Everything You Need to Know About C & M Wire Rope & Supply Co Sourcing in 2025

Introduction: Navigating the Global Market for c & m wire rope & supply co

In today’s competitive landscape, sourcing high-quality wire rope products for industrial applications is a critical challenge for international B2B buyers. C&M Wire Rope & Supply Co. stands out as a premier manufacturer and supplier, renowned for its extensive range of wire rope products, including steel, stainless steel, and galvanized options. This guide delves deep into the intricacies of navigating the global market for C&M Wire Rope & Supply Co., offering insights into various types of wire ropes, their applications across industries such as construction, mining, marine, and oil and gas, and essential supplier vetting processes.

As international buyers from regions such as Africa, South America, the Middle East, and Europe face unique challenges in sourcing these products, this comprehensive guide aims to empower informed purchasing decisions. It will cover critical topics such as cost considerations, customization options, and the importance of quality assurance through testing and certification. By understanding these elements, buyers can confidently select the right wire rope solutions that meet their specific operational needs while ensuring compliance with industry standards.

With C&M Wire Rope & Supply Co. as a trusted partner, this guide will equip you with the knowledge to navigate the complexities of the wire rope market, ensuring your projects are supported by reliable and sustainable products. Whether you are looking to enhance operational efficiency or meet rigorous safety standards, the insights provided here will help you make strategic procurement decisions.

Understanding c & m wire rope & supply co Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Wire Rope | High tensile strength, resistance to abrasion | Construction, mining, oil & gas | Pros: Durable, versatile; Cons: Heavier, less corrosion-resistant than stainless steel |

| Stainless Steel Wire Rope | Corrosion-resistant, suitable for harsh environments | Marine, food processing, pharmaceuticals | Pros: Long-lasting, hygienic; Cons: Higher cost, less tensile strength than steel |

| Galvanized Wire Rope | Coated for corrosion resistance | Construction, outdoor applications | Pros: Affordable, good durability; Cons: Can be less flexible than other types |

| Non-Rotating Wire Rope | Designed to minimize rotation during lifting | Cranes, hoists, and rigging applications | Pros: Stable load handling; Cons: Limited applications compared to standard ropes |

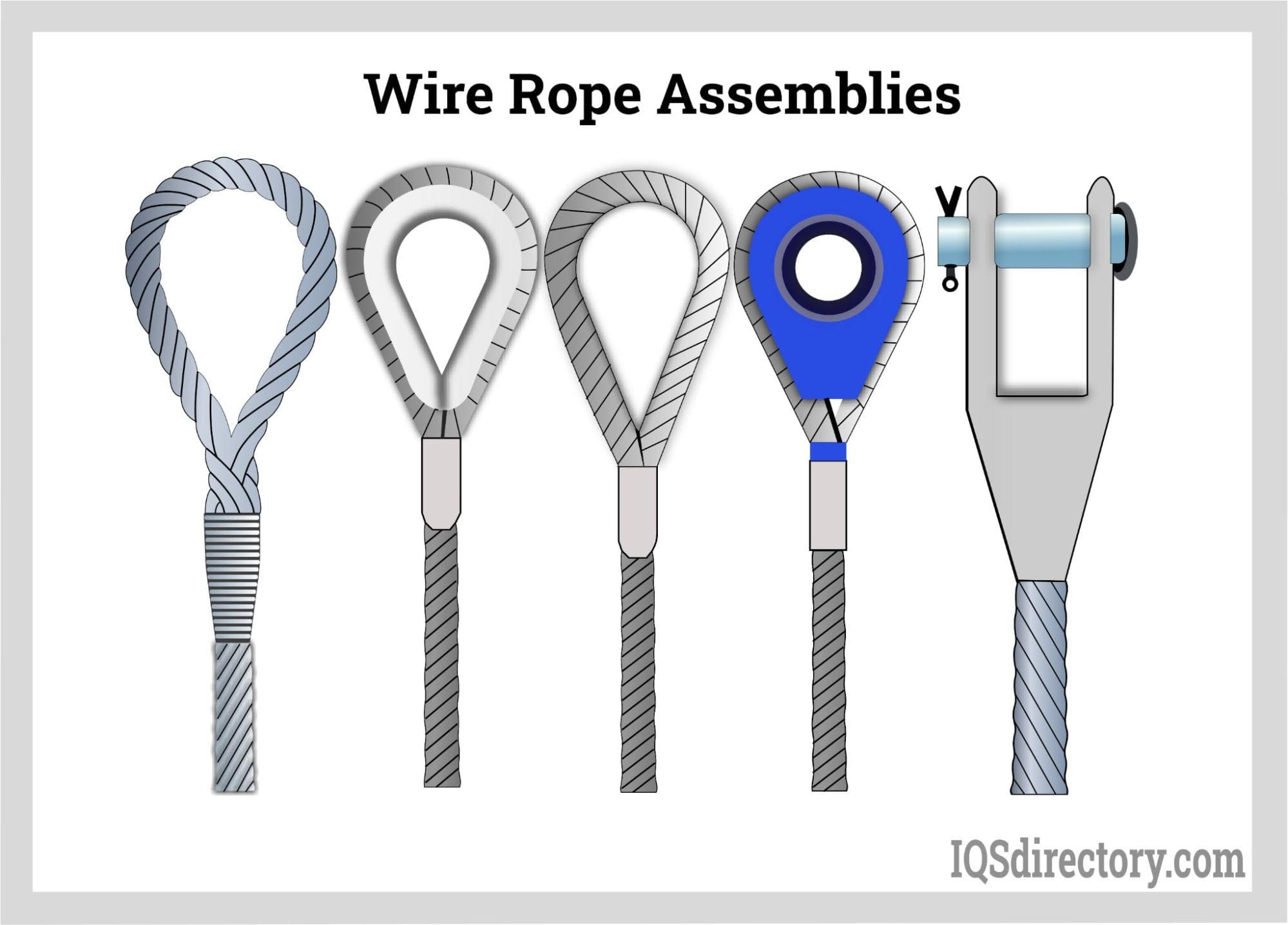

| Wire Rope Assemblies | Combination of wire rope with end fittings | Lifting and hoisting heavy loads | Pros: Customizable, ready-to-use; Cons: Can be more expensive than unassembled rope |

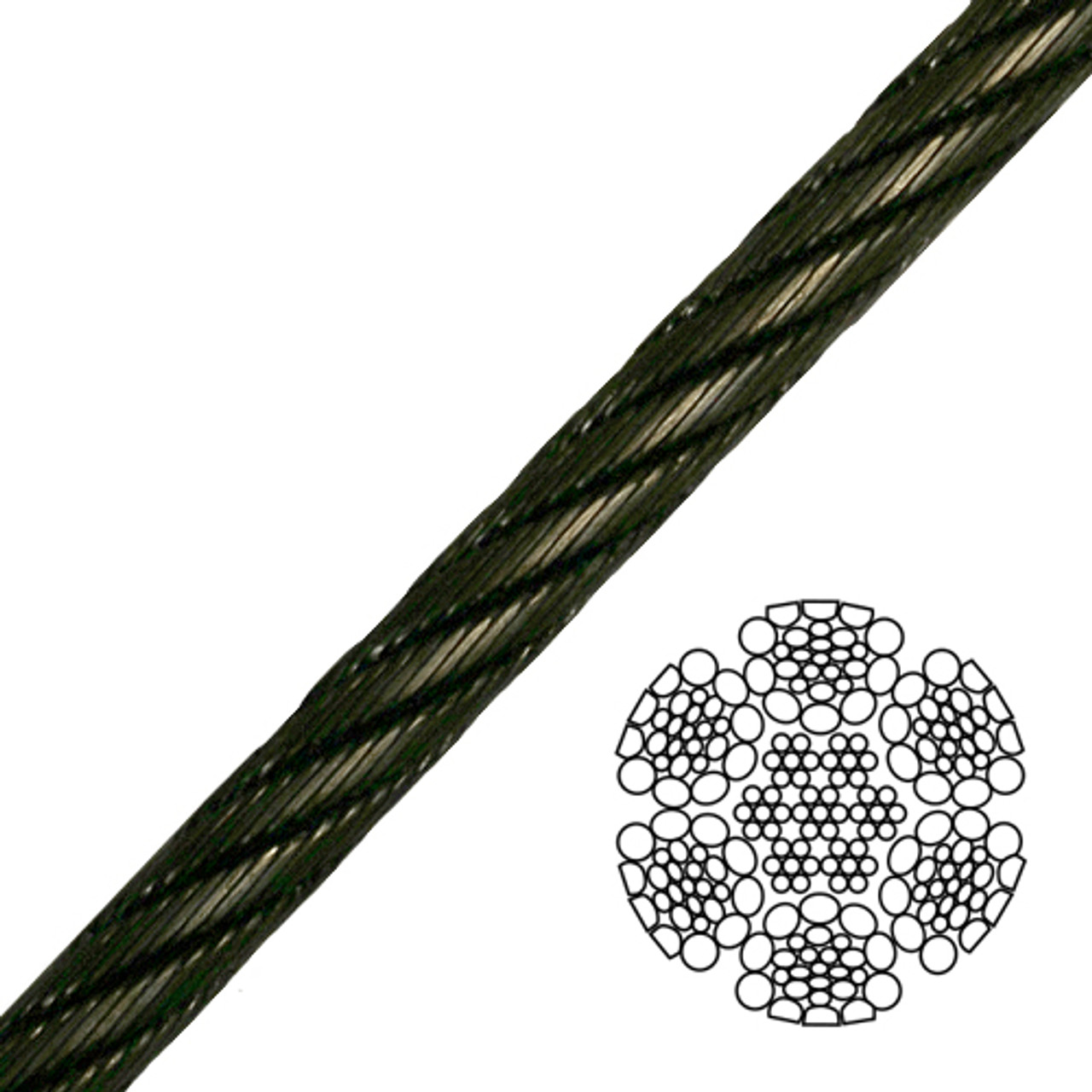

What Are the Key Characteristics of Steel Wire Rope for B2B Buyers?

Steel wire rope is renowned for its high tensile strength and durability, making it a preferred choice across various heavy-duty applications. Its construction involves multiple strands of steel wires twisted together, providing superior resistance to abrasion and wear. B2B buyers should consider this type for industries like construction and mining, where strength and resilience are paramount. However, its weight can be a drawback for certain applications, and it may not perform as well in corrosive environments compared to other materials.

Why Choose Stainless Steel Wire Rope for Specific Industries?

Stainless steel wire rope is specifically designed to withstand corrosive environments, making it ideal for marine, food processing, and pharmaceutical applications. Its resistance to rust and staining ensures that it maintains its integrity over time, crucial for industries that require high hygiene standards. B2B buyers should weigh the benefits of longevity and low maintenance against the higher initial cost. This type of wire rope is suitable for projects where durability and cleanliness are critical.

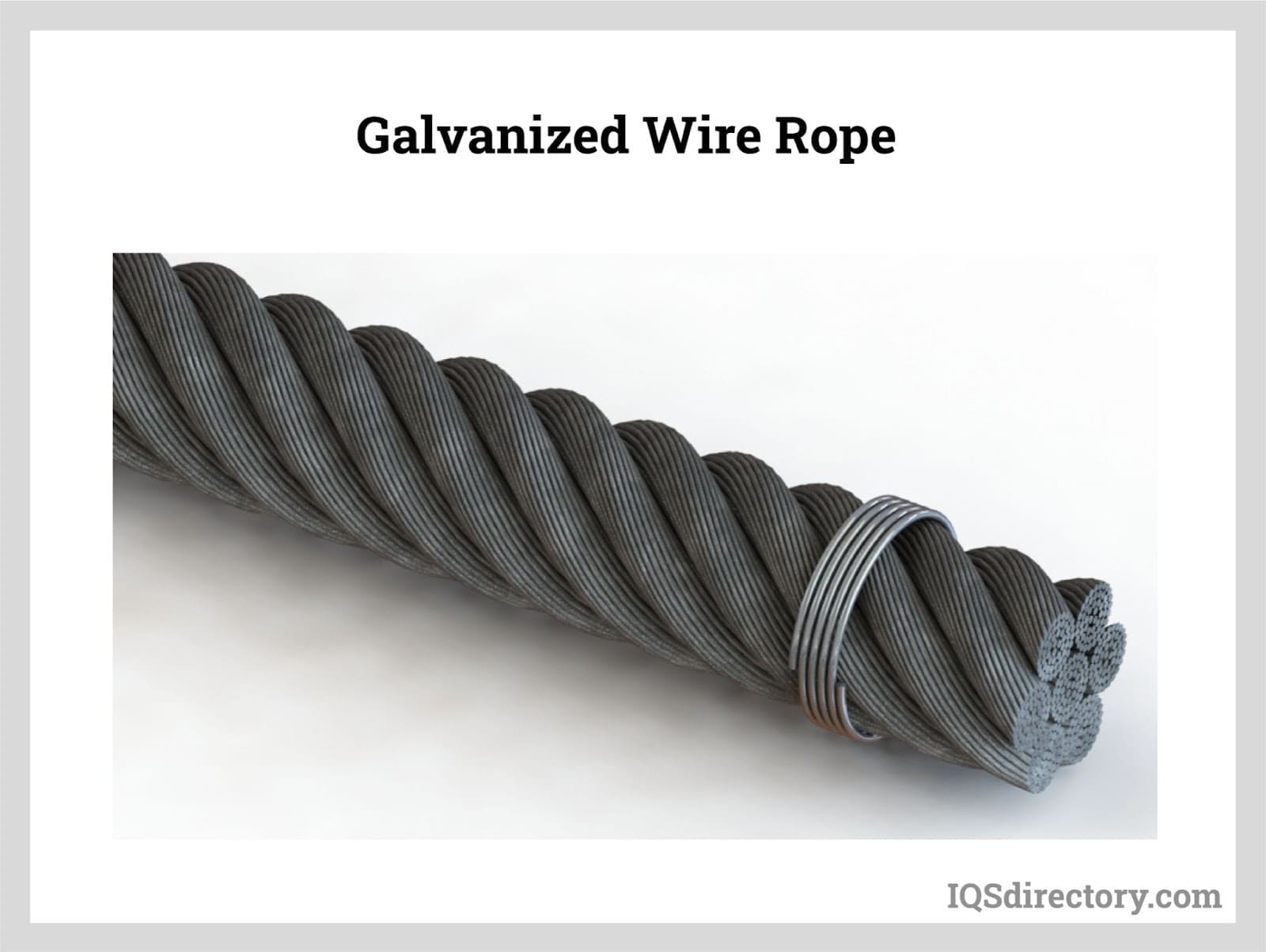

How Does Galvanized Wire Rope Compare to Other Types?

Galvanized wire rope features a protective zinc coating that enhances its resistance to rust, making it a cost-effective option for outdoor and construction applications. While it offers a good balance of affordability and durability, it may not provide the flexibility required for certain specialized tasks. B2B purchasers should consider the environment in which the rope will be used, as its performance can diminish in highly corrosive settings.

What Are the Advantages of Non-Rotating Wire Rope?

Non-rotating wire rope is engineered to prevent twisting during lifting operations, which is essential for maintaining load stability. This feature is particularly beneficial in applications involving cranes and hoists, where load control is critical. B2B buyers should evaluate the specific needs of their projects, as while this type offers enhanced stability, its applications can be somewhat limited compared to more versatile rope types.

Why Invest in Wire Rope Assemblies for Efficiency?

Wire rope assemblies combine wire rope with end fittings, creating ready-to-use solutions for lifting and hoisting tasks. This customization allows B2B buyers to tailor assemblies to their specific requirements, saving time and enhancing operational efficiency. However, the convenience of pre-assembled options may come at a higher price point, making it essential for buyers to consider their budget and project needs when selecting this option.

Key Industrial Applications of c & m wire rope & supply co

| Industry/Sector | Specific Application of c & m wire rope & supply co | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy lifting and rigging for structural components | Enhanced safety and efficiency in construction operations | Compliance with local regulations and standards |

| Mining | Hoisting systems for ore extraction | Increased productivity and reduced downtime | Durability under harsh conditions and custom specifications |

| Marine | Mooring and anchoring systems | Reliable performance in harsh marine environments | Corrosion resistance and certification for marine use |

| Oil and Gas | Cable systems for drilling rigs | Improved safety and operational reliability | Ability to handle high loads and environmental factors |

| Transportation | Custom wire rope assemblies for vehicles | Enhanced safety and performance in transport systems | Availability of custom lengths and fittings |

How Does C & M Wire Rope & Supply Co. Support the Construction Industry?

In the construction sector, C & M Wire Rope & Supply Co. provides essential heavy lifting and rigging solutions for structural components. Their products facilitate the safe and efficient handling of materials, ensuring that projects meet tight deadlines and safety standards. International buyers, especially from regions like Africa and the Middle East, need to consider local compliance regulations and the specific load requirements of their construction projects. C & M’s ability to offer customized solutions, including various lengths and diameters, ensures that clients get the exact specifications needed for their unique applications.

What Role Does C & M Wire Rope & Supply Co. Play in Mining Operations?

In mining, C & M Wire Rope & Supply Co. supplies hoisting systems critical for ore extraction processes. The durability and strength of their wire ropes significantly enhance productivity and minimize equipment downtime, which is vital in this high-stakes industry. Buyers from South America and Africa should focus on the ropes’ ability to withstand the harsh conditions prevalent in mining operations, including extreme temperatures and abrasive materials. Custom specifications tailored to specific mining environments can lead to better performance and safety.

How Are Marine Applications Enhanced by C & M Wire Rope & Supply Co.?

C & M Wire Rope & Supply Co. serves the marine industry by providing reliable mooring and anchoring systems. Their products are engineered to perform under extreme conditions, ensuring the safety of vessels in turbulent waters. Buyers from Europe and the Middle East must prioritize corrosion resistance and the certification of materials for marine applications. The company’s commitment to quality ensures that their wire ropes meet stringent maritime safety standards, which is crucial for operational integrity.

What Solutions Does C & M Wire Rope & Supply Co. Offer for Oil and Gas?

In the oil and gas sector, C & M Wire Rope & Supply Co. delivers cable systems designed for use in drilling rigs. Their products enhance safety and operational reliability, crucial in this high-risk industry. International buyers, particularly from regions like the Middle East, should assess the ropes’ load-bearing capabilities and their performance under environmental stressors, such as extreme weather conditions. C & M’s focus on customized solutions ensures that clients receive tailored products that meet the specific demands of their operations.

How Can C & M Wire Rope & Supply Co. Improve Transportation Systems?

C & M Wire Rope & Supply Co. supplies custom wire rope assemblies critical for various transportation applications, including lifting equipment for vehicles. Their products improve safety and performance, ensuring that transport systems operate efficiently. Buyers from regions like Africa and South America should consider the availability of custom lengths and fittings to match their specific transportation needs. By providing high-quality assemblies, C & M helps businesses enhance their operational capabilities and meet safety regulations effectively.

3 Common User Pain Points for ‘c & m wire rope & supply co’ & Their Solutions

Scenario 1: Difficulty Sourcing Customized Wire Rope Solutions

The Problem: International B2B buyers often face challenges in sourcing wire rope products that meet specific project requirements, particularly in industries such as construction and mining. Standard products may not fit the unique needs of a project, leading to delays and increased costs. Buyers may struggle with identifying suppliers capable of providing custom solutions that adhere to local regulations and safety standards, especially when operating in diverse regions like Africa or the Middle East.

The Solution: To effectively source customized wire rope solutions from C&M Wire Rope & Supply, buyers should first engage directly with their engineering team. C&M specializes in customizing wire ropes to fit precise specifications, including dimensions, material types, and coatings. Buyers can initiate this process by providing detailed project requirements and usage scenarios to C&M. Utilizing their expertise, the team can recommend the most suitable materials and configurations, ensuring compliance with both local and international safety standards. Additionally, buyers should leverage C&M’s commitment to exceptional customer service by requesting quotes and timelines for production to align with project schedules.

Scenario 2: Concerns Over Product Quality and Safety Compliance

The Problem: When procuring wire rope products, especially for critical applications in sectors like oil and gas, buyers often worry about product quality and safety compliance. The stakes are high—substandard products can lead to accidents, operational downtime, and significant financial losses. Buyers may find it challenging to verify that the products meet industry standards and regulations, particularly when sourcing from overseas suppliers.

The Solution: C&M Wire Rope & Supply addresses these concerns through rigorous quality assurance processes and state-of-the-art testing facilities. Buyers should inquire about the specific testing methods used to certify their wire rope products, including tensile strength tests and fatigue evaluations. Additionally, C&M provides comprehensive documentation and certifications that validate product quality and compliance with industry standards. Buyers are encouraged to request these documents during the procurement process to ensure that the products meet their safety requirements. Establishing a robust communication channel with C&M can further enhance transparency and build trust, allowing buyers to feel confident in their purchase decisions.

Scenario 3: Inefficiencies in Wire Rope Handling and Maintenance

The Problem: B2B buyers often encounter inefficiencies related to wire rope handling and maintenance, particularly in large-scale operations. Improper handling can lead to premature wear and tear, resulting in increased operational costs and potential safety hazards. Buyers may lack access to proper training and resources on how to maintain wire ropes effectively, leading to further complications in the supply chain.

The Solution: C&M Wire Rope & Supply offers valuable resources and services that help buyers optimize wire rope handling and maintenance. To mitigate inefficiencies, buyers should take advantage of C&M’s training programs and workshops focused on best practices in wire rope maintenance and usage. These programs can equip teams with the knowledge necessary to handle wire ropes properly, enhancing their lifespan and performance. Furthermore, C&M provides additional services such as wire rope splicing and inspection, ensuring that the ropes are in optimal condition before deployment. By proactively engaging with C&M’s resources, buyers can significantly reduce the risk of operational disruptions and enhance overall productivity in their operations.

Strategic Material Selection Guide for c & m wire rope & supply co

What Are the Key Properties of Steel Wire Rope in B2B Applications?

Steel wire rope is a primary material used by C&M Wire Rope & Supply Co. for various applications across industries such as construction, mining, and marine. Its key properties include high tensile strength, excellent fatigue resistance, and the ability to withstand extreme temperatures and pressures. Steel wire rope is also known for its corrosion resistance, particularly when galvanized or coated, making it suitable for outdoor and marine applications where exposure to moisture and salt is prevalent.

However, while steel wire rope is durable, it can be heavy, which may impact its handling and installation. Additionally, its susceptibility to rust if not properly treated can be a concern in humid environments, necessitating regular maintenance or the use of protective coatings. For international buyers, compliance with standards such as ASTM A1023 for steel wire rope is crucial, ensuring that the products meet safety and performance benchmarks.

Illustrative image related to c & m wire rope & supply co

How Does Stainless Steel Wire Rope Compare in Performance and Applications?

Stainless steel wire rope is another popular choice, especially in environments requiring enhanced corrosion resistance. Its key properties include exceptional resistance to rust and oxidation, making it ideal for applications in marine, chemical, and food processing industries. Stainless steel wire rope maintains its integrity at high temperatures, making it suitable for various industrial applications.

The primary advantage of stainless steel wire rope is its longevity and lower maintenance requirements compared to carbon steel. However, it comes at a higher cost, which may be a consideration for budget-conscious buyers. Additionally, while stainless steel is strong, it may not have the same load-bearing capacity as high-carbon steel wire rope in certain applications. Buyers from regions with strict environmental regulations, such as Europe, may find stainless steel wire rope aligns better with sustainability goals and compliance with standards like EN 12385.

What Are the Benefits and Limitations of Galvanized Wire Rope?

Galvanized wire rope is coated with zinc to enhance its corrosion resistance, making it a cost-effective option for outdoor applications. Its key properties include good tensile strength and resistance to wear and tear, which are essential for lifting and rigging operations. Galvanized wire rope is particularly popular in construction and agriculture due to its affordability and decent performance.

While galvanized wire rope is generally durable, the coating can wear off over time, especially in abrasive environments, leading to potential rusting. The manufacturing process can also introduce variability in quality, which may concern buyers looking for consistency. For international buyers, understanding the local standards for galvanized products, such as ASTM A475, is essential to ensure compliance and quality assurance.

How Do Non-Rotating Wire Ropes Enhance Safety and Performance?

Non-rotating wire ropes are designed to minimize twisting during lifting operations, making them ideal for applications where load stability is critical. Their key properties include a unique construction that allows for better control and handling, particularly in cranes and hoists. This feature is especially beneficial in industries like construction and entertainment, where safety is paramount.

Illustrative image related to c & m wire rope & supply co

The main advantage of non-rotating wire ropes is their ability to maintain load orientation, reducing the risk of accidents. However, they can be more complex to manufacture, resulting in higher costs. International buyers should consider the specific safety standards applicable in their region, such as OSHA regulations in the U.S. or ISO standards globally, to ensure that the products meet the necessary safety requirements.

Summary Table of Material Selection for C&M Wire Rope & Supply Co.

| Material | Typical Use Case for C&M Wire Rope & Supply Co | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Wire Rope | Heavy lifting in construction and mining | High tensile strength and durability | Susceptible to rust without treatment | Medium |

| Stainless Steel Wire Rope | Marine and chemical applications | Excellent corrosion resistance | Higher cost than carbon steel | High |

| Galvanized Wire Rope | Outdoor lifting and rigging operations | Cost-effective with decent corrosion resistance | Coating may wear off over time | Low |

| Non-Rotating Wire Rope | Cranes and hoists in construction | Reduces risk of load twisting | More complex manufacturing process | Medium |

This analysis provides a comprehensive overview of material selection for C&M Wire Rope & Supply Co., equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for c & m wire rope & supply co

What are the Main Stages of Manufacturing Wire Rope at C&M Wire Rope & Supply Co.?

C&M Wire Rope & Supply Co. employs a comprehensive manufacturing process that ensures the production of high-quality wire rope products. This process can be divided into four main stages: material preparation, forming, assembly, and finishing.

How is Material Prepared for Wire Rope Production?

The manufacturing journey begins with the careful selection of raw materials. C&M prioritizes high-grade steel, stainless steel, and galvanized wire to ensure durability and strength. The selected materials undergo rigorous inspections to verify their quality and compliance with international standards.

Once the materials are approved, they are processed into the desired specifications. This includes cutting the wire to the appropriate lengths and applying any necessary coatings or treatments that enhance corrosion resistance and overall performance.

What Techniques Are Used in the Forming Stage?

The forming stage is critical in shaping the wire into rope. C&M utilizes advanced techniques such as strand twisting and braiding. This process involves twisting multiple strands together to create a strong, flexible wire rope that can withstand high tensile loads. The precise control of tension during this stage is essential to prevent weak points that could compromise the rope’s integrity.

In addition, specialized machinery is employed to ensure consistency in diameter and stranding, which are vital for the rope’s performance in various applications, from construction to marine uses.

How is the Assembly Process Conducted?

After forming, the wire rope enters the assembly stage, where it is combined with end fittings, terminals, or lanyards. C&M offers customized solutions, allowing B2B buyers to specify unique configurations based on their project requirements.

This stage may also include additional processes such as swaging, where fittings are permanently attached to the wire rope through a compressive force, ensuring a secure connection that meets safety and operational standards.

What Finishing Techniques Are Applied to Ensure Quality?

The final stage, finishing, involves inspecting the completed wire rope products for defects and applying protective coatings if necessary. C&M Wire Rope & Supply Co. implements processes that not only enhance the aesthetic appeal of the products but also improve their resistance to environmental factors.

During this phase, products are cleaned, and any burrs or sharp edges are removed to ensure safety during handling and use. The finishing process is crucial for preparing the wire rope for shipping and ensuring it meets the specific needs of international clients.

How Does C&M Wire Rope & Supply Co. Ensure Quality Assurance?

Quality assurance is a cornerstone of C&M Wire Rope & Supply Co.’s operations. The company adheres to relevant international standards, including ISO 9001, which outlines the criteria for a quality management system. This commitment to quality is essential for B2B buyers who require reliable and safe products.

What International Standards are Relevant for Wire Rope Quality Assurance?

In addition to ISO 9001, C&M complies with industry-specific certifications such as CE marking and API standards for products used in the oil and gas sector. These certifications indicate that the products meet stringent safety and performance requirements, providing peace of mind for international buyers.

What are the Key Quality Control Checkpoints in the Manufacturing Process?

C&M Wire Rope & Supply Co. implements several quality control checkpoints throughout the manufacturing process:

Illustrative image related to c & m wire rope & supply co

-

Incoming Quality Control (IQC): This stage involves the inspection of raw materials upon delivery. Only materials that meet the established quality criteria are accepted.

-

In-Process Quality Control (IPQC): During production, various checks are conducted to monitor the manufacturing process. This includes regular inspections of the forming and assembly stages to ensure consistency and adherence to specifications.

-

Final Quality Control (FQC): Once the products are completed, they undergo a thorough inspection to verify that they meet all quality standards and specifications before shipping.

What Testing Methods Are Commonly Used to Verify Quality?

C&M employs a range of testing methods to ensure the integrity and performance of its wire rope products. Common techniques include:

- Tensile Strength Testing: To measure the maximum load the wire rope can bear before failure.

- Fatigue Testing: To evaluate how the wire rope performs under repeated loading cycles.

- Corrosion Resistance Testing: To assess the durability of the rope when exposed to harsh environmental conditions.

These tests are conducted in state-of-the-art facilities, ensuring that all products exceed industry standards.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international buyers, verifying the quality assurance processes of suppliers like C&M Wire Rope & Supply Co. is crucial. Here are several methods to ensure compliance and reliability:

What Should B2B Buyers Look for in Supplier Audits?

Buyers can request audits of the manufacturing facilities to assess compliance with quality standards and certifications. An on-site visit allows buyers to witness the processes firsthand, ensuring that the supplier maintains high-quality practices.

How Can Buyers Access Quality Reports and Certifications?

C&M Wire Rope & Supply Co. provides detailed quality reports and certifications upon request. These documents outline the testing methodologies and results, giving buyers transparency regarding the quality of the products they are purchasing.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can further validate the quality assurance processes of suppliers. These independent inspectors can conduct assessments at various stages of production, providing an unbiased evaluation of the manufacturing processes and the quality of the final products.

What are the Quality Control Nuances for International Buyers?

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, B2B buyers should be aware of specific quality control nuances:

-

Cultural Differences: Different regions may have varying interpretations of quality standards. Understanding these differences can aid in communication and set realistic expectations.

-

Regulatory Compliance: Buyers must ensure that suppliers comply with the regulations applicable in their own countries. This may include specific certifications or compliance with local laws regarding safety and environmental impact.

-

Supply Chain Considerations: International shipping can introduce additional risks, such as damage during transit. Buyers should ensure that suppliers have robust packaging and handling processes in place.

By understanding C&M Wire Rope & Supply Co.’s manufacturing processes and quality assurance protocols, international B2B buyers can make informed decisions and establish long-term partnerships that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘c & m wire rope & supply co’

Introduction

In the competitive landscape of industrial supply, sourcing wire rope products from C&M Wire Rope & Supply Co. requires a strategic approach. This guide aims to equip B2B buyers with a step-by-step checklist to ensure a smooth procurement process, focusing on quality, customization, and service. By following these actionable steps, you can make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before initiating contact with suppliers, it’s essential to clearly outline your technical requirements. This includes the type of wire rope needed (e.g., steel, stainless steel, or galvanized), the required diameter, and specific load-bearing capacities. Understanding these specifications will help you communicate effectively with suppliers and ensure that the products meet your operational demands.

Step 2: Research C&M Wire Rope & Supply Co.

Conduct thorough research on C&M Wire Rope & Supply Co. to understand their product offerings and reputation in the market. Review their website and available documentation to gather information about their manufacturing capabilities, customization options, and industry experience. This insight will aid in assessing whether they can meet your specific requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet C&M Wire Rope & Supply Co. thoroughly. Request case studies, customer testimonials, and references from clients within your industry. This will provide you with valuable insights into their reliability and product performance, ensuring you make a sound investment.

Illustrative image related to c & m wire rope & supply co

Step 4: Verify Supplier Certifications

Ensure that C&M Wire Rope & Supply Co. holds relevant industry certifications and adheres to quality standards. Certifications such as ISO 9001 can indicate a commitment to quality management practices. Ask for documentation proving compliance with safety and environmental regulations, as this can impact your project’s risk management.

Step 5: Request Customization Options

C&M Wire Rope & Supply Co. specializes in customized solutions. Engage with their engineering team to discuss your specific needs, including custom lengths, diameters, or special coatings. Understanding their capabilities will help you determine if they can provide tailored solutions that align with your operational requirements.

Step 6: Evaluate Support Services

In addition to product offerings, assess the range of support services provided by C&M Wire Rope & Supply Co. This includes wire rope splicing, swaging, cutting, and testing services. A supplier that offers comprehensive support can streamline your procurement process and enhance operational efficiency.

Step 7: Establish Communication Channels

Finally, set up clear communication channels with C&M Wire Rope & Supply Co. Establish points of contact for inquiries, orders, and support. Good communication is vital for addressing any issues that may arise during the procurement process and can lead to a more fruitful long-term partnership.

By following this checklist, B2B buyers can effectively navigate the procurement process with C&M Wire Rope & Supply Co., ensuring they receive high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for c & m wire rope & supply co Sourcing

What Are the Key Cost Components in C&M Wire Rope & Supply Co’s Pricing Structure?

In analyzing the cost structure of C&M Wire Rope & Supply Co, it’s essential to consider several components that contribute to the overall pricing of their wire rope products. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of wire rope—be it steel, stainless steel, galvanized, or non-rotating—significantly influences material costs. High-quality raw materials, sourced responsibly, can increase initial costs but ensure durability and performance, which is particularly crucial in industries such as construction and marine.

-

Labor: Skilled labor is required for manufacturing, splicing, and customizing wire rope products. The labor cost will vary based on the complexity of the product and the expertise of the workforce, impacting overall pricing.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can help mitigate overhead costs, thereby positively influencing pricing strategies.

-

Tooling: The cost of tools and machinery used in production, including specialized equipment for custom orders, is a significant factor. Investment in advanced technology can enhance production efficiency but may also raise initial costs.

-

Quality Control: C&M Wire Rope & Supply Co emphasizes high-quality standards, requiring thorough inspection and testing of products before delivery. The costs associated with QC processes ensure compliance with industry regulations, contributing to the final price.

-

Logistics: Shipping and handling costs play a vital role in the overall pricing, particularly for international buyers. Factors such as distance, shipping method, and customs duties can substantially affect the final cost.

-

Margin: The profit margin applied by C&M Wire Rope & Supply Co will vary based on competitive positioning and market demand. Understanding this margin is crucial for buyers looking to negotiate favorable terms.

How Do Price Influencers Affect C&M Wire Rope & Supply Co’s Pricing Strategy?

Several price influencers can impact the cost of sourcing from C&M Wire Rope & Supply Co:

-

Volume/MOQ: Larger orders often qualify for discounts, allowing buyers to optimize their procurement budgets. Understanding minimum order quantities (MOQs) can lead to cost savings.

-

Specifications/Customization: Custom orders may incur additional costs, depending on the complexity and materials required. Buyers should clarify their specifications upfront to avoid unexpected charges.

-

Materials Quality/Certifications: High-quality materials or specific certifications can elevate costs but provide assurance of performance and safety, crucial for industries like oil and gas.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. C&M’s established history and commitment to quality may justify higher costs compared to lesser-known manufacturers.

-

Incoterms: The choice of Incoterms can significantly impact logistics costs and responsibilities, affecting the total landed cost for international buyers. Familiarity with these terms is essential for accurate budgeting.

What Buyer Tips Can Help Optimize Sourcing Costs from C&M Wire Rope & Supply Co?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Terms: Engage in discussions to clarify pricing structures and explore potential discounts for bulk purchases or long-term contracts.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the TCO, which includes maintenance, durability, and potential downtime costs. Investing in higher-quality products can reduce long-term expenses.

-

Understand Pricing Nuances: Be aware that prices may vary based on market conditions, currency fluctuations, and geopolitical factors. Staying informed can help in making timely purchasing decisions.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regular communication can also ensure that your needs are understood and met efficiently.

Disclaimer: Prices can fluctuate based on market conditions and specific customer requirements. Always request a detailed quote from C&M Wire Rope & Supply Co to ensure accurate pricing for your particular needs.

Alternatives Analysis: Comparing c & m wire rope & supply co With Other Solutions

Understanding Alternative Solutions in Wire Rope Supply

When evaluating suppliers for wire rope products, it’s essential to consider various alternatives that meet specific operational needs. C & M Wire Rope & Supply Co. has established itself as a formidable player in this industry, but several other options may also offer unique advantages. This comparison aims to highlight key aspects of C & M alongside alternative solutions, aiding international B2B buyers in making informed decisions.

Comparison Table

| Comparison Aspect | C & M Wire Rope & Supply Co | Alternative 1 Name: Bergen Cable Technology, Inc. | Alternative 2 Name: Lexco Cable Manufacturing |

|---|---|---|---|

| Performance | High-quality, custom solutions | Specialized cables for various applications | Wide variety of wire rope products |

| Cost | Moderate pricing | Competitive pricing with bulk discounts | Cost-effective for standard products |

| Ease of Implementation | Requires consultation for custom orders | Online ordering available for standard products | User-friendly ordering system |

| Maintenance | Comprehensive support services | Limited support for installation | Maintenance services available |

| Best Use Case | Tailored solutions for diverse industries | Ideal for specific industrial applications | Suitable for large-scale projects |

Detailed Breakdown of Alternatives

Bergen Cable Technology, Inc.

Bergen Cable Technology specializes in the manufacturing of cables and related products, making it a strong alternative to C & M Wire Rope & Supply Co. Their offerings are particularly beneficial for industries requiring specialized cables, such as aerospace and medical applications. The pros include competitive pricing, especially for bulk orders, and a focus on customization. However, the cons include limited support for installation and maintenance, which may necessitate additional resources for buyers who require comprehensive service.

Lexco Cable Manufacturing

Lexco Cable Manufacturing offers a broad range of wire rope products and is known for its user-friendly online ordering system. This makes it particularly appealing to companies that prioritize ease of procurement. Lexco provides cost-effective solutions for standard wire rope products, which can be advantageous for large-scale projects that do not require customization. Nevertheless, their maintenance services may not be as extensive as those offered by C & M, which could be a drawback for companies needing ongoing support.

Conclusion: How to Choose the Right Wire Rope Supplier

Selecting the right wire rope supplier depends on several factors, including the specific requirements of your project, budget constraints, and the level of support needed. C & M Wire Rope & Supply Co. excels in providing customized solutions and comprehensive service, making it an excellent choice for businesses with unique demands. However, alternatives like Bergen Cable Technology and Lexco Cable Manufacturing can offer competitive pricing and ease of ordering for standard products. By carefully assessing these aspects, B2B buyers can align their choice with their operational needs, ensuring optimal performance and cost-effectiveness in their wire rope supply.

Essential Technical Properties and Trade Terminology for c & m wire rope & supply co

What Are the Key Technical Properties of C&M Wire Rope Products?

Understanding the technical specifications of wire rope products is crucial for B2B buyers to ensure the right choice for their applications. Here are some essential properties to consider:

1. Material Grade

Wire ropes are typically manufactured from different grades of steel, including carbon steel and stainless steel. The material grade affects the rope’s strength, durability, and resistance to corrosion. For industries operating in harsh environments, such as marine or oil and gas, stainless steel ropes may be preferred due to their superior resistance to rust and degradation.

2. Diameter

The diameter of the wire rope is a critical specification that directly influences its load-bearing capacity. Thicker ropes can generally support heavier loads but may also be less flexible. When selecting wire rope, buyers must balance the required strength with the flexibility needed for their specific applications, such as lifting or rigging.

Illustrative image related to c & m wire rope & supply co

3. Lay Direction

Wire ropes can have different lay directions: right lay or left lay. This refers to the direction in which the strands are twisted. The lay direction is essential for applications requiring precise control and stability, as it can affect the rope’s behavior under load. Understanding lay direction helps buyers avoid complications in operational setups, particularly in mechanical systems.

4. Breaking Strength

Breaking strength, often expressed in pounds or kilograms, is a measure of the maximum load a rope can withstand before failure. This property is vital for safety and performance in high-stress applications. Buyers should always choose wire ropes with a breaking strength that exceeds the maximum expected load to ensure safety and reliability.

5. Tolerance

Tolerance refers to the acceptable deviation in the rope’s diameter and weight. This specification is significant for applications requiring precise measurements, especially in automated systems. Consistent tolerance ensures compatibility with fittings and equipment, reducing the risk of operational failures.

6. Coating

Coatings, such as galvanization, can enhance the wire rope’s resistance to environmental factors. Coatings protect against corrosion, abrasion, and wear, extending the lifespan of the product. Buyers should consider the environmental conditions where the wire rope will be used to determine the most suitable coating.

Illustrative image related to c & m wire rope & supply co

What Are Common Trade Terms Used in the Wire Rope Industry?

B2B buyers should familiarize themselves with industry-specific terminology to facilitate effective communication and negotiation. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are used in another company’s end product. In the wire rope industry, understanding OEM relationships can help buyers identify quality suppliers and ensure compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management. Buyers should assess their needs and storage capabilities before committing to orders, especially when dealing with specialized wire rope products.

Illustrative image related to c & m wire rope & supply co

3. RFQ (Request for Quote)

An RFQ is a document sent by potential buyers to suppliers to solicit pricing and terms for specific products. This process allows buyers to compare offers and negotiate better terms. Providing detailed specifications in an RFQ helps suppliers deliver accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping costs, risk management, and delivery timelines.

5. Lead Time

Lead time refers to the amount of time it takes for a supplier to fulfill an order, from receipt to delivery. Understanding lead times is essential for project planning and inventory management, especially for industries that require just-in-time delivery.

6. Certification

Certification refers to the documentation proving that a product meets specific industry standards or regulations. For wire ropes, certifications can indicate compliance with safety and quality standards, providing assurance to buyers about the reliability of their purchases.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance their operational efficiency and safety.

Navigating Market Dynamics and Sourcing Trends in the c & m wire rope & supply co Sector

What Are the Current Market Dynamics and Key Trends in the C&M Wire Rope & Supply Sector?

The global wire rope market is experiencing robust growth, driven by increasing demand across various industries such as construction, mining, marine, and oil and gas. Emerging economies in Africa, South America, the Middle East, and parts of Europe are witnessing a surge in infrastructure projects, resulting in heightened demand for high-quality wire rope products. International B2B buyers should be aware of the trends favoring custom solutions, as companies like C&M Wire Rope & Supply are increasingly tailoring products to meet specific needs. This customization trend is often facilitated by advancements in B2B technology, such as online quoting systems and customer relationship management (CRM) tools, which enhance the procurement process.

Moreover, sustainability is becoming a crucial factor in sourcing decisions. Buyers are now prioritizing suppliers that adopt environmentally friendly manufacturing practices and materials, aligning with global sustainability goals. This shift is particularly significant in regions like Europe, where stringent regulations on environmental impact are in place. As a result, companies that can demonstrate a commitment to quality, safety, and environmental responsibility stand to gain a competitive edge in the market.

How Is Sustainability and Ethical Sourcing Shaping the C&M Wire Rope & Supply Sector?

Sustainability and ethical sourcing are at the forefront of the C&M Wire Rope & Supply sector, as the environmental impact of manufacturing processes becomes increasingly scrutinized. B2B buyers are now more informed and concerned about the ecological footprint of their suppliers. This trend encourages suppliers to adopt greener manufacturing processes, such as utilizing recycled materials and implementing energy-efficient practices. C&M Wire Rope & Supply, for instance, emphasizes its commitment to sustainability through environmentally friendly manufacturing methods, which not only reduce waste but also appeal to eco-conscious customers.

In addition, the importance of ethical supply chains cannot be overstated. Buyers are now looking for suppliers who ensure fair labor practices and transparency in sourcing. Certifications that validate a company’s adherence to environmental and ethical standards are becoming essential. For instance, certifications such as ISO 14001 for environmental management systems can serve as a valuable indicator for international buyers assessing potential suppliers in the wire rope market. By prioritizing sustainability and ethical sourcing, companies can strengthen their brand reputation and foster long-term relationships with clients who share similar values.

What Is the Evolution of C&M Wire Rope & Supply in the Global Market?

Founded over 60 years ago, C&M Wire Rope & Supply has evolved from a local supplier to a significant player in the global wire rope industry. The company’s growth has been fueled by its commitment to quality and customer service, as well as its ability to adapt to changing market needs. Initially focused on standard wire rope products, C&M has expanded its offerings to include a diverse range of customized solutions, catering to various industries such as construction, marine, and transportation.

Throughout its history, C&M has consistently invested in technology and training, ensuring that its products meet or exceed industry standards. This focus on innovation and quality has solidified C&M’s reputation as a trusted partner for B2B buyers worldwide. As the market continues to evolve, C&M Wire Rope & Supply remains poised to leverage its expertise and commitment to sustainability, positioning itself as a leader in the wire rope sector for years to come.

Frequently Asked Questions (FAQs) for B2B Buyers of c & m wire rope & supply co

-

How do I ensure I am sourcing high-quality wire rope products?

To guarantee the quality of wire rope products, start by verifying the manufacturer’s certifications and industry compliance standards. C&M Wire Rope & Supply, for instance, adheres to rigorous testing and certification processes to meet or exceed safety and quality benchmarks. Additionally, request product samples and perform your own inspections or testing if feasible. Engaging in direct communication with the supplier about their manufacturing processes and quality assurance measures can also provide deeper insights into their commitment to product integrity. -

What customization options are available for wire rope products?

C&M Wire Rope & Supply offers extensive customization options, allowing B2B buyers to specify lengths, diameters, coatings, and end fittings tailored to their unique applications. When discussing your requirements, provide detailed specifications to their engineering team, who can collaborate with you to develop a product that meets your operational needs. Custom solutions are particularly beneficial for industries such as construction and marine, where specific load capacities and environmental factors must be considered. -

What are the typical minimum order quantities (MOQs) for wire rope products?

The minimum order quantities for wire rope products can vary significantly based on the type of product and the level of customization required. C&M Wire Rope & Supply typically accommodates varying MOQs, with standard products often available in lower quantities compared to highly customized solutions. It’s advisable to discuss your specific needs with their sales team to understand the MOQs applicable to your order and explore any potential flexibility in order sizes, especially for international shipments. -

What payment terms can I expect when ordering from C&M Wire Rope & Supply?

Payment terms for B2B transactions can vary depending on the order size and the buyer’s relationship with the supplier. C&M Wire Rope & Supply generally offers flexible payment options, including upfront payments, net terms, or letters of credit for international buyers. It’s crucial to clarify payment terms during the quotation process to ensure transparency and avoid any misunderstandings. Establishing a good rapport with the supplier can also lead to more favorable payment arrangements. -

How does C&M Wire Rope & Supply handle logistics for international shipments?

C&M Wire Rope & Supply collaborates with reliable logistics partners to facilitate efficient international shipping. They can assist with the logistics process, including customs clearance and documentation, ensuring that your order arrives on time and complies with local regulations. As an international buyer, it’s beneficial to discuss your shipping preferences, including delivery timelines and cost implications, upfront to ensure a smooth transaction. -

What quality assurance processes are in place at C&M Wire Rope & Supply?

C&M Wire Rope & Supply employs stringent quality assurance processes, including comprehensive testing and inspection of their products. Each product undergoes rigorous assessments to ensure it meets industry standards for strength and safety. They utilize state-of-the-art testing facilities and skilled personnel to perform these checks. As a buyer, you can request detailed quality reports or certifications to verify the compliance and reliability of the products you intend to purchase. -

Can C&M Wire Rope & Supply provide references from previous international clients?

Yes, C&M Wire Rope & Supply can provide references from previous international clients upon request. These references can give you valuable insights into the experiences of other buyers, including product quality, customer service, and logistics efficiency. Engaging with these references can help you assess the supplier’s reliability and suitability for your specific needs, especially in terms of meeting international standards and expectations. -

What industries does C&M Wire Rope & Supply primarily serve?

C&M Wire Rope & Supply caters to a diverse range of industries, including construction, mining, marine, oil and gas, and transportation. Their extensive product line and customization capabilities make them a suitable supplier for companies in need of specialized wire rope solutions. Understanding the specific applications and challenges faced by your industry can help you better articulate your needs to C&M, allowing them to provide tailored recommendations that enhance your operational efficiency.

Top 6 C & M Wire Rope & Supply Co Manufacturers & Suppliers List

1. C & M Wire Rope – Wire Rope and Chain Slings

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, C & M Wire Rope – Wire Rope and Chain Slings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Yelp – Wire Rope & Safety Equipment

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: Specializing in Wire Rope, Chain, and Related Items – Industrial & Contractors Supplies, Gloves & Safety Equipment.

3. Construction Equipment – Your Source for Insights

Domain: constructionequipment.com

Registered: 1995 (30 years)

Introduction: This company, Construction Equipment – Your Source for Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. C & M Wire Rope – Industrial Supplies

Domain: app.makersrow.com

Registered: 2012 (13 years)

Introduction: This company, C & M Wire Rope – Industrial Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. C&M Wire Rope & Supply – Rigging and Lifting Products

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: C&M Wire Rope & Supply provides a variety of rigging and lifting products including wire rope, chain, and nylon slings.

6. C & M Wire Rope – Supply Solutions

Domain: thebluebook.com

Registered: 1995 (30 years)

Introduction: This company, C & M Wire Rope – Supply Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for c & m wire rope & supply co

In the competitive landscape of wire rope products, C&M Wire Rope & Supply Co. emerges as a trusted partner for businesses across various industries, including construction, mining, and transportation. With over 60 years of experience, the company not only provides a comprehensive range of high-quality wire ropes, including customized solutions, but also offers vital services such as splicing, swaging, and testing to ensure product integrity and safety.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the strategic sourcing of wire rope products from C&M can significantly enhance operational efficiency and reliability. The emphasis on customization and quality assurance positions C&M as an ideal supplier for projects requiring specific product specifications and compliance with international standards.

Looking ahead, as global markets continue to evolve, C&M Wire Rope & Supply Co. is poised to meet the growing demand for sustainable and innovative wire rope solutions. B2B buyers are encouraged to leverage C&M’s expertise and commitment to quality by initiating inquiries or requesting quotes to explore how these solutions can drive success in their respective industries. Partnering with C&M ensures not only high-quality products but also a collaborative approach to meeting unique project requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to c & m wire rope & supply co