Everything You Need to Know About Canopy Material Fabric Sourcing in 2025

Introduction: Navigating the Global Market for canopy material fabric

In an increasingly competitive global marketplace, sourcing high-quality canopy material fabric that meets diverse environmental and aesthetic requirements poses a significant challenge for B2B buyers. Whether your focus is on providing shade solutions for outdoor events in the Middle East or durable coverings for agricultural applications in South America, understanding the nuances of canopy fabrics is essential. This comprehensive guide delves into the various types of canopy materials, their applications, and the critical factors to consider when selecting suppliers.

Navigating the complexities of fabric specifications, such as UV resistance, waterproofing, and fire retardancy, is crucial for making informed purchasing decisions. This guide will explore the myriad options available—from traditional canvas to advanced synthetic blends—equipping international buyers from Africa, Europe, and beyond with the knowledge necessary to evaluate quality and price effectively.

Additionally, we will provide insights into supplier vetting processes, cost structures, and market trends to help you identify reliable partners that align with your business objectives. By leveraging the information presented in this guide, you will be empowered to make strategic decisions that enhance your product offerings and meet the evolving demands of your customers, ensuring your business thrives in the dynamic landscape of the canopy material fabric market.

Understanding canopy material fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic | UV resistant, vibrant colors, durable | Awnings, tents, outdoor furniture | Pros: Excellent color retention, easy to clean; Cons: May fade over time in extreme conditions. |

| Polyester | Lightweight, affordable, water-resistant | Event canopies, trade show displays | Pros: Cost-effective, versatile; Cons: Less durable than other materials, prone to wear. |

| Canvas | Heavy-duty, breathable, customizable | Permanent structures, outdoor canopies | Pros: Strong and durable, good insulation; Cons: Heavier, may require more maintenance. |

| PVC Coated | Waterproof, tear-resistant, easy to clean | Industrial applications, temporary shelters | Pros: Highly durable, excellent weather resistance; Cons: Less breathable, can be heavier. |

| Mesh | Lightweight, breathable, allows airflow | Shade structures, outdoor events | Pros: Great for ventilation, lightweight; Cons: Limited sun protection, less durable in extreme weather. |

What are the Characteristics and Suitability of Acrylic Canopy Fabric?

Acrylic fabrics are known for their vibrant colors and excellent UV resistance, making them ideal for outdoor applications. This type of fabric is durable and can withstand various weather conditions, which is essential for businesses operating in regions with high sun exposure. When purchasing acrylic canopies, buyers should consider the fabric’s color retention and ease of cleaning, as these factors can affect the longevity and aesthetic appeal of the product.

Illustrative image related to canopy material fabric

Why Choose Polyester Canopy Fabric for Your Business Needs?

Polyester is a popular choice among B2B buyers due to its lightweight nature and affordability. It is water-resistant, making it suitable for temporary installations such as event canopies or trade show displays. However, polyester may not be as durable as other materials, so buyers should evaluate the expected lifespan based on usage and environmental conditions. This fabric is ideal for companies looking for a cost-effective solution without compromising too much on quality.

How Does Canvas Canopy Fabric Stand Out in Durability?

Canvas is a heavy-duty fabric that offers breathability and customization options, making it perfect for permanent structures and outdoor canopies. Its strength and durability make it a preferred choice for businesses that require long-lasting solutions. However, the weight of canvas can complicate installation and maintenance. Buyers should consider the balance between durability and the ease of handling when selecting canvas for their projects.

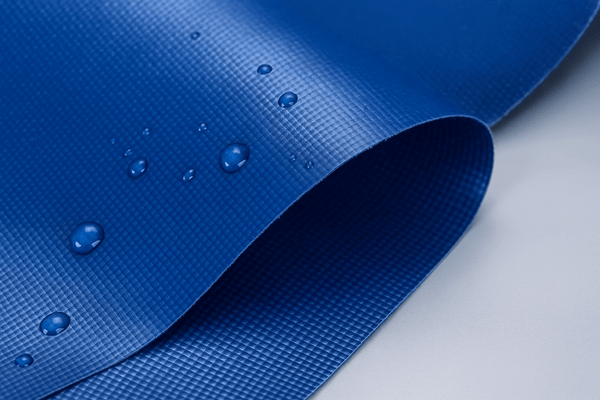

What Benefits Does PVC Coated Fabric Offer for Industrial Applications?

PVC-coated fabrics are highly regarded for their waterproof and tear-resistant properties, making them suitable for industrial applications and temporary shelters. These fabrics are easy to clean and maintain, which is advantageous for businesses that prioritize hygiene. However, they can be heavier and less breathable than other options, which may impact their usability in certain environments. Buyers should assess the specific needs of their applications to determine if PVC-coated fabric is the right choice.

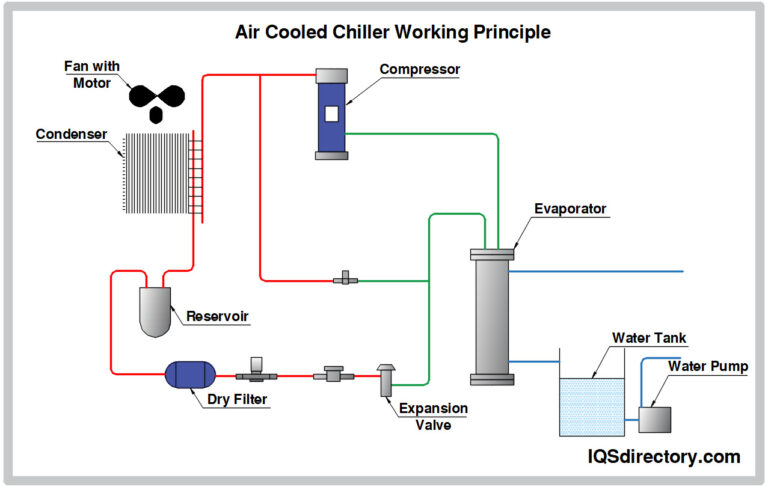

Illustrative image related to canopy material fabric

When Should You Consider Mesh Canopy Fabric for Shade Structures?

Mesh fabrics are lightweight and breathable, allowing airflow while providing some shade. They are commonly used in outdoor events where ventilation is crucial. However, mesh fabrics offer limited sun protection and may not withstand extreme weather conditions. B2B buyers should consider the specific requirements of their shade structures, balancing the need for ventilation against the necessity for durability and protection from the elements.

Key Industrial Applications of canopy material fabric

| Industry/Sector | Specific Application of Canopy Material Fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Outdoor Event Tents | Enhances guest experience by providing shelter and shade. | Durability, UV resistance, and aesthetic appeal are crucial. |

| Construction | Temporary Worksite Canopies | Protects workers and materials from weather conditions. | Fire retardancy and waterproofing are essential features. |

| Agriculture | Shade Structures for Livestock | Improves animal comfort and productivity in extreme weather. | Must be durable and UV resistant to withstand environmental stress. |

| Retail | Pop-Up Shops and Market Stalls | Creates attractive, functional spaces for customer engagement. | Lightweight, easy to transport, and customizable options are preferred. |

| Recreation and Leisure | Sports Event Canopies | Provides shelter for spectators and participants during outdoor events. | Weatherproofing and ease of setup are key factors for selection. |

How is Canopy Material Fabric Utilized in Hospitality Settings?

In the hospitality sector, canopy material fabric is primarily used for outdoor event tents that serve as venues for weddings, corporate events, and festivals. These tents not only enhance the guest experience by providing shelter from the elements but also contribute to the aesthetic appeal of the event. Buyers in this sector should prioritize fabrics that are durable, UV resistant, and aesthetically versatile to accommodate various themes and styles. Additionally, ease of setup and breakdown is essential for maximizing operational efficiency.

What Role Does Canopy Material Fabric Play in Construction?

In construction, canopy material fabric is often employed for temporary worksite canopies that shield workers and materials from adverse weather conditions. This application is vital for maintaining safety and productivity on-site, particularly in regions with unpredictable climates. Buyers should look for fabrics that offer fire retardancy and waterproofing to ensure compliance with safety regulations. Furthermore, the fabric’s durability is critical to withstand harsh environmental conditions over extended periods.

How is Canopy Material Fabric Beneficial in Agriculture?

Agriculture leverages canopy material fabric to create shade structures for livestock, improving their comfort and productivity during extreme weather conditions. This application is particularly significant in regions with high temperatures, as it helps reduce heat stress in animals. Buyers should focus on sourcing fabrics that are not only durable but also UV resistant, as prolonged exposure to sunlight can degrade materials quickly. Additionally, easy maintenance and cleaning are essential factors for agricultural applications.

In What Ways is Canopy Material Fabric Used in Retail?

In the retail industry, canopy material fabric is utilized to create pop-up shops and market stalls that attract customers and provide functional spaces for engagement. This application is crucial for seasonal promotions and outdoor markets, where flexibility and mobility are key. Buyers should consider lightweight fabrics that are easy to transport and set up, along with customizable options to reflect brand identity. Durability and weather resistance are also important to ensure these structures can withstand varying outdoor conditions.

What Importance Does Canopy Material Fabric Hold in Recreation and Leisure?

For recreation and leisure, canopy material fabric is essential for sports event canopies that provide shelter for spectators and participants. This application enhances the comfort of attendees during outdoor events, making it a valuable investment for organizers. Buyers should prioritize weatherproof fabrics that can endure rain and sun exposure, alongside easy setup features to facilitate quick deployment at various venues. The ability to customize designs for branding purposes can also add significant value to these applications.

3 Common User Pain Points for ‘canopy material fabric’ & Their Solutions

Scenario 1: Navigating Diverse Climate Challenges with Canopy Fabrics

The Problem: B2B buyers, particularly those in regions like Africa and the Middle East, often face the challenge of selecting canopy material fabrics that can withstand extreme weather conditions. For instance, a buyer sourcing fabric for outdoor events may encounter unexpected rain, high UV exposure, or strong winds. The consequences of selecting the wrong fabric can include damage to the structure, financial loss, and potential liability issues if the canopy fails during an event.

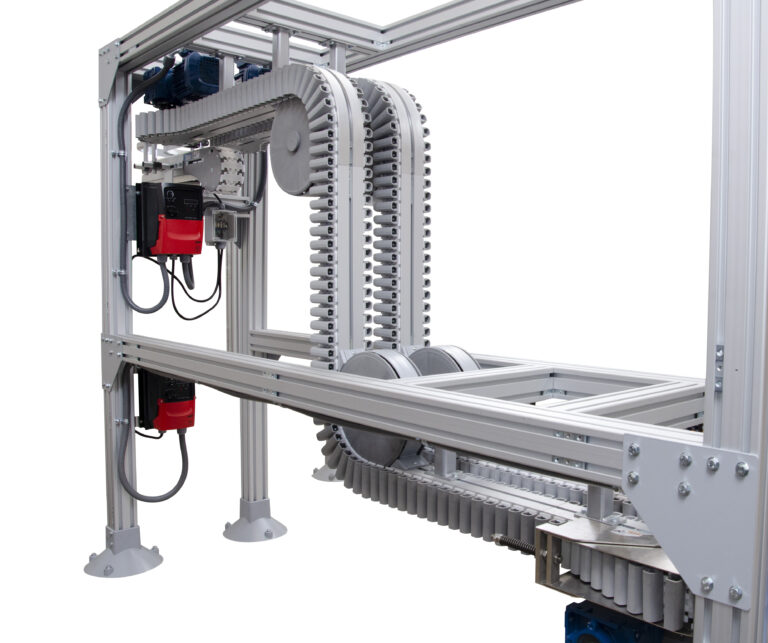

Illustrative image related to canopy material fabric

The Solution: To address these concerns, buyers should prioritize sourcing fabrics that are specifically designed for durability in adverse weather. Look for materials labeled as UV resistant, waterproof, and tear-resistant. A practical approach is to engage with suppliers who offer detailed specifications, including performance data for different weather conditions. For example, fabrics made from solution-dyed acrylic are excellent for UV resistance, while heavy-duty vinyl can provide waterproof properties. Additionally, buyers should consider local climate patterns and select materials that are proven to perform well in similar conditions. Conducting field tests with samples before committing to large orders can also help ensure that the chosen fabric meets the necessary performance criteria.

Scenario 2: Managing Inventory and Supply Chain Delays

The Problem: International buyers often grapple with supply chain disruptions that can lead to delays in receiving canopy materials. This situation is particularly acute for businesses that rely on timely delivery for seasonal events or projects. For instance, a company in South America may face unexpected delays in the import of specialized canopy fabrics, which can hinder their ability to deliver services on time, damaging client relationships and impacting revenue.

The Solution: To mitigate these risks, businesses should adopt a proactive inventory management strategy. This includes establishing strong relationships with multiple suppliers across different regions to diversify sourcing options. Implementing just-in-time inventory practices can help manage stock levels efficiently while ensuring that materials are available when needed. Additionally, investing in inventory forecasting tools can assist in predicting demand based on historical data and upcoming events. It’s also beneficial to negotiate terms that allow for flexibility in orders, enabling quick adjustments based on changing project timelines. By enhancing supply chain resilience, buyers can significantly reduce the impact of delays on their operations.

Scenario 3: Understanding Fabric Specifications and Compliance Standards

The Problem: B2B buyers, especially those in the events or construction industries, often struggle with understanding the technical specifications and compliance standards associated with canopy materials. A buyer might need to ensure that the fabric meets safety regulations, such as fire retardancy or environmental impact standards, but may find it challenging to navigate the myriad of options and certifications available.

The Solution: To effectively address this issue, buyers should invest time in research and education regarding fabric specifications and industry standards. Engaging with suppliers who provide comprehensive product documentation, including certifications and compliance reports, is crucial. Buyers should also participate in industry workshops or webinars that focus on the latest regulations and best practices in canopy fabric usage. Additionally, consulting with industry experts or third-party testing labs can provide clarity on the necessary certifications required for specific applications. By ensuring a thorough understanding of fabric specifications and compliance, buyers can make informed decisions that align with regulatory requirements and safeguard their business interests.

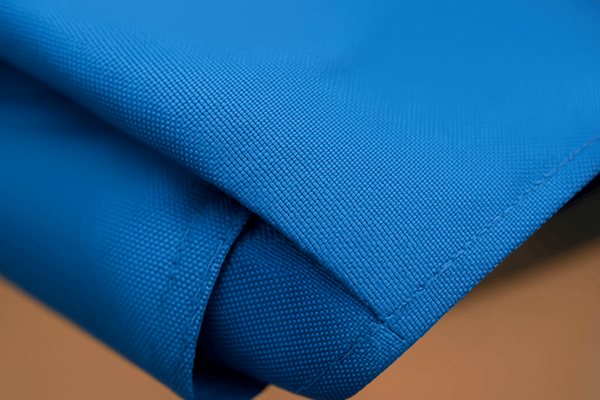

Illustrative image related to canopy material fabric

Strategic Material Selection Guide for canopy material fabric

What Are the Key Properties of Common Canopy Material Fabrics?

When selecting canopy material fabrics for various applications, understanding the properties of different materials is crucial. Here, we analyze four common materials: Polyester, Acrylic, PVC, and Canvas. Each material has unique characteristics that influence its performance, durability, and suitability for specific applications.

How Does Polyester Perform as Canopy Material Fabric?

Polyester is a widely used synthetic fabric known for its durability and resistance to UV rays. It typically has a temperature rating of -40°F to 140°F, making it suitable for diverse climates. Polyester is lightweight, easy to clean, and can be treated for water resistance, which enhances its usability in outdoor settings.

Pros: Polyester is relatively low-cost and offers good durability, making it suitable for temporary structures like pop-up tents. Its lightweight nature facilitates easy transport and setup.

Cons: While it is durable, polyester may not withstand extreme weather conditions as effectively as other materials. Over time, it can degrade under prolonged UV exposure if not treated.

Impact on Application: Polyester is compatible with dye sublimation printing, allowing for vibrant designs, which is advantageous for branding purposes.

Illustrative image related to canopy material fabric

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for UV resistance and water repellency, particularly in regions with intense sunlight, such as the Middle East and Africa.

What Are the Advantages of Acrylic Canopy Fabrics?

Acrylic fabrics are known for their excellent UV resistance and color retention, making them ideal for permanent installations. They can withstand temperatures from -20°F to 180°F, providing versatility across various climates.

Pros: Acrylic is highly durable and resistant to mold and mildew, making it suitable for humid environments. Its vibrant color options enhance aesthetic appeal.

Cons: Acrylic fabrics tend to be more expensive than polyester, which may deter budget-conscious buyers. Additionally, they can be heavier, complicating transportation and installation.

Impact on Application: Acrylic is often used for permanent structures like awnings and shade sails, where longevity and appearance are critical.

Considerations for International Buyers: Compliance with local fire safety standards is essential, especially in regions like Europe, where regulations can be stringent.

How Does PVC Compare in Canopy Fabric Selection?

PVC (Polyvinyl Chloride) is a robust material known for its waterproof properties and high tensile strength. It is suitable for a wide range of temperatures, typically from -40°F to 120°F, making it adaptable for different climates.

Pros: PVC is highly durable and resistant to chemicals, making it ideal for industrial applications. Its waterproof nature ensures protection from rain and moisture.

Cons: The environmental impact of PVC production and disposal is a concern, as it is not biodegradable. Additionally, it can be more expensive than other materials.

Impact on Application: PVC is commonly used in commercial canopies and tents, where durability and weather resistance are paramount.

Considerations for International Buyers: Buyers should be aware of environmental regulations regarding PVC use, particularly in Europe, where sustainability is a growing concern.

What Role Does Canvas Play in Canopy Fabric Applications?

Canvas is a traditional fabric known for its strength and durability. It can handle various temperatures, generally ranging from -20°F to 150°F, making it versatile for different environments.

Pros: Canvas is highly durable and offers excellent wind resistance, making it suitable for outdoor applications. It can also be treated for water resistance and fire retardancy.

Cons: Canvas tends to be heavier, which can complicate transport and installation. It may also require more maintenance to prevent mold and mildew.

Impact on Application: Canvas is often used for larger structures like tents and canopies in events and festivals, where durability is crucial.

Considerations for International Buyers: Compliance with fire safety standards is essential, particularly in regions prone to wildfires, such as parts of South America and the Middle East.

Summary Table of Canopy Material Fabrics

| Material | Typical Use Case for canopy material fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Temporary structures like pop-up tents | Lightweight and cost-effective | Less durable in extreme weather | Low |

| Acrylic | Permanent installations like awnings | Excellent UV resistance | Higher cost and weight | High |

| PVC | Commercial canopies and tents | Waterproof and chemical resistant | Environmental concerns | Med |

| Canvas | Larger structures like event tents | Highly durable and wind-resistant | Heavier and requires maintenance | Med |

This guide provides essential insights for B2B buyers looking to select the most suitable canopy material fabric for their specific needs, considering performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for canopy material fabric

What Are the Key Stages in the Manufacturing Process of Canopy Material Fabric?

The manufacturing process for canopy material fabric consists of several critical stages, each playing a vital role in ensuring the final product meets industry standards and customer expectations. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate fibers and raw materials based on the desired properties of the canopy fabric. Common materials include polyester, acrylic, and nylon, each offering different benefits such as UV resistance, waterproofing, and durability. The materials undergo treatments like dyeing and waterproofing to enhance their performance.

-

Forming: In this stage, the prepared materials are transformed into fabric. Techniques such as weaving, knitting, or non-woven processes are utilized depending on the required characteristics of the fabric. Weaving is prevalent for its strength and durability, while knitting can provide additional stretch and comfort. Quality control measures should be in place to monitor the consistency of fabric weight, texture, and color.

-

Assembly: After forming, the fabric is cut into specific patterns and assembled into the desired shape. This may involve sewing, heat sealing, or bonding techniques to ensure the fabric remains robust under various environmental conditions. Reinforcement techniques, such as adding double stitching or using specialized seams, help enhance durability, particularly in high-stress areas.

-

Finishing: The final stage involves applying coatings or treatments to enhance the fabric’s properties. Common finishing processes include flame retardant treatments, water repellency, and UV protection. These finishes are crucial for outdoor applications where exposure to elements is inevitable. Additionally, fabrics may undergo a quality check to ensure they meet the required specifications for weight, colorfastness, and durability.

What Quality Assurance Standards Are Relevant for Canopy Material Fabric?

Quality assurance is critical in the manufacturing of canopy material fabric, ensuring the final product meets both international standards and specific industry requirements. For B2B buyers, understanding these standards is essential for verifying supplier credibility.

Illustrative image related to canopy material fabric

-

International Standards: ISO 9001 is one of the most recognized quality management standards globally, focusing on maintaining consistent quality in products and services. Compliance with ISO 9001 indicates that a manufacturer has established a quality management system that meets customer and regulatory requirements.

-

Industry-Specific Standards: Depending on the application, there may be additional standards to consider. For example, CE marking is essential for products sold within the European Economic Area, ensuring they meet safety, health, and environmental protection standards. Similarly, the American Petroleum Institute (API) standards may apply for fabrics used in specific industrial applications.

How Are Quality Control Checkpoints Established in the Manufacturing Process?

To ensure the highest quality of canopy material fabric, manufacturers implement several quality control checkpoints throughout the production process. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial check occurs when raw materials arrive at the manufacturing facility. It involves inspecting the materials for defects, verifying specifications, and ensuring that they meet the required standards before they proceed to production.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checkpoints are established to monitor the quality of the fabric as it is being produced. This may involve regular sampling and testing of the fabric for properties such as tensile strength, color consistency, and adherence to specifications.

-

Final Quality Control (FQC): Once production is complete, the finished products undergo rigorous testing to ensure they meet all quality standards. This includes assessing the fabric for durability, resistance to environmental factors, and overall performance. FQC is crucial for identifying any defects that may have occurred during the manufacturing process.

What Testing Methods Are Commonly Used for Canopy Material Fabric?

Various testing methods are employed to evaluate the quality and performance of canopy material fabric. These methods include:

- Tensile Testing: Measures the fabric’s strength and durability by applying a force until the material breaks.

- UV Resistance Testing: Assesses how well the fabric withstands prolonged exposure to ultraviolet light, which can cause fading and degradation.

- Water Resistance Testing: Determines the fabric’s ability to repel water, which is vital for outdoor applications.

- Flame Retardant Testing: Evaluates the fabric’s resistance to ignition and its ability to self-extinguish when exposed to flames.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is critical to ensuring reliable sourcing. Here are several methods to consider:

Illustrative image related to canopy material fabric

-

Supplier Audits: Conducting regular audits of suppliers can help assess their compliance with quality standards and operational practices. This may involve on-site visits to review manufacturing processes, quality control measures, and facilities.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their quality management systems, testing procedures, and performance metrics. These reports should outline the results of various tests and inspections conducted throughout the production process.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality assurance practices. These inspectors can conduct tests and audits, providing an additional layer of verification for B2B buyers.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International buyers must be aware of several nuances that may affect the quality control of canopy material fabric:

-

Cultural Differences: Variations in manufacturing practices and quality expectations can exist across different regions. Buyers should consider these cultural aspects when evaluating suppliers and negotiating quality standards.

-

Regulatory Compliance: Different countries may have specific regulations regarding materials and safety standards. It is crucial for buyers to understand these requirements to ensure compliance and avoid potential legal issues.

-

Supply Chain Challenges: Factors such as transportation delays, customs regulations, and local sourcing can impact the quality of materials and finished products. Buyers should maintain clear communication with suppliers to mitigate these risks and ensure timely delivery of high-quality products.

By understanding the manufacturing processes, quality assurance standards, and verification methods, B2B buyers can make informed decisions when sourcing canopy material fabric, ensuring they receive products that meet their specifications and requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘canopy material fabric’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure canopy material fabric. Whether you are sourcing for outdoor events, commercial installations, or decorative purposes, following these steps will help ensure that you make informed decisions that align with your specific needs and standards.

Step 1: Define Your Technical Specifications

Before diving into the sourcing process, clearly define the technical specifications of the canopy fabric you require. Consider factors such as durability, weight, and intended use.

– Key Attributes: Identify whether you need waterproof, UV-resistant, or fire-retardant materials based on your geographical location and application.

Step 2: Research Available Materials and Fabrics

Take the time to understand the various types of fabrics available for canopies, such as polyester, acrylic, and vinyl. Each material has its strengths and weaknesses, impacting durability, maintenance, and cost.

– Material Properties: Look for fabrics that are easy to clean and maintain, as well as those that offer resistance to mold and mildew, especially in humid climates.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure they can meet your requirements. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Supplier Credibility: Look for certifications that indicate quality assurance, such as ISO or industry-specific standards, to help gauge reliability.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted suppliers, request samples of the canopy fabric for evaluation. This step is crucial to assess the fabric’s feel, color, and overall quality.

– Sample Testing: Evaluate the samples for factors such as colorfastness, texture, and resistance to wear and tear, which can significantly affect the final product’s performance.

Step 5: Review Pricing and Terms of Sale

Analyze pricing structures, including bulk purchase discounts and shipping costs. Understanding the total cost of acquisition will help you make a more informed decision.

– Contract Clarity: Ensure that the terms of sale are clear, including return policies, warranties, and delivery timelines, to avoid potential disputes later.

Step 6: Ensure Compliance with Local Regulations

Different regions have varying regulations regarding materials used for canopies, especially concerning fire safety and environmental impact.

– Regulatory Awareness: Familiarize yourself with local laws and standards to ensure that the materials you procure comply with safety and environmental regulations.

Step 7: Establish a Communication Plan with Suppliers

Once you’ve selected a supplier, set up a communication plan to facilitate ongoing dialogue. Regular updates on production timelines, potential issues, and quality checks can help maintain a smooth procurement process.

– Feedback Loop: Create a system for providing feedback on the materials received and any concerns that arise, fostering a strong supplier relationship.

By following these steps, B2B buyers can ensure a successful procurement process for canopy material fabric, leading to high-quality results that meet specific business needs.

Comprehensive Cost and Pricing Analysis for canopy material fabric Sourcing

What Are the Key Cost Components in Canopy Material Fabric Sourcing?

When sourcing canopy material fabric, understanding the cost structure is essential for effective budgeting and procurement strategies. The primary cost components include:

-

Materials: The choice of fabric significantly influences costs. Options range from basic polyester to high-end acrylic or vinyl, each with varying durability and performance characteristics. Specialty treatments for UV resistance or waterproofing can also increase material costs.

-

Labor: Labor costs can vary based on the complexity of manufacturing processes. Skilled labor may be required for custom designs or intricate patterns, impacting overall expenses.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: If custom designs or specific dimensions are needed, tooling costs for molds or cutting dies may be incurred. These costs can be amortized over larger orders, making bulk purchases more cost-effective.

-

Quality Control (QC): Implementing stringent QC measures is vital to ensure that the fabric meets specified standards. This can involve additional inspections and testing, which contribute to overall costs.

-

Logistics: Shipping costs can be substantial, particularly for international orders. Factors such as distance, shipping method, and customs duties must be factored into the total cost.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding market dynamics and competitive pricing can aid in negotiating better terms.

How Do Price Influencers Affect Canopy Material Fabric Sourcing?

Several factors influence the pricing of canopy material fabric, which international B2B buyers should consider:

-

Volume/MOQ: Bulk purchasing often leads to discounts. Understanding minimum order quantities (MOQs) can help buyers negotiate better prices.

-

Specifications and Customization: Customized fabrics with specific dimensions, colors, or treatments can lead to higher costs. Buyers should weigh the necessity of customization against budget constraints.

-

Material Quality and Certifications: High-quality fabrics, especially those with certifications (e.g., fire retardant, UV resistant), command higher prices. Buyers should ensure that the benefits of premium materials justify the cost.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can significantly impact pricing. Established suppliers may charge a premium for their experience and quality assurances.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) can help buyers assess the total cost of procurement, including freight, insurance, and responsibility for customs clearance.

What Tips Can Buyers Use for Negotiating and Ensuring Cost-Efficiency?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Terms: Leverage your purchasing power by negotiating prices, payment terms, and delivery schedules. Building long-term relationships with suppliers can lead to better deals over time.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate the total cost, including maintenance, durability, and potential need for replacements. A higher upfront cost may lead to lower long-term expenses if the fabric lasts longer.

-

Research Market Prices: Stay informed about market trends and pricing fluctuations. This knowledge will empower buyers during negotiations and help avoid overpaying.

-

Utilize Local Suppliers: Where feasible, sourcing from local suppliers can reduce logistics costs and import duties, enhancing overall cost-effectiveness.

-

Understand Pricing Nuances for International Purchases: Be aware of currency fluctuations, tariffs, and local economic conditions that can impact pricing. This understanding is crucial for budgeting and financial planning.

Disclaimer on Indicative Prices

Pricing for canopy material fabric can vary widely based on the aforementioned factors. This analysis serves as a guideline, and actual prices may differ based on specific requirements, supplier negotiations, and market conditions. Always conduct thorough research and obtain multiple quotes to ensure the best possible deal.

Alternatives Analysis: Comparing canopy material fabric With Other Solutions

When evaluating solutions for outdoor protection and shade, it’s essential to consider various alternatives to canopy material fabric. While canopy fabric is a popular choice for its versatility and durability, other options may also meet specific needs and preferences. This analysis compares canopy material fabric with alternative solutions such as metal awnings and retractable shade systems, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Canopy Material Fabric | Metal Awnings | Retractable Shade Systems |

|---|---|---|---|

| Performance | Highly durable, waterproof, UV resistant | Excellent durability, weather-resistant | Moderate durability, varies by material |

| Cost | Generally low to moderate | Higher initial cost | Variable, often high due to mechanisms |

| Ease of Implementation | Easy to install; can be DIY | Requires professional installation | Requires professional installation |

| Maintenance | Low maintenance; easy to clean | Moderate; may need rust protection | High; mechanisms may require service |

| Best Use Case | Temporary structures, events, leisure spaces | Permanent shade solutions for buildings | Adjustable shade for patios, decks |

Detailed Breakdown of Alternatives

Metal Awnings

Metal awnings provide a robust alternative to canopy material fabric, often made from aluminum or steel. Their primary advantage lies in their durability and ability to withstand extreme weather conditions. However, they come with a higher initial investment and typically require professional installation. Maintenance can be moderate; while they resist many environmental factors, they may still need rust protection, especially in humid climates. Metal awnings are best suited for permanent installations on commercial or residential buildings, providing consistent shade and protection.

Retractable Shade Systems

Retractable shade systems offer flexibility, allowing users to adjust their coverage according to weather conditions. These systems can be motorized or manual and are often made from various fabrics, including canvas or synthetic materials. While they provide excellent versatility, the cost can be significantly higher due to the mechanical components and professional installation requirements. Maintenance can also be demanding, as the mechanisms may require periodic servicing. Retractable shades are ideal for patios and decks, where users desire the option to open or close their shade based on immediate needs.

Illustrative image related to canopy material fabric

Conclusion

Choosing the right shading solution depends on a variety of factors, including budget, intended use, and maintenance preferences. Canopy material fabric excels in affordability and ease of use, making it suitable for temporary setups or events. In contrast, metal awnings provide a permanent solution with superior durability but at a higher cost. Retractable shade systems offer flexibility and modern aesthetics but require more investment and maintenance. B2B buyers should assess their specific needs, considering factors such as location, climate, and usage frequency, to select the most appropriate solution for their outdoor protection requirements.

Essential Technical Properties and Trade Terminology for canopy material fabric

What Are the Key Technical Properties of Canopy Material Fabric?

Understanding the essential technical properties of canopy material fabric is crucial for B2B buyers, especially when sourcing durable and effective materials for various applications. Here are some critical specifications to consider:

1. Material Composition

Canopy fabrics can be made from a variety of materials, including polyester, acrylic, and PVC. Each material has unique properties affecting durability, UV resistance, and water repellency. For instance, polyester is known for its strength and color retention, while acrylic offers superior UV protection. Choosing the right material composition is vital for ensuring the longevity and effectiveness of the canopy in harsh weather conditions.

2. Weight and Denier

The weight of the fabric, often measured in ounces per square yard, impacts its durability and usability. Denier, a unit measuring the fiber’s thickness, also plays a crucial role; higher denier fabrics are typically more robust and resistant to tearing. For B2B buyers, selecting the appropriate weight and denier ensures that the fabric can withstand specific environmental stresses, thereby reducing replacement costs over time.

3. Water Resistance and Breathability

These properties determine how well the fabric repels water while allowing air circulation. Water-resistant fabrics are often treated with coatings to enhance their performance, which is particularly important for outdoor canopies exposed to rain. Breathability prevents moisture buildup underneath the canopy, ensuring comfort for users. Understanding these features helps buyers select fabrics that meet their specific environmental needs.

4. Fire Retardancy

This is a critical safety feature for many applications, particularly in public spaces. Fire-retardant fabrics are treated with chemicals that reduce flammability. For B2B buyers, knowing whether a fabric meets local fire safety standards is essential for compliance and safety assurance, especially in regions with stringent regulations.

5. UV Resistance

UV-resistant fabrics are treated to withstand prolonged sun exposure without degrading or fading. This property is particularly important for canopies used in sunny climates, as it extends the lifespan of the fabric and maintains its aesthetic appeal. For buyers, this translates to longer-lasting products and reduced maintenance costs.

Which Trade Terminology Should B2B Buyers Understand?

Familiarity with industry jargon can greatly enhance communication and negotiation in the canopy fabric market. Here are some common terms that every buyer should know:

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify potential suppliers and assess product quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers, as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their purchasing capabilities and market demand.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. It typically outlines specific requirements for the product, including specifications and quantities. This process allows buyers to compare prices and terms effectively, ensuring they secure the best deals.

4. Incoterms (International Commercial Terms)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce that are widely used in international transactions. Understanding Incoterms helps buyers clarify shipping responsibilities, risk management, and cost allocation, which is particularly relevant for international sourcing.

5. Lead Time

Lead time is the time taken between placing an order and receiving the product. It is essential for buyers to understand lead times to manage project schedules and inventory effectively. Long lead times can impact business operations, making timely communication with suppliers critical.

6. Bulk Pricing

This refers to the discounted rates provided for large volume purchases. Buyers should be aware of bulk pricing structures to optimize their procurement strategies and reduce costs. Understanding how to negotiate bulk pricing can lead to significant savings and better profit margins.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing canopy material fabric, ensuring they select the best products for their specific needs.

Illustrative image related to canopy material fabric

Navigating Market Dynamics and Sourcing Trends in the canopy material fabric Sector

What Are the Current Market Dynamics and Key Trends in the Canopy Material Fabric Sector?

The canopy material fabric sector is experiencing significant growth, driven by global demand for outdoor leisure spaces, event management, and protective structures. Emerging markets in Africa, South America, the Middle East, and Europe are particularly active, with countries like Saudi Arabia and Vietnam showcasing increasing investments in outdoor infrastructure. B2B buyers are seeking durable, versatile, and aesthetically pleasing fabric options that can withstand varying weather conditions, thereby driving demand for materials that are UV resistant, waterproof, and fire retardant.

Technological advancements are reshaping sourcing strategies within this sector. The rise of e-commerce platforms and digital supply chain management tools has made it easier for international buyers to connect with manufacturers and suppliers. B2B buyers are increasingly leveraging data analytics to assess market trends and customer preferences, enabling them to make informed purchasing decisions. Additionally, the trend towards customization is gaining momentum, as businesses look for unique fabric patterns and colors to differentiate their offerings in competitive markets.

Moreover, the sustainability movement is influencing procurement choices, with a growing emphasis on eco-friendly materials. Buyers are looking for suppliers who can provide transparency in their sourcing processes, ensuring that the fabrics they purchase are produced responsibly and sustainably. This alignment with consumer values is not only vital for compliance but also enhances brand reputation.

How Is Sustainability and Ethical Sourcing Shaping the Canopy Material Fabric Market?

Sustainability is becoming a cornerstone of the canopy material fabric sector. Environmental concerns regarding plastic pollution and resource depletion are prompting B2B buyers to seek fabrics made from renewable and recycled materials. Sustainable options, such as organic cotton, recycled polyester, and acrylics, are gaining traction, reflecting a broader industry shift towards reducing carbon footprints.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the practices of their suppliers, ensuring that they adhere to fair labor standards and environmentally friendly processes. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming essential for buyers seeking to validate the sustainability claims of their suppliers. These certifications not only assure the quality of the fabric but also demonstrate a commitment to ethical manufacturing practices.

Illustrative image related to canopy material fabric

Incorporating sustainable and ethically sourced materials can enhance the marketability of products, particularly in regions where consumers are willing to pay a premium for eco-friendly options. This trend is especially relevant in Europe and North America, where regulatory frameworks increasingly favor sustainable practices, making it crucial for B2B buyers to align with these values to maintain competitiveness.

What Is the Historical Context of the Canopy Material Fabric Sector?

The canopy material fabric sector has evolved significantly over the years, transitioning from traditional materials like cotton and canvas to modern synthetic fabrics that offer enhanced durability and performance. Historically, canopies were primarily used for agricultural and military purposes, providing shelter and protection in various environments. As urbanization increased, the demand for decorative and functional outdoor structures surged, leading to innovations in fabric technology.

The introduction of synthetic fibers in the mid-20th century revolutionized the industry, offering lightweight, water-resistant, and UV-protective options that were not possible with natural fibers alone. This shift not only broadened the application of canopy materials in recreational and commercial spaces but also paved the way for the current focus on sustainability and ethical sourcing. Today, the sector continues to adapt, driven by technological advancements and changing consumer preferences, making it a dynamic field for B2B buyers to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of canopy material fabric

-

How do I select the right canopy material fabric for outdoor use?

When selecting canopy material fabric for outdoor applications, prioritize durability and weather resistance. Look for fabrics labeled as UV resistant, waterproof, and mold resistant to ensure longevity. Additionally, consider the weight and thickness of the fabric; heavier fabrics tend to withstand harsh conditions better. Request samples from suppliers to evaluate texture and color, and ensure the fabric meets your specific application needs, whether for tents, awnings, or decorative purposes. -

What are the most suitable fabrics for commercial canopies?

For commercial canopies, high-performance fabrics like acrylic, polyester, and vinyl are ideal due to their durability and weather resistance. Acrylic fabrics offer excellent UV protection and color retention, while vinyl is waterproof and easy to clean. Polyester blends can provide a balance of affordability and durability, making them suitable for various applications. Ensure the chosen fabric complies with local fire safety standards, especially for public events or spaces. -

What customization options are available for canopy material fabric?

Customization options for canopy material fabric include color, print patterns, and fabric treatments. Many suppliers offer dye-sublimation printing for unique designs, which is perfect for branding or thematic events. Additional treatments can enhance the fabric’s properties, such as flame retardancy or enhanced UV protection. Discuss your specific requirements with potential suppliers to explore their customization capabilities and lead times. -

What are the minimum order quantities (MOQ) for canopy fabric?

Minimum order quantities (MOQ) for canopy fabric can vary significantly by supplier and fabric type. Generally, MOQs may range from 50 to 500 yards, depending on the fabric’s popularity and the supplier’s production capabilities. For bulk orders, negotiate with suppliers to find flexible MOQ arrangements that suit your needs, particularly if you are a new buyer or require a smaller initial order for testing purposes. -

How do I vet suppliers when sourcing canopy material fabric internationally?

To vet suppliers, start by checking their certifications, production capabilities, and client reviews. Request references from existing customers and evaluate their response times and communication skills. Utilize platforms like Alibaba or Global Sources to assess supplier ratings and transaction histories. Additionally, consider visiting the supplier’s facility or utilizing third-party inspection services to ensure quality standards are met before placing significant orders. -

What payment terms should I expect when sourcing fabric suppliers?

Payment terms can vary among suppliers, but common practices include a 30% deposit with the order and the remaining 70% prior to shipment. Some suppliers may offer letters of credit or escrow services for added security. Always clarify payment terms upfront and negotiate favorable conditions that align with your cash flow needs. Additionally, ensure that the payment methods are secure and provide buyer protection. -

How can I ensure quality assurance for my canopy fabric orders?

To ensure quality assurance, establish clear specifications and standards with your supplier before production begins. Request samples and conduct pre-production inspections to verify that the fabric meets your requirements. Consider implementing a quality control process, including third-party inspections during manufacturing and before shipment. Document all agreements and inspections to create accountability and protect against discrepancies. -

What logistics considerations should I keep in mind when importing canopy fabric?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with international trade and the specific requirements for importing textiles. Factor in potential customs duties and taxes, as these can significantly affect your total cost. Ensure that your supplier provides all necessary documentation, including certificates of origin and compliance, to facilitate smooth customs clearance and timely delivery.

Top 8 Canopy Material Fabric Manufacturers & Suppliers List

1. Sunbrella – Outdoor Fabrics and Awnings

Domain: sunbrella.com

Registered: 1995 (30 years)

Introduction: Awnings, Canopies, and Pergolas featuring Sunbrella fabrics are designed for outdoor living with innovative technology. The fabrics are UV protective, fade resistant, and durable, available in a wide range of colors and styles. The Skin Cancer Foundation recommends certain Sunbrella fabrics for sun protection. Products include various shades like Marine Blue, Natural, Oyster, Cadet Grey, Charcoal …

2. Outdoor Textiles – Shade Fabrics

Domain: outdoortextiles.com

Registered: 1998 (27 years)

Introduction: Shade Fabrics – Durable shade fabrics for marine applications. UV-resistant and mildew-resistant solution-dyed acrylic and vinyl-coated options. Ideal for boat awnings, canopies, and pergolas. Available by the yard for custom shade solutions. Key brands include Sunbrella, Sattler, Recacril, and Textilene. Fabric widths range from 30 to 150 inches. Prices range from approximately $13.48 to $81.28 d…

3. Fabric Wholesale Direct – Canopy Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Canopy Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Decorative Fabrics Direct – High Performance Awning & Canopy Fabric

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Awning Fabric | Canopy Fabric

– Free Shipping Coupon Code: SHIPFREE for Most $199 Orders

– High Performance Awning & Canopy Fabric

– Suitable for retractable and fixed awnings

– Mold resistant, water repellent, and UV protection

– Versatile for windows, businesses, RVs, campers, or homes

– Replacement fabric or for new installations

– Available by the yard in various colors

– Brands: Sunbrella, Co…

5. EZ Up – Professional Grade Canopy Solutions

Domain: ezup.com

Registered: 1995 (30 years)

Introduction: Professional Grade Fabric – Canopy Technology

– Custom Printed & Sewn in the USA

– Free Shipping on Orders Over $199

– Canopy Sizes Available: 10′ x 10′, 10′ x 15′, 10′ x 20′, 13′ x 13′, 5′ x 5′, 8′ x 12′

– Frame Material Options: Endeavor™, Eclipse®, Express™

– Warranty Information: 14 Items

– Price Range: Starting from $289.00 to $2,043.00

– Featured Canopies: Custom Endeavor® 10′ x 10′, Custom …

6. MVP Visuals – Canopy Fabric

Domain: mvpvisuals.com

Registered: 2005 (20 years)

Introduction: Canopy fabric is used for creating shelter for shade, rain protection, and brand visibility. Key types of canopy fabric include: 1. Polyester (150D–600D): Most common and versatile, durable, easy to handle, treated for water and UV resistance. MVP uses 600D polyester for pop-up tents due to its balance of strength, weight, and print quality. Best for pop-up tents, event canopies, backyard covers, …

7. Trivantage – Industry-Leading Awning Fabrics

Domain: trivantage.com

Registered: 2000 (25 years)

Introduction: Trivantage offers a variety of industry-leading awning fabrics that balance performance, pricing, and style. Key brands include Sunbrella®, Herculite®, Dickson®, and Serge Ferrari. The fabrics are resistant to mildew, mold, UV, and water, providing protection from heat and UV waves. Applications include awnings for homes, businesses, RVs, campers, and shade for pergolas or outdoor living areas. Cl…

8. Shelter Structures – Key Product Details

Domain: shelter-structures.com

Registered: 2009 (16 years)

Introduction: Key Product Details for Pop-up Canopy Fabrics: 1. PVC Coated Polyester: Water Resistance: 1000-1500mm, UV Stability: Medium, Breathability: Good, Durability: 2-4 years, Weight: Light, Notable Features: Affordable, good rainfall performance. 2. Polyester: Water Resistance: Low, UV Stability: Low, Breathability: Very Good, Durability: 2-3 years, Weight: Very Light, Notable Features: Inexpensive, eas…

Strategic Sourcing Conclusion and Outlook for canopy material fabric

How Can Strategic Sourcing Enhance Your Canopy Material Fabric Procurement?

In today’s competitive landscape, strategic sourcing is vital for international B2B buyers in the canopy material fabric sector. By engaging with reliable suppliers who offer a diverse range of durable and customizable fabrics, businesses can achieve significant cost savings and ensure high-quality products that meet specific application needs. The ability to source fabrics that are waterproof, UV resistant, and fire retardant enhances the value proposition for end-users, particularly in regions with diverse climates like Africa, South America, the Middle East, and Europe.

Moreover, understanding the local market trends and consumer preferences can provide a competitive edge. Buyers should leverage data analytics and market intelligence to identify emerging patterns, such as the growing demand for sustainable materials. As the market evolves, aligning procurement strategies with these insights will be essential.

Looking ahead, international B2B buyers are encouraged to foster strong partnerships with fabric manufacturers and distributors to navigate future challenges and capitalize on opportunities. By prioritizing strategic sourcing practices, companies can enhance their supply chain resilience and better meet the dynamic needs of their customers. Embrace this journey towards strategic sourcing to stay ahead in the canopy material fabric market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.