Everything You Need to Know About Bolts Studs And Nuts Sourcing in 2025

Introduction: Navigating the Global Market for bolts studs and nuts

In an increasingly interconnected global market, sourcing bolts, studs, and nuts presents unique challenges for B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. Understanding the nuances of these essential fasteners—ranging from their types and applications to material specifications—can be daunting. This guide serves as a comprehensive resource, meticulously designed to navigate the complexities of the fastener industry. It covers various categories including flange nuts, metric platenuts, and specialized bolts, alongside critical insights into supplier vetting, pricing strategies, and industry standards.

By equipping international buyers with essential knowledge, this guide empowers them to make informed purchasing decisions. It highlights key factors such as durability, compatibility with existing systems, and cost-effectiveness, ensuring that buyers can confidently select the right fasteners for their specific applications. Furthermore, understanding the regional market dynamics—including regulatory standards and shipping logistics—can significantly enhance procurement efficiency.

Whether you are in Germany, Saudi Arabia, or any other global market, this guide aims to simplify the sourcing process, helping businesses find reliable suppliers and secure high-quality products that meet their operational needs. Dive in to uncover actionable insights that will streamline your purchasing strategy in the competitive landscape of bolts, studs, and nuts.

Understanding bolts studs and nuts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Bolts | Hexagonal head, often used with a nut; available in various grades and lengths. | Machinery assembly, construction, automotive. | Pros: High strength, easy to install. Cons: Limited to applications requiring a nut. |

| Stud Bolts | Threaded on both ends, with no head; can be used with nuts on both ends. | Structural applications, piping, and fastening. | Pros: Versatile, allows for easy adjustment. Cons: Requires two nuts for installation. |

| Flange Nuts | Features a wide flange that distributes load; often used with bolts. | HVAC systems, automotive, and structural joints. | Pros: Enhanced load distribution, prevents loosening. Cons: May require specific bolts to match size. |

| Lock Nuts | Designed to resist loosening under vibration; includes nylon insert or serrated edges. | Aerospace, automotive, and heavy machinery. | Pros: Increased reliability in dynamic applications. Cons: More expensive than standard nuts. |

| Platenuts | Specially designed for use with flanges; typically found in vacuum systems. | Semiconductor manufacturing, laboratory equipment. | Pros: Excellent sealing capability, easy to install. Cons: Limited to specific applications. |

What are the key characteristics of Hex Bolts and their applications?

Hex bolts are characterized by their hexagonal heads, which allow for a wrench or socket to easily grip them. They come in various grades, including carbon steel and stainless steel, making them suitable for a wide range of applications. In B2B environments, hex bolts are commonly used in machinery assembly, construction, and automotive applications due to their strength and ease of installation. Buyers should consider the specific grade and length required for their projects, as well as the compatibility with nuts and washers.

How do Stud Bolts differ from traditional bolts in functionality?

Stud bolts are unique in that they are threaded on both ends and do not have a head. This design allows them to be used with nuts on both sides, providing a versatile fastening solution for structural applications, piping, and other fastening needs. In B2B transactions, stud bolts are particularly valued for their adaptability, enabling easy adjustments during assembly. Buyers should assess the length and thread specifications needed for their specific applications, as well as the materials used to ensure compatibility with environmental conditions.

Why are Flange Nuts preferred in certain applications?

Flange nuts are designed with a wide flange that effectively distributes load over a larger surface area, which is particularly beneficial in applications like HVAC systems, automotive assembly, and structural joints. Their design helps prevent loosening, making them a reliable choice in environments subject to vibration or movement. When purchasing flange nuts, buyers should ensure they select the correct size and type of bolt to match, as compatibility is crucial for optimal performance.

What advantages do Lock Nuts offer in high-vibration environments?

Lock nuts are engineered to resist loosening under vibration, utilizing features such as nylon inserts or serrated edges to enhance grip. They are widely used in aerospace, automotive, and heavy machinery applications where reliability is paramount. For B2B buyers, the primary considerations include the added cost compared to standard nuts and the specific requirements for installation. Lock nuts provide peace of mind in dynamic environments, ensuring that assemblies remain secure.

In what scenarios are Platenuts most effectively utilized?

Platenuts are specifically designed for use with flanges, making them ideal for applications in vacuum systems, semiconductor manufacturing, and laboratory equipment. They excel in providing excellent sealing capabilities and are easy to install, which is crucial in high-tech environments. When sourcing platenuts, B2B buyers should focus on the specific dimensions and thread types needed for their equipment, as well as the material properties to ensure they meet operational standards.

Key Industrial Applications of bolts studs and nuts

| Industry/Sector | Specific Application of bolts studs and nuts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Assembly of vehicle components, such as engines and chassis | Ensures structural integrity and safety of vehicles | Quality certifications, material specifications, and compliance with local regulations |

| Construction and Civil Engineering | Fastening structural steel beams and frameworks | Provides stability and durability to buildings and structures | Sourcing from reliable suppliers, adherence to load-bearing specifications, and corrosion resistance |

| Aerospace and Defense | Securing aircraft assemblies and components | High reliability and performance under extreme conditions | Compliance with aerospace standards, weight considerations, and materials that withstand high stress |

| Oil and Gas Industry | Fastening pipelines and drilling equipment | Enhances safety and efficiency in extraction processes | Resistance to corrosive environments, high tensile strength, and compliance with industry standards |

| Renewable Energy | Securing wind turbine components and solar panel mounts | Supports sustainable energy initiatives and reduces downtime | Durability against environmental factors, sourcing for bulk orders, and alignment with green certifications |

How Are Bolts, Studs, and Nuts Used in Automotive Manufacturing?

In the automotive sector, bolts, studs, and nuts are critical for assembling various components, including engines, transmissions, and chassis. These fasteners ensure that parts are securely attached, contributing to the vehicle’s overall safety and performance. International buyers, especially from regions like Africa and South America, must prioritize sourcing high-quality fasteners that comply with local and international automotive standards to ensure reliability and safety in their vehicle production lines.

What Role Do Fasteners Play in Construction and Civil Engineering?

In construction, bolts, studs, and nuts are essential for fastening steel beams and other structural elements. They provide the necessary strength and stability to buildings and infrastructure, which is vital for safety and longevity. Buyers in this sector should focus on sourcing fasteners that meet load-bearing specifications and are resistant to environmental factors, particularly in regions prone to extreme weather conditions, such as the Middle East. Ensuring compliance with local building codes is also crucial.

How Are Bolts, Studs, and Nuts Critical in Aerospace and Defense?

In the aerospace and defense industries, bolts, studs, and nuts are used to secure critical components of aircraft and military equipment. These fasteners must meet stringent quality standards due to the high-stress environments they operate in. Buyers must ensure that their sourcing partners provide materials that not only comply with aerospace regulations but also offer high strength-to-weight ratios. This is particularly important for international buyers in Europe, where compliance with EU aerospace standards is mandatory.

Why Are Fasteners Important in the Oil and Gas Industry?

In the oil and gas sector, bolts, studs, and nuts are vital for securing pipelines and drilling equipment. Their reliability directly impacts safety and operational efficiency during extraction processes. Buyers should consider sourcing fasteners that are resistant to corrosive environments and can withstand high pressures. Additionally, compliance with industry-specific standards is essential, especially for international operations in regions like the Middle East, where environmental conditions can be harsh.

How Do Bolts, Studs, and Nuts Support Renewable Energy Initiatives?

In renewable energy applications, such as wind turbines and solar panel installations, bolts, studs, and nuts play a significant role in securing components against environmental stressors. Sourcing durable and corrosion-resistant fasteners is crucial for maintaining the longevity and efficiency of these energy systems. International buyers, particularly in Europe, should look for suppliers who offer fasteners that align with sustainability goals and green certifications, ensuring that their projects contribute positively to environmental initiatives.

3 Common User Pain Points for ‘bolts studs and nuts’ & Their Solutions

Scenario 1: Sourcing the Right Fasteners for Unique Applications

The Problem: B2B buyers often struggle with sourcing bolts, studs, and nuts that meet specific engineering requirements for unique applications. For instance, a manufacturer in the aerospace sector may require fasteners that can withstand extreme temperatures and corrosive environments. Inadequate knowledge of material properties and specifications can lead to sourcing generic fasteners that fail to meet safety and performance standards, resulting in project delays and increased costs.

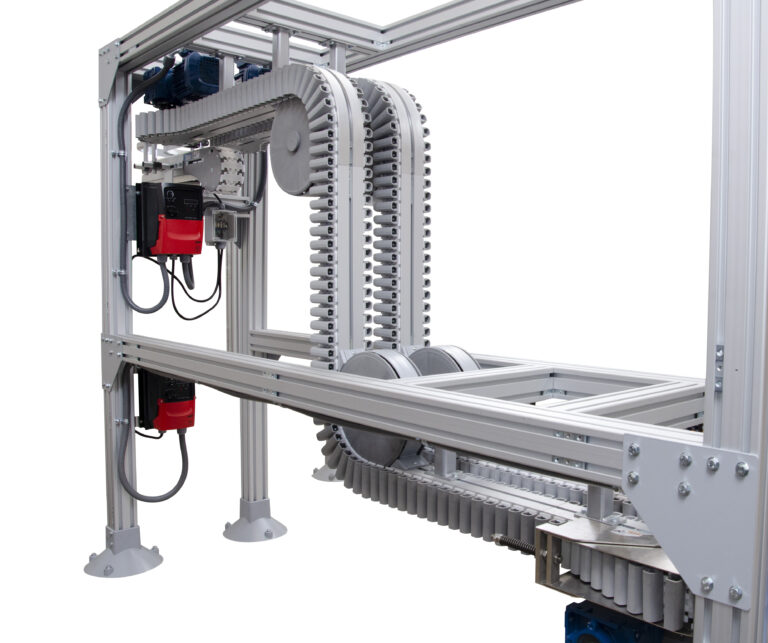

Illustrative image related to bolts studs and nuts

The Solution: To effectively source the right fasteners, buyers should begin by clearly defining their application requirements, including load capacity, environmental conditions, and material compatibility. Collaborating with suppliers who specialize in custom fasteners can provide tailored solutions. For instance, utilizing corrosion-resistant materials such as stainless steel or titanium for marine applications or selecting bolts with specific coatings to enhance durability can significantly impact performance. Furthermore, buyers should leverage detailed product specifications and certifications to ensure compliance with industry standards, such as ASTM or ISO, to minimize risks associated with subpar fasteners.

Scenario 2: Managing Inventory and Supply Chain Challenges

The Problem: Maintaining adequate inventory levels of bolts, studs, and nuts can be a major headache for B2B buyers, particularly those in manufacturing and construction. Fluctuations in demand, unexpected project changes, or delays in supply can lead to stockouts, halting production lines and impacting project timelines. Conversely, overstocking can tie up capital in inventory that may become obsolete.

The Solution: Implementing an efficient inventory management system can alleviate these challenges. Buyers should utilize just-in-time (JIT) inventory practices to reduce excess stock while ensuring that critical components are available when needed. Working closely with reliable suppliers who can provide rapid replenishment and flexible order quantities is essential. Additionally, employing inventory tracking software can help monitor usage patterns, predict future needs, and automate reorder processes. Regularly reviewing and adjusting order quantities based on project timelines and historical usage data can enhance responsiveness and reduce costs.

Scenario 3: Ensuring Proper Installation and Compatibility

The Problem: Even with the right bolts, studs, and nuts, improper installation or compatibility issues can lead to catastrophic failures in structures and machinery. A B2B buyer may purchase high-quality fasteners, but if they are not installed correctly or are mismatched with the components they are intended to secure, the results can be disastrous, leading to safety hazards and costly repairs.

The Solution: To ensure proper installation, buyers should invest in training for their assembly teams on best practices for fastening techniques. This includes understanding torque specifications, using the correct tools, and recognizing the importance of thread engagement. Additionally, implementing a standard operating procedure (SOP) for fastener installation can help maintain consistency and quality control. Buyers should also confirm compatibility between fasteners and the materials they are securing, such as checking for thread types and sizes, to prevent mechanical failures. Regular inspections and maintenance of installed fasteners can help identify potential issues before they escalate, ensuring safety and reliability in operations.

Illustrative image related to bolts studs and nuts

Strategic Material Selection Guide for bolts studs and nuts

When selecting materials for bolts, studs, and nuts, understanding their properties and suitability for specific applications is crucial for international B2B buyers. This guide analyzes four common materials: carbon steel, stainless steel, brass, and aluminum. Each material presents unique advantages and limitations that affect their performance in various environments.

What are the Key Properties of Carbon Steel for Bolts, Studs, and Nuts?

Carbon steel is a widely used material in the manufacturing of fasteners due to its excellent strength and hardness. It typically exhibits good tensile strength, making it suitable for high-stress applications. However, carbon steel is prone to corrosion if not properly treated, which can limit its use in harsh environments. The material can be heat-treated to enhance its properties, allowing it to withstand higher temperatures and pressures.

Pros: High strength, cost-effective, and readily available.

Cons: Susceptible to corrosion, requires protective coatings for longevity.

Impact on Application: Ideal for structural applications but may not be suitable for environments with moisture or corrosive substances.

Considerations for International Buyers: Compliance with standards such as ASTM A307 or DIN 933 is essential, especially in regions like Germany and Saudi Arabia, where quality assurance is critical.

How Does Stainless Steel Compare for Fasteners?

Stainless steel is renowned for its corrosion resistance, making it a preferred choice for applications exposed to moisture or aggressive chemicals. It maintains strength at elevated temperatures and offers good ductility. The various grades of stainless steel (like 304 and 316) provide options tailored to specific environmental conditions.

Pros: Excellent corrosion resistance, high strength, and aesthetic appeal.

Cons: Higher cost compared to carbon steel and may require specialized machining due to its toughness.

Impact on Application: Suitable for marine, chemical processing, and food-grade applications.

Considerations for International Buyers: Familiarity with standards such as ASTM A193 or DIN 1.4401 can aid in sourcing the appropriate grade for specific applications, particularly in Europe.

What are the Benefits of Using Brass for Fasteners?

Brass, an alloy of copper and zinc, is often used for smaller fasteners due to its excellent machinability and corrosion resistance. It is particularly effective in electrical applications due to its conductivity. However, brass is not as strong as steel, which limits its use in high-load applications.

Pros: Good corrosion resistance, easy to machine, and non-magnetic.

Cons: Lower tensile strength than steel, can be more expensive than carbon steel.

Impact on Application: Ideal for plumbing and electrical fittings but not recommended for structural applications.

Considerations for International Buyers: Compliance with standards like ASTM B16 or JIS H3250 is essential, especially for applications in the Middle East where regulations can be stringent.

Illustrative image related to bolts studs and nuts

Why Choose Aluminum for Lightweight Applications?

Aluminum is a lightweight material that offers excellent corrosion resistance and is highly malleable. It is often used in applications where weight reduction is critical, such as in aerospace and automotive industries. However, aluminum fasteners may not withstand the same loads as steel counterparts.

Pros: Lightweight, excellent corrosion resistance, and good thermal conductivity.

Cons: Lower strength compared to steel, can be more expensive, and may require special coatings for certain environments.

Impact on Application: Best suited for applications where weight is a concern, like in automotive or aerospace sectors.

Considerations for International Buyers: Understanding compliance with standards such as ASTM B211 or DIN 1725 is crucial for ensuring quality and compatibility in various applications across regions like Africa and South America.

Summary Table of Material Selection for Bolts, Studs, and Nuts

| Material | Typical Use Case for bolts studs and nuts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural applications | High strength and cost-effective | Prone to corrosion | Low |

| Stainless Steel | Marine and chemical processing | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Brass | Plumbing and electrical fittings | Good machinability and corrosion resistance | Lower tensile strength than steel | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

This selection guide provides international B2B buyers with the necessary insights to make informed decisions based on material properties, application suitability, and compliance with relevant standards. Understanding these factors is vital for optimizing performance and ensuring product longevity in diverse environments.

In-depth Look: Manufacturing Processes and Quality Assurance for bolts studs and nuts

What Are the Main Stages of Manufacturing Bolts, Studs, and Nuts?

The manufacturing processes for bolts, studs, and nuts involve several critical stages, each designed to ensure that the final products meet industry standards and customer specifications. Understanding these stages can help B2B buyers assess the capabilities of their suppliers effectively.

Illustrative image related to bolts studs and nuts

How Is Material Prepared for Manufacturing Bolts and Nuts?

The first step in manufacturing is material preparation. Typically, high-quality steel or alloys are selected based on the required strength, corrosion resistance, and application. Raw materials often undergo processes such as cutting, shearing, or blanking to achieve the initial shape required for further processing. For metric products, international standards dictate specific material grades, which can include carbon steel, stainless steel, and other specialized alloys.

What Forming Techniques Are Commonly Used in Bolt Production?

Forming is a crucial stage where the prepared material is shaped into the desired bolt or nut configuration. Common techniques include:

- Cold Heading: This process involves shaping metal at room temperature, which enhances the mechanical properties of the material.

- Hot Forging: Involves heating the metal to a high temperature and then shaping it, which is ideal for larger or more complex parts.

- Thread Rolling: This technique is employed to create threads on bolts and studs, ensuring precise dimensions and enhancing the product’s strength.

Each technique has its advantages, and the choice depends on factors such as the size of the fastener, the material used, and the production volume.

Illustrative image related to bolts studs and nuts

How Are Bolts, Studs, and Nuts Assembled and Finished?

Once formed, the next stage is assembly, where various components such as washers, nuts, and bolts are combined. This may involve additional processes such as welding, soldering, or mechanical assembly, depending on the product’s complexity.

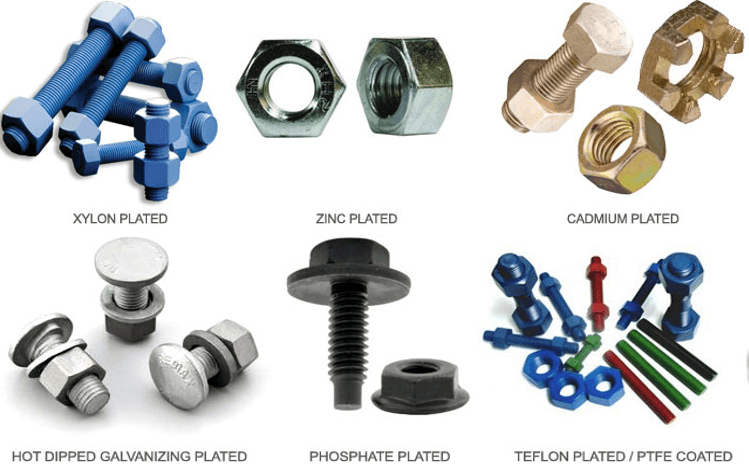

Finishing processes are essential for enhancing the product’s durability and corrosion resistance. Common finishing techniques include:

- Plating: This involves applying a thin layer of metal (e.g., zinc or nickel) to protect against corrosion.

- Coating: Paint or powder coating may be applied for additional protection and aesthetic appeal.

- Heat Treatment: Used to alter the material properties, enhancing strength and hardness.

These finishing touches ensure that the bolts, studs, and nuts not only meet functional requirements but also withstand environmental factors.

What Quality Assurance Practices Are Essential for Fastener Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of bolts, studs, and nuts to ensure that products meet international and industry-specific standards. For B2B buyers, understanding these practices is vital for verifying supplier quality.

Illustrative image related to bolts studs and nuts

Which International Standards Should B2B Buyers Be Aware Of?

Several international standards govern the quality of fasteners, including:

- ISO 9001: A standard for quality management systems that ensures consistent product quality and customer satisfaction.

- ISO 4014 and ISO 4017: Standards specifically for bolts and nuts, detailing dimensions and mechanical properties.

- API Standards: Particularly relevant for industries such as oil and gas, where fasteners must meet stringent safety and quality requirements.

These standards provide a framework for quality assurance and are essential for buyers looking to ensure compliance and reliability in their sourcing.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before manufacturing begins.

- In-Process Quality Control (IPQC): During manufacturing, operators perform checks at various stages to ensure that the products are being made to the correct specifications.

- Final Quality Control (FQC): After manufacturing, finished products undergo rigorous testing to verify compliance with all relevant standards.

By implementing these checkpoints, manufacturers can identify defects early and reduce the risk of faulty products reaching the market.

What Testing Methods Are Commonly Used for Bolts and Nuts?

To ensure that bolts, studs, and nuts meet the necessary specifications, several testing methods are employed:

- Tensile Testing: Measures the strength and ductility of the material.

- Hardness Testing: Assesses the material’s resistance to deformation.

- Torque Testing: Evaluates the torque needed to tighten or loosen fasteners, which is crucial for applications where precise torque is required.

These tests help verify that the products will perform as expected in their intended applications, providing confidence to B2B buyers.

How Can B2B Buyers Verify Supplier Quality Assurance?

When sourcing bolts, studs, and nuts, B2B buyers must ensure that their suppliers adhere to strict quality assurance practices. Here are several strategies to verify supplier quality:

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and QA protocols. This firsthand assessment can reveal the level of commitment to quality.

-

Quality Reports: Request detailed quality assurance reports from suppliers, including results from IQC, IPQC, and FQC tests. These documents should outline compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. This is particularly useful for international transactions where buyers may not have direct access to suppliers.

-

Certifications: Verify that suppliers hold relevant certifications (e.g., ISO 9001, API) that demonstrate their commitment to quality standards. These certifications should be current and verifiable through the issuing bodies.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Key considerations include:

- Regulatory Compliance: Different regions may have specific regulations governing fastener quality. Buyers must ensure that suppliers are compliant with local laws and standards.

- Cultural Differences: Variations in manufacturing practices and quality perceptions can exist across different regions. Effective communication and clear expectations can help bridge these gaps.

- Logistical Challenges: International shipping can complicate quality assurance efforts. Buyers should consider logistics when planning inspections and audits, ensuring that products arrive in compliance with standards.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions, ensuring they source high-quality bolts, studs, and nuts that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bolts studs and nuts’

To ensure a successful procurement process for bolts, studs, and nuts, B2B buyers must follow a structured approach. This checklist offers a comprehensive guide for international buyers, particularly in Africa, South America, the Middle East, and Europe, to streamline their sourcing efforts and secure the best products for their needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing the right fasteners. Consider factors such as material type (e.g., stainless steel, zinc-plated), dimensions (length, diameter, thread pitch), and application requirements (e.g., load-bearing capacity). This clarity helps prevent costly errors and ensures that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in bolts, studs, and nuts. Look for manufacturers with a strong reputation in your industry, focusing on those who have experience serving clients in your region. Utilize platforms like industry directories, trade shows, and online marketplaces to gather a list of viable candidates.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with international standards. Certifications such as ISO 9001 demonstrate a commitment to quality management systems, while others may indicate adherence to specific industry standards. This step is essential to ensure the reliability and safety of the fasteners you intend to purchase.

Step 4: Request Samples for Testing

Always request samples from shortlisted suppliers before making bulk purchases. Testing samples allows you to assess the quality, durability, and compatibility of the bolts, studs, and nuts with your applications. Pay attention to aspects such as finish, threading, and overall construction quality during this evaluation.

Step 5: Analyze Pricing and Payment Terms

Gather detailed pricing from multiple suppliers, ensuring you understand the total cost of ownership, including shipping, customs duties, and potential tariffs. Compare payment terms and conditions, as favorable terms can significantly impact cash flow. Look for options such as net payment terms, discounts for early payment, or flexible payment plans.

Step 6: Assess Delivery and Lead Times

Understanding delivery times is critical for maintaining your production schedules. Discuss lead times with suppliers and consider their ability to meet your deadlines consistently. It’s also wise to inquire about their capacity to handle urgent orders or fluctuations in demand, which can help mitigate potential delays.

Illustrative image related to bolts studs and nuts

Step 7: Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Establish a clear communication plan with your chosen supplier that outlines preferred channels, response times, and points of contact. This proactive approach helps address any issues promptly and fosters a stronger business relationship.

By following these steps, B2B buyers can streamline their procurement process for bolts, studs, and nuts, ensuring they select high-quality products that meet their specific needs while fostering reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for bolts studs and nuts Sourcing

When sourcing bolts, studs, and nuts, understanding the cost structure and pricing dynamics is essential for making informed purchasing decisions. This analysis covers the key cost components, price influencers, and practical tips for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Bolt, Stud, and Nut Sourcing?

The cost structure for bolts, studs, and nuts typically comprises several components:

-

Materials: The choice of material significantly affects pricing. Common materials include steel, stainless steel, brass, and aluminum. Specialty materials or coatings (like zinc plating) can increase costs due to their enhanced properties and durability.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Automated processes can reduce labor costs but may require higher initial capital investment.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Overhead costs can fluctuate based on location and operational efficiency.

-

Tooling: Custom tooling for specific designs or specifications can be a significant upfront cost. However, it can lead to lower unit costs in high-volume production runs.

-

Quality Control (QC): Ensuring that products meet specified standards incurs costs related to inspection and testing. Certifications (e.g., ISO, ASTM) can also add to the overall price.

-

Logistics: Shipping and handling costs can vary widely based on distance, mode of transport, and packaging requirements. For international buyers, understanding Incoterms is crucial to navigating shipping responsibilities.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market conditions and supplier relationships.

What Factors Influence Pricing for Bolts, Studs, and Nuts?

Several factors can influence the pricing of fasteners:

-

Volume/MOQ: Higher order volumes can lead to lower per-unit costs. Suppliers often have Minimum Order Quantities (MOQs) that can affect pricing structures.

-

Specifications and Customization: Customized products tailored to specific applications may incur additional costs. Standard products usually offer better pricing due to economies of scale.

-

Material Quality and Certifications: Higher-quality materials and certified products typically command premium prices. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Local suppliers may offer lower shipping costs, while overseas suppliers might provide competitive pricing but involve higher logistics expenses.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, influencing the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices for Fasteners?

To achieve cost-efficiency when sourcing bolts, studs, and nuts, consider the following strategies:

-

Negotiate Terms: Engage in discussions with suppliers to negotiate pricing, payment terms, and delivery schedules. Building strong relationships can lead to better deals.

-

Assess Total Cost of Ownership (TCO): Look beyond the purchase price. TCO includes maintenance, replacement, and operational costs, which can significantly impact long-term expenditures.

-

Research Market Trends: Stay informed about market conditions and pricing trends. This knowledge can empower you during negotiations and help you identify the right time to buy.

-

Evaluate Multiple Suppliers: Obtaining quotes from several suppliers can provide insights into pricing benchmarks and enable better negotiation leverage.

-

Consider Bulk Purchases: If feasible, bulk purchasing can reduce costs per unit, but ensure that your inventory management can handle increased stock levels.

In conclusion, navigating the cost and pricing landscape for bolts, studs, and nuts requires a comprehensive understanding of various factors. By considering the cost components, pricing influencers, and effective negotiation strategies, international B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing bolts studs and nuts With Other Solutions

Introduction: Exploring Alternatives to Bolts, Studs, and Nuts

In the realm of fastening solutions, bolts, studs, and nuts have long been the go-to choice for securing components in various industries. However, as technology and methodologies evolve, several alternatives have emerged that can offer distinct advantages depending on specific applications. This section explores some viable alternatives, including rivets and adhesive bonding, enabling B2B buyers to make informed decisions based on their unique requirements.

Comparison Table

| Comparison Aspect | Bolts, Studs, and Nuts | Rivets | Adhesive Bonding |

|---|---|---|---|

| Performance | High tensile strength; versatile | Strong shear strength; good for static loads | Excellent for uniform stress distribution; good for dissimilar materials |

| Cost | Moderate cost; requires additional hardware | Generally lower cost; labor-intensive | Variable cost; can be cost-effective for large areas |

| Ease of Implementation | Requires tools for installation; straightforward | Requires specialized tools; skill-intensive | Simple application; no special tools needed |

| Maintenance | May require periodic checks; can be re-used | Permanent; difficult to replace | Permanent; can be difficult to repair |

| Best Use Case | Heavy machinery, automotive, and aerospace applications | Sheet metal assembly, aircraft structures | Electronics, automotive, and construction where vibration is a concern |

Detailed Breakdown of Alternatives

Rivets: When Should You Consider Them?

Rivets are a popular alternative for fastening materials, especially in applications where high shear strength is required. They are typically used in sheet metal work and aerospace structures due to their ability to withstand significant loads. One of the main advantages of rivets is their lower cost compared to bolts and nuts, especially when large quantities are required. However, their installation can be labor-intensive, requiring specialized tools and skilled labor, which may increase overall project costs. Furthermore, rivets are permanent fixtures, making replacements challenging.

Adhesive Bonding: Is It Right for Your Application?

Adhesive bonding is increasingly being utilized across various industries, particularly in applications involving dissimilar materials or when a seamless finish is desired. This method distributes stress evenly across the bonded surfaces, which can enhance durability and reduce the risk of failure under load. Adhesives can be a cost-effective solution for large surface areas and are relatively easy to apply without the need for extensive tools. However, the choice of adhesive must be carefully considered based on the materials involved and environmental factors, as some adhesives may not perform well under extreme conditions. Additionally, once cured, adhesive bonds are permanent and can be difficult to repair or remove.

Conclusion: How to Choose the Right Fastening Solution

Selecting the appropriate fastening solution depends on various factors, including the specific application, environmental conditions, and budget constraints. For heavy-duty applications requiring high tensile strength, bolts, studs, and nuts may still be the best choice. However, for projects prioritizing cost-efficiency and ease of installation, rivets or adhesive bonding could offer compelling alternatives. B2B buyers should assess the performance requirements, installation capabilities, and long-term maintenance considerations to determine the most suitable fastening solution for their needs. By thoroughly understanding the advantages and limitations of each option, businesses can enhance their operational efficiency and product reliability.

Essential Technical Properties and Trade Terminology for bolts studs and nuts

What Are the Essential Technical Properties of Bolts, Studs, and Nuts?

Understanding the technical specifications of bolts, studs, and nuts is crucial for B2B buyers looking to make informed purchasing decisions. Here are some key properties that define the quality and suitability of these fasteners:

1. Material Grade

The material grade specifies the type of metal used in manufacturing bolts, studs, and nuts, which directly impacts their strength, durability, and corrosion resistance. Common materials include carbon steel, stainless steel, and alloy steel. For instance, stainless steel grades like 304 and 316 offer excellent resistance to rust and are ideal for outdoor or marine applications. Selecting the right material grade is essential for ensuring the longevity and reliability of the components in specific environments.

2. Tolerance

Tolerance refers to the allowable variation in the dimensions of a fastener, such as diameter, length, and thread pitch. This specification is vital for ensuring compatibility with mating parts. Tight tolerances are critical in high-precision applications, such as aerospace or automotive industries, where even minor deviations can lead to mechanical failures. Understanding tolerance levels helps buyers ensure that their components will fit and function correctly within their assemblies.

3. Thread Type and Pitch

Threads are the helical ridges on bolts and studs that allow for secure fastening. There are various thread types, including coarse, fine, and metric threads. The pitch, or distance between threads, affects how tightly a bolt can be secured. Fine threads provide better resistance to loosening under vibration, making them suitable for high-stress applications. Buyers should consider the specific thread type and pitch based on the intended use of the fastener.

4. Coating and Plating

Coatings and platings, such as zinc plating, provide additional protection against corrosion and wear. This specification is particularly important for fasteners used in harsh environments. For example, zinc-coated bolts can resist rust and oxidation, extending their service life. Buyers should assess the coating options available to ensure they meet the environmental demands of their applications.

Illustrative image related to bolts studs and nuts

5. Load Capacity

Load capacity indicates the maximum load a fastener can withstand without failing. This property is critical for ensuring safety and performance in structural applications. Buyers need to calculate the loads their assemblies will experience and select fasteners that can handle those stresses, preventing premature failure and enhancing overall system reliability.

What Are Common Trade Terms Related to Bolts, Studs, and Nuts?

Familiarity with industry jargon can streamline communication and negotiations in the B2B sector. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications helps buyers identify compatible parts for their machinery or systems, ensuring quality and performance.

Illustrative image related to bolts studs and nuts

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest order size that a supplier is willing to accept. Knowing the MOQ is essential for buyers to manage inventory effectively and to avoid overcommitting resources, especially for specialized or custom fasteners.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting pricing and terms for specific products or services. Crafting a clear RFQ can facilitate more accurate responses from suppliers, enabling better decision-making based on cost and availability.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is crucial for B2B transactions, as they clarify who bears the risk and cost of transportation, insurance, and customs duties.

Illustrative image related to bolts studs and nuts

5. Lead Time

Lead time is the time taken from placing an order to its delivery. For B2B buyers, understanding lead times is vital for project planning and ensuring timely availability of components, which can significantly impact production schedules.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement processes, ensuring they select the right fasteners for their applications while effectively navigating industry dynamics.

Navigating Market Dynamics and Sourcing Trends in the bolts studs and nuts Sector

Market Overview & Key Trends: What Are the Current Dynamics in the Bolts, Studs, and Nuts Sector?

The global market for bolts, studs, and nuts is witnessing significant growth driven by increasing demand across various industries, including construction, automotive, aerospace, and machinery. Key factors propelling this market include urbanization in emerging economies, particularly in Africa and South America, and the resurgence of manufacturing in Europe and the Middle East. Technological advancements in manufacturing processes, such as automation and the integration of Industry 4.0 practices, are reshaping sourcing strategies. B2B buyers are increasingly leveraging digital platforms to streamline procurement processes, facilitating faster decision-making and better price comparisons.

Emerging trends include a shift towards customized fasteners to meet specific engineering requirements, alongside a growing interest in high-strength and lightweight materials, such as titanium and advanced alloys. Additionally, the adoption of predictive analytics and AI in inventory management is enabling suppliers to optimize stock levels and respond more swiftly to market fluctuations. Buyers from regions like Germany and Saudi Arabia are particularly focused on sourcing high-quality products that meet stringent international standards, which further emphasizes the need for robust supply chain management.

How Is Sustainability Influencing Sourcing Decisions in the Bolts, Studs, and Nuts Market?

Sustainability is increasingly becoming a priority for B2B buyers in the bolts, studs, and nuts sector. The environmental impact of manufacturing processes and material sourcing is under heightened scrutiny, prompting companies to seek eco-friendly options. This shift is not just a regulatory response; it reflects changing consumer preferences and corporate social responsibility commitments. Buyers are looking for suppliers who can demonstrate sustainable practices, such as reduced carbon emissions, waste minimization, and responsible sourcing of raw materials.

Ethical sourcing is vital, with many companies now requiring their suppliers to obtain certifications that validate their commitment to sustainability. Certifications such as ISO 14001 for environmental management and adherence to the UN Sustainable Development Goals are becoming critical in supplier evaluations. Buyers are also favoring manufacturers that utilize recycled materials or offer products with lower environmental footprints, such as zinc-plated or eco-friendly coated fasteners. This focus on sustainability not only helps in compliance with regulations but also enhances brand reputation and customer loyalty.

What Is the Historical Context Behind the Evolution of Bolts, Studs, and Nuts in B2B Markets?

The evolution of bolts, studs, and nuts dates back to ancient civilizations, where rudimentary fastening systems were used in construction and machinery. As industrialization gained momentum in the 19th century, the demand for more reliable and standardized fasteners increased, leading to the development of modern manufacturing techniques. The introduction of standardized threads and sizes revolutionized the industry, facilitating mass production and improving interoperability across different applications.

In recent decades, the sector has witnessed significant technological advancements, including the introduction of high-strength materials and automated manufacturing processes. These innovations have enabled manufacturers to produce more efficient and durable fasteners, catering to the growing demands of various industries. As global trade expanded, the supply chains for bolts, studs, and nuts have become increasingly complex, requiring B2B buyers to navigate a dynamic landscape of sourcing options that prioritize quality, sustainability, and cost-effectiveness. Understanding this historical context is essential for buyers to appreciate the ongoing shifts in market dynamics and to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of bolts studs and nuts

-

How do I choose the right bolts, studs, and nuts for my project?

Choosing the right fasteners begins with understanding the specific requirements of your project. Consider factors such as load capacity, material compatibility, environmental conditions, and thread specifications. For instance, if you’re working in a corrosive environment, stainless steel or coated fasteners may be necessary. Additionally, assess the size and length needed, and whether you require standard or metric measurements. Collaborating with a supplier who offers technical support can also streamline this process, ensuring you select the appropriate products. -

What is the best material for bolts, studs, and nuts in harsh environments?

For harsh environments, materials such as stainless steel, titanium, or coated fasteners are often recommended due to their superior corrosion resistance and strength. Stainless steel (like 316 grade) is commonly used in marine applications, while titanium is suitable for aerospace due to its lightweight and high strength. Additionally, consider specialized coatings such as zinc plating or nylon to enhance corrosion resistance. Always consult with your supplier to match the material with your specific environmental conditions. -

What are the typical minimum order quantities (MOQ) for international suppliers?

Minimum order quantities (MOQ) can vary significantly between suppliers and product types. Generally, MOQs for bolts, studs, and nuts range from 100 to 1,000 pieces, depending on the manufacturer and product specifications. Some suppliers may offer flexibility for smaller orders, especially for established customers or ongoing contracts. It’s advisable to discuss your requirements upfront and explore options for bulk purchasing, which can also lead to cost savings. -

How can I ensure the quality of bolts, studs, and nuts I purchase?

Ensuring product quality involves several steps. First, source from reputable suppliers with established quality assurance processes. Request certifications such as ISO 9001 or material test reports to verify compliance with international standards. Additionally, consider requesting samples before placing large orders to assess quality firsthand. Implementing a quality control process within your procurement team can also help monitor incoming shipments for defects or discrepancies. -

What payment terms are commonly offered by international suppliers?

Payment terms can vary widely among international suppliers, but common options include advance payment, letter of credit, or net terms (30, 60, or 90 days). Many suppliers require a deposit upfront, especially for large orders, with the balance due upon shipment or delivery. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Always ensure the payment method is secure and consider using escrow services for larger transactions to protect both parties. -

What logistics considerations should I keep in mind when sourcing internationally?

Logistics play a critical role in international sourcing. Consider factors such as shipping methods (air freight vs. sea freight), customs clearance, and delivery timelines. Evaluate the supplier’s ability to handle logistics, including their experience with export regulations and documentation. It’s also beneficial to work with a freight forwarder who can manage shipping and customs processes efficiently. Additionally, factor in potential delays due to customs inspections or geopolitical issues, and plan your inventory accordingly. -

How can I vet suppliers for bolts, studs, and nuts?

Vetting suppliers is essential for ensuring reliability and quality. Start by researching their background, including years in business, customer reviews, and industry certifications. Request references from previous clients and consider conducting site visits if feasible. Utilize platforms like Alibaba or ThomasNet to find verified suppliers, and leverage trade associations for recommendations. Engaging in direct communication to discuss your needs and assess their responsiveness can also provide insights into their operational capabilities. -

What customization options are available for bolts, studs, and nuts?

Many suppliers offer customization options, including specific dimensions, thread types, coatings, and materials to meet unique project requirements. Customization can also extend to packaging and labeling for brand consistency. When discussing your needs with a supplier, be clear about your specifications and the intended application. Keep in mind that customized products may have longer lead times and higher costs, so it’s important to plan accordingly.

Top 2 Bolts Studs And Nuts Manufacturers & Suppliers List

1. MSC Direct – Threaded Studs with Nuts

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: This company, MSC Direct – Threaded Studs with Nuts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. MW Components – API Fasteners

Domain: mwcomponents.com

Registered: 2017 (8 years)

Introduction: API Fasteners – API 20E Stud Bolts & Nuts

Strategic Sourcing Conclusion and Outlook for bolts studs and nuts

In today’s competitive marketplace, strategic sourcing of bolts, studs, and nuts is more crucial than ever for international B2B buyers. By leveraging a well-structured sourcing strategy, businesses can ensure not only cost-effectiveness but also access to high-quality materials that meet stringent industry standards. Understanding the nuances between different types of fasteners, such as bolts and studs, allows for informed purchasing decisions that enhance operational efficiency and product reliability.

Moreover, the importance of supplier relationships cannot be overstated. Building strong partnerships with reliable manufacturers can lead to better pricing, timely deliveries, and innovative solutions tailored to specific needs. As the global supply chain continues to evolve, staying ahead of market trends, including sustainability practices and technological advancements, will be vital for maintaining a competitive edge.

Looking forward, it is essential for buyers from regions such as Africa, South America, the Middle East, and Europe to actively engage with suppliers, explore new sourcing opportunities, and adapt to changing market dynamics. Embrace strategic sourcing as a pathway to not only meet current demands but to position your business for future growth and success. Take the next step—evaluate your sourcing strategy today and unlock the potential for enhanced operational performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.