Everything You Need to Know About Blister Box Sourcing in 2025

Introduction: Navigating the Global Market for blister box

In the competitive landscape of global commerce, sourcing the right blister box can pose a significant challenge for B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. As businesses seek packaging solutions that ensure product protection, visibility, and sustainability, understanding the intricacies of blister packaging becomes paramount. This guide is designed to equip international buyers with essential insights into the various types of blister boxes, their applications across industries, and key factors to consider when vetting suppliers.

Throughout this comprehensive resource, we delve into the nuances of blister packaging, exploring material options, customization capabilities, and cost considerations. Buyers will learn how to identify reputable suppliers who align with their specific needs, ensuring both quality and reliability in their packaging choices. Additionally, we address the importance of eco-friendly options in today’s market, guiding businesses towards sustainable practices that resonate with consumers.

By empowering B2B buyers with actionable knowledge, this guide aims to facilitate informed purchasing decisions, ultimately enhancing product presentation and consumer satisfaction. As you navigate the global market for blister boxes, let this resource serve as your trusted companion, helping you streamline your sourcing process and optimize your packaging strategy.

Understanding blister box Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Slide Blister Tray | Clear PET material, customizable backer card, tamper-proof | Retail, fishing tackle, beauty products | Pros: Excellent visibility, customizable; Cons: Limited protection against moisture. |

| Standard Blister Pack | Thermoformed plastic with a sealed cavity | Pharmaceuticals, electronics | Pros: Strong barrier against moisture and tampering; Cons: Less aesthetic flexibility. |

| Clamshell Packaging | Hinged design, often made from rigid plastic | Toys, tools, consumer goods | Pros: Reusable, offers good protection; Cons: Higher production costs. |

| Carded Blister Pack | Blister attached to a cardboard backing | Hardware, cosmetics | Pros: Cost-effective, enhances branding; Cons: Less visual appeal compared to clear options. |

| Eco-Friendly Blister | Made from recycled or biodegradable materials | Sustainable products, food packaging | Pros: Supports sustainability initiatives; Cons: May have higher costs and limited availability. |

What Are the Characteristics of Slide Blister Trays?

Slide blister trays are notable for their clear PET material and customizable backer cards, making them ideal for products that benefit from visibility, such as fishing tackle and beauty items. Their tamper-proof design ensures product integrity during transit and display. When purchasing, B2B buyers should consider the material’s food safety certification, especially for products in the food or health sectors. The trays are also recyclable, aligning with sustainability goals.

How Do Standard Blister Packs Work for Pharmaceuticals and Electronics?

Standard blister packs are created through a thermoforming process that produces a sealed cavity, providing strong protection against moisture and tampering. These packs are commonly used in pharmaceuticals for pills and in electronics for small components. Buyers should evaluate the material type, as variations exist (e.g., PVC, PVDC) that can affect product compatibility and regulatory compliance. The uniformity of design can be a plus for branding, but it limits aesthetic customization.

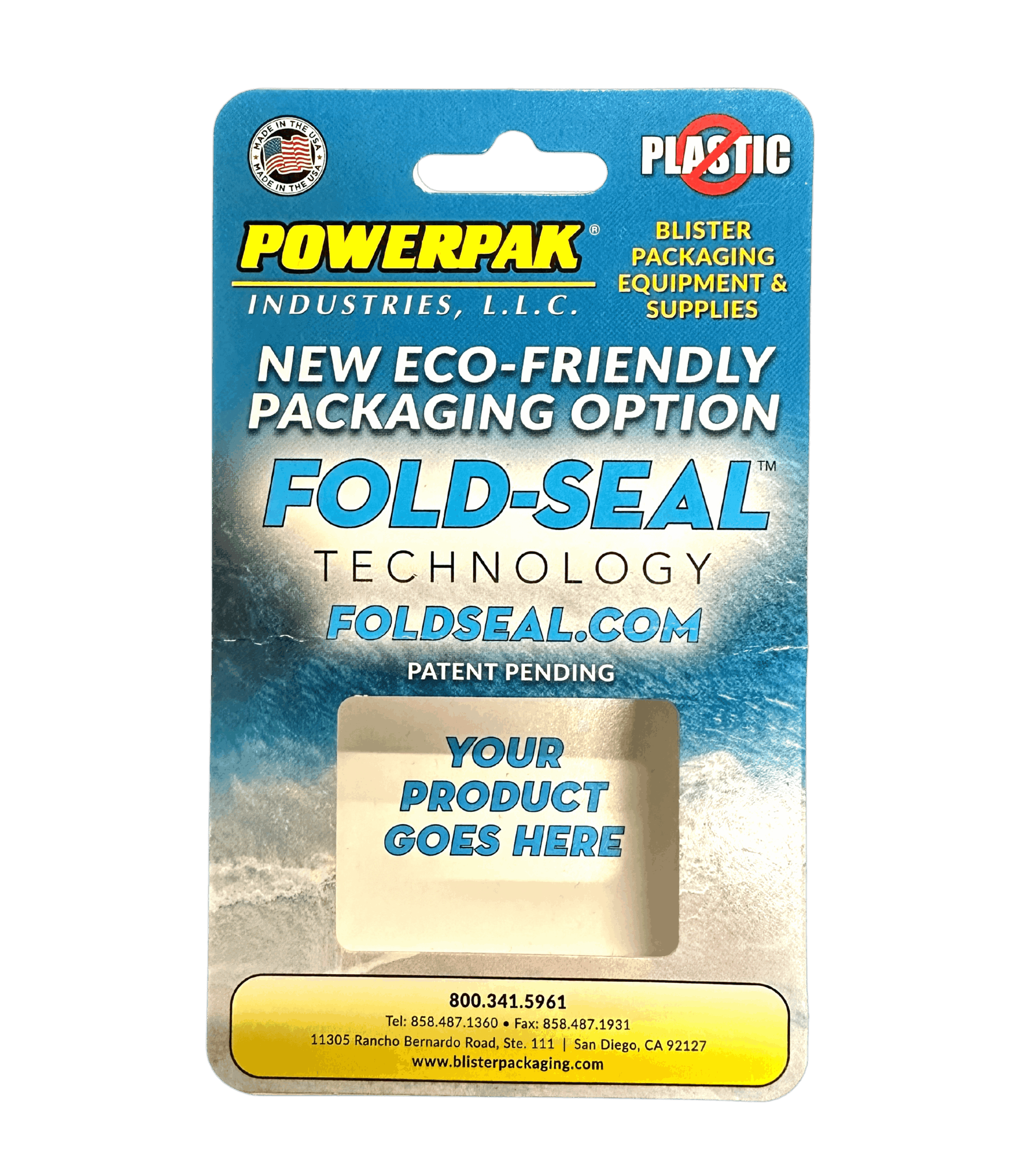

Illustrative image related to blister box

What Are the Advantages of Clamshell Packaging?

Clamshell packaging features a hinged design, often made from rigid plastic, which allows for easy access while providing robust protection for products like toys and tools. This type of packaging is reusable, appealing to environmentally conscious consumers. However, B2B buyers should be aware of potentially higher production costs and the need for specialized machinery for sealing. This type of packaging is particularly effective for items that require a higher level of consumer engagement.

Why Choose Carded Blister Packs for Hardware and Cosmetics?

Carded blister packs consist of a blister attached to a cardboard backing, making them a cost-effective option for hardware and cosmetics. This design enhances branding opportunities by allowing for printed graphics and information on the card. However, while they are economical, they may lack the visual appeal of fully transparent options. Buyers should consider the trade-off between cost and product presentation when selecting this packaging type.

What Makes Eco-Friendly Blister Options Attractive?

Eco-friendly blister packaging is increasingly important for businesses aiming to reduce their environmental footprint. These packages are made from recycled or biodegradable materials and are suitable for sustainable products and food packaging. While they support corporate social responsibility initiatives, buyers must evaluate the potential for higher costs and availability issues. Eco-friendly options can enhance brand reputation and appeal to environmentally conscious consumers, making them a worthwhile investment.

Key Industrial Applications of blister box

| Industry/Sector | Specific Application of blister box | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Packaging for tablets and capsules | Ensures product integrity, safety, and compliance | Compliance with regulations, child-resistant features, material safety |

| Consumer Electronics | Packaging for small electronic components | Enhances product visibility and reduces damage | Customization options, protection from static, clear visibility |

| Food and Beverage | Packaging for snack foods and confectioneries | Extends shelf life and maintains freshness | Food-safe materials, eco-friendly options, and tamper-evident seals |

| Cosmetics and Personal Care | Packaging for beauty products and accessories | Attracts consumers and provides product protection | Aesthetic design, customization capabilities, and material quality |

| Hardware and Tools | Packaging for small tools and hardware items | Increases retail appeal and minimizes theft | Durability, ease of opening, and compatibility with retail displays |

How Is Blister Packaging Used in Pharmaceuticals?

In the pharmaceutical sector, blister boxes are crucial for packaging tablets and capsules. They provide a barrier against moisture and contamination, ensuring the safety and efficacy of medications. Compliance with stringent regulations is a priority, which requires blister packs to have features like child resistance and clear labeling. Buyers from regions with varying regulatory standards, such as Africa and Europe, must ensure that the packaging meets local compliance requirements while also considering the environmental impact of materials used.

What Role Do Blister Boxes Play in Consumer Electronics?

Blister packaging is commonly used for small electronic components, such as batteries and connectors. The transparent nature of blister boxes enhances product visibility, making it easier for consumers to see the items on retail shelves. Additionally, these packages protect against damage during transit and display. B2B buyers need to consider customization options for branding and the need for anti-static materials to protect sensitive electronic components, especially when sourcing from international suppliers.

How Are Blister Boxes Beneficial in Food and Beverage?

In the food and beverage industry, blister boxes are employed for packaging snack foods, candies, and other perishables. These packages help extend shelf life by providing a protective barrier against environmental factors. Buyers should prioritize food-safe materials and consider eco-friendly options to align with sustainability goals. Additionally, tamper-evident seals are essential for consumer safety, making it crucial for businesses to source blister packs that comply with health and safety regulations.

Why Are Blister Boxes Important for Cosmetics and Personal Care?

Blister packaging is widely used in the cosmetics and personal care sector for items like makeup, skincare products, and beauty accessories. The appealing design and clear visibility of products encourage consumer purchases. For B2B buyers, it is important to focus on customization capabilities to reflect brand identity and ensure that the materials used are of high quality to prevent degradation of cosmetic products. Sourcing from manufacturers that offer a variety of design options can enhance product differentiation in a competitive market.

What Advantages Do Blister Boxes Offer in Hardware and Tools?

In the hardware and tools industry, blister boxes provide an effective solution for packaging small tools and accessories. They enhance retail appeal and deter theft by securely displaying products. For international buyers, considerations should include the durability of the packaging to withstand rough handling and the ease of opening for end-users. Additionally, compatibility with retail displays is crucial for maximizing visibility and sales potential, making it important for buyers to work with suppliers who understand these retail dynamics.

3 Common User Pain Points for ‘blister box’ & Their Solutions

Scenario 1: Navigating Packaging Regulations and Compliance

The Problem:

B2B buyers, especially those in industries like pharmaceuticals, food, and cosmetics, often face a complex web of regulations regarding packaging. Compliance with international standards can be daunting, particularly when it comes to materials used in blister packaging. For instance, a buyer might find that the blister box they initially selected does not meet the safety and environmental regulations required in their target market, which can lead to costly delays and potential fines.

The Solution:

To effectively navigate these regulatory challenges, B2B buyers should partner with blister packaging suppliers who are well-versed in the compliance requirements of various regions, including Europe’s REACH regulations and the FDA standards in the U.S. When sourcing blister boxes, inquire about the materials used and their compliance certifications. For instance, suppliers offering RPET (Recycled Polyethylene Terephthalate) options are not only eco-friendly but also align with growing sustainability mandates. It’s crucial to review documentation that confirms the blister boxes are food-safe or suitable for medical products, depending on the application. Engaging with suppliers who provide transparency about their manufacturing processes and material sourcing can save time and ensure adherence to necessary regulations.

Scenario 2: Ensuring Product Visibility and Customer Appeal

The Problem:

In competitive markets, product visibility can be a significant pain point for B2B buyers. Many businesses struggle with packaging that fails to highlight their products effectively on retail shelves or online platforms. A common scenario involves a buyer selecting a blister box that is too opaque or poorly designed, resulting in diminished consumer interest and lower sales.

The Solution:

To enhance product visibility, buyers should focus on selecting blister boxes made from high-quality, clear materials such as PET, which offers excellent transparency and durability. When specifying blister packaging, consider features that enhance display, such as rounded edges or unique shapes that attract attention. Collaborating with suppliers who offer customizable designs can help tailor the blister box to fit the brand’s identity while maximizing product exposure. For instance, adding a custom backer card with appealing graphics can enhance the overall presentation. Testing different prototypes in a retail environment can also provide insights into consumer preferences, allowing for adjustments before full-scale production.

Illustrative image related to blister box

Scenario 3: Balancing Cost and Quality in Blister Packaging

The Problem:

Cost management is a critical concern for B2B buyers, particularly for small to medium-sized enterprises. Many buyers find themselves in a bind where they need high-quality blister boxes to protect their products but are also pressured to keep costs low. This can lead to a frustrating trade-off between quality and affordability, especially when dealing with bulk orders.

The Solution:

To strike the right balance between cost and quality, buyers should explore suppliers that offer tiered pricing based on order volume. This approach allows businesses to benefit from economies of scale without compromising on the quality of materials. For instance, suppliers that provide options for both stock sizes and custom designs can accommodate varying budget levels. Buyers should also consider investing in eco-friendly materials, as these often come with long-term savings and appeal to a growing demographic of environmentally-conscious consumers. Additionally, requesting samples or engaging in a pilot program can help assess the quality of the blister boxes before committing to larger orders, ensuring that the chosen packaging meets both budgetary constraints and quality expectations.

By addressing these common pain points with actionable strategies, B2B buyers can optimize their blister packaging solutions to better align with their business objectives and market demands.

Strategic Material Selection Guide for blister box

What Are the Key Properties of Common Materials Used in Blister Boxes?

Blister boxes are crucial for packaging a wide range of products, and the choice of material significantly influences performance, cost, and suitability for specific applications. Here, we analyze four common materials used in blister box manufacturing: PVC, PET, RPET, and PP.

How Does PVC Perform as a Material for Blister Boxes?

Polyvinyl Chloride (PVC) is a popular choice for blister packaging due to its excellent clarity and rigidity. It can withstand moderate temperatures, making it suitable for various applications. However, PVC is less resistant to extreme temperatures and may warp if exposed to high heat.

Pros: PVC offers a cost-effective solution with good barrier properties against moisture and oxygen, which is essential for preserving product integrity. It is also widely available and can be easily formed into complex shapes.

Cons: The primary drawback of PVC is its environmental impact, as it is not biodegradable and can release harmful chemicals during production and disposal. Additionally, it may not be compatible with certain chemicals, limiting its application in industries like pharmaceuticals.

For international buyers, especially in regions with strict environmental regulations, the use of PVC may be scrutinized. Compliance with local standards such as ASTM or DIN is essential to avoid potential legal issues.

What Advantages Does PET Offer for Blister Packaging?

Polyethylene Terephthalate (PET) is increasingly favored for blister packaging due to its superior clarity and recyclability. PET has a higher temperature resistance compared to PVC, making it suitable for products that may require sterilization.

Illustrative image related to blister box

Pros: PET is known for its strength and durability, providing excellent protection against physical damage. It is also food-safe, making it ideal for packaging food items and pharmaceuticals.

Cons: The main limitation of PET is its higher cost compared to PVC. Additionally, while PET is recyclable, the recycling infrastructure may not be as developed in certain regions, particularly in developing countries.

International buyers should consider the availability of recycling facilities in their region and the potential for using recycled PET to enhance sustainability efforts.

Why Choose RPET for Eco-Friendly Blister Boxes?

Recycled PET (RPET) is an eco-friendly alternative that utilizes post-consumer plastic waste. RPET maintains many of the beneficial properties of PET while significantly reducing environmental impact.

Pros: RPET offers similar strength and clarity to virgin PET but at a lower environmental cost. It is increasingly accepted in markets focused on sustainability, appealing to eco-conscious consumers.

Illustrative image related to blister box

Cons: The primary challenge with RPET is the variability in quality due to the recycling process, which may affect performance in certain applications. Additionally, its cost can be higher than that of virgin materials, depending on market conditions.

For international buyers, the growing trend towards sustainability means that using RPET can enhance brand reputation and compliance with environmental regulations, particularly in European markets.

What Role Does Polypropylene Play in Blister Packaging?

Polypropylene (PP) is another material used in blister packaging, known for its flexibility and resistance to fatigue. It can withstand higher temperatures than PVC and is often used for products that require sterilization.

Pros: PP is lightweight and offers good chemical resistance, making it suitable for a variety of applications, including medical and food packaging. It is also recyclable, contributing to sustainability efforts.

Cons: However, PP has lower clarity compared to PVC and PET, which may reduce product visibility on retail shelves. Additionally, it can be more expensive than PVC.

International buyers should be aware of the specific regulations regarding food safety and recyclability in their markets, as compliance can vary significantly between regions.

Summary Table of Material Selection for Blister Boxes

| Material | Typical Use Case for blister box | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General consumer goods, toys | Cost-effective with good barrier properties | Environmental impact and chemical compatibility issues | Low |

| PET | Food and pharmaceutical products | Strong, durable, and food-safe | Higher cost than PVC, recycling infrastructure needed | Medium |

| RPET | Eco-friendly packaging solutions | Reduces environmental impact, maintains PET properties | Quality variability and potentially higher cost | Medium |

| PP | Medical and food packaging | High temperature resistance and chemical resistance | Lower clarity and potentially higher cost | Medium |

This guide aims to equip international B2B buyers with the insights needed to make informed decisions regarding blister box material selection, considering both performance and compliance in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for blister box

What Are the Key Stages in the Manufacturing Process of Blister Boxes?

The manufacturing process for blister boxes involves several critical stages, each designed to ensure the final product meets quality standards and is suitable for its intended application. Understanding these stages can help B2B buyers make informed decisions when sourcing blister packaging.

1. Material Preparation

The first step in manufacturing blister boxes is selecting the appropriate materials. Common materials include PVC, PET, and RPET, each offering different properties such as clarity, flexibility, and recyclability. The materials are typically sourced in large rolls and undergo pre-treatment to enhance adhesion and compatibility with printing inks.

During this stage, manufacturers must consider the specific requirements of the end product. For instance, if the blister box is intended for food products, food-safe materials must be used. This stage often includes quality checks to verify that the materials meet industry standards, ensuring they are free from defects and contaminants.

2. Forming

Once the materials are prepared, the next stage is forming. This involves heating the plastic until it becomes pliable, after which it is shaped into the desired blister form using specialized molds. Techniques such as thermoforming or cold forming are common in this process.

Thermoforming is particularly prevalent for producing clear blister boxes, as it allows for high precision and excellent clarity, enhancing product visibility. The formed blisters must be carefully inspected to ensure they meet dimensional specifications and visual quality standards.

3. Assembly

After forming, the blister boxes are assembled. This may involve attaching a backing card, which often serves as both a product display and a means of securing the items within the blister. The assembly can be automated or manual, depending on the scale of production.

In this stage, manufacturers should employ quality control measures to check the integrity of the seals and the overall assembly. Proper sealing is critical to prevent tampering and ensure product safety. Any defects in assembly can lead to product loss or damage, which is particularly crucial for high-value items.

Illustrative image related to blister box

4. Finishing

The final stage of the manufacturing process involves finishing touches, which can include printing, labeling, and additional treatments to enhance durability. Printing can provide vital product information and branding, contributing to the overall appeal of the blister box.

Quality checks during the finishing stage are essential to ensure that all printed materials are accurate and that the final product meets aesthetic and functional specifications. This stage may also involve the application of coatings to improve scratch resistance or provide a matte finish, depending on the customer’s requirements.

How Is Quality Assurance Implemented in Blister Box Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of blister boxes, ensuring that products not only meet customer expectations but also comply with international standards. For B2B buyers, understanding these quality assurance measures can significantly impact their sourcing decisions.

Relevant International Standards for Blister Packaging

Manufacturers of blister boxes should adhere to various international standards, such as ISO 9001, which focuses on quality management systems. This certification assures buyers that the manufacturer has established processes for consistent quality control.

In addition, industry-specific standards may apply, such as CE marking for products sold in Europe or API standards for pharmaceutical packaging. Compliance with these standards is crucial for ensuring product safety and efficacy, particularly in regulated industries.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically implemented throughout the manufacturing process to catch defects early and ensure consistent product quality. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections assess the quality of the forming, assembly, and finishing processes. This helps identify any deviations from standards early in production.

-

Final Quality Control (FQC): After production, a thorough inspection of the finished blister boxes occurs. This includes checks for dimensional accuracy, seal integrity, and aesthetic quality.

These checkpoints help mitigate risks associated with defects and ensure that the final products meet the required quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is critical. Here are several strategies to ensure that potential suppliers meet your quality expectations:

Conduct Supplier Audits

One of the most effective ways to assess a supplier’s quality assurance practices is through supplier audits. These audits can be conducted by your team or through third-party inspection services. Auditors will evaluate the supplier’s adherence to quality standards, manufacturing processes, and compliance with international regulations.

Request Quality Assurance Documentation

Buyers should request quality assurance documentation from suppliers, including certifications such as ISO 9001, CE, or other relevant industry standards. Documentation should also include quality control reports and testing results for previous batches of blister boxes.

Utilize Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality control practices. These services can conduct inspections at various stages of production, ensuring that the products meet the specified quality standards before shipment.

Illustrative image related to blister box

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, it’s essential to be aware of certain nuances in quality control that may affect the procurement process. Different countries may have varying standards and practices, which can impact product quality and compliance.

For example, regulations in Europe are often stricter compared to those in some developing markets. B2B buyers should familiarize themselves with these differences and ensure that suppliers can meet the necessary compliance requirements for their target markets.

Moreover, cultural differences may influence communication and expectations regarding quality. Establishing clear lines of communication and understanding each other’s quality standards can help avoid misunderstandings and ensure a successful partnership.

In summary, the manufacturing processes and quality assurance practices for blister boxes are critical components that directly impact product quality and compliance. By understanding these elements, B2B buyers can make informed decisions when sourcing blister packaging solutions, ensuring they partner with suppliers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blister box’

Introduction

This guide provides a step-by-step checklist for B2B buyers looking to source blister boxes effectively. Blister packaging offers significant advantages in product protection and visibility, making it essential for various industries. By following these actionable steps, you can streamline your procurement process and ensure that you select the right supplier and product specifications for your needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline your technical requirements for the blister boxes. Consider factors such as size, material (e.g., PVC, PET), thickness, and design features. Defining these specifications helps you communicate effectively with suppliers and ensures that you receive products that meet your specific needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in blister packaging. Look for companies with experience in your industry and positive customer reviews. Utilize platforms like trade directories, industry forums, and social media to gather insights about the suppliers’ reputations and capabilities.

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality standards of potential suppliers. Look for ISO certifications, food safety compliance (if applicable), and eco-friendly practices. Certifications indicate a supplier’s commitment to quality and can help mitigate risks associated with product recalls or safety issues.

Step 4: Request Samples

Always request product samples before making a bulk order. This step allows you to assess the quality, durability, and suitability of the blister boxes for your products. Pay attention to the clarity of the material, the strength of seals, and the overall design to ensure they align with your expectations.

Illustrative image related to blister box

Step 5: Compare Pricing Structures

Gather quotes from multiple suppliers and compare their pricing structures. Consider not just the unit price, but also any additional costs such as shipping, customization, and tooling fees. Understanding the total cost of ownership will help you make an informed decision that balances quality and budget.

Step 6: Assess Customization Options

Evaluate the customization capabilities of each supplier. Custom blister packaging can enhance your product’s visibility and branding. Check if the suppliers can accommodate your design needs, including printing options, unique shapes, and sizes that align with your product specifications.

Step 7: Establish Communication and Support Channels

Ensure that the supplier offers robust communication and support channels. A responsive supplier will be more effective in addressing any issues that arise during the procurement process. Establish points of contact for order updates, support, and any potential quality concerns to maintain a smooth partnership.

Illustrative image related to blister box

By following this checklist, B2B buyers can effectively navigate the sourcing process for blister boxes, ensuring they select the right products and suppliers to enhance their packaging solutions.

Comprehensive Cost and Pricing Analysis for blister box Sourcing

What Are the Key Cost Components in Blister Box Manufacturing?

When sourcing blister boxes, understanding the cost structure is essential for informed decision-making. The primary cost components include:

-

Materials: The choice of material significantly impacts the overall cost. Common materials such as PVC, PET, and RPET vary in price based on their thickness and quality. Eco-friendly options may carry a premium but can enhance brand value and appeal to environmentally conscious consumers.

-

Labor: Labor costs encompass wages for workers involved in the manufacturing process. Regions with lower labor costs can offer competitive pricing, but this may affect quality if not managed properly.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Custom designs may necessitate specific tooling, which can be a significant upfront cost. However, suppliers often provide stock sizes with no tooling charges, enabling cost savings for standard products.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specifications and standards. While this adds to costs, it ultimately protects your brand from quality issues and recalls.

-

Logistics: Shipping costs can vary widely based on the distance and mode of transportation. Consideration of Incoterms is crucial here, as they define the responsibilities of buyers and sellers in international trade.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the expected margins in your industry can help you assess whether you’re getting a fair deal.

How Do Price Influencers Affect Blister Box Sourcing?

Several factors can influence the price of blister boxes, particularly for international buyers:

-

Volume/MOQ: Bulk orders often attract discounts. Understanding minimum order quantities (MOQs) can help in negotiating better rates.

-

Specifications and Customization: Custom features such as unique designs or special materials can increase costs. Buyers should evaluate whether these enhancements justify the additional expense.

-

Material Quality and Certifications: Higher-quality materials or those with certifications (e.g., food safety standards) can command higher prices. Ensure that the chosen materials align with your product’s requirements.

-

Supplier Factors: The reputation and reliability of the supplier play a critical role. Established suppliers may charge more due to their proven track record but can offer better service and quality assurance.

What Are Some Effective Buyer Tips for Cost-Efficiency?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following strategies for effective sourcing:

-

Negotiate Terms: Always negotiate pricing and payment terms. Suppliers may be willing to offer discounts or flexible payment options for long-term contracts or larger volumes.

-

Assess Total Cost of Ownership (TCO): Beyond the purchase price, consider all costs associated with sourcing, including logistics, potential tariffs, and quality assurance. This holistic view can lead to better decision-making.

-

Understand Pricing Nuances: Be aware of regional pricing differences, especially when sourcing from countries with varying economic conditions. This knowledge can aid in negotiations and help identify cost-effective suppliers.

-

Utilize Incoterms Wisely: Familiarize yourself with Incoterms to clarify responsibilities related to shipping, insurance, and tariffs. This understanding can mitigate unexpected costs and delays.

Conclusion and Disclaimer on Pricing

While the information above provides a framework for understanding the costs and pricing of blister box sourcing, prices can vary widely based on supplier, location, and market conditions. Always seek quotes from multiple suppliers and conduct thorough due diligence to ensure you secure the best value for your investment.

Alternatives Analysis: Comparing blister box With Other Solutions

Exploring Alternatives to Blister Boxes for Packaging Solutions

In the competitive landscape of product packaging, businesses often seek the most effective solutions to enhance product visibility, protection, and cost efficiency. While blister boxes are a popular choice, understanding alternative packaging methods can help B2B buyers make informed decisions tailored to their specific needs. Below, we compare blister boxes against two viable alternatives: clamshell packaging and cardboard boxes.

Illustrative image related to blister box

| Comparison Aspect | Blister Box | Clamshell Packaging | Cardboard Boxes |

|---|---|---|---|

| Performance | Excellent visibility and protection; ideal for retail displays. | Strong visibility and protection; suitable for heavier items. | Good protection but less visibility; better for bulk shipping. |

| Cost | Moderate cost; custom options can increase price. | Generally higher due to material and design complexity. | Low cost; highly economical for large quantities. |

| Ease of Implementation | Simple to implement; requires minimal setup. | More complex; requires tooling for custom designs. | Easy to implement; readily available in various sizes. |

| Maintenance | Low maintenance; durable and reusable. | Moderate maintenance; can be less durable over time. | Low maintenance; recyclable but may not be reusable. |

| Best Use Case | Ideal for consumer goods, electronics, and pharmaceuticals. | Best for retail items, toys, and tools needing extra security. | Perfect for bulk products, shipping, and storage. |

What Are the Pros and Cons of Clamshell Packaging?

Clamshell packaging provides a robust alternative to blister boxes. Its design offers excellent visibility while enhancing product protection, making it suitable for heavier items. The dual plastic halves can securely encase products, reducing the risk of damage during transit. However, clamshells tend to be more expensive due to their manufacturing complexity and may require custom tooling for unique designs. Additionally, they can be more challenging to open for consumers, potentially leading to frustration.

How Do Cardboard Boxes Compare?

Cardboard boxes represent a highly economical option for businesses, especially for bulk shipping. They are readily available and can be customized in size and design, making them versatile for various applications. While they provide adequate protection for products, their visibility is limited compared to blister boxes and clamshells. Cardboard is also recyclable, aligning with sustainability goals, but it may not offer the same level of durability as plastic alternatives. This makes it less suitable for retail displays where product visibility is crucial.

Conclusion: Which Packaging Solution Should B2B Buyers Choose?

Choosing the right packaging solution depends on various factors, including product type, budget, and target market. Blister boxes excel in visibility and protection, making them ideal for consumer-focused products. Clamshell packaging offers added security for heavier items but comes at a higher cost. Conversely, cardboard boxes are perfect for cost-sensitive applications, particularly in bulk shipping. B2B buyers should carefully assess their specific requirements and consider the trade-offs of each option to select a packaging solution that best aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for blister box

What Are the Key Technical Properties of a Blister Box?

When selecting blister boxes for packaging, understanding the essential technical properties can significantly impact product safety, visibility, and overall marketing effectiveness. Here are some critical specifications:

-

Material Grade

Blister boxes are typically made from various plastics such as PVC, PET, and RPET. Each material has unique properties affecting durability, clarity, and cost. For instance, PET is known for its high strength and recyclability, making it a popular choice for eco-conscious brands. In B2B contexts, selecting the right material ensures that the packaging aligns with product requirements and brand values. -

Thickness

The thickness of the blister material is crucial for product protection. Common thicknesses range from 14 mil to 30 mil. Thicker materials provide enhanced durability against punctures and impacts, which is vital for high-value products. For B2B buyers, understanding thickness helps in evaluating the cost-to-benefit ratio of packaging solutions. -

Tolerance

Tolerance refers to the allowable variation in dimensions during manufacturing. A typical tolerance for blister boxes might be +/- 1/16 inch. This specification is critical for ensuring that the blister fits the product snugly, preventing movement that could lead to damage. In B2B transactions, precise tolerances can reduce returns and increase customer satisfaction. -

Cavity Dimensions

The inner cavity dimensions dictate how well the blister box can accommodate the product. For example, a blister box with a cavity measuring 2 3/4″ x 1 3/8″ x 2 3/4″ is tailored for specific items. Understanding cavity dimensions is essential for B2B buyers to ensure compatibility with their products, which can streamline the packing and shipping processes. -

Sealing Method

Different blister packaging solutions employ various sealing methods, such as heat sealing or self-sealing options. The choice of sealing method can affect the ease of use and product security. For B2B buyers, selecting the appropriate sealing method can enhance the unboxing experience and ensure product integrity during transit. -

Food Safety Compliance

For industries dealing with food products, ensuring that blister boxes meet food safety standards is critical. Packaging materials should be food-safe and compliant with local regulations. B2B buyers in the food sector must prioritize these specifications to avoid legal issues and ensure consumer safety.

What Are the Common Trade Terms Used in Blister Box Procurement?

Navigating the blister packaging industry requires familiarity with specific jargon and trade terminology. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of blister packaging, an OEM may produce customized blister boxes for another brand’s product line. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory costs and cash flow. Negotiating a favorable MOQ can lead to cost savings for large-scale purchases. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers. It typically includes specifications, quantities, and delivery timelines. For B2B transactions, issuing an RFQ ensures that buyers receive competitive pricing and can evaluate multiple suppliers efficiently. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping, insurance, and delivery responsibilities, reducing the risk of misunderstandings. -

Customization

This refers to tailoring the blister box design, size, and materials to meet specific customer needs. Customization is a significant advantage in B2B transactions, allowing brands to differentiate themselves in the market. -

Sustainability

This term encompasses practices that reduce environmental impact, such as using recyclable materials or minimizing waste during production. As sustainability becomes a priority for many businesses, B2B buyers should consider eco-friendly options in their blister packaging selections.

Understanding these properties and terms equips B2B buyers with the knowledge needed to make informed decisions regarding blister box procurement, ensuring their products are well-packaged and market-ready.

Navigating Market Dynamics and Sourcing Trends in the blister box Sector

What Are the Current Market Dynamics Influencing the Blister Box Sector?

The blister box sector is experiencing notable growth driven by several global factors. Increasing demand for product visibility and protection in industries such as pharmaceuticals, electronics, and consumer goods is pushing manufacturers toward innovative blister packaging solutions. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek efficient and reliable packaging, they must adapt to emerging sourcing trends. Key trends include the rise of automation in packaging processes, which enhances production efficiency and reduces lead times. Moreover, the integration of advanced materials such as RPET and biodegradable plastics is becoming a prominent feature, appealing to environmentally conscious businesses.

The shift towards e-commerce is another significant market dynamic. As online retail expands, there is an increased need for durable packaging that can withstand shipping conditions while showcasing products effectively. This has prompted suppliers to focus on customizable blister packaging that meets specific product requirements and enhances brand visibility. Furthermore, with the advent of Industry 4.0, the utilization of data analytics and IoT in supply chain management is streamlining sourcing processes, offering buyers real-time insights into inventory and demand patterns.

How Is Sustainability Shaping the Sourcing of Blister Boxes?

Sustainability is no longer an option but a necessity in the blister box sector. B2B buyers are increasingly prioritizing environmentally friendly practices and materials in their sourcing decisions. The environmental impact of packaging waste is a pressing concern, leading many companies to explore sustainable alternatives. Blister packaging made from recycled materials, such as RPET, not only reduces carbon footprints but also appeals to a growing consumer base that values eco-conscious products.

Ethical sourcing has gained traction as businesses strive to ensure their supply chains are transparent and responsible. This includes adherence to fair labor practices and sustainable sourcing of raw materials. Certifications such as FSC (Forest Stewardship Council) and Cradle to Cradle provide assurance to buyers looking for packaging solutions that align with their corporate social responsibility goals. By opting for suppliers who demonstrate commitment to sustainability, B2B buyers can enhance their brand image while contributing positively to environmental conservation efforts.

What Is the Historical Context of Blister Box Packaging in B2B Markets?

The evolution of blister packaging dates back to the early 20th century when it was first used in the pharmaceutical industry to package pills and tablets securely. Initially, the focus was primarily on functionality—providing a protective barrier against contamination and ensuring product integrity. However, as retail environments evolved, so did the design and application of blister packaging.

By the 1980s, blister packaging began to incorporate aesthetic elements, enhancing product visibility and consumer appeal on retail shelves. This shift marked the beginning of the customization trend, with manufacturers offering tailored solutions to meet diverse market needs. Today, blister boxes are not only functional but also integral to branding strategies, reflecting the dynamic nature of consumer preferences and technological advancements in packaging materials and design.

Illustrative image related to blister box

In summary, understanding these market dynamics, sustainability imperatives, and historical developments equips international B2B buyers with the insights needed to navigate the evolving blister box sector effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of blister box

-

How do I select the right blister box for my product?

Choosing the appropriate blister box involves evaluating your product’s dimensions, weight, and fragility. Consider the material options, such as PVC, PET, or RPET, which offer different levels of protection and visibility. It’s also crucial to assess the packaging’s aesthetic appeal to enhance product presentation. Engaging with suppliers for samples can help you determine the best fit for your product while ensuring compliance with any industry-specific regulations. -

What are the benefits of custom blister boxes for my business?

Custom blister boxes provide enhanced brand visibility and product protection. They can be tailored to meet specific dimensions, shapes, and materials, ensuring your product stands out on shelves. Moreover, custom designs can improve user experience by making products easier to access. Additionally, custom packaging can align with your marketing strategy, creating a cohesive brand image that resonates with your target audience. -

What are the typical minimum order quantities (MOQs) for blister boxes?

MOQs for blister boxes can vary significantly by supplier, with some offering low MOQs for custom designs while others may require larger orders. Generally, MOQs can range from 100 to several thousand units, depending on the complexity of the design and materials used. It’s essential to discuss your needs with potential suppliers to find a balance between your budget and inventory requirements. -

What payment terms should I expect when sourcing blister boxes internationally?

Payment terms for international purchases of blister boxes can vary widely among suppliers. Common options include upfront payment, partial payment with the balance upon delivery, or payment after a specified credit period. It’s important to negotiate terms that protect both parties and ensure timely transactions. Always verify the payment methods accepted, such as bank transfers or letters of credit, to avoid potential complications. -

How can I ensure quality assurance (QA) for my blister boxes?

To ensure quality assurance, consider working with suppliers who have established QA processes, including material testing and inspection protocols. Request samples before placing large orders to evaluate the packaging’s durability and aesthetic appeal. Additionally, inquire about certifications, such as ISO standards, which indicate adherence to quality management practices. Regular communication with your supplier during production can also help address any concerns proactively. -

What logistics considerations should I keep in mind when ordering blister boxes?

Logistics play a critical role in the timely delivery of blister boxes. Assess shipping options, including air freight and sea freight, to determine the most cost-effective and timely method for your needs. Additionally, consider the location of the supplier’s warehouse and the associated shipping costs. It’s also wise to discuss customs requirements and potential duties to avoid unexpected expenses when importing packaging. -

How do I vet a supplier for blister boxes?

Vetting a supplier involves researching their reputation, production capabilities, and experience in the blister packaging industry. Look for customer reviews, case studies, and examples of previous work to gauge their reliability. It’s also beneficial to request references and conduct background checks. Engaging in direct communication with potential suppliers can help assess their responsiveness and willingness to meet your specific needs. -

What eco-friendly options are available for blister boxes?

Many suppliers now offer eco-friendly blister box options made from recyclable or biodegradable materials. When sourcing, inquire about the use of sustainable materials like RPET or biodegradable plastics, which minimize environmental impact. Additionally, some manufacturers provide eco-certifications, ensuring compliance with environmental standards. Choosing eco-friendly packaging can enhance your brand image and appeal to environmentally conscious consumers.

Top 7 Blister Box Manufacturers & Suppliers List

1. eBay – Blister Packaging Supplies

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Blister Packaging for sale on eBay includes various types of products such as empty blister packs, clamshell blister packaging, and blister pack machines. Popular items listed include Bostitch SP191/4 1/4″ Staples (Pack of 5000) for $7.49, handheld postal scales, and various packaging and shipping equipment. Brands featured include Unbranded, Videojet, and Mettler Toledo. The listings also highlig…

2. Andex – Blister Packaging Solutions

Domain: andex.net

Registered: 1998 (27 years)

Introduction: Blister Packaging Supplier: Andex offers high-quality blister packaging designed for various industries, ensuring product protection, visibility, and convenience. Key features include:

– Volumes: Low, moderate, or high volumes available.

– Materials: Various blister pack types such as PVC and RPET plastic in different thicknesses.

– Designs: Unique features including footed and secondary die cu…

3. Univpack – Blister Packaging Solutions

Domain: univpack.com

Registered: 2002 (23 years)

Introduction: Blister packaging is an inexpensive option for creating durable, transparent, and tamper-proof packages. These clear plastic blister packs are used with a cardboard blister card to keep the product visible for customer examination. The blister packaging is attached to the blister card through a heat-sealing process, allowing for various display methods. It is suitable for lightweight items, while …

4. Reddit – Blister Pack Booster Packs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Blister packs contain two booster packs sealed in a cardboard packaging, providing better security against tampering compared to loose booster packs. Blister packs are generally sold for a lower price than single booster packs, despite being slightly more expensive than regular booster packs. Booster packs typically come from booster boxes and may have different pull rates compared to blister pack…

5. VisiPak – Blister Packaging Solutions

Domain: visipak.com

Registered: 2000 (25 years)

Introduction: Blister packaging, also known as blister packs, consists of pre-formed clear plastic cavities used for securely packaging small consumer goods. Key components include a clear plastic bubble or cavity and a backing, often made of paperboard. Blister packs can feature various hanging elements for merchandising. Types of blister packaging include Face Seal, Full-Face Seal, Trapped, and Slide blisters…

6. E-Blister – Clamshell Blisters

Domain: e-blister.com

Registered: 2007 (18 years)

Introduction: [{‘name’: ‘Clamshell blister 45*78*25mm’, ‘inner_dimensions’: ’45 x 78 x 25 mm’, ‘depth_of_cavity’: 45, ‘cavity_length’: 78, ‘width_cavity’: 25, ‘carton_quantity’: 864, ‘production_time’: ‘2-3 weeks’, ‘regular_price’: ‘€170,29’, ‘price_per_blister’: ‘€0,19’}, {‘name’: ‘Clamshell blister 60*85*25mm’, ‘inner_dimensions’: ’60 x 85 x 25 mm’, ‘depth_of_cavity’: 60, ‘cavity_length’: 85, ‘width_cavity’: …

7. Jones Healthcare Group – FlexRx™ One

Domain: adherence.joneshealthcaregroup.com

Registered: 2019 (6 years)

Introduction: Blister Packs from Jones Healthcare Group offer a range of medication adherence packaging solutions designed for various healthcare settings. Key products include: 1. **FlexRx™ One**: Monthly unit-dose medication manager for up to 31 days, made from recyclable Bio-PET, designed for automation, with easy access to medications via push-through blisters. 2. **31-Day Unit-Dose**: Monthly single-dose m…

Strategic Sourcing Conclusion and Outlook for blister box

Why is Strategic Sourcing Essential for Blister Packaging?

In the dynamic landscape of blister packaging, strategic sourcing is paramount for B2B buyers aiming to optimize their supply chain while ensuring product integrity and visibility. By aligning with reputable suppliers, businesses can access a diverse range of customizable options that meet specific requirements across various industries—from pharmaceuticals to consumer goods. The ability to choose eco-friendly materials and innovative designs not only enhances brand reputation but also caters to the increasing consumer demand for sustainability.

What Are the Key Benefits of Investing in Blister Packaging?

Investing in high-quality blister packaging solutions offers numerous advantages, including superior product protection, enhanced consumer visibility, and cost-effectiveness. These factors contribute to improved customer satisfaction and increased sales potential. Additionally, leveraging volume discounts and efficient logistics from suppliers can significantly reduce overall operational costs, making it a financially sound decision for international buyers.

Illustrative image related to blister box

How Can International Buyers Prepare for Future Trends in Blister Packaging?

As global markets evolve, staying ahead of trends in blister packaging—such as automation, sustainability, and customization—will be crucial. International buyers, particularly from Africa, South America, the Middle East, and Europe, should actively engage with suppliers to discuss innovative solutions that align with their growth strategies. Embracing these changes now will position businesses favorably in the competitive landscape.

In conclusion, the future of blister packaging is bright for those who prioritize strategic sourcing. Begin exploring your options today to ensure your packaging solutions are not only effective but also sustainable and aligned with market demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.