Everything You Need to Know About Capital Rubber In Sacramento Sourcing in 2025

Introduction: Navigating the Global Market for capital rubber in sacramento

In today’s competitive landscape, sourcing high-quality capital rubber products in Sacramento presents a unique set of challenges for international B2B buyers. With diverse applications ranging from industrial hoses to custom gaskets, businesses must navigate a complex market to find reliable suppliers that meet their specific needs. This guide serves as a comprehensive resource, addressing the various types of capital rubber products available, their applications across industries, and best practices for supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Brazil and Nigeria, will find this guide invaluable for making informed purchasing decisions. It provides insights into cost considerations, quality standards, and supplier capabilities, ensuring that buyers can confidently assess their options. By understanding the nuances of the Sacramento rubber supply market, B2B buyers can optimize their procurement processes, reduce risks, and enhance operational efficiency.

In the following sections, we will delve deeper into the specific product categories, explore the latest trends in rubber applications, and offer expert tips on how to evaluate potential suppliers effectively. This guide is designed to empower you with the knowledge needed to make strategic purchasing decisions, ultimately driving success in your business operations.

Understanding capital rubber in sacramento Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Hose | High-pressure capability, custom lengths, and fittings | Construction, agriculture, manufacturing | Pros: Customizable, reliable performance. Cons: Higher initial cost for custom solutions. |

| Gaskets | Custom fabrication, various materials (e.g., Teflon) | Food processing, automotive, industrial machinery | Pros: Tailored to specific applications. Cons: Longer lead times for custom orders. |

| Conveyor Belting | Heavy-duty materials, various widths and lengths | Manufacturing, logistics, food processing | Pros: Durable and efficient. Cons: Requires maintenance and periodic replacement. |

| Specialty Hose | Designed for unique applications (e.g., steam, chemicals) | Industrial, construction, food transfer | Pros: Safety in demanding environments. Cons: Limited availability for niche applications. |

| Rubber Sheets | Available in various grades, thicknesses, and durometers | General manufacturing, construction, sealing | Pros: Versatile and customizable. Cons: May require additional processing for specific needs. |

What Are the Key Characteristics of Hydraulic Hoses for B2B Buyers?

Hydraulic hoses are essential for high-pressure applications, making them a critical component in industries like construction and agriculture. They can be customized to specific lengths and fittings, ensuring a perfect fit for various machinery. When purchasing hydraulic hoses, B2B buyers should consider the operating pressure, compatibility with fluids, and environmental factors that might affect performance. While the initial investment may be higher for custom options, the long-term reliability and efficiency often justify the cost.

How Do Gaskets Serve Diverse Industrial Needs?

Gaskets are critical for ensuring airtight and leak-proof seals in applications ranging from food processing to automotive manufacturing. Capital Rubber offers custom gasket fabrication, allowing businesses to select materials that meet their specific requirements. Buyers should assess the material properties, such as temperature resistance and chemical compatibility, when selecting gaskets. Although custom gaskets provide tailored solutions, they may come with longer lead times, which should be factored into project timelines.

Why Are Conveyor Belts Important in Manufacturing and Logistics?

Conveyor belting is vital for efficient material handling in manufacturing and logistics sectors. Capital Rubber provides heavy-duty conveyor belts that can withstand rigorous use and are available in various widths and lengths. Buyers should evaluate the belt’s load capacity, durability, and maintenance needs to ensure optimal performance. While conveyor belts are robust and efficient, they require regular maintenance and eventual replacement, which can add to operational costs over time.

What Makes Specialty Hoses Unique for Specific Applications?

Specialty hoses are engineered for particular applications, such as steam transfer or chemical handling, where standard hoses may not suffice. These hoses are designed to operate safely under demanding conditions, making them suitable for industries like construction and food transfer. B2B buyers should focus on the specific requirements of their applications, including temperature ranges and chemical compatibility. Although these hoses offer enhanced safety and performance, their niche nature may lead to limited availability.

How Do Rubber Sheets Provide Versatility in Industrial Applications?

Rubber sheets are available in various grades, thicknesses, and durometers, making them a versatile choice for numerous industrial applications. They can be used for sealing, cushioning, and insulation in manufacturing and construction. Buyers should consider the specific requirements of their applications, including material properties and potential processing needs. While rubber sheets are customizable and adaptable, additional processing may be necessary to meet particular specifications, which can impact lead times and costs.

Key Industrial Applications of capital rubber in sacramento

| Industry/Sector | Specific Application of Capital Rubber in Sacramento | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Custom Hose Assemblies for Irrigation Systems | Enhances water delivery efficiency and reduces downtime | Ensure compatibility with local water quality standards |

| Food Processing | Sealing Solutions for Food Safety Compliance | Ensures product integrity and minimizes contamination risks | Verify compliance with FDA and EU food safety regulations |

| Construction | Heavyweight Conveyor Belts for Material Handling | Increases productivity by optimizing material transport | Assess durability under local environmental conditions |

| Oil & Gas | Oil Transfer Hoses for Petrochemical Transport | Reduces spillage and enhances safety in hazardous environments | Confirm resistance to high aromatic content fuels |

| Manufacturing | Custom Gaskets for Machinery Sealing | Prevents leaks and maintains operational efficiency | Evaluate material specifications for specific machinery needs |

How Are Custom Hose Assemblies Used in Agriculture?

In the agricultural sector, Capital Rubber provides custom hose assemblies tailored for irrigation systems. These hoses are designed to withstand varying pressures and deliver water efficiently across extensive fields. By using high-quality, durable materials, these assemblies help farmers optimize water usage, which is crucial in regions facing water scarcity. International buyers should consider local water quality standards and ensure compatibility with existing irrigation infrastructure to maximize effectiveness.

What Role Do Sealing Solutions Play in Food Processing?

In food processing, Capital Rubber’s sealing solutions are vital for maintaining food safety and compliance with health regulations. Custom gaskets and seals prevent contamination, ensuring that food products remain uncontaminated during processing and packaging. Buyers from international markets must verify that the materials used meet FDA and EU food safety standards to avoid compliance issues and ensure consumer safety.

How Do Heavyweight Conveyor Belts Benefit Construction Projects?

Construction companies rely on heavyweight conveyor belts from Capital Rubber for the efficient transport of materials on job sites. These belts are engineered to handle heavy loads, improving productivity and reducing the risk of workplace accidents. When sourcing, companies should assess the durability of the belts under local environmental conditions, such as extreme temperatures or exposure to chemicals, to ensure long-term performance.

Why Are Oil Transfer Hoses Critical in the Oil & Gas Industry?

Oil transfer hoses are essential in the oil and gas sector for the safe transport of petrochemicals. Capital Rubber’s hoses are designed to minimize spillage and withstand the harsh conditions typical in this industry. For international buyers, it is important to confirm the hoses’ resistance to high aromatic content fuels, as this can significantly impact safety and operational efficiency in various environments.

How Do Custom Gaskets Improve Manufacturing Efficiency?

In manufacturing, custom gaskets from Capital Rubber play a crucial role in sealing machinery components, preventing leaks, and maintaining operational efficiency. These gaskets are tailored to meet specific machinery requirements, ensuring a perfect fit and optimal performance. Buyers should evaluate the material specifications carefully to match the demands of their machinery and operational environment, thereby reducing maintenance costs and downtime.

3 Common User Pain Points for ‘capital rubber in sacramento’ & Their Solutions

Scenario 1: Difficulty in Sourcing Custom Hose Assemblies

The Problem: B2B buyers often face challenges when sourcing custom hose assemblies that meet specific requirements for their industrial applications. Many suppliers provide off-the-shelf products that may not fit precise specifications or performance standards, leading to inefficiencies and potential operational failures. For buyers in diverse industries such as agriculture or construction, the inability to find the right size, length, or type of hose can result in project delays and increased costs.

The Solution: To address this issue, buyers should leverage the custom hose assembly services offered by Capital Rubber in Sacramento. By directly consulting with their experienced team, buyers can specify their exact needs, including size, coupling type, and material. Capital Rubber specializes in creating custom hose assemblies tailored to the unique requirements of various applications, ensuring optimal performance and durability. Engaging in a dialogue about your specific needs and potential applications allows for the development of a solution that not only meets but exceeds expectations. Additionally, take advantage of their extensive inventory and expertise to ensure timely delivery, minimizing downtime and keeping projects on schedule.

Scenario 2: Ensuring Compliance with Hose Testing and Certification

The Problem: Another common pain point for B2B buyers is ensuring that the hoses and rubber products they use comply with industry safety and performance standards. Without proper testing and certification, businesses may face operational risks, potential legal liabilities, and costly equipment failures. This concern is particularly relevant for industries such as food processing and manufacturing, where compliance is crucial to maintaining operational integrity and safety.

The Solution: Capital Rubber offers comprehensive hose testing and certification services through their partnership with OnGuard™ Asset Management. Buyers should prioritize utilizing these services to ensure that all hoses are thoroughly tested for safety and performance before being put into operation. By scheduling regular inspections and maintenance through Capital Rubber, businesses can proactively identify and address potential issues, thus extending the life of their hoses and reducing the risk of failures. Moreover, buyers should request detailed reports on testing outcomes to maintain compliance and enhance operational reliability. This proactive approach not only safeguards operations but also fosters a culture of safety and accountability within the organization.

Scenario 3: Challenges in Obtaining Precision Gaskets for Unique Applications

The Problem: B2B buyers often encounter difficulties when sourcing precision gaskets that meet specific dimensions and performance criteria. Many suppliers lack the capability to produce custom gaskets, leaving businesses to settle for generic options that may not provide the necessary sealing performance. This issue can be particularly frustrating for industries that rely on high-performance materials, such as the oil and gas sector, where leaks can have significant financial and environmental repercussions.

The Solution: Buyers can overcome this challenge by utilizing the custom gasket cutting services offered by Capital Rubber. Their advanced waterjet cutting technology allows for the production of gaskets with precise dimensions and specifications, ensuring a perfect fit for any application. To effectively source the right gasket, buyers should provide detailed drawings or samples to the Capital Rubber team. This collaborative approach ensures that the final product meets all operational requirements, reducing the risk of leaks and enhancing overall system performance. Furthermore, leveraging Capital Rubber’s expertise in materials can help buyers select the most suitable elastomers for their specific applications, ensuring optimal durability and performance under varying conditions. By investing in high-quality, custom gaskets, businesses can protect their systems and enhance operational efficiency.

Strategic Material Selection Guide for capital rubber in sacramento

What Are the Key Materials Used in Capital Rubber Products in Sacramento?

When selecting materials for rubber products, particularly in the industrial sector, it is crucial to understand the properties, advantages, and limitations of each material. This knowledge enables international B2B buyers to make informed decisions that align with their operational requirements and compliance standards.

How Do Different Rubber Materials Perform in Industrial Applications?

1. Nitrile Rubber (NBR)

Key Properties: Nitrile rubber is known for its excellent oil and fuel resistance, along with good abrasion resistance. It typically operates effectively in temperatures ranging from -40°F to 250°F (-40°C to 121°C) and can withstand moderate pressures.

Pros & Cons: Nitrile is highly durable and cost-effective, making it a popular choice for applications involving petroleum-based products. However, it has limitations in extreme temperatures and can degrade when exposed to ozone or sunlight.

Impact on Application: NBR is ideal for hoses and seals in automotive and industrial applications where oil exposure is common. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with ASTM standards, as NBR is often specified for oil transfer and hydraulic applications. Understanding local regulations regarding material safety and environmental impact is also essential.

2. EPDM Rubber

Key Properties: Ethylene Propylene Diene Monomer (EPDM) rubber excels in weather resistance, ozone resistance, and high-temperature applications, typically functioning well between -40°F to 300°F (-40°C to 149°C).

Pros & Cons: EPDM is highly durable and suitable for outdoor applications, making it ideal for roofing and automotive seals. However, it is not recommended for use with petroleum-based oils and solvents, which limits its applications in certain industries.

Impact on Application: Its resistance to UV light and aging makes EPDM suitable for outdoor applications, such as seals and gaskets in agricultural equipment.

Considerations for International Buyers: Buyers in the Middle East, where UV exposure is high, should prioritize EPDM for outdoor applications. Compliance with international standards like DIN and JIS is vital for ensuring product quality and safety.

3. Silicone Rubber

Key Properties: Silicone rubber is known for its exceptional temperature resistance, functioning effectively in temperatures ranging from -100°F to 500°F (-73°C to 260°C). It also exhibits excellent flexibility and electrical insulation properties.

Pros & Cons: While silicone rubber is highly versatile and can withstand extreme conditions, it tends to be more expensive than other rubber types. Its lower tensile strength compared to nitrile and EPDM can limit its use in high-stress applications.

Impact on Application: Silicone is often used in applications requiring high-temperature resistance, such as seals in food processing and pharmaceutical industries, where cleanliness and non-toxicity are critical.

Considerations for International Buyers: Buyers from Europe should be aware of food safety regulations and certifications when using silicone in food-related applications. Compliance with FDA standards is essential for ensuring product acceptability.

4. Neoprene Rubber

Key Properties: Neoprene rubber offers good chemical stability and maintains flexibility over a wide temperature range, typically from -40°F to 200°F (-40°C to 93°C). It also has decent resistance to oils and ozone.

Pros & Cons: Neoprene is versatile and durable, making it suitable for a variety of applications, including gaskets and hoses. However, it is generally more expensive than NBR and may not perform as well in high-temperature applications.

Impact on Application: Its chemical resistance makes neoprene ideal for applications in chemical processing and refrigeration.

Considerations for International Buyers: Buyers in regions like Nigeria should consider the local climate and operational conditions when selecting neoprene. Understanding the specific chemical compatibility is crucial for ensuring long-term performance.

Summary Table of Material Selection

| Material | Typical Use Case for capital rubber in sacramento | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nitrile Rubber (NBR) | Oil transfer hoses, seals in automotive applications | Excellent oil and fuel resistance | Limited temperature range and ozone degradation | Medium |

| EPDM Rubber | Outdoor seals, gaskets in agricultural equipment | Superior weather and ozone resistance | Not suitable for petroleum-based products | Medium |

| Silicone Rubber | Seals in food processing and pharmaceutical industries | Exceptional temperature resistance | Higher cost and lower tensile strength | High |

| Neoprene Rubber | Gaskets and hoses in chemical processing | Good chemical stability and flexibility | More expensive and limited high-temperature performance | Medium |

By understanding these materials and their implications, international B2B buyers can make strategic decisions that enhance operational efficiency and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for capital rubber in sacramento

What Are the Main Stages of Manufacturing Rubber Products in Sacramento?

The manufacturing process for rubber products at Capital Rubber in Sacramento encompasses several key stages, ensuring that each product meets rigorous industry standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality rubber compounds that meet specific industry requirements. These compounds may include natural rubber, synthetic rubber, or a blend of both, depending on the intended application. The materials undergo thorough inspection upon arrival to ensure they comply with pre-defined specifications.

-

Forming: Once the materials are prepared, they are subjected to various forming techniques. Techniques like extrusion and molding are common in this phase. For instance, extrusion is often used to create continuous profiles, such as hoses and seals, while compression or injection molding is employed for producing complex shapes like gaskets. The choice of technique depends on the product design and required properties.

-

Assembly: After forming, the components undergo assembly. This step can involve combining different parts, such as attaching couplings to hoses or assembling gaskets with additional sealing materials. The assembly process is critical for ensuring that the final product meets functional specifications and is ready for rigorous use.

-

Finishing: The finishing stage includes processes such as trimming excess material, surface treatment, and applying protective coatings. These steps enhance the product’s durability, aesthetic appeal, and performance. Quality checks are conducted at each phase to confirm that the products adhere to design specifications and industry standards.

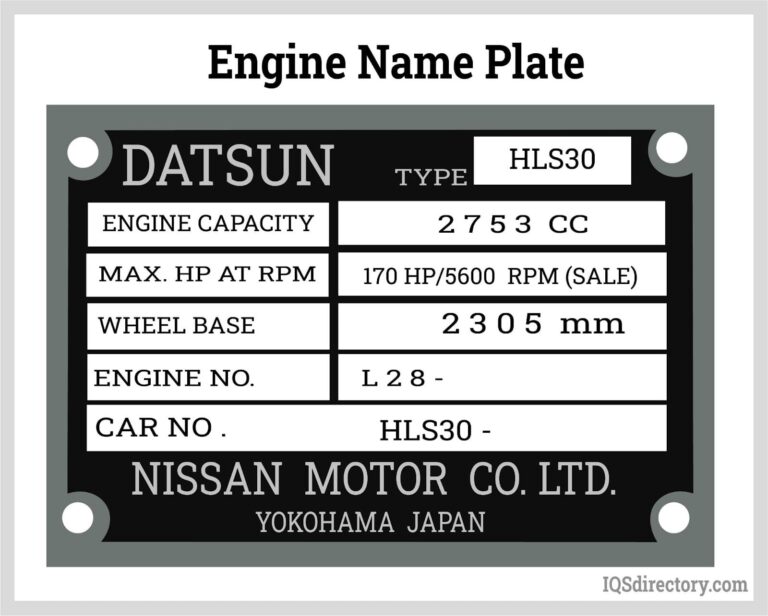

How Is Quality Assurance Integrated Into the Manufacturing Process?

Quality assurance (QA) is a fundamental aspect of the manufacturing process at Capital Rubber. The company adheres to international standards, such as ISO 9001, which outlines requirements for a quality management system. This commitment to quality ensures that products are consistently produced to meet customer expectations and regulatory requirements.

-

International Standards Compliance: Capital Rubber complies with various international standards, including ISO 9001 for quality management and CE marking for certain products, indicating conformity with health, safety, and environmental protection standards. This compliance is crucial for international B2B buyers, as it assures them of the product’s safety and reliability.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control checkpoints are established:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during production ensures that any deviations from quality standards are addressed immediately.

– Final Quality Control (FQC): Finished products undergo rigorous testing and inspections before they are shipped. This includes functional tests, dimensional checks, and visual inspections to ensure that each item meets the required standards. -

Testing Methods: Various testing methods are employed to evaluate the performance of rubber products. Common tests include tensile strength, elongation, hardness, and chemical resistance. For certain applications, specialized tests such as hydrostatic pressure testing for hoses may also be performed. These tests help identify potential weaknesses and ensure that products can withstand the conditions they will face in the field.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should be proactive in verifying the quality assurance practices of their suppliers. Here are several actionable steps they can take:

-

Supplier Audits: Conducting audits of the manufacturing facility can provide insight into the supplier’s quality control practices. During an audit, buyers can assess the production processes, quality management systems, and compliance with international standards.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports, including test results and compliance certifications. These documents serve as evidence of the supplier’s commitment to quality and can help identify any potential risks associated with the products.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These independent organizations can conduct quality assessments and provide unbiased reports on the supplier’s practices and product quality.

-

Understanding Certification Nuances: International buyers should be aware of the specific certifications relevant to their industry and region. For instance, certifications from the American Petroleum Institute (API) may be crucial for buyers in the oil and gas sector, while food-grade certifications may be necessary for those in the food processing industry. Familiarizing themselves with these nuances helps buyers ensure they are sourcing compliant products.

What Are the Key Considerations for International B2B Buyers Regarding Quality Control?

When sourcing rubber products from Capital Rubber, international B2B buyers should consider several key factors related to quality control:

-

Cultural and Regulatory Differences: Understanding the regulatory environment and cultural nuances of the supplier’s country is essential. Different regions may have varying standards and expectations regarding quality, which could impact product performance and compliance.

-

Communication of Quality Standards: Clear communication of quality expectations is vital. Buyers should articulate their specific requirements and ensure that suppliers understand and can meet them.

-

Building Long-Term Relationships: Establishing a long-term relationship with suppliers can lead to improved quality and reliability over time. Frequent communication, feedback, and collaboration can help suppliers better understand buyer needs and adapt their processes accordingly.

By thoroughly understanding the manufacturing processes and quality assurance practices at Capital Rubber, B2B buyers can make informed decisions that enhance their supply chain reliability and product performance. These insights empower buyers to mitigate risks, ensure compliance, and foster successful international partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘capital rubber in sacramento’

Introduction

Navigating the procurement landscape for industrial rubber products, particularly from suppliers like Capital Rubber in Sacramento, requires a strategic approach. This guide provides a step-by-step checklist to help international B2B buyers streamline their sourcing process, ensuring they acquire quality products and services tailored to their needs.

Step 1: Identify Your Specific Needs

Before reaching out to suppliers, clearly define your requirements. Consider the types of products needed, such as hoses, gaskets, or sealing solutions, and the specific applications they will serve. This clarity will help you communicate effectively with potential suppliers and ensure they can meet your specifications.

- Product Types: Determine if you need custom assemblies, standard products, or specialized items like waterjet-cut gaskets.

- Application Context: Understand the environmental conditions and operational demands your products will face, which can impact material selection.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in the products you need. Look for companies with a strong reputation in the industry, such as Capital Rubber, which has decades of experience.

- Company Background: Investigate their history, market presence, and areas of expertise.

- Product Range: Ensure they offer a comprehensive selection of products that align with your requirements.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is essential for ensuring product quality and compliance with industry standards. Suppliers like Capital Rubber may have certifications relevant to safety and quality management systems.

- ISO Certification: Look for ISO certifications that indicate adherence to international quality standards.

- Industry-Specific Certifications: Depending on your industry, check for certifications that apply to specific materials or applications (e.g., ASTM or Mil Spec).

Step 4: Request Samples and Prototypes

Before making a bulk purchase, request samples or prototypes of the products you intend to buy. This step allows you to assess the quality and suitability of the products for your specific applications.

- Quality Assessment: Evaluate the materials, construction, and performance of the samples.

- Fit and Functionality: Ensure that the products meet your operational requirements in real-world conditions.

Step 5: Inquire About Customization Options

If your project requires specific dimensions or features, discuss customization capabilities with potential suppliers. Companies like Capital Rubber specialize in custom hose assemblies and gaskets, which can be tailored to unique specifications.

- Customization Flexibility: Confirm the supplier’s ability to accommodate your specific needs, including size, material, and design.

- Lead Times: Understand the production timelines for custom products to align with your project schedules.

Step 6: Review Pricing and Payment Terms

Once you have identified suitable suppliers and confirmed their capabilities, request detailed pricing information. Comparing quotes will help you find the best value for your budget.

- Transparent Pricing: Ensure that the quote includes all potential costs, such as shipping and handling.

- Payment Terms: Discuss payment options, including credit terms, to facilitate smoother transactions.

Step 7: Establish Communication and Support Channels

Effective communication is vital for a successful partnership. Ensure that the supplier provides robust support channels for any inquiries or issues that may arise post-purchase.

- Customer Support: Verify the availability of customer service and technical support to assist with any product-related questions.

- Feedback Mechanism: Establish a clear line of communication for feedback and potential adjustments during the procurement process.

By following this checklist, B2B buyers can confidently navigate the sourcing process for rubber products in Sacramento, ensuring they partner with suppliers that meet their specific needs and uphold high standards of quality and service.

Comprehensive Cost and Pricing Analysis for capital rubber in sacramento Sourcing

What Are the Key Cost Components in Sourcing Capital Rubber Products in Sacramento?

When sourcing capital rubber products in Sacramento, understanding the cost structure is critical for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of rubber and plastic materials significantly affects pricing. High-performance elastomers, which may be required for specialized applications, tend to be more expensive than standard materials. Buyers should assess their specific needs to determine the appropriate material grade.

-

Labor: Labor costs can vary based on the complexity of the product and the level of customization required. Skilled labor for custom fabrication, such as hose assemblies and gaskets, typically incurs higher costs due to the expertise involved.

-

Manufacturing Overhead: This includes costs associated with running production facilities, such as utilities, maintenance, and equipment depreciation. Efficient production processes can help minimize these overhead costs, ultimately benefiting the buyer.

-

Tooling: For custom products, tooling costs can be significant. This includes the initial investment for molds and cutting tools. Buyers should inquire about the tooling costs upfront, as these can impact overall pricing.

-

Quality Control: Ensuring product quality through rigorous QC processes can add to the cost. However, investing in quality assurance can reduce long-term costs associated with product failures and replacements.

-

Logistics: Transportation and handling fees must be considered, especially for international shipments. Costs can fluctuate based on the distance, shipping method, and supplier’s location.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding market rates and comparing multiple suppliers can help buyers negotiate better terms.

How Do Price Influencers Affect Capital Rubber Sourcing?

Several factors influence pricing for capital rubber products, especially for international buyers.

-

Volume/MOQ: Larger orders often lead to reduced per-unit pricing. Establishing a minimum order quantity (MOQ) can help suppliers manage production costs while providing buyers with better pricing.

-

Specifications and Customization: Custom products generally come at a premium. Buyers should clearly define their specifications to avoid unexpected costs during production.

-

Materials Quality and Certifications: Higher quality materials and certifications (such as ASTM or Mil-Spec) can lead to increased pricing but may be necessary for specific applications. Buyers should evaluate the total cost of ownership when considering these options.

-

Supplier Factors: Supplier reputation, reliability, and customer service levels can all impact pricing. Engaging with suppliers who have a proven track record can lead to better long-term cost efficiency.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who bears the costs at various stages of transportation, affecting the final landed cost.

What Are the Best Negotiation and Cost-Efficiency Strategies for International Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, employing effective negotiation strategies can yield significant savings.

-

Total Cost of Ownership (TCO): Assessing TCO rather than just upfront costs can provide a clearer picture of long-term expenses. Consider factors such as maintenance, downtime, and replacement costs when evaluating suppliers.

-

Building Relationships: Establishing strong relationships with suppliers can lead to better pricing, exclusive deals, and priority service. Frequent communication and transparency can foster trust.

-

Understanding Local Market Dynamics: Buyers should familiarize themselves with local market conditions, including currency fluctuations and trade tariffs, which can impact pricing.

-

Leverage Multiple Quotes: Obtaining quotes from several suppliers can create competitive tension, potentially lowering prices. It also provides leverage during negotiations.

-

Flexibility in Specifications: If possible, being flexible with specifications or materials can open up alternatives that may be more cost-effective.

Disclaimer on Indicative Prices

Prices for capital rubber products can vary significantly based on the factors discussed above. It is advisable for buyers to obtain detailed quotes tailored to their specific requirements and to consider market fluctuations when making purchasing decisions.

Alternatives Analysis: Comparing capital rubber in sacramento With Other Solutions

When exploring options for industrial rubber supplies and solutions, it’s essential to consider various alternatives that meet specific operational needs. This analysis compares Capital Rubber in Sacramento with two viable alternatives: a global supplier of industrial rubber products and a local manufacturer specializing in custom rubber solutions. Each option has unique strengths and weaknesses, making it crucial for international B2B buyers to evaluate them against their requirements.

| Comparison Aspect | Capital Rubber In Sacramento | Global Supplier of Industrial Rubber Products | Local Manufacturer of Custom Rubber Solutions |

|---|---|---|---|

| Performance | High-quality, tailored solutions; strong focus on custom assemblies | Wide product range; varying quality based on supplier | Superior customization; optimized for specific applications |

| Cost | Competitive pricing with good value for custom work | Generally lower prices due to scale; potential hidden costs | Potentially higher costs for custom work, but justified by quality |

| Ease of Implementation | Quick turnaround times; local presence aids in logistics | Streamlined ordering process; may require longer shipping times | Longer lead times due to customization processes |

| Maintenance | Regular support and maintenance services available | Limited after-sales support; depends on supplier policies | High-touch support; proactive maintenance options available |

| Best Use Case | Ideal for businesses needing reliable, customized rubber products in various industries | Suitable for bulk orders and standard rubber products at lower costs | Best for specialized applications requiring unique rubber solutions |

What Are the Advantages and Disadvantages of a Global Supplier of Industrial Rubber Products?

Global suppliers often offer a vast array of products at competitive prices due to their economies of scale. This can be advantageous for companies looking to purchase standard rubber products in bulk. However, the trade-off may include inconsistent product quality and longer lead times, as shipping from overseas can introduce delays. Additionally, after-sales support may not be as robust, leading to potential challenges in addressing issues post-purchase. For international buyers, shipping costs and logistics also need to be factored into the overall pricing.

How Does a Local Manufacturer of Custom Rubber Solutions Compare?

Local manufacturers specializing in custom rubber solutions provide tailored products that meet specific operational requirements. They typically offer high-quality craftsmanship and flexibility in design, which is beneficial for unique applications. However, the customization process can lead to longer lead times and potentially higher costs compared to off-the-shelf solutions. For businesses that prioritize quality and specific performance metrics, this option can be worth the investment, especially when local support and quick turnaround times are essential.

How Can B2B Buyers Make the Right Choice for Their Needs?

When selecting the right rubber solution, B2B buyers should assess their specific requirements, including the nature of their operations, budget constraints, and the desired level of customization. Capital Rubber in Sacramento offers a blend of quality, local service, and competitive pricing that can be particularly advantageous for businesses in need of tailored solutions. Conversely, global suppliers may appeal to those with bulk purchasing needs, while local manufacturers could be the best fit for specialized applications. By carefully evaluating these aspects, buyers can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for capital rubber in sacramento

What Are the Key Technical Properties of Capital Rubber Products in Sacramento?

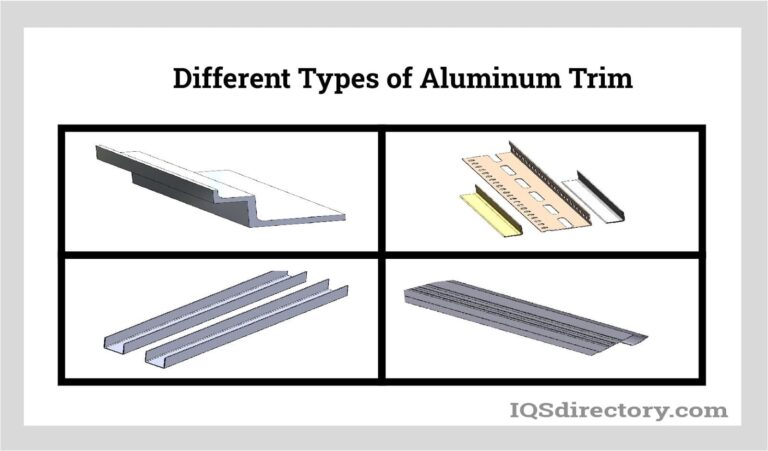

When sourcing rubber products, especially in a B2B context, understanding essential technical properties can significantly influence purchasing decisions. Here are critical specifications to consider:

-

Material Grade

This refers to the specific type of rubber used in manufacturing, such as natural rubber, neoprene, or EPDM. Each material grade has distinct properties such as temperature resistance, flexibility, and durability. For instance, EPDM is excellent for outdoor applications due to its UV resistance, making it suitable for agricultural uses in hot climates like Sacramento. -

Tolerance

Tolerance indicates the permissible limit of variation in a product’s dimensions. In rubber manufacturing, tight tolerances ensure that parts fit correctly, which is crucial for applications requiring precision, such as hydraulic systems. For B2B buyers, understanding tolerances helps in evaluating whether the rubber components will perform reliably in their specific applications. -

Durometer

This measurement indicates the hardness of rubber on a scale, typically from 0 to 100. A lower durometer indicates a softer material, while a higher number denotes increased hardness. Selecting the appropriate durometer is vital in applications where flexibility and compression are required, such as gaskets and seals. -

Temperature Range

Different rubber materials can withstand various temperature extremes. Knowing the operational temperature range is essential for industries like food processing or chemical manufacturing, where materials are exposed to high or low temperatures. This specification helps in preventing premature failure of rubber products under specific environmental conditions. -

Chemical Resistance

This property reflects a rubber material’s ability to withstand exposure to various chemicals without degrading. For applications in oil transfer or food processing, understanding chemical resistance is crucial to ensure product longevity and compliance with safety standards. -

Custom Fabrication Capabilities

The ability to customize rubber products, such as hose assemblies and gaskets, is essential for meeting unique operational needs. Custom fabrication ensures that the products fit specific machinery or processes, optimizing performance and reducing downtime.

What Are Common Trade Terms Used in the Capital Rubber Industry?

Understanding industry jargon can enhance communication and negotiation efficiency. Here are several common terms used in the rubber supply chain:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the rubber industry, understanding OEM relationships can help buyers identify reliable suppliers who manufacture components to original specifications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it impacts inventory levels and cash flow. Suppliers like Capital Rubber may set MOQs based on production costs and demand. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific products or services. This is a critical step in the procurement process, enabling buyers to compare options and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can aid in understanding shipping costs, risks, and responsibilities, which is especially important for international buyers sourcing rubber products from Sacramento. -

Lead Time

Lead time refers to the amount of time between the initiation of an order and its fulfillment. Understanding lead times is vital for inventory planning and can impact project timelines, especially when dealing with custom rubber products. -

Quality Assurance (QA)

QA refers to the systematic processes designed to ensure that products meet specified requirements and standards. In the rubber industry, QA practices are essential to guarantee that products are reliable and safe for use in various applications, thus protecting the buyer’s investment.

By understanding these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing capital rubber products in Sacramento, ensuring that they meet their operational needs effectively and efficiently.

Navigating Market Dynamics and Sourcing Trends in the capital rubber in sacramento Sector

What Are the Current Market Dynamics and Key Trends in the Capital Rubber Sector?

The capital rubber sector in Sacramento is currently experiencing significant growth, driven by a combination of global demand, technological advancements, and evolving consumer preferences. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking to source high-quality rubber products to support various industries, including construction, agriculture, and manufacturing. Key trends include the rise of custom solutions tailored to specific applications, such as industrial hoses and gaskets, which are gaining traction due to their enhanced performance and longevity.

Moreover, the emergence of digital platforms and B2B e-commerce is transforming the way businesses engage in procurement. Buyers can now access extensive inventories and customization options online, streamlining the sourcing process. Innovations in manufacturing techniques, such as waterjet cutting and advanced hose assembly technologies, are also enhancing product precision and reducing lead times. As businesses seek to optimize their supply chains, the ability to track and manage assets through integrated software solutions is becoming essential.

Additionally, the push for sustainability is reshaping market dynamics. B2B buyers are increasingly favoring suppliers who prioritize environmentally friendly practices and materials. This shift is particularly evident in sectors that are heavily regulated or under pressure to reduce their carbon footprint. As such, suppliers in Sacramento are adapting by incorporating sustainable materials and practices into their offerings to meet these changing demands.

How Can Sustainability and Ethical Sourcing Influence B2B Transactions?

The environmental impact of rubber production and supply chains is a growing concern among international buyers. Ethical sourcing is now a critical factor in purchasing decisions, with businesses looking for suppliers that demonstrate a commitment to sustainability. This includes the use of renewable materials, reduced waste in manufacturing processes, and adherence to environmental regulations.

In the capital rubber sector, sustainable practices can take various forms, such as sourcing recycled rubber for products or utilizing eco-friendly adhesives and sealants. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability. By opting for suppliers with these certifications, buyers can enhance their corporate social responsibility (CSR) profiles while also meeting regulatory requirements in their respective markets.

Moreover, ethical supply chains contribute to long-term business viability. Companies that prioritize sustainability not only improve their brand image but also mitigate risks associated with non-compliance and environmental degradation. As international markets increasingly demand transparency, suppliers in Sacramento are encouraged to adopt sustainable practices and communicate their efforts effectively to attract discerning buyers.

What Is the Historical Context of the Capital Rubber Sector in Sacramento?

The capital rubber sector in Sacramento has a rich history, dating back to the mid-20th century. Established in the 1940s, businesses such as Capital Rubber & Gasket have played a pivotal role in serving the industrial marketplace, catering to various sectors including construction, agriculture, and food processing. Over the decades, the industry has evolved significantly, driven by technological advancements and changing market needs.

The consolidation of expertise and resources, as seen in partnerships like that of Capital Rubber with Pacific Waterjet & Supply, has further strengthened the sector’s capabilities. This evolution has not only enhanced product offerings but also improved service delivery for B2B clients. As the market continues to adapt to global trends and consumer demands, the legacy of innovation and quality remains a cornerstone of the capital rubber sector in Sacramento, providing a solid foundation for future growth.

Frequently Asked Questions (FAQs) for B2B Buyers of capital rubber in sacramento

1. How do I solve issues with sourcing high-quality rubber products from suppliers?

To resolve sourcing issues, conduct thorough market research to identify reputable suppliers like Capital Rubber in Sacramento. Evaluate their product offerings, quality certifications, and customer reviews. Establish direct communication to inquire about their manufacturing processes and material sourcing. It’s also beneficial to request samples to assess quality before placing larger orders. Building a strong relationship with suppliers through regular communication can help address any issues that arise during the procurement process.

2. What is the best type of hose for agricultural applications?

For agricultural applications, the best type of hose is typically a heavy-duty discharge or suction hose designed to withstand rigorous use. Look for hoses that are reinforced with durable materials, like rubber or PVC, and can handle varying pressures and temperatures. Capital Rubber offers a range of hoses specifically designed for agricultural settings, ensuring they meet industry standards for safety and performance. Always consult with the supplier to determine the right specifications for your specific needs.

3. How can I ensure that my custom rubber products meet international quality standards?

To ensure your custom rubber products meet international quality standards, request certifications from the supplier, such as ISO 9001 or ASTM compliance. Engage in detailed discussions about their quality assurance processes, including testing methods and material sourcing. Suppliers like Capital Rubber often provide documentation on their production standards and testing results. Additionally, consider third-party inspections or audits to verify compliance before shipment.

4. What are the minimum order quantities (MOQs) for rubber products from suppliers?

Minimum order quantities (MOQs) can vary significantly among suppliers, depending on the type of product and customization requirements. Capital Rubber typically offers flexible MOQs, especially for custom hose assemblies and gaskets. It’s essential to communicate your specific needs and explore options with the supplier to find a suitable arrangement. Smaller orders may incur higher costs per unit, so balancing volume and budget is crucial in your sourcing strategy.

5. What payment terms can I expect when purchasing rubber products internationally?

Payment terms can vary by supplier and may include options such as advance payment, letter of credit, or net terms (e.g., net 30 or net 60 days). It’s advisable to negotiate terms that align with your cash flow and risk tolerance. Capital Rubber, like many suppliers, may offer flexible payment options for international buyers. Ensure you understand any additional costs related to currency exchange and international banking fees to accurately budget your procurement.

6. How do I vet suppliers for reliability and quality in the rubber industry?

To vet suppliers effectively, start by checking their industry reputation through online reviews, testimonials, and case studies. Verify their experience and expertise in the rubber industry, particularly in the products you need. Request references from previous international clients and inquire about their experiences. It’s also beneficial to visit their facilities if possible or conduct virtual meetings to assess their capabilities and quality control processes firsthand.

7. What logistics considerations should I keep in mind when importing rubber products?

When importing rubber products, consider logistics factors such as shipping methods, lead times, and customs regulations in your destination country. Collaborate with your supplier to determine the best shipping options, whether by air or sea, based on your urgency and budget. Familiarize yourself with import tariffs and documentation requirements to avoid delays and additional costs. Partnering with a reliable freight forwarder can streamline the logistics process and ensure compliance with international trade regulations.

8. How can I customize rubber products to meet specific industry needs?

Customizing rubber products begins with a clear understanding of your application requirements, including dimensions, materials, and performance specifications. Work closely with suppliers like Capital Rubber to communicate your needs, as they often have the expertise to suggest suitable materials and designs. Utilize their capabilities in custom cutting, waterjet cutting, and hose assembly to create tailored solutions. Request prototypes or samples to ensure that the final products meet your expectations before full-scale production.

Top 4 Capital Rubber In Sacramento Manufacturers & Suppliers List

1. Capital Rubber & Gasket – Industrial Equipment & Rubber Supplies

Domain: capitalrubberco.com

Registered: 2000 (25 years)

Introduction: Capital Rubber & Gasket offers a wide range of industrial equipment and rubber supply products, including: 1. Hydraulic Hose 2. Hydraulic Couplings 3. Industrial Hose 4. Industrial Couplings 5. Expansion Joint Gaskets 6. Heavyweight Conveyor Belt 7. Lightweight Conveyor Belt 8. Sheet Rubber 9. Sealing Products 10. Industrial Valves Additionally, they provide custom hose assemblies, conveyor beltin…

2. Capital Rubber – Discharge & Suction Hoses

Domain: capitalrubber.com

Registered: 2016 (9 years)

Introduction: {‘discharge_hose’: {‘description’: ‘Dependable in rigorous pump and agricultural applications.’, ‘materials’: [‘lightweight PVC’, ‘heavy duty reinforced rubber’], ‘features’: ‘Wide range of sizes and configurations.’}, ‘suction_hose’: {‘description’: ‘Designed to maintain negative pressures up to full vacuum.’, ‘materials’: [‘lightweight PVC’, ‘durable wire-reinforced rubber’], ‘customization’: ‘C…

3. Capital Rubber & Gasket – Industrial Equipment & Rubber Products

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Capital Rubber & Gasket – Industrial Equipment & Rubber Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Capital Rubber & Gasket Co. – Conveyor Belts & Hoses

Domain: industrialsupplymagazine.com

Registered: 2009 (16 years)

Introduction: Capital Rubber & Gasket Co. offers conveyor belt & installation, industrial & hydraulic hoses, and gaskets. They serve customers in the aggregate, agriculture, construction, and general MRO end markets.

Strategic Sourcing Conclusion and Outlook for capital rubber in sacramento

In the competitive landscape of industrial rubber sourcing, businesses must prioritize strategic partnerships to ensure quality, reliability, and cost-effectiveness. Capital Rubber & Gasket stands out as a premier supplier in Sacramento, offering a diverse range of products, including custom hose assemblies and precision gaskets. The company’s commitment to exceptional service and tailored solutions positions it as a valuable resource for industries ranging from agriculture to manufacturing.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, can greatly benefit from Capital Rubber’s extensive inventory and expertise. Strategic sourcing not only mitigates risks associated with supply chain disruptions but also enhances operational efficiency through customized solutions.

As you explore opportunities in the industrial rubber market, consider leveraging the capabilities of trusted suppliers like Capital Rubber. By partnering with industry leaders, you can secure high-quality products that meet your specific needs while optimizing costs. Reach out today to discover how Capital Rubber can support your business goals and help you navigate the complexities of global sourcing in the rubber industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.