultimately enhancing operational reliability and longevity of the pumps.

Strategic Material Selection Guide for centrifugal pump parts

What Are the Key Materials for Centrifugal Pump Parts?

When selecting materials for centrifugal pump parts, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. The choice of material can significantly impact the pump’s performance, longevity, and overall operational efficiency. Below, we analyze four common materials used in centrifugal pump components.

How Does Stainless Steel Perform in Centrifugal Pump Applications?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. Common grades include 304 and 316, which offer varying levels of corrosion resistance, particularly in harsh environments.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, making it ideal for applications involving aggressive fluids. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase production costs.

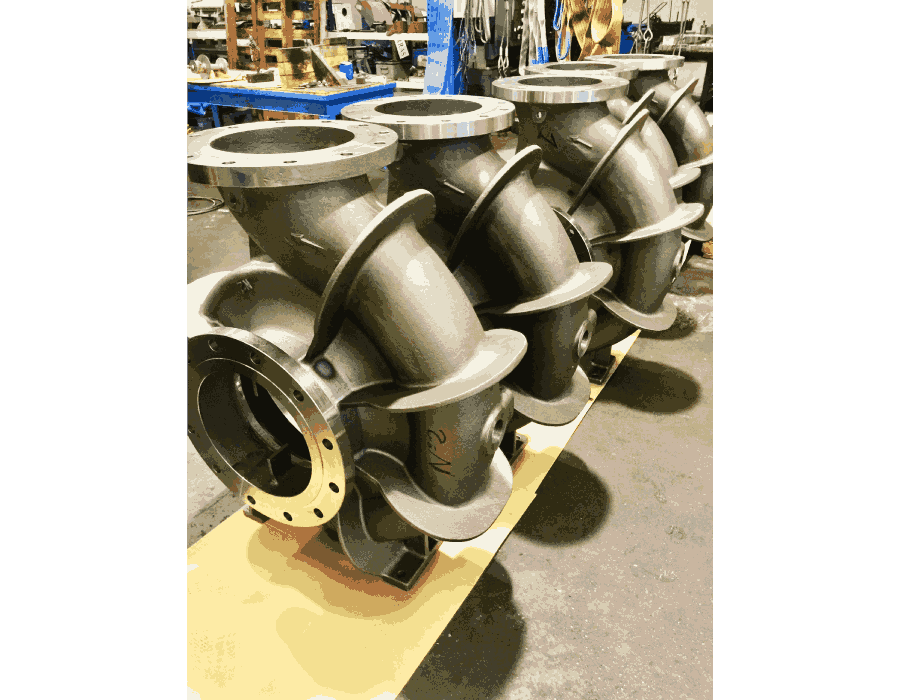

Illustrative image related to centrifugal pump parts

Impact on Application: Stainless steel is compatible with a wide range of media, including water, chemicals, and food products. Its properties make it suitable for industries such as food processing, pharmaceuticals, and petrochemicals.

Considerations for International Buyers: Buyers in regions like Africa, South America, and the Middle East should ensure compliance with international standards such as ASTM and ISO. The availability of specific grades can vary by region, impacting procurement strategies.

What Advantages Does Cast Iron Offer for Centrifugal Pumps?

Key Properties: Cast iron is characterized by its excellent wear resistance and ability to absorb shock. It typically operates well under moderate temperature and pressure conditions, making it suitable for a variety of applications.

Pros & Cons: The main advantage of cast iron is its cost-effectiveness and durability in less corrosive environments. However, it is susceptible to corrosion and may not be suitable for applications involving aggressive chemicals or high temperatures.

Impact on Application: Cast iron is commonly used in municipal water systems and wastewater treatment facilities, where the media is less aggressive. Its weight and strength make it a reliable choice for heavy-duty applications.

Considerations for International Buyers: Buyers should be aware of regional manufacturing standards (e.g., DIN for Europe) and ensure that the cast iron components meet the necessary specifications for their specific applications.

Why Choose Polypropylene for Certain Centrifugal Pump Parts?

Key Properties: Polypropylene is a thermoplastic polymer known for its excellent chemical resistance, lightweight nature, and low-cost manufacturing. It can withstand temperatures up to 80°C (176°F) and is often used in less demanding applications.

Pros & Cons: The primary advantage of polypropylene is its resistance to a wide range of chemicals, making it suitable for handling corrosive fluids. However, it has lower mechanical strength compared to metals and may not be suitable for high-pressure applications.

Impact on Application: Polypropylene is ideal for applications in the chemical processing industry, particularly for transporting acids and bases. Its lightweight nature can also reduce installation costs.

Considerations for International Buyers: Buyers should verify compliance with local and international standards, especially when dealing with food-grade applications. Understanding the specific chemical compatibility is crucial for ensuring safe operations.

Illustrative image related to centrifugal pump parts

How Does Bronze Compare for Centrifugal Pump Components?

Key Properties: Bronze is an alloy of copper and tin, known for its excellent corrosion resistance, especially in seawater and other aggressive environments. It also exhibits good wear resistance and thermal conductivity.

Pros & Cons: The key advantage of bronze is its durability and ability to withstand corrosion in marine applications. However, it is generally more expensive than cast iron and may require more complex manufacturing processes.

Impact on Application: Bronze is often used in pumps that handle seawater, brine, or other corrosive fluids, making it a popular choice in marine and chemical industries.

Considerations for International Buyers: Buyers should ensure that the bronze components meet industry standards such as ASTM B584. Availability and cost can vary significantly by region, impacting procurement decisions.

Summary Table of Material Selection for Centrifugal Pump Parts

| Material | Typical Use Case for centrifugal pump parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Cast Iron | Municipal water systems, wastewater treatment | Cost-effective and durable | Susceptible to corrosion | Medium |

| Polypropylene | Chemical processing, handling acids | Lightweight and chemically resistant | Lower mechanical strength | Low |

| Bronze | Marine applications, corrosive fluids | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides a comprehensive overview of the key materials used in centrifugal pump parts, enabling international B2B buyers to make informed decisions tailored to their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for centrifugal pump parts

Centrifugal pumps are crucial components in various industrial applications, and their efficiency largely depends on the quality of their parts. Understanding the manufacturing processes and quality assurance protocols for these parts is essential for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This guide outlines the typical stages involved in the manufacturing of centrifugal pump parts, highlights key quality control (QC) measures, and provides actionable insights for international buyers.

What Are the Main Stages of Manufacturing Centrifugal Pump Parts?

Manufacturing centrifugal pump parts involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets industry standards and performs reliably under various operating conditions.

How Is Material Prepared for Centrifugal Pump Parts?

Material preparation begins with selecting high-quality raw materials, typically metals such as cast iron, stainless steel, or various alloys, depending on the application requirements. This selection process is crucial, as it impacts durability, corrosion resistance, and overall performance.

Once the materials are chosen, they undergo processes such as cutting, machining, and surface treatment to enhance their properties. Machining techniques like turning, milling, and grinding are employed to achieve precise dimensions and tolerances essential for components like impellers, casings, and shafts.

What Forming Techniques Are Used in Manufacturing?

The forming stage involves shaping the prepared materials into specific components. Common techniques include casting, forging, and stamping.

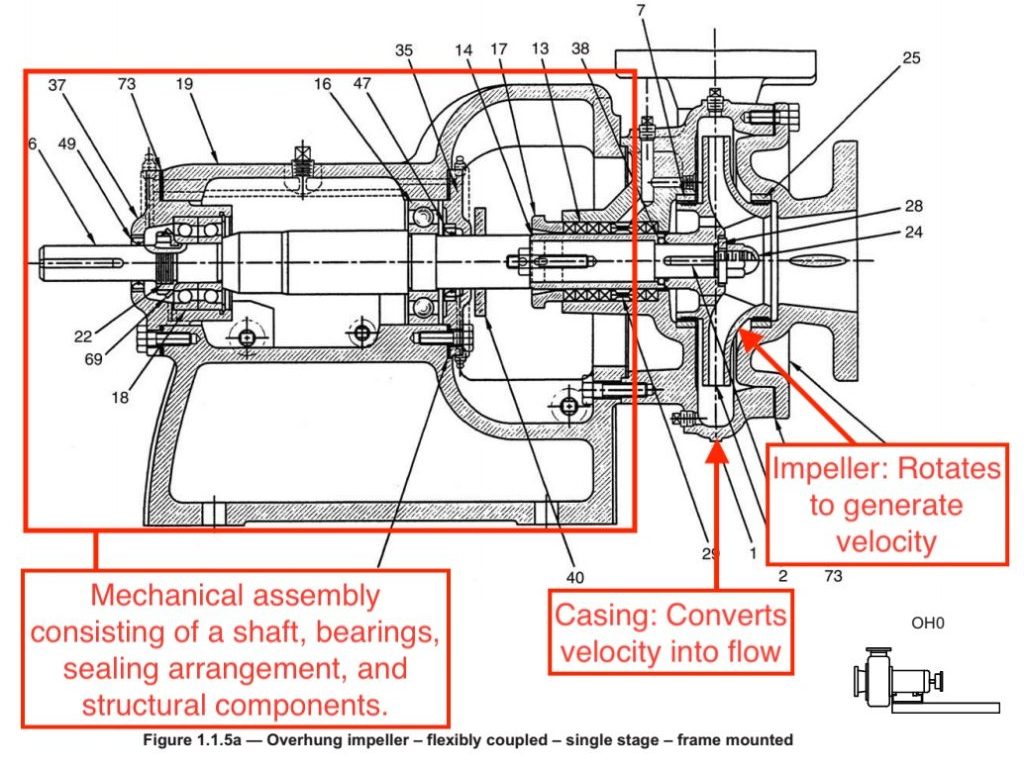

Illustrative image related to centrifugal pump parts

- Casting: Used predominantly for creating complex shapes, this process involves pouring molten metal into molds. It is particularly effective for producing impellers and volute casings.

- Forging: This technique involves shaping metal using compressive forces. Forged components tend to exhibit superior strength and durability, making them ideal for high-stress applications.

- Stamping: Used for producing flat parts, stamping involves pressing metal sheets into desired shapes. This is often used for simpler components like flanges or brackets.

How Are Centrifugal Pump Parts Assembled?

Assembly is a critical phase that combines individual components into a complete pump system. This stage includes fitting impellers onto shafts, attaching seals, and integrating bearings. Proper alignment and torque specifications are vital to ensure the pump operates efficiently and reliably.

Automated assembly lines are becoming increasingly common, as they enhance precision and reduce assembly time. However, manual assembly is still prevalent for complex or custom configurations.

What Finishing Processes Are Important for Centrifugal Pump Parts?

The finishing stage is essential for improving the surface quality and performance of centrifugal pump parts. Techniques include:

- Surface Treatment: Processes such as polishing, coating, or anodizing enhance corrosion resistance and reduce wear.

- Heat Treatment: This involves heating and cooling materials to alter their physical properties, increasing strength and toughness.

- Balancing: Particularly for rotating components like impellers, balancing is crucial to minimize vibrations during operation.

What Quality Assurance Measures Are Standard in Centrifugal Pump Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that every component meets international standards and client specifications.

Which International Standards Are Relevant for Quality Assurance?

Several international standards guide the quality assurance of centrifugal pump parts:

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries, ensuring consistent product quality and customer satisfaction.

- CE Marking: For products sold within the European Union, CE marking indicates compliance with safety, health, and environmental protection standards.

- API Standards: The American Petroleum Institute provides specifications for pumps used in oil and gas applications, focusing on performance and safety.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses raw materials and components to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and identify any deviations from quality standards.

- Final Quality Control (FQC): After assembly, a comprehensive inspection is performed to verify that the finished product meets all design and performance criteria.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods play a significant role in quality assurance. Common techniques include:

- Hydraulic Testing: This test evaluates the pump’s performance under pressure, ensuring it can handle operational conditions without leaks.

- Non-Destructive Testing (NDT): Methods like ultrasonic testing or X-ray inspection assess the integrity of materials without damaging them.

- Performance Testing: This involves running the pump under controlled conditions to measure flow rates, efficiency, and vibration levels.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is crucial for ensuring product reliability. Here are some strategies:

- Supplier Audits: Conducting regular audits of suppliers can help assess their adherence to quality standards and manufacturing processes. This can involve reviewing their quality management systems, production capabilities, and compliance with international standards.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their QC processes, including results from various tests and inspections.

- Third-Party Inspections: Engaging third-party inspection agencies to evaluate the manufacturing facility and its processes can offer an impartial view of the supplier’s quality assurance practices.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating quality control and certification can vary significantly between regions. Buyers from Africa, South America, the Middle East, and Europe should be aware of the following nuances:

- Regional Regulations: Different regions may have specific regulations regarding pump manufacturing and quality standards. Understanding local requirements is essential for compliance.

- Cultural Considerations: Building relationships and trust with suppliers can vary by culture. Engaging in transparent communication and understanding local business practices can facilitate smoother transactions.

- Documentation: Ensure that suppliers provide all necessary documentation, including certifications, quality control reports, and compliance statements, to prevent issues during customs clearance or regulatory inspections.

In conclusion, understanding the manufacturing processes and quality assurance measures for centrifugal pump parts is vital for B2B buyers. By focusing on these aspects, buyers can ensure they source reliable and high-quality components that meet their operational needs while complying with relevant international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘centrifugal pump parts’

When sourcing centrifugal pump parts, a structured approach is essential to ensure that you obtain quality components that meet your operational needs. This checklist will guide you through the critical steps necessary for making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as the type of fluid being pumped, flow rates, pressure requirements, and environmental conditions. Ensure you also identify the specific components needed, such as impellers, casings, and seals, to avoid any compatibility issues later on.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers who specialize in centrifugal pump parts. Look for companies with a strong reputation in your industry and those that have experience with international shipping, especially if you are sourcing from regions like Africa or South America. Utilize online directories, trade shows, and industry forums to compile a list of qualified suppliers.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that potential suppliers hold relevant certifications and comply with industry standards. Look for certifications such as ISO 9001 for quality management and specific certifications related to the materials used in centrifugal pump components. This step is crucial to ensure that the parts you receive will meet safety and performance standards.

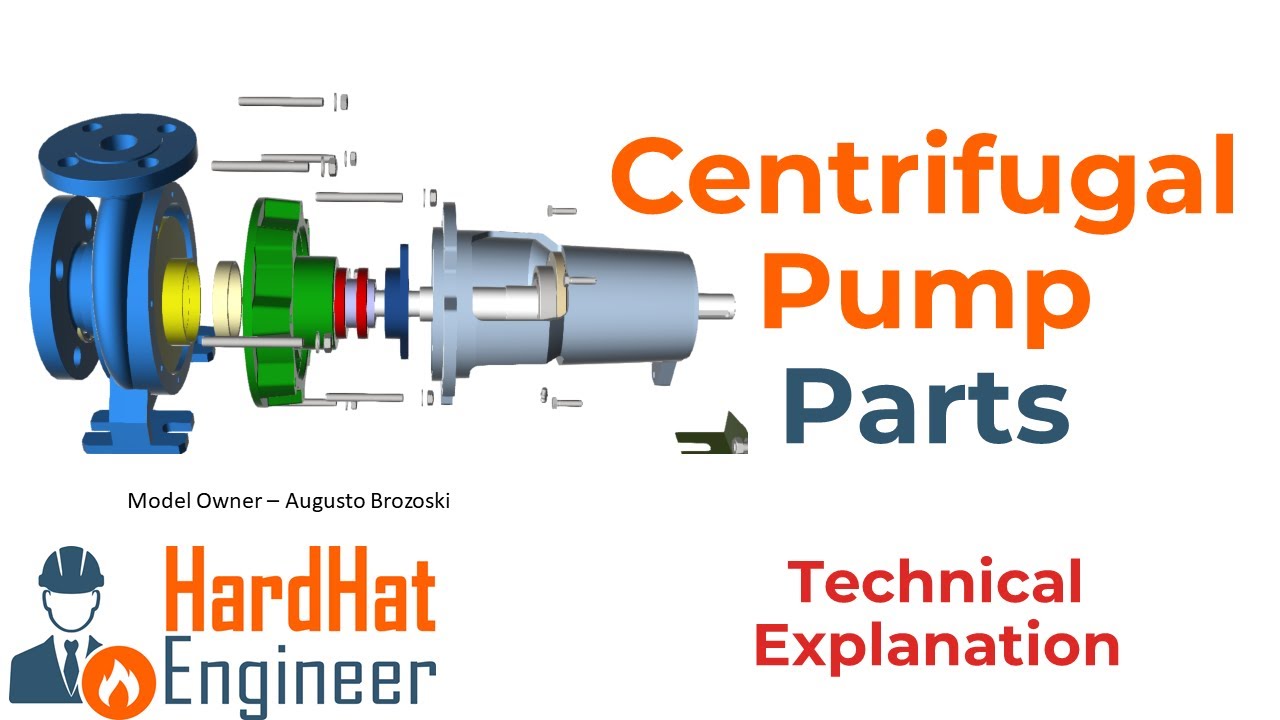

Illustrative image related to centrifugal pump parts

Step 4: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotes that include pricing, lead times, and payment terms. Pay attention to the breakdown of costs for individual components as well as shipping fees. Compare these quotes carefully, considering not just the price but also the supplier’s reliability and service levels.

Step 5: Assess Quality Assurance Processes

Inquire about the quality assurance processes each supplier implements to ensure the reliability of their products. This includes testing protocols, materials used, and any warranties offered. Suppliers should provide documentation of testing results and certifications for the parts being supplied, which is critical for maintaining operational efficiency.

Step 6: Check Customer References and Reviews

Reach out to previous customers to gather feedback on their experiences with the suppliers you are considering. Look for reviews specifically related to product quality, delivery times, and customer service. This firsthand information can help you gauge the supplier’s reliability and commitment to customer satisfaction.

Step 7: Finalize Contracts and Terms

Once you have chosen a supplier, ensure that all terms are clearly outlined in a written contract. This should include delivery schedules, payment terms, and liability clauses. Having a legally binding agreement protects both parties and sets clear expectations, reducing the potential for disputes down the line.

By following this checklist, you can streamline your procurement process for centrifugal pump parts, ensuring that you make informed decisions that will support your operational needs effectively.

Illustrative image related to centrifugal pump parts

Comprehensive Cost and Pricing Analysis for centrifugal pump parts Sourcing

What Are the Key Cost Components of Centrifugal Pump Parts?

Understanding the cost structure of centrifugal pump parts is essential for B2B buyers looking to optimize their procurement strategies. The primary components that contribute to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly influences the cost of centrifugal pump parts. Common materials include stainless steel, cast iron, and specialized alloys, each varying in price based on market conditions and properties such as corrosion resistance and strength. Higher-grade materials generally lead to increased costs but can enhance durability and performance.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process. This can vary widely depending on the geographic location of the supplier and the complexity of the manufacturing process. Regions with lower labor costs may offer more competitive pricing, but this must be weighed against quality and reliability.

-

Manufacturing Overhead: This includes expenses such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize overhead costs, ultimately affecting the pricing of the final product.

-

Tooling: The cost of tooling refers to the equipment and molds used in the production of pump parts. Custom tooling can be expensive, but it may be necessary for specialized components, impacting the overall cost structure.

-

Quality Control (QC): Ensuring the reliability and performance of centrifugal pump parts requires a robust QC process. This adds to the cost but is essential for maintaining high standards, particularly in industries with strict regulatory requirements.

-

Logistics: Transportation and warehousing costs are crucial, especially for international shipments. Factors such as distance, shipping method, and customs duties can significantly impact logistics costs.

-

Margin: Suppliers typically apply a profit margin to their costs, which can vary based on market demand, competition, and perceived value of the product.

What Influences the Pricing of Centrifugal Pump Parts?

Several factors affect the pricing of centrifugal pump parts, which B2B buyers should consider when negotiating and sourcing:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ), and larger orders can result in volume discounts. Understanding the supplier’s pricing model can help buyers negotiate better terms.

-

Specifications/Customization: Customized components may come with a higher price tag due to the additional engineering and manufacturing processes required. Buyers should weigh the benefits of customization against the costs.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as ISO or API) can significantly impact pricing. Higher quality often translates to higher costs, but it can also lead to reduced Total Cost of Ownership (TCO) through improved reliability and lower maintenance needs.

-

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers with a track record of quality may charge more but can offer better support and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can affect total costs.

What Are the Best Practices for Negotiating Prices on Centrifugal Pump Parts?

Effective negotiation strategies can lead to significant cost savings for B2B buyers:

-

Research and Benchmarking: Buyers should conduct thorough research to understand market rates and benchmark prices. This information can empower them during negotiations.

-

Total Cost of Ownership (TCO): When evaluating costs, consider the TCO, which includes initial purchase price, maintenance, and operational costs. A higher upfront investment in quality parts may yield lower long-term costs.

-

Flexibility in Specifications: If possible, being flexible with specifications can allow for alternative sourcing options that may be more cost-effective.

-

Building Relationships: Establishing strong relationships with suppliers can lead to better pricing, favorable terms, and priority service, especially in competitive markets.

-

Regional Considerations: For buyers in Africa, South America, the Middle East, and Europe, understanding regional economic conditions and trade agreements can aid in negotiating better prices.

Disclaimer on Pricing

Prices for centrifugal pump parts are subject to fluctuations based on market conditions, currency exchange rates, and other external factors. Therefore, the figures mentioned in this analysis are indicative and should be verified with suppliers for current pricing.

Alternatives Analysis: Comparing centrifugal pump parts With Other Solutions

Exploring Alternatives to Centrifugal Pump Parts in Industrial Applications

In the industrial landscape, selecting the right pumping solution is crucial for operational efficiency and cost-effectiveness. While centrifugal pumps are a popular choice due to their reliability and versatility, several alternative technologies can also meet similar needs. This analysis provides a comparative overview of centrifugal pump parts against two viable alternatives: positive displacement pumps and diaphragm pumps.

| Comparison Aspect | Centrifugal Pump Parts | Positive Displacement Pumps | Diaphragm Pumps |

|---|---|---|---|

| Performance | High flow rates; suitable for low-viscosity fluids | Excellent for high-viscosity and high-pressure applications | Good for precise flow control; handles slurries well |

| Cost | Generally lower initial investment; moderate operating costs | Higher upfront cost; can have lower operating costs depending on application | Moderate initial cost; maintenance can be costly |

| Ease of Implementation | Straightforward installation; widely available | More complex installation; may require specific training | Easy to install but may need specific fittings |

| Maintenance | Requires regular maintenance; parts can wear out | Lower maintenance frequency; parts can be expensive | Regular maintenance needed; diaphragm replacement can be costly |

| Best Use Case | Water treatment, chemical processing, and food production | Oil and gas, chemical processing, and high-pressure systems | Pharmaceutical, food processing, and hazardous materials |

In-Depth Analysis of Alternatives

Positive Displacement Pumps

Positive displacement pumps operate by trapping a fixed amount of fluid and forcing it through the pump’s discharge. They excel in applications requiring high pressure and the ability to handle viscous fluids. The main advantage of these pumps is their consistent flow rate, regardless of the pressure. However, they typically have a higher upfront cost and can be more complex to install and maintain. In environments where fluid viscosity varies significantly, the adaptability of positive displacement pumps makes them a strong contender.

Diaphragm Pumps

Diaphragm pumps use a flexible diaphragm to create a vacuum that draws in fluid and then pushes it out. This technology is especially beneficial for applications that require precise flow control and the handling of corrosive or abrasive materials. The primary benefits include their ability to handle slurries and their inherent leak-proof design. However, maintenance can be more frequent due to diaphragm wear, and the cost of replacement parts can accumulate over time. They are ideal for industries like pharmaceuticals and food processing, where fluid integrity is paramount.

Making the Right Choice for Your Needs

When selecting between centrifugal pump parts and alternative solutions, B2B buyers should consider several factors, including the specific application requirements, fluid characteristics, and operational constraints. Centrifugal pumps are often favored for their efficiency and cost-effectiveness in moderate-pressure applications, while positive displacement and diaphragm pumps may offer advantages in high-viscosity or hazardous fluid scenarios. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for centrifugal pump parts

What Are the Key Technical Properties of Centrifugal Pump Parts?

Understanding the technical specifications of centrifugal pump parts is crucial for B2B buyers, as it directly impacts the pump’s performance, longevity, and suitability for specific applications. Here are some essential properties to consider:

-

Material Grade

The choice of material grade, such as stainless steel, cast iron, or bronze, influences the pump’s durability and resistance to corrosion, wear, and temperature variations. For instance, stainless steel is ideal for chemical processing applications due to its resistance to corrosive substances, while cast iron is often used in water and wastewater applications due to its strength and cost-effectiveness. Selecting the appropriate material is vital for ensuring that the pump meets operational requirements and reduces maintenance costs. -

Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension of a component. Tight tolerances are critical in parts like shafts and impellers, where precise fit is essential for efficient operation. In industries where pumps are subjected to high pressures or temperatures, maintaining exact tolerances can prevent failures and ensure optimal performance. Buyers should verify tolerance specifications to align with their operational needs. -

Flow Rate

The flow rate is a measure of the volume of fluid that a pump can move in a specific period, usually expressed in gallons per minute (GPM) or liters per second (L/s). This property is crucial for determining whether a pump can meet the demands of a particular application. Understanding the required flow rate helps in selecting the right pump size and configuration, thereby optimizing productivity. -

Pressure Rating

This specification indicates the maximum pressure the pump can handle during operation. It is essential for applications in high-pressure environments, such as oil and gas extraction or chemical processing. Exceeding the pressure rating can lead to catastrophic failures, making it critical for buyers to ensure the selected pump meets the pressure requirements of their specific application. -

Efficiency

Efficiency is a measure of how effectively a pump converts input energy into hydraulic energy. High-efficiency pumps consume less energy, leading to cost savings and reduced environmental impact. Buyers should prioritize energy-efficient models, especially in large-scale operations where energy costs significantly affect the bottom line. -

Temperature Range

This property defines the operational temperature limits of the pump materials and components. Pumps used in industries like petrochemicals or food processing must withstand varying temperatures without compromising performance. Understanding the temperature range helps in selecting the right pump for specific applications, ensuring reliability and safety.

What Are Common Trade Terms Related to Centrifugal Pumps?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of centrifugal pumps, OEM parts are essential for maintaining quality and compatibility. Buyers often prefer OEM parts to ensure reliability and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and cost calculations. Buyers should negotiate MOQs that align with their operational needs without overcommitting to excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document that potential buyers send to suppliers to request pricing and other terms for specific products. This process is essential for obtaining competitive pricing and understanding supplier capabilities. Crafting a detailed RFQ can lead to better negotiations and sourcing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs, risks, and delivery responsibilities, facilitating smoother transactions. -

Lead Time

Lead time is the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for project planning and inventory management, as longer lead times can impact operational efficiency. -

Aftermarket Support

This term refers to services provided after the sale, including maintenance, repairs, and parts replacement. Strong aftermarket support can significantly reduce downtime and maintenance costs, making it a key consideration when selecting a supplier.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and align with their business goals.

Navigating Market Dynamics and Sourcing Trends in the centrifugal pump parts Sector

What Are the Key Market Drivers for Centrifugal Pump Parts?

The centrifugal pump parts market is experiencing significant growth driven by several global factors. Industrialization across emerging markets, particularly in Africa, South America, and parts of Europe, is propelling demand for reliable pumping solutions. The oil and gas sector remains a primary consumer, necessitating high-performance centrifugal pumps for various applications. Furthermore, advancements in technology, such as IoT-enabled pumps and predictive maintenance, are reshaping how businesses source and manage pump systems. These innovations enhance operational efficiency, reduce downtime, and optimize resource allocation, making them attractive to international B2B buyers.

Illustrative image related to centrifugal pump parts

Emerging trends also indicate a shift toward modular and customizable pump components. As industries increasingly seek tailored solutions to meet specific operational requirements, suppliers are adapting by offering modular designs that allow for easier upgrades and maintenance. Additionally, the growing focus on automation in industrial processes is influencing sourcing strategies, with buyers looking for suppliers that can provide integrated systems rather than standalone components. This trend is particularly relevant in regions like Brazil and Vietnam, where technological adoption is accelerating.

How Is Sustainability Shaping Sourcing Practices for Centrifugal Pump Parts?

Sustainability has become a crucial consideration for B2B buyers in the centrifugal pump parts sector. The environmental impact of manufacturing processes and the lifecycle of pump components are now under scrutiny. As a result, companies are prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes sourcing materials that are recyclable or made from renewable resources, as well as adopting manufacturing processes that minimize waste and energy consumption.

Ethical sourcing is also gaining importance, with buyers increasingly demanding transparency in supply chains. This shift is driven by consumer awareness and regulatory pressures, particularly in Europe, where stringent environmental regulations are in place. Companies that achieve ‘green’ certifications or utilize eco-friendly materials can differentiate themselves in a competitive market. Buyers are more inclined to partner with suppliers that not only meet their technical needs but also align with their sustainability goals, fostering long-term business relationships.

Illustrative image related to centrifugal pump parts

What Is the Historical Context of Centrifugal Pump Parts in the B2B Market?

The evolution of centrifugal pump parts can be traced back to the late 19th century when the industrial revolution necessitated efficient fluid transfer systems. Initially, centrifugal pumps were designed with limited materials and technology, focusing primarily on functionality. Over the decades, advancements in metallurgy, hydrodynamics, and automation have significantly improved pump efficiency and durability.

In the mid-20th century, the introduction of standardized designs, such as ANSI and API pumps, revolutionized the market, allowing for greater interchangeability of parts and simplified sourcing. This standardization paved the way for international trade, enabling B2B buyers from diverse regions to access high-quality centrifugal pump components. Today, the focus has shifted towards integrating digital technologies and sustainable practices, reflecting the ongoing transformation of the sector to meet modern industrial demands.

Frequently Asked Questions (FAQs) for B2B Buyers of centrifugal pump parts

-

How do I choose the right centrifugal pump parts for my application?

Selecting the appropriate centrifugal pump parts involves understanding the specific requirements of your application, including the type of fluid being pumped, flow rate, pressure requirements, and operational conditions. Evaluate the compatibility of materials with the fluid to prevent corrosion and wear. Additionally, consider the pump’s configuration—whether you need a single-stage or multi-stage pump—and the impeller type, as these factors significantly influence efficiency and performance. Collaborating with a knowledgeable supplier can provide insights tailored to your unique needs. -

What are the common materials used in centrifugal pump parts?

Centrifugal pump parts are typically made from materials like stainless steel, cast iron, bronze, and thermoplastics. Stainless steel is preferred for its corrosion resistance and strength, making it suitable for chemical processing and wastewater applications. Cast iron is commonly used for its durability and cost-effectiveness in general applications. For corrosive or high-temperature fluids, specialized alloys or plastics may be necessary. Always consult with suppliers to ensure the selected materials are compatible with your specific application and environment. -

What is the minimum order quantity (MOQ) for centrifugal pump parts?

The minimum order quantity (MOQ) for centrifugal pump parts can vary significantly depending on the supplier and the specific components you require. Some manufacturers may have MOQs as low as one unit for standard parts, while others may require larger orders for specialized components. It is essential to communicate your needs clearly with potential suppliers to understand their MOQ policies and negotiate terms that work for your procurement strategy, especially when sourcing internationally. -

How can I ensure the quality of centrifugal pump parts before purchasing?

To ensure the quality of centrifugal pump parts, request certifications and quality assurance documentation from suppliers, such as ISO certifications or specific industry standards. It’s advisable to conduct a thorough supplier vetting process, which may include visiting their manufacturing facilities or requesting samples for testing. Customer reviews and case studies can also provide insights into the supplier’s reliability. Establishing a good relationship with your supplier can facilitate transparency and improve quality control. -

What payment terms are typically offered by suppliers of centrifugal pump parts?

Payment terms for centrifugal pump parts can vary widely among suppliers, but common options include net 30, net 60, or even payment upon delivery. Some suppliers may offer discounts for upfront payments or larger orders. It’s essential to discuss payment terms early in negotiations and ensure they align with your cash flow management. Additionally, consider using secure payment methods, especially for international transactions, to protect against fraud. -

How do logistics and shipping impact the procurement of centrifugal pump parts?

Logistics and shipping play a crucial role in the timely procurement of centrifugal pump parts. Factors such as shipping method, lead times, customs regulations, and costs can significantly affect your supply chain. When sourcing internationally, it’s vital to work with suppliers who have experience in global logistics and can provide clear timelines and tracking for shipments. Ensure that you understand the total landed cost, including duties and taxes, to avoid unexpected expenses. -

What customization options are available for centrifugal pump parts?

Many suppliers offer customization options for centrifugal pump parts, allowing you to tailor components to meet specific application requirements. Customization may include adjusting dimensions, selecting specific materials, or modifying designs for unique operational conditions. Discuss your needs with potential suppliers early in the process, as custom parts may require longer lead times and additional costs. A collaborative approach can help ensure that the final product meets all performance specifications. -

What are the common applications for centrifugal pump parts across different industries?

Centrifugal pump parts are utilized in various industries, including oil and gas, chemical processing, water treatment, food and beverage manufacturing, and more. In the oil and gas sector, pumps facilitate the transfer of crude oil and refined products. In water treatment, they are essential for moving and filtering wastewater. Understanding the specific requirements of your industry can guide you in selecting the right components and configurations, ensuring optimal performance and reliability in your applications.

Top 9 Centrifugal Pump Parts Manufacturers & Suppliers List

1. DXPE – Centrifugal Pumps

Domain: dxpe.com

Registered: 1997 (28 years)

Introduction: Centrifugal pumps are pressure-producing mechanical devices that transfer kinetic energy generated from centrifugal force to hydrodynamic energy, facilitating the flow of various industrial fluids. Key components include: 1. Impeller – Spins at the same speed as the shaft, gaining velocity and kinetic energy. 2. Diffuser or Volute Casing – Contains fluid and generates pressure by slowing down flui…

2. Asimer Group – Centrifugal Pumps

Domain: asimergroup.com

Registered: 2020 (5 years)

Introduction: Centrifugal pumps are essential in various industrial applications, featuring key components such as: 1. Impeller: Increases liquid velocity, available in types including Open (for liquids with suspended solids), Semi-Open (for viscous/corrosive liquids), and Closed (for clean liquids). 2. Casing: Guides liquid flow, available in Single-Stage (moderate pressure) and Multi-Stage (significant pressu…

3. Springer Parts – Centrifugal Pump Components

Domain: springerparts.com

Registered: 2009 (16 years)

Introduction: Centrifugal Pump Parts & Replacement Kits, Heavy Duty Centrifugal Pump Parts, Pump Seal & Repair Kits, Positive Displacement Pump Parts, ANSI Pump Parts, Progressive Cavity Pump Parts, Sanitary Pump Parts, Vacuum Pump Parts, Wastewater Pump Parts, Diaphragm Pump Parts, Lift Station Parts including Base Elbows, Lift-Out Flange, Pump Adapter Flange, Guide Rail Brackets, Chain & Components, Basin Acc…

4. TOP-FLO® – Centrifugal Pump Replacement Parts

Domain: sanitaryfittings.us

Registered: 2016 (9 years)

Introduction: Centrifugal Pump Replacement Parts from TOP-FLO® designed to fit both TOP-FLO® and major pump suppliers. Components are rugged and provide necessary sealing conditions under various conditions. Products include: Drive Collar (MAR00), 83C Stuffing Box Follower, Castellated Nut (Acme Thread), Centrifugal Pump Stub Shaft (MAR006), and Impeller. Total of 6 results available.

5. Rotech Pumps – Centrifugal Pumps

Domain: rotechpumps.com

Registered: 2002 (23 years)

Introduction: Centrifugal pumps are mechanical devices used to transport fluids by converting mechanical energy from an external source into kinetic energy in the fluid. They consist of three main components: an impeller, a casing, and a shaft. The impeller rotates to create centrifugal force, moving the fluid through the pump. Types of centrifugal pumps include single-stage, multi-stage, axial-flow, and radial…

6. Pumps & Parts Online – Quality Pumps & Repair Services

Domain: pumpsandpartsonline.com

Registered: 2010 (15 years)

Introduction: This company, Pumps & Parts Online – Quality Pumps & Repair Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Dynaproco – Key Components of Pump Systems

Domain: dynaproco.com

Registered: 2021 (4 years)

Introduction: 1. Impeller: Rotating component that transfers energy from the motor to the fluid, consisting of curved blades that create centrifugal force. 2. Casing: Stationary component that surrounds the impeller, providing support and directing fluid flow while creating a pressure difference. 3. Shaft: Connects the impeller to the motor, transmitting power and designed to withstand stresses. 4. Bearings: Su…

8. Pioneer Pump – Centrifugal Pump Parts Kits

Domain: pioneerpump.com

Registered: 1999 (26 years)

Introduction: Priming Assisted & Standard Centrifugal Pump Parts Kits offer a single-part number solution for various maintenance and repair tasks. These kits ensure shorter maintenance times as they include genuine OEM parts, which are the same as those used in the original equipment. This provides manufacturing tolerances that extend the life and performance of the pump. The product line includes Pump Repair …

9. Nuclear Power – Centrifugal Pump Components

Domain: nuclear-power.com

Registered: 2017 (8 years)

Introduction: Main Parts of a Centrifugal Pump: 1. Impeller: A rotor used to increase the kinetic energy of the flow. 2. Casing (Volute): Contains the liquid and directs flow in and out of the pump, converting kinetic energy into pressure. 3. Shaft (Rotor): Transmits torque from the motor to the impeller. 4. Shaft Sealing: Prevents leakage of the pumped liquid using packing rings or mechanical seals. 5. Bearing…

Strategic Sourcing Conclusion and Outlook for centrifugal pump parts

In conclusion, the strategic sourcing of centrifugal pump parts is pivotal for ensuring operational efficiency and reliability across diverse industrial applications. By understanding the critical components—such as impellers, casings, shafts, and seals—B2B buyers can make informed decisions that enhance their procurement strategies. Collaborating with reputable suppliers who offer tailored solutions can significantly reduce downtime and maintenance costs, ultimately leading to increased productivity.

As international markets evolve, particularly in Africa, South America, the Middle East, and Europe, the demand for high-quality centrifugal pump parts will continue to rise. Buyers should prioritize partnerships that not only provide robust products but also offer technical support and expertise in selecting the right configurations for specific applications.

Looking ahead, the emphasis on sustainability and efficiency in industrial processes will drive innovations in pump technology and sourcing practices. Now is the time for B2B buyers to embrace strategic sourcing initiatives that align with their operational goals and market demands. By proactively engaging with suppliers and leveraging industry insights, businesses can position themselves for success in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.