Everything You Need to Know About Casting Wheels Sourcing in 2025

Introduction: Navigating the Global Market for casting wheels

In the competitive landscape of global manufacturing, sourcing high-quality casting wheels poses a significant challenge for international B2B buyers. The demand for durable, reliable, and versatile wheels, particularly in heavy-duty applications, is ever-increasing across diverse industries—from warehousing in Brazil to furniture manufacturing in Saudi Arabia. This guide is designed to equip you with the essential knowledge needed to navigate the complexities of the casting wheel market, ensuring you make informed purchasing decisions that align with your operational needs.

Throughout this comprehensive guide, we will delve into various types of casting wheels, including cast iron, polyurethane, and semi-steel options, each tailored for specific applications. You will gain insights into the diverse functionalities these wheels offer, from enhancing mobility in industrial settings to adding aesthetic value in commercial spaces. Additionally, we will provide actionable advice on supplier vetting, cost analysis, and best practices for procurement, ensuring that you can identify reputable manufacturers and secure competitive pricing.

By leveraging the insights presented in this guide, B2B buyers from Africa, South America, the Middle East, and Europe will be empowered to streamline their sourcing processes and enhance their operational efficiency. With a focus on quality, performance, and cost-effectiveness, this resource serves as your roadmap to successfully navigating the global market for casting wheels.

Understanding casting wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cast Iron Casters | Durable, high load capacity, rustic aesthetic | Industrial manufacturing, warehousing, furniture | Pros: High strength, aesthetic appeal. Cons: Heavier, may rust if not maintained. |

| Polyurethane Casters | Non-marking, quieter operation, versatile design | Medical facilities, retail carts, office furniture | Pros: Floor protection, smooth movement. Cons: Less durable under extreme conditions. |

| Swivel Casters | 360-degree rotation, enhanced maneuverability | Service carts, mobile workstations | Pros: Easy navigation in tight spaces. Cons: Potential instability under heavy loads. |

| Rigid Casters | Fixed direction, robust construction | Heavy-duty machinery, shelving units | Pros: Stability, high load capacity. Cons: Limited maneuverability. |

| Dual-Wheel Casters | Two wheels per caster for load distribution | Heavy equipment, industrial carts | Pros: Better weight distribution, enhanced stability. Cons: Larger footprint may limit space. |

What Are the Characteristics of Cast Iron Casters?

Cast iron casters are renowned for their durability and load-bearing capabilities, making them ideal for heavy-duty applications in industrial settings. They often feature a rustic appearance that can enhance the aesthetic of restored furniture or vintage designs. When considering cast iron casters, buyers should evaluate their load requirements and the environment, as these casters can be prone to rust without proper treatment.

How Do Polyurethane Casters Benefit Various Industries?

Polyurethane casters are designed to provide a non-marking, quieter operation, making them suitable for environments like hospitals and retail spaces. Their versatility allows them to be used on various surfaces without causing damage. Buyers should consider the specific applications and flooring types, as polyurethane casters excel in environments where floor protection is paramount but may not withstand extreme temperatures or heavy impacts.

What Advantages Do Swivel Casters Offer in Mobility?

Swivel casters allow for 360-degree movement, making them perfect for service carts and mobile workstations that require frequent changes in direction. Their enhanced maneuverability is particularly beneficial in tight spaces, allowing for efficient navigation. However, buyers should assess the stability of swivel casters under heavy loads, as their design can sometimes compromise balance.

Why Choose Rigid Casters for Heavy-Duty Applications?

Rigid casters are characterized by their fixed direction, providing exceptional stability and high load capacity. They are commonly used in settings that require the transport of heavy machinery or shelving units. Buyers should weigh the benefits of stability against the limitations in maneuverability, especially in environments where flexibility is required.

How Do Dual-Wheel Casters Enhance Stability?

Dual-wheel casters distribute weight more evenly, providing enhanced stability for heavy equipment and industrial carts. This design minimizes floor pressure and allows for smoother movement across various surfaces. However, buyers should be mindful of the larger footprint of dual-wheel casters, which may limit their use in confined spaces. Understanding the balance between stability and space efficiency is key for B2B buyers.

Key Industrial Applications of casting wheels

| Industry/Sector | Specific Application of Casting Wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhances efficiency in material handling and production flow | Load capacity, durability under high temperatures, and ease of installation |

| Warehousing | Pallet Jacks and Carts | Streamlines logistics and improves mobility of goods | Weight tolerance, compatibility with existing equipment, and maintenance requirements |

| Construction | Heavy Equipment Mobility | Facilitates movement of heavy machinery and tools on site | Resistance to wear, environmental factors (e.g., heat, debris), and safety features |

| Retail and Hospitality | Furniture Mobility | Provides flexible arrangements for displays and seating | Aesthetic options, load capacity for furniture, and noise reduction features |

| Medical Facilities | Hospital Equipment and Carts | Ensures safe transport of patients and medical supplies | Sanitation standards, maneuverability in tight spaces, and durability for frequent use |

How Are Casting Wheels Used in Manufacturing Conveyor Systems?

In manufacturing settings, casting wheels are integral to conveyor systems, facilitating the smooth movement of materials along production lines. Their robust construction allows them to handle heavy loads and endure the rigors of high-speed operations. For international buyers, especially in emerging markets like Africa and South America, sourcing wheels that meet specific load capacities and temperature tolerances is crucial to ensure operational efficiency and safety.

What Role Do Casting Wheels Play in Warehousing with Pallet Jacks and Carts?

Casting wheels are essential for pallet jacks and carts in warehousing applications, enabling the easy transport of goods from one location to another. They improve logistical efficiency by allowing for quick and safe maneuvering of heavy items. Buyers must consider the wheel’s weight tolerance and compatibility with existing equipment to optimize their material handling processes, especially in regions like the Middle East and Europe, where warehousing operations are scaling up.

Illustrative image related to casting wheels

How Do Casting Wheels Enhance Mobility in Construction Sites?

In construction, casting wheels are vital for the mobility of heavy equipment and tools, allowing for efficient site management. Their durability and resistance to wear make them suitable for various terrains and conditions. For B2B buyers, particularly in construction-heavy regions like Brazil and Saudi Arabia, sourcing wheels that can withstand environmental challenges while ensuring safety and stability is paramount.

Why Are Casting Wheels Important for Retail and Hospitality Furniture?

In the retail and hospitality sectors, casting wheels are used to enhance the mobility of furniture, allowing for flexible arrangements that can adapt to changing customer needs. They provide a functional yet aesthetic solution for moving displays and seating. International buyers should focus on sourcing wheels that not only meet load capacity requirements but also align with the desired design and noise reduction features to create a pleasant customer experience.

How Are Casting Wheels Utilized in Medical Facilities for Equipment Mobility?

In medical facilities, casting wheels are critical for the mobility of hospital equipment and carts, ensuring the safe transport of patients and medical supplies. Their design must meet stringent sanitation standards and be capable of maneuvering in tight spaces. Buyers in this sector, particularly in regions like Europe and the Middle East, should prioritize sourcing durable, easy-to-clean wheels that comply with health regulations while maintaining high performance in demanding environments.

Illustrative image related to casting wheels

3 Common User Pain Points for ‘casting wheels’ & Their Solutions

Scenario 1: The Challenge of Load Capacity Management

The Problem: Many B2B buyers encounter difficulties when selecting the appropriate casting wheels for their specific load requirements. An inadequate understanding of load capacity can lead to premature wheel failure, resulting in costly downtime and potential damage to equipment or goods. For instance, a manufacturing facility may opt for standard wheels that cannot support the weight of heavy machinery, leading to accidents or operational inefficiencies. The mismatch between wheel specifications and actual usage scenarios is a common frustration that can disrupt logistics and production schedules.

The Solution: To address this issue, it is essential to conduct a thorough load analysis before purchasing casting wheels. Start by assessing the maximum weight that the wheels will need to support, including the weight of the cart or equipment as well as any additional loads. It is advisable to choose wheels with a load capacity that exceeds your requirements by at least 20-30% to account for unexpected weight fluctuations. Additionally, engage with suppliers who provide detailed specifications and recommendations based on the intended application. Consider using heavy-duty cast iron wheels for industrial settings, as they offer exceptional strength and durability. Regularly review your load requirements and wheel performance to ensure continuous alignment with operational demands.

Scenario 2: Navigating Floor Surface Compatibility

The Problem: Another prevalent issue for B2B buyers is the compatibility of casting wheels with various floor surfaces. Different environments, from smooth concrete floors to uneven outdoor surfaces, require specific wheel types to prevent damage and ensure smooth mobility. For example, using hard metal wheels on delicate flooring can cause scratches and reduce the lifespan of both the wheels and the floors. This oversight not only affects aesthetics but can also lead to increased maintenance costs and operational disruptions.

The Solution: To overcome this challenge, it is crucial to evaluate the flooring type where the casting wheels will be utilized. For sensitive surfaces, opt for polyurethane-coated wheels, as they provide excellent shock absorption and prevent marking. In contrast, for rugged outdoor environments, choose heavy-duty cast iron wheels designed for rough terrain. Additionally, consider the wheel’s diameter and tread design; larger wheels with a wider tread can navigate uneven surfaces more effectively. Engaging in a dialogue with your supplier about your specific flooring conditions will yield valuable insights into the best wheel choices tailored to your needs.

Scenario 3: The Complexity of Installation and Maintenance

The Problem: The installation and maintenance of casting wheels can often be a daunting task for B2B buyers, especially when dealing with diverse equipment and mounting options. Incorrect installation can lead to operational inefficiencies and safety hazards. Furthermore, buyers may struggle with ongoing maintenance, including lubrication and wheel replacement, which can add unexpected costs and downtime to their operations. This complexity often results in frustration and reluctance to optimize existing systems.

The Solution: To streamline installation and maintenance processes, start by selecting casting wheels that come with standardized mounting options such as plate or stem mounts, which simplify compatibility with various equipment. Ensure that your purchasing decision includes wheels that require minimal maintenance, such as those with sealed bearings or maintenance-free designs. Implement a routine inspection schedule to monitor wheel performance and condition; this proactive approach helps identify potential issues before they escalate. Providing training to staff on proper installation techniques and maintenance practices can also enhance operational efficiency. Collaborating with suppliers for guidance on best practices will further empower your team to manage casting wheels effectively.

Illustrative image related to casting wheels

Strategic Material Selection Guide for casting wheels

What Materials Are Commonly Used for Casting Wheels?

In the manufacturing of casting wheels, the choice of material significantly influences performance, durability, and suitability for specific applications. Understanding the properties, advantages, and limitations of various materials is crucial for international B2B buyers, especially those operating in diverse environments such as Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in casting wheels: cast iron, polyurethane, steel, and aluminum.

How Does Cast Iron Perform in Casting Wheels?

Cast iron is renowned for its exceptional strength and durability, making it a popular choice for heavy-duty applications. It can withstand high loads and is resistant to wear, which is vital in industrial settings. Additionally, cast iron has good thermal properties, allowing it to perform well in high-temperature environments.

Pros: Cast iron wheels offer superior strength and load-bearing capacity, making them ideal for heavy machinery and industrial carts. Their rustic aesthetic also appeals to certain markets, particularly in furniture applications.

Cons: However, cast iron is prone to corrosion if not properly coated, which can be a concern in humid or coastal environments. The manufacturing process can also be complex, leading to higher production costs.

Impact on Application: Cast iron wheels are suitable for environments where heavy loads are common, such as manufacturing plants and warehouses. Buyers should consider the local climate and potential for corrosion when selecting cast iron wheels.

Illustrative image related to casting wheels

What Advantages Does Polyurethane Offer for Casting Wheels?

Polyurethane is increasingly favored for its versatility and performance characteristics. It provides excellent abrasion resistance and can handle a range of temperatures, making it suitable for various applications.

Pros: The primary advantage of polyurethane wheels is their ability to absorb shock and reduce noise, which is beneficial in environments where quiet operation is essential. They also offer good floor protection, making them suitable for delicate surfaces.

Cons: On the downside, polyurethane can be more expensive than other materials, and its performance may degrade in extreme temperatures or under heavy loads.

Impact on Application: Polyurethane wheels are ideal for applications requiring mobility on sensitive surfaces, such as hospitals and retail environments. Buyers should ensure compliance with local standards for materials used in sensitive settings.

How Does Steel Compare as a Material for Casting Wheels?

Steel wheels, particularly semi-steel options, are known for their high load capacities and durability. They are often used in heavy-duty applications where strength is paramount.

Pros: Steel wheels are incredibly strong and resistant to deformation, making them suitable for high-impact environments. They are also less prone to cracking compared to cast iron.

Cons: However, steel can be heavy and may require additional effort for maneuverability. It is also susceptible to rust if not properly treated.

Impact on Application: Steel wheels are commonly used in industrial settings, such as warehouses and manufacturing facilities. Buyers in humid regions should consider corrosion-resistant coatings to enhance longevity.

What Role Does Aluminum Play in Casting Wheels?

Aluminum wheels are lightweight and corrosion-resistant, making them an attractive option for applications where mobility and ease of handling are priorities.

Pros: The lightweight nature of aluminum allows for easier maneuverability, which is beneficial in environments where frequent movement is required. Additionally, aluminum’s resistance to corrosion makes it suitable for outdoor applications.

Cons: However, aluminum wheels may not support as heavy a load as cast iron or steel, limiting their use in heavy-duty scenarios. They can also be more expensive due to the cost of raw materials.

Impact on Application: Aluminum wheels are well-suited for applications in the automotive and aerospace industries, where weight and corrosion resistance are critical. Buyers should assess load requirements to ensure aluminum is a suitable choice.

Summary Table of Material Selection for Casting Wheels

| Material | Typical Use Case for casting wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Heavy machinery, industrial carts | Superior strength and durability | Prone to corrosion without coating | Medium |

| Polyurethane | Hospitals, retail environments | Shock absorption and noise reduction | More expensive, temperature sensitive | High |

| Steel | Warehouses, manufacturing facilities | High load capacity and durability | Heavy, rust-prone without treatment | Medium |

| Aluminum | Automotive, aerospace applications | Lightweight and corrosion-resistant | Limited load capacity, higher cost | High |

This comprehensive analysis of materials for casting wheels equips international B2B buyers with the insights needed to make informed decisions tailored to their specific operational requirements and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for casting wheels

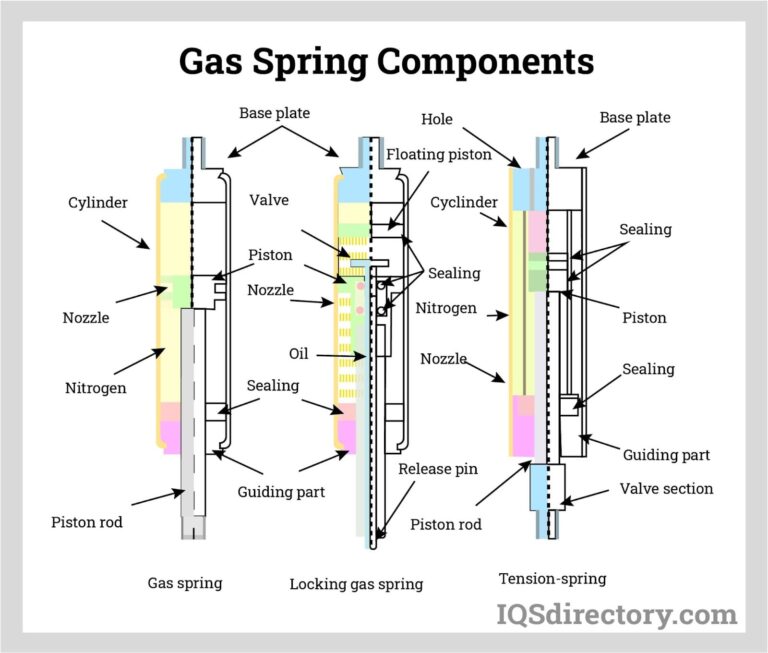

What Are the Main Stages in the Manufacturing Process of Casting Wheels?

The manufacturing process of casting wheels involves several critical stages designed to ensure the final product meets the rigorous demands of various industrial applications. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial phase focuses on sourcing and preparing the raw materials. Typically, cast iron or steel is used due to its strength and durability. The materials are melted in a furnace, which may reach temperatures exceeding 1,500 degrees Celsius. The quality of the raw materials is crucial; impurities can compromise the integrity of the final product. Suppliers often conduct chemical analysis on the metal to ensure compliance with industry standards.

-

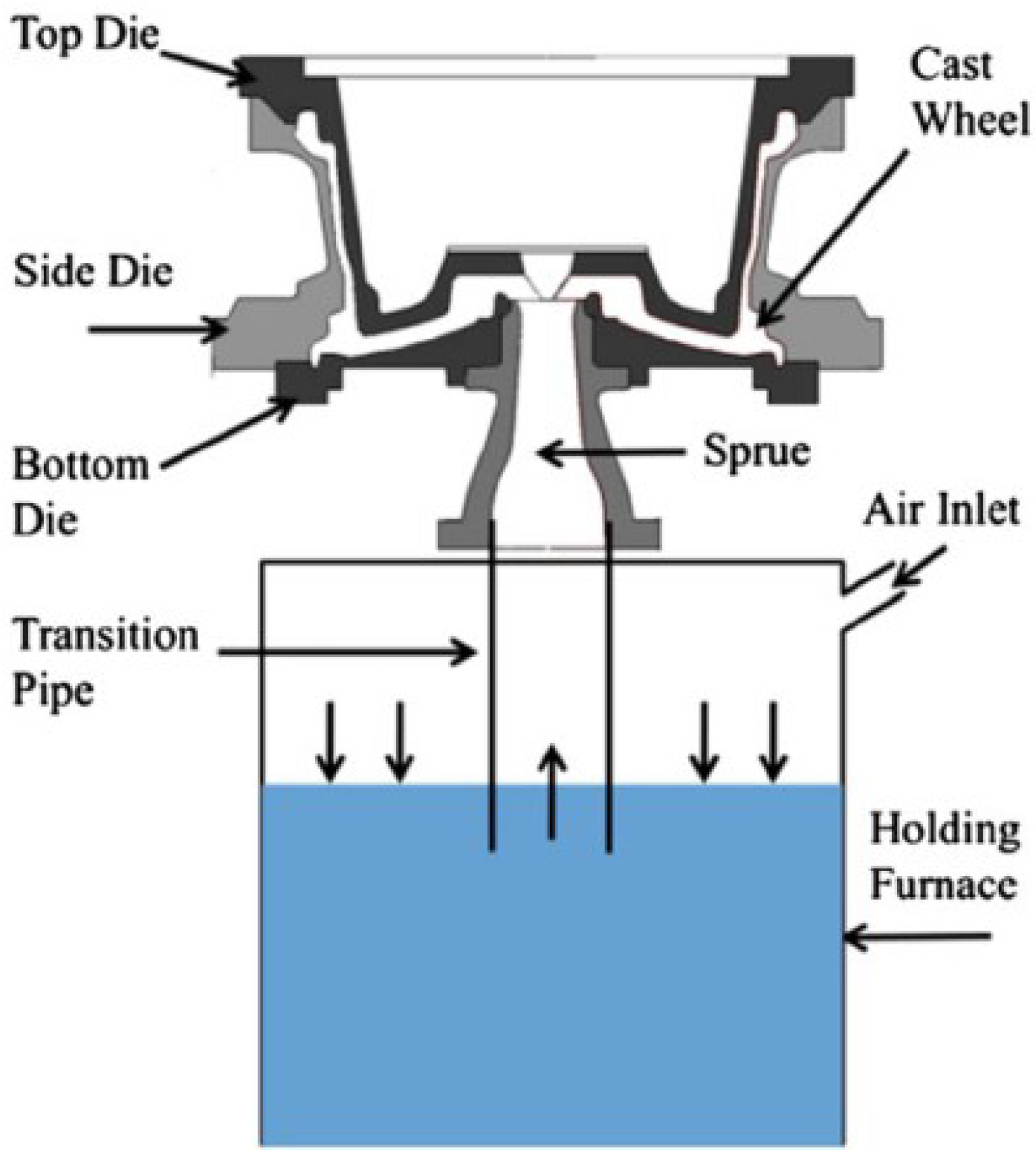

Forming: In this stage, the molten metal is poured into molds to form the wheels. The choice of mold—whether sand, metal, or ceramic—affects the wheel’s surface finish and dimensional accuracy. Advanced techniques such as precision casting or sand casting can be utilized depending on the desired specifications. The cooling process is equally important, as it influences the final properties of the casting, including its hardness and strength.

-

Assembly: After forming, the wheels may require assembly with other components, such as bearings and mounting plates. This step often includes machining operations to achieve precise dimensions and surface finishes, enhancing the wheel’s performance and compatibility with various applications.

-

Finishing: The final stage involves surface treatment processes such as painting, powder coating, or galvanizing, which protect against corrosion and enhance aesthetic appeal. Quality assurance checks are often integrated into this stage to confirm that the wheels meet predefined specifications.

What Quality Control Measures Are Essential for Casting Wheels?

Quality control (QC) is critical in ensuring that casting wheels meet both industry standards and customer expectations. Various international and industry-specific standards guide the QC processes.

Illustrative image related to casting wheels

-

International Standards: Compliance with ISO 9001 is fundamental, as it outlines requirements for a quality management system. This certification assures B2B buyers that the manufacturer adheres to consistent quality processes. Other relevant certifications may include CE marking for compliance with European health and safety standards and API certifications for specific industrial applications.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Tests may include chemical composition analysis and physical inspections to ensure materials meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is essential. This involves regular checks at various stages, such as before and after forming, to ensure that the process remains within acceptable parameters.

– Final Quality Control (FQC): The last checkpoint occurs after finishing. Detailed inspections and tests, such as dimensional checks and load tests, confirm that the finished wheels meet all specifications. -

Common Testing Methods: B2B buyers should look for suppliers who employ various testing methods, including tensile strength tests, hardness tests, and fatigue tests. These assessments help ascertain the durability and performance of the wheels under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is paramount to ensure reliability and performance.

-

Supplier Audits: Conducting regular audits can provide insights into a supplier’s manufacturing processes and quality control measures. These audits can assess compliance with international standards and identify areas for improvement.

-

Quality Reports: Requesting detailed quality reports from suppliers is another effective way to verify their QC practices. These reports should include information on testing results, compliance with standards, and corrective actions taken in response to any quality issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can perform inspections at various stages of production and provide certifications that assure compliance with industry standards.

What Are the Nuances of Quality Control for International B2B Buyers?

When dealing with international suppliers, B2B buyers must consider several nuances regarding quality control and compliance.

-

Cultural Differences: Understand that quality standards and practices may vary significantly between regions. For instance, suppliers in Europe may have stricter compliance protocols compared to those in other areas. Awareness of these differences can help buyers set realistic expectations.

-

Documentation and Certifications: Ensure that suppliers provide comprehensive documentation, including certifications for both raw materials and finished products. This documentation should be readily available and transparent to facilitate easy verification.

-

Communication: Establishing clear communication channels with suppliers is essential. This includes discussing quality expectations upfront and maintaining ongoing dialogue regarding any quality concerns that may arise during the manufacturing process.

-

Local Regulations: Be aware of local regulations that may impact quality standards. For instance, specific countries may have unique compliance requirements that affect how casting wheels are manufactured and tested.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing casting wheels, ensuring they receive products that meet their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘casting wheels’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of casting wheels, ensuring that you secure the best products for your operational needs. Whether you are in manufacturing, logistics, or furniture design, understanding the nuances of casting wheels will enable you to make informed decisions that enhance efficiency and durability in your applications.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right casting wheels. Consider the load capacity, wheel diameter, and material type based on the intended application. For example, heavy-duty operations may require cast iron wheels, while lighter applications could benefit from polyurethane options.

- Load Capacity: Determine the maximum weight the wheels will need to support.

- Diameter: Larger wheels facilitate easier movement over obstacles and uneven surfaces.

Step 2: Assess Application Requirements

Different applications necessitate specific features in casting wheels. Identify whether your use case demands swivel or rigid wheels, locking mechanisms, or specialized treads for floor protection. This assessment will guide you in selecting wheels that meet your operational demands effectively.

- Swivel vs. Rigid: Swivel wheels offer greater maneuverability, while rigid wheels provide stability.

- Braking Systems: Locking casters can prevent unwanted movement in stationary equipment.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Request company profiles, client testimonials, and case studies that demonstrate their expertise in your industry. It’s essential to verify that they can meet your specific needs and standards.

- Supplier Reputation: Look for reviews and ratings from other businesses in your region.

- Product Range: Ensure the supplier offers a variety of casting wheels to accommodate future needs.

Step 4: Verify Compliance and Certifications

Compliance with industry standards and certifications is a non-negotiable aspect of sourcing casting wheels. Check for certifications such as ISO or ASTM that indicate adherence to quality and safety regulations. This step mitigates risks associated with product failures and ensures reliability.

- Quality Assurance: Ask about the supplier’s quality control processes.

- Material Certifications: Ensure that materials used meet required safety and performance standards.

Step 5: Request Samples for Testing

Prior to placing a large order, request samples of the casting wheels you intend to purchase. Testing these samples in your operational environment allows you to evaluate performance under actual working conditions. This proactive step can prevent costly mistakes later.

- Performance Testing: Assess how the wheels handle weight, movement, and wear over time.

- Compatibility Checks: Ensure the wheels fit with your existing equipment or furniture.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier and tested the products, negotiate the purchase terms. Discuss pricing, delivery timelines, and after-sales support to ensure you receive the best deal. Establish clear communication channels for any future queries or issues.

- Bulk Purchase Discounts: Inquire about pricing structures for larger orders.

- Warranty and Support: Clarify the warranty terms and available customer support.

Step 7: Plan for Ongoing Maintenance

Consider the maintenance requirements of the casting wheels you choose. Establish a plan for regular inspections and maintenance to prolong the lifespan of the wheels. This step not only enhances safety but also contributes to overall operational efficiency.

- Inspection Schedule: Set a timeline for regular checks on wheel condition and performance.

- Maintenance Resources: Ensure access to replacement parts and servicing if necessary.

By following this checklist, B2B buyers can confidently source casting wheels that align with their specific needs, ensuring long-term operational success.

Comprehensive Cost and Pricing Analysis for casting wheels Sourcing

When sourcing casting wheels, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers. Several cost components contribute to the overall pricing of these products, and various factors influence these prices, especially for international buyers.

Illustrative image related to casting wheels

What Are the Key Cost Components in Sourcing Casting Wheels?

-

Materials: The primary cost driver for casting wheels is the raw materials used in their production. Common materials include cast iron and polyurethane. The choice of material not only affects the durability and performance of the wheels but also significantly influences the cost. For instance, wheels made from high-quality, abrasion-resistant materials will typically command a higher price.

-

Labor: Labor costs can vary significantly depending on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but it’s essential to assess the trade-off between cost and quality. Skilled labor is often necessary for precision manufacturing, particularly for customized solutions.

-

Manufacturing Overhead: This includes indirect costs such as utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help reduce these costs, resulting in better pricing for buyers.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider whether the supplier can absorb these costs based on volume commitments or if they will be passed on to the buyer.

-

Quality Control (QC): Implementing stringent quality control measures is vital to ensure that the wheels meet the required specifications and standards. Higher QC costs can lead to increased prices but will ultimately enhance product reliability.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. Factors such as distance, freight rates, and customs duties will impact the total cost. Buyers should also consider delivery times, as expedited shipping can increase costs.

-

Margin: Suppliers will typically include a margin to cover their operational costs and profit. Understanding the margin expectations of potential suppliers can aid in negotiations.

How Do Price Influencers Impact the Sourcing of Casting Wheels?

Several factors can affect the pricing of casting wheels:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their needs while ensuring they benefit from volume discounts.

-

Specifications and Customization: Custom specifications can significantly influence pricing. While standard products may be more cost-effective, tailored solutions may be necessary for specific applications, which could increase costs.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO standards) can raise prices but may be necessary for certain industries. Buyers should weigh the importance of certifications against potential cost savings.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities play a critical role in pricing. Established suppliers with a proven track record may charge more, reflecting their quality assurance and service reliability.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is essential as they dictate the responsibilities of buyers and sellers during the shipping process. This can affect the total cost of ownership and should be a focal point in negotiations.

What Tips Can Help Buyers Optimize Their Casting Wheel Sourcing Costs?

-

Negotiation Strategies: Engage in open discussions with suppliers about pricing structures and potential discounts based on order volumes. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Focus on Cost-Efficiency: Consider the total cost of ownership rather than just the initial purchase price. Evaluate factors like maintenance, replacement rates, and downtime costs associated with lower-quality wheels.

-

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe must be aware of additional costs such as tariffs, taxes, and import fees that can significantly impact overall pricing.

-

Seek Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to better pricing and service. Consider signing contracts that provide stable pricing over time, which can protect against market fluctuations.

In conclusion, understanding the comprehensive cost structure and the various price influencers is vital for B2B buyers looking to source casting wheels. By leveraging negotiation tactics and focusing on total cost efficiency, buyers can ensure they make informed purchasing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing casting wheels With Other Solutions

When considering mobility solutions for industrial and commercial applications, it’s essential to explore various options beyond casting wheels. This analysis presents a comparison between casting wheels and two viable alternatives: heavy-duty steel casters and rubber wheel casters. Each option has unique attributes that cater to different operational needs.

| Comparison Aspect | ‘Casting Wheels’ | Heavy-Duty Steel Casters | Rubber Wheel Casters |

|---|---|---|---|

| Performance | Excellent durability and weight-bearing capacity; ideal for heavy loads | High strength and abrasion resistance; suited for extreme conditions | Good shock absorption; ideal for delicate floors |

| Cost | Moderate to high, depending on specifications | Generally higher due to material quality | Generally lower, offering budget-friendly options |

| Ease of Implementation | Standard mounting options for easy installation | May require additional hardware for mounting | Simple installation with various mounting styles |

| Maintenance | Low maintenance; resistant to wear | Moderate maintenance; may require periodic checks | Higher maintenance; can wear out faster on rough surfaces |

| Best Use Case | Ideal for heavy-duty applications in warehouses, manufacturing, and construction | Suitable for environments with heavy machinery and high abrasion | Best for indoor environments where floor protection is critical |

What Are the Pros and Cons of Heavy-Duty Steel Casters?

Heavy-duty steel casters are designed for high-capacity applications, often used in environments that demand exceptional durability and load-bearing capabilities. The primary advantage of steel casters lies in their strength; they can handle extreme weights and resist abrasions effectively. However, their cost can be prohibitive, and they may require more frequent maintenance checks to ensure optimal performance. Additionally, their rigidity may not provide the same level of maneuverability as casting wheels.

What Are the Benefits and Drawbacks of Rubber Wheel Casters?

Rubber wheel casters excel in environments that require floor protection and noise reduction. Their shock-absorbing properties make them ideal for delicate surfaces and applications where minimizing impact is crucial. They are typically more affordable than casting wheels and are easy to install, making them attractive for budget-conscious buyers. However, rubber wheels may not withstand heavy loads as effectively as casting wheels and can wear out more quickly when used in rugged conditions, necessitating more frequent replacements.

How Can B2B Buyers Choose the Right Mobility Solution?

When selecting the appropriate mobility solution, B2B buyers should assess their specific operational requirements. For heavy-duty applications where load capacity and durability are paramount, casting wheels or heavy-duty steel casters may be preferable. In contrast, if the primary concern is protecting flooring and reducing noise, rubber wheel casters might be the better choice. Evaluating the intended use, environmental conditions, and budget constraints will guide buyers to the most suitable option, ensuring optimal performance and cost-effectiveness in their operations.

Illustrative image related to casting wheels

Essential Technical Properties and Trade Terminology for casting wheels

What Are the Key Technical Properties of Casting Wheels?

1. Material Grade

The material grade of casting wheels, typically ranging from cast iron to polyurethane, significantly influences their performance. Cast iron offers excellent durability and load-bearing capacity, making it ideal for heavy-duty applications. In contrast, polyurethane wheels provide better floor protection and quieter operation, which is essential in environments where noise reduction is a priority. B2B buyers must assess material grades to ensure they meet the specific demands of their operational environments.

2. Load Capacity

Load capacity refers to the maximum weight a wheel can safely support. This specification is crucial for B2B buyers, especially in industries like manufacturing and warehousing, where heavy loads are common. Wheels with inadequate load capacity can lead to operational failures, safety hazards, and costly damages. Understanding the load capacity helps businesses select the right wheels for their equipment, thereby enhancing efficiency and reducing downtime.

3. Wheel Diameter

The diameter of the wheel affects its mobility and the ease with which it can navigate various surfaces. Larger wheels are better suited for uneven or rough terrains, providing smoother movement and reducing the effort needed to maneuver heavy loads. Conversely, smaller wheels may excel in tighter spaces but can struggle on rough surfaces. B2B buyers should consider wheel diameter based on their specific operational needs and the environments in which they will be used.

4. Tread Design

Tread design, whether smooth, patterned, or flanged, directly impacts traction and floor protection. For instance, wheels with a soft tread are less likely to damage delicate flooring but may wear out faster under heavy loads. On the other hand, harder treads provide better durability but can leave marks on sensitive surfaces. Understanding tread design helps businesses choose wheels that align with their operational requirements and floor care policies.

5. Swivel vs. Rigid Casters

Swivel casters allow for greater maneuverability, enabling equipment to navigate around corners easily. Rigid casters, however, provide stability and are better suited for straight-line movement. The choice between swivel and rigid casters depends on the specific application, such as whether the equipment will frequently change directions or requires stable, straight travel. B2B buyers should evaluate their operational layouts to determine the appropriate caster type.

What Are Common Trade Terms Related to Casting Wheels?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of casting wheels, understanding OEM relationships can help buyers identify quality standards and compatibility with existing equipment, ensuring they procure the right components for their needs.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management. A high MOQ may require businesses to purchase more than they need, impacting cash flow and storage capacity.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to suppliers to solicit price quotes for specific products or services. This process is vital for B2B transactions, as it allows buyers to compare prices, terms, and conditions, leading to more informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers engaged in global trade, as they define who bears the risk and costs at various stages of the shipping process.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. For businesses, understanding lead times is critical for planning and managing inventory levels. Longer lead times can affect production schedules, while shorter lead times can enhance responsiveness to market demands.

6. Customization Options

Customization options allow buyers to tailor products to meet specific operational requirements. This can include variations in wheel material, size, tread design, and mounting types. Understanding available customization options can help B2B buyers optimize performance and ensure that casting wheels integrate seamlessly into their operations.

Navigating Market Dynamics and Sourcing Trends in the casting wheels Sector

What Are the Current Market Dynamics and Key Trends in the Casting Wheels Sector?

The global market for casting wheels is experiencing notable growth driven by increased industrialization and the demand for efficient material handling solutions. In regions like Africa, South America, the Middle East, and Europe, buyers are looking for durable and versatile options that can withstand heavy loads while offering ease of mobility. The rise of e-commerce and logistics operations is a significant driver, as businesses seek reliable equipment to optimize their supply chains. Additionally, the trend towards automation in manufacturing processes is influencing the demand for specialized casters, including those designed for automated guided vehicles (AGVs) and conveyor systems.

Emerging B2B technologies are reshaping sourcing strategies. Digital platforms and marketplaces are streamlining procurement processes, allowing buyers to access a broader range of suppliers and products. Data analytics and AI are also being utilized to forecast demand, manage inventory, and enhance supply chain transparency. This evolution is particularly beneficial for international buyers who can leverage these tools to make informed decisions based on market trends and supplier performance.

Furthermore, customization is becoming a key trend. Buyers are increasingly seeking casters that can be tailored to specific applications, whether for industrial use or aesthetic needs in furniture design. This shift towards bespoke solutions is prompting manufacturers to innovate and offer a wider variety of materials and configurations, catering to diverse market segments.

How Is Sustainability and Ethical Sourcing Influencing the Casting Wheels Market?

Sustainability is emerging as a critical factor in the casting wheels sector. As environmental concerns grow, international B2B buyers are prioritizing suppliers that adopt sustainable practices. This includes using eco-friendly materials, such as recycled metals and low-impact manufacturing processes, which reduce the overall environmental footprint of casting wheels.

Ethical sourcing is also gaining traction, with buyers increasingly interested in the origins of materials and the working conditions within supply chains. Certifications such as ISO 14001 for environmental management and adherence to fair labor practices are becoming essential criteria for supplier selection. Companies that can demonstrate their commitment to sustainability and ethical practices not only enhance their brand reputation but also attract a growing segment of environmentally conscious consumers.

Moreover, buyers are looking for products that contribute to sustainability goals, such as reducing waste or improving energy efficiency. For example, casters designed with low-resistance wheels can enhance mobility and reduce energy consumption in material handling operations. As the demand for ‘green’ products increases, manufacturers are responding by developing innovative solutions that meet these evolving expectations.

What Is the Historical Context Behind the Development of Casting Wheels?

The evolution of casting wheels dates back to the industrial revolution, where the need for efficient movement of heavy goods led to the development of robust wheel designs. Initially made from wood and metal, the introduction of cast iron in the 19th century marked a significant advancement, offering greater strength and durability.

Over the years, advancements in material science have led to the incorporation of various materials such as polyurethane and semi-steel, enhancing the performance characteristics of casting wheels. The design has also evolved to include features like swivel capabilities and locking mechanisms, catering to diverse applications in industrial and commercial settings. Today, the casting wheels market continues to innovate, focusing on versatility, durability, and sustainability to meet the demands of modern businesses.

In summary, understanding the dynamics of the casting wheels market, including the importance of sustainability and historical context, is crucial for international B2B buyers looking to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of casting wheels

-

How do I choose the right casting wheels for my application?

Selecting the appropriate casting wheels involves assessing several key factors, including load capacity, wheel material, and environmental conditions. For heavy-duty applications, consider cast iron or semi-steel wheels due to their durability and abrasion resistance. If your application requires quieter operation or floor protection, polyurethane wheels may be more suitable. Additionally, consider whether you need swivel or rigid wheels based on maneuverability requirements. Always match the wheel specifications with the equipment and intended use to ensure optimal performance. -

What are the common applications for casting wheels in industrial settings?

Casting wheels are widely used in various industrial applications, including material handling, warehousing, and manufacturing. They are ideal for equipment such as pallet jacks, carts, and conveyor systems, where heavy loads and durability are critical. In high-temperature environments, specialized casting wheels designed to withstand heat can be beneficial. Furthermore, these wheels can also enhance mobility for furniture and equipment in office and retail settings, making them versatile across different sectors. -

What customization options are available for casting wheels?

Many suppliers offer customization options for casting wheels to meet specific needs. Customization can include variations in wheel diameter, load capacity, material type, and tread design. Additionally, features such as locking mechanisms or specific mounting styles (plate or stem mount) can often be tailored. When discussing your requirements with suppliers, provide detailed specifications and any particular performance criteria to ensure the wheels meet your operational demands. -

What should I consider when vetting suppliers for casting wheels?

When vetting suppliers, consider factors such as their manufacturing capabilities, quality certifications, and industry experience. Look for suppliers with a proven track record in producing durable and reliable products. Request samples and references from previous clients to gauge product performance and customer service. Additionally, inquire about their compliance with international standards, especially if you are importing to regions with strict regulations. Establishing clear communication channels and assessing their responsiveness can also indicate their reliability as a partner. -

What is the typical minimum order quantity (MOQ) for casting wheels?

The MOQ for casting wheels can vary significantly based on the supplier and the customization required. Standard products may have lower MOQs, while custom-designed wheels usually require larger quantities to make production economically viable. It’s essential to discuss your needs directly with suppliers to determine their MOQ and explore options for smaller initial orders, especially if you’re testing products or entering a new market. -

What payment terms are common for international B2B transactions involving casting wheels?

Payment terms in international B2B transactions can vary but typically include options like upfront payment, partial payment upon order confirmation, and balance upon delivery. Letters of credit are also common to secure transactions, providing assurance to both buyers and sellers. Discussing flexible payment terms with suppliers can help facilitate smoother transactions, especially when working with larger orders or long-term contracts. -

How do I ensure quality assurance (QA) when sourcing casting wheels?

To ensure quality assurance, request detailed product specifications and certifications from your suppliers. Many manufacturers adhere to international quality standards, such as ISO certifications, which can provide assurance of their production processes. Additionally, consider implementing a third-party quality inspection before shipment, especially for large orders. Establishing clear quality expectations and conducting regular audits of the supplier can further enhance product reliability and consistency. -

What logistics considerations should I keep in mind when importing casting wheels?

When importing casting wheels, consider logistics aspects such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder experienced in handling industrial equipment to ensure timely delivery. Be aware of import duties and taxes specific to your country, as these can impact overall costs. Additionally, communicate with your supplier about packaging requirements to prevent damage during transit, and ensure all documentation is complete for smooth customs clearance.

Top 8 Casting Wheels Manufacturers & Suppliers List

1. Caster Connection – Cast Iron Casters

Domain: casterconnection.com

Registered: 1999 (26 years)

Introduction: Cast Iron Casters available in various types including Kingpin Swivel, Kingpinless Swivel, and Rigid. Wheel diameters range from 3″ to 12″ with materials including Polyurethane, Cast Iron, and Rubber. Wheel widths vary from 1/2″ to 3″. Suitable for various applications and environments.

2. ServiceCaster – Heavy Duty Cast Iron Casters

Domain: shop.servicecaster.com

Registered: 1999 (26 years)

Introduction: Heavy Duty Cast Iron Casters, available in various sizes and types including 2″ to 12″ wheels, with options for grip ring stems, threaded stems, and top plates. Materials include glass filled nylon, phenolic, polyurethane, and cast iron. Suitable for heavy-duty applications with features like swivel locks and various tread types. Orders placed by 3 pm EST ship the same day.

3. CasterHQ – Clearance Casters

Domain: casterhq.com

Registered: 2017 (8 years)

Introduction: Clearance Casters: High-Quality, Low-Price Wheels | CasterHQ

– Free Shipping on Orders Over $325 (USA)

– ANSI-Tested Casters for Proven Safety & Performance

– Price Match Guarantee

– Limited-Time Flash Sale: Save Over 50% on Select Casters

– Expert Support Available Weekdays 8 am – 5 pm

Key Products:

1. 8″ x 3″ Rubber on Cast Iron Wheel – 900 lbs capacity, List Price: $70.99, Sale Price: $39.99, …

4. Hamilton Caster – Polyurethane & Metal Solutions

Domain: hamiltoncaster.com

Registered: 1996 (29 years)

Introduction: {“Polyurethane”:{“Capacity Range”:”475 – 34,000 lbs.”,”Description”:”High carrying capacity, floor protection, quiet operation, wide range of compounds and configurations.”},”Metal”:{“Capacity Range”:”250 – 23,000 lbs.”,”Description”:”Highest capacity & tensile strength, easiest rolling sans floor protection, popular for high heat applications.”},”Nylon”:{“Capacity Range”:”350 – 10,000 lbs.”,”Desc…

5. Caster Concepts – Heavy Duty Caster Wheels

Domain: casterconcepts.com

Registered: 1998 (27 years)

Introduction: Caster Wheels: Heavy Duty Casters, Maintenance Free, High Temperature Casters, Ergonomic Casters, Noise Reducing Ground Support Casters, Motorized Casters, Spring Loaded / Shock Absorbing. Capacity: 35,000 – 100,000 lbs. (Super Heavy Duty), 15,000 – 34,999 lbs. (Extra Heavy Duty), 5,000 – 14,999 lbs. (Heavy Duty). Series: 99, 97, 95, 91, 90, 87, 85, 80. Brands: TWERGO®, TWERGO® Xtreme, TWERGO® Lit…

6. JC Forged Wheels – Cast Wheels

Domain: jcforgedwheels.com

Registered: 2022 (3 years)

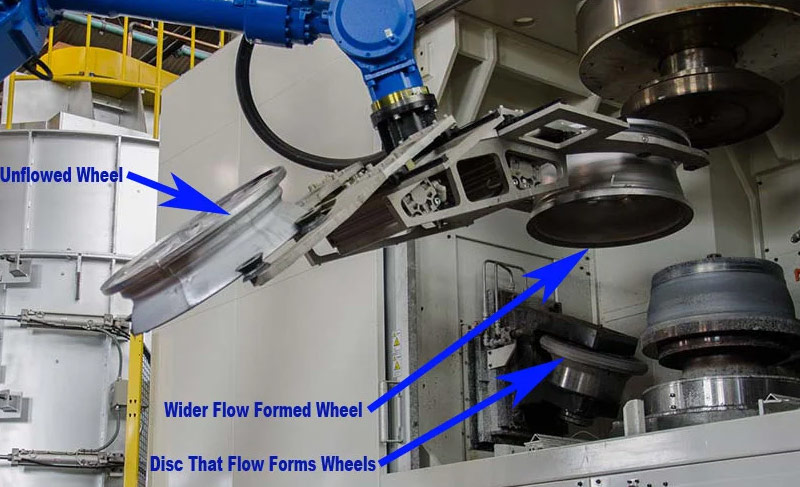

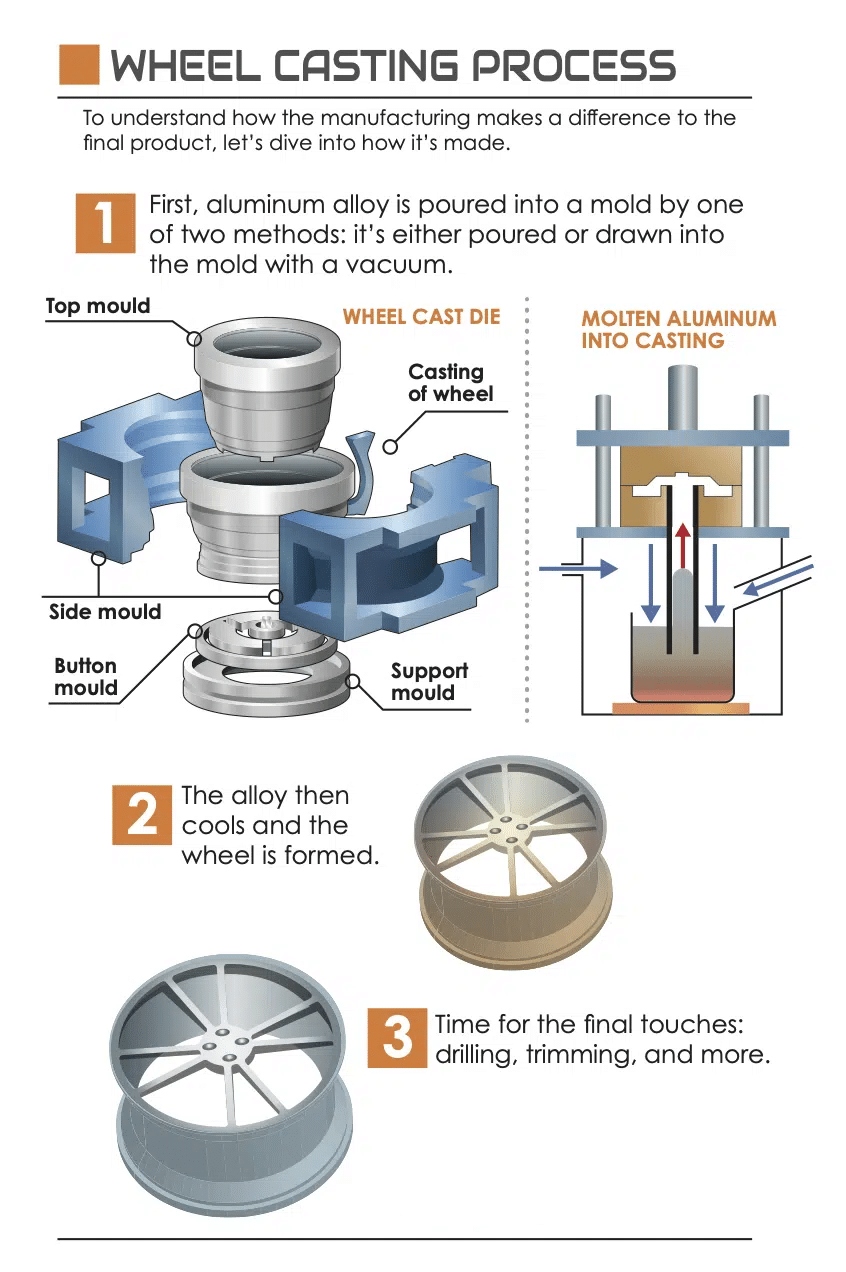

Introduction: 1. **Cast Wheels**:

– Most common type of aftermarket wheels (90% of OE wheels).

– Made by pouring molten aluminum into a mold (gravity or low-pressure casting).

– **Gravity Casting**: Cost-effective, relies on gravity, may have voids leading to heavier wheels.

– **Low-Pressure Casting**: Denser and consistent wheels, better mechanical properties, slightly higher cost.

2. **Rotary Fo…

7. DH Castors – C-MHD5SSS 5 Cast Iron/Steel Wheel

Domain: dhcasters.com

Registered: 2004 (21 years)

Introduction: {‘SKU’: ‘C-MHD5SSS’, ‘Wheel Diameter’: ‘5 inches’, ‘Wheel Width’: ‘2 inches’, ‘Load Capacity’: ‘1000 lbs’, ‘Wheel Material’: ‘Cast Iron / Steel’, ‘Mounting Type’: ‘Plate’, ‘Overall Plate Dimensions’: ‘3-15/16″ x 4-1/2″‘, ‘Bolt Hole Spacing’: ‘2-5/8″ x 3-5/8″ slotted to 3″ x 3″‘, ‘Overall Height’: ‘6-1/2 inches’, ‘Swivel Radius’: ‘3-7/8 inches’, ‘Weight’: ‘6.39 lbs’, ‘Recommended Flooring Types’: ‘…

8. Caster Solutions – Caster Wheels

Domain: castersolutions.com

Registered: 1998 (27 years)

Introduction: Caster Wheel Manufacturer – Shop Casters & Wheels Today! Free Shipping on all orders over $250.00 in contiguous U.S. Categories: Top Plate Casters, Stem Casters, Made in USA Casters, Best Selling, Stainless Steel, OEM Replacement, Low Profile, Dual Wheel, Specialty, Leveling, Scaffolding. Popular Top Plates: 2-3/8″ x 3-5/8″, 4″ x 4-1/2″, 4-1/2″ x 6-1/4″, 5-1/4″ x 7-1/4″, 6-1/4″ x 7-1/2″, 8-1/2″ x …

Strategic Sourcing Conclusion and Outlook for casting wheels

In the competitive landscape of industrial mobility solutions, strategic sourcing of casting wheels stands out as a vital component for enhancing operational efficiency and reducing costs. Buyers must prioritize quality, durability, and versatility in their sourcing decisions. The diverse applications of cast iron casters—ranging from industrial settings to home décor—underscore their adaptability and essential role in various sectors.

Leveraging the right suppliers can significantly impact supply chain resilience, particularly for international markets such as Africa, South America, the Middle East, and Europe. By focusing on suppliers that offer a wide range of products, including heavy-duty options and customizable features, businesses can ensure they meet their unique operational requirements while maintaining a competitive edge.

As we look ahead, the demand for innovative and sustainable mobility solutions is set to grow. International buyers are encouraged to explore partnerships with manufacturers that prioritize both performance and eco-friendliness in their offerings. By doing so, they can not only enhance their operational capabilities but also align with global sustainability goals. Engage with trusted suppliers today to elevate your sourcing strategy and secure the best casting wheels for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to casting wheels

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.