Everything You Need to Know About Balloon Stuffing Machine Sourcing in 2025

Introduction: Navigating the Global Market for balloon stuffing machine

In the dynamic landscape of the global gift and event planning industry, sourcing a reliable balloon stuffing machine presents a significant challenge for B2B buyers. As businesses look to enhance their product offerings with innovative gift solutions, understanding the nuances of these machines becomes crucial. This guide serves as a comprehensive resource, exploring the various types of balloon stuffing machines available, their diverse applications, and essential tips for supplier vetting. Furthermore, we delve into cost considerations, helping buyers make informed financial decisions that align with their business goals.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—navigating this market requires a strategic approach. This guide empowers you with actionable insights, ensuring that you can confidently select the right equipment for your operational needs. By addressing common concerns, such as machine reliability and inflation efficiency, and offering guidance on supplier partnerships, we aim to facilitate a smoother purchasing process. With the right information at your fingertips, you’ll be well-equipped to capitalize on the growing demand for unique balloon arrangements and elevate your business’s competitive edge.

Understanding balloon stuffing machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Balloon Stuffing Machine | Operated by hand; no electricity required | Small event planners, DIY gift shops | Pros: Cost-effective, portable. Cons: Labor-intensive, slower production rate. |

| Electric Balloon Stuffing Machine | Automated inflation and stuffing; higher efficiency | Large event planners, balloon retailers | Pros: Fast operation, consistent results. Cons: Higher initial investment, requires power source. |

| Professional Balloon Stuffing Kit | Includes machine, accessories, and quality balloons | Startups, small businesses | Pros: Comprehensive setup, good quality materials. Cons: Can be expensive, may include unused extras. |

| Compact Balloon Stuffing Device | Lightweight and portable; designed for small operations | Pop-up shops, mobile vendors | Pros: Easy to transport, space-saving. Cons: Limited capacity, may not handle larger items. |

| Specialty Balloon Stuffing Machine | Features for specific items (e.g., plush toys, gifts) | Custom gift shops, party supply stores | Pros: Versatile for unique items, attracts niche markets. Cons: Higher cost, may require training. |

What Are the Key Characteristics of Manual Balloon Stuffing Machines?

Manual balloon stuffing machines are operated by hand and do not require electricity, making them highly portable and cost-effective. They are ideal for small businesses, event planners, or DIY gift shops that need a simple solution for balloon stuffing. However, they can be labor-intensive and may result in slower production rates compared to electric models. B2B buyers should consider their operational scale and the volume of orders when evaluating this option.

How Do Electric Balloon Stuffing Machines Enhance Efficiency?

Electric balloon stuffing machines automate the inflation and stuffing process, significantly increasing efficiency and consistency in production. These machines are perfect for large event planners and balloon retailers who require a high output with minimal manual labor. Although the initial investment is higher and they require a power source, the time savings and reliability can lead to increased profitability for businesses that operate at scale.

What Should Startups Know About Professional Balloon Stuffing Kits?

Professional balloon stuffing kits typically include a machine, accessories, and high-quality balloons, providing a comprehensive setup for startups or small businesses. These kits are designed to facilitate easy entry into the balloon stuffing market. However, they can be expensive, and buyers may find themselves with additional items that they may not need. It’s essential for B2B buyers to assess their specific needs and budget before making a purchase.

What Advantages Do Compact Balloon Stuffing Devices Offer?

Compact balloon stuffing devices are lightweight and designed for small operations, making them suitable for pop-up shops and mobile vendors. They save space and are easy to transport, which is advantageous for businesses that need flexibility. However, these devices often have limited capacity and may struggle with larger items, so businesses should evaluate their product offerings to ensure compatibility.

How Can Specialty Balloon Stuffing Machines Cater to Niche Markets?

Specialty balloon stuffing machines are tailored for specific items, such as plush toys or unique gifts, enabling businesses to cater to niche markets. This versatility can attract customers looking for customized gifts, enhancing the business’s appeal. However, these machines often come at a higher cost and may require additional training to operate effectively. B2B buyers should consider their target market and the potential return on investment when exploring this option.

Key Industrial Applications of balloon stuffing machine

| Industry/Sector | Specific Application of Balloon Stuffing Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Event Planning & Decoration | Creating customized balloon centerpieces for events | Enhances event aesthetics and personalization of gifts | Quality and durability of balloons; ease of use of the machine |

| Retail & E-commerce | Offering stuffed balloon gifts for special occasions | Differentiates product offerings and increases customer engagement | Availability of diverse balloon sizes and styles; reliable suppliers |

| Gift Shops | Producing unique gift options for various celebrations | Boosts sales through innovative gift solutions | Consistency in balloon quality; machine maintenance support |

| Party Supplies Wholesale | Supplying bulk stuffed balloons for parties and events | Streamlines production and reduces labor costs | Bulk pricing options; machine capacity to handle large volumes |

| Floristry | Integrating balloon stuffing into floral arrangements | Expands service offerings and enhances floral displays | Compatibility with floral materials; training for staff usage |

How is the Balloon Stuffing Machine Used in Event Planning and Decoration?

In the event planning industry, balloon stuffing machines are utilized to create visually striking centerpieces and decorations that enhance the overall aesthetic of various events, from weddings to corporate gatherings. By allowing planners to personalize gifts and decorations with unique items inside clear balloons, these machines solve the problem of standardization in event decor. Buyers in this sector should prioritize machines that are easy to operate and maintain, ensuring a reliable supply of high-quality balloons that can withstand diverse environmental conditions.

What Role Does the Balloon Stuffing Machine Play in Retail and E-commerce?

Retailers and e-commerce businesses leverage balloon stuffing machines to produce customized balloon gifts for birthdays, anniversaries, and other special occasions. This capability not only differentiates their product offerings but also fosters customer loyalty through personalized gift options. For international buyers, particularly in regions like Africa and South America, sourcing durable machines with a variety of balloon sizes and styles is essential to meet diverse consumer preferences and withstand varying shipping conditions.

How Can Gift Shops Benefit from Balloon Stuffing Machines?

Gift shops utilize balloon stuffing machines to create unique and memorable gift options that stand out in a competitive market. The ability to offer stuffed balloons filled with toys, flowers, or other items can significantly boost sales and attract a diverse clientele. For buyers, ensuring a consistent quality of balloons and reliable machine performance is crucial for maintaining customer satisfaction and operational efficiency, especially in high-demand periods.

Illustrative image related to balloon stuffing machine

In What Ways Do Party Supplies Wholesalers Use Balloon Stuffing Machines?

Party supplies wholesalers capitalize on balloon stuffing machines to produce large quantities of stuffed balloons for various celebrations, including birthdays and holidays. This streamlining of production not only reduces labor costs but also increases the speed of order fulfillment, enhancing overall business efficiency. Key considerations for these buyers include negotiating bulk pricing options and ensuring that the machines have sufficient capacity to meet high-volume demands, particularly during peak seasons.

How Do Florists Integrate Balloon Stuffing Machines into Their Offerings?

Florists are increasingly incorporating balloon stuffing machines into their floral arrangements, creating unique combinations of flowers and balloons that capture customer interest. This integration allows florists to expand their service offerings and enhance the visual appeal of their arrangements. Buyers in this sector should consider the compatibility of the machine with floral materials and the need for staff training to effectively use the equipment, ensuring a seamless blend of products that meets customer expectations.

3 Common User Pain Points for ‘balloon stuffing machine’ & Their Solutions

Scenario 1: Difficulty in Balloon Inflation Leading to Poor Quality Products

The Problem: Many B2B buyers experience frustration when the balloon stuffing machines they invest in fail to inflate balloons properly. This can lead to inconsistent product quality, where some balloons are under-inflated and others are at risk of bursting. This inconsistency can damage client relationships, especially when high-quality, well-presentation gifts are expected for events such as weddings or corporate functions. Buyers may also find themselves wasting time and materials, further escalating costs.

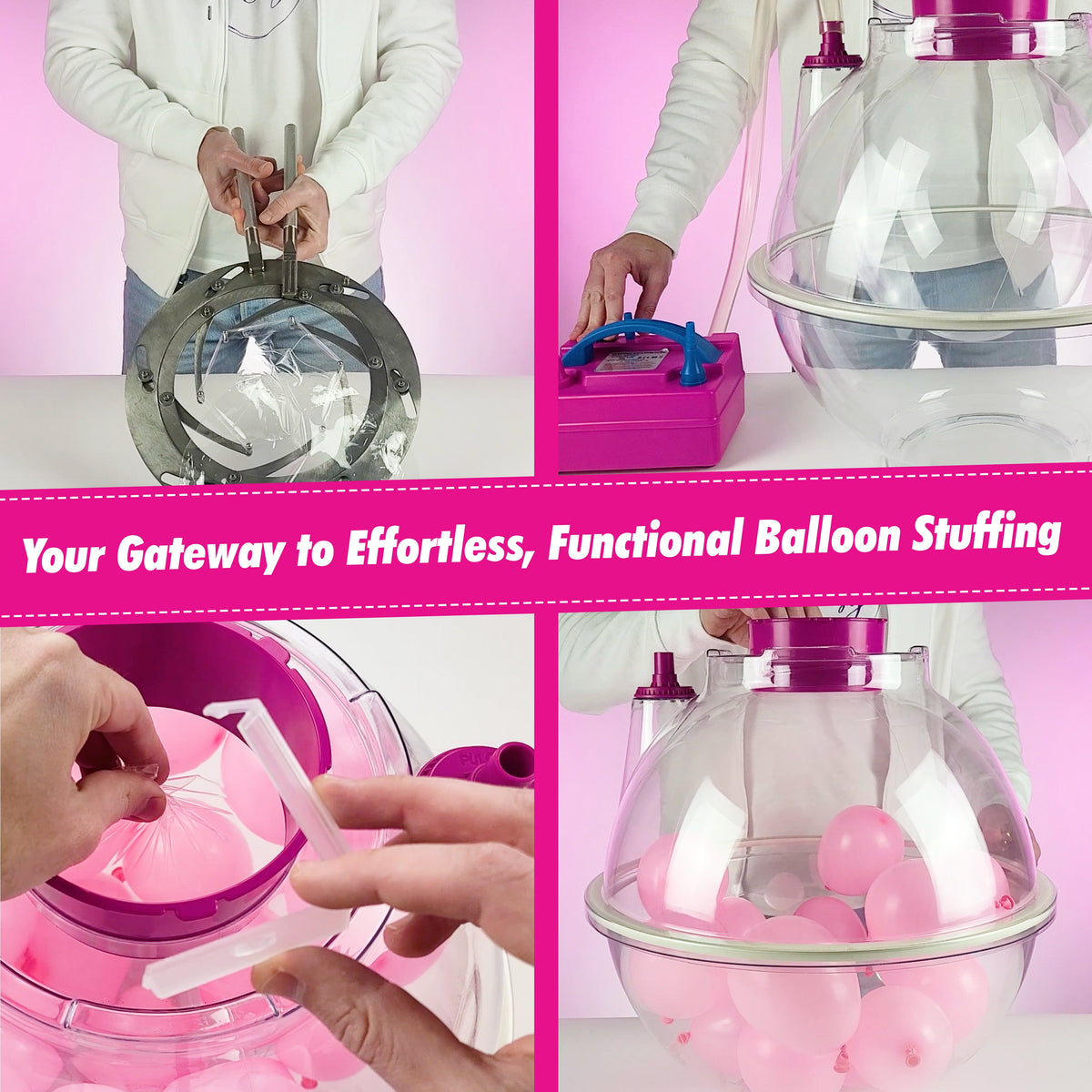

Illustrative image related to balloon stuffing machine

The Solution: To mitigate this issue, B2B buyers should focus on sourcing machines with robust inflation capabilities. Look for machines that feature high-quality electric pumps specifically designed for balloon stuffing. Additionally, selecting machines that come with adjustable inflation settings can allow users to customize the inflation level based on the size and type of balloon. Investing in a reputable brand known for its reliability can also reduce the risk of receiving faulty equipment. Prioritize suppliers who offer thorough product demonstrations and user manuals to ensure that your team is well-trained in using the equipment effectively.

Scenario 2: Inefficiency in Operation Leading to Increased Labor Costs

The Problem: A common pain point for businesses using balloon stuffing machines is the inefficiency of operation, which often results in longer production times and increased labor costs. When machines are cumbersome or complicated to operate, staff may struggle to keep up with demand, leading to delays in fulfilling orders. This inefficiency can also result in employee frustration and decreased morale, further complicating operations.

The Solution: To address this inefficiency, B2B buyers should seek out machines that are ergonomically designed and user-friendly. Look for features such as lightweight construction and compact designs that facilitate easy setup and transportation. Additionally, machines that offer automated functions—such as auto-inflation and auto-stuffing—can significantly reduce manual labor and streamline the process. It’s also beneficial to invest in comprehensive training programs for staff to ensure they are fully aware of the machine’s features and capabilities, maximizing productivity and minimizing downtime.

Scenario 3: Poor Quality Materials Resulting in High Failure Rates

The Problem: Another prevalent issue is the poor quality of balloons and stuffing materials that come with many balloon stuffing machines. When buyers opt for cheaper options, they often find that the balloons are prone to popping or tearing, leading to waste and additional costs. This can be particularly damaging in a competitive market where reputation and product quality are paramount.

The Solution: To overcome this challenge, B2B buyers should prioritize sourcing machines that come with high-quality, durable balloons. Look for suppliers that provide detailed specifications about the materials used in their balloons, such as thickness and elasticity. Additionally, consider establishing partnerships with trusted suppliers who specialize in high-quality balloons and stuffing materials. This not only ensures better quality products but also fosters stronger business relationships. Regularly reviewing customer feedback and product performance can guide future purchasing decisions, allowing businesses to adapt their inventory to focus on the most reliable materials for their balloon stuffing needs.

Illustrative image related to balloon stuffing machine

Strategic Material Selection Guide for balloon stuffing machine

What Are the Key Materials Used in Balloon Stuffing Machines?

When selecting a balloon stuffing machine, the choice of materials significantly influences its performance, durability, and suitability for various applications. Below, we analyze four common materials used in the construction of balloon stuffing machines, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Plastic Impact the Performance of Balloon Stuffing Machines?

Plastic is a prevalent material in balloon stuffing machines, often used for components such as the body and various fittings. Key properties include lightweight design, corrosion resistance, and ease of molding into complex shapes.

Pros: Plastic is generally cost-effective and lightweight, facilitating easier handling and operation. It also resists corrosion, making it suitable for various environments.

Cons: However, plastic may not withstand high temperatures or pressures compared to metals, which can limit its application in more demanding environments. Additionally, lower-grade plastics can degrade over time, especially when exposed to UV light or harsh chemicals.

Illustrative image related to balloon stuffing machine

Impact on Application: Plastic components are typically compatible with air and non-corrosive gases, making them ideal for standard balloon stuffing operations.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with local regulations and standards, such as ASTM or DIN, particularly in regions like Europe, where material safety is heavily regulated.

What Role Does Metal Play in Balloon Stuffing Machine Design?

Metals, particularly aluminum and stainless steel, are often used in balloon stuffing machines for structural components and high-stress areas. These materials offer superior strength, durability, and heat resistance.

Illustrative image related to balloon stuffing machine

Pros: Metals provide excellent mechanical properties, allowing machines to handle higher pressures and more substantial operational loads. They also have a longer lifespan than plastic components.

Cons: The primary downside is the higher cost of metal parts and the increased weight, which can affect portability. Additionally, metals may corrode if not adequately treated, especially in humid or saline environments.

Impact on Application: Metal components are suitable for high-performance machines that require robust construction and longevity, making them ideal for commercial applications.

Illustrative image related to balloon stuffing machine

Considerations for International Buyers: Buyers should be aware of corrosion resistance ratings and ensure compliance with international standards, particularly in coastal regions or areas with high humidity.

How Do Rubber Seals Enhance Balloon Stuffing Machines?

Rubber is commonly used for seals and gaskets in balloon stuffing machines, providing a crucial barrier against air leaks. Key properties include elasticity, excellent sealing capabilities, and resistance to wear.

Pros: Rubber seals can accommodate various shapes and sizes, ensuring a tight fit that prevents air loss during the stuffing process. They are also relatively inexpensive and easy to replace.

Illustrative image related to balloon stuffing machine

Cons: However, rubber can degrade over time, especially when exposed to oils, UV light, or extreme temperatures. This degradation can lead to failures in the sealing function.

Impact on Application: Rubber seals are essential for maintaining pressure within the machine, directly impacting the efficiency of the balloon stuffing process.

Considerations for International Buyers: Buyers should consider the specific rubber grades used and their compatibility with local environmental conditions, ensuring they meet relevant standards.

What Are the Advantages of Using Composite Materials in Balloon Stuffing Machines?

Composite materials, often a combination of plastic and metal, are increasingly used in advanced balloon stuffing machines. They offer a balance of strength and weight.

Pros: Composites can provide excellent strength-to-weight ratios, reducing the overall weight of the machine while maintaining durability. They are also resistant to corrosion and can be engineered for specific applications.

Cons: The manufacturing process for composites can be complex and costly, which may lead to higher initial investment costs.

Impact on Application: Composites are suitable for high-performance, lightweight machines designed for mobile or frequent use.

Considerations for International Buyers: Buyers should verify that composite materials meet local standards and regulations, particularly in regions with strict material safety guidelines.

Illustrative image related to balloon stuffing machine

Summary Table of Material Selection for Balloon Stuffing Machines

| Material | Typical Use Case for balloon stuffing machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Body and fittings | Lightweight and corrosion-resistant | Limited high-temperature tolerance | Low |

| Metal | Structural components | High strength and durability | Higher cost and potential corrosion | High |

| Rubber | Seals and gaskets | Excellent sealing capabilities | Degrades over time | Medium |

| Composite | Advanced, lightweight machines | Strength-to-weight ratio | Complex and costly manufacturing | High |

This strategic material selection guide provides valuable insights for international B2B buyers considering balloon stuffing machines, helping them make informed decisions based on material properties, advantages, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for balloon stuffing machine

What Are the Key Stages in the Manufacturing Process of Balloon Stuffing Machines?

The manufacturing process of balloon stuffing machines is crucial in ensuring that the final product meets the required performance standards and customer expectations. The process can be broken down into several main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation

The first stage involves sourcing high-quality raw materials, including metals for the machine frame and components, plastics for the balloon holders, and electrical parts for the pump systems. Manufacturers often prioritize materials that are durable and resistant to wear and tear, which is essential for machines designed to operate continuously in commercial settings. This stage may also include testing raw materials to ensure compliance with international standards. -

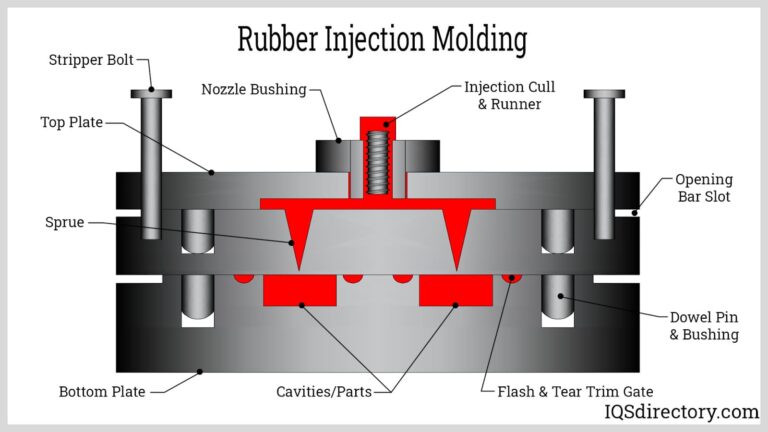

Forming

In this stage, the prepared materials are shaped into the various components of the balloon stuffing machine. Techniques such as injection molding for plastic parts and CNC machining for metal components are commonly used. These methods allow for precision in manufacturing, which is critical for the machine’s overall functionality. Advanced techniques like laser cutting may also be employed for intricate designs or components. -

Assembly

The assembly stage involves bringing together the formed components into a cohesive machine. This is typically done in a clean, controlled environment to prevent contamination and ensure the integrity of the parts. Automated assembly lines may be used to enhance efficiency, but skilled technicians also play a vital role in ensuring that each machine is assembled correctly. Proper alignment and calibration are crucial during this stage to ensure optimal performance. -

Finishing

The final stage of manufacturing is finishing, which involves applying protective coatings, conducting surface treatments, and packaging the machines. This stage ensures that the machines are not only functional but also aesthetically appealing. Quality checks are performed to ensure that the machines are free from defects and ready for distribution.

How Is Quality Assurance Implemented in Balloon Stuffing Machine Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each balloon stuffing machine meets specific standards and operates reliably. The QA process typically adheres to both international and industry-specific standards.

-

International Standards

Manufacturers often comply with ISO 9001, a globally recognized standard for quality management systems. This certification ensures that companies have established processes to enhance customer satisfaction and continually improve their products. Additionally, compliance with CE marking regulations is essential for machines sold in Europe, indicating conformity with health, safety, and environmental protection standards. -

Industry-Specific Certifications

In some regions, manufacturers may need to adhere to industry-specific standards, such as those set by the American Petroleum Institute (API) or other relevant bodies, depending on the intended use of the machine. These certifications can provide additional assurance regarding the machine’s performance and safety.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) involves various checkpoints throughout the manufacturing process to ensure that the machines meet the required specifications. Key checkpoints include:

-

Incoming Quality Control (IQC)

This checkpoint occurs at the beginning of the manufacturing process. Raw materials and components are inspected for quality before they are used in production. This step helps prevent defects from being introduced into the assembly line. -

In-Process Quality Control (IPQC)

Throughout the manufacturing process, periodic inspections are conducted to verify that each stage is performed correctly. This includes checking the accuracy of machining processes, the quality of welds, and the proper functioning of electrical components. -

Final Quality Control (FQC)

Before a machine is packaged and shipped, it undergoes a final inspection to ensure that it meets all specifications. This includes functional testing to verify that the machine operates as intended and that safety features are functional.

What Testing Methods Are Commonly Used for Balloon Stuffing Machines?

Manufacturers employ various testing methods to ensure that balloon stuffing machines meet quality and performance standards. Common testing methods include:

-

Functional Testing: This involves operating the machine under normal conditions to ensure it performs all intended functions correctly. This test checks for issues such as inflation capacity, ease of use, and overall reliability.

-

Durability Testing: Machines are subjected to extended use conditions to evaluate their long-term performance. This testing helps identify potential weaknesses in materials or design.

-

Safety Testing: Compliance with safety standards is crucial. Machines are tested for electrical safety, mechanical stability, and any potential hazards that could arise during operation.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers looking to ensure the quality of balloon stuffing machines should consider several strategies to verify a supplier’s QC processes:

-

Supplier Audits

Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. This on-site evaluation allows buyers to assess compliance with international standards and identify any potential risks. -

Quality Reports

Requesting quality assurance reports and documentation from suppliers can help buyers understand the testing methods used and the results obtained. These reports should outline the QC checkpoints and any corrective actions taken. -

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing processes and product quality. These inspections can occur at various stages of production to ensure compliance with agreed-upon standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control:

-

Regulatory Compliance: Different countries may have varying regulations regarding manufacturing standards and certifications. Understanding these requirements is crucial for ensuring that imported machines comply with local laws.

-

Cultural Differences: Cultural attitudes towards quality assurance can vary significantly. Buyers should be prepared to navigate these differences when engaging with suppliers and assessing their QC processes.

-

Logistical Considerations: The logistics of international shipping can affect product quality. Buyers should ensure that suppliers have robust packaging and shipping protocols to prevent damage during transit.

By understanding the manufacturing processes and quality assurance protocols associated with balloon stuffing machines, international B2B buyers can make informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘balloon stuffing machine’

To assist B2B buyers in procuring balloon stuffing machines, this practical sourcing guide outlines essential steps to ensure a successful purchase. Whether you’re looking to start a balloon-stuffing business or enhance your existing operations, following these steps will help you make informed decisions.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is critical before starting your search. Consider factors such as the size of balloons you’ll be working with, the volume of production, and the types of materials you’ll need to stuff inside the balloons. Clearly defining these specifications helps narrow down your options and ensures the machine meets your operational needs.

Step 2: Research and Compare Suppliers

Conduct thorough research on potential suppliers to identify the most reliable options. Look for companies with a solid track record in manufacturing balloon stuffing machines. Pay attention to customer reviews, ratings, and testimonials to gauge the reliability of each supplier. A well-established supplier is more likely to provide quality products and reliable customer support.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step is important to confirm the supplier’s experience and reliability, as well as to ensure they understand the unique needs of your market.

Illustrative image related to balloon stuffing machine

Step 4: Check for Certifications and Compliance

Verify that the suppliers comply with industry standards and possess relevant certifications. This is particularly important if you plan to sell stuffed balloons in regulated markets. Look for certifications that indicate quality control measures, safety standards, and environmental compliance. Suppliers with these certifications are more likely to provide high-quality machinery.

Step 5: Assess Machine Features and Warranty

When evaluating specific machines, compare the features they offer. Key features to consider include ease of use, speed of operation, and maintenance requirements. Additionally, inquire about warranties and after-sales support. A robust warranty indicates confidence in the product’s durability, while good after-sales support ensures you can resolve any issues that may arise.

Step 6: Request Samples and Demonstrations

Before making a final decision, request samples or demonstrations of the balloon stuffing machines. This allows you to see the machine in action and assess its performance firsthand. It’s also an opportunity to evaluate the quality of the balloons and materials provided with the machine, ensuring they meet your standards.

Step 7: Negotiate Terms and Pricing

Finally, engage in discussions about pricing, payment terms, and delivery schedules. Don’t hesitate to negotiate for better pricing, especially if you’re placing a bulk order. Understanding the total cost of ownership, including maintenance and operational costs, will help you make a financially sound decision.

By following this checklist, B2B buyers can ensure they select the right balloon stuffing machine that meets their specific needs, ultimately enhancing their business operations.

Illustrative image related to balloon stuffing machine

Comprehensive Cost and Pricing Analysis for balloon stuffing machine Sourcing

What Are the Key Cost Components of Balloon Stuffing Machines?

When sourcing balloon stuffing machines, it is essential to understand the various cost components involved. The primary factors influencing the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The quality of raw materials significantly impacts the machine’s durability and performance. High-quality components, such as robust motors and inflation mechanisms, can lead to higher initial costs but may reduce long-term operational expenses due to fewer breakdowns.

-

Labor: Labor costs vary by region and production methods. Automated manufacturing may reduce labor costs but can require a larger upfront investment in machinery.

-

Manufacturing Overhead: This encompasses costs related to utilities, maintenance, and administrative expenses in the production facility. A facility with advanced technology may have higher overhead but can improve efficiency.

-

Tooling: Initial tooling costs for specialized parts can be significant, especially for custom machines. Buyers should inquire about the tooling process and costs associated with customization.

-

Quality Control (QC): Investing in stringent QC processes can increase upfront costs but ensures the reliability and safety of the machines, reducing the likelihood of costly repairs or replacements later.

-

Logistics: Shipping and handling costs can vary widely based on the machine’s size, weight, and destination. Understanding Incoterms (International Commercial Terms) is crucial, as they define the responsibilities of buyers and sellers in shipping.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. This margin can vary based on market conditions and competition.

What Price Influencers Should Buyers Consider?

Several factors influence the pricing of balloon stuffing machines, which can significantly affect the overall cost for international buyers.

-

Volume/MOQ: Manufacturers often provide discounts for bulk purchases. Understanding the minimum order quantities (MOQ) can help negotiate better pricing.

-

Specifications/Customization: Custom machines tailored to specific needs usually come at a premium. Buyers should weigh the necessity of customization against potential cost savings with standard models.

-

Materials and Quality/Certifications: Machines made from higher-grade materials or those certified for safety and performance may carry a higher price tag. However, investing in quality can lead to lower maintenance and operational costs.

-

Supplier Factors: The supplier’s reputation, experience, and customer service can also influence pricing. Established suppliers may charge more but offer better support and reliability.

-

Incoterms: Familiarizing oneself with Incoterms will help clarify who is responsible for shipping costs, insurance, and tariffs. This knowledge is crucial for accurately calculating total costs.

What Tips Can Help Buyers Negotiate Better Prices?

Negotiating effectively can lead to significant savings when sourcing balloon stuffing machines.

-

Research and Compare: Conduct thorough research on various suppliers to understand market pricing. Utilize online resources and trade shows to gather competitive quotes.

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs, including maintenance, energy consumption, and potential downtime. A cheaper upfront price may lead to higher long-term expenses.

-

Be Flexible with Payment Terms: Offering to pay upfront or negotiating longer payment terms can often result in better pricing.

-

Leverage Relationships: Building a rapport with suppliers can lead to better pricing and service. Long-term partnerships often yield favorable terms.

-

Consider Local Suppliers: For international buyers, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall value.

Disclaimer on Indicative Prices

Prices for balloon stuffing machines can vary widely based on the factors outlined above. While indicative prices range from $200 to $1,000, it is crucial for buyers to conduct their due diligence to obtain accurate quotes tailored to their specific requirements.

Alternatives Analysis: Comparing balloon stuffing machine With Other Solutions

Introduction: Exploring Alternatives to Balloon Stuffing Machines

In the competitive landscape of event planning and gift customization, businesses often seek efficient solutions for creating unique balloon-stuffed gifts. While balloon stuffing machines are popular for their specialized functionality, there are several alternative methods and technologies that can achieve similar outcomes. Understanding these alternatives can help B2B buyers make informed decisions based on their specific operational needs and budget constraints.

Comparison Table

| Comparison Aspect | Balloon Stuffing Machine | Manual Stuffing Method | Pre-Stuffed Balloons |

|---|---|---|---|

| Performance | High efficiency; can handle multiple balloons simultaneously | Lower efficiency; time-consuming | Consistent quality; ready to use |

| Cost | Initial investment typically ranges from $200 to $1,000 | Minimal upfront cost, mainly labor | Higher upfront cost for bulk purchase |

| Ease of Implementation | Requires training; setup can be complex | Simple; no special training needed | Immediate use; no setup required |

| Maintenance | Requires regular maintenance; potential repair costs | Minimal; primarily labor-related | No maintenance required post-purchase |

| Best Use Case | High-volume orders; customization for events | Small-scale operations; personalized gifts | Quick gifting solutions; no preparation time |

Detailed Breakdown of Alternatives

Manual Stuffing Method

The manual stuffing method involves physically inserting gifts and items into balloons by hand. This approach is straightforward and requires no specialized equipment, making it accessible for small businesses or individual crafters. However, the downside is that it is labor-intensive and can lead to inconsistencies in the final product due to varying techniques among staff. Manual stuffing is best for small orders or personalized gifts where attention to detail is paramount, but it may not be suitable for large-scale operations.

Pre-Stuffed Balloons

Pre-stuffed balloons are commercially available balloons that come already filled with gifts or decorations. This method eliminates the need for additional equipment or labor, as these balloons can be purchased in bulk and are ready for immediate sale. While this option offers convenience and consistent quality, the cost can be higher due to the premium associated with pre-stuffed products. This method works well for businesses that prioritize speed and ease of use, particularly for last-minute gift solutions.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a solution for balloon stuffing, B2B buyers should evaluate their specific operational requirements, budget, and target market. For businesses that handle large volumes of orders and require customization, investing in a balloon stuffing machine may offer the best long-term value. Conversely, for those focusing on personalized gifts or small-scale operations, manual stuffing or pre-stuffed balloons may be more suitable options. By carefully considering these alternatives, businesses can optimize their workflows and enhance customer satisfaction, ultimately driving growth in their balloon-gifting endeavors.

Illustrative image related to balloon stuffing machine

Essential Technical Properties and Trade Terminology for balloon stuffing machine

What Are the Key Technical Properties of Balloon Stuffing Machines?

When selecting a balloon stuffing machine, understanding its technical specifications is crucial for ensuring it meets your business needs. Here are some essential properties to consider:

-

Material Grade

The construction material of a balloon stuffing machine significantly impacts its durability and performance. High-grade materials such as stainless steel or heavy-duty plastics are preferred for their resistance to wear and corrosion. Machines made from lower-grade materials may not withstand the rigors of frequent use, leading to increased maintenance costs and downtime. -

Inflation Pressure Capacity

This specification indicates the maximum pressure at which the machine can inflate balloons. A higher inflation pressure capacity allows for the use of larger balloons or the ability to stuff heavier items inside the balloons without compromising their integrity. For businesses that cater to high-demand events or require versatile balloon sizes, this feature is essential. -

Cycle Time

The cycle time refers to the duration it takes to inflate and stuff a balloon. A shorter cycle time enhances productivity, enabling businesses to fulfill more orders in a given timeframe. This is particularly important for high-volume operations, as efficiency directly correlates to profitability. -

User Interface and Controls

The ease of use of the machine is determined by its user interface and controls. Machines equipped with intuitive controls and digital displays simplify the operation, reducing the learning curve for new users. For businesses that require multiple operators, a user-friendly design minimizes training time and errors. -

Size and Portability

The dimensions and weight of a balloon stuffing machine can affect its usability in various settings. Compact and lightweight models are easier to transport, making them suitable for mobile businesses or event-based services. Conversely, larger machines may offer more features but can be cumbersome to move. -

Power Supply Requirements

Understanding the power requirements is essential for ensuring compatibility with local electrical standards. Machines that operate on different voltage levels may require additional transformers or adapters, which could incur extra costs.

What Are Common Trade Terminologies Related to Balloon Stuffing Machines?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some key terms commonly used in the balloon stuffing machine market:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of balloon stuffing machines, purchasing from an OEM often guarantees high-quality components and reliable performance, which is crucial for businesses relying on these machines. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, especially for businesses looking to stock up on machines or accessories without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers for specific products or services. When considering a balloon stuffing machine, issuing an RFQ can help gather multiple offers, allowing for better comparison and negotiation. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms is essential for international buyers, as they dictate who bears the costs and risks at various stages of the shipping process. -

Lead Time

Lead time refers to the period from placing an order to receiving the product. Understanding lead times is crucial for inventory management and ensuring that your business can meet customer demands without delays. -

Warranty and Service Agreements

These terms pertain to the guarantees provided by manufacturers regarding the performance and repair of their machines. Knowing the warranty coverage and service options available can help businesses make informed decisions, ensuring they invest in reliable equipment backed by support.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the balloon stuffing machine Sector

What Are the Current Market Dynamics and Key Trends in the Balloon Stuffing Machine Sector?

The balloon stuffing machine market is experiencing significant growth, driven by a surge in demand for personalized gifting solutions across various regions, particularly in Africa, South America, the Middle East, and Europe. B2B buyers are increasingly looking for innovative ways to enhance customer experiences, with balloon stuffing machines offering a unique avenue for creating memorable gifts. Key trends include the rise of e-commerce platforms that simplify procurement, the integration of advanced technologies such as electric air pumps and digital controls, and the emergence of subscription-based models for supplies.

Moreover, the shift towards sustainability is influencing purchasing decisions, with buyers favoring suppliers that provide eco-friendly materials and practices. As the market evolves, the competition is also intensifying, compelling manufacturers to enhance product features and customer service. For international B2B buyers, understanding regional preferences and local market conditions is crucial for successful sourcing. Buyers from Germany may prioritize efficiency and quality, while those in Nigeria might focus on affordability and durability, reflecting the diverse needs across different markets.

How Is Sustainability Impacting the Sourcing of Balloon Stuffing Machines?

Sustainability is becoming a central theme in the sourcing of balloon stuffing machines, as businesses are increasingly aware of their environmental impact. The production of balloons, traditionally made from latex and plastic, poses significant ecological challenges. As a result, there is a growing demand for machines and supplies that utilize biodegradable materials or sustainably sourced components.

Ethical sourcing is also gaining traction, with B2B buyers seeking suppliers who adhere to fair labor practices and transparency in their supply chains. Certifications for ‘green’ materials, such as biodegradable latex or recycled plastics, are becoming essential for businesses looking to enhance their brand reputation and appeal to environmentally conscious consumers. By prioritizing sustainability, companies not only comply with regulatory standards but also align themselves with a growing consumer preference for eco-friendly products, thus improving their market positioning.

What Is the Evolution of Balloon Stuffing Machines in the B2B Context?

The balloon stuffing machine has evolved significantly from its rudimentary origins to become a sophisticated tool essential for modern gifting and event planning. Initially designed for basic inflation and stuffing, contemporary machines incorporate advanced technologies such as electric pumps and automated features that streamline the stuffing process.

The evolution reflects broader trends in consumer behavior, where personalized and unique gifts are increasingly sought after. As a result, manufacturers have developed machines that cater to varying needs, from small-scale operations to large event planning businesses. This evolution has not only increased the accessibility of balloon stuffing machines for B2B buyers but has also spurred innovation in related supplies, such as high-quality biodegradable balloons and customizable stuffing options.

Illustrative image related to balloon stuffing machine

In summary, the balloon stuffing machine sector is witnessing a transformative phase marked by technological advancements, sustainability initiatives, and evolving consumer preferences, creating a dynamic landscape for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of balloon stuffing machine

-

How do I solve issues with my balloon stuffing machine not inflating balloons properly?

If your balloon stuffing machine is struggling to inflate balloons, first check for blockages in the air pump or tubing. Ensure that all connections are secure and that you’re using the correct type of balloon for your machine. Additionally, inspect the quality of the balloons; lower-quality options may not inflate well. If problems persist, consult the manufacturer’s manual for troubleshooting tips or consider reaching out to customer support for guidance. -

What is the best balloon stuffing machine for starting a small business?

The ideal balloon stuffing machine for a small business should balance quality and affordability. Look for machines that are user-friendly, have a good warranty, and are capable of handling various balloon sizes. Models priced between $400 to $800 often provide the best performance for small businesses. Research customer reviews and consider purchasing from reputable suppliers who offer support and training resources. -

How can I verify the reliability of a supplier for balloon stuffing machines?

To vet a supplier, start by researching their reputation through online reviews and ratings. Check their business history, years of operation, and customer testimonials. Request references from other businesses that have purchased equipment from them. Additionally, inquire about their certifications and quality assurance processes to ensure they meet international standards. Engaging in direct communication can also provide insights into their customer service responsiveness. -

What are the typical payment terms when sourcing balloon stuffing machines internationally?

Payment terms can vary significantly among suppliers, but common practices include a deposit upfront (usually 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net terms, allowing payment within a specified period after delivery. Always clarify payment methods accepted, such as wire transfers, credit cards, or letters of credit, and ensure that they align with your financial processes. -

What is the minimum order quantity (MOQ) for balloon stuffing machines?

MOQs for balloon stuffing machines can differ based on the supplier and the specific model. Typically, MOQs can range from one unit for small businesses to larger quantities for bulk orders. When negotiating, consider your business needs and potential growth to establish an MOQ that aligns with your budget and operational capabilities. Discussing your requirements with the supplier can often lead to more flexible arrangements. -

How can I customize my balloon stuffing machine for specific business needs?

Many suppliers offer customization options for balloon stuffing machines, such as different sizes, colors, or additional features like built-in LED lights. To pursue customization, communicate your specific needs directly with the supplier during the inquiry process. Be prepared to discuss design specifications and any additional functionalities that could enhance your product offerings. Request prototypes or samples if possible to evaluate quality before placing a bulk order. -

What quality assurance measures should I look for in a balloon stuffing machine?

When sourcing a balloon stuffing machine, inquire about the manufacturer’s quality assurance (QA) protocols. Look for certifications that demonstrate compliance with international quality standards, such as ISO 9001. Additionally, ask about testing procedures for the machines, warranty terms, and post-sale support. A reliable supplier should provide documentation regarding the machine’s quality checks and offer customer support to address any operational issues. -

What logistics considerations should I keep in mind when importing balloon stuffing machines?

When importing balloon stuffing machines, consider shipping costs, delivery times, and customs regulations in your country. Ensure that the supplier can provide necessary documentation for customs clearance, including invoices and certificates of origin. It’s also essential to work with a logistics partner familiar with international shipping to navigate potential delays or issues. Planning for these factors can help ensure a smooth import process and timely delivery of your equipment.

Top 5 Balloon Stuffing Machine Manufacturers & Suppliers List

1. Keepsake Stuffer – Balloon Stuffer Machine

Domain: keepsakestuffer.com

Registered: 2005 (20 years)

Introduction: Keepsake Stuffer Balloon Stuffer is a machine designed for wrapping gifts in balloons. It offers various kits including ST-1 Core, ST-5 Beginner Kit, ST-10 Elite Kit, ST-15 Ultimate Kit, and ST-20 Enterprise Kit. The product range includes stuffing balloons in assorted prints, clear balloons, and themed balloons like ‘It’s a Boy’ and ‘It’s a Girl’. Prices for products range from $18.90 for clear b…

2. Bloonsy – Balloon Stuffing Machine Kit

Domain: bloonsy.com

Registered: 2019 (6 years)

Introduction: Bloonsy offers a Balloon Stuffing Machine and accessories for creating personalized gifts or starting a balloon-stuffing business. Key products include: 1. Balloon Stuffing Machine Kit with Electric Air Pump and Expander Tool – Regular price: $399.00 2. Bloonsy 24 Inch Clear Bobo Balloons (Pack of 10) – Regular price: $19.99 3. Bloonsy Pro-Grade 18-Inch Clear Latex Balloons (Pack of 10) – Regular …

3. Laballoons – Silver Rainbow T-REX™ MK2 Balloon Stuffing Tool

Domain: laballoons.com

Registered: 2002 (23 years)

Introduction: Balloon Stuffing Tools collection includes various tools for creating balloon decorations. Key products include: 1. Silver Rainbow T-REX™ MK2 Balloon Stuffing Tool – $107.10, 85 available. 2. Premium Conwin Insider Balloon Stuffing Tool Kit – Air Force 4 / Precision Air – $119.79, 1 available. 3. Premium Conwin Insider Balloon Stuffing Tool Kit – Dual Sizer / Duplicator 2 – $162.69, 3 available. 4…

4. eBay – Balloon Stuffing Machine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Balloon Stuffing Machine available on eBay with various options including new, open box, and used conditions. Prices range from approximately $20.00 to $620.00. Shipping options include free delivery and local pickup within 25 miles. Common features include electric air pumps and balloon expander tools. The machines are suitable for filling toy balloon bouquets and decorative gifts. Various colors…

5. Sonic E-Party – Professional Balloon Stuffing Machines

Domain: soniceparty.com

Registered: 2018 (7 years)

Introduction: Professional Balloon Stuffing Machines are essential for starting a balloon stuffing business. Prices range from $150 to $1,000, with an average cost of around $200. Key considerations include the quality of inflation, durability, ease of use, and included balloons. Notable models include: 1. Puff ‘N Stuff with Expander – lightweight, portable, 5-inch collar opening, includes balloon expander and …

Strategic Sourcing Conclusion and Outlook for balloon stuffing machine

As the balloon gifting industry continues to thrive globally, strategic sourcing of balloon stuffing machines becomes paramount for international B2B buyers. Understanding the diverse range of machines available—from basic models to professional-grade options—can significantly impact your operational efficiency and product offerings. Key considerations include the quality of materials, ease of use, and the potential for long-term reliability, all of which directly influence your bottom line.

Investing in high-quality equipment not only enhances the customer experience but also positions your business to meet increasing demand for unique gifting solutions. By sourcing from reputable manufacturers, you can ensure that you receive durable machines designed for high performance, minimizing downtime and maximizing productivity.

Looking ahead, the balloon stuffing market offers substantial opportunities for growth across regions such as Africa, South America, the Middle East, and Europe. Now is the time to explore partnerships with trusted suppliers and invest in innovative solutions that can elevate your business. Embrace the future of balloon gifting—start your sourcing journey today and watch your business flourish in this vibrant industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to balloon stuffing machine

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.