Everything You Need to Know About Butterfly Valve Parts Sourcing in 2025

Introduction: Navigating the Global Market for butterfly valve parts

In today’s global market, sourcing high-quality butterfly valve parts can present significant challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The complexity of navigating different suppliers, varying product specifications, and fluctuating costs can be overwhelming. This comprehensive guide addresses these challenges head-on, providing a detailed overview of butterfly valve parts—including their types, applications, and critical components—to help buyers make informed decisions.

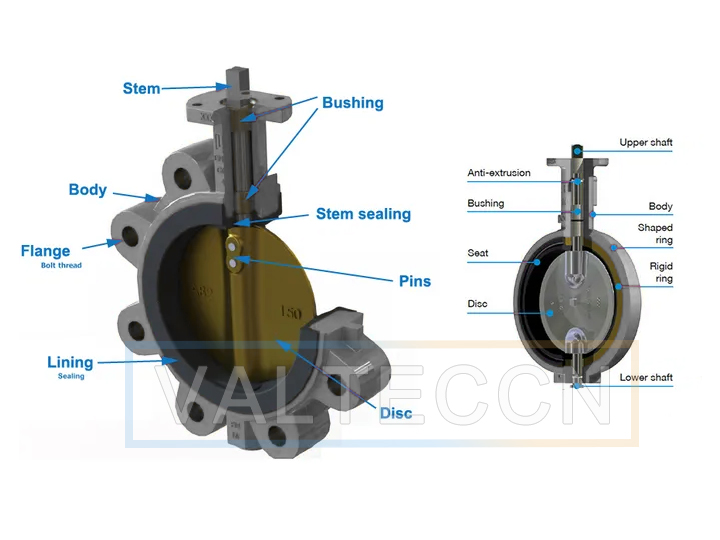

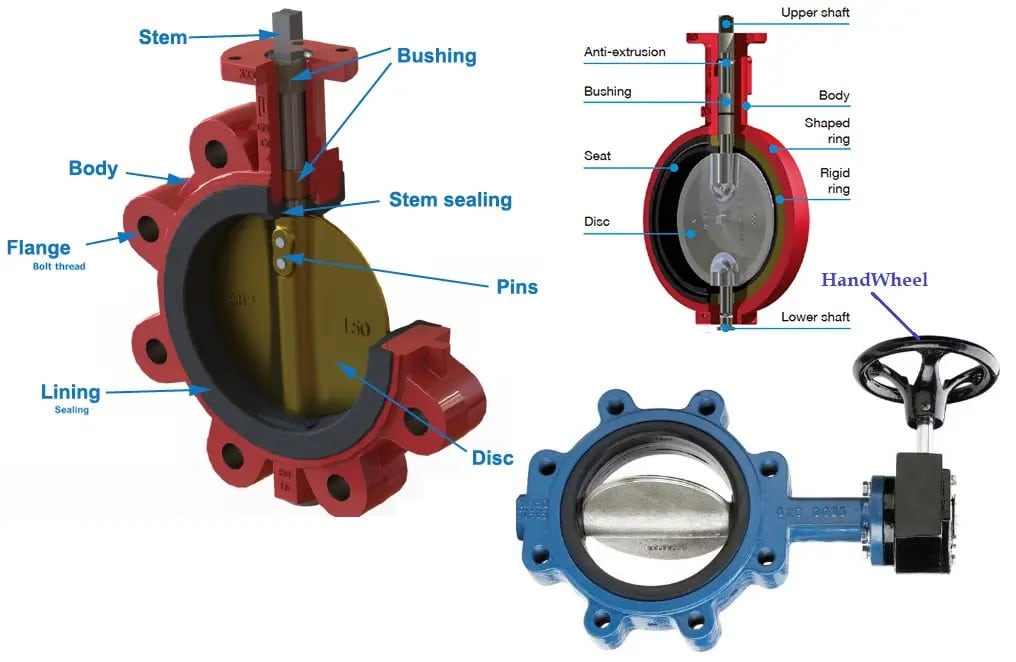

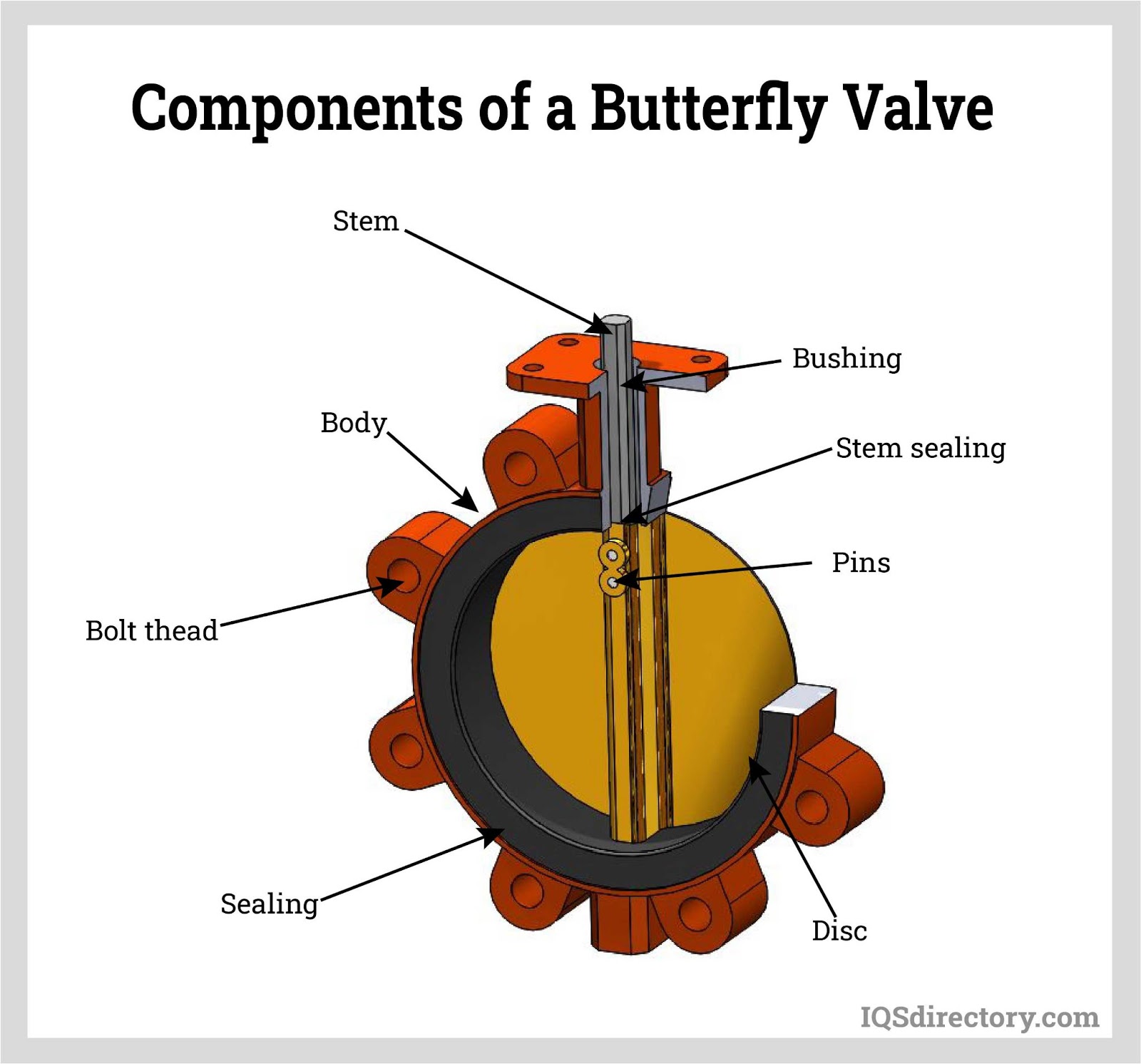

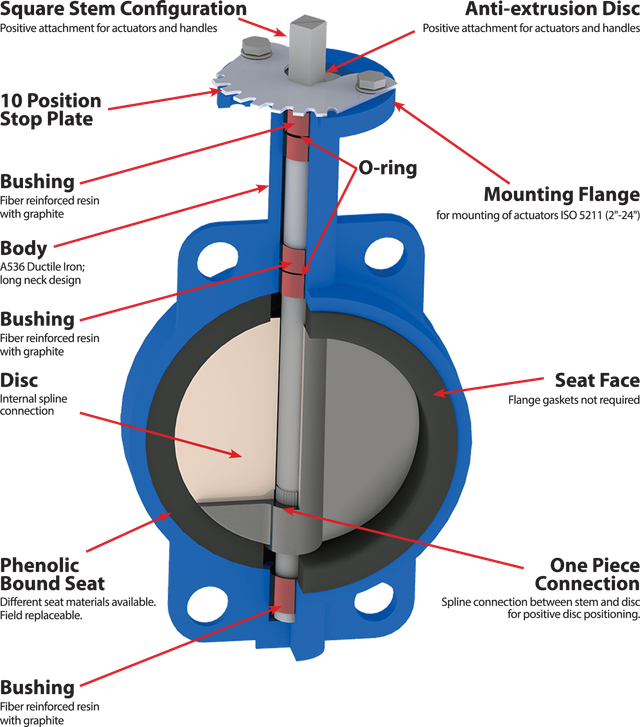

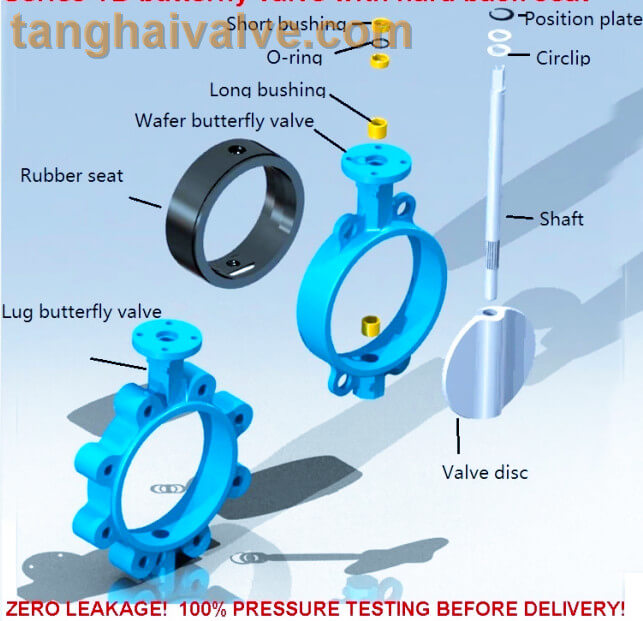

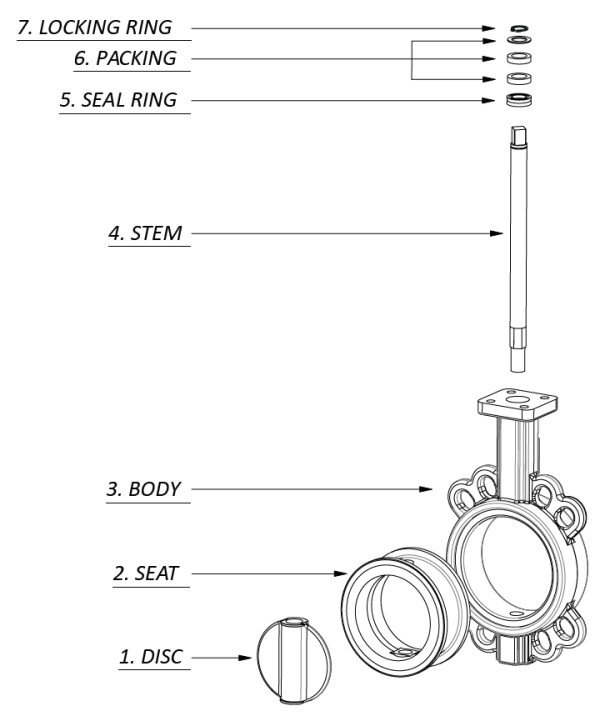

Within these pages, we delve into the essential components of butterfly valves, such as stems, seats, and actuators, while exploring their suitability for various industrial applications ranging from HVAC systems to chemical processing. Additionally, we offer insights on effective supplier vetting processes, ensuring that buyers can identify reputable manufacturers and secure the best value for their investments.

By leveraging the information and actionable insights contained in this guide, B2B buyers will be empowered to navigate the complexities of sourcing butterfly valve parts with confidence. Whether you are based in Brazil, Nigeria, or elsewhere, understanding the nuances of this market will enhance your procurement strategies, ultimately leading to improved operational efficiency and cost-effectiveness.

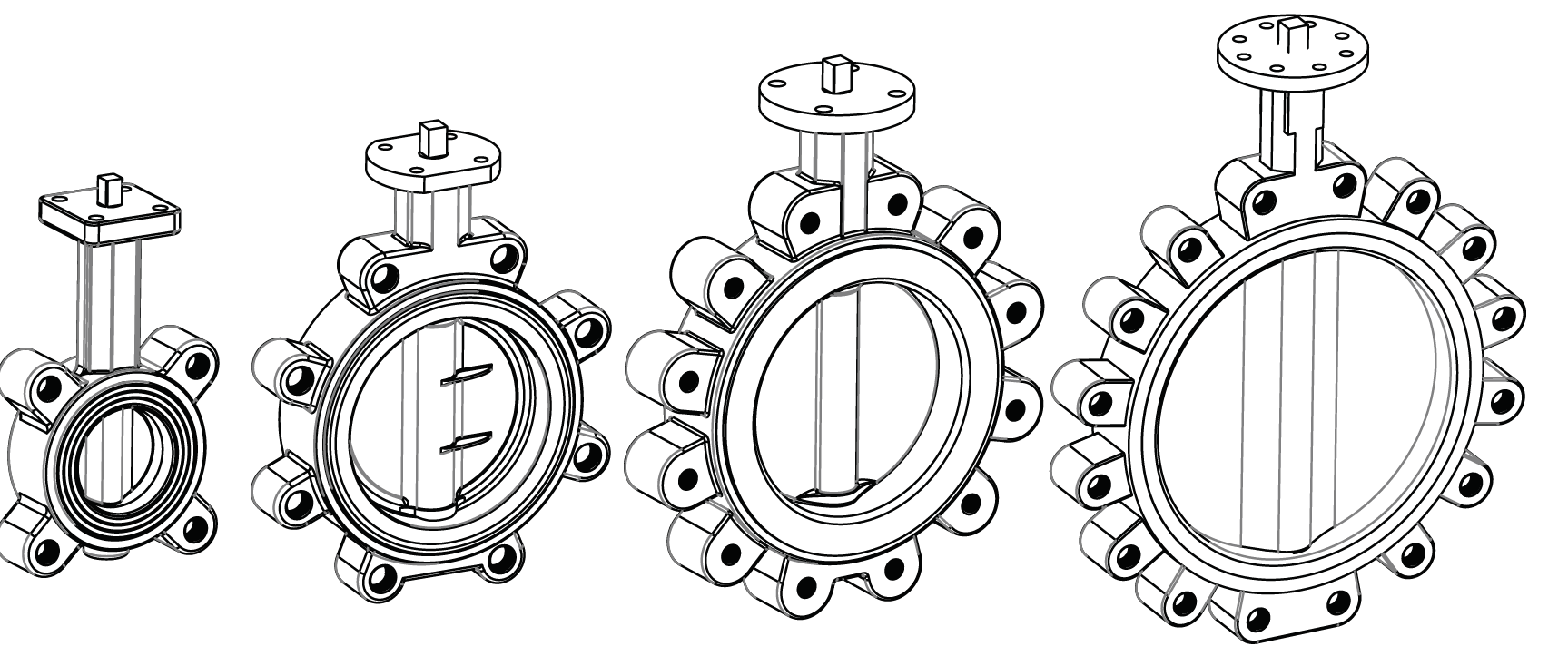

Understanding butterfly valve parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lug Body Butterfly Valve | Features protruding lugs for bolting directly to flanges | Oil & Gas, Water Treatment | Pros: Easy to install; allows for dead-end service. Cons: Heavier and more expensive than wafer types. |

| Wafer Body Butterfly Valve | Compact design with no protruding parts, sandwiched between flanges | HVAC, Chemical Processing | Pros: Cost-effective and lightweight. Cons: Limited to non-dead-end applications. |

| High-Performance Butterfly Valve | Designed for high pressure and temperature, often includes metal seats | Power Generation, Heavy Industry | Pros: Excellent sealing and durability under extreme conditions. Cons: Higher initial cost and complexity. |

| Resilient Seated Butterfly Valve | Utilizes elastomeric seats for tight sealing | Water Supply, Wastewater Management | Pros: Affordable and effective in low-pressure applications. Cons: Limited temperature and chemical resistance. |

| Triple Offset Butterfly Valve | Features three offsets for improved sealing and reduced wear | Oil & Gas, Marine Applications | Pros: Superior sealing and longevity. Cons: More complex and costly than standard designs. |

What Are the Key Characteristics of Lug Body Butterfly Valves?

Lug body butterfly valves are characterized by their protruding lugs that allow direct bolting to flanges. This design facilitates easy installation and maintenance, making them suitable for applications where downstream piping may need to be removed. They are commonly used in oil and gas and water treatment industries. Buyers should consider their heavier weight and higher cost compared to wafer types, which may impact installation logistics.

How Do Wafer Body Butterfly Valves Differ from Other Types?

Wafer body butterfly valves have a compact design without protruding parts, allowing them to be sandwiched between flanges. This design is cost-effective and lightweight, making it ideal for HVAC and chemical processing applications. However, buyers should be aware that wafer valves are not suitable for dead-end service, which can limit their versatility in some installations.

What Makes High-Performance Butterfly Valves Unique?

High-performance butterfly valves are engineered for extreme conditions, featuring metal seats that can withstand high pressure and temperature. They are commonly used in power generation and heavy industry applications where reliability is critical. While they offer excellent sealing capabilities, the higher initial investment and complexity may deter some buyers. It’s essential to assess the specific environmental conditions to justify this choice.

Why Choose Resilient Seated Butterfly Valves?

Resilient seated butterfly valves utilize elastomeric materials to ensure tight sealing, making them effective for applications in water supply and wastewater management. Their affordability and ease of maintenance are significant advantages for budget-conscious buyers. However, their limitations in temperature and chemical resistance should be considered when selecting valves for more demanding environments.

What Are the Advantages of Triple Offset Butterfly Valves?

Triple offset butterfly valves are designed with three offsets that enhance sealing performance and reduce wear, making them ideal for oil and gas and marine applications. They provide superior sealing capabilities, which translates to longer service life. However, their complexity and higher cost compared to standard designs require careful consideration, particularly for budget-sensitive projects.

Key Industrial Applications of butterfly valve parts

| Industry/Sector | Specific Application of butterfly valve parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC Systems | Flow control in air handling units and chillers | Enhances energy efficiency and maintains desired temperature levels | Compatibility with existing systems, material durability, and size |

| Chemical Processing | Regulation of hazardous chemicals and flammable liquids | Ensures safety and precise flow control in critical applications | Material compatibility, pressure ratings, and safety certifications |

| Water Treatment | Water flow regulation and backflow prevention | Protects infrastructure and ensures safe water supply | Compliance with local regulations, corrosion resistance, and size |

| Pulp and Paper | Control of slurry flow during processing | Improves operational efficiency and reduces waste | Material selection for chemical resistance and flow characteristics |

| Oil and Gas | Isolation of pipelines and flow control | Minimizes leaks and enhances safety in high-pressure environments | High-pressure ratings, material strength, and fire-safe designs |

How Are Butterfly Valve Parts Utilized in HVAC Systems?

In HVAC systems, butterfly valve parts are crucial for controlling the flow of air and water in air handling units, chillers, and cooling towers. By allowing precise adjustments to flow rates, these valves enhance energy efficiency and maintain optimal temperature levels. For international buyers, particularly in regions like Africa and South America, sourcing butterfly valve parts that are compatible with existing systems and made from durable materials is essential to ensure longevity and performance.

Illustrative image related to butterfly valve parts

What Role Do Butterfly Valve Parts Play in Chemical Processing?

In chemical processing, butterfly valve parts regulate the flow of hazardous and flammable substances, providing a critical function in maintaining safety and operational efficiency. These valves must meet stringent safety standards and be made from materials that can withstand aggressive chemicals. Buyers in the Middle East and Europe should prioritize sourcing valves with high-pressure ratings and appropriate certifications to comply with local regulations and ensure the safe handling of materials.

Why Are Butterfly Valve Parts Important in Water Treatment?

Butterfly valve parts are vital in water treatment facilities for regulating water flow and preventing backflow, which protects infrastructure and ensures a safe water supply. The selection of materials that resist corrosion and comply with local water quality standards is paramount for international buyers. Additionally, the size and design of these valves must fit seamlessly into existing systems to optimize performance and reliability.

How Do Butterfly Valve Parts Enhance Efficiency in the Pulp and Paper Industry?

In the pulp and paper industry, butterfly valve parts are used to control the flow of slurry during processing, significantly improving operational efficiency and minimizing waste. For businesses in regions like Brazil and Nigeria, sourcing valves that can handle the specific flow characteristics of pulp and paper production is crucial. The right material selection for chemical resistance and durability will also ensure sustained performance in harsh processing environments.

What Is the Importance of Butterfly Valve Parts in Oil and Gas Applications?

In the oil and gas sector, butterfly valve parts serve as isolators and flow controllers in pipelines, minimizing leaks and enhancing safety in high-pressure environments. Buyers should consider sourcing high-performance valves that meet the rigorous demands of the industry, including high-pressure ratings and fire-safe designs. Ensuring that these components meet international safety standards is vital for operational integrity and compliance in global markets.

3 Common User Pain Points for ‘butterfly valve parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Butterfly Valve Parts

The Problem: B2B buyers often struggle with sourcing reliable and high-quality butterfly valve parts, especially when dealing with suppliers across different regions. The challenge intensifies in areas like Africa or South America, where local suppliers may not meet international quality standards. Issues such as inconsistent material quality, lack of proper certifications, and the risk of counterfeit parts can lead to operational inefficiencies and increased maintenance costs.

Illustrative image related to butterfly valve parts

The Solution: To overcome these challenges, buyers should prioritize sourcing from reputable manufacturers with a proven track record. Research suppliers thoroughly by checking their certifications, industry reputation, and reviews from other B2B customers. Establish long-term partnerships with manufacturers that offer comprehensive quality assurance processes. Additionally, consider utilizing third-party inspection services to verify the quality of parts before they are shipped. This proactive approach not only ensures the procurement of high-quality components but also builds a more reliable supply chain, ultimately reducing the risk of downtime and increasing overall operational efficiency.

Scenario 2: Compatibility Issues with Existing Systems

The Problem: Another common pain point for B2B buyers is the compatibility of butterfly valve parts with existing systems. Many companies operate in environments with older infrastructure, which may not be compatible with modern valve designs. This misalignment can lead to performance issues, increased installation costs, and delays in project timelines.

The Solution: To address compatibility concerns, it is crucial to conduct a thorough assessment of the existing system before procurement. Buyers should work closely with engineers to understand the specific requirements, including size, pressure ratings, and material compatibility. When sourcing butterfly valve parts, opt for suppliers who provide detailed specifications and compatibility information. Additionally, consider customization options offered by manufacturers, which can help bridge the gap between modern components and older systems. By ensuring that all parts are compatible from the outset, businesses can minimize installation headaches and ensure smooth operations.

Scenario 3: Long Lead Times and Unreliable Delivery Schedules

The Problem: Long lead times and unreliable delivery schedules can be a significant pain point for B2B buyers of butterfly valve parts. Delays in receiving essential components can halt production lines and disrupt project timelines, leading to financial losses and strained relationships with clients. This issue is exacerbated when dealing with international suppliers, where shipping times can be unpredictable.

The Solution: To mitigate the risks associated with lead times, buyers should implement a strategic inventory management system. By forecasting demand accurately and maintaining a buffer stock of essential butterfly valve parts, companies can cushion against unexpected delays. Additionally, establishing relationships with multiple suppliers can provide alternative options in case of delays with the primary source. It is also advisable to negotiate delivery terms upfront, ensuring that suppliers commit to realistic timelines and penalties for non-compliance. By taking these proactive measures, businesses can enhance their operational resilience and maintain continuity in their production processes.

Strategic Material Selection Guide for butterfly valve parts

What Are the Key Properties of Common Materials Used in Butterfly Valve Parts?

When selecting materials for butterfly valve parts, several factors must be considered, including mechanical properties, compatibility with media, and environmental conditions. Below, we analyze four common materials used in the manufacturing of butterfly valve components, focusing on their properties, advantages, and limitations.

1. Cast Iron

Key Properties: Cast iron exhibits excellent strength and durability, with a temperature rating typically up to 400°F (204°C) and good pressure resistance. It also has decent corrosion resistance when coated.

Pros & Cons: The primary advantage of cast iron is its cost-effectiveness and high strength-to-weight ratio. However, it is prone to rust if not properly coated, and its brittleness can be a disadvantage in high-stress applications.

Impact on Application: Cast iron is suitable for water and wastewater applications due to its strength and sealing capabilities. However, it may not be ideal for corrosive environments.

Considerations for International Buyers: Compliance with ASTM standards is essential, particularly for buyers in Europe and the Middle East. Cast iron valves are widely accepted, but buyers should ensure proper coatings to prevent corrosion, especially in humid climates.

2. Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance, high-temperature tolerance (up to 1,500°F or 815°C), and good mechanical strength.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to a wide range of chemicals, making it suitable for various applications. However, it is generally more expensive than cast iron and may require specialized manufacturing processes.

Illustrative image related to butterfly valve parts

Impact on Application: Stainless steel is ideal for applications involving aggressive chemicals, such as in chemical processing or food and beverage industries. Its compatibility with various media ensures reliable performance.

Considerations for International Buyers: Buyers must consider compliance with international standards, such as DIN and JIS, particularly in Europe and Asia. Stainless steel valves are often preferred in industries requiring high hygiene standards.

3. PVC (Polyvinyl Chloride)

Key Properties: PVC is lightweight, has a temperature rating up to 140°F (60°C), and offers excellent chemical resistance against acids and bases.

Pros & Cons: The lightweight nature of PVC makes it easy to install and handle, and it is cost-effective for low-pressure applications. However, its temperature limitations and lower mechanical strength compared to metals can restrict its use.

Impact on Application: PVC is commonly used in water treatment and irrigation systems. Its chemical resistance makes it suitable for corrosive media, but it may not perform well in high-temperature environments.

Considerations for International Buyers: Compliance with local regulations regarding plastic materials is crucial, especially in regions like Africa and South America, where standards may vary. Buyers should ensure that PVC valves meet local safety and environmental regulations.

4. EPDM (Ethylene Propylene Diene Monomer)

Key Properties: EPDM is a synthetic rubber known for its excellent weather and ozone resistance, with a temperature range of -40°F to 300°F (-40°C to 149°C).

Pros & Cons: EPDM is flexible and provides a good seal, making it suitable for various applications. However, it is not compatible with oils and certain solvents, which limits its use in specific environments.

Impact on Application: EPDM is widely used in HVAC systems and water applications due to its sealing capabilities. Its resistance to aging and environmental factors makes it a reliable choice.

Considerations for International Buyers: Buyers should verify that EPDM materials comply with relevant standards, such as ASTM or ISO, particularly in regions with strict regulations like Europe. Understanding the specific media compatibility is essential for ensuring long-term performance.

Summary Table of Material Selection for Butterfly Valve Parts

| Material | Typical Use Case for butterfly valve parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Water and wastewater applications | Cost-effective and strong | Prone to rust without coating | Low |

| Stainless Steel | Chemical processing, food and beverage | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| PVC | Water treatment, irrigation systems | Lightweight and chemically resistant | Limited temperature and strength | Low |

| EPDM | HVAC systems, water applications | Good sealing and environmental resistance | Not oil-resistant | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on application requirements, environmental conditions, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for butterfly valve parts

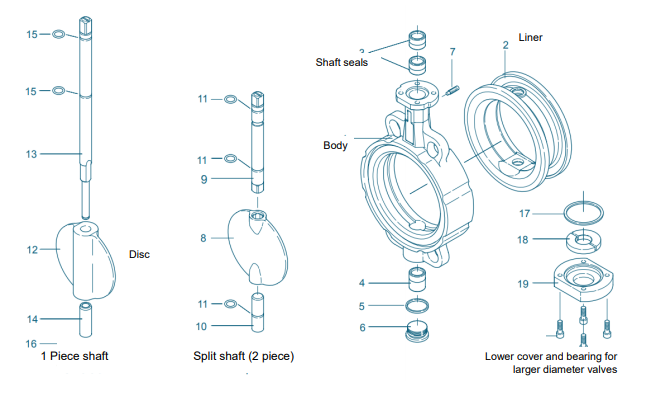

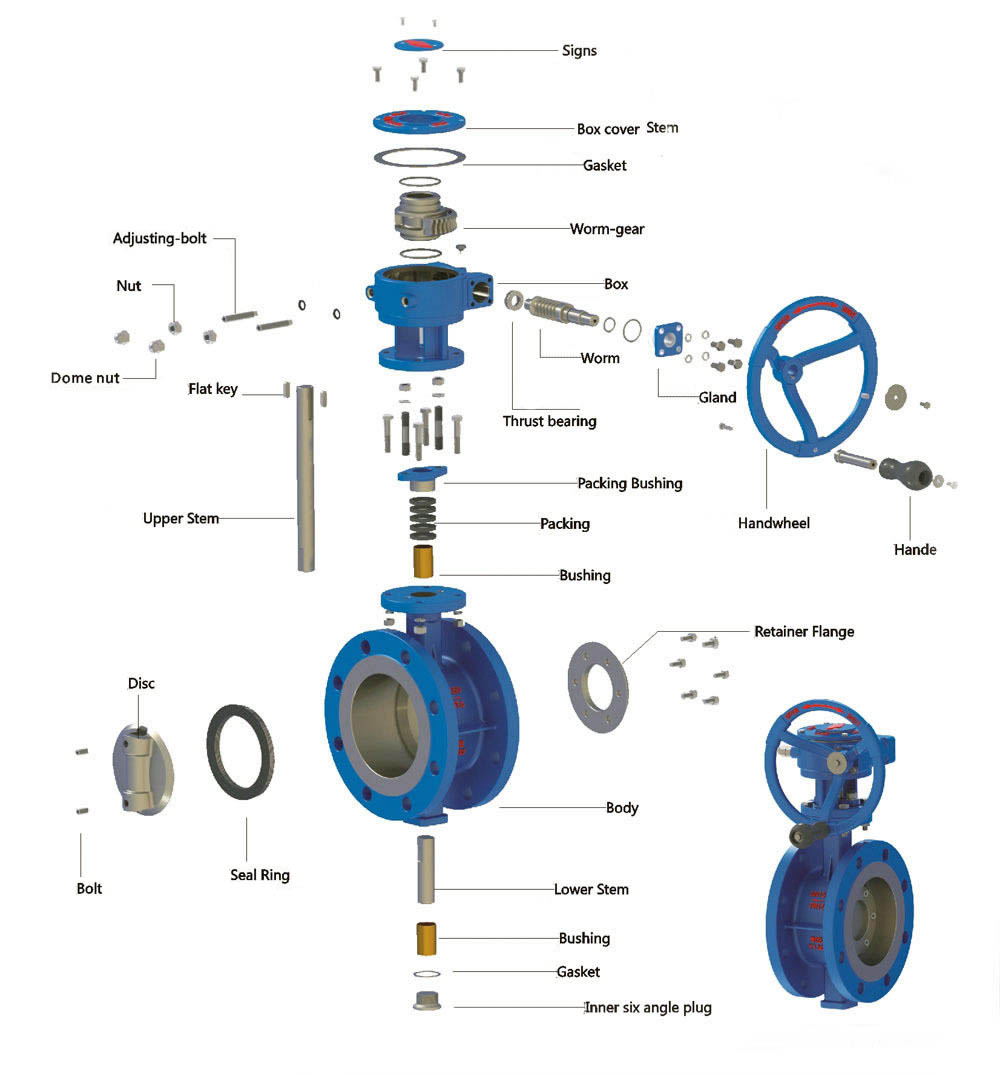

What Are the Main Stages in the Manufacturing Process of Butterfly Valve Parts?

The manufacturing process for butterfly valve parts is systematic and involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial to ensure the end product meets quality standards and performance requirements.

Material Preparation

The first step involves selecting appropriate materials based on the application requirements. Common materials include cast iron, stainless steel, and various polymers for seals. Suppliers often perform material testing to verify composition and quality. This may include tensile strength tests and hardness tests to ensure that the selected materials can withstand operational conditions.

Forming Techniques

Once the materials are prepared, forming techniques come into play. Common methods include casting, forging, and machining. For example, the body of a butterfly valve is typically cast, while the disc and stem might undergo precision machining to achieve tight tolerances. Advanced techniques such as CNC machining allow for high precision and repeatability, essential for parts that must fit together seamlessly.

Assembly Process

The assembly stage involves putting together the various components, including the body, disc, stem, and actuator. This stage is critical as it affects the operational efficiency and longevity of the butterfly valve. Manufacturers often employ automated assembly lines to enhance precision and reduce human error. During assembly, components are checked for proper fit and alignment, ensuring that they meet design specifications.

Finishing Touches

Finishing processes include surface treatments, coatings, and inspections. Surface treatments might involve polishing or applying protective coatings to enhance corrosion resistance. These processes not only improve the aesthetic quality but also prolong the lifespan of the parts. Final inspections are carried out to ensure all components meet the necessary quality standards before packaging and shipping.

How is Quality Assurance Implemented in Butterfly Valve Parts Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that every butterfly valve part meets international and industry-specific standards. Various checkpoints and testing methods are employed throughout production.

International Standards and Certifications

Compliance with international standards such as ISO 9001 is essential for manufacturers targeting global markets. This certification indicates a commitment to quality management systems, ensuring consistent product quality and customer satisfaction. Additionally, industry-specific certifications such as CE marking for European markets and API standards for oil and gas applications further validate the manufacturer’s credibility.

Quality Control Checkpoints

Quality control (QC) is typically divided into several checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC focuses on raw materials, ensuring they meet specified requirements before they are used in production.

- IPQC involves monitoring the manufacturing process itself, with regular inspections at various stages to identify any deviations from quality standards.

- FQC occurs after assembly, where finished products undergo rigorous testing for functionality, durability, and safety.

What Testing Methods Are Commonly Used for Butterfly Valve Parts?

Testing methods are vital in verifying the performance and reliability of butterfly valve parts. Some common methods include:

Illustrative image related to butterfly valve parts

- Hydraulic Testing: This method assesses the valve’s ability to withstand pressure without leaking. It simulates real-world conditions and is crucial for ensuring that the valve can perform under high pressure.

- Functional Testing: This involves operating the valve to ensure it opens and closes smoothly and seals properly. Any irregularities in motion or sealing effectiveness are identified and rectified.

- Material Testing: Tests such as tensile strength, impact resistance, and corrosion resistance are conducted to ensure that the materials used can withstand the operational environment.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are some effective methods:

Conducting Supplier Audits

One of the most reliable ways to assess a supplier’s quality control measures is through on-site audits. This allows buyers to evaluate manufacturing processes, quality systems, and compliance with international standards firsthand.

Requesting Quality Reports

Buyers should ask for quality assurance reports, including inspection and testing records. These documents provide insights into the manufacturer’s QC processes and the outcomes of various tests conducted on the products.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can occur at various stages of production, ensuring adherence to required standards and specifications.

Illustrative image related to butterfly valve parts

What Are the Unique Quality Control Challenges for International B2B Buyers?

International buyers face specific challenges when it comes to quality control in the procurement of butterfly valve parts, particularly from regions like Africa, South America, the Middle East, and Europe.

Regulatory Differences

Different regions have varying regulations and standards, which can complicate the procurement process. Buyers must familiarize themselves with local regulations and ensure that their suppliers comply with both international and local standards.

Supply Chain Variability

The global supply chain can introduce variability in quality. Different suppliers may have different quality control processes, and this inconsistency can impact the final product. It is essential for buyers to establish strong relationships with trusted suppliers who maintain high-quality standards.

Cultural and Communication Barriers

Cultural differences can affect business practices, including approaches to quality assurance. Clear communication is essential to ensure that expectations regarding quality standards are understood and met.

Conclusion

A thorough understanding of the manufacturing processes and quality assurance measures for butterfly valve parts is essential for B2B buyers. By focusing on supplier capabilities, conducting audits, and understanding international standards, buyers can make informed decisions that ensure the reliability and performance of the valves they procure. This diligence not only safeguards their investment but also enhances operational efficiency in their respective industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘butterfly valve parts’

To successfully procure butterfly valve parts, it’s essential to follow a structured approach that ensures quality, compatibility, and cost-effectiveness. This guide provides a step-by-step checklist to help B2B buyers navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the butterfly valve parts you need. This includes dimensions, materials, pressure ratings, and compatibility with existing systems. By having precise specifications, you reduce the risk of procuring parts that do not meet operational requirements, which can lead to costly downtime.

Illustrative image related to butterfly valve parts

- Identify the application: Understand the environment in which the valve will be used (e.g., chemical, water treatment).

- Determine operating conditions: Consider factors such as temperature and pressure to select suitable materials.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in butterfly valve parts. Use industry-specific directories, trade shows, and online marketplaces to compile a list of potential vendors. This step is crucial as it lays the groundwork for ensuring that you are dealing with reliable and experienced manufacturers.

- Check online reviews: Look for feedback from other buyers regarding quality and service.

- Evaluate industry experience: Suppliers with a proven track record are more likely to understand your specific needs.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international standards. This is particularly important for industries that require stringent quality assurance, such as oil and gas or pharmaceuticals. Certifications can indicate a supplier’s commitment to quality and safety.

- Ask for documentation: Request ISO or other relevant certifications.

- Inquire about testing procedures: Ensure the supplier has quality control measures in place.

Step 4: Request Samples for Evaluation

Once you have shortlisted potential suppliers, request samples of the butterfly valve parts for evaluation. Testing samples allows you to assess the quality, fit, and functionality before making a larger purchase. This step helps mitigate the risk of receiving subpar products.

- Conduct performance testing: Evaluate how the samples perform under your specific conditions.

- Inspect for quality assurance: Look for any defects or inconsistencies in the materials.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your selected suppliers to secure the best pricing and contractual terms. Consider factors such as payment terms, delivery schedules, and warranty provisions. Effective negotiation can lead to significant cost savings and favorable conditions.

- Discuss bulk discounts: Inquire about pricing for larger orders to maximize savings.

- Clarify delivery timelines: Ensure that the supplier can meet your project deadlines.

Step 6: Establish a Long-term Relationship

After successfully procuring butterfly valve parts, focus on building a long-term relationship with your supplier. A strong partnership can lead to better pricing, priority support, and insights into new product offerings. Long-term collaborations can enhance supply chain stability and reliability.

- Communicate regularly: Maintain open lines of communication to address any issues promptly.

- Explore future collaboration: Discuss potential opportunities for joint development or custom solutions.

By following this checklist, B2B buyers can enhance their sourcing process for butterfly valve parts, ensuring they obtain the right components for their operational needs while fostering relationships with dependable suppliers.

Comprehensive Cost and Pricing Analysis for butterfly valve parts Sourcing

What Are the Key Cost Components in Butterfly Valve Parts Sourcing?

When sourcing butterfly valve parts, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The selection of materials significantly impacts costs. Common materials for butterfly valve components include cast iron, stainless steel, and various elastomers for seals. For example, PTFE is often used for seats due to its chemical resistance, but it is more expensive than standard rubber options. The material choice should align with the application requirements, as high-performance valves may require specialized materials, leading to higher costs.

-

Labor: Labor costs can vary widely based on the location of the manufacturing facility and the complexity of the valve components. Skilled labor is often necessary for precise machining and assembly, especially for customized components. Factoring in labor costs is crucial for determining the overall pricing strategy.

-

Manufacturing Overhead: This includes expenses related to the operation of the manufacturing facility, such as utilities, equipment maintenance, and facility depreciation. Efficient production processes can help minimize these costs, but they should be considered when evaluating supplier quotes.

-

Tooling: The initial investment in tooling can be significant, particularly for custom parts. Tooling costs are typically amortized over the production volume, so larger orders can help distribute this expense more effectively.

-

Quality Control: Ensuring that all parts meet industry standards and specifications is vital, especially for applications in sectors like oil and gas or pharmaceuticals. The costs associated with quality control processes, including testing and certification, should be incorporated into the pricing.

-

Logistics: Shipping and handling costs can vary based on the location of the supplier and the destination. International buyers should be aware of potential tariffs, customs duties, and shipping delays that can affect overall costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary depending on market conditions and competitive factors. Understanding the expected margin can aid in negotiations.

How Do Price Influencers Impact Butterfly Valve Parts Sourcing?

Several factors influence the pricing of butterfly valve parts, which international B2B buyers should consider:

-

Volume/MOQ: Minimum order quantities (MOQ) and volume discounts play a significant role in pricing. Larger orders often lead to lower per-unit costs, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom components tailored to specific applications may incur additional costs. Buyers should clearly communicate their requirements to suppliers to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and any required certifications (e.g., ISO, API) can impact pricing. High-quality materials and certified products generally command higher prices but can lead to lower maintenance costs and better performance.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their expertise, while newer companies might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting the total landed cost.

What Buyer Tips Can Help Ensure Cost-Efficiency in Sourcing Butterfly Valve Parts?

To maximize cost-efficiency when sourcing butterfly valve parts, buyers should consider the following strategies:

-

Negotiation: Engage suppliers in negotiations to explore potential discounts or better terms, especially for larger orders. Building a relationship with suppliers can lead to more favorable pricing arrangements.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the initial purchase price. Consider long-term maintenance, operational efficiency, and potential downtime costs associated with lower-quality components.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and shipping complexities that may affect pricing. It’s advisable to obtain quotes in local currency and factor in all associated costs.

-

Research and Compare: Conduct thorough research to compare prices and quality across multiple suppliers. Utilize industry networks and online platforms to gather insights and recommendations.

Disclaimer on Indicative Prices

Prices for butterfly valve parts can vary significantly based on the factors discussed. It is essential for buyers to seek specific quotes and conduct market research to obtain accurate pricing relevant to their needs.

Alternatives Analysis: Comparing butterfly valve parts With Other Solutions

Introduction to Alternatives in Valve Solutions

In the industrial landscape, selecting the right valve system is crucial for optimizing fluid control and ensuring operational efficiency. While butterfly valve parts are widely recognized for their simplicity and effectiveness, it is essential to explore alternative solutions that may better suit specific applications or budget constraints. This comparison will analyze butterfly valve parts against two viable alternatives: ball valves and gate valves. Each option has distinct advantages and challenges that can influence a buyer’s decision.

Illustrative image related to butterfly valve parts

Comparison Table

| Comparison Aspect | Butterfly Valve Parts | Ball Valve | Gate Valve |

|---|---|---|---|

| Performance | Quick actuation, good sealing | Excellent sealing, minimal pressure drop | Effective for on/off control, but slower operation |

| Cost | Economical to manufacture and maintain | Generally higher initial cost | Moderate cost, but higher long-term maintenance |

| Ease of Implementation | Simple installation, lightweight | Requires careful alignment | Heavier, may need support structures |

| Maintenance | Low, fewer moving parts | Moderate, may require periodic inspection | Higher, prone to wear and tear |

| Best Use Case | HVAC, waterworks, chemical processing | Oil and gas, water distribution | Power plants, fire protection systems |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Ball Valves?

Ball valves are known for their excellent sealing capabilities and minimal pressure drop across the valve, making them ideal for applications requiring full flow. They are versatile and can handle a wide range of fluids, including corrosive and hazardous substances. However, their initial cost tends to be higher than that of butterfly valves, and they may require more careful installation to ensure proper alignment. Maintenance is moderate; while they have fewer moving parts than some other valves, they may still need periodic inspections, especially in high-pressure applications.

How Do Gate Valves Compare in Performance and Use Cases?

Gate valves provide reliable on/off control and are well-suited for applications where a straight-line flow of fluid is essential. They are commonly used in power plants and fire protection systems, where they can effectively handle high flow rates. However, gate valves can be slower to operate compared to butterfly valves, which may impact efficiency in processes that require rapid flow regulation. Additionally, they have a higher maintenance requirement due to wear and tear over time, which can lead to increased operational costs.

Conclusion: How Should B2B Buyers Choose the Right Valve Solution?

When evaluating valve solutions, B2B buyers should consider their specific operational needs, budget constraints, and long-term maintenance plans. Butterfly valve parts offer a balanced combination of affordability, ease of installation, and low maintenance, making them a compelling choice for many applications. Conversely, ball valves may be better suited for high-pressure environments requiring superior sealing, while gate valves excel in applications needing reliable on/off control despite their slower operation. Ultimately, understanding the unique advantages and limitations of each option will enable buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for butterfly valve parts

What Are the Key Technical Properties of Butterfly Valve Parts?

When sourcing butterfly valve parts, understanding the technical specifications is crucial for ensuring compatibility and performance within your systems. Below are critical specifications that every B2B buyer should consider:

Illustrative image related to butterfly valve parts

1. Material Grade

The material grade of butterfly valve components—such as the body, disc, and seat—determines their durability and suitability for specific applications. Common materials include ductile iron, stainless steel, and various polymers. For instance, stainless steel offers excellent corrosion resistance, making it ideal for chemical processing environments. Selecting the appropriate material can impact the valve’s lifespan and maintenance costs.

2. Pressure Rating

Pressure rating, typically measured in pounds per square inch (psi), indicates the maximum pressure a valve can handle without failure. Understanding this specification is essential for ensuring the valve can operate safely within the intended system conditions. For applications involving high-pressure fluids, such as in oil and gas pipelines, selecting a valve with a suitable pressure rating is critical to prevent leaks and failures.

3. Temperature Range

The temperature range specification indicates the operating temperatures that the valve can withstand. This is particularly important in industries like HVAC and chemical processing, where extreme temperatures can be encountered. Choosing a valve that can operate effectively within the required temperature range ensures reliability and safety in your operations.

4. Tolerance Levels

Tolerance levels refer to the permissible variations in the dimensions of valve parts. These are critical for ensuring that components fit together correctly, which affects the overall performance of the valve. High tolerance levels can be especially important in applications requiring precise flow control, as even minor misalignments can lead to inefficiencies or failures.

5. Actuation Type

Butterfly valves can be operated manually or automatically, with various actuation methods available, including electric, pneumatic, and hydraulic systems. Understanding the actuation type is essential for integrating the valve into existing systems and ensuring it meets operational requirements. For example, pneumatic actuators are often preferred in high-speed applications due to their quick response times.

What Are Common Trade Terms Used in the Butterfly Valve Industry?

Familiarity with industry terminology can facilitate smoother transactions and clearer communication among stakeholders. Here are key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing butterfly valve parts, identifying the OEM can ensure quality and compatibility, particularly for replacement parts.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management, especially when dealing with suppliers in different regions, where minimum quantities may vary.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to potential suppliers requesting pricing and terms for specific products or services. This is a critical step in the procurement process, enabling buyers to compare offers and negotiate better deals.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers regarding the delivery of goods. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, which is especially important in international transactions.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. Understanding lead times is vital for project planning and ensuring that the necessary parts arrive on schedule to avoid delays in operations.

Illustrative image related to butterfly valve parts

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions, optimize procurement processes, and enhance operational efficiency in their industries.

Navigating Market Dynamics and Sourcing Trends in the butterfly valve parts Sector

What Are the Current Market Dynamics and Key Trends in the Butterfly Valve Parts Sector?

The butterfly valve parts market is experiencing a transformative phase driven by several global factors. Increased industrialization and urbanization in regions such as Africa, South America, the Middle East, and Europe are propelling demand for efficient flow control solutions. Additionally, the rise of automation technologies is reshaping the procurement landscape, with smart actuators and IoT-enabled devices gaining traction. This digital transformation allows for real-time monitoring and predictive maintenance, enhancing operational efficiency and reducing downtime.

Emerging trends indicate a growing preference for modular and customizable valve designs, which cater to specific industry needs, such as chemical processing and HVAC systems. Furthermore, the shift towards sustainability is influencing sourcing decisions, with buyers increasingly favoring suppliers who prioritize eco-friendly materials and manufacturing processes. In this competitive market, B2B buyers must stay informed about technological advancements and leverage digital platforms for streamlined procurement processes, ensuring access to a diverse range of butterfly valve components.

How Is Sustainability and Ethical Sourcing Impacting the Butterfly Valve Parts Market?

Sustainability is becoming a cornerstone of the butterfly valve parts industry, significantly affecting sourcing strategies. As global awareness of environmental issues grows, businesses are under pressure to minimize their carbon footprint. This has led to the adoption of sustainable practices, such as using recyclable materials and reducing waste during manufacturing. B2B buyers are now prioritizing suppliers that demonstrate a commitment to environmental responsibility, which can include sourcing from companies with certifications like ISO 14001 or utilizing materials with lower environmental impacts, such as recycled metals or eco-friendly polymers.

The importance of ethical supply chains cannot be overstated, especially for international buyers. Ensuring that suppliers adhere to ethical labor practices and environmental regulations is crucial for maintaining brand integrity and compliance with local and international standards. Buyers should seek out partnerships with manufacturers who not only provide high-quality butterfly valve parts but also share a commitment to sustainability and ethical sourcing. This alignment can enhance corporate reputation and foster long-term relationships built on trust and shared values.

Illustrative image related to butterfly valve parts

What Is the Historical Context of Butterfly Valves and Their Parts for B2B Buyers?

The evolution of butterfly valves dates back to the 19th century, initially developed as a simple and efficient flow control mechanism. Over the years, advancements in materials and design have expanded their application across various industries, including water treatment, oil and gas, and food processing. The introduction of resilient seat designs and modern actuation methods has significantly improved the performance and reliability of butterfly valves.

For B2B buyers, understanding the historical context of butterfly valves is essential as it underscores the technological advancements that have shaped the current market. Today’s butterfly valve parts are not only designed for functionality but also for longevity and adaptability, responding to the diverse needs of global industries. As the market continues to evolve, buyers can leverage this historical knowledge to make informed decisions about sourcing and investment in butterfly valve technologies.

Frequently Asked Questions (FAQs) for B2B Buyers of butterfly valve parts

-

How do I choose the right butterfly valve parts for my application?

Choosing the right butterfly valve parts involves understanding the specific requirements of your application, including the type of media being handled, pressure and temperature conditions, and the need for sealing. Evaluate the materials of the valve components—such as the body, seat, and disc—to ensure compatibility with the media. Additionally, consider the valve’s design (wafer or lug) based on installation constraints. Consulting with suppliers about your operational needs and obtaining samples can help ensure the best fit for your application. -

What are the common materials used in butterfly valve parts?

Common materials for butterfly valve parts include cast iron, stainless steel, and various polymers such as PTFE for seats. The choice of material largely depends on the media’s properties, such as corrosiveness and temperature. For high-performance applications, consider metal seats for durability under extreme conditions. Always ensure that the selected materials meet industry standards and regulations pertinent to your region to avoid compliance issues. -

What is the minimum order quantity (MOQ) for butterfly valve parts?

Minimum order quantities (MOQs) for butterfly valve parts can vary significantly by supplier and specific part type. Typically, manufacturers may set MOQs ranging from a few pieces to hundreds, depending on production costs and inventory levels. When sourcing, inquire about MOQs directly with suppliers, as they may offer flexibility based on your needs or establish lower MOQs for repeat customers or long-term contracts. -

What payment terms should I expect when sourcing butterfly valve parts internationally?

Payment terms for international transactions can vary widely among suppliers. Common arrangements include advance payment, letters of credit, or net 30 to 90 days after shipment. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Be sure to clarify any additional costs, such as shipping or customs duties, which may affect the total expenditure. Establishing a good rapport with suppliers can also facilitate more favorable payment terms. -

How can I ensure the quality of butterfly valve parts before purchasing?

To ensure quality, request certifications and test reports from suppliers, such as ISO or other relevant industry standards. Consider conducting a factory audit or visiting the manufacturing site if feasible. Additionally, ask for samples to evaluate the material and performance before committing to a larger order. Establishing a quality assurance process with your supplier can help maintain standards throughout the supply chain. -

What logistics considerations should I keep in mind when importing butterfly valve parts?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with the regulations of both the exporting and importing countries. Ensure that all documentation, including invoices, packing lists, and certificates of origin, is accurate to avoid delays. Planning for potential customs duties and taxes in your budget is also essential to avoid unexpected costs. -

Can I customize butterfly valve parts for specific applications?

Yes, many suppliers offer customization options for butterfly valve parts. This can include alterations in size, material selection, and modifications to design features to meet specific performance requirements. When seeking customization, provide detailed specifications and operational parameters to the supplier. Keep in mind that custom orders may involve longer lead times and higher costs, so plan accordingly. -

What industries commonly use butterfly valves, and why are they preferred?

Butterfly valves are widely used in industries such as water treatment, HVAC, chemical processing, and oil and gas due to their simple design, affordability, and efficiency. They provide quick and reliable flow control, making them ideal for high-flow, low-pressure applications. Their lightweight and compact design also reduces installation costs and space requirements, making them a preferred choice across various sectors.

Top 9 Butterfly Valve Parts Manufacturers & Suppliers List

1. Syveco – Butterfly Valve Spare Parts

Domain: syveco.com

Registered: 2018 (7 years)

Introduction: The range includes spare parts for butterfly valves: levers, handles, gearboxes and seats in EPDM, NBR, FKM, silicone and high temperature EPDM. Specific items include: 1196 Cast iron sleeve to fit in EN558-S14, Handle for TTV butterfly valve old type before 2015, Handwheel lockout device, 1198 Gearbox for cast iron butterfly valve, 1192 Gearbox for ductile iron butterfly valve, Lever for butterfl…

2. Perolo – Butterfly Valve Spare Parts

Domain: perolousa.net

Registered: 2011 (14 years)

Introduction: {“Butterfly Valve Spare Parts”: [{“Product Name”: “2” BSP TANKFLY MKI SPARE PARTS”}, {“Product Name”: “2” BSP TANKFLY MKII SPARE PARTS”}, {“Product Name”: “2” CLAMPED TANKFLY MKI SPARE PARTS”}, {“Product Name”: “2” FLANGED TANKFLY MKI SPARE PARTS”}, {“Product Name”: “2” FLANGED TANKFLY MKII SPARE PARTS”}, {“Product Name”: “3” CLAMPED TANKFLY SPARE PARTS”}, {“Product Name”: “3” FLANGED TANKFLY SPAR…

3. Commercial Filtration Supply – Butterfly Valves

Domain: commercialfiltrationsupply.com

Registered: 2016 (9 years)

Introduction: Butterfly valves are quarter-turn rotational motion valves made up of four main components: body, disk, stem, and seat. The body comes in two styles: wafer (economical, easy to install, prevents backflow) and lug (supports piping weight, allows dead-end servicing). The disk controls flow and can be concentric (for low pressure) or eccentric (prevents contact with the seal). The stem connects the d…

4. Hamby Dairy Supply – Butterfly Valves

Domain: hambydairysupply.com

Registered: 2003 (22 years)

Introduction: Butterfly Valves for Pipeline Milking Equipment & Spare Parts available at Hamby Dairy Supply. Free shipping for orders of $250 or more. Various sizes and types may be available to fit different milking systems.

5. STPATS – Butterfly Valve Seats

Domain: stpats.com

Registered: 1996 (29 years)

Introduction: {“Parts for Valves and Fittings”: {“Butterfly Valve Seats”: [{“size”: “1 inch”, “color”: “black”, “price”: “$10.00”}, {“size”: “1.5 inch”, “color”: “black”, “price”: “$10.00”}, {“size”: “2 inch”, “color”: “black”, “price”: “$11.00”}, {“size”: “2.5 inch”, “color”: “black”, “price”: “$12.00”}, {“size”: “3 inch”, “color”: “black”, “price”: “$13.00”}, {“size”: “4 inch”, “color”: “black”, “price”: “$16…

6. Bulk Tank Inc – Replacement Seats

Domain: hose.com

Registered: 1995 (30 years)

Introduction: [{“item_number”:”BTV-3-SEAT-530″,”description”:”Replacement Seat, Black 3””,”brand”:”Bulk Tank Inc (BTI)”,”price”:”$20.78″,”unit_of_measure”:”EA”},{“item_number”:”BTV-4-SEAT-530″,”description”:”Replacement Seat Black 4””,”brand”:”Bulk Tank Inc (BTI)”,”price”:”$23.55″,”unit_of_measure”:”EA”},{“item_number”:”3-500-522700″,”description”:”3” 345 Nitrile Seat Black”,”brand”:”Knappco Civacon”,”price”:”$…

7. Savree – Butterfly Valves

Domain: savree.com

Registered: 2017 (8 years)

Introduction: Butterfly valves are fast acting (1/4 turn) rotary motion valves used to start, stop, and regulate flow. They offer advantages in weight and space savings compared to other valves like ball, gate, globe, and plug. Suitable for high flow, low pressure systems, they have low maintenance costs and a simple design. Key components include stem, body, sealing arrangement, upper and lower bearings, bonne…

8. Pov Butterfly Valve – Key Product

Domain: povbutterflyvalve.com

Registered: 2018 (7 years)

Introduction: Butterfly valves are used to regulate the flow of liquids and gases in industrial applications. Key components include: 1. Body: Made from cast iron or stainless steel, it protects internal components and serves as an anchor for pipe connections. 2. Disc: Connected to a stem or axle, it regulates flow velocity by varying size. 3. Stem/Axle: Controls the movement of the disc and can be round or ova…

9. Access Truck Parts – Grooved Butterfly Valve

Domain: accesstruckparts.com

Registered: 2008 (17 years)

Introduction: Grooved Butterfly Valve, SKU: 182, Available Sizes: 2″, 2.5″, 3″, 4″, 5″, 6″, Connection Type: Grooved, Features: Manually operated with included handle, stainless steel drive shaft, bronze bushings for corrosion resistance, powder coated ductile iron body, EPDM rubber coated ductile iron wafer for durability, rated up to 362 PSI.

Strategic Sourcing Conclusion and Outlook for butterfly valve parts

The strategic sourcing of butterfly valve parts offers significant advantages for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. By focusing on high-quality components like stems, discs, and seats, companies can enhance the performance and longevity of their valve systems. Understanding the unique specifications and applications of butterfly valves enables businesses to make informed purchasing decisions, ultimately leading to reduced operational costs and increased efficiency.

Moreover, the simplicity and reliability of butterfly valves contribute to lower maintenance expenses and ease of installation. As industries across various sectors—such as chemical processing, HVAC, and plumbing—continue to evolve, the demand for versatile and efficient valve solutions will grow.

Looking ahead, B2B buyers are encouraged to leverage strategic sourcing partnerships that emphasize quality and innovation. By doing so, organizations can position themselves for success in an increasingly competitive landscape. Investing in robust supply chains and reliable manufacturers will not only streamline operations but also ensure compliance with international standards, paving the way for sustainable growth in your respective markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.