Everything You Need to Know About Carvable Foam Pumpkins Sourcing in 2025

Introduction: Navigating the Global Market for carvable foam pumpkins

In today’s competitive landscape, sourcing high-quality carvable foam pumpkins poses a significant challenge for international B2B buyers. With the growing demand for versatile and durable Halloween decor, businesses must navigate a complex market filled with various product offerings, materials, and suppliers. This comprehensive guide is designed to streamline your purchasing process by delving into the different types of carvable foam pumpkins, their applications, and effective supplier vetting strategies.

Throughout this guide, we will explore essential factors such as product specifications, cost considerations, and market trends that influence buying decisions. By equipping you with actionable insights, we aim to empower B2B buyers from Africa, South America, the Middle East, and Europe—specifically targeting regions like Vietnam and Brazil—to make informed choices that enhance their product offerings and meet customer expectations.

As the demand for unique and customizable Halloween decorations continues to rise, understanding the nuances of the carvable foam pumpkin market is crucial. From identifying reputable suppliers to evaluating product quality, this guide serves as a valuable resource for businesses seeking to secure reliable and cost-effective solutions in this niche market. Prepare to elevate your procurement strategy and ensure your inventory is stocked with the finest carvable foam pumpkins available.

Understanding carvable foam pumpkins Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Round | Classic round shape, available in various sizes, often hollow | Retail, event decoration, crafting workshops | Pros: Easy to carve, widely available. Cons: Limited customization options. |

| Tall and Slim | Elongated shape, suitable for vertical displays | Themed events, decorative installations | Pros: Unique aesthetic, stands out in displays. Cons: Less traditional for Halloween. |

| Squat and Wide | Shorter, broader pumpkins ideal for stable displays | Home décor, outdoor settings | Pros: Stable base, great for outdoor use. Cons: May have less carving depth. |

| Specialty Designs | Unique shapes or themed pumpkins (e.g., ghosts, monsters) | Seasonal events, themed parties | Pros: Eye-catching, enhances thematic decor. Cons: May require more care in handling. |

| Customizable Foam Pumpkins | Blank foam pumpkins that can be painted or decorated | Crafting, DIY projects, educational workshops | Pros: High versatility, encourages creativity. Cons: Requires additional supplies for customization. |

What Are the Characteristics of Traditional Round Carvable Foam Pumpkins?

Traditional round carvable foam pumpkins are the quintessential choice for Halloween decor. Available in a range of sizes, they are primarily hollow, allowing for easy carving and customization. These pumpkins are perfect for retail settings, event decorations, and crafting workshops. When purchasing, buyers should consider the size variations and ensure they are sourcing from reputable suppliers to avoid solid foam versions that cannot be carved.

How Do Tall and Slim Carvable Foam Pumpkins Differ?

Tall and slim pumpkins offer a modern twist on traditional designs, making them suitable for vertical displays. These pumpkins are often utilized in themed events or decorative installations where height can add visual interest. When considering these options, B2B buyers should evaluate their target market’s preferences, as this unique shape may appeal to specific customer demographics looking for non-traditional decor.

What Are the Benefits of Using Squat and Wide Carvable Foam Pumpkins?

Squat and wide pumpkins provide stability, making them ideal for outdoor settings where wind or movement may be a concern. Their broader shape allows for a more substantial carving area, which can be advantageous for detailed designs. Buyers should assess their intended use, as these pumpkins can enhance home decor or be used in community events, offering a more substantial presence than traditional shapes.

What Makes Specialty Designed Carvable Foam Pumpkins Attractive?

Specialty designs cater to niche markets by offering unique shapes or themes, such as ghosts or monsters. These pumpkins are particularly effective for seasonal events and themed parties, helping to create a distinctive atmosphere. B2B buyers should keep in mind the seasonal demand and potential for higher profit margins when sourcing these specialty items, as they can attract customers looking for unique decor.

Why Choose Customizable Foam Pumpkins for Your Business?

Customizable foam pumpkins are blank canvases that allow for extensive creativity, making them ideal for crafting and DIY projects. These pumpkins can be painted or decorated, appealing to educational workshops and craft retailers. When purchasing, buyers should consider the quality of foam and the availability of additional supplies needed for customization, ensuring they can meet customer expectations for creativity and quality.

Key Industrial Applications of carvable foam pumpkins

| Industry/Sector | Specific Application of carvable foam pumpkins | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Seasonal Decor for Halloween Displays | Attracts customers with eye-catching, customizable displays | Ensure variety in sizes and designs to cater to diverse customer preferences. |

| Event Management | Theming for Halloween Events and Festivals | Enhances event aesthetics, providing a memorable experience | Look for bulk purchasing options and customizable designs for branding. |

| Education | Arts and Crafts Supplies for Schools | Encourages creativity in students while providing safe crafting options | Source non-toxic materials suitable for children; consider bulk orders for schools. |

| Interior Design | Home and Office Decor for Seasonal Themes | Provides a unique, reusable decor option that appeals to eco-conscious consumers | Focus on durability and aesthetic appeal; ensure availability of various colors and sizes. |

| Theatrical Productions | Props for Halloween-themed Plays and Performances | Enhances production quality with realistic-looking props | Seek suppliers that offer a range of sizes and custom designs for specific production needs. |

How Are Carvable Foam Pumpkins Utilized in Retail Environments?

In the retail sector, carvable foam pumpkins serve as an integral part of Halloween displays, enhancing visual merchandising strategies. These pumpkins can be customized with paint, lights, and other decorative elements, allowing retailers to create engaging and thematic experiences that attract shoppers. For international buyers, it’s important to source a variety of sizes and designs to accommodate different cultural preferences and market demands, particularly in regions like Africa and South America where Halloween may be gaining popularity.

What Role Do Carvable Foam Pumpkins Play in Event Management?

Event management companies frequently utilize carvable foam pumpkins to create immersive Halloween-themed experiences at festivals, parties, and corporate events. These pumpkins offer a safe and reusable alternative to real pumpkins, which can rot and create messes. Buyers in this sector should consider bulk purchasing options to lower costs and ensure a consistent supply. Additionally, customizable designs can enhance branding opportunities, making them an attractive option for event planners in the Middle East and Europe.

How Are Carvable Foam Pumpkins Beneficial for Educational Institutions?

Educational institutions can leverage carvable foam pumpkins as a versatile crafting material for arts and crafts projects. These pumpkins provide a safe, non-toxic option for students to express their creativity, especially during Halloween-themed projects. For schools in regions like Vietnam and Brazil, sourcing non-toxic materials is crucial, and bulk orders can help manage costs effectively. This application fosters creativity and engagement among students, making it a valuable addition to educational supplies.

How Do Carvable Foam Pumpkins Enhance Interior Design?

Interior designers incorporate carvable foam pumpkins into seasonal decor for homes and offices, appealing to clients seeking unique and reusable decorations. These pumpkins can be painted and decorated to match various design aesthetics, providing flexibility in decor choices. When sourcing for this application, buyers should focus on the durability and aesthetic appeal of the pumpkins, ensuring they can withstand multiple seasons of use. This is particularly relevant in Europe, where sustainability and eco-friendliness are increasingly prioritized.

What Are the Theatrical Applications of Carvable Foam Pumpkins?

Theatrical productions often require realistic props to enhance storytelling, and carvable foam pumpkins fit this need perfectly. They can be used in Halloween-themed plays and performances, adding authenticity to the stage environment. Buyers in the theater sector should seek suppliers offering a range of sizes and the possibility of custom designs to meet specific production requirements. This ensures that the props not only look good but also fit seamlessly into the overall production design.

3 Common User Pain Points for ‘carvable foam pumpkins’ & Their Solutions

Scenario 1: Difficulty Sourcing High-Quality Carvable Foam Pumpkins

The Problem:

Many B2B buyers, especially those in regions like Africa and South America, struggle to find reliable suppliers of high-quality carvable foam pumpkins. Often, what is advertised as “carvable” turns out to be solid foam or of inferior quality, leading to disappointment after purchase. This can hinder businesses that rely on these products for seasonal promotions, events, or decorations, as they may end up with unsatisfactory inventory that doesn’t meet customer expectations.

The Solution:

To overcome this sourcing challenge, buyers should conduct thorough research and establish relationships with reputable suppliers that specialize in foam products. Utilizing online marketplaces, industry-specific trade shows, and networking within community forums can lead to discovering manufacturers that provide high-quality carvable foam pumpkins. When engaging with suppliers, it is crucial to request samples and specifications to ensure the pumpkins meet the desired criteria. Establishing clear communication regarding size, density, and carve-ability can help mitigate risks associated with poor-quality products. Additionally, consider bulk purchasing agreements to negotiate better prices and ensure consistent supply, which can be particularly advantageous for businesses preparing for peak seasonal demands.

Scenario 2: Limited Variety in Pumpkin Shapes and Sizes

The Problem:

Buyers frequently encounter a lack of variety in shapes and sizes of carvable foam pumpkins available in their local markets. This limitation can stifle creativity in Halloween or autumn-themed displays, leading to a monotonous aesthetic that fails to attract customers. For businesses looking to create unique experiences or themed events, the absence of diverse options can be a significant drawback.

The Solution:

To address this issue, businesses should explore global suppliers who offer a broader range of shapes and sizes. Online platforms such as Alibaba or specialized craft suppliers can provide access to international manufacturers who produce a wide array of foam pumpkins. Additionally, buyers can collaborate with suppliers to customize orders based on specific needs—such as larger, squat pumpkins or unique shapes that can enhance visual merchandising. Offering pre-orders for exclusive designs can also generate buzz and ensure that a diverse selection is available for customers. By being proactive in sourcing and customizing products, businesses can create visually appealing displays that stand out in a competitive marketplace.

Scenario 3: Issues with Product Durability and Carvability

The Problem:

Another common pain point is the durability and ease of carving of foam pumpkins. Many buyers find that the foam used in cheaper products is too dense or thick, making it difficult to carve cleanly, which can lead to frustration and wasted resources. This issue not only affects the quality of the final product but can also lead to negative customer experiences if the pumpkins do not hold up well during events.

The Solution:

To ensure that the foam pumpkins are both durable and easy to carve, buyers should prioritize sourcing products made from low-density foam with a thin plastic or resin shell. This combination allows for easier carving while maintaining structural integrity. When placing orders, buyers should inquire about the specific foam density and shell thickness from suppliers. Additionally, sharing feedback with manufacturers regarding the performance of their products can encourage them to improve their offerings. For added durability, businesses can also consider implementing a protective coating or sealant on the pumpkins after carving, which can enhance their longevity, especially for outdoor displays. Offering workshops or instructional content on proper carving techniques can also empower customers, ensuring that they achieve the best results with their purchases.

Strategic Material Selection Guide for carvable foam pumpkins

What Materials Are Commonly Used for Carvable Foam Pumpkins?

When selecting materials for carvable foam pumpkins, several options are available, each with distinct properties and implications for performance, durability, and cost. Understanding these materials is crucial for international B2B buyers who need to align their product offerings with market demands and compliance requirements.

What Are the Key Properties of Polyurethane Foam for Carvable Pumpkins?

Polyurethane foam is a popular choice for carvable pumpkins due to its lightweight and versatile nature. It offers good insulation properties and can be produced in various densities, allowing for customization based on the desired firmness. Polyurethane foam is generally resistant to moisture, which can be beneficial in humid environments.

Pros: The material is relatively easy to mold and shape, making it suitable for intricate designs. It also provides a realistic texture that mimics natural pumpkins, enhancing aesthetic appeal.

Cons: However, polyurethane foam can be sensitive to UV light, leading to degradation over time if exposed to sunlight. Additionally, it may have a higher production cost compared to other foam types.

How Does EVA Foam Compare for Use in Carvable Pumpkins?

Ethylene-Vinyl Acetate (EVA) foam is another viable option for carvable pumpkins. Known for its flexibility and resilience, EVA foam can withstand repeated use without losing its shape. It is also resistant to cracking and provides a smooth surface for painting and decorating.

Pros: EVA foam is lightweight and easy to handle, making it a favorite for DIY projects. Its durability means that pumpkins made from EVA can last multiple seasons, appealing to eco-conscious consumers.

Cons: On the downside, EVA foam can be more expensive than traditional polyethylene foams, and its production processes may require specialized equipment, which can complicate manufacturing.

What Are the Benefits and Drawbacks of Polyethylene Foam for Carvable Pumpkins?

Polyethylene foam is often used in lower-cost carvable pumpkins. This material is lightweight and offers decent shock absorption, making it suitable for seasonal decorations that may be handled frequently.

Pros: Its affordability is a significant advantage, making it an attractive option for bulk purchases. Additionally, polyethylene foam is resistant to moisture and chemicals, which can be beneficial in various climates.

Cons: However, polyethylene foam is less durable than polyurethane or EVA, leading to a shorter lifespan. It may also lack the aesthetic appeal of higher-end materials, which could affect consumer perception.

What Should International Buyers Consider When Selecting Materials?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider local compliance standards when selecting materials for carvable foam pumpkins. Familiarity with regulations such as ASTM (American Society for Testing and Materials) in the U.S., DIN (Deutsches Institut für Normung) in Germany, and JIS (Japanese Industrial Standards) can ensure product safety and quality.

Additionally, buyers should assess the availability of materials in their local markets and consider logistical factors such as shipping costs and import duties. Understanding regional preferences for sustainability and product longevity can also guide material selection, as eco-friendly options are increasingly favored.

Summary Table of Material Selection for Carvable Foam Pumpkins

| Material | Typical Use Case for carvable foam pumpkins | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Foam | High-end, realistic carvable pumpkins | Excellent texture and customization | Sensitive to UV light | High |

| EVA Foam | Flexible, durable carvable pumpkins | Resilient and eco-friendly | Higher production costs | Medium |

| Polyethylene Foam | Budget-friendly carvable pumpkins | Cost-effective and moisture resistant | Shorter lifespan and less aesthetic | Low |

This analysis provides a comprehensive overview of the materials used in carvable foam pumpkins, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for carvable foam pumpkins

What Are the Main Stages in the Manufacturing Process of Carvable Foam Pumpkins?

The manufacturing of carvable foam pumpkins involves several key stages, each contributing to the final product’s quality and usability. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

Material Preparation

The first stage involves selecting the right materials. Carvable foam pumpkins are typically made from low-density polyethylene foam (LDPE) or similar materials, which allow for easy carving while maintaining structural integrity. Manufacturers prepare these materials by sourcing them from certified suppliers to ensure consistency in quality. The materials may undergo a pre-treatment process to enhance their properties, such as adding color or improving UV resistance.

Forming Techniques

Once the materials are prepared, the next step is forming. This is often achieved through one of two primary methods: molding or sculpting.

-

Molding: In this method, foam is poured into molds designed to create specific shapes and sizes of pumpkins. High-quality molds ensure that each pumpkin has uniform dimensions, which is critical for mass production. The molds can be crafted from various materials, including metal or high-grade plastic, depending on the required durability and precision.

-

Sculpting: For more intricate designs, sculpting techniques may be employed. This involves manually shaping the foam or using CNC (Computer Numerical Control) machines for precision. Sculpting allows for more artistic designs, appealing to markets that demand unique or customized products.

Assembly and Finishing Processes

After forming, the pumpkins may undergo an assembly process, which is particularly relevant for designs that require multiple components, such as removable stems or decorative elements. Assembly is typically done by hand or with automated machinery, depending on the scale of production.

Finishing processes include painting, applying coatings, and adding textures. The paint used is often non-toxic and designed to withstand the elements, ensuring longevity, especially for outdoor displays. Quality control during this stage is crucial, as it affects the aesthetic appeal and durability of the product.

How Is Quality Assurance Implemented in the Production of Carvable Foam Pumpkins?

Quality assurance (QA) in the manufacturing of carvable foam pumpkins involves adherence to both international and industry-specific standards. These standards ensure that the final products meet the expectations of B2B buyers regarding safety, durability, and performance.

What International Standards Are Relevant for Carvable Foam Pumpkin Production?

One of the most recognized international standards is ISO 9001, which outlines the criteria for a quality management system. Companies that adhere to this standard demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Additionally, compliance with CE marking may be necessary for products sold in the European market, indicating conformity with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to ensuring product quality throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any non-conforming materials are rejected, preventing future quality issues.

-

In-Process Quality Control (IPQC): This occurs during the manufacturing stages, where random samples are tested for consistency in size, shape, and material properties. IPQC helps identify defects early, reducing waste and rework.

-

Final Quality Control (FQC): At this stage, finished products undergo thorough inspections. This may include visual checks for defects, measurements for dimensional accuracy, and tests for durability.

What Testing Methods Are Commonly Used for Quality Assurance in Carvable Foam Pumpkins?

Common testing methods for quality assurance include:

-

Mechanical Testing: This assesses the foam’s resistance to impacts and cuts, ensuring that the pumpkins can withstand carving without collapsing.

-

Environmental Testing: Products may be subjected to UV exposure tests to verify that colors do not fade and materials do not degrade when exposed to sunlight.

-

Safety Testing: For markets that require safety certifications, products may need to undergo flammability tests to ensure compliance with safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying supplier quality control is critical to ensuring that products meet required standards. Here are several methods to achieve this:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Audits can be performed by the buyer or through third-party inspection services.

-

Quality Assurance Reports: Requesting detailed QA reports can help buyers understand a supplier’s commitment to quality. These reports should outline testing methods, results, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality. These services can conduct inspections at various stages of production, from raw materials to finished products.

What QC and Certification Nuances Should International B2B Buyers Be Aware Of?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification.

-

Regulatory Requirements: Different markets may have varying regulatory requirements for product safety and quality. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Cultural Considerations: Understanding cultural expectations regarding product quality and safety can also impact purchasing decisions. Some markets may prioritize eco-friendly materials or specific aesthetic qualities.

-

Communication with Suppliers: Establishing clear communication channels with suppliers is essential for addressing any concerns regarding quality. This includes discussing quality expectations, compliance with standards, and any specific market requirements.

By understanding the manufacturing processes and quality assurance measures for carvable foam pumpkins, B2B buyers can make informed decisions that align with their market needs and consumer expectations. This knowledge not only fosters better supplier relationships but also enhances product satisfaction in the marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carvable foam pumpkins’

To assist B2B buyers in efficiently sourcing carvable foam pumpkins, this guide outlines key steps to ensure a successful procurement process. Whether you are looking to stock seasonal items for retail or seeking materials for crafting and decoration, following this checklist will help you make informed decisions.

Step 1: Define Your Product Specifications

Establishing clear specifications for your carvable foam pumpkins is essential. Consider factors such as size, shape, density, and color. For instance, many buyers prefer pumpkins that are at least 14 inches in diameter and have a low-density foam composition to facilitate easier carving.

- Size and Shape: Determine the dimensions and style (round, squat, or flat) that best fit your market needs.

- Density Requirements: Look for low-density foam options that are durable yet easy to carve.

Step 2: Research Potential Suppliers

Identifying reliable suppliers is crucial for sourcing quality products. Use online platforms, trade directories, and industry forums to compile a list of potential vendors.

- Supplier Reviews: Check for testimonials or reviews from other buyers to gauge their reliability and product quality.

- Location Considerations: Favor suppliers with a strong presence in your target regions to reduce shipping costs and lead times.

Step 3: Verify Supplier Certifications

Before proceeding with any orders, ensure that your chosen suppliers meet industry standards and certifications. This verification process helps avoid potential quality issues down the line.

- Quality Assurance: Request documentation on quality control processes and certifications (e.g., ISO) that demonstrate compliance with safety standards.

- Sustainability Practices: Inquire about eco-friendly practices if this aligns with your company’s values or customer expectations.

Step 4: Request Samples for Evaluation

Before making a bulk purchase, it’s prudent to request samples of the carvable foam pumpkins. This allows you to assess the product quality firsthand.

- Testing for Carvability: Evaluate how well the sample can be carved and painted, ensuring it meets the artistic needs of your end customers.

- Durability Assessment: Check the durability of the foam over time and under different conditions to confirm long-term viability.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier and evaluated samples, engage in pricing negotiations. This step is crucial to ensuring you achieve a favorable deal.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce your overall costs.

- Payment Terms: Clarify payment terms, including deposits and payment schedules, to maintain healthy cash flow.

Step 6: Establish Clear Delivery Timelines

Setting clear expectations for delivery timelines is essential to ensure your products arrive on schedule. Discuss lead times with your suppliers and factor in potential delays.

- Shipping Options: Explore different shipping methods and their associated costs to find the most efficient solution.

- Contingency Plans: Develop a backup plan in case of unexpected delays, ensuring that your supply chain remains uninterrupted.

Step 7: Monitor and Evaluate Supplier Performance

After your first order, it’s important to continuously monitor supplier performance. Regular evaluations can help maintain quality and reliability.

- Feedback Loop: Create a system for gathering feedback on product quality and service levels from your team.

- Long-term Partnerships: Consider establishing long-term relationships with suppliers who consistently meet your expectations, fostering stability in your supply chain.

By following this checklist, B2B buyers can effectively navigate the sourcing process for carvable foam pumpkins, ensuring quality products that meet market demands.

Comprehensive Cost and Pricing Analysis for carvable foam pumpkins Sourcing

What Are the Key Cost Components for Sourcing Carvable Foam Pumpkins?

When considering the sourcing of carvable foam pumpkins, it’s essential to analyze the cost structure, which consists of several key components:

-

Materials: The primary materials for carvable foam pumpkins include low-density foam and a thin plastic or resin shell. Quality materials directly impact both the durability and the carving experience, which can affect buyer satisfaction and repeat orders.

-

Labor: Labor costs can vary significantly based on the manufacturing location. Countries with lower labor costs may provide an initial advantage; however, it’s crucial to ensure that labor practices align with ethical standards, especially when sourcing from regions like Africa and South America.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient management of these overheads can lead to cost reductions, benefiting both manufacturers and buyers.

-

Tooling: Initial tooling costs for molds and specialized equipment can be substantial. These costs are typically amortized over a larger production run, which highlights the importance of negotiating minimum order quantities (MOQs) to distribute these costs effectively.

-

Quality Control (QC): Implementing a robust QC process is vital to ensure that the final product meets specifications. While this adds to costs, it can prevent larger issues down the line, such as returns and dissatisfied customers.

-

Logistics: Transportation and shipping costs can fluctuate based on the Incoterms agreed upon. Understanding these terms is crucial for international buyers to anticipate additional costs related to duties, tariffs, and insurance.

-

Margin: Suppliers often set their margins based on market demand and competition. Buyers should be aware of prevailing market prices to engage in effective negotiations.

What Influences the Pricing of Carvable Foam Pumpkins?

Several factors influence the pricing of carvable foam pumpkins:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract lower unit prices, making it beneficial for buyers to consolidate their purchases.

-

Specifications and Customization: Custom features, such as unique sizes or colors, can increase costs. Buyers should clarify their requirements early in the negotiation process.

-

Materials and Quality Certifications: Higher-quality materials and certified products often command premium prices. Buyers should evaluate whether the additional cost aligns with their target market’s expectations.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can influence pricing. Established suppliers may offer better reliability but might also charge more.

-

Incoterms: The agreed-upon terms of shipping can significantly impact total costs. Buyers should consider whether they will manage logistics or if the supplier will handle shipping, as this can affect pricing.

How Can Buyers Optimize Costs When Sourcing Carvable Foam Pumpkins?

To maximize cost-efficiency, buyers should consider the following tips:

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing structures and seek to negotiate better terms, especially for larger orders.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with quality, durability, and potential returns. Investing in higher-quality products can reduce TCO.

-

Understand Pricing Nuances for International Markets: Buyers from diverse regions may face different market dynamics. Understanding local demand, competition, and economic conditions can help in negotiating better prices.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms over time. Consistent orders and timely payments can foster goodwill and result in discounts or improved service.

Disclaimer

Prices for carvable foam pumpkins can vary widely based on the factors outlined above. It is advisable for buyers to conduct thorough market research and supplier assessments to obtain accurate and indicative pricing tailored to their specific needs.

Alternatives Analysis: Comparing carvable foam pumpkins With Other Solutions

Exploring Alternative Solutions to Carvable Foam Pumpkins

In the quest for versatile and appealing Halloween decorations, especially in the B2B market, understanding alternatives to carvable foam pumpkins is essential. While these foam pumpkins offer a unique solution for crafting and decoration, several other methods or products can achieve similar results, catering to different needs and preferences.

| Comparison Aspect | Carvable Foam Pumpkins | Natural Pumpkins | Plastic Jack-o’-lanterns |

|---|---|---|---|

| Performance | High-quality carving; durable and reusable | Natural appearance; can rot and decay | Lightweight; easy to handle but less realistic |

| Cost | Moderate to high cost per unit | Varies seasonally; typically lower cost | Generally low cost; can be mass-produced |

| Ease of Implementation | Requires carving tools and artistic skill | Simple; available pre-carved or uncarved | Ready to use; no carving needed |

| Maintenance | Minimal; can last several seasons | Requires disposal; potential for mess | Minimal; can be stored for future use |

| Best Use Case | Ideal for themed events, parties, and seasonal displays | Perfect for traditional decorations and cooking | Suitable for children’s events or short-term displays |

What Are the Pros and Cons of Natural Pumpkins?

Natural pumpkins provide a classic Halloween experience, often sought after for their authenticity and charm. However, their seasonal availability and tendency to rot can be drawbacks. They offer a lower upfront cost, making them budget-friendly, especially for large events. Yet, they require more maintenance, as they can attract pests and create messes as they decay. Additionally, natural pumpkins are not reusable, which can lead to increased waste.

How Do Plastic Jack-o’-lanterns Compare?

Plastic Jack-o’-lanterns are a popular alternative, particularly for family-friendly events. They are lightweight, durable, and often come in bright colors, appealing to younger audiences. These decorations are ready to use right out of the box, eliminating the need for carving or artistic skills. However, they may lack the realistic appearance of foam pumpkins and can be less environmentally friendly due to their plastic composition. Despite being low-cost, they may not provide the same visual impact as more premium options like carvable foam pumpkins.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate Halloween decoration solution, B2B buyers must consider various factors, including the target audience, event type, and budget constraints. Carvable foam pumpkins offer a balance of durability and aesthetic appeal, making them suitable for high-end events or themed parties. In contrast, natural pumpkins may appeal to businesses looking for traditional, rustic charm but require more upkeep. Lastly, plastic jack-o’-lanterns serve well for casual, family-oriented gatherings where ease of use is paramount. Ultimately, the decision should align with the buyer’s specific needs, ensuring a memorable and effective display.

Essential Technical Properties and Trade Terminology for carvable foam pumpkins

What Are the Key Technical Properties of Carvable Foam Pumpkins?

Understanding the essential technical properties of carvable foam pumpkins is crucial for B2B buyers, particularly for those sourcing products for resale or decorative purposes. Here are some critical specifications to consider:

-

Material Composition

Carvable foam pumpkins are typically made from low-density polyethylene (LDPE) or polyurethane foam. These materials offer a lightweight yet durable option, allowing for easy carving and decorating. The choice of material affects not only the product’s feel and appearance but also its longevity and resistance to wear and tear, which are significant considerations for retailers. -

Size and Dimensions

Common sizes range from small (around 9 inches) to larger varieties (up to 14 inches or more). Buyers should specify size requirements based on market demand and consumer preferences. Larger pumpkins often attract more attention and can be used for various display purposes, making them a desirable option in the retail space. -

Wall Thickness

The wall thickness of foam pumpkins can vary, typically ranging from 1/4 inch to 1 inch. Thicker walls provide enhanced durability, allowing for more extensive carving and decoration without compromising the structural integrity of the pumpkin. Buyers should assess their target market’s needs; thicker pumpkins may be more suited for high-traffic environments or for repeated use. -

Surface Finish

The surface finish can influence paint adhesion and carving ease. Options include smooth finishes for easy painting and textured finishes for a more realistic appearance. A higher-quality finish can enhance the overall aesthetic appeal, making the pumpkins more attractive to consumers. -

Density Rating

The density of the foam impacts both weight and durability. Low-density foams are lighter and easier to handle, while higher-density options provide better durability and resistance to damage. This is particularly important for businesses that plan to offer these products for outdoor use or in settings where they may be subjected to wear and tear. -

Color Options

Standard colors include orange, white, and green, but custom color options may be available. Offering a variety of colors can cater to diverse customer preferences and seasonal trends, enhancing marketability. Customization can also be a selling point for retailers looking to differentiate themselves from competitors.

What Are Common Trade Terms in the Carvable Foam Pumpkin Industry?

Familiarity with industry jargon is essential for effective communication and successful transactions. Here are some common terms used in the carvable foam pumpkin market:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end products. Understanding OEM relationships can help buyers identify potential suppliers and negotiate better terms. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory and cash flow effectively. It can also impact pricing, as larger orders often lead to discounts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products. This helps buyers compare prices and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and freight. Familiarity with these terms helps buyers understand shipping costs, liability, and delivery timelines, which are critical for international transactions. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving it. Understanding lead times is essential for inventory management, particularly for seasonal products like carvable foam pumpkins, where timing can significantly impact sales. -

Customs Duties and Tariffs

These are taxes imposed on imported goods. Buyers should be aware of potential additional costs when sourcing internationally, as these can affect overall profitability.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they source the right products that meet market demands while optimizing their operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the carvable foam pumpkins Sector

What Are the Key Market Dynamics and Trends for Carvable Foam Pumpkins?

The carvable foam pumpkins market is experiencing notable growth driven by seasonal demand, particularly around Halloween. This surge is particularly evident in regions like Africa, South America, the Middle East, and Europe, where festive celebrations are gaining traction. B2B buyers are increasingly seeking high-quality products that offer durability and aesthetic appeal, as they cater to a growing consumer base interested in creative and reusable decorations. The trend toward DIY crafts is also influencing purchasing decisions, with businesses looking for versatile products that can be customized for various themes and celebrations.

Emerging technologies are shaping sourcing strategies, with e-commerce platforms becoming essential for international buyers. Businesses are leveraging digital marketplaces to access a broader range of suppliers and products, allowing them to compare quality and pricing effectively. Additionally, social media platforms are playing a critical role in influencing consumer preferences and trends, prompting suppliers to create unique and engaging product offerings that stand out in a competitive market. The demand for larger, more intricately designed foam pumpkins is increasing, as seen in discussions among consumers looking for specific shapes and sizes that are not readily available in traditional retail outlets.

How Does Sustainability and Ethical Sourcing Impact the Carvable Foam Pumpkins Sector?

Sustainability is becoming a cornerstone of B2B operations in the carvable foam pumpkins sector. With increasing awareness of environmental issues, buyers are prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes using eco-friendly materials, such as low-density foam with recyclable properties, and ensuring ethical labor practices throughout the supply chain. For international buyers, particularly those in regions where sustainability regulations are becoming stricter, sourcing from suppliers who can provide transparency about their production processes is crucial.

The importance of certifications cannot be overstated. Products that are labeled with ‘green’ certifications or made from biodegradable materials resonate well with eco-conscious consumers. Companies that adopt these practices not only enhance their brand reputation but also cater to a growing segment of the market that values sustainability. This shift is not only beneficial for the environment but also opens new avenues for marketing and sales, as consumers increasingly prefer brands that align with their values.

How Has the Carvable Foam Pumpkins Market Evolved Over Time?

The carvable foam pumpkins market has evolved significantly over the past few decades. Originally, Halloween decorations were predominantly made from natural materials like pumpkins and gourds, but the introduction of foam alternatives offered a more durable and reusable option. Early foam pumpkins were often solid and less realistic, but advancements in manufacturing techniques have led to the development of more lifelike, carvable designs. This evolution aligns with broader trends in the crafting and home décor industries, where customization and quality are increasingly valued.

As the global market continues to expand, particularly in emerging economies, the demand for versatile and attractive decorations will likely drive further innovation in the carvable foam pumpkins sector. Businesses that stay ahead of these trends by adopting sustainable practices and leveraging technology will be well-positioned to thrive in this competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of carvable foam pumpkins

-

How do I find reliable suppliers for carvable foam pumpkins?

To locate dependable suppliers for carvable foam pumpkins, start by attending international trade shows and industry exhibitions, where you can meet manufacturers and wholesalers directly. Utilize online B2B marketplaces such as Alibaba, Global Sources, or TradeIndia, filtering by supplier ratings and reviews. Engage with local trade associations in your region, which can often provide recommendations for reputable suppliers. Additionally, consider requesting samples before placing bulk orders to assess quality firsthand. -

What are the minimum order quantities (MOQ) for carvable foam pumpkins?

Minimum order quantities for carvable foam pumpkins can vary significantly by supplier and product type. Generally, MOQs can range from as low as 50 pieces for smaller manufacturers to 500 or more for larger suppliers. When negotiating with suppliers, inquire about tiered pricing based on order volume, as larger orders may lead to reduced per-unit costs. Always confirm MOQs early in discussions to align your purchasing strategy with supplier capabilities. -

What payment terms should I expect when sourcing carvable foam pumpkins?

Payment terms for international B2B transactions typically include options such as upfront payment, a deposit followed by a balance payment upon delivery, or letters of credit. Standard practices often involve a 30% deposit with the order and the remaining 70% prior to shipping. Ensure that the payment method is secure and offers buyer protection. Discuss and agree upon payment terms before finalizing the order to avoid any misunderstandings later. -

How can I customize carvable foam pumpkins for my business?

Customization options for carvable foam pumpkins often include size, color, and design modifications. Many suppliers offer the ability to create bespoke designs based on your specifications. To initiate this process, provide detailed requirements and artwork to the supplier. Be sure to inquire about the costs and lead times associated with customization, as these can vary widely depending on the complexity of the design and the supplier’s capabilities. -

What quality assurance measures should I consider when sourcing foam pumpkins?

Implementing quality assurance (QA) measures is critical when sourcing carvable foam pumpkins. Request product samples before committing to a bulk order to evaluate materials, durability, and finish. It’s also advisable to ask suppliers for certifications that verify compliance with safety and quality standards relevant to your market. Establish clear QA checkpoints throughout the production process, including inspections at the factory and before shipment, to mitigate risks of defective products. -

How do logistics impact the sourcing of carvable foam pumpkins?

Logistics plays a significant role in the sourcing of carvable foam pumpkins, affecting costs, delivery times, and overall supply chain efficiency. Consider the shipping methods available (air freight vs. sea freight) and their associated costs based on your order volume and urgency. Collaborate with suppliers who have established logistics partners to streamline the shipping process. Additionally, factor in customs clearance processes and potential tariffs, especially when importing from different countries. -

What are the best practices for negotiating with suppliers of carvable foam pumpkins?

Negotiating effectively with suppliers involves clear communication, research, and a strategic approach. Start by understanding market prices and competitor offerings to establish a baseline for negotiations. Build rapport with suppliers and express your interest in long-term partnerships, which can incentivize them to offer better terms. Be prepared to discuss volume discounts, payment flexibility, and shipping arrangements to create a mutually beneficial agreement. -

What should I look for in terms of product safety and compliance for carvable foam pumpkins?

When sourcing carvable foam pumpkins, ensure that they meet safety and compliance standards relevant to your market. This may include certifications for non-toxic materials, flame resistance, and adherence to safety regulations for children’s products. Request documentation from suppliers that verify compliance, and stay informed about any local regulations that might affect the sale of these products in your region. Prioritizing safety not only protects your customers but also enhances your brand’s reputation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Carvable Foam Pumpkins Manufacturers & Suppliers List

1. Funkins – Masters Carving Tools

Domain: funkins.com

Registered: 1998 (27 years)

Introduction: This company, Funkins – Masters Carving Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Halloween Forum – Carvable Foam Pumpkins

Domain: halloweenforum.com

Registered: 2002 (23 years)

Introduction: Big round carvable foam pumpkins

3. HauntForum – Affordable Foam Pumpkins

Domain: hauntforum.com

Registered: 2006 (19 years)

Introduction: Foam pumpkins made using fiberglass molds; cost-effective (approx $5 per pumpkin); uses pourable foam; requires carnuba wax as a release agent; involves measuring water for mold volume; fiberglass mold provides good flexibility for de-molding; includes tips for successful foam pouring and de-molding.

4. Facebook – Carvable Foam Pumpkins

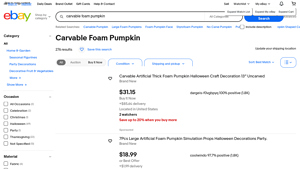

5. Carvable Foam Pumpkin – Halloween Craft Decoration

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Carvable Foam Pumpkin, Halloween Craft Decoration, Various Sizes, Brand New, Prices range from $6.99 to $34.99, Delivery options available, Free returns on select items.

6. Hobby Lobby – Carvable Pumpkin

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Carvable Pumpkin”, “SKU”: “5320817”, “Discounted Price”: “$23.99”, “Original Price”: “$39.99”, “Discount”: “40% Off”, “Color”: “White”, “Dimensions”: “12.8\” H x 9.75\” W x 9.75\” D”, “Material”: “Foam”, “Quantity”: “1”, “Shipping Information”: “Most orders will ship within 1-2 business days and delivery usually takes an additional 3-4 business days.”, “Returns Policy”: “Qualifyi…

Strategic Sourcing Conclusion and Outlook for carvable foam pumpkins

As the demand for carvable foam pumpkins continues to grow, strategic sourcing becomes crucial for B2B buyers navigating this competitive market. Key takeaways indicate that buyers should prioritize suppliers who offer a diverse range of sizes and styles, especially large, round options that are currently in demand. Notably, the market is shifting towards products that feature higher quality and durability, addressing consumer preferences for reliable and aesthetically pleasing decorations.

Moreover, understanding the seasonal nature of the Halloween market can guide procurement strategies, ensuring timely availability of stock to meet customer needs. International buyers from regions such as Africa, South America, the Middle East, and Europe should leverage partnerships with manufacturers who can provide customized solutions, including low-density foam options that are both cost-effective and attractive.

Looking ahead, the carvable foam pumpkin market presents significant opportunities for growth. Buyers are encouraged to explore innovative sourcing strategies and maintain flexibility in their purchasing approaches. By aligning with reliable suppliers and anticipating market trends, businesses can enhance their product offerings and ultimately drive sales. Embrace this opportunity to carve out your niche in the seasonal décor market!