Everything You Need to Know About Bulk Twin Needle Sewing Machine 6.0 Sourcing in 2025

Introduction: Navigating the Global Market for bulk twin needle sewing machine 6.0

In the fast-evolving landscape of textile manufacturing, sourcing the right equipment can be a formidable challenge for international B2B buyers. The bulk twin needle sewing machine 6.0 stands out as a pivotal tool for enhancing efficiency and precision in production lines, yet navigating the myriad of options available can overwhelm even the most seasoned procurement professionals. This comprehensive guide delves into the intricacies of the bulk twin needle sewing machine 6.0, providing insights into various types, applications, and critical considerations for effective supplier vetting.

Throughout this guide, buyers will discover essential information that empowers them to make informed purchasing decisions, addressing critical factors such as cost, compatibility with existing machinery, and the specific needs of their target markets. With a focus on buyers from Africa, South America, the Middle East, and Europe—including key regions like Germany and Brazil—this resource is tailored to meet the unique challenges faced by diverse industries.

By equipping buyers with actionable insights and practical knowledge, this guide aims to simplify the sourcing process, ultimately enhancing operational efficiency and product quality. Whether you are looking to optimize your production capabilities or expand your product offerings, understanding the global market for bulk twin needle sewing machines is crucial for achieving your business objectives.

Understanding bulk twin needle sewing machine 6.0 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Universal Twin Needles | Round point design, suitable for general sewing | Apparel manufacturing, home textile production | Pros: Versatile, widely available. Cons: May not be ideal for specialty fabrics. |

| Stretch Ball Point Needles | Slightly rounded point, designed for knit fabrics | Sportswear, activewear, and stretch garment production | Pros: Reduces fabric damage, enhances stitch quality. Cons: Limited to stretchy materials. |

| Chrome Bulk Needles | Reinforced blade, chrome finish for reduced friction | Overlock and cover stitch machines | Pros: Durable, minimizes heat buildup. Cons: Higher upfront cost. |

| Jersey Twin Needles | Specially designed for knits, with a wider space between needles | Knit fabric production, T-shirt manufacturing | Pros: Prevents skipped stitches, ideal for jersey fabrics. Cons: Not suitable for woven materials. |

| Denim Twin Needles | Stronger construction, designed for thick fabrics | Denim apparel, upholstery, and heavy-duty textiles | Pros: Handles multiple layers well. Cons: Not recommended for delicate fabrics. |

What Are the Characteristics of Universal Twin Needles?

Universal twin needles are designed for general sewing tasks, featuring a standard round point that makes them suitable for a variety of fabrics. They are commonly used in both commercial and domestic sewing settings, making them a staple in apparel manufacturing and home textile production. When purchasing, B2B buyers should consider the needle size and compatibility with their sewing machines, as well as the volume needed for production.

How Do Stretch Ball Point Needles Benefit B2B Buyers?

Stretch ball point needles are specifically designed to handle knit fabrics, featuring a slightly rounded tip that prevents snagging. These needles are essential for producing high-quality sportswear and activewear, where fabric elasticity is crucial. B2B buyers should evaluate their fabric types and the volume of stretch garments produced to determine the appropriate needle quantity, ensuring efficiency and quality in their manufacturing processes.

Why Choose Chrome Bulk Needles?

Chrome bulk needles offer a reinforced blade and a chrome finish, reducing friction and heat during sewing. These needles are ideal for overlock and cover stitch machines, making them a popular choice in large-scale textile production. Buyers should consider the long-term durability and performance benefits of chrome needles against their initial investment, as these needles can lead to lower operational costs over time due to reduced wear.

What Are the Advantages of Jersey Twin Needles?

Jersey twin needles are specifically crafted for knit fabrics, featuring a wider space between the needles to accommodate the stretch. This design minimizes the risk of skipped stitches, making them perfect for T-shirt manufacturing and other knit garment production. B2B buyers should assess their fabric types and production needs to decide on the best needle choice, as these needles may not be suitable for woven fabrics.

How Do Denim Twin Needles Enhance Heavy-Duty Sewing?

Denim twin needles are engineered for strength, making them perfect for sewing through thick materials like denim and upholstery. Their robust construction allows them to handle multiple layers without breaking, which is a significant advantage for manufacturers producing heavy-duty textiles. Buyers should consider their specific fabric requirements and production volumes, as investing in these needles can lead to improved efficiency and product quality.

Key Industrial Applications of bulk twin needle sewing machine 6.0

| Industry/Sector | Specific Application of bulk twin needle sewing machine 6.0 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel Manufacturing | Seam construction for high-volume garment production | Increases efficiency and reduces labor costs | Quality of needles, machine compatibility, bulk pricing options |

| Textile Industry | Decorative stitching on upholstery and home textiles | Enhances product appeal and market competitiveness | Needle size and type, machine specifications, delivery timelines |

| Automotive Industry | Stitching upholstery for vehicle interiors | Improves durability and aesthetic quality | Needle strength, fabric compatibility, volume requirements |

| Footwear Manufacturing | Attaching multiple layers of material in shoe production | Ensures strong seams and reduces production time | Needle durability, machine speed, and maintenance support |

| Leather Goods Production | Sewing leather goods like bags and belts | Provides high-quality finishes and strength | Needle type for leather, machine adaptability, sourcing for bulk orders |

How Is the Bulk Twin Needle Sewing Machine 6.0 Used in Apparel Manufacturing?

In the apparel manufacturing sector, the bulk twin needle sewing machine 6.0 is essential for creating seams in high-volume garment production. This machine allows for simultaneous stitching, which enhances the speed of production while ensuring consistent seam quality. For international buyers, particularly in emerging markets in Africa and South America, sourcing machines that offer reliable performance and durability is crucial. Buyers should also consider the availability of replacement needles and parts to minimize downtime.

What Role Does the Bulk Twin Needle Sewing Machine 6.0 Play in the Textile Industry?

Within the textile industry, this machine is employed for decorative stitching on upholstery and home textiles, adding value to products through intricate designs. The ability to create parallel rows of stitching not only improves aesthetics but also reinforces fabric strength. Buyers in Europe, particularly in design-centric markets like Germany, should focus on sourcing machines that can handle various fabric types and offer customization options to meet specific design requirements.

Why Is the Bulk Twin Needle Sewing Machine 6.0 Important for the Automotive Industry?

In the automotive industry, the bulk twin needle sewing machine 6.0 is utilized for stitching upholstery in vehicle interiors, where both durability and appearance are paramount. This machine ensures that seams can withstand wear and tear while providing a polished look. For B2B buyers in the Middle East, where luxury automotive markets thrive, sourcing machines that specialize in high-strength needles and robust stitching capabilities is essential to meet industry standards.

How Does the Bulk Twin Needle Sewing Machine 6.0 Enhance Footwear Manufacturing?

Footwear manufacturers leverage the bulk twin needle sewing machine 6.0 for attaching multiple layers of materials, ensuring that shoes are both functional and stylish. This machine allows for rapid production while maintaining the integrity of the seams. Buyers, especially in South American markets, should prioritize machines that offer fast operation and easy maintenance, as well as reliable suppliers who can provide bulk ordering options.

What Advantages Does the Bulk Twin Needle Sewing Machine 6.0 Offer in Leather Goods Production?

In the production of leather goods, such as bags and belts, the bulk twin needle sewing machine 6.0 is vital for achieving high-quality finishes and strong seams. This machine is designed to handle the unique challenges presented by leather, ensuring that stitches are both aesthetically pleasing and durable. B2B buyers should focus on sourcing machines that are specifically designed for leather applications, offering the right needle types and ensuring compatibility with various leather thicknesses.

3 Common User Pain Points for ‘bulk twin needle sewing machine 6.0’ & Their Solutions

Scenario 1: Difficulty in Finding Compatible Needles for Specific Fabrics

The Problem: Many B2B buyers encounter challenges when sourcing the correct twin needles for various fabric types. For instance, a textile manufacturer might need to sew delicate fabrics like chiffon and stretchy materials like spandex. Using inappropriate needles can lead to skipped stitches, fabric snags, and compromised product quality. This inconsistency can ultimately affect production efficiency and customer satisfaction, leading to potential financial losses.

The Solution: To mitigate this issue, buyers should prioritize sourcing twin needles that are specifically designed for the types of fabrics they commonly work with. For example, opting for the #100/6.0 twin universal needles is advantageous for general sewing tasks. However, for stretch fabrics, consider using stretch ball point twin needles, which feature a rounded tip that gently pushes the fibers apart rather than piercing them. This reduces the risk of damage to delicate materials. Establishing a reliable relationship with suppliers who understand fabric compatibility is essential. Regularly review inventory and maintain a diverse selection of needles to ensure that the right tool is available for every project.

Scenario 2: High Volume Production and Needle Breakage

The Problem: In high-volume production environments, such as garment manufacturing, needle breakage can significantly disrupt workflow. A B2B buyer may find that during extended runs, the twin needles frequently break, leading to downtime, wasted materials, and increased labor costs for re-threading machines. This not only affects productivity but can also lead to missed deadlines and dissatisfied clients.

The Solution: To address needle breakage, it’s crucial to implement a preventive maintenance schedule for sewing machines. Ensure that the machines are regularly serviced and properly calibrated, as misalignment can lead to excessive wear on needles. Additionally, investing in high-quality bulk twin needles, such as those with reinforced blades or chrome finishes, can enhance durability and reduce breakage. Educate the staff on proper threading techniques and machine operation to minimize strain on the needles. Consider using a needle monitoring system that alerts operators when it’s time to replace needles based on usage hours, thus avoiding unexpected breakdowns during production runs.

Scenario 3: Inconsistent Stitch Quality Across Production Batches

The Problem: Another common pain point for B2B buyers is achieving consistent stitch quality across different production batches. Variations in needle quality, fabric tension, and machine settings can lead to uneven stitches, which may not meet the quality standards of clients. This inconsistency can damage a brand’s reputation and result in costly returns or rework.

The Solution: To ensure uniform stitch quality, buyers should standardize their needle selection and sewing parameters across all production lines. Using bulk twin needles of the same brand and type can help maintain consistency. Additionally, establish a quality control process that includes regular inspections of the stitching and fabric tension settings. Implementing a training program for operators can ensure they understand how to adjust settings based on fabric type and thickness. Utilizing fabric guides and tension adjustment tools can further enhance stitch quality. Finally, consider conducting periodic audits of production processes to identify and rectify any deviations in quality promptly. By focusing on these areas, businesses can enhance their overall product quality and customer satisfaction.

Strategic Material Selection Guide for bulk twin needle sewing machine 6.0

When selecting materials for bulk twin needle sewing machines, particularly the 6.0 model, it’s essential to consider the specific properties and applications of various needle types. This guide will analyze four common materials used in the manufacturing of twin needles, focusing on their key properties, advantages and disadvantages, and their implications for international B2B buyers.

What Are the Key Properties of Steel Needles for Bulk Twin Needle Sewing Machines?

Steel is the most common material used for sewing needles, including twin needles. Its key properties include high tensile strength, durability, and resistance to wear. Steel needles can withstand significant pressure and temperature variations, making them suitable for various fabrics, including heavy-duty materials.

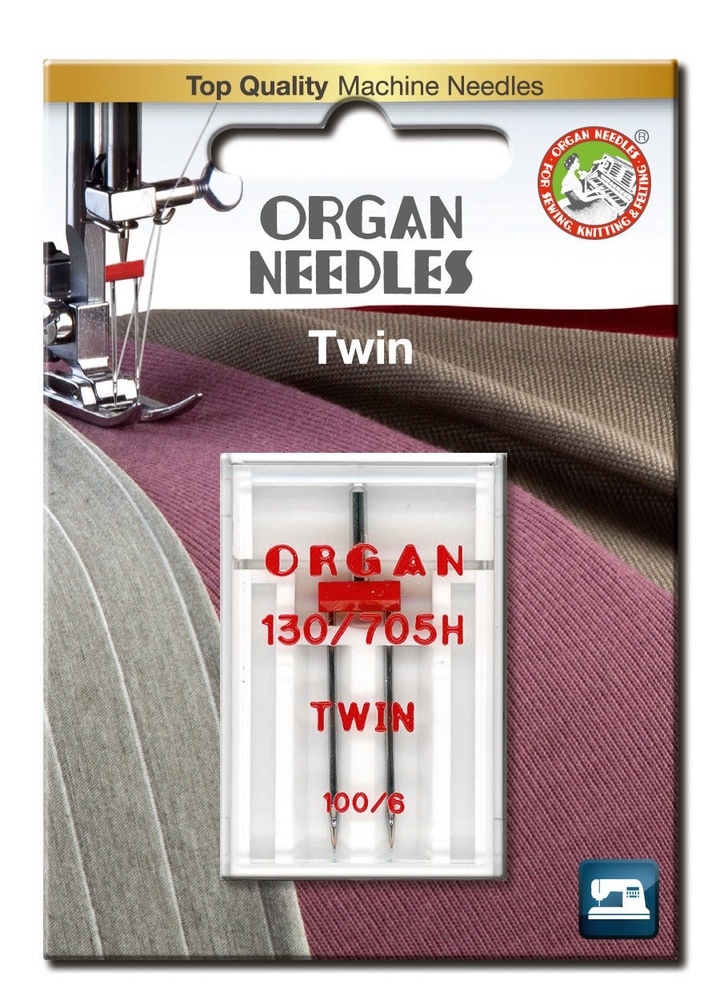

Illustrative image related to bulk twin needle sewing machine 6.0

Pros: Steel needles are durable and cost-effective, making them a preferred choice for many manufacturers. They are widely compatible with different sewing machines and fabrics.

Cons: While steel needles are strong, they can be prone to corrosion if not properly maintained. Additionally, they may not perform as well with very delicate fabrics, which could lead to snags or damage.

Impact on Application: Steel needles are versatile and can be used for woven and knit fabrics, but buyers should consider the specific fabric types they will be working with to ensure compatibility.

Considerations for International Buyers: Buyers from regions like Africa and South America may need to consider local humidity and temperature conditions that could affect needle performance. Compliance with local standards, such as ASTM or JIS, is crucial for ensuring quality.

How Do Chrome-Plated Needles Enhance Performance in Bulk Twin Needle Sewing Machines?

Chrome-plated needles feature a layer of chrome that enhances their performance by reducing friction and heat buildup during sewing. This makes them ideal for high-speed sewing applications.

Pros: The chrome finish increases the needle’s lifespan and reduces the frequency of replacements. They also glide through fabrics more smoothly, reducing the risk of skipped stitches.

Cons: Chrome-plated needles are generally more expensive than standard steel needles. Additionally, they may require specific care to maintain their finish.

Impact on Application: Chrome-plated needles are particularly effective for synthetic and stretchy fabrics, making them suitable for fashion and sportswear applications.

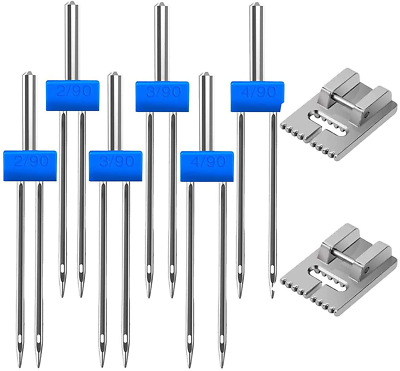

Illustrative image related to bulk twin needle sewing machine 6.0

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prefer chrome-plated needles due to their superior performance. Compliance with EU standards for manufacturing quality is also a consideration.

What Advantages Do Titanium-Coated Needles Offer for Bulk Twin Needle Sewing Machines?

Titanium-coated needles are designed to provide enhanced durability and resistance to wear. The titanium coating helps to reduce the friction between the needle and fabric, allowing for smoother sewing.

Pros: These needles last significantly longer than standard steel needles and are less likely to bend or break under pressure. They are ideal for sewing multiple layers of fabric.

Cons: The cost of titanium-coated needles is generally higher, which may be a consideration for bulk buyers. They may also require specific handling to prevent damage to the coating.

Illustrative image related to bulk twin needle sewing machine 6.0

Impact on Application: Titanium-coated needles are well-suited for heavy fabrics and multiple layers, making them a great choice for upholstery and industrial applications.

Considerations for International Buyers: Buyers from the Middle East may find titanium-coated needles particularly beneficial due to the region’s diverse fabric requirements. Understanding local import regulations is essential to ensure compliance.

How Do Specialty Needles Affect the Performance of Bulk Twin Needle Sewing Machines?

Specialty needles, such as ballpoint or stretch needles, are designed for specific fabric types. Ballpoint needles have a rounded tip that allows them to push aside fibers rather than cutting through them, which is ideal for knits.

Pros: Specialty needles can significantly improve the quality of sewing on specific fabrics, reducing the risk of damage. They are essential for achieving professional results in garment manufacturing.

Cons: These needles may not be as versatile as standard needles and can be more expensive. Additionally, they may not be readily available in all markets.

Illustrative image related to bulk twin needle sewing machine 6.0

Impact on Application: Specialty needles are crucial for sewing stretchy or delicate fabrics, making them a must-have for fashion and activewear manufacturers.

Considerations for International Buyers: Buyers should ensure that specialty needles comply with local standards and are readily available in their regions, particularly in South America, where access to specific products can vary.

| Material | Typical Use Case for bulk twin needle sewing machine 6.0 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General sewing on various fabrics | Cost-effective and durable | Prone to corrosion | Low |

| Chrome-Plated | High-speed sewing applications | Reduced friction and longer lifespan | Higher cost and care required | Medium |

| Titanium-Coated | Heavy fabrics and multiple layers | Enhanced durability and wear resistance | Higher initial cost | High |

| Specialty (e.g., Ballpoint) | Knits and delicate fabrics | Improved sewing quality on specific fabrics | Limited versatility and availability | Medium |

This strategic material selection guide provides B2B buyers with a comprehensive understanding of the materials available for bulk twin needle sewing machines, enabling informed purchasing decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for bulk twin needle sewing machine 6.0

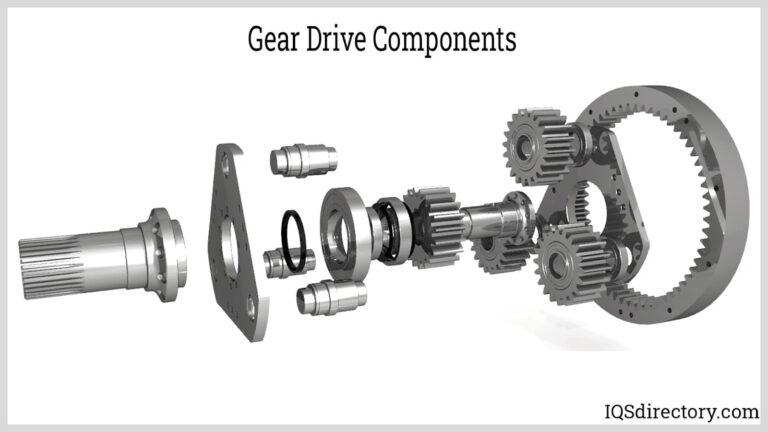

What Are the Main Stages in the Manufacturing Process of Bulk Twin Needle Sewing Machines 6.0?

The manufacturing process of bulk twin needle sewing machines 6.0 involves several key stages that ensure the final product meets quality and performance expectations. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials, primarily metals and plastics, that are crucial for the machine’s components. Steel alloys are typically used for the needle and shaft due to their durability and strength. Quality checks on raw materials are essential to ensure they meet the required specifications, which often involves testing for tensile strength and corrosion resistance.

-

Forming: The forming stage utilizes advanced machining techniques such as CNC (Computer Numerical Control) machining, which allows for precise shaping of components. Each part, including the needle bar, presser foot, and feed dogs, is crafted to exact specifications. Techniques like forging and stamping may also be employed for parts that require high strength. This stage is crucial as any inaccuracies can affect the machine’s performance.

-

Assembly: During assembly, various components are meticulously put together. Automated assembly lines are commonly used, incorporating robotic systems to enhance efficiency and accuracy. Each machine undergoes a preliminary assembly where sub-assemblies are combined, followed by a detailed inspection to ensure all parts fit correctly and function as intended.

-

Finishing: The finishing stage involves several processes aimed at enhancing the machine’s aesthetic and functional qualities. This includes surface treatment, painting, and lubrication. Quality control checks at this stage ensure that the final product is free of defects and meets both aesthetic and functional standards.

How Is Quality Assurance Implemented in the Production of Twin Needle Sewing Machines 6.0?

Quality assurance (QA) is critical in the manufacturing of bulk twin needle sewing machines 6.0, focusing on maintaining high standards throughout the production process. Various international and industry-specific standards guide these practices.

-

International Standards: Compliance with ISO 9001 is essential for manufacturers, as it outlines requirements for a quality management system. Adhering to this standard helps ensure that the manufacturing process is consistent and meets customer expectations. For European markets, CE marking is required, indicating that the machine complies with health, safety, and environmental protection standards.

-

Industry-Specific Certifications: Other certifications, such as API (American Petroleum Institute) for specific industrial applications, may also be relevant depending on the machine’s intended use. These certifications provide additional assurance of quality and reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that the final product meets all quality standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components before they enter the production line. Tests may include dimensional checks, material verification, and functionality tests to ensure that all materials meet predetermined standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are conducted at various stages, particularly after forming and assembly. These checks often involve visual inspections, functional tests, and measurements to ensure that components are being produced to specifications.

-

Final Quality Control (FQC): Once the machines are fully assembled, a comprehensive final inspection is performed. This includes testing the machine’s operational capabilities, assessing noise levels, and checking for any cosmetic defects. Performance testing under various conditions may also be included to verify the machine’s reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability and compliance with local standards. Here are some effective methods:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, production processes, and quality control measures firsthand. Audits should focus on the implementation of quality management systems, adherence to international standards, and the capability of the supplier to meet specific requirements.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, including results from IQC, IPQC, and FQC. These reports should outline any issues encountered during production and how they were resolved.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and quality assurance practices. These inspections often include random sampling of products for testing and verification against industry standards.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

International B2B buyers must navigate various nuances related to quality control and certification when sourcing bulk twin needle sewing machines 6.0. These nuances include:

-

Regional Compliance Requirements: Different regions may have specific compliance requirements that affect product certification. For instance, European buyers may prioritize CE compliance, while buyers in other regions may focus on different standards. Understanding these requirements is crucial for ensuring smooth market entry.

-

Cultural and Language Differences: Communication barriers can impact the effectiveness of quality assurance processes. Buyers should ensure that there is a mutual understanding of quality expectations and standards between themselves and the suppliers.

-

Continuous Improvement Practices: Engaging suppliers that emphasize continuous improvement in their QC processes can enhance product reliability. Buyers should look for evidence of ongoing training, process optimization, and responsiveness to feedback in their supplier partnerships.

In conclusion, understanding the manufacturing processes and quality assurance protocols for bulk twin needle sewing machines 6.0 is essential for B2B buyers. By focusing on the key stages of production, relevant quality standards, and effective verification methods, buyers can make informed decisions and establish reliable supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bulk twin needle sewing machine 6.0’

In the competitive landscape of textile manufacturing, sourcing the right bulk twin needle sewing machines, particularly the 6.0 size, is crucial for enhancing productivity and ensuring quality in finished products. This guide provides a step-by-step checklist for B2B buyers to streamline their procurement process.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is fundamental before initiating a sourcing journey. Specify the type of materials you will be working with, such as woven or knit fabrics, and the intended applications. This clarity helps in selecting the right machine features, such as needle size and type, which can significantly impact sewing efficiency and the quality of seams.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in sewing machines. Look for companies with a proven track record in the industry and favorable reviews from other B2B clients. Utilize online platforms, industry trade shows, and local distributors to gather a comprehensive list of candidates.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, it’s crucial to verify their certifications and compliance with international quality standards. Check for ISO certifications or other relevant accreditations that demonstrate their commitment to quality and reliability. This step ensures that the machines you procure meet safety and performance benchmarks.

Step 4: Request Product Samples and Specifications

Always request product samples and detailed specifications from your shortlisted suppliers. Assess the quality of the machines firsthand to ensure they meet your standards. Pay attention to aspects such as needle precision, ease of operation, and compatibility with your existing equipment.

Step 5: Assess Pricing and Payment Terms

Compare pricing structures among different suppliers to ensure you receive competitive rates. Inquire about bulk purchasing discounts and flexible payment options, such as installment plans or credit terms. Understanding the total cost, including shipping and duties, is essential for budgeting effectively.

Step 6: Verify After-Sales Support and Warranty Policies

A reliable after-sales support system can save you time and money in the long run. Inquire about warranty terms, maintenance services, and the availability of spare parts. A supplier that offers robust support can help you minimize downtime and ensure your operations run smoothly.

Step 7: Finalize the Contract and Place Your Order

Once you have thoroughly vetted your chosen supplier, it’s time to finalize the contract. Ensure all terms, including delivery timelines, payment conditions, and quality expectations, are clearly outlined. This step is crucial to avoid misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can make informed decisions, ensuring they source bulk twin needle sewing machines that align with their operational needs and quality standards.

Comprehensive Cost and Pricing Analysis for bulk twin needle sewing machine 6.0 Sourcing

Understanding the comprehensive cost structure and pricing for bulk twin needle sewing machine 6.0 sourcing is crucial for international B2B buyers looking to optimize their purchasing strategies. This analysis explores the various cost components, price influencers, and provides actionable tips for effective negotiations and procurement.

What Are the Key Cost Components in Sourcing Twin Needle Sewing Machines?

The cost structure for bulk twin needle sewing machines typically includes several essential components:

-

Materials: The primary materials for these needles include high-quality steel and coatings that enhance durability and reduce friction. The choice of materials directly impacts the performance and longevity of the needles, influencing the overall cost.

-

Labor: Labor costs encompass wages for skilled workers involved in the manufacturing process. Labor rates can vary significantly by region, affecting the final pricing structure, especially for buyers in regions with lower labor costs.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, rent, and equipment maintenance. Manufacturers often allocate a portion of these costs to each unit produced, which can vary based on production efficiency.

-

Tooling: Investment in specialized tooling for needle production is essential for ensuring precision and quality. This upfront cost can be substantial but is critical for achieving high standards in needle production.

-

Quality Control (QC): Rigorous QC processes ensure that the needles meet specified standards and certifications. This involves additional costs but is necessary to maintain product integrity and customer satisfaction.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, are significant factors, especially for international shipments. These costs can vary based on the shipping method and distance.

-

Margin: Finally, manufacturers typically apply a profit margin that reflects their operational costs and market conditions. This margin can fluctuate based on demand and competition.

How Do Price Influencers Affect Bulk Twin Needle Pricing?

Several factors can influence the pricing of bulk twin needle sewing machines:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQ terms to secure better pricing.

-

Specifications and Customization: Custom designs or specific requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Needles made from premium materials or those that come with quality certifications (e.g., ISO, CE) generally command higher prices. Buyers should weigh the benefits of quality against cost.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to capture market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers in shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the final cost and should be carefully negotiated.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

To achieve cost-efficiency and maximize value, B2B buyers should consider the following strategies:

-

Negotiate Terms: Engage in discussions with suppliers about pricing, payment terms, and delivery schedules. Leverage the potential for bulk orders to negotiate discounts.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, replacement, and operational efficiency. A higher initial investment may yield lower overall costs.

-

Understand Pricing Nuances: International buyers must be aware of currency fluctuations, import tariffs, and local taxes that can impact the final cost. Pricing may differ significantly across regions, so thorough market research is essential.

-

Build Strong Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and insider knowledge on upcoming trends and products.

Disclaimer on Indicative Prices

It is important to note that the prices for bulk twin needle sewing machines can vary widely based on market conditions, supplier negotiations, and order specifics. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing bulk twin needle sewing machine 6.0 With Other Solutions

Introduction to Alternative Solutions in Sewing Technology

In the realm of textile production, selecting the right sewing technology is crucial for operational efficiency and product quality. While the bulk twin needle sewing machine 6.0 is a popular choice for high-volume sewing tasks, various alternatives exist that may better suit specific operational needs. Understanding these options enables B2B buyers to make informed decisions that align with their production goals and financial constraints.

Comparison Table

| Comparison Aspect | Bulk Twin Needle Sewing Machine 6.0 | Overlock Sewing Machine | Single Needle Sewing Machine |

|---|---|---|---|

| Performance | High, capable of parallel stitching | Very high, ideal for finishing edges | Moderate, suitable for standard sewing |

| Cost | Moderate (approx. $1,200) | Moderate to high (approx. $1,500) | Low to moderate (approx. $500) |

| Ease of Implementation | Requires skilled operators | Moderate, some training needed | Easy, minimal training required |

| Maintenance | Regular needle changes, parts may wear | Moderate, needs maintenance for blade sharpness | Low, less frequent maintenance needed |

| Best Use Case | Decorative and functional seams | Edge finishing on woven/knit fabrics | General sewing and lightweight tasks |

Detailed Breakdown of Alternatives

Overlock Sewing Machine

Overlock sewing machines are designed primarily for finishing seams and edges, making them indispensable in garment manufacturing. They excel at creating a clean, professional finish on knit and woven fabrics, preventing fraying. While they can be slightly more expensive than the bulk twin needle machine, their performance in high-speed environments is unmatched. However, they may not be as versatile for decorative stitching as the twin needle machine, which could limit their application in certain production scenarios.

Illustrative image related to bulk twin needle sewing machine 6.0

Single Needle Sewing Machine

Single needle sewing machines are the most common type of sewing machine used globally. They are particularly user-friendly, making them an excellent choice for businesses with less experienced operators. Their cost-effectiveness and lower maintenance needs add to their appeal. However, they lack the capability to perform complex stitches simultaneously, which can slow down production in high-demand settings. This makes them less suitable for businesses focused on high-volume outputs requiring intricate stitching.

Conclusion: Choosing the Right Sewing Solution

When selecting a sewing solution, B2B buyers must assess their specific production needs, budget constraints, and the skill level of their workforce. The bulk twin needle sewing machine 6.0 is ideal for businesses aiming for decorative and functional stitching in high volumes. In contrast, overlock sewing machines are best for companies focused on edge finishing, while single needle machines are suitable for general sewing tasks with lower operational demands. By evaluating these factors and comparing the features of each option, buyers can make a strategic decision that enhances their operational efficiency and product quality.

Essential Technical Properties and Trade Terminology for bulk twin needle sewing machine 6.0

What Are the Key Technical Properties of a Bulk Twin Needle Sewing Machine 6.0?

When evaluating a bulk twin needle sewing machine, understanding its technical properties is essential for making informed purchasing decisions. Here are several critical specifications to consider:

Illustrative image related to bulk twin needle sewing machine 6.0

-

Needle Size and Type

The size of the twin needle is indicated by numbers such as 100/6.0. The first number (100) refers to the needle’s thickness, while the second number (6.0) indicates the space between the needles in millimeters. This specification is crucial as it directly affects the type of fabric that can be sewn and the stitch width produced. For example, a larger needle size is better suited for thicker fabrics. -

Material Grade

Twin needles are typically made from high-grade stainless steel or chrome-plated materials. The material grade affects durability, resistance to wear, and the needle’s ability to glide through various fabric types. High-quality materials lead to fewer needle breaks, which is vital for maintaining production efficiency in bulk operations. -

Tolerance

Tolerance refers to the permissible limit of variation in needle size and spacing. Tight tolerances ensure consistent stitching quality, which is particularly important in industries where precision is critical, such as garment manufacturing. Low tolerance levels can lead to defects in finished products, impacting customer satisfaction and brand reputation. -

Scarf Design

The scarf is the area of the needle that helps form the stitch. A well-designed scarf reduces skipped stitches and improves fabric feed. This property is vital for maintaining high-quality output, particularly when working with delicate or stretchy materials. -

Groove Length and Shape

The groove on the needle allows the thread to flow smoothly during stitching. A longer or differently shaped groove can accommodate various thread types, which can enhance the sewing process, especially in bulk production environments where different thread materials are used. -

Recommended Applications

Understanding the recommended applications for the twin needle is critical for B2B buyers. For instance, some needles are specifically designed for stretch fabrics, while others are better for woven materials. This knowledge ensures that buyers select the right needle for their specific sewing needs, thus optimizing productivity.

Which Trade Terms Should B2B Buyers Know When Purchasing Twin Needle Sewing Machines?

Familiarity with industry-specific jargon can significantly enhance the purchasing process. Here are key terms to understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that can be rebranded by another company. In the context of sewing machines, knowing the OEM can help buyers assess the quality and reliability of the products they are considering. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management, especially for international buyers looking to optimize shipping costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For bulk purchases, submitting an RFQ can help buyers secure the best pricing and terms, leading to significant cost savings. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps prevent misunderstandings regarding shipping, insurance, and delivery responsibilities. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times can help businesses plan their production schedules and inventory levels, which is crucial in the fast-paced manufacturing environment. -

Warranty Period

This term indicates the duration for which a manufacturer offers repairs or replacements for defective products. Knowing the warranty period can give buyers peace of mind and help them evaluate the long-term value of their investment.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when purchasing bulk twin needle sewing machines, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the bulk twin needle sewing machine 6.0 Sector

What Are the Current Market Dynamics for Bulk Twin Needle Sewing Machine 6.0?

The market for bulk twin needle sewing machines, particularly the 6.0 variant, is experiencing notable growth driven by several global factors. The rise in demand for high-quality textile production, coupled with the increasing trend toward automated and efficient manufacturing processes, is propelling this sector forward. Industries such as fashion, upholstery, and home textiles are increasingly adopting twin needle technology to enhance their production capabilities, allowing for more intricate designs and faster turnaround times.

Emerging technologies such as Industry 4.0 are reshaping sourcing trends, making it essential for international B2B buyers to leverage digital platforms for procurement. The integration of IoT (Internet of Things) in sewing machines offers real-time monitoring and predictive maintenance, which can significantly reduce downtime. B2B buyers from regions like Africa, South America, the Middle East, and Europe, particularly Germany and Brazil, should focus on suppliers that adopt these innovative solutions to stay competitive.

Moreover, the push for customization in the textile industry is influencing the demand for bulk twin needle sewing machines. Buyers are increasingly looking for machines that can handle a variety of fabrics, from woven to knit, reflecting a broader trend toward versatility in manufacturing. This adaptability is crucial in meeting the diverse needs of end customers, thereby enhancing market competitiveness.

How Is Sustainability Shaping Sourcing Practices for Bulk Twin Needle Sewing Machines?

Sustainability has become a cornerstone of sourcing strategies in the B2B landscape, particularly for industries reliant on bulk twin needle sewing machines. The environmental impact of textile production is significant, prompting buyers to seek suppliers that prioritize eco-friendly practices. This includes using sustainable materials and processes that minimize waste and energy consumption.

Ethical sourcing is equally important, as consumers increasingly demand transparency in supply chains. B2B buyers are encouraged to partner with manufacturers that hold ‘green’ certifications, such as OEKO-TEX® or GOTS (Global Organic Textile Standard), which indicate compliance with environmental and social standards. These certifications not only enhance brand reputation but also align with global sustainability goals, providing a competitive edge in the market.

Furthermore, the adoption of recycled materials in the manufacturing of sewing machines and accessories is gaining traction. This trend not only reduces the carbon footprint but also appeals to environmentally conscious consumers, creating a win-win situation for businesses looking to optimize their supply chains while maintaining ethical standards.

What Is the Historical Context Behind the Evolution of Twin Needle Sewing Machines?

The evolution of twin needle sewing machines can be traced back to the early 20th century, when advancements in textile technology began to revolutionize the industry. Initially designed for straight stitching, twin needle machines quickly adapted to meet the growing demands for decorative stitching and more complex fabric handling.

Over the decades, these machines have undergone significant enhancements, including the introduction of computerized systems and advanced needle technology, allowing for greater precision and efficiency. The 6.0 twin needle variant emerged as a popular choice for both industrial and home sewing applications, offering versatility that accommodates a wide range of fabrics and stitching styles.

Today, as the textile industry faces challenges related to sustainability and rapid production cycles, the twin needle sewing machine continues to evolve. This evolution emphasizes the need for B2B buyers to remain informed about technological advancements and market trends to make well-informed sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of bulk twin needle sewing machine 6.0

-

1. How do I choose the right bulk twin needle sewing machine for my production needs?

Selecting the appropriate bulk twin needle sewing machine involves assessing your specific production requirements. Consider factors such as fabric type, stitch patterns needed, and production volume. Machines designed for heavier fabrics might require different needle sizes and types compared to those for lighter materials. Additionally, evaluate the machine’s speed, durability, and maintenance needs to ensure it aligns with your operational capacity. -

2. What are the benefits of using a twin needle sewing machine in bulk production?

Using a twin needle sewing machine enhances productivity by allowing simultaneous stitching of two parallel lines, which is ideal for hems, decorative stitching, and elastic applications. This efficiency not only speeds up the manufacturing process but also improves consistency and quality in finished products. Furthermore, twin needles can create unique stitch patterns, adding value to your offerings without requiring additional machines. -

3. What should I consider when vetting suppliers of twin needle sewing machines?

When vetting suppliers, prioritize their reputation, experience, and product quality. Request samples of the twin needle sewing machines to assess their performance firsthand. Check for certifications and compliance with international quality standards. Additionally, inquire about customer service support, warranty terms, and the supplier’s ability to meet your specific production timelines and quantities. -

4. What is the typical minimum order quantity (MOQ) for bulk twin needle sewing machines?

The MOQ for bulk twin needle sewing machines can vary significantly between suppliers. Generally, it ranges from 50 to 200 units depending on the manufacturer’s production capacity and your customization requirements. It’s advisable to discuss your specific needs with the supplier to negotiate favorable terms that align with your budget and production schedule. -

5. How can I ensure quality assurance (QA) for bulk twin needle sewing machines?

To ensure quality assurance, establish clear specifications and standards before placing your order. Request detailed product documentation and performance guarantees from the supplier. Consider conducting factory visits or third-party inspections during production. Additionally, implementing a robust incoming inspection process upon delivery can help catch any quality issues early, ensuring that the machines meet your operational standards. -

6. What payment terms are typically available for international B2B purchases of sewing machines?

Payment terms for international purchases often include options such as full upfront payment, a deposit with the balance due upon delivery, or letter of credit arrangements. It’s essential to negotiate terms that provide adequate protection for both parties. Consider using escrow services or trade finance options to mitigate risks associated with international transactions, especially when dealing with new suppliers. -

7. What logistics considerations should I keep in mind when importing sewing machines?

When importing sewing machines, factor in shipping methods, customs duties, and import regulations in your country. Choose a reliable logistics partner experienced in handling machinery to ensure safe and timely delivery. Additionally, understand the documentation required for customs clearance and prepare for potential delays by allowing ample lead time for shipping and processing. -

8. Can I customize twin needle sewing machines for specific applications?

Yes, many manufacturers offer customization options for twin needle sewing machines to suit specific applications, such as different needle sizes, types, or additional features. Discuss your requirements with the supplier to explore available modifications. Customization can improve efficiency and effectiveness in your production processes, allowing you to better meet your clients’ unique needs.

Top 3 Bulk Twin Needle Sewing Machine 6.0 Manufacturers & Suppliers List

1. Superior Threads – Twin Universal Needles 100/16

Domain: superiorthreads.com

Registered: 1998 (27 years)

Introduction: Twin Universal Needles – 6.0mm, 100/16; Designed for general sewing on a home sewing machine; Normal round point; Space between each needle measured in millimeters; Size: #100/6.0; Quantity: 1 Needle; Item number: org-twi-100-60; Price: $6.99, Sale Price: $5.59 (20% off); No customer reviews.

2. Schmetz – Twin Needles

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Twin needles, bulk purchasing, recommended brands: Schmetz, Organ, Wawak, Cleaner’s Supply (Canada), compatible with Kenmore and Singer machines, concerns about quality of no-name brands on Amazon, looking for cheaper options, potential sales at Joann’s with coupons.

3. Schmetz – Twin Needle 6.0

Domain: lundeenanimalhospital.com

Registered: 2021 (4 years)

Introduction: Schmetz Twin Needle 6.0 – Sewing Supplies

Strategic Sourcing Conclusion and Outlook for bulk twin needle sewing machine 6.0

In conclusion, the strategic sourcing of bulk twin needle sewing machines, particularly the 6.0mm variant, presents significant advantages for international buyers across diverse markets in Africa, South America, the Middle East, and Europe. By prioritizing quality suppliers, such as those offering universal and specialized twin needles, businesses can enhance their production efficiency and product quality. The focus on strategic sourcing not only mitigates risks associated with supply chain disruptions but also ensures that companies maintain a competitive edge through cost-effective procurement practices.

As the demand for high-performance sewing equipment continues to rise globally, it is imperative for B2B buyers to evaluate their sourcing strategies meticulously. Investing in reliable suppliers and understanding the specific needs of their target markets will be crucial for success in this evolving landscape.

Looking ahead, businesses are encouraged to take proactive steps towards forming partnerships with reputable manufacturers and distributors, ensuring they are well-positioned to meet the growing demands of the textile and apparel industries. By doing so, they can secure a sustainable supply chain and drive innovation in their product offerings. The time to act is now—embrace strategic sourcing and position your business for future success.

Illustrative image related to bulk twin needle sewing machine 6.0

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.