Everything You Need to Know About Ball Screw Driven Sourcing in 2025

Introduction: Navigating the Global Market for ball screw driven

In today’s rapidly evolving industrial landscape, sourcing ball screw driven actuators poses a significant challenge for B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. With their ability to deliver precise motion control under high loads, ball screw actuators are integral to a variety of applications, from automation in manufacturing to advanced robotics. However, navigating the complexities of this global market requires a deep understanding of the different types of ball screw systems, their applications, and the factors influencing supplier reliability and pricing.

This comprehensive guide is designed to empower international B2B buyers by providing actionable insights into the ball screw driven actuator market. We will explore the various types of ball screw actuators available, their specific applications, and the critical considerations for vetting suppliers. Additionally, we will address cost implications and best practices for ensuring quality and efficiency in procurement. By equipping buyers with this knowledge, we aim to facilitate informed purchasing decisions that align with the unique operational needs of businesses in diverse regions, including Nigeria and Vietnam.

As you delve into this guide, you will gain valuable strategies for navigating the complexities of the ball screw driven market, ensuring that your sourcing efforts yield optimal performance and value.

Understanding ball screw driven Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Precision Ball Screws | High accuracy with preloaded nuts; low backlash | CNC machinery, robotics, aerospace | Pros: Excellent positioning accuracy; high load capacity. Cons: Higher cost; requires regular maintenance. |

| Rolled Ball Screws | Cost-effective; lower precision than precision screws | General manufacturing, conveyor systems | Pros: More affordable; good for lower precision tasks. Cons: Limited accuracy; less suitable for high-speed applications. |

| Miniature Ball Screws | Compact design; suitable for tight spaces | Medical devices, small robotics | Pros: Space-saving; lightweight. Cons: Lower load capacity; limited stroke length. |

| Ground Ball Screws | Precision-ground threads for enhanced performance | High-speed applications, semiconductor manufacturing | Pros: Superior accuracy; high durability. Cons: Higher manufacturing cost; longer lead times. |

| Double Nut Ball Screws | Dual nut design reduces backlash; enhances rigidity | High-precision applications, automation | Pros: Improved accuracy; better load distribution. Cons: More complex design; potentially higher costs. |

What Are the Key Characteristics of Precision Ball Screws?

Precision ball screws are engineered for high accuracy and minimal backlash, making them ideal for applications requiring precise positioning, such as CNC machinery and robotics. Their preloaded nuts ensure tight tolerances, which is crucial for industries like aerospace where precision is non-negotiable. Buyers should consider the higher initial investment and the need for regular maintenance to keep the system operating smoothly.

How Do Rolled Ball Screws Differ in Cost and Applications?

Rolled ball screws are a more economical option compared to precision variants. They are produced through a rolling process, which makes them suitable for general manufacturing and conveyor systems where extreme precision is not critical. While they offer good performance at a lower price point, buyers should be aware that they may not provide the same level of accuracy or speed as precision ball screws.

Why Choose Miniature Ball Screws for Compact Applications?

Miniature ball screws are designed for applications with space constraints, such as in medical devices or small robotic systems. Their compact design allows for integration into tight spaces while providing adequate performance. However, they come with a trade-off in terms of load capacity and stroke length, which buyers must consider based on their specific application requirements.

What Advantages Do Ground Ball Screws Offer for High-Speed Operations?

Ground ball screws feature precision-ground threads that enhance performance in high-speed applications, such as semiconductor manufacturing. They provide superior accuracy and durability, making them suitable for tasks requiring rapid movement and precise control. However, the higher manufacturing costs and longer lead times may deter budget-conscious buyers.

How Do Double Nut Ball Screws Enhance Performance?

Double nut ball screws are designed with two nuts that work together to minimize backlash and enhance rigidity. This design is particularly beneficial for high-precision applications and automated systems where consistent performance is crucial. While they offer improved accuracy and load distribution, their complexity and potential for higher costs may require careful consideration for buyers evaluating their overall project budget.

Key Industrial Applications of ball screw driven

| Industry/Sector | Specific Application of ball screw driven | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machining Centers | High precision in machining operations, reducing waste | Material quality, load capacity, and maintenance requirements |

| Robotics | Robotic Arm Actuators | Enhanced accuracy in automation tasks, improving efficiency | Speed, thrust capacity, and environmental adaptability |

| Aerospace | Aircraft Control Surfaces | Reliable and precise control, ensuring safety and performance | Certification standards, weight restrictions, and reliability |

| Medical Equipment | Surgical Robotics and Imaging Systems | Improved surgical precision, leading to better patient outcomes | Compliance with medical standards and serviceability |

| Packaging | Automated Packaging Lines | Increased throughput and reduced labor costs | Customization options, durability, and ease of integration |

How is Ball Screw Driven Technology Used in Manufacturing CNC Machining Centers?

In CNC machining centers, ball screw driven systems are integral for translating rotary motion into precise linear movement. This technology enhances the accuracy of cutting tools, minimizing material wastage and ensuring high-quality finishes. For international buyers, especially from regions like Africa and South America, sourcing ball screws that can withstand harsh operating conditions is crucial. Factors such as material quality, load capacity, and maintenance requirements should be prioritized to ensure long-term operational efficiency.

What Role Does Ball Screw Driven Technology Play in Robotics?

Ball screw driven actuators are pivotal in robotic arm applications, where precision and repeatability are essential. These systems enable robots to perform intricate tasks with high levels of accuracy, which is critical in sectors like automotive and electronics manufacturing. Buyers from the Middle East and Europe should consider the speed and thrust capacity of these actuators, as well as their adaptability to various environmental conditions, to ensure optimal performance.

How is Ball Screw Driven Technology Applied in Aerospace?

In the aerospace industry, ball screw driven mechanisms are used in control surfaces of aircraft, providing reliable and precise adjustments during flight. This technology is vital for maintaining safety and performance standards in aviation. International buyers must be aware of the stringent certification standards and weight restrictions associated with aerospace components. Ensuring that ball screws meet these requirements is essential for compliance and operational reliability.

What Benefits Does Ball Screw Driven Technology Offer in Medical Equipment?

Ball screw driven systems are crucial in surgical robotics and imaging equipment, where precision is paramount. These systems facilitate accurate movements that improve surgical outcomes and enhance imaging quality. Buyers in the medical sector, particularly in Europe and Africa, should focus on sourcing components that comply with rigorous medical standards while also considering serviceability and maintenance ease to ensure continuous operation.

How Does Ball Screw Driven Technology Enhance Packaging Operations?

In automated packaging lines, ball screw driven actuators contribute to increased throughput and efficiency by enabling rapid and accurate movements for packaging machinery. This results in lower labor costs and higher production rates. For businesses in South America and Africa, sourcing robust and customizable ball screw systems can significantly enhance operational efficiency. It’s important to evaluate durability and ease of integration with existing machinery to achieve seamless automation.

3 Common User Pain Points for ‘ball screw driven’ & Their Solutions

Scenario 1: Limited Load Capacity in High-Force Applications

The Problem: Many B2B buyers in sectors such as manufacturing and automation often encounter challenges when their ball screw driven systems cannot handle the required load capacity. For example, an automotive parts manufacturer may need to lift heavy components that exceed the limits of standard ball screw actuators, resulting in equipment failure or production downtime. This scenario not only disrupts operations but also leads to increased costs due to repairs and lost productivity.

The Solution: To overcome this pain point, buyers should carefully evaluate their load requirements and select ball screw actuators designed specifically for high-load applications. This includes opting for actuators with robust design features such as reinforced screws, larger diameters, and additional bearing support to enhance load distribution. Furthermore, collaborating with manufacturers who offer custom solutions can ensure that the ball screw systems are tailored to handle specific load thresholds. Regular maintenance and inspections are also crucial to ensure that the actuator continues to perform optimally under high-load conditions.

Scenario 2: Precision Challenges in High-Accuracy Applications

The Problem: In industries such as aerospace and medical device manufacturing, the need for precision is paramount. B2B buyers often face difficulties when ball screw actuators fail to provide the required accuracy and repeatability, leading to flawed products and potential safety hazards. For instance, a medical device company may find that variations in positioning accuracy cause their devices to fail quality control tests, resulting in costly recalls and damage to their reputation.

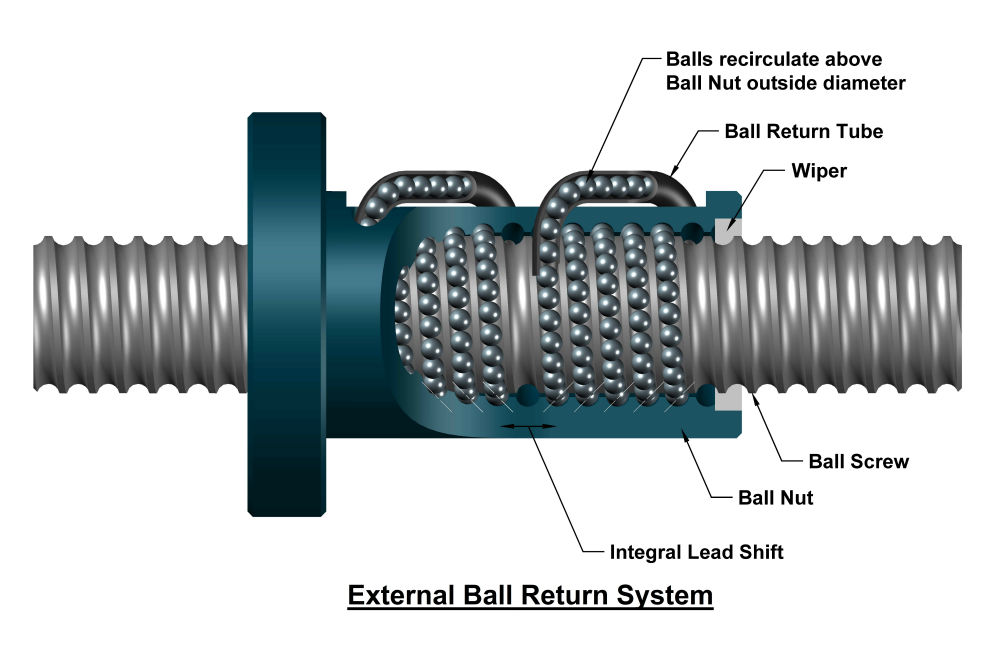

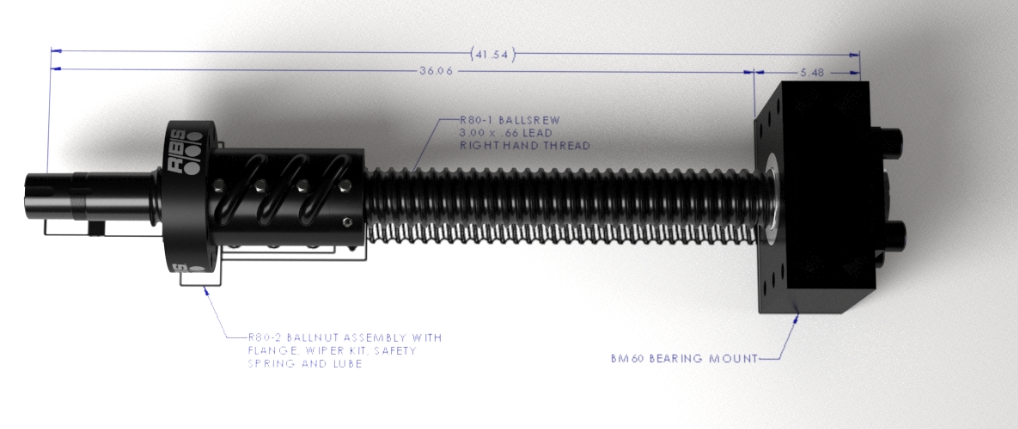

Illustrative image related to ball screw driven

The Solution: To address precision challenges, buyers should consider investing in high-quality preloaded ball screw systems that minimize backlash and enhance accuracy. It’s essential to choose ball screws that are precision-ground and utilize high-grade materials. Additionally, implementing closed-loop control systems can enhance positioning accuracy by providing real-time feedback, allowing for adjustments to be made instantly. Regular calibration and maintenance of the system are also critical to maintaining the desired level of precision over time.

Scenario 3: Maintenance and Downtime Concerns

The Problem: A common issue faced by B2B buyers is the maintenance requirements of ball screw driven systems, which can lead to unexpected downtime. For companies operating in fast-paced environments, like packaging or food processing, even minor delays can have significant financial implications. The need for regular lubrication and inspection of components can be overlooked, resulting in wear and tear that eventually leads to system failure.

The Solution: To mitigate maintenance-related downtime, businesses should establish a proactive maintenance schedule that includes routine inspections and lubrication of the ball screw and associated components. Utilizing automated lubrication systems can also reduce manual maintenance efforts and ensure that the system is consistently operating at peak efficiency. Additionally, investing in ball screw actuators designed for longer life cycles and reduced maintenance needs can minimize the frequency of downtime, allowing companies to focus on production and growth rather than repairs. By choosing high-quality, durable components and implementing a robust maintenance plan, buyers can significantly enhance the reliability of their systems.

Strategic Material Selection Guide for ball screw driven

What Are the Key Materials Used in Ball Screw Driven Systems?

When selecting materials for ball screw driven systems, several factors must be considered, including mechanical properties, environmental conditions, and compliance with international standards. The following analysis explores four common materials used in the manufacturing of ball screws and their respective nuts: carbon steel, stainless steel, aluminum, and plastic composites.

How Does Carbon Steel Perform in Ball Screw Applications?

Key Properties: Carbon steel is known for its high tensile strength and hardness, making it suitable for applications requiring significant load-bearing capabilities. It typically has a temperature rating up to 300°C and can withstand moderate pressure.

Pros & Cons: The durability of carbon steel is a major advantage, as it can handle heavy loads and high-stress applications. However, it is susceptible to corrosion unless properly treated, which can increase maintenance costs. Manufacturing complexity can also be a concern, as carbon steel components may require additional processes like heat treatment to enhance their properties.

Impact on Application: Carbon steel is compatible with various media but may not be suitable for corrosive environments. Buyers in regions with high humidity or exposure to chemicals should consider protective coatings or alternative materials.

Illustrative image related to ball screw driven

Considerations for International Buyers: Compliance with standards such as ASTM A108 for carbon steel is essential. Buyers from Africa and South America should ensure that suppliers can meet local quality certifications.

What Role Does Stainless Steel Play in Ball Screw Systems?

Key Properties: Stainless steel offers excellent corrosion resistance, high strength, and good thermal stability, with temperature ratings typically up to 600°C. It is particularly suitable for applications in harsh environments.

Pros & Cons: The primary advantage of stainless steel is its resistance to rust and oxidation, making it ideal for applications in the food, pharmaceutical, and marine industries. However, it is generally more expensive than carbon steel, which may impact budget considerations. The manufacturing process can also be more complex due to its hardness.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances. This makes it a preferred choice in industries requiring high hygiene standards.

Illustrative image related to ball screw driven

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM A276 or AISI 304/316. In regions like the Middle East, where corrosive environments are common, stainless steel is often the material of choice.

How Does Aluminum Compare in Ball Screw Applications?

Key Properties: Aluminum is lightweight and has good corrosion resistance, with temperature ratings typically up to 150°C. It is also known for its excellent machinability.

Pros & Cons: The lightweight nature of aluminum allows for faster motion and lower energy consumption. However, it has lower load-bearing capabilities compared to steel, which may limit its use in high-load applications. Additionally, aluminum can be more expensive than carbon steel.

Impact on Application: Aluminum is suitable for applications where weight reduction is crucial, such as in aerospace and robotics. However, its lower strength limits its use in heavy-duty applications.

Considerations for International Buyers: Compliance with standards like ASTM B221 for aluminum is important. Buyers in Europe may prefer aluminum due to its lightweight properties, which align with energy efficiency goals.

What Advantages Do Plastic Composites Offer in Ball Screw Systems?

Key Properties: Plastic composites are lightweight, resistant to corrosion, and can operate at temperatures up to 80°C. They also have good wear resistance.

Pros & Cons: The main advantage of plastic composites is their resistance to corrosion and chemical exposure, making them suitable for various environments. However, they typically have lower load capacities and can be less durable than metals, limiting their application scope.

Impact on Application: Plastic composites are ideal for applications requiring lightweight components that are resistant to chemicals. However, they may not be suitable for high-load or high-temperature applications.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM D638 for plastics. In regions with limited access to metal resources, plastic composites can offer a cost-effective alternative.

Summary Table of Material Selection for Ball Screw Driven Systems

| Material | Typical Use Case for ball screw driven | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy machinery and industrial equipment | High strength and load capacity | Susceptible to corrosion | Medium |

| Stainless Steel | Food, pharmaceutical, and marine sectors | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Aerospace and robotics | Lightweight and good machinability | Lower load capacity | Medium |

| Plastic Composites | Chemical processing and lightweight applications | Corrosion resistance | Lower strength and durability | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance requirements, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ball screw driven

What Are the Key Stages in the Manufacturing Process of Ball Screw Driven Actuators?

The manufacturing of ball screw driven actuators involves several critical stages that ensure the final product meets high standards of performance and reliability. Understanding these stages is essential for B2B buyers aiming to source quality components.

1. Material Preparation

The first step in the manufacturing process is material selection and preparation. High-grade materials such as alloy steel are commonly used for ball screws due to their strength and wear resistance. The selected materials undergo various treatments, such as heat treatment and surface hardening, to enhance their durability. This process ensures that the materials can withstand the mechanical stresses and environmental conditions they will encounter during operation.

Illustrative image related to ball screw driven

2. Forming Techniques: How Are Ball Screws Shaped?

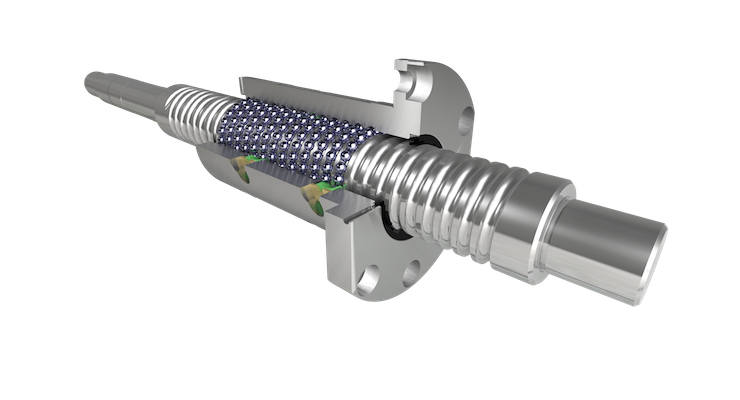

Forming techniques for ball screws typically involve precision machining processes, including turning, milling, and grinding. The ball screw is often produced using a combination of rolled and ground methods. In rolled ball screws, a thread profile is formed through a process of cold forming, while ground screws undergo grinding to achieve tighter tolerances. This dual approach allows manufacturers to balance cost and precision, catering to various application needs.

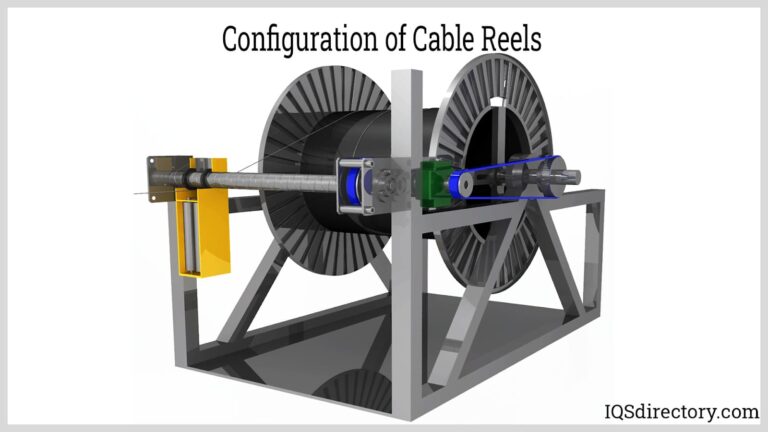

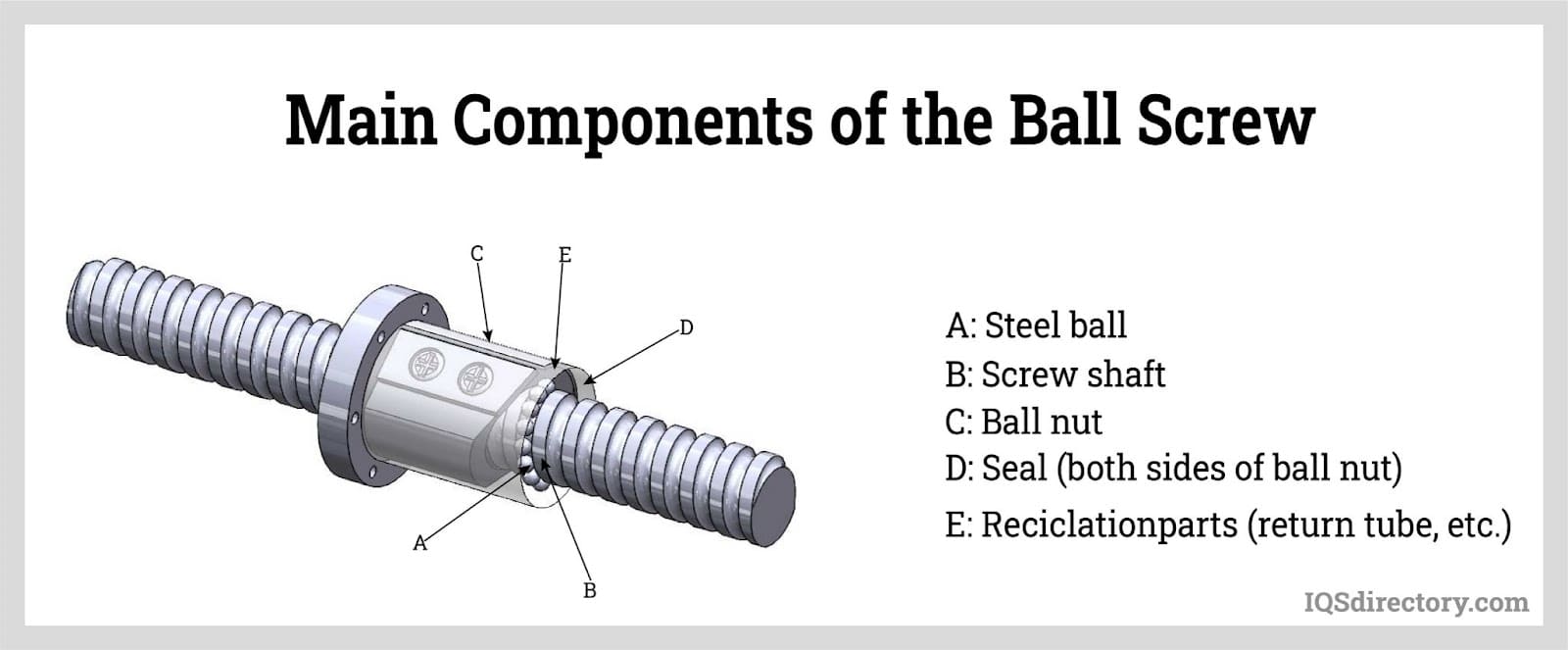

3. Assembly: What Are the Key Components and Their Assembly?

The assembly of ball screw driven actuators involves integrating several components, including the ball screw, ball nut, and carriage. The ball screw is fitted with precision balls that circulate within the grooves of the screw and nut. This assembly is critical, as it directly impacts the actuator’s performance, including load capacity and accuracy. The components are assembled in a clean environment to prevent contamination and ensure the smooth operation of the actuator.

4. Finishing Processes: How Is Quality Enhanced?

Finishing processes, such as surface treatment and coating, are crucial in enhancing the lifespan and performance of ball screw actuators. Common finishing techniques include anodizing, plating, and applying lubricants. These treatments reduce friction, enhance corrosion resistance, and improve overall aesthetics. Proper finishing is essential for meeting the specific operational requirements of different industries, such as automotive and aerospace.

What Quality Control Measures Are Essential for Ball Screw Driven Actuators?

Quality assurance is paramount in the manufacturing of ball screw driven actuators. B2B buyers need to understand the various quality control measures that manufacturers implement to ensure product reliability and compliance with international standards.

1. What International Standards Should Buyers Look For?

Manufacturers of ball screw driven actuators often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a commitment to quality, continuous improvement, and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are essential for ensuring that products meet specific regulatory requirements.

2. What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Conducting inspections during the manufacturing stages to monitor compliance with design specifications.

- Final Quality Control (FQC): Performing comprehensive testing and inspections on the finished product before shipment to ensure it meets all quality standards.

By implementing these checkpoints, manufacturers can identify and rectify issues early in the production process, reducing the risk of defects.

3. What Common Testing Methods Are Used for Ball Screw Driven Actuators?

Various testing methods are employed to verify the performance and reliability of ball screw driven actuators. Common tests include:

- Load Testing: Assessing the actuator’s ability to handle specified loads without failure.

- Precision Testing: Evaluating positioning accuracy and repeatability using laser measurement systems.

- Durability Testing: Simulating operational conditions over extended periods to assess wear and performance degradation.

These tests ensure that the actuators meet the required specifications and can perform reliably in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial in making informed purchasing decisions.

1. What Steps Can Buyers Take to Audit Suppliers?

Buyers should consider conducting supplier audits to assess the manufacturing and quality assurance processes. This can involve site visits to observe the production environment, review quality control documentation, and interview personnel responsible for quality assurance. Such audits help build trust and provide insight into the supplier’s commitment to quality.

2. How Can Buyers Utilize Quality Reports and Certifications?

Requesting quality reports and certifications from suppliers is another effective way to verify their quality control processes. Buyers should look for detailed documentation that outlines the manufacturing process, quality control measures, and test results. Certifications from recognized bodies can serve as additional assurance of compliance with international standards.

3. What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These services can conduct independent evaluations, ensuring that the products meet specified standards before shipment. This step is particularly valuable for buyers who may not have the resources or expertise to perform thorough inspections themselves.

Conclusion: Why Understanding Manufacturing and QC is Vital for B2B Buyers

Understanding the manufacturing processes and quality assurance measures for ball screw driven actuators is essential for B2B buyers seeking reliable and high-performance components. By focusing on material preparation, forming techniques, assembly, finishing processes, and stringent quality control standards, buyers can make informed decisions that align with their operational needs and industry requirements. Engaging in supplier audits, requesting quality documentation, and utilizing third-party inspections are effective strategies for ensuring that the products sourced meet the highest standards of quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ball screw driven’

When sourcing ball screw driven actuators, it’s essential to follow a structured approach to ensure that you choose the right products for your application. This guide provides a step-by-step checklist to facilitate your procurement process, helping you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your ball screw driven actuator. This includes parameters such as load capacity, stroke length, speed, and accuracy. Knowing these specifications is crucial as they will guide your selection and ensure that the actuator meets the demands of your specific application.

- Load Capacity: Determine the maximum load the actuator will handle.

- Stroke Length: Identify the required travel distance for your application.

- Speed and Accuracy: Specify the necessary speed and precision for optimal performance.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers specializing in ball screw actuators. Look for companies with a strong reputation, extensive experience, and a track record of supplying high-quality products. Supplier reliability is critical for maintaining production efficiency and minimizing downtime.

- Industry Experience: Evaluate how long the supplier has been in the market.

- Customer Reviews: Seek feedback from other buyers in similar industries to gauge supplier performance.

Step 3: Evaluate Product Options

Once you have a list of potential suppliers, review their product offerings in detail. Compare different models of ball screw driven actuators based on your defined specifications. This step ensures that you select a product that aligns with your technical needs and operational goals.

- Technical Data Sheets: Request detailed specifications and performance data.

- Customizability: Check if the supplier offers customization options to fit unique requirements.

Step 4: Verify Supplier Certifications

Before finalizing a supplier, ensure they possess the necessary certifications and comply with industry standards. Certifications indicate a commitment to quality and safety, which is vital for the performance of ball screw actuators.

- ISO Certifications: Look for ISO 9001 or other relevant quality management certifications.

- Industry Compliance: Ensure compliance with regional and international standards specific to your industry.

Step 5: Request Samples and Conduct Testing

Whenever possible, request samples of the ball screw driven actuators for testing. This hands-on evaluation allows you to assess the product’s performance in real-world conditions, ensuring it meets your expectations before making a larger investment.

- Performance Testing: Evaluate factors such as speed, load handling, and accuracy.

- Compatibility Checks: Test compatibility with existing systems to avoid integration issues.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier and confirmed product suitability, engage in negotiations regarding pricing, delivery times, and payment terms. Effective negotiation can lead to cost savings and favorable conditions that benefit your procurement strategy.

- Volume Discounts: Inquire about discounts for bulk purchases.

- Delivery Terms: Clarify lead times and shipping arrangements to avoid delays.

Step 7: Establish a Maintenance Plan

Finally, consider the long-term maintenance requirements for your ball screw driven actuators. Establish a maintenance plan that includes regular inspections, lubrication schedules, and prompt repairs to ensure optimal performance over time.

- Lubrication Needs: Determine the frequency and type of lubrication required.

- Maintenance Training: Consider training for your staff on proper maintenance procedures.

By following these steps, you can streamline your sourcing process for ball screw driven actuators, ensuring you select the right products from reliable suppliers that meet your operational needs.

Comprehensive Cost and Pricing Analysis for ball screw driven Sourcing

What Are the Key Cost Components in Sourcing Ball Screw Driven Actuators?

When sourcing ball screw driven actuators, understanding the cost structure is critical. The primary cost components include:

-

Materials: High-quality steel and precision-engineered components are essential for durability and performance. The choice of materials directly impacts the actuator’s load capacity and lifespan, influencing overall costs.

-

Labor: Skilled labor is necessary for assembly and quality control. The labor costs can vary significantly based on the manufacturing location, with regions having lower labor costs potentially providing a competitive edge.

-

Manufacturing Overhead: This encompasses the indirect costs related to production, such as facility costs, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Investment in specialized tooling and machinery for producing ball screw actuators can be substantial. These costs are amortized over production volumes, impacting unit pricing.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure that actuators meet performance specifications. This adds to the cost but is crucial for reliability, especially in high-stakes applications.

-

Logistics: Transportation and warehousing costs must be factored in, particularly for international buyers. These costs can fluctuate based on fuel prices and shipping methods.

-

Margin: Suppliers typically add a margin to cover their costs and profit, which can vary based on market conditions and the competitive landscape.

How Do Price Influencers Affect Ball Screw Driven Actuators?

Several factors can influence pricing in the market for ball screw driven actuators:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often benefit from economies of scale, resulting in lower per-unit costs.

-

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized materials and processes. Standardized products usually offer better pricing due to streamlined production.

-

Materials Quality and Certifications: Higher quality materials and necessary certifications (like ISO or CE) can increase costs. However, they also assure buyers of the product’s reliability and compliance with industry standards.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record and better service.

-

Incoterms: The terms of shipping (Incoterms) determine who bears the risk and costs at various points in the shipping process. Buyers should be aware of these terms to avoid unexpected charges.

What Are Effective Buyer Tips for Negotiating Ball Screw Pricing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings. Here are some tips:

-

Research and Compare: Conduct thorough market research to understand the pricing landscape. Comparing multiple suppliers can provide leverage in negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate the TCO, which includes initial purchase price, maintenance, and operational costs. Highlighting the long-term benefits of quality can justify higher initial prices.

-

Leverage Volume Discounts: If feasible, consolidate orders to meet MOQs and negotiate for volume discounts. This approach can lower per-unit costs significantly.

-

Build Relationships: Establishing a rapport with suppliers can lead to better terms and pricing flexibility. Long-term partnerships often yield more favorable conditions.

-

Be Mindful of Pricing Nuances: Understand the impact of currency fluctuations and local economic conditions on pricing. This awareness can help in making informed purchasing decisions.

What Are the Price Considerations for International Buyers?

International buyers must navigate additional complexities when sourcing ball screw driven actuators. Consider the following:

Illustrative image related to ball screw driven

-

Tariffs and Duties: Be aware of potential tariffs and import duties that can inflate costs significantly.

-

Shipping Costs: International logistics can be unpredictable. Factor in potential delays and varying shipping rates.

-

Local Regulations: Compliance with local standards and regulations may necessitate additional certifications, affecting overall pricing.

Disclaimer on Indicative Prices

Prices for ball screw driven actuators can vary widely based on the factors discussed above. It is advisable for buyers to obtain specific quotes from suppliers, taking into account their unique requirements and circumstances.

Alternatives Analysis: Comparing ball screw driven With Other Solutions

When evaluating linear motion solutions, it is essential for B2B buyers to consider various alternatives to ball screw driven systems. Each technology offers unique advantages and limitations, making it vital to assess how these alternatives align with specific application requirements and operational goals.

| Comparison Aspect | Ball Screw Driven | Belt-Driven Actuator | Linear Motor Actuator |

|---|---|---|---|

| Performance | High load capacity and accuracy | High speed but lower accuracy | Exceptional speed and precision |

| Cost | Higher initial investment | Generally lower cost | Higher upfront and operational cost |

| Ease of Implementation | Moderate complexity | Simple installation | Complex setup |

| Maintenance | Requires regular lubrication | Lower maintenance needs | Minimal maintenance, but high expertise needed |

| Best Use Case | Heavy loads and precise positioning | Long travel distances, moderate loads | High-speed applications requiring precision |

What Are the Advantages and Disadvantages of Belt-Driven Actuators Compared to Ball Screw Driven Systems?

Belt-driven actuators convert rotary motion to linear motion using a timing belt, making them suitable for applications where speed is critical. They excel in scenarios requiring long travel distances, achieving speeds of up to 15 m/s. However, they typically handle lower load capacities (around 2,000 lbs) and may experience issues with accuracy due to belt stretching over time. For applications where high speed is essential but load requirements are moderate, belt-driven systems may be the preferred choice.

How Do Linear Motor Actuators Compare to Ball Screw Driven Systems?

Linear motor actuators provide direct linear motion without the need for mechanical conversion, resulting in exceptionally high speeds and positioning accuracy. They are ideal for applications in robotics and automation, where speed and precision are paramount. However, the cost associated with linear motors can be significant, and their installation often requires specialized knowledge and expertise. Businesses focused on high-performance applications may find that the benefits outweigh the costs, especially in high-throughput environments.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right linear motion solution depends on a thorough understanding of the specific operational requirements. Buyers should evaluate factors such as load capacity, speed, accuracy, and budget constraints. For high-load, precise applications, ball screw driven systems remain a strong contender. Conversely, if speed and long travel lengths are the priority, belt-driven actuators may be more suitable. For cutting-edge applications requiring maximum speed and precision, linear motor actuators are worth considering, despite their higher costs. By aligning the chosen technology with application needs, B2B buyers can optimize performance and efficiency in their operations.

Essential Technical Properties and Trade Terminology for ball screw driven

What Are the Key Technical Properties of Ball Screw Driven Systems?

Ball screw driven actuators are critical components in precision motion applications. Understanding their technical properties can significantly influence procurement decisions. Here are some essential specifications:

1. Load Capacity

Load capacity refers to the maximum weight that a ball screw can safely handle. Typically, ball screw systems can support loads ranging from a few hundred grams to over 13,000 pounds. This is crucial for B2B buyers as it directly impacts the choice of actuator for specific applications. Ensuring that the actuator can handle the required load without compromising performance or safety is paramount.

2. Stroke Length

Stroke length is the maximum distance a ball screw can move its load. While ball screws can achieve lengths up to 6 meters, they are best utilized within 1 meter for optimal performance. For B2B buyers, understanding stroke length is vital for matching the actuator to the operational requirements of their machinery, especially in applications requiring precise movement over varying distances.

3. Accuracy and Repeatability

Accuracy measures how close the actuator’s movement is to the desired position, while repeatability indicates how consistently it can achieve that position. Ball screw systems can achieve positioning accuracy of 5-15 micrometers, making them ideal for applications demanding high precision. For businesses, investing in actuators with superior accuracy can enhance product quality and reduce waste, ultimately leading to cost savings.

Illustrative image related to ball screw driven

4. Material Grade

The material grade of ball screws affects their durability and performance. Common materials include hardened steel for the screw and nut, which provide strength and wear resistance. For B2B buyers, selecting the right material can influence the lifespan and reliability of the actuator, thereby reducing the frequency of replacements and maintenance.

5. Tolerance

Tolerance indicates the allowable deviation from specified dimensions. High tolerance levels are essential for applications requiring precision, as even minor discrepancies can lead to significant operational issues. For international buyers, particularly in high-stakes industries such as aerospace or medical devices, understanding tolerance levels ensures compliance with industry standards and regulations.

What Are Common Trade Terms Related to Ball Screw Driven Systems?

Navigating the world of ball screw driven systems also involves understanding specific trade terminology. Here are some common terms that B2B buyers should know:

Illustrative image related to ball screw driven

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers, as it can affect the quality and compatibility of the components they purchase.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for businesses to manage inventory and cash flow effectively, particularly when dealing with high-value components like ball screw actuators.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. It is an essential step in the procurement process, allowing businesses to compare options and make informed purchasing decisions.

Illustrative image related to ball screw driven

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and the logistics involved in transporting ball screw driven systems across borders.

5. Tolerance

In the context of manufacturing, tolerance also refers to the acceptable range of variation in a physical dimension. It is critical for ensuring that components fit together correctly and function as intended, thereby minimizing operational disruptions.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing ball screw driven actuators, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the ball screw driven Sector

What are the Current Market Dynamics and Key Trends in the Ball Screw Driven Sector?

The global ball screw driven actuator market is experiencing significant growth, driven by the increasing demand for automation across various industries, including manufacturing, aerospace, and robotics. Key factors propelling this trend include the push for enhanced precision in automated systems and the need for efficient motion control solutions. In regions such as Africa, South America, the Middle East, and Europe, the adoption of Industry 4.0 principles is accelerating, leading to greater investments in advanced manufacturing technologies. As international B2B buyers seek reliable and high-performance solutions, the focus is shifting toward suppliers that can offer innovative designs and robust materials.

Emerging technologies, such as smart actuators integrated with IoT capabilities, are transforming sourcing strategies. Buyers are increasingly looking for ball screw actuators that provide real-time performance data, allowing for predictive maintenance and increased operational efficiency. Moreover, as production facilities expand in developing markets, there is a notable shift towards local sourcing to reduce lead times and costs. This trend is particularly relevant for companies in Nigeria and Vietnam, where establishing a strong local supply chain can enhance competitiveness.

Additionally, the market is witnessing a trend towards customization, with suppliers offering tailored solutions to meet specific application needs. This shift allows buyers to optimize their systems for unique operational requirements, enhancing overall performance and reducing waste.

How is Sustainability Impacting the Sourcing of Ball Screw Driven Actuators?

Sustainability is becoming a pivotal consideration in the sourcing of ball screw driven actuators. As global awareness of environmental issues rises, businesses are under pressure to adopt more sustainable practices. This includes sourcing components that have minimal environmental impact. For ball screw driven systems, this means selecting materials and suppliers that prioritize eco-friendly manufacturing processes and sustainable sourcing.

Illustrative image related to ball screw driven

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices, seeking certifications that demonstrate commitment to sustainability. Green certifications, such as ISO 14001, indicate that a supplier adheres to environmental management standards, ensuring that their operations minimize negative impacts on the environment. Additionally, the use of recyclable materials in the production of ball screw actuators is gaining traction, appealing to companies aiming to reduce their carbon footprint.

Moreover, manufacturers are exploring innovations in design that enhance energy efficiency, such as optimizing the geometry of ball screws to reduce friction and energy consumption. This not only benefits the environment but also leads to cost savings for businesses in the long run. International buyers are encouraged to engage with suppliers who are transparent about their sustainability efforts and can provide evidence of their commitment to ethical practices.

What is the Evolution of Ball Screw Driven Technology in the B2B Market?

The evolution of ball screw driven technology has been marked by significant advancements in precision engineering and materials science. Initially developed for basic linear motion applications, ball screw actuators have evolved to meet the demands of increasingly complex automation systems. The introduction of high-precision machining techniques has improved the accuracy and reliability of ball screws, making them a preferred choice for applications requiring tight tolerances.

In recent years, the integration of digital technologies, such as IoT and AI, has further enhanced the capabilities of ball screw driven systems. These advancements allow for smarter designs that can adapt to changing operational conditions, providing businesses with enhanced control over their manufacturing processes. This evolution reflects a broader trend in the B2B sector, where the intersection of traditional engineering and modern technology is reshaping how companies approach automation and motion control solutions. As the market continues to innovate, international buyers must stay informed about these advancements to make strategic sourcing decisions that align with their operational goals.

Frequently Asked Questions (FAQs) for B2B Buyers of ball screw driven

1. How do I choose the right ball screw actuator for my application?

Choosing the right ball screw actuator involves assessing your specific application requirements, including load capacity, travel length, speed, and accuracy. Consider the maximum load your system will need to handle; ball screw actuators typically support heavier loads than belt-driven alternatives. Evaluate the required stroke length and speed; while ball screws excel in precision, they may not be ideal for very long distances or extremely high speeds compared to belt drives. Additionally, think about your mounting orientation and maintenance capabilities, as these factors can influence actuator performance.

2. What are the key advantages of ball screw actuators over belt-driven systems?

Ball screw actuators offer several advantages, including superior load capacity, higher positioning accuracy, and better repeatability. They can deliver significant output forces, making them suitable for high-thrust applications. Ball screws also prevent backdriving, enhancing safety in vertical applications. While they may have limitations in terms of speed compared to belt-driven systems, their rigidity allows for precise control, making them a preferred choice in automation tasks where accuracy is critical.

3. What factors should I consider when vetting suppliers for ball screw actuators?

When vetting suppliers, consider their industry experience, production capabilities, and certifications. Look for suppliers with a proven track record in manufacturing ball screw actuators, especially those serving similar markets to yours. Evaluate their quality assurance processes and customer service responsiveness. Request references or case studies from previous clients to gauge reliability. Additionally, assess their ability to provide customization options that meet your specific needs, as well as their logistics capabilities for timely delivery.

4. Can I customize ball screw actuators for my specific needs?

Yes, many manufacturers offer customization options for ball screw actuators. You can tailor specifications such as length, load capacity, and precision levels to fit your application. Some suppliers also provide modifications for specific mounting orientations or environmental conditions. When discussing customization, clearly communicate your requirements to ensure the final product aligns with your operational needs. Be sure to confirm any implications on lead times and costs associated with customized designs.

5. What is the minimum order quantity (MOQ) for ball screw actuators?

Minimum order quantities can vary significantly between suppliers and often depend on the actuator specifications and customization requirements. Some manufacturers may have low MOQs for standard products, while others might require larger quantities for customized solutions. It’s advisable to inquire directly with potential suppliers about their MOQs and any price breaks available for larger orders. Understanding MOQs can help you plan your budget and inventory needs more effectively.

6. What payment terms should I expect when sourcing ball screw actuators internationally?

Payment terms can vary widely depending on the supplier and your negotiation. Common terms include upfront deposits, payment upon delivery, or net payment within a specified period post-delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing contracts to avoid misunderstandings and ensure smooth transactions.

7. How do I ensure quality assurance for my ball screw actuators?

To ensure quality assurance, request documentation regarding the supplier’s quality control processes and certifications. Many reputable manufacturers will provide test reports, inspection certificates, or compliance with international standards like ISO. You may also consider conducting on-site visits or audits to evaluate their manufacturing practices. Additionally, establish clear quality specifications in your purchase agreement, including performance metrics and acceptable tolerances to guarantee the actuators meet your operational requirements.

8. What logistics considerations should I keep in mind when importing ball screw actuators?

When importing ball screw actuators, consider shipping methods, customs regulations, and lead times. Evaluate whether air freight or sea freight is more suitable based on your urgency and budget. Understand the import duties and tariffs that may apply to your products in your region. Collaborate with logistics providers who have experience in handling machinery components to streamline the shipping process. Lastly, ensure you have a plan for receiving and inspecting the actuators upon arrival to address any potential issues promptly.

Top 4 Ball Screw Driven Manufacturers & Suppliers List

1. PBC Linear – PLA Series Ball Screw Linear Actuators

Domain: pbclinear.com

Registered: 2008 (17 years)

Introduction: Ball Screw Linear Actuators with V-Roller Guides from the PLA Series feature pre-loaded ball bearing cam V-rollers on patent-pending Integral-V™ hardened steel v-groove raceways. They are encased in a robust 68 mm x 55 mm anodized aluminum housing that resists debris. The actuators support a horizontal payload of 220 lb (980 N) and offer a stroke length of up to 2,692 mm (106 in). Key benefits inc…

2. McMaster – Ball-Screw-Driven Actuators

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Ball-Screw-Driven Actuators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. SMC – LEFS Electric Actuator

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: This company, SMC – LEFS Electric Actuator, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. THK – Ball Screw

Domain: thk.com

Registered: 1995 (30 years)

Introduction: Ball Screw: A high-efficiency feed screw with rolling motion between screw axis and nut, reducing drive torque to one-third or less compared to conventional sliding screws.

1. DIN Standard Compliant Ball Screw: Features infinite rolling motion with balls circulating under load.

– Model numbers: EPB-V, EBB-V

2. Precision, Caged Ball Screw: Low noise, small torque fluctuations, long-term mai…

Strategic Sourcing Conclusion and Outlook for ball screw driven

In conclusion, the strategic sourcing of ball screw driven actuators presents significant advantages for businesses looking to enhance their automation capabilities. Key takeaways highlight that while ball screw systems excel in load capacity, accuracy, and high thrust applications, they may be more suited for tasks requiring precision and reliability. In contrast, belt-driven actuators offer benefits in speed and longer stroke lengths, making them ideal for lighter applications.

For international B2B buyers, particularly those in emerging markets like Africa, South America, the Middle East, and Europe, investing in the right actuator technology is crucial for optimizing operational efficiency. Leveraging strategic sourcing can lead to better pricing, improved supplier relationships, and enhanced product quality.

As industries evolve and automation demands increase, aligning your sourcing strategy with innovative actuator solutions will be essential. We encourage you to evaluate your current systems, explore the potential of ball screw driven actuators, and engage with trusted suppliers to drive your business forward. Embrace the future of automation and position your company for success in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.