Everything You Need to Know About Baseboard Rubber Sourcing in 2025

Introduction: Navigating the Global Market for baseboard rubber

In the competitive landscape of international B2B sourcing, navigating the complexities of acquiring baseboard rubber can pose significant challenges for buyers. Whether you are sourcing durable wall bases for commercial spaces or exploring options for residential projects, understanding the nuances of this market is essential. This guide delves into the diverse types of baseboard rubber available, their various applications, and critical factors for vetting suppliers. From cost considerations to product specifications, we aim to equip B2B buyers from Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Saudi Arabia—with actionable insights that facilitate informed purchasing decisions.

As the demand for high-quality, sustainable building materials continues to rise globally, understanding the characteristics and benefits of rubber wall bases becomes imperative. This guide not only highlights the leading suppliers and their offerings but also addresses the importance of compliance with regional standards and certifications. By providing a comprehensive overview of the market landscape, we empower buyers to make strategic choices that align with their project requirements and budget constraints. Our aim is to ensure that you, as an international B2B buyer, can confidently navigate the global market for baseboard rubber, ultimately enhancing your procurement process and project outcomes.

Understanding baseboard rubber Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rubber Cove Base | Flexible, available in various heights and colors | Commercial spaces, healthcare | Pros: Durable, moisture-resistant. Cons: Installation may require skilled labor. |

| Thermoplastic Rubber (TPR) Base | Made from a blend of rubber and plastic, highly flexible | Retail environments, schools | Pros: Easy to install, resistant to fading. Cons: May be more expensive than vinyl. |

| Vinyl Wall Base | Economical option, available in various colors and finishes | Residential, light commercial | Pros: Cost-effective, easy to maintain. Cons: Less durable than rubber options. |

| Sanitary Wall Base | Designed for hygiene, seamless installation, available in many colors | Hospitals, laboratories | Pros: Reduces germ accumulation, easy to clean. Cons: Higher initial cost. |

| Decorative Rubber Base | Mimics wood or stone patterns, available in multiple designs | High-end retail, hospitality | Pros: Aesthetic appeal, customizable. Cons: May require specialized installation. |

What are the Characteristics of Rubber Cove Base?

Rubber Cove Base is characterized by its flexibility and the ability to conform to various wall shapes and heights. Typically available in a range of colors, it is ideal for commercial spaces, particularly in healthcare environments where cleanliness is paramount. Buyers should consider the ease of installation, which may require skilled labor, and the long-term durability that rubber provides against wear and tear.

How Does Thermoplastic Rubber (TPR) Base Compare?

Thermoplastic Rubber (TPR) Base combines the best features of rubber and plastic, making it highly flexible and easy to install. It is particularly suitable for retail environments and schools where foot traffic is heavy. TPR’s resistance to fading and scratching makes it a reliable choice, although it tends to be more expensive than standard vinyl options. B2B buyers should weigh the upfront costs against the longevity and performance benefits.

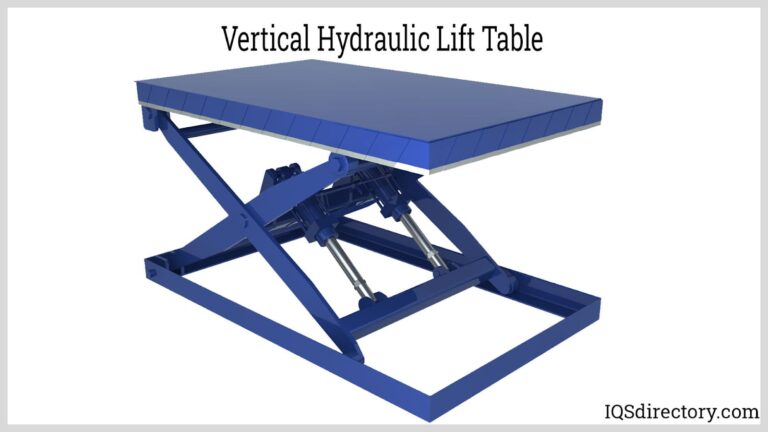

Illustrative image related to baseboard rubber

What Advantages Does Vinyl Wall Base Offer?

Vinyl Wall Base is a cost-effective solution for both residential and light commercial applications. Its availability in various colors and finishes allows for easy integration into different design schemes. While it is easier to maintain compared to rubber, it may not offer the same level of durability. Buyers should assess their budget and the expected foot traffic in the area to determine if vinyl meets their needs.

Why Choose Sanitary Wall Base for High-Hygiene Areas?

Sanitary Wall Base is specifically designed to minimize germ accumulation, making it ideal for hospitals and laboratories. Its seamless installation helps reduce the chances of dirt and bacteria collecting in gaps. Although the initial investment may be higher compared to other options, the long-term hygiene benefits can justify the cost for businesses prioritizing cleanliness.

What Makes Decorative Rubber Base a Unique Option?

Decorative Rubber Base offers aesthetic versatility, mimicking the appearance of wood or stone while maintaining the durability of rubber. This option is favored in high-end retail and hospitality settings where design plays a crucial role. While it provides a customizable look, buyers should be aware that installation may require specialized skills, potentially increasing overall project costs.

Illustrative image related to baseboard rubber

Key Industrial Applications of baseboard rubber

| Industry/Sector | Specific Application of baseboard rubber | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Wall protection in hospitals and clinics | Enhances hygiene by preventing moisture and bacteria buildup | Ensure compliance with health regulations and durability standards |

| Education | Flooring transitions in schools and universities | Provides safety and aesthetic appeal, reducing slip hazards | Look for color options and flexibility for various designs |

| Hospitality | Decorative and protective baseboards in hotels | Improves guest experience and protects against wear and tear | Consider custom colors and patterns to match branding |

| Food Service | Sanitary wall bases in kitchens and dining areas | Facilitates easy cleaning and enhances food safety | Sourcing must prioritize non-porous materials resistant to stains |

| Retail | Visual merchandising and protection in stores | Attracts customers while protecting walls from damage | Evaluate design options that align with the retail environment |

How is Baseboard Rubber Utilized in Healthcare Settings?

In healthcare environments, baseboard rubber is essential for wall protection in hospitals and clinics. It helps maintain hygiene by creating a barrier that prevents moisture accumulation and bacterial growth, which is critical in preventing infections. Buyers in this sector should prioritize sourcing products that meet health regulations, ensuring durability to withstand frequent cleaning and impact from equipment. Selecting rubber baseboards that are easy to install and maintain can significantly enhance operational efficiency.

What Role Does Baseboard Rubber Play in Educational Institutions?

In educational settings, baseboard rubber is used for flooring transitions in schools and universities, providing a safe and aesthetically pleasing environment. These rubber bases help to reduce slip hazards while accommodating various flooring materials. Buyers in this sector should consider color options and flexibility, as schools often require designs that can adapt to different classroom configurations and themes. Durability is also key, given the high foot traffic in these facilities.

How Can Baseboard Rubber Enhance Hospitality Venues?

In the hospitality industry, baseboard rubber serves both decorative and protective functions within hotels. It not only enhances the guest experience through its visual appeal but also protects walls from wear and tear caused by luggage and cleaning equipment. When sourcing baseboard rubber, businesses should consider custom colors and patterns that align with their branding. Additionally, durability and ease of maintenance are crucial for long-term cost efficiency in high-traffic areas.

Why is Baseboard Rubber Important in Food Service Areas?

In food service environments, baseboard rubber is critical for maintaining sanitation standards. It is used in kitchens and dining areas to create a non-porous barrier that facilitates easy cleaning and minimizes the risk of contamination. Buyers in this sector should prioritize sourcing materials that are resistant to stains and moisture, ensuring compliance with health codes. Flexibility in design can also help in creating seamless transitions between different areas of food preparation and serving.

How Does Baseboard Rubber Benefit Retail Spaces?

In retail environments, baseboard rubber contributes to both visual merchandising and wall protection. It helps create an attractive shopping atmosphere while safeguarding walls from damage caused by shopping carts and foot traffic. Retail buyers should evaluate design options that complement their store’s aesthetic and consider the durability of the rubber to withstand everyday wear. Additionally, sourcing options that offer a range of colors can enhance the overall shopping experience and brand representation.

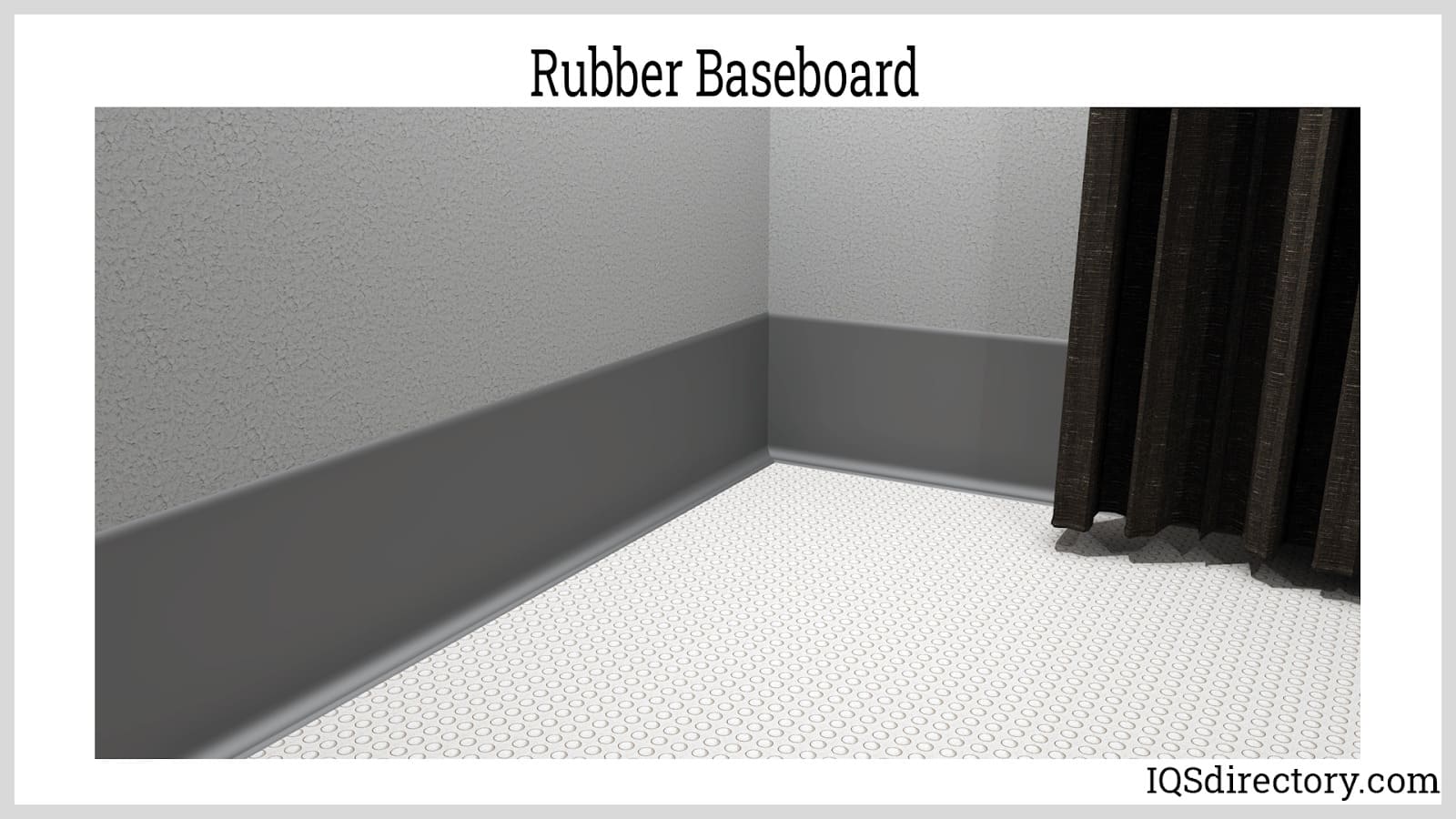

Illustrative image related to baseboard rubber

3 Common User Pain Points for ‘baseboard rubber’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Rubber Baseboard for Specific Applications

The Problem: B2B buyers often struggle to identify the appropriate type of rubber baseboard for unique environments. For instance, a buyer responsible for outfitting a healthcare facility may face the challenge of selecting a product that not only meets aesthetic standards but also adheres to strict hygiene requirements. The available options can be overwhelming, and without a clear understanding of the specifications needed, they risk purchasing materials that do not fulfill the necessary performance criteria, leading to potential compliance issues.

The Solution: To navigate this challenge, buyers should start by conducting thorough research on the specific requirements of their applications. For healthcare environments, sourcing rubber baseboards that are anti-microbial and resistant to moisture is crucial. Look for products explicitly labeled as suitable for high-traffic and sterile environments, such as those made from thermoplastic rubber (TPR) that can withstand frequent cleaning without degrading. Establish a direct line of communication with suppliers to clarify specifications and request samples before making a bulk purchase. This proactive approach ensures that the right material is chosen for the intended application.

Scenario 2: Installation Challenges Leading to Increased Costs

The Problem: Another significant pain point is the installation of rubber baseboards, which can often lead to unexpected costs and delays. Buyers may find that their chosen products are not as easy to install as anticipated, requiring specialized tools or additional labor. This situation is particularly common in regions with limited access to skilled labor, resulting in project delays and increased expenditure.

The Solution: To mitigate installation challenges, buyers should opt for rubber baseboards that come with detailed installation guides and support from the manufacturer. When sourcing, inquire about products that feature self-adhesive backing or interlocking designs, which simplify the installation process and reduce the need for specialized tools. Additionally, consider investing in training sessions for local installation teams to enhance their skills with rubber baseboard application. This not only ensures proper installation but also fosters a sense of confidence and competence within the workforce, ultimately leading to smoother project execution.

Scenario 3: Concerns Over Longevity and Maintenance of Rubber Baseboards

The Problem: Buyers frequently worry about the longevity and maintenance requirements of rubber baseboards. In environments such as schools or commercial spaces, where foot traffic is high, there is a fear that the baseboards will wear down quickly, resulting in frequent replacements and added costs. Furthermore, inadequate maintenance can lead to unsightly wear and reduced overall aesthetic appeal.

The Solution: To address longevity concerns, B2B buyers should focus on sourcing high-quality rubber baseboards that are specifically designed for durability. Look for products that offer warranties and have been tested for resistance to scuffing, fading, and cracking. Additionally, implement a proactive maintenance plan that includes regular cleaning with non-abrasive products to extend the lifespan of the baseboards. Educating facility managers on best practices for maintenance can also be beneficial. By ensuring that the right products are chosen and proper care is taken, buyers can achieve a long-lasting, attractive solution that minimizes the need for replacements and keeps maintenance costs low.

Strategic Material Selection Guide for baseboard rubber

What are the Key Properties of Different Baseboard Rubber Materials?

When selecting baseboard rubber for various applications, understanding the properties of the materials is crucial. The most common materials include natural rubber, synthetic rubber (like EPDM), thermoplastic rubber (TPR), and vinyl. Each material has unique characteristics that affect performance, durability, and suitability for specific environments.

Natural Rubber: What Makes it Stand Out?

Natural rubber is known for its excellent elasticity and resilience, making it suitable for high-traffic areas. It can withstand a wide range of temperatures but may degrade when exposed to UV light and certain chemicals.

Pros:

– Exceptional durability and flexibility.

– Good resistance to wear and tear.

– Cost-effective for large projects.

Cons:

– Limited UV and chemical resistance.

– May require additional treatments for outdoor use.

For international buyers, particularly in regions with high UV exposure like Africa and the Middle East, it’s essential to consider protective coatings or alternative materials that offer better longevity.

Synthetic Rubber (EPDM): Why Choose This Option?

Ethylene Propylene Diene Monomer (EPDM) is a synthetic rubber that excels in outdoor applications due to its superior UV and ozone resistance. It can handle extreme temperatures and is often used in environments where moisture is a concern.

Pros:

– Excellent weather resistance and longevity.

– Low maintenance and easy to install.

– Good thermal stability.

Cons:

– Higher upfront cost compared to natural rubber.

– May not be as flexible as natural rubber.

For buyers in Europe and South America, compliance with environmental regulations regarding synthetic materials is crucial. EPDM often meets these standards, making it a reliable choice.

Thermoplastic Rubber (TPR): What Advantages Does it Offer?

Thermoplastic rubber (TPR) combines the properties of rubber and plastic, offering flexibility and durability. It is particularly popular in commercial settings due to its ease of installation and maintenance.

Pros:

– Resistant to chemicals and moisture.

– Available in various colors and designs.

– Can be recycled, making it an eco-friendly option.

Cons:

– Generally more expensive than natural rubber.

– May not perform as well in extreme temperatures.

International buyers should consider the sustainability aspect of TPR, especially in regions like Europe where eco-conscious purchasing is becoming increasingly important.

Vinyl: How Does it Compare?

Vinyl is a synthetic material that is often used for baseboard applications due to its affordability and versatility. It is resistant to moisture and can mimic the appearance of other materials.

Pros:

– Cost-effective and widely available.

– Easy to clean and maintain.

– Available in various designs and colors.

Cons:

– Less durable than rubber options.

– Can crack or fade over time, especially in direct sunlight.

For B2B buyers in Africa and South America, the cost-effectiveness of vinyl makes it an attractive option for budget-conscious projects. However, understanding its limitations is essential for long-term applications.

Illustrative image related to baseboard rubber

Summary Table of Baseboard Rubber Materials

| Material | Typical Use Case for baseboard rubber | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | High-traffic indoor areas | Exceptional durability and flexibility | Limited UV and chemical resistance | Low |

| Synthetic Rubber (EPDM) | Outdoor applications | Excellent weather resistance | Higher upfront cost | High |

| Thermoplastic Rubber (TPR) | Commercial and residential settings | Resistant to chemicals and moisture | More expensive than natural rubber | Medium |

| Vinyl | Budget-friendly projects | Cost-effective and widely available | Less durable than rubber options | Low |

This comprehensive analysis provides B2B buyers with actionable insights into the various materials available for baseboard rubber, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for baseboard rubber

What Are the Main Stages in the Manufacturing Process of Baseboard Rubber?

The manufacturing process of baseboard rubber involves several critical stages that ensure the final product meets the quality and performance expectations of B2B buyers. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality raw materials, primarily rubber compounds. Suppliers typically use natural rubber or synthetic alternatives, such as thermoplastic rubber (TPR), depending on the desired characteristics of the final product. These materials are tested for consistency in chemical composition, elasticity, and durability. Pre-processing may also include grinding rubber scraps for recycling, ensuring minimal waste during production.

-

Forming: Once the materials are prepared, they are mixed with various additives to enhance performance attributes such as flexibility, color, and resistance to wear. The mixture is then processed using techniques such as extrusion or molding. Extrusion involves forcing the rubber through a die to create long strips, while molding shapes the rubber into specific designs, including coved or toeless profiles. This stage requires precision to ensure uniformity in thickness and dimensions.

-

Assembly: After forming, the rubber components may undergo assembly, particularly for products that require multiple pieces or additional features like adhesive backing. This stage can involve manual labor or automated processes, depending on the complexity of the design. Ensuring proper alignment and fit is crucial for the integrity of the final product.

-

Finishing: The final stage involves surface treatments that may include polishing, coating, or adding texture. Finishing not only enhances the aesthetic appeal of the baseboard rubber but also improves its functional properties, such as slip resistance and ease of cleaning. This stage may also include cutting the rubber to specified lengths and packaging the product for distribution.

Which Quality Control Measures Are Essential for Baseboard Rubber?

Quality assurance is paramount in the manufacturing of baseboard rubber, especially for B2B suppliers aiming to meet international standards. Implementing robust quality control (QC) processes ensures that the products are reliable and meet customer specifications.

-

International Standards Compliance: Adhering to internationally recognized standards such as ISO 9001 is crucial. This standard focuses on quality management systems and continuous improvement. Additionally, products may need to comply with industry-specific regulations, such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Effective QC involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This stage assesses raw materials upon arrival to ensure they meet predefined specifications. It may include testing for mechanical properties and chemical composition.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects or deviations from quality standards. This includes checking dimensions and material consistency at various stages.

– Final Quality Control (FQC): Before packaging, a comprehensive inspection is conducted to verify that the final product meets all quality criteria. This may involve physical testing for durability, flexibility, and aesthetic defects. -

Common Testing Methods: Various testing methods are utilized to ensure product quality, including:

– Tensile Strength Testing: Measures the rubber’s ability to withstand pulling forces.

– Hardness Testing: Assesses the firmness of the rubber, which can impact its durability and application.

– Dimensional Inspection: Ensures that all dimensions conform to specifications, crucial for proper installation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is essential to ensure product reliability.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and QC protocols directly. This hands-on approach provides insights into the supplier’s operational efficiency and commitment to quality.

-

Requesting Quality Reports: Suppliers should provide documentation of their QC processes, including results from IQC, IPQC, and FQC. Reports detailing compliance with international standards like ISO 9001 can also be requested to verify adherence to quality management practices.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing and QC processes. These inspections can include comprehensive assessments of raw materials, production methods, and final product testing.

What Are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of QC and certification is critical for B2B buyers operating in international markets. Different regions may have varying standards and regulations that impact product acceptance.

-

Regional Standards Variability: Buyers should be aware that while some standards like ISO 9001 are globally recognized, others may be region-specific. For instance, CE marking is crucial for products sold in Europe, while certain countries in the Middle East may require compliance with local standards.

-

Cultural Considerations in Quality Expectations: Cultural differences can influence perceptions of quality. For example, buyers from Europe may prioritize aesthetic quality, while those from Africa may focus on durability and cost-effectiveness. Understanding these nuances can help suppliers tailor their offerings to meet diverse market needs.

-

Documentation and Traceability: Ensuring that suppliers maintain thorough documentation of their QC processes and product traceability is vital. This not only aids in compliance but also builds trust between buyers and suppliers, facilitating smoother transactions.

In conclusion, the manufacturing and quality assurance processes for baseboard rubber are intricate and require diligent attention to detail. For B2B buyers, understanding these processes and implementing thorough verification practices can significantly enhance their procurement strategies, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘baseboard rubber’

In the competitive landscape of B2B procurement, sourcing high-quality baseboard rubber can significantly impact your project outcomes. This guide aims to provide a practical checklist to streamline the sourcing process for international buyers, ensuring that you make informed decisions tailored to your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Determine the material properties you require, such as durability, flexibility, and resistance to wear and tear. Consider the environment in which the baseboard rubber will be installed, as factors like moisture levels and foot traffic can affect performance.

- Material Types: Decide between options such as thermoplastic rubber (TPR) or traditional rubber, each with distinct benefits.

- Dimensions and Styles: Specify the required height, length, and profile type (e.g., coved or toeless) to align with your design requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that meet your specifications. Utilize online marketplaces, industry directories, and trade shows to compile a list of potential vendors. Understanding the supplier landscape helps you gauge availability and pricing.

- Market Presence: Look for suppliers with a strong reputation in your target regions, including Africa, South America, the Middle East, and Europe.

- Product Range: Ensure that suppliers offer a variety of baseboard rubber options to cater to diverse project needs.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier choice, verify that they possess necessary certifications. This includes compliance with international quality standards and environmental regulations, ensuring that the products meet safety and performance criteria.

- ISO Certifications: Check for ISO certifications relevant to manufacturing and quality management.

- Sustainability Practices: Inquire about eco-friendly practices and materials, which can be crucial for projects with sustainability goals.

Step 4: Request Samples

Requesting product samples is essential to evaluate the quality and suitability of the baseboard rubber. This hands-on approach allows you to assess the material’s texture, color, and flexibility before making a bulk purchase.

- Color Matching: Ensure that the sample matches your design specifications, especially if color consistency is critical.

- Performance Testing: Consider conducting performance tests on samples to verify durability and resistance to common wear factors.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier and evaluated samples, enter into negotiations regarding pricing, payment terms, and delivery schedules. Establishing clear terms upfront can prevent misunderstandings later in the procurement process.

- Volume Discounts: Inquire about pricing breaks for larger orders or long-term contracts.

- Delivery Times: Confirm lead times for production and shipping, especially if you are working within a tight project timeline.

Step 6: Finalize the Order and Review Contracts

After negotiations, finalize the order by reviewing the contract carefully. Ensure that all specifications, pricing, and delivery terms are documented clearly to avoid any discrepancies.

- Clear Terms: Look for clauses related to warranty, return policies, and dispute resolution to safeguard your interests.

- Payment Security: Choose secure payment methods to protect your investment.

Step 7: Plan for Installation and Maintenance

Consider the installation process and any maintenance requirements for the baseboard rubber. Engaging professionals for installation can ensure longevity and proper fitting, while understanding maintenance needs will help preserve the aesthetic and functional quality of the product.

- Installation Guidelines: Verify that the supplier provides comprehensive installation instructions.

- Maintenance Recommendations: Ask for care instructions to maximize the lifespan of the rubber baseboards.

By following these steps, B2B buyers can effectively navigate the sourcing process for baseboard rubber, ensuring that they select high-quality products that meet their project requirements.

Comprehensive Cost and Pricing Analysis for baseboard rubber Sourcing

What Are the Key Cost Components in Baseboard Rubber Sourcing?

When sourcing baseboard rubber, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The type of rubber used significantly influences costs. Standard rubber typically ranges from $2.00 to $3.57 per square foot, while specialized or custom formulations can increase the price. Sourcing high-quality raw materials from reputable suppliers ensures durability and compliance with international standards.

-

Labor: Labor costs encompass both manufacturing and installation. The complexity of the installation process, particularly in custom applications, can lead to higher labor expenses. For international buyers, labor costs can vary widely based on local wage rates.

-

Manufacturing Overhead: This includes costs related to production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, impacting overall pricing.

-

Tooling: Custom designs may require specialized tooling, which can add significant upfront costs. Buyers should consider whether the investment in tooling will provide long-term savings through reduced unit costs.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes is essential, especially for B2B applications. The costs associated with QC can vary based on the supplier’s standards and the certifications they hold, such as ISO compliance.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. Factors such as distance, shipping method, and customs duties can significantly affect total costs.

-

Margin: Supplier margins can vary based on market conditions and competition. Understanding the typical margin for baseboard rubber can help buyers negotiate better terms.

How Do Price Influencers Affect Baseboard Rubber Costs?

Several factors can influence the pricing of baseboard rubber, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to optimize order quantities.

-

Specifications and Customization: Customized products typically incur additional costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials or certifications can lead to increased costs but may provide better long-term value. It’s essential to weigh the benefits of quality against the initial investment.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can significantly affect total landed costs.

What Are the Best Tips for Buyers Negotiating Baseboard Rubber Prices?

Effective negotiation and strategic procurement can lead to significant cost savings. Consider these tips:

-

Leverage Volume Discounts: If possible, consolidate orders to meet or exceed MOQs for better pricing. Discuss potential discounts for larger orders upfront.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Negotiating favorable terms can also strengthen supplier relationships.

-

Calculate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and potential replacements. A higher upfront cost may result in lower TCO if the product is more durable.

-

Research Market Prices: Stay informed about current market prices and trends in the baseboard rubber industry. This knowledge can provide leverage during negotiations.

-

Consider Sourcing Locally: For buyers in Africa, South America, the Middle East, and Europe, local suppliers may offer competitive pricing without the added costs of international shipping.

-

Understand Pricing Nuances: Recognize that international buyers may face different pricing structures due to tariffs, exchange rates, and varying labor costs. Always factor these into your budgeting process.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Always seek updated quotes and conduct thorough due diligence when sourcing baseboard rubber.

Alternatives Analysis: Comparing baseboard rubber With Other Solutions

Exploring Alternatives to Baseboard Rubber in Commercial Spaces

When selecting wall base solutions for commercial environments, buyers often consider various materials that serve similar purposes as baseboard rubber. Understanding the strengths and weaknesses of different options can lead to informed purchasing decisions. Below, we compare baseboard rubber with two viable alternatives: vinyl wall base and wood wall base.

| Comparison Aspect | Baseboard Rubber | Vinyl Wall Base | Wood Wall Base |

|---|---|---|---|

| Performance | Highly durable, flexible, and resistant to moisture and damage. | Good durability, but can be less flexible than rubber. | Natural aesthetics but susceptible to moisture and warping. |

| Cost | Moderate price range ($2.00 – $4.00/sq. ft.). | Typically lower cost ($1.50 – $3.00/sq. ft.). | Higher initial investment ($3.00 – $6.00/sq. ft.). |

| Ease of Implementation | Generally easy to install, especially in curved areas. | Easy installation, often available in rolls for quick application. | Requires skilled installation, especially for custom cuts. |

| Maintenance | Low maintenance; requires occasional cleaning. | Low maintenance, easy to clean. | Higher maintenance; needs refinishing and potential repairs. |

| Best Use Case | Ideal for high-traffic areas needing durability and flexibility. | Suitable for budget-conscious projects with moderate wear. | Best for aesthetic-focused applications in low-traffic areas. |

What Are the Pros and Cons of Vinyl Wall Base as an Alternative?

Vinyl wall base is a popular choice for many commercial spaces due to its affordability and ease of installation. It is available in various colors and styles, making it a versatile option for different interior designs. However, while vinyl is generally durable, it may not offer the same level of flexibility as rubber, which can be a disadvantage in spaces with many curves or angles. Additionally, vinyl may not be as resistant to certain impacts or abrasions, which could lead to quicker wear in high-traffic environments.

How Does Wood Wall Base Compare to Baseboard Rubber?

Wood wall base provides a classic and elegant finish that appeals to many businesses looking to enhance their interior aesthetics. It offers a warm and natural look that can complement various design themes. However, wood is more vulnerable to moisture damage and can warp or swell in humid conditions, making it less suitable for areas prone to spills or water exposure. Furthermore, the installation process can be more complex, often requiring professional skills for precise cuts and fittings. Maintenance is also a consideration, as wood may require periodic refinishing to maintain its appearance.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right wall base solution depends on various factors, including the specific environment, budget constraints, and aesthetic preferences. Baseboard rubber stands out for its durability and flexibility, making it ideal for high-traffic areas. Vinyl wall base offers a cost-effective solution for moderate use, while wood wall base provides a refined look for spaces where moisture is less of a concern. B2B buyers should assess their unique requirements, including traffic levels and maintenance capabilities, to make an informed choice that aligns with their operational needs and design goals.

Illustrative image related to baseboard rubber

Essential Technical Properties and Trade Terminology for baseboard rubber

What Are the Key Technical Properties of Baseboard Rubber?

When selecting baseboard rubber for commercial applications, understanding its technical properties is crucial for ensuring durability, functionality, and overall value. Here are several critical specifications to consider:

-

Material Composition: Baseboard rubber is typically made from natural rubber, synthetic rubber, or thermoplastic rubber (TPR). Natural rubber offers excellent flexibility and resilience, while synthetic options can provide enhanced durability and chemical resistance. TPR combines the best of both worlds, offering flexibility and ease of installation. Understanding the material composition helps buyers select the right product for specific environments, such as high-traffic areas or moisture-prone locations.

-

Thickness and Height: The thickness of rubber baseboards usually ranges from 1/8 inch to 1/4 inch. The height can vary from 2 to 6 inches, with some products available in custom sizes. Thicker baseboards provide better protection against impacts and scuffing, making them ideal for commercial spaces. Height is essential for aesthetic alignment with flooring and wall finishes, as well as for functionality in preventing wall damage.

-

Durability and Wear Resistance: The durability of baseboard rubber is often measured by its abrasion resistance and tensile strength. High-quality rubber should resist wear, tear, and impact, maintaining its appearance and structural integrity over time. Buyers should look for products that meet industry standards for commercial use, ensuring they withstand the demands of busy environments.

-

Chemical Resistance: Depending on the application, baseboard rubber may be exposed to various chemicals, including cleaning agents and oils. A product with high chemical resistance will not fade, crack, or degrade when exposed to these substances. This is particularly important in sectors such as healthcare, food service, and industrial settings, where hygiene and safety are paramount.

-

Color and Finish Options: Baseboard rubber is available in a wide range of colors and finishes, including matte and gloss. This versatility allows businesses to match their interior design schemes while ensuring functionality. Additionally, some products feature UV resistance to prevent fading in sunlit areas, which can be an important consideration for long-term aesthetic maintenance.

What Are Common Trade Terms Related to Baseboard Rubber?

Navigating the procurement process for baseboard rubber involves understanding specific industry terminology. Here are several key terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure they are sourcing products that meet specific quality standards.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQ requirements to effectively manage inventory and budget constraints. Negotiating MOQs can sometimes lead to cost savings, particularly for larger orders.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price quote for specific products or services. It outlines the buyer’s requirements, such as quantity, specifications, and delivery timelines. Using RFQs can streamline the procurement process and ensure competitive pricing.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in shipping and logistics. Familiarity with Incoterms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), can help buyers understand their obligations regarding shipping costs and risk transfer.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for project planning and inventory management, particularly in industries where timing is critical.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing baseboard rubber, ensuring they select products that meet their specific needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the baseboard rubber Sector

What Are the Current Market Dynamics and Key Trends in the Baseboard Rubber Sector?

The baseboard rubber sector is experiencing significant transformation driven by various global factors. The increasing demand for high-performance flooring solutions in commercial and industrial applications is a primary driver. As urbanization accelerates in regions like Africa and South America, there is a rising need for durable and aesthetically pleasing wall base products. Furthermore, the adoption of advanced manufacturing technologies, such as automated production and digital supply chain management, is reshaping sourcing strategies, enabling buyers to obtain customized products efficiently.

Emerging trends include the integration of smart technologies in manufacturing processes. This allows for real-time tracking of inventory levels and product performance, enhancing supply chain efficiency. Additionally, sustainability is becoming a crucial consideration, with buyers increasingly favoring suppliers who demonstrate a commitment to eco-friendly practices. In markets like the Middle East and Europe, where regulations around sustainability are tightening, there is a growing preference for products that meet stringent environmental standards.

International B2B buyers should remain vigilant about price fluctuations driven by raw material availability and geopolitical tensions. The ongoing shift towards e-commerce platforms for procurement also presents opportunities for buyers to access a broader range of suppliers and negotiate better terms. As competition intensifies, understanding these dynamics will be crucial for making informed sourcing decisions.

How Important Is Sustainability and Ethical Sourcing in the Baseboard Rubber Sector?

Sustainability is becoming an essential pillar in the baseboard rubber market, impacting purchasing decisions for B2B buyers. The environmental impact of rubber production, including deforestation and greenhouse gas emissions, is prompting companies to seek sustainable alternatives. Ethical sourcing practices are increasingly important, as consumers and businesses alike demand transparency in supply chains. Buyers are encouraged to engage with suppliers who prioritize responsible sourcing, utilizing recycled materials or sustainable rubber sources.

Certifications such as LEED (Leadership in Energy and Environmental Design) and Cradle to Cradle can serve as valuable indicators of a product’s environmental credentials. These certifications not only enhance a company’s marketability but also align with global sustainability goals. Buyers should assess suppliers based on their commitment to sustainability and ethical practices, fostering partnerships that contribute to a greener supply chain.

Moreover, the shift towards sustainable materials is not just a trend but a necessity for compliance with increasing regulations in various regions. By prioritizing ethical sourcing and sustainability, businesses can mitigate risks and enhance their brand reputation, ultimately attracting more environmentally conscious customers.

What Has Been the Evolution of the Baseboard Rubber Sector?

The baseboard rubber sector has evolved significantly over the past few decades. Initially, the focus was primarily on functionality, with rubber products serving basic protective and aesthetic purposes in commercial settings. However, as design preferences have shifted, manufacturers began to explore innovative designs and colors, catering to the evolving tastes of architects and interior designers.

The introduction of advanced materials, such as thermoplastic rubber (TPR), marked a turning point in the industry, providing improved durability and flexibility. This evolution has enabled the production of versatile baseboard solutions suitable for various applications, from healthcare facilities to educational institutions. Furthermore, the rising emphasis on sustainability has led to the development of eco-friendly rubber products, reflecting a broader industry shift towards responsible manufacturing practices.

Illustrative image related to baseboard rubber

As the market continues to grow, B2B buyers must stay informed about these historical developments to better understand current trends and make strategic sourcing decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of baseboard rubber

-

1. How do I solve issues with baseboard rubber installation?

To address installation challenges with baseboard rubber, ensure that the surface is clean, dry, and free from debris. Use a strong adhesive specifically designed for rubber wall bases to ensure a secure bond. If you’re working with curved walls or corners, consider using flexible rubber materials that can easily conform to the shape. Additionally, always follow manufacturer guidelines for installation techniques, as variations may exist between different brands and products. -

2. What is the best baseboard rubber for high-traffic commercial spaces?

For high-traffic commercial environments, opt for commercial-grade rubber wall bases that are at least 1/8 inch thick. Products made from thermoplastic rubber (TPR) are highly recommended due to their durability, scuff resistance, and ability to withstand heavy foot traffic. Brands like Roppe and Johnsonite offer extensive options designed specifically for demanding applications, ensuring longevity and minimal maintenance. -

3. What are the customization options available for baseboard rubber?

Many suppliers provide customization options for baseboard rubber, including various colors, profiles, and lengths. Some manufacturers allow you to specify dimensions to fit unique installation requirements. It’s advisable to discuss your customization needs directly with suppliers to explore available options, including the possibility of custom colors or patterns that align with your brand identity or design aesthetics. -

4. What is the minimum order quantity (MOQ) for baseboard rubber?

The minimum order quantity for baseboard rubber can vary significantly between suppliers and product types. Generally, MOQs range from as low as 100 linear feet to several hundred feet for bulk orders. It’s essential to inquire with potential suppliers about their specific MOQs, as well as any potential discounts for larger orders, which could significantly reduce your overall cost. -

5. How do I vet potential suppliers for baseboard rubber?

To vet suppliers effectively, begin by checking their reputation through online reviews, client testimonials, and industry references. Request samples to assess product quality firsthand. Additionally, verify their compliance with international standards and certifications, such as ISO or ASTM, which ensure product safety and quality. Engaging in direct communication and asking about their manufacturing processes and timelines can also provide insights into their reliability. -

6. What payment terms should I expect when sourcing baseboard rubber internationally?

Payment terms can vary widely based on the supplier’s policies and your negotiation. Common arrangements include payment in full upfront, a partial deposit with the balance due upon shipment, or payment against documents. Letter of Credit (LC) can also be a secure method for large orders. Always clarify payment terms before placing orders to avoid misunderstandings and ensure a smooth transaction. -

7. How is quality assurance managed in baseboard rubber production?

Quality assurance in baseboard rubber production typically involves multiple stages, including material selection, in-process inspections, and final product testing. Reputable suppliers will adhere to international quality standards, conducting regular audits and tests to ensure their products meet specific performance criteria. Requesting documentation of these quality checks can give you confidence in the products you are sourcing. -

8. What logistics considerations should I keep in mind for importing baseboard rubber?

When importing baseboard rubber, consider factors such as shipping methods, lead times, and customs regulations in your country. It’s crucial to work with suppliers who have experience in international shipping to ensure compliance with import duties and taxes. Additionally, confirm that the supplier can provide the necessary shipping documents, such as a bill of lading and commercial invoice, to facilitate a smooth import process. Collaborating with a reliable logistics provider can also help streamline the shipping and delivery process.

Top 4 Baseboard Rubber Manufacturers & Suppliers List

1. Coveworks – Rubber Wall Base Profiles

Domain: coveworks.com

Registered: 2000 (25 years)

Introduction: Coveworks offers rubber wall base profiles that combine the aesthetic of architectural wood moldings with the durability and low maintenance of thermoplastic rubber. They provide 29 distinctive profiles in 83 standard colors of sculptured rubber wall base, along with traditional 1/8″ wallbase available in vinyl or rubber. Additionally, there are 34 profiles of matching accessories for finishing de…

2. Rubber Baseboard Trim – Durable Solutions for Commercial Spaces

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Rubber baseboard trim is typically used in commercial applications, particularly in healthcare or manufacturing facilities that require frequent washdown procedures. It has evolved from basic designs to more aesthetically pleasing options that mimic MDF while providing durability. However, it can be pricey and may not be suitable for novice DIYers due to its complexity and potential messiness duri…

3. Johnsonite – Rubber Wall Base Molding

Domain: installerstore.com

Registered: 2002 (23 years)

Introduction: Johnsonite Rubber Wall Base – Rubber Baseboard Molding

– Available Heights: 4 inch and 6 inch

– Thickness: .125 inch

– Length Options: 4 foot strips, special order coils in 120 foot or 100 foot lengths

– Colors: Over 30 popular colors plus non-stock colors

– Types: Coved (with toe) and straight (toeless) base

– Application: Easy to apply with Cove Base Adhesive or Step Tape

– Durability: Will not …

4. Roppe – Pinnacle Rubber Wall Base

Domain: flooringinc.com

Registered: 2000 (25 years)

Introduction: Product Name: Roppe Pinnacle 1/8″ x 120′ Rubber Wall Base

Material: 100% thermoset rubber, PVC free, Phthalate Free

Certification: FloorScore certified, qualifies for LEED Credits

Dimensions: Length – 120′, Thickness – 1/8″ (3.2 mm), Height – Available in several heights

Features: Extremely flexible and durable, won’t shrink, gap, or cup, recyclable, easy to install around columns and corners

Pric…

Strategic Sourcing Conclusion and Outlook for baseboard rubber

In today’s competitive landscape, strategic sourcing of baseboard rubber is essential for international B2B buyers. This material not only enhances aesthetic appeal but also provides durability and functionality across various applications, from commercial spaces to residential interiors. By understanding market trends, product specifications, and sourcing strategies, buyers can make informed decisions that align with their project needs and budget constraints.

Investing in high-quality rubber wall base products can lead to long-term cost savings through reduced maintenance and replacement frequency. Additionally, leveraging suppliers who offer diverse product lines, competitive pricing, and quick delivery options can significantly enhance procurement efficiency.

Looking ahead, the demand for baseboard rubber is poised to grow, driven by increasing construction activities and a trend towards sustainable materials. For buyers in Africa, South America, the Middle East, and Europe, now is the time to engage with reliable suppliers who can meet your unique requirements. Embrace the opportunity to streamline your sourcing process, ensuring you stay ahead in the market. Start your journey towards strategic sourcing today, and transform your procurement practices into a competitive advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.