Everything You Need to Know About Base Rubber Sourcing in 2025

Introduction: Navigating the Global Market for base rubber

The quest for high-quality base rubber can be daunting for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With varying product standards, supplier reliability, and fluctuating prices, sourcing the right materials for applications in industries ranging from automotive to consumer goods requires a strategic approach. This guide is designed to navigate the complexities of the global base rubber market, providing insights into types of rubber, their applications, and crucial factors for vetting suppliers.

In this comprehensive resource, we delve into the myriad forms of base rubber available, including their specific properties and uses, to help buyers identify the best fit for their needs. We also discuss the vital aspects of supplier evaluation, including quality assurance, certifications, and logistical considerations that are critical for successful procurement. Furthermore, we cover cost factors and market trends, equipping B2B buyers with the knowledge they need to make informed purchasing decisions.

By leveraging this guide, businesses can enhance their sourcing strategies, ensuring they select the right base rubber products to meet their operational demands. Whether you are based in Nigeria, Germany, or anywhere in between, this resource aims to empower you with actionable insights, facilitating a smoother purchasing process and fostering long-term supplier relationships.

Understanding base rubber Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Rubber Base | Offers high elasticity and flexibility, adapts to nail movements | Nail salons, beauty products | Pros: Durable, enhances nail strength; Cons: May require specific curing equipment. |

| HEMA-Free Rubber Base | Formulated without HEMA, reducing allergy risks | Sensitive skin products, salons | Pros: Safer for clients with sensitivities; Cons: May have limited availability. |

| Tinted Rubber Base | Provides color options while acting as a base coat | Nail art, fashion industries | Pros: Versatile for creative applications; Cons: Color selection may be limited. |

| Builder Rubber Base | Combines strength with a self-leveling formula | Professional nail enhancements | Pros: Excellent for nail extensions; Cons: Requires skilled application. |

| Shimmer Rubber Base | Contains reflective particles for added visual appeal | Fashion-forward salons, events | Pros: Unique aesthetic qualities; Cons: May be more expensive than standard bases. |

What Are the Characteristics of Flexible Rubber Base?

Flexible rubber base is characterized by its exceptional elasticity, allowing it to bend with the natural movement of the nail. This type is ideal for enhancing the durability of nails, particularly for clients with brittle or flaky nail beds. B2B buyers should consider the compatibility of this base with their existing curing equipment, as it typically requires specific LED or UV lamps for optimal performance. Its ability to provide a long-lasting finish makes it a favored choice among nail salons looking to deliver quality services.

Why Choose HEMA-Free Rubber Base for Sensitive Clients?

HEMA-free rubber base is specially formulated to eliminate the common allergen HEMA (2-Hydroxyethyl Methacrylate), making it a safer alternative for clients with sensitivities. This type maintains similar performance characteristics to traditional rubber bases but focuses on client safety. B2B buyers should assess the demand for hypoallergenic products in their target markets, particularly in regions with a higher incidence of allergies. While HEMA-free products may not be as widely available, their unique selling point can differentiate a salon’s offerings.

What Are the Benefits of Tinted Rubber Base?

Tinted rubber base options provide a dual function as both a base coat and a color application, catering to creative professionals in the nail art industry. This product allows nail technicians to achieve a polished look without the need for additional color coats. B2B buyers should evaluate the range of shades available, as a diverse palette can attract a wider customer base. However, it is essential to balance color variety with inventory management to avoid overstocking less popular shades.

How Does Builder Rubber Base Enhance Nail Extensions?

Builder rubber base is designed with a thicker consistency, providing superior strength and support for nail extensions. Its self-leveling properties make it easier for technicians to achieve a smooth finish, which is critical for professional applications. B2B buyers should consider the skill level of their technicians when investing in this product, as proper application techniques are necessary for optimal results. This type is particularly advantageous for salons specializing in nail enhancements and longer-lasting services.

What Makes Shimmer Rubber Base a Trendy Choice?

Shimmer rubber base incorporates reflective particles, offering a unique visual appeal that caters to fashion-forward clients. This type is particularly popular for special events, where clients seek standout nail designs. B2B buyers should assess market trends to determine if shimmer options align with their clientele’s preferences. While they can be priced higher than standard bases, the aesthetic benefits and potential for premium pricing can justify the investment for salons aiming to provide trendy services.

Key Industrial Applications of base rubber

| Industry/Sector | Specific Application of base rubber | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Tire manufacturing | Enhanced durability and performance of tires | Quality certifications, resistance to wear and weather conditions |

| Construction | Sealants and adhesives for building materials | Improved structural integrity and weather resistance | Compliance with local regulations, environmental impact assessments |

| Healthcare | Medical device manufacturing | Biocompatibility and flexibility for medical applications | Certifications (ISO, FDA), material safety data sheets |

| Consumer Goods | Footwear production | Comfort and flexibility in design | Sourcing from sustainable suppliers, variety in rubber types |

| Cosmetics and Beauty | Nail enhancement products | Long-lasting wear and aesthetic appeal | Color variety, compatibility with other products, compliance with cosmetic regulations |

How is Base Rubber Used in the Automotive Industry?

In the automotive sector, base rubber is primarily utilized in tire manufacturing. The inherent flexibility and strength of rubber make it ideal for producing tires that can withstand varying road conditions. Additionally, base rubber’s resistance to wear and weathering enhances the durability of tires, leading to improved vehicle safety and performance. For international buyers, especially in regions like Africa and Europe, sourcing high-quality rubber that meets specific performance standards is crucial to ensure the longevity and safety of their products.

Illustrative image related to base rubber

What Role Does Base Rubber Play in Construction?

Base rubber is widely employed in the construction industry as a key ingredient in sealants and adhesives. Its flexible properties allow for effective sealing of joints and gaps in building materials, which is essential for maintaining structural integrity and providing weather resistance. Buyers in this sector should prioritize suppliers that offer rubber products compliant with local building codes and environmental standards, particularly in regions with diverse climates like South America and the Middle East.

Why is Base Rubber Important in Healthcare Applications?

In healthcare, base rubber is integral to the manufacturing of medical devices, such as flexible tubing and surgical gloves. Its biocompatibility ensures that products are safe for patient use, while its flexibility allows for ease of handling and application. International buyers must focus on sourcing rubber that meets stringent health and safety regulations, such as ISO and FDA certifications, especially when operating in diverse markets across Europe and Africa.

How is Base Rubber Used in Consumer Goods?

The consumer goods industry leverages base rubber in the production of footwear, where it provides comfort and flexibility. Rubber soles enhance the durability and traction of shoes, making them suitable for various activities. Buyers should consider sourcing from suppliers that offer a range of rubber types, ensuring they can meet consumer demands for both style and functionality, particularly in competitive markets in South America and Europe.

What is the Significance of Base Rubber in Cosmetics and Beauty?

In the cosmetics and beauty sector, base rubber is essential for nail enhancement products, such as gel polishes and base coats. Its properties allow for long-lasting wear and a smooth finish, which are critical for consumer satisfaction. B2B buyers in this industry should seek out suppliers that provide a diverse range of colors and formulations, ensuring compatibility with existing product lines while adhering to cosmetic regulations across various international markets.

Illustrative image related to base rubber

3 Common User Pain Points for ‘base rubber’ & Their Solutions

Scenario 1: Ensuring Quality Consistency in Base Rubber Products

The Problem: B2B buyers often encounter significant challenges with product consistency when sourcing base rubber. Variability in quality can stem from differences in manufacturing processes, raw material sources, or even regional standards. This inconsistency can lead to performance issues in final products, impacting customer satisfaction and potentially damaging a brand’s reputation. For example, a beauty product manufacturer might find that one batch of rubber base does not adhere properly, leading to increased returns and customer complaints.

The Solution: To ensure consistent quality, buyers should establish strong relationships with reputable suppliers known for their rigorous quality control processes. It’s advisable to request samples from multiple suppliers and conduct thorough testing before making a larger order. Additionally, implementing a standardized quality assessment procedure upon receipt of the product can help verify adherence to specifications. Buyers should also inquire about the supplier’s sourcing methods and any certifications (e.g., ISO standards) that ensure product reliability. By prioritizing these practices, businesses can mitigate risks associated with product variability and enhance customer trust.

Scenario 2: Navigating Regulatory Compliance for Base Rubber Products

The Problem: International B2B buyers face complexities with regulatory compliance when importing base rubber products. Different countries have varying regulations concerning chemical compositions, safety standards, and environmental impact, which can complicate sourcing decisions. For instance, a company in Germany may struggle to understand the HEMA regulations compared to a supplier in Nigeria, leading to potential legal issues or delays at customs.

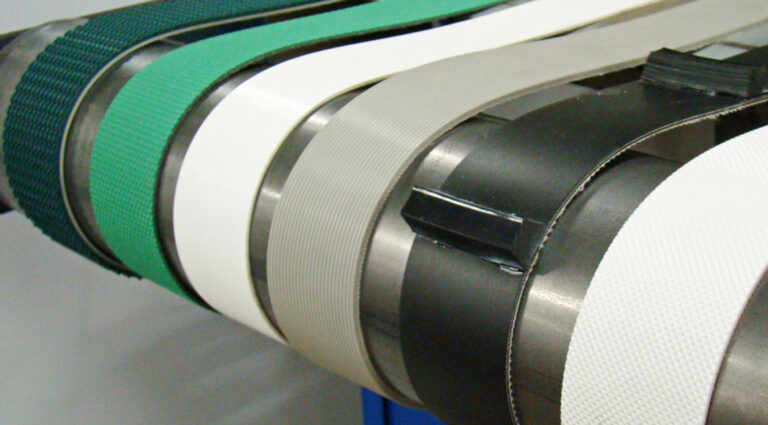

Illustrative image related to base rubber

The Solution: To navigate these regulatory challenges, buyers should invest in comprehensive research regarding the regulations governing base rubber in both the exporting and importing countries. Engaging with a legal expert or compliance consultant who specializes in international trade can provide invaluable insights into regulatory requirements. Buyers should also ensure that their suppliers can provide documentation, such as Material Safety Data Sheets (MSDS) and certificates of compliance, to facilitate smoother customs processes. Establishing a checklist of required documents and maintaining open communication with suppliers can further streamline compliance efforts and reduce the risk of costly delays.

Scenario 3: Addressing Performance Issues with Base Rubber in Applications

The Problem: Many B2B buyers experience performance issues with base rubber in their applications, particularly in the beauty and cosmetic industries. Problems such as poor adhesion, brittleness, or difficulty in curing can lead to subpar products that fail to meet consumer expectations. This is particularly problematic for businesses that rely on creating durable nail enhancements or other cosmetic products where longevity and appearance are critical.

The Solution: To address performance issues, it’s essential for buyers to select the appropriate formulation of base rubber that aligns with their specific application needs. This involves understanding the unique properties of various base rubbers, such as flexibility, curing time, and compatibility with other materials. Conducting pilot tests with different formulations can help identify the best option for the desired end product. Furthermore, providing detailed usage guidelines and training to staff on the correct application techniques can significantly enhance performance. Collaborating with suppliers to receive tailored recommendations based on specific application requirements will also empower businesses to achieve superior results and customer satisfaction.

Strategic Material Selection Guide for base rubber

What are the Key Materials Used in Base Rubber and Their Properties?

When selecting base rubber for various applications, understanding the properties and implications of different materials is crucial for B2B buyers. Here, we analyze four common materials used in base rubber formulations: Polyurethane, Styrene-Butadiene Rubber (SBR), Natural Rubber, and Silicone Rubber. Each material has unique characteristics that impact performance, cost, and suitability for specific applications.

How Does Polyurethane Perform as a Base Rubber Material?

Polyurethane is renowned for its excellent elasticity and resistance to abrasion, making it ideal for applications requiring durability. It can withstand a wide temperature range, typically from -30°C to 80°C, and offers good chemical resistance against oils and solvents. However, its manufacturing complexity can lead to higher costs compared to other materials.

Pros: Exceptional durability, high abrasion resistance, and good flexibility.

Cons: Higher production costs and complexity in processing.

Impact on Application: Suitable for automotive and industrial applications where wear resistance is crucial.

Considerations for Buyers: Compliance with international standards such as ASTM and DIN is essential, especially in regions like Germany, where quality standards are stringent.

What are the Advantages of Styrene-Butadiene Rubber (SBR)?

SBR is a synthetic rubber that combines the properties of natural rubber with the durability of synthetic materials. It has a moderate temperature range of -50°C to 100°C and exhibits good resistance to wear and aging. SBR is cost-effective, making it a popular choice for various applications, including tires and seals.

Pros: Cost-effective, good wear resistance, and relatively easy to process.

Cons: Limited chemical resistance compared to other synthetic rubbers and lower elasticity.

Impact on Application: Ideal for automotive and construction applications, but may not be suitable for exposure to certain chemicals.

Considerations for Buyers: Buyers in Africa and South America should ensure that SBR products meet local compliance standards, as regulations may vary significantly.

How Does Natural Rubber Compare in Base Rubber Applications?

Natural rubber is known for its excellent tensile strength and resilience. It performs well in a temperature range of -40°C to 100°C and has superior elasticity. However, it is less resistant to oils and chemicals, which can limit its applications in certain environments.

Pros: High elasticity, good tensile strength, and excellent wear resistance.

Cons: Poor chemical resistance and susceptibility to aging.

Impact on Application: Suitable for applications where flexibility and strength are paramount, such as in footwear and gaskets.

Considerations for Buyers: Compliance with sustainability standards is increasingly important, especially in European markets where eco-friendliness is prioritized.

What Role Does Silicone Rubber Play in Base Rubber Formulations?

Silicone rubber is characterized by its high-temperature resistance, typically ranging from -60°C to 200°C. It offers excellent chemical stability and is non-toxic, making it suitable for food-grade applications. However, its cost is generally higher than that of other rubber materials, which may deter some buyers.

Pros: Exceptional temperature stability, chemical resistance, and biocompatibility.

Cons: Higher cost and lower tensile strength compared to other rubber types.

Impact on Application: Ideal for medical and food applications where safety and stability are critical.

Considerations for Buyers: International buyers should verify that silicone rubber meets the necessary health and safety regulations in their respective markets.

Summary Table of Material Selection for Base Rubber

| Material | Typical Use Case for base rubber | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Automotive parts, industrial applications | Exceptional durability | Higher production costs | High |

| Styrene-Butadiene Rubber (SBR) | Tires, seals, construction materials | Cost-effective, good wear resistance | Limited chemical resistance | Medium |

| Natural Rubber | Footwear, gaskets | High elasticity, good tensile strength | Poor chemical resistance | Medium |

| Silicone Rubber | Medical devices, food applications | Exceptional temperature stability | Higher cost, lower tensile strength | High |

This analysis provides a strategic overview of material selection for base rubber, guiding international B2B buyers in making informed decisions tailored to their specific applications and regional compliance requirements.

Illustrative image related to base rubber

In-depth Look: Manufacturing Processes and Quality Assurance for base rubber

What Are the Key Stages in the Manufacturing Process of Base Rubber?

The manufacturing of base rubber involves several critical stages, each contributing to the overall quality and functionality of the final product. Understanding these processes is essential for B2B buyers seeking reliable suppliers.

Material Preparation: How Are Raw Materials Processed?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials, primarily natural rubber and various synthetic elastomers. Suppliers often use a mix of polymers to achieve desired properties such as flexibility, durability, and resistance to environmental factors. The raw materials undergo thorough testing to ensure they meet predefined specifications.

Next, these materials are blended with additives such as curing agents, colorants, and stabilizers. The blending process is typically carried out in a controlled environment using advanced machinery to ensure uniformity. This phase is crucial because it determines the physical and chemical properties of the base rubber.

Illustrative image related to base rubber

What Techniques Are Used in Forming Base Rubber?

The forming stage is where the blended material is transformed into usable shapes. This can be done using various techniques, including extrusion, molding, and casting.

-

Extrusion: This method forces the rubber through a die to create continuous shapes, such as sheets or tubes. It is particularly useful for producing large quantities of rubber with consistent cross-sections.

-

Molding: In this process, the rubber is placed into a mold and subjected to heat and pressure. This allows for the creation of complex shapes and is commonly used for products requiring high precision.

-

Casting: This involves pouring the rubber mixture into a mold and allowing it to cure at room temperature or in an oven. It is typically used for smaller production runs or specialized applications.

How Is Base Rubber Assembled and Finished?

After forming, the next stage is assembly, which may include combining different rubber components or integrating them with other materials, such as fabrics or metals. This step is crucial for applications where base rubber is part of a more extensive product, such as automotive parts or medical devices.

Finishing processes, such as trimming, surface treatment, and coating, are also vital. These steps enhance the product’s appearance and functionality, such as improving adhesion properties or providing additional protection against wear and tear.

Illustrative image related to base rubber

What Quality Assurance Measures Are Essential for Base Rubber?

Quality assurance (QA) is a critical component of the manufacturing process for base rubber. For B2B buyers, understanding the relevant international standards and industry-specific certifications is vital for ensuring product reliability.

Which International Standards Should B2B Buyers Consider?

The most recognized standard for quality management systems is ISO 9001. Compliance with ISO 9001 ensures that the supplier has established a framework for consistent quality and continuous improvement. Other industry-specific standards may include:

- CE Marking: For products sold in the European Union, indicating conformity with health, safety, and environmental protection standards.

- API Standards: Relevant for products used in the oil and gas industry, ensuring they meet specific performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints throughout the manufacturing process help maintain product integrity. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial step involves inspecting raw materials for compliance with specifications before they enter the production process.

-

In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to ensure that the processes are yielding products within acceptable limits. This may include measuring dimensions, hardness, and other critical parameters.

-

Final Quality Control (FQC): After the product is completed, it undergoes a final inspection to verify that it meets all specifications and quality standards before shipping.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some actionable strategies:

What Auditing Processes Should Be Implemented?

Conducting regular audits of potential suppliers is an effective way to evaluate their manufacturing practices and quality control measures. Audits should focus on compliance with international standards, production capabilities, and quality management systems.

How Important Are Quality Reports and Third-Party Inspections?

Requesting quality reports and certifications from suppliers can provide insights into their QC processes. Third-party inspections add an extra layer of verification. Independent organizations can assess compliance with industry standards and provide unbiased evaluations of product quality.

What Nuances Should International Buyers Consider in Quality Control?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of regional variations in quality standards and regulations. Understanding local market requirements, such as specific certifications or testing methods, is essential for ensuring compliance and market entry.

Furthermore, language barriers and differences in business practices can complicate communication about quality expectations. Establishing clear agreements and maintaining open lines of communication with suppliers can help mitigate these challenges.

Illustrative image related to base rubber

Conclusion: The Importance of Manufacturing Processes and Quality Assurance

For B2B buyers, understanding the manufacturing processes and quality assurance measures for base rubber is essential for making informed purchasing decisions. By focusing on material preparation, forming techniques, and robust QC practices, buyers can ensure they partner with reliable suppliers that meet their quality standards. This knowledge not only enhances product quality but also fosters long-term business relationships in the competitive rubber market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘base rubber’

To assist B2B buyers in navigating the procurement of base rubber, this guide provides a comprehensive checklist that outlines essential steps for effective sourcing. By following this structured approach, you can ensure that your purchasing decisions are informed, strategic, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of any successful procurement strategy. Define the physical properties of the base rubber you need, such as flexibility, durability, and compatibility with other materials. Consider the end-use applications, as different formulations may be required for various products, such as nail enhancements or industrial applications.

Illustrative image related to base rubber

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in base rubber products. Look for companies with a proven track record in the industry and positive customer reviews. Utilize online platforms, trade shows, and industry publications to gather information about suppliers’ capabilities and product offerings.

- Consider regional suppliers: Depending on your location, sourcing from nearby suppliers can reduce shipping costs and lead times.

- Review product portfolios: Check if the suppliers offer a variety of base rubber formulations to suit your diverse needs.

Step 3: Evaluate Supplier Certifications

Before moving forward, it’s crucial to verify that your selected suppliers hold relevant certifications. Look for compliance with international standards such as ISO, which indicates quality assurance and operational excellence. Certifications also ensure that the products meet safety and environmental regulations, which is particularly important for industries like cosmetics and manufacturing.

Step 4: Request Samples for Testing

Always request samples from shortlisted suppliers to evaluate the quality and performance of their base rubber products. Testing samples allows you to assess factors such as adhesion, strength, and flexibility under real-world conditions. This step is vital to ensure that the materials will perform as expected in your specific applications.

Illustrative image related to base rubber

- Conduct comparative analysis: Test samples from multiple suppliers to determine the best fit for your needs.

- Involve technical teams: Engage your product development or technical teams in the testing process to gather insights on usability.

Step 5: Negotiate Terms and Pricing

Once you have selected a preferred supplier based on product quality, it’s time to negotiate terms. Discuss pricing, payment options, and delivery timelines to ensure they align with your budget and operational needs. Be transparent about your expectations to foster a positive relationship with the supplier.

- Consider bulk discounts: If you plan to order large quantities, inquire about volume discounts or long-term contract options.

- Discuss logistics: Clarify shipping methods and lead times to avoid any disruptions in your supply chain.

Step 6: Establish Communication Channels

Effective communication with your supplier is key to a successful partnership. Set up regular check-ins or updates to discuss order statuses, potential issues, or changes in requirements. Clear communication ensures that both parties are aligned and can respond swiftly to any challenges.

Step 7: Monitor Supplier Performance

After procurement, it’s important to continuously monitor the performance of your suppliers. Evaluate their adherence to delivery schedules, product quality, and responsiveness to inquiries. Regular assessments will help you identify any potential issues early and allow for timely interventions.

By following these steps, B2B buyers can streamline their sourcing process for base rubber, ensuring that they select the right suppliers and materials to meet their business objectives effectively.

Comprehensive Cost and Pricing Analysis for base rubber Sourcing

What are the Key Cost Components in Base Rubber Sourcing?

When sourcing base rubber, understanding the cost structure is essential for international B2B buyers. The primary components include:

-

Materials: The quality of raw materials significantly impacts pricing. Base rubber typically consists of natural rubber, synthetic rubber, or a blend, which can vary in cost based on global supply and demand dynamics.

-

Labor: Labor costs can fluctuate based on the region of production. In regions like Africa and South America, labor may be less expensive compared to Europe, which can affect the overall cost of production.

-

Manufacturing Overhead: This encompasses costs associated with factory operation, including utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, ultimately lowering the price for buyers.

-

Tooling: Initial tooling costs for molds and production equipment can be significant, especially for custom specifications. These costs are typically amortized over the production volume, impacting unit pricing.

-

Quality Control (QC): Rigorous quality control processes are vital to ensure the consistency and reliability of base rubber products. Investing in QC can lead to higher upfront costs but can save money in the long run by reducing defects and returns.

-

Logistics: Transportation and warehousing costs can vary widely depending on the location of the supplier and the buyer. For international transactions, understanding shipping costs, tariffs, and delivery times is crucial.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure sustainability. This margin can vary based on market conditions and the supplier’s positioning.

How Do Price Influencers Affect Base Rubber Costs?

Several factors influence the pricing of base rubber, particularly for international buyers:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to negotiate better terms.

-

Specifications and Customization: Custom formulations or specific grades of rubber may incur additional costs. Buyers should clarify their requirements upfront to avoid unexpected price increases.

-

Material Quality and Certifications: High-quality materials and certifications (e.g., ISO, ASTM) can lead to higher prices but may be essential for certain applications. Buyers should weigh the cost against the benefits of quality assurance.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers with a proven track record may charge more but often provide better service and product consistency.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, impacting the total cost of ownership.

What Are the Best Buyer Tips for Cost-Efficiency in Base Rubber Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are actionable tips for optimizing costs:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, payment terms, and delivery schedules. Building a long-term relationship with suppliers can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but all associated costs, including logistics, storage, and potential wastage. This comprehensive view can lead to more informed purchasing decisions.

-

Stay Informed About Market Trends: Keep abreast of market conditions that affect rubber prices, such as changes in raw material availability or geopolitical factors. This knowledge can provide leverage during negotiations.

-

Leverage Technology for Efficiency: Utilize supply chain management software and analytics to optimize procurement processes, reduce waste, and improve forecasting accuracy.

-

Explore Local Suppliers: For buyers in Africa and South America, consider sourcing from local suppliers to reduce shipping costs and lead times. This strategy can also support local economies.

Conclusion

In summary, understanding the cost components and price influencers in base rubber sourcing is crucial for B2B buyers. By employing strategic negotiation techniques and considering the total cost of ownership, buyers can optimize their procurement processes and achieve cost efficiency in their operations. Always remember that prices can fluctuate, so staying informed and adaptable is key to successful sourcing.

Alternatives Analysis: Comparing base rubber With Other Solutions

Understanding Alternative Solutions to Base Rubber

In the competitive landscape of B2B product sourcing, understanding the alternatives to base rubber is essential for informed decision-making. Base rubber is frequently utilized for its flexibility and strength in various applications, including nail enhancements and industrial products. However, there are several alternative materials and technologies that can serve similar purposes. This analysis will compare base rubber against two notable alternatives: acrylic gel and poly gel.

Comparison Table

| Comparison Aspect | Base Rubber | Acrylic Gel | Poly Gel |

|---|---|---|---|

| Performance | Excellent flexibility and adhesion | Strong, durable, and versatile | Lightweight, easy to mold |

| Cost | Mid-range pricing | Generally higher than base rubber | Typically lower than acrylic |

| Ease of Implementation | Requires specific curing techniques | Moderate; needs skill for application | User-friendly, ideal for beginners |

| Maintenance | Regular touch-ups required | Long-lasting with occasional maintenance | Fewer touch-ups needed |

| Best Use Case | Nail enhancements and molds | Professional nail art and repairs | DIY applications and beginners |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Acrylic Gel?

Acrylic gel is a popular choice among nail technicians due to its strength and durability. It offers a robust finish that can withstand daily wear and tear, making it suitable for professional nail applications. However, the cost of acrylic gel tends to be higher than base rubber, which can be a consideration for budget-conscious buyers. Furthermore, the application process requires a certain level of skill, making it less accessible for beginners. While acrylic gel provides a long-lasting solution, it may necessitate more time-consuming maintenance to keep nails looking fresh.

Illustrative image related to base rubber

How Does Poly Gel Compare to Base Rubber?

Poly gel is an innovative alternative that combines the best features of both acrylic and gel systems. It is lightweight, easy to mold, and generally more affordable than acrylic gel. This makes it an attractive option for DIY enthusiasts and beginners who are looking for user-friendly solutions. One significant advantage of poly gel is its lower maintenance requirement; it tends to last longer between applications, reducing the need for frequent touch-ups. However, its performance may not match that of base rubber in terms of flexibility, which can be a critical factor depending on the specific application.

Conclusion: Which Solution Should B2B Buyers Choose?

When selecting between base rubber and its alternatives, B2B buyers should consider their specific needs and the context of their applications. Base rubber excels in flexibility and strength, making it ideal for professional nail enhancements. Acrylic gel offers superior durability but at a higher cost and requires more skill for application. Poly gel presents a budget-friendly, user-friendly alternative, especially for those new to the industry. Ultimately, the choice will depend on factors such as budget, expertise, and the desired performance of the final product. By carefully weighing these alternatives, buyers can make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for base rubber

What Are the Essential Technical Properties of Base Rubber?

Base rubber is a critical component in various industries, particularly in the production of flexible and durable products. Understanding its technical properties is essential for B2B buyers to ensure they are selecting the right material for their specific applications. Here are some key properties:

1. Material Grade

Material grade refers to the classification of rubber based on its composition and intended application. Common grades include natural rubber (NR), styrene-butadiene rubber (SBR), and ethylene propylene diene monomer (EPDM). Each grade has distinct characteristics such as elasticity, tensile strength, and heat resistance. For B2B buyers, selecting the appropriate grade is crucial for product performance and longevity.

2. Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress that a rubber material can withstand before failing. It is usually expressed in megapascals (MPa). High tensile strength is vital for applications that involve stretching or heavy loads, such as automotive tires and industrial belts. Buyers should prioritize this property to ensure the durability of their products.

3. Elongation at Break

Elongation at break indicates how much a rubber material can stretch before it breaks, expressed as a percentage of its original length. This property is particularly important for applications requiring flexibility and resilience, such as seals and gaskets. Understanding this characteristic helps buyers assess how well the rubber will perform under dynamic conditions.

4. Hardness (Shore A)

Hardness is measured using the Shore A scale, which quantifies the resistance of rubber to indentation. The hardness level affects the rubber’s flexibility, durability, and overall performance. Softer rubbers are typically used in applications requiring a high degree of flexibility, while harder rubbers are used for more rigid applications. Buyers must consider hardness to match their product requirements with the right rubber type.

5. Compression Set

Compression set refers to the rubber’s ability to return to its original thickness after being compressed under a specified load for a set period. A low compression set indicates better performance in maintaining shape and functionality over time. This property is essential for products like seals and gaskets, where maintaining a tight fit is crucial for preventing leaks.

What Are Common Trade Terms Associated with Base Rubber?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms related to base rubber:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the rubber industry, this term often refers to manufacturers who supply rubber components to larger brands for final products. Understanding OEM relationships can help buyers identify quality suppliers who meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers who need to understand their purchasing limits and inventory requirements. Knowing the MOQ helps in budgeting and planning for production runs.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products. It typically includes detailed specifications, quantities, and delivery timelines. Submitting a well-structured RFQ is essential for receiving accurate and competitive pricing from potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) dictate the shipping responsibilities and costs, making them vital for B2B transactions involving base rubber.

5. Lead Time

Lead time is the duration between the initiation of an order and its completion. For base rubber procurement, understanding lead times is critical for production scheduling and inventory management. Buyers should factor in lead times when planning their supply chain operations to avoid delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing base rubber, ensuring that they select the right materials and suppliers for their needs.

Navigating Market Dynamics and Sourcing Trends in the base rubber Sector

What Are the Current Market Dynamics and Key Trends in the Base Rubber Sector?

The base rubber market is experiencing significant shifts driven by various global factors. Notably, the increasing demand for sustainable and eco-friendly products is shaping sourcing strategies. B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focusing on suppliers that prioritize sustainable practices. This is partly due to stringent regulations in European markets, where companies are expected to comply with environmental standards. Furthermore, the ongoing digitization of supply chains has led to a rise in e-commerce platforms that facilitate easier sourcing and purchasing of base rubber products.

Emerging technologies such as blockchain are also influencing the base rubber sector, allowing for enhanced traceability and transparency in supply chains. This is particularly relevant for B2B buyers who need assurance regarding the origins of their materials. Additionally, innovations in production processes, including the use of synthetic alternatives and recycled materials, are gaining traction. These advancements are not only addressing the environmental concerns associated with traditional rubber sourcing but are also providing cost-effective solutions for businesses.

Furthermore, as consumer preferences shift towards customized and high-quality products, B2B buyers must adapt their sourcing strategies to include suppliers who can offer diverse product ranges, such as tinted rubber bases and specialized formulations that cater to specific market needs.

How Is Sustainability Influencing Sourcing Practices in the Base Rubber Industry?

Sustainability is becoming a cornerstone of sourcing practices in the base rubber sector. With the environmental impact of rubber production under scrutiny, companies are prioritizing ethical sourcing and supply chain transparency. B2B buyers are increasingly seeking suppliers who can demonstrate compliance with environmental standards and sustainability certifications. This is not only a response to consumer demand for greener products but also a proactive approach to mitigate risks associated with regulatory changes.

Ethical sourcing involves ensuring that the raw materials used in base rubber production are obtained responsibly, without contributing to deforestation or exploiting labor. Buyers should look for suppliers who are certified by recognized organizations, such as the Forest Stewardship Council (FSC) or those adhering to the Global Organic Textile Standard (GOTS). These certifications indicate that the materials are sourced sustainably and meet high environmental and social standards.

In addition, the development of bio-based and recycled rubber materials is gaining momentum. These alternatives reduce reliance on petrochemical resources and lower carbon footprints, making them attractive options for environmentally conscious B2B buyers. By investing in sustainable materials, companies not only enhance their brand reputation but also align themselves with global sustainability goals.

What Is the Historical Context of the Base Rubber Market and Its Evolution?

The base rubber market has evolved significantly over the past few decades. Initially dominated by natural rubber sourced from rubber trees, the industry has seen a substantial shift towards synthetic rubber due to its versatility and cost-effectiveness. The rise of synthetic alternatives was largely driven by the need for consistent quality and supply, as well as the growing demand from various industries such as automotive and consumer goods.

In recent years, the focus has shifted again towards sustainability, with a renewed interest in natural rubber production. The development of sustainable harvesting practices and the introduction of high-yield rubber tree varieties are helping to meet the increasing demand without compromising environmental integrity. As a result, today’s base rubber market is characterized by a blend of traditional practices and modern innovations, making it essential for B2B buyers to stay informed about the latest trends and sourcing strategies.

In summary, understanding the dynamics of the base rubber market—encompassing current trends, sustainability practices, and historical context—enables international B2B buyers to make informed decisions that align with both their business goals and global sustainability initiatives.

Frequently Asked Questions (FAQs) for B2B Buyers of base rubber

-

How do I solve sourcing challenges for base rubber in international markets?

To address sourcing challenges for base rubber, start by identifying reliable suppliers in regions with a strong rubber industry, such as Southeast Asia or Africa. Conduct thorough research on potential suppliers, focusing on their certifications, production capacity, and delivery timelines. Utilize trade platforms and attend industry trade shows to network with manufacturers and distributors. Establishing relationships with local agents can also facilitate smoother transactions and provide insights into market trends and pricing. -

What is the best base rubber for durable applications?

The best base rubber for durable applications often includes synthetic options like SBR (Styrene-Butadiene Rubber) or EPDM (Ethylene Propylene Diene Monomer) due to their excellent wear resistance and flexibility. For applications requiring high performance, consider rubber blends that incorporate additives to enhance strength and longevity. Evaluate the specific requirements of your application, including exposure to chemicals or extreme temperatures, to select the most suitable base rubber type. -

How can I vet suppliers for quality assurance in base rubber?

To vet suppliers effectively, request samples of their base rubber products for testing against industry standards. Verify their certifications, such as ISO or ASTM, which indicate compliance with quality management systems. Conduct factory visits if possible, or rely on third-party audits to assess their production processes. Additionally, seek references from other businesses that have previously sourced from the supplier to gauge their reliability and product quality. -

What are the typical minimum order quantities (MOQs) for base rubber?

Minimum order quantities for base rubber can vary significantly depending on the supplier and the type of rubber. Generally, MOQs may range from 100 kg to several tons for bulk orders. It’s crucial to discuss MOQs directly with suppliers, as some may offer flexibility for first-time orders or for specific applications. Always clarify the terms during negotiations to avoid unexpected costs. -

What payment terms are standard for international transactions of base rubber?

Standard payment terms for international transactions often include options like Letter of Credit (LC), advance payment, or payment upon delivery. Many suppliers may require a deposit upfront, typically ranging from 30% to 50% of the total order value. Be sure to confirm the payment terms before finalizing the contract, and consider using secure payment platforms that provide buyer protection to mitigate risks associated with international trade. -

How do I handle logistics and shipping for base rubber purchases?

When managing logistics for base rubber purchases, coordinate closely with your supplier to determine the best shipping method, whether by air or sea. Consider factors such as cost, delivery time, and the volume of the order. Utilize freight forwarders who specialize in international shipping to navigate customs regulations and ensure compliance with import/export laws. Additionally, track shipments regularly to preempt any delays in delivery. -

What customization options should I consider when sourcing base rubber?

Customization options for base rubber can include variations in hardness, color, and specific chemical formulations tailored to your application needs. Discuss your requirements with suppliers to explore available options, such as adding specific additives for enhanced performance. Many manufacturers can accommodate custom orders, so providing detailed specifications will help ensure that the final product meets your expectations. -

What are the common quality control measures for base rubber?

Common quality control measures for base rubber involve routine testing for mechanical properties, such as tensile strength and elasticity, as well as chemical composition analysis. Suppliers should implement strict quality assurance protocols throughout the production process, including raw material inspection and finished product testing. Request documentation of these quality control processes, including test results, to ensure that the base rubber meets your quality standards before shipment.

Top 5 Base Rubber Manufacturers & Suppliers List

1. V Beauty Pure – Rubber Base & Gel Polish

Domain: vbeautypure.com

Registered: 2021 (4 years)

Introduction: Rubber Base | Gel Polish | V Beauty Pure

Collections:

– Beginner Kit: $71.75 (Sale: $53.81)

– The Originals Collection: $101.70 (Sale: $76.27)

– Romantic Retreat Collection: $101.70 (Sale: $76.27)

– In Luxe With You Collection: $101.70 (Sale: $76.27)

– Glitter Addiction Collection: $101.70 (Sale: $76.27)

Individual Products:

– Bejeweled: $16.95 (Sale: $12.71)

– Bet On It: $16.95 (Sale: $12.71)

-…

2. Kiarasky – Rubber Base Starter Kit

Domain: kiarasky.com

Registered: 2014 (11 years)

Introduction: Rubber Base Starter Kit designed for all skill levels. Includes Prep and Primer for nail bed preparation and adhesion, a precision Nail Art Brush M Liner for detailed application, and a choice of 3 Tinted Rubber Top Coats that serve as a strengthening base and tinted top coat. Ideal for professionals and beginners, providing essentials for durable nail enhancements. Available Tinted Rubber Top Coa…

3. The GelBottle Inc™ – Rubber Base Gel

Domain: thegelbottle.us

Registered: 2017 (8 years)

Introduction: Rubber Base | Clear Base Gel | The GelBottle Inc™

– Type: Rubber nail base coat

– Features: Flexible, bends with the nail, designed for extra strength

– Ideal for: Flaky, brittle, thin, or splitting nails

– Sizes available: 20ml (approx. 75 sets), 7ml (approx. 25 sets)

– Price: $21.00 (incl. TAX) / $21.00 (excl. TAX)

– Ingredients: DIPENTAERYTHRITOL PENTAACRYLATE, HYDROXYPROPYL METHACRYLATE, 2-HYD…

4. Reddit – Rubber Base Gel

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Rubber base is a flexible base gel used in nail applications. It is not strong enough for extensions but can be used underneath them. It is particularly beneficial for individuals with flexible or weak nails, as it helps prevent extensions from popping off and allows natural nails to grow without breaking. Users report that it holds better than regular nail glue and provides protection while allow…

5. Tones Products – Rubber Base Gel

Domain: tonesproducts.com

Registered: 2012 (13 years)

Introduction: This company, Tones Products – Rubber Base Gel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for base rubber

In the ever-evolving landscape of base rubber sourcing, understanding market dynamics and leveraging strategic partnerships is paramount. As highlighted throughout this guide, the diverse applications of base rubber—from nail enhancements to industrial uses—underscore its growing significance across various sectors. International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, must prioritize suppliers who not only offer competitive pricing but also guarantee quality and compliance with global standards.

Investing in strategic sourcing initiatives can significantly enhance operational efficiency and product reliability. By focusing on sustainable practices and innovative solutions, businesses can ensure long-term success and resilience against market fluctuations. Collaborating with suppliers who demonstrate a commitment to quality and customer satisfaction will yield substantial benefits.

Looking ahead, the demand for high-quality base rubber is set to rise as industries continue to innovate and expand. Now is the opportune moment for B2B buyers to engage with reputable suppliers, explore new products, and strengthen their supply chains. By doing so, they can position themselves advantageously in a competitive market, ready to seize emerging opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to base rubber