Everything You Need to Know About Aviation Cable Sourcing in 2025

Introduction: Navigating the Global Market for aviation cable

In the ever-evolving landscape of the aviation industry, sourcing reliable aviation cable can pose significant challenges for international B2B buyers. As businesses from regions such as Africa, South America, the Middle East, and Europe strive to enhance their operational capabilities, the need for high-quality, durable, and compliant aviation cables becomes paramount. This guide aims to demystify the complexities of the aviation cable market, providing insights into various types of cables, their specific applications, and the critical factors to consider when selecting suppliers.

From understanding the distinctions between aircraft cable and wire rope to exploring the latest advancements in materials and technology, this guide offers a comprehensive overview tailored to meet the needs of diverse industries. Additionally, it covers essential topics such as supplier vetting, pricing strategies, and compliance with international standards, ensuring that buyers can make informed decisions that align with their business objectives.

By equipping B2B buyers with actionable insights and best practices, this guide serves as a valuable resource for navigating the global market for aviation cable. Whether you are based in Brazil, Vietnam, or elsewhere, you will find the necessary tools to enhance your procurement strategy, streamline your supply chain, and ultimately drive growth and innovation within your organization.

Understanding aviation cable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aircraft Cable | Diameter up to 3/8 inch, typically 7×7 or 7×19 construction | Winch lines, rigging, fences | Pros: Lightweight, versatile. Cons: Limited to lighter loads. |

| Galvanized Wire Rope | Corrosion-resistant, available in various diameters | Construction, marine applications | Pros: High strength, cost-effective. Cons: Less corrosion resistance than stainless steel. |

| Stainless Steel Aircraft Cable | Corrosion-resistant, available in Type 304 and 316 | Marine environments, high moisture | Pros: Superior rust resistance. Cons: Higher cost, slightly lower strength than galvanized. |

| Rotation-Resistant Wire Rope | Designed to minimize rotation during use | Heavy lifting, cranes | Pros: Enhanced stability, minimizes wear. Cons: More expensive, specific applications only. |

| Swaged & Compacted Wire Rope | High-density construction for increased strength | Industrial applications, lifting | Pros: Excellent strength-to-weight ratio. Cons: Requires specific handling and installation. |

What Are the Key Characteristics of Aircraft Cable?

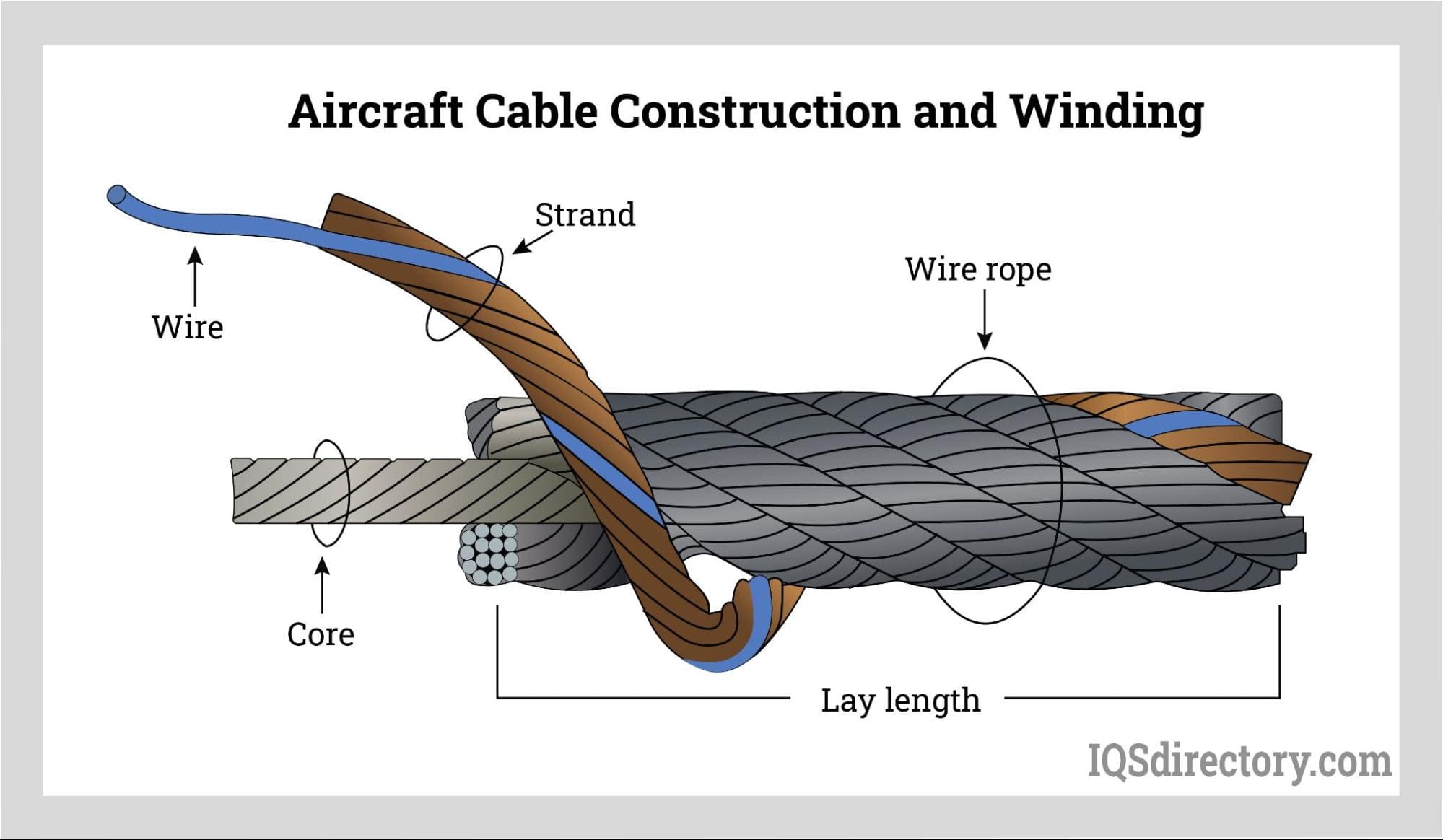

Aircraft cable is a lightweight wire rope, generally constructed with a diameter of up to 3/8 inch. The most common configurations are 7×7 and 7×19, which denote the number of strands and wires per strand. This type of cable is particularly suited for applications where flexibility and strength are required, such as winch lines and rigging for sailboats. Buyers should consider the specific tensile strength and application requirements when selecting aircraft cable, as it is not designed for overhead lifting or critical safety applications.

How Does Galvanized Wire Rope Compare?

Galvanized wire rope is known for its high strength and durability, making it a popular choice in construction and marine applications. This type of cable is coated with zinc to enhance its corrosion resistance, although it may not withstand highly corrosive environments as effectively as stainless steel. Buyers should assess the environmental conditions of their applications and the required load capacities when opting for galvanized wire rope, as it provides a cost-effective solution for many standard lifting and rigging needs.

Why Choose Stainless Steel Aircraft Cable?

Stainless steel aircraft cable, available in Type 304 and 316, offers enhanced corrosion resistance, making it ideal for marine and high-moisture environments. Type 316 contains molybdenum, providing superior rust resistance compared to Type 304. However, this comes at a higher price point, and it may have slightly lower strength. B2B buyers should evaluate the specific environmental conditions and strength requirements when selecting stainless steel cable, especially for applications where durability is critical.

What Are the Benefits of Rotation-Resistant Wire Rope?

Rotation-resistant wire rope is engineered to minimize twisting and rotation during lifting operations, making it an excellent choice for cranes and heavy lifting equipment. This type of cable provides enhanced stability and reduces wear on equipment, which can lead to longer service life. However, it is typically more expensive and designed for specific applications, so buyers must ensure that their operational needs align with the benefits offered by rotation-resistant wire rope.

When to Use Swaged & Compacted Wire Rope?

Swaged and compacted wire rope features a high-density construction that enhances its strength and reduces its overall diameter. This makes it suitable for industrial applications where weight and space are critical factors. While it provides an excellent strength-to-weight ratio, it requires specialized handling and installation techniques. Buyers should consider the specific demands of their projects and whether the benefits of this type of wire rope justify its use in their applications.

Key Industrial Applications of aviation cable

| Industry/Sector | Specific Application of aviation cable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace & Defense | Control systems in aircraft | Ensures safety and reliability in critical systems | Compliance with aviation standards, corrosion resistance |

| Maritime & Shipping | Rigging and mooring systems | Enhances durability and safety in marine environments | Marine-grade materials, resistance to saltwater corrosion |

| Construction & Infrastructure | Elevators and hoisting systems | Provides reliable lifting solutions | Load capacity, length variations, and safety certifications |

| Telecommunications | Cable support for antennas and towers | Facilitates robust and stable communication networks | UV resistance, tensile strength, and custom lengths |

| Entertainment & Events | Stage rigging and lighting systems | Ensures safety and efficiency in event setups | Weight ratings, flexibility, and quick deployment features |

How is Aviation Cable Used in Aerospace & Defense Applications?

In the aerospace and defense sector, aviation cables are critical for control systems that manage aircraft operations. These cables must adhere to stringent safety standards due to the high stakes involved. Buyers from regions like Africa and South America should prioritize suppliers who can provide cables that meet international aviation regulations, ensuring reliability in extreme conditions. Corrosion resistance is also essential, particularly for aircraft operating in diverse climates.

What Role Does Aviation Cable Play in Maritime & Shipping?

Aviation cables are widely utilized in rigging and mooring systems within the maritime industry. Their high tensile strength and durability make them ideal for securing ships and handling heavy loads. Businesses in the Middle East and Europe should seek cables that are specifically designed for marine applications, offering resistance to saltwater corrosion. Sourcing from manufacturers who provide marine-grade materials can enhance safety and longevity in these applications.

How is Aviation Cable Essential for Construction & Infrastructure?

In construction, aviation cables are often employed in elevator systems and hoisting applications, where reliable lifting mechanisms are paramount. Companies involved in large-scale infrastructure projects in developing regions, such as Brazil or Vietnam, should focus on sourcing cables that meet rigorous load capacity requirements. It’s crucial to ensure that the selected cables have the necessary safety certifications to comply with local regulations, thereby minimizing risk during operation.

What is the Importance of Aviation Cable in Telecommunications?

Aviation cables serve as vital supports for antennas and communication towers in the telecommunications sector. Their ability to withstand environmental stresses ensures stable and robust communication networks. B2B buyers in regions with varying climates should consider cables that offer UV resistance and high tensile strength to prevent degradation over time. Custom lengths may also be necessary to meet specific installation requirements.

How Does Aviation Cable Enhance Safety in Entertainment & Events?

In the entertainment industry, aviation cables are integral to stage rigging and lighting systems, providing safety and efficiency during events. The need for flexibility and quick deployment features is essential for event organizers. Buyers should evaluate the weight ratings and overall quality of the cables to ensure they can handle the demands of various setups, particularly in large venues or outdoor events in diverse environments.

3 Common User Pain Points for ‘aviation cable’ & Their Solutions

Scenario 1: Sourcing Quality Aviation Cable for Diverse Applications

The Problem: B2B buyers often face the challenge of sourcing aviation cable that meets specific industry standards and application requirements. With numerous suppliers offering various types of cables, it can be overwhelming to determine which product will deliver the necessary performance, durability, and compliance. For instance, a buyer from a marine engineering company may require stainless steel aviation cable that can withstand high-moisture environments, while another buyer in construction might need galvanized cable for its strength and cost-effectiveness. Misjudging the specifications can lead to project delays, increased costs, and safety hazards.

The Solution: To overcome sourcing challenges, buyers should start by thoroughly understanding their application requirements, including load capacity, environmental conditions, and regulatory standards. Create a detailed specification document outlining these needs. When approaching suppliers, inquire about their certifications, such as ASTM or federal specifications, to ensure compliance with industry standards. Additionally, consider sourcing from manufacturers who provide detailed product data sheets, including material composition, break strength, and corrosion resistance. This not only ensures you select the right aviation cable but also establishes a trustworthy relationship with suppliers, enhancing the likelihood of receiving high-quality products.

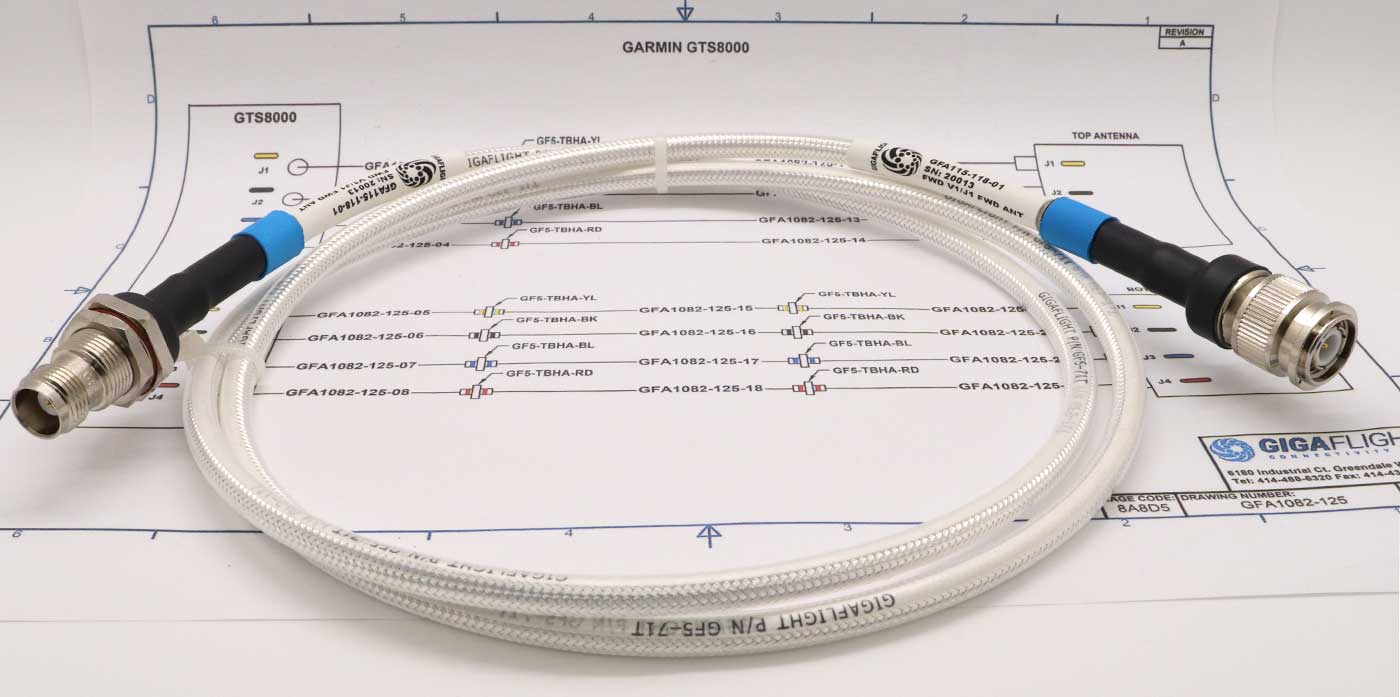

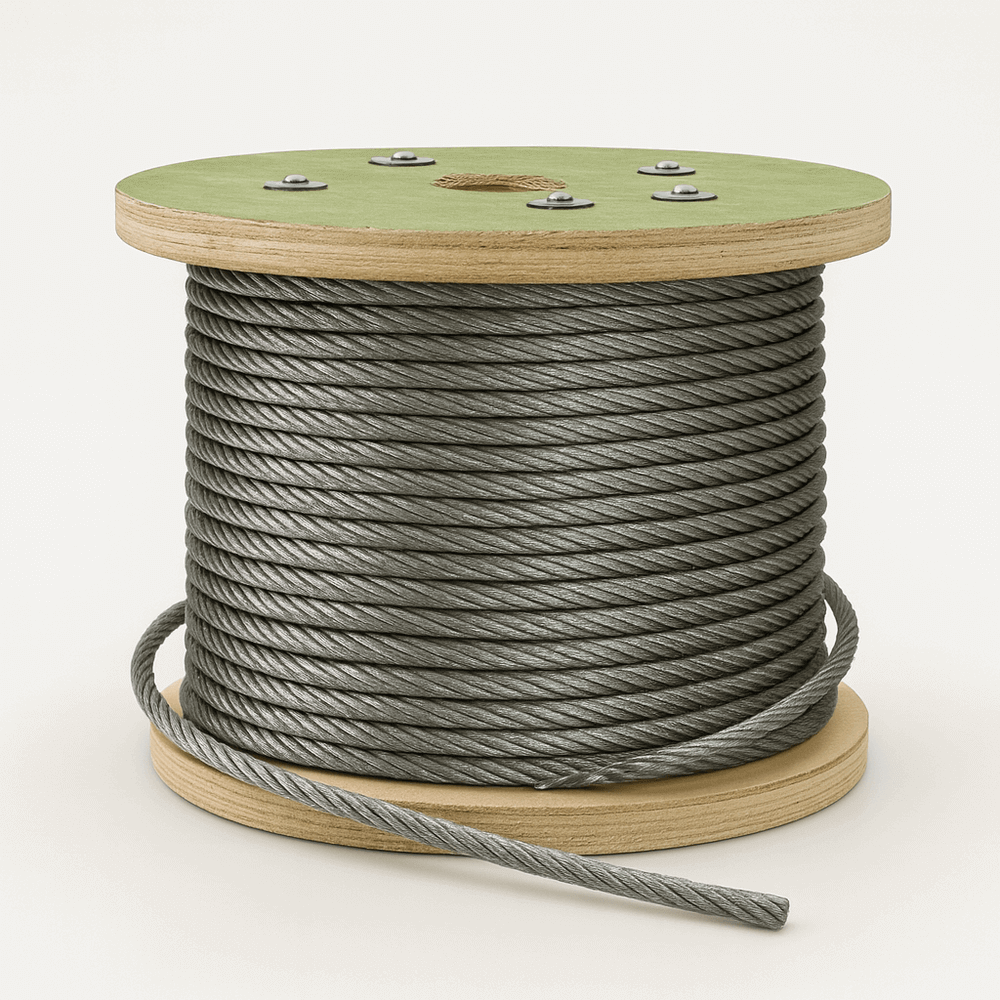

Illustrative image related to aviation cable

Scenario 2: Ensuring the Right Specifications for Safety and Compliance

The Problem: Another common issue is the difficulty in understanding the technical specifications of aviation cable, which can lead to the procurement of incorrect or inadequate products. Buyers may struggle with differentiating between various cable constructions, such as 7×19 versus 6×36, and their respective applications. This confusion can result in using a cable that is unsuitable for its intended purpose, potentially compromising safety and leading to costly rework or even accidents.

The Solution: To navigate these complexities, it’s essential for buyers to invest time in education regarding cable specifications and their implications. Engage with technical resources, such as webinars or training sessions offered by suppliers, to gain a deeper understanding of cable constructions and their appropriate uses. When placing an order, always double-check the specifications against a checklist that includes the diameter, construction type, material, and load requirements. Collaborating with engineers or technical specialists during the selection process can also help ensure that the chosen aviation cable meets both safety and compliance standards, thereby reducing the risk of project delays and enhancing overall safety.

Scenario 3: Managing Supply Chain Disruptions and Delivery Timelines

The Problem: Supply chain disruptions can significantly impact the procurement of aviation cable, leading to delays that affect project timelines. Buyers may encounter unexpected shortages or extended lead times, particularly for specialized cables that are not widely available. Such disruptions can cause frustration and financial loss, especially if contracts are time-sensitive or involve penalties for delays.

The Solution: To mitigate supply chain risks, buyers should adopt a proactive approach by diversifying their supplier base and establishing relationships with multiple manufacturers. This allows for greater flexibility and options in case of disruptions with one supplier. Additionally, consider maintaining a safety stock of critical aviation cables to buffer against unexpected shortages. Regularly reviewing market trends and potential geopolitical factors that could affect supply chains can also provide valuable insights for strategic planning. Lastly, clear communication with suppliers regarding delivery expectations can help manage timelines effectively, ensuring that projects stay on track despite external challenges.

Strategic Material Selection Guide for aviation cable

What Are the Key Properties of Common Materials Used in Aviation Cable?

When selecting materials for aviation cable, understanding the properties and performance characteristics of each type is crucial. The most commonly used materials include galvanized steel, stainless steel, aluminum, and composite materials. Each material offers distinct advantages and disadvantages that can significantly impact the performance and suitability of the cable in various applications.

How Does Galvanized Steel Perform in Aviation Cable Applications?

Galvanized steel is a popular choice for aviation cable due to its high strength and corrosion resistance. The galvanization process involves coating the steel with a layer of zinc, which protects it from rust and environmental degradation. This material typically withstands temperatures ranging from -40°F to 300°F (-40°C to 149°C) and can handle moderate pressure without deformation.

Pros: Galvanized steel is durable, cost-effective, and readily available. It is suitable for a variety of applications, including winch lines and rigging.

Cons: However, it may not perform well in highly corrosive environments, such as marine settings, where stainless steel would be preferred. Additionally, galvanized cables can become brittle over time if exposed to extreme temperatures.

Illustrative image related to aviation cable

Impact on Application: Galvanized steel is ideal for general-purpose applications where exposure to moisture is limited. International buyers should ensure compliance with ASTM A1023 standards for quality assurance.

What Advantages Does Stainless Steel Offer for Aviation Cable?

Stainless steel, particularly types 304 and 316, is renowned for its superior corrosion resistance, making it the go-to choice for aviation cables used in marine or high-moisture environments. Type 316 stainless steel contains molybdenum, enhancing its resistance to rust and corrosion. This material can withstand temperatures up to 500°F (260°C) and is capable of handling significant pressure.

Pros: The key advantages of stainless steel include its long lifespan, high strength-to-weight ratio, and excellent resistance to environmental factors.

Illustrative image related to aviation cable

Cons: The primary drawback is its higher cost compared to galvanized steel. Additionally, while it is strong, it can be less robust under certain conditions, such as extreme tensile loads.

Impact on Application: Stainless steel is particularly suited for applications requiring high corrosion resistance, such as in coastal regions. Buyers from regions like the Middle East should consider local environmental conditions when choosing stainless steel types.

How Do Aluminum and Composite Materials Compare for Aviation Cable?

Aluminum and composite materials are increasingly used in aviation cables, especially in lightweight applications. Aluminum offers a high strength-to-weight ratio and excellent corrosion resistance, making it suitable for applications where weight savings are critical.

Pros: Aluminum is lightweight, cost-effective, and easy to manufacture. It performs well in a variety of environments and is often used in aerospace applications.

Cons: However, aluminum is generally less strong than steel, which may limit its use in high-load applications. Composite materials, while lightweight and resistant to corrosion, can be more expensive and complex to manufacture.

Illustrative image related to aviation cable

Impact on Application: Aluminum is ideal for applications requiring lightweight solutions, while composites are best for specialized applications where traditional materials may not suffice. International buyers should be aware of compliance with relevant standards such as JIS and DIN.

Summary of Material Selection for Aviation Cable

| Material | Typical Use Case for aviation cable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | General-purpose rigging and winch lines | Cost-effective and durable | Limited corrosion resistance | Low |

| Stainless Steel | Marine and high-moisture environment cables | Superior corrosion resistance | Higher cost compared to galvanized | High |

| Aluminum | Lightweight aerospace applications | Lightweight and easy to manufacture | Less strength than steel | Medium |

| Composite Materials | Specialized applications in aerospace | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

This guide aims to assist international B2B buyers in making informed decisions regarding aviation cable material selection, considering both performance and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for aviation cable

What Are the Key Manufacturing Processes for Aviation Cable?

Aviation cable manufacturing involves several critical stages that ensure the final product meets the rigorous demands of the aerospace industry. Understanding these processes is essential for B2B buyers seeking reliable suppliers.

What Materials Are Used in Aviation Cable Production?

The manufacturing of aviation cable typically begins with the selection of high-strength steel, which is the primary material used. This steel may be treated or coated to enhance its properties, such as corrosion resistance, which is crucial for applications in various environments. Common options include galvanized steel and stainless steel (types 304 and 316), each offering distinct advantages regarding durability and resistance to environmental factors.

How Is Aviation Cable Formed?

Once the raw materials are prepared, the forming stage begins. This involves several techniques:

-

Stranding: Multiple wires are twisted together to form strands, creating the foundational structure of the cable. The number of wires and the configuration (e.g., 7×19 or 6×36) will determine the cable’s strength and flexibility.

-

Swaging: This process compresses the cable to enhance its strength and reduce its diameter. Swaging is particularly important for applications requiring high tensile strength.

-

Compacting: By compressing the strands together, manufacturers can reduce the overall size while maintaining strength. This technique is often used for cables that need to fit into tight spaces.

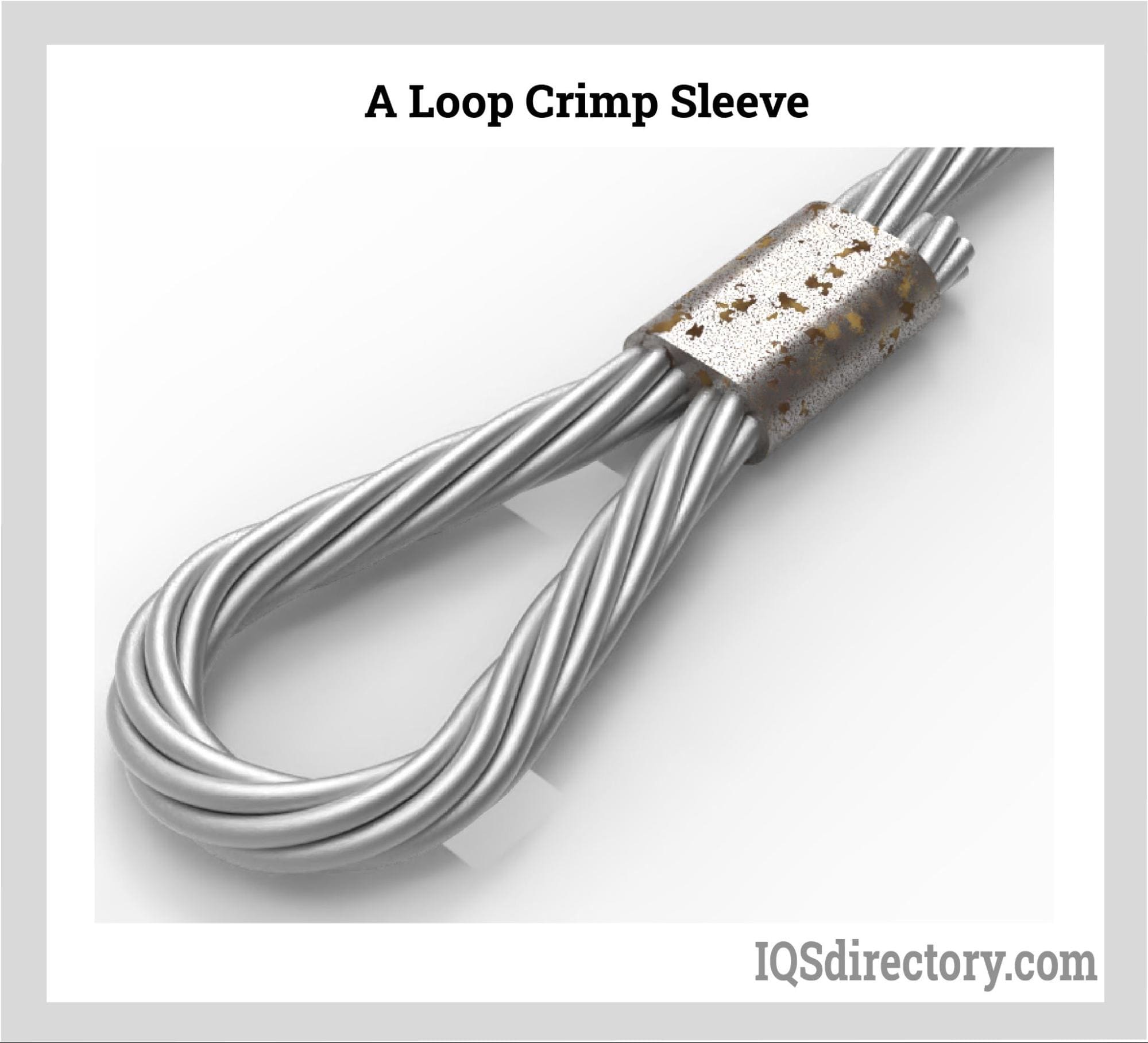

What Assembly Techniques Are Commonly Used?

The assembly stage integrates various components of the cable, such as end fittings and connectors, which may require specialized techniques for secure attachment. This stage often involves:

- Mechanical Crimping: A method used to attach fittings to the cable, ensuring a secure connection that can withstand significant loads.

- Welding: In some cases, components may be welded to provide a more permanent and robust attachment.

How Is Quality Assurance Implemented in Aviation Cable Production?

Quality assurance (QA) is vital in the manufacturing of aviation cables, as it guarantees that the final product meets industry standards and customer expectations.

What International Standards Are Relevant to Aviation Cable Quality?

B2B buyers should be aware of the international standards that govern the production of aviation cables. Notable standards include:

- ISO 9001: This standard outlines the requirements for a quality management system and emphasizes customer satisfaction and continuous improvement.

- CE Marking: In Europe, the CE mark indicates that the product meets safety, health, and environmental protection standards.

- API Standards: These standards are applicable for cables used in the oil and gas sector, ensuring that products meet specific performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is performed at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted to identify any deviations from quality standards. This may involve monitoring the stranding and swaging processes.

- Final Quality Control (FQC): Once the product is completed, a final inspection is carried out, which includes testing for strength, flexibility, and compliance with relevant standards.

What Testing Methods Are Commonly Used for Aviation Cables?

B2B buyers should understand the various testing methods employed to ensure product quality:

- Tensile Testing: This measures the strength of the cable by applying a load until it fails, providing insights into its performance under stress.

- Fatigue Testing: This simulates the repeated loading and unloading that cables may experience in real-world applications, helping to predict lifespan and durability.

- Corrosion Resistance Testing: This is particularly important for cables intended for marine or high-moisture environments, ensuring they can withstand harsh conditions.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high standards of quality control, B2B buyers can take several steps:

Illustrative image related to aviation cable

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational efficiency of potential suppliers.

-

Requesting Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from various tests and certifications obtained.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s capabilities and compliance with international standards.

What Are the Nuances of Quality Control for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when sourcing aviation cables.

-

Regulatory Compliance: Different regions may have varying regulations regarding aviation components. Understanding these requirements is crucial for ensuring compliance and avoiding legal issues.

-

Supply Chain Considerations: Buyers must also consider the reliability of the supply chain, including transportation logistics, which can impact lead times and product availability.

-

Cultural Differences: Communication styles and business practices may vary significantly across regions. Building strong relationships with suppliers can facilitate smoother transactions and better quality assurance.

By understanding the manufacturing processes and quality assurance measures involved in aviation cable production, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aviation cable’

Introduction

Sourcing aviation cable requires careful consideration of technical specifications, supplier reliability, and compliance with industry standards. This guide aims to equip international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, with a practical checklist to streamline the procurement process and ensure optimal purchasing decisions.

1. Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the aviation cable you need. This includes specifications such as diameter, construction type (e.g., 7×19 or 7×7), and material (galvanized or stainless steel).

– Why It Matters: Accurate specifications ensure that the cable meets your operational needs and safety standards.

– What to Look For: Consider the environment where the cable will be used; for example, stainless steel offers superior corrosion resistance in humid conditions.

2. Assess Compliance with Industry Standards

Verify that the aviation cable complies with relevant industry standards such as ASTM A1023 and federal specifications like RR-W-410.

– Why It Matters: Compliance with these standards ensures safety, reliability, and performance, reducing the risk of operational failures.

– What to Look For: Request documentation from suppliers that certifies compliance and review their manufacturing processes to ensure adherence to these standards.

3. Evaluate Potential Suppliers

Before making any commitments, conduct a thorough evaluation of potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Why It Matters: A reliable supplier can significantly impact the quality of the cable and your overall procurement experience.

– What to Look For: Focus on suppliers with a proven track record in aviation cable distribution and those who can provide testimonials from satisfied clients.

4. Request Samples for Testing

Ask for samples of the aviation cable you are considering to conduct your own tests.

– Why It Matters: Testing samples allows you to evaluate the cable’s quality, strength, and suitability for your specific applications.

– What to Look For: Assess the break strength and flexibility of the cable, and consider conducting environmental tests if applicable.

5. Negotiate Pricing and Terms

Engage in negotiations regarding pricing, delivery schedules, and payment terms.

– Why It Matters: Effective negotiation can lead to better pricing and favorable terms that align with your budget and project timelines.

– What to Look For: Ensure that pricing reflects the quality of the product and consider bulk purchasing discounts or long-term contracts for better rates.

Illustrative image related to aviation cable

6. Verify Logistics and Delivery Capabilities

Confirm the supplier’s logistics capabilities, including shipping methods and estimated delivery times.

– Why It Matters: Timely delivery is crucial to maintaining your project schedules and avoiding costly delays.

– What to Look For: Evaluate the supplier’s track record for on-time deliveries and inquire about their processes for handling international shipments.

7. Establish a Quality Assurance Process

Implement a quality assurance process for ongoing assessments of the aviation cable once received.

– Why It Matters: Continuous quality checks help to ensure that the cable maintains performance standards throughout its usage.

– What to Look For: Set up a system for regular inspections and establish criteria for evaluating cable performance over time.

By following this checklist, B2B buyers can enhance their sourcing strategy for aviation cable, ensuring they select the right products and suppliers while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for aviation cable Sourcing

What Are the Key Cost Components in Aviation Cable Sourcing?

When sourcing aviation cable, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

Illustrative image related to aviation cable

-

Materials: The type of materials used, such as stainless steel or galvanized wire, significantly impacts the cost. Stainless steel, particularly Type 316, provides superior corrosion resistance but typically comes at a higher price point compared to galvanized options.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled labor is often required for high-quality production, which can increase overall costs.

-

Manufacturing Overhead: This includes expenses related to the factory’s operation, such as utilities, rent, and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: The initial investment in tooling can be substantial, especially for custom or specialized cables. However, once the tooling is amortized over production runs, it can significantly reduce unit costs.

-

Quality Control (QC): Ensuring the product meets industry standards and regulations incurs additional costs. Rigorous QC processes are essential, particularly for aviation applications where safety is paramount.

-

Logistics: Shipping costs can vary widely based on distance, transport mode, and Incoterms. Import duties and taxes should also be factored into the total logistics cost.

-

Margin: Suppliers will add a margin to cover their costs and profit. This margin can vary based on market demand, competition, and the supplier’s positioning in the market.

How Do Price Influencers Affect Aviation Cable Costs?

Several factors influence the pricing of aviation cables, impacting both suppliers and buyers:

-

Volume/MOQ: Bulk purchasing can lead to significant cost savings. Suppliers often have minimum order quantities (MOQs), and higher volumes can negotiate better pricing structures.

-

Specifications and Customization: Custom specifications, such as unique lengths, diameters, or coatings, can increase costs. Standard products usually have lower prices due to economies of scale.

-

Quality and Certifications: High-quality cables that meet stringent aviation standards often come at a premium. Certifications can enhance a product’s credibility but may also add to its cost.

-

Supplier Factors: The supplier’s location, reputation, and financial stability can affect pricing. Established suppliers with a strong track record may charge more for their reliability and service.

-

Incoterms: The chosen Incoterms can influence the final price. For instance, “Ex Works” may have lower upfront costs but could lead to higher logistics expenses for the buyer.

What Are Some Effective Buyer Tips for Aviation Cable Sourcing?

B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to optimize their procurement process:

-

Negotiation: Always engage in negotiations. Suppliers may have flexibility in pricing, especially for large orders or long-term contracts. Building a good relationship can also yield better terms.

-

Cost Efficiency: Assess the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and potential replacement costs. A lower upfront price may not always be the best value if the product has a shorter lifespan.

-

Pricing Nuances for International Buyers: Understand the local market conditions, currency fluctuations, and trade regulations that could impact pricing. Engaging local agents or consultants can provide valuable insights.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Comparing multiple suppliers can reveal significant price variations and lead to better deals.

Disclaimer on Pricing

Please note that prices for aviation cables can fluctuate based on market conditions, supplier pricing strategies, and other external factors. Therefore, the indicative prices provided should be used as a guideline rather than a definitive cost. Always request updated quotes and verify specifications before making a purchasing decision.

Alternatives Analysis: Comparing aviation cable With Other Solutions

Understanding Alternatives to Aviation Cable

In the aviation industry, selecting the right cable solution is critical for safety, efficiency, and cost-effectiveness. While aviation cable is a popular choice for various applications, there are alternative solutions that can offer specific advantages depending on the context. This analysis explores key alternatives, comparing their performance, cost, ease of implementation, maintenance, and best use cases to help international B2B buyers make informed decisions.

Illustrative image related to aviation cable

| Comparison Aspect | Aviation Cable | Steel Wire Rope | Synthetic Rope |

|---|---|---|---|

| Performance | High tensile strength, corrosion-resistant options | Exceptional load-bearing capacity; suitable for heavy lifting | Lightweight, flexible, and resistant to abrasion |

| Cost | Moderate, varies by material | Generally lower cost, especially for bulk purchases | Higher initial cost, but long-term savings on maintenance |

| Ease of Implementation | Requires specialized fittings and installation techniques | Easier to handle and install; versatile configurations | Simple to install, but requires careful handling to prevent damage |

| Maintenance | Regular inspections needed; can be susceptible to wear | Requires periodic checks; durable under various conditions | Minimal maintenance; may degrade over time under UV exposure |

| Best Use Case | Aircraft rigging, suspension systems | Heavy lifting, industrial applications | Maritime environments, outdoor applications |

Detailed Breakdown of Alternatives

1. Steel Wire Rope

Steel wire rope is often utilized in heavy-duty applications due to its robust load-bearing capabilities. It is typically more affordable than aviation cable, making it an attractive option for companies looking to manage costs. The ease of installation is another significant advantage, as it can be configured in various ways to meet specific needs. However, steel wire rope may require regular inspections to ensure safety and performance, especially in harsh environments.

2. Synthetic Rope

Synthetic ropes, such as those made from materials like polyester or nylon, offer unique advantages, particularly in terms of weight and flexibility. These ropes are significantly lighter than both aviation and steel wire cables, making them easier to handle and transport. They are also resistant to abrasion, which is beneficial in applications where wear and tear are concerns. Despite their advantages, synthetic ropes can have a higher upfront cost and may require more attention to UV exposure, which can degrade the material over time.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a cable solution, B2B buyers must consider various factors, including application requirements, budget constraints, and long-term maintenance. Aviation cable excels in environments requiring high tensile strength and corrosion resistance, making it ideal for aviation applications. Steel wire rope presents a cost-effective alternative with strong performance in heavy lifting, while synthetic rope offers lightweight and flexible options for specific use cases, particularly in maritime settings. Ultimately, understanding the unique advantages and limitations of each alternative will empower buyers to make decisions that align with their operational goals and industry standards.

Essential Technical Properties and Trade Terminology for aviation cable

What Are the Key Technical Properties of Aviation Cable?

Aviation cable, often referred to as aircraft cable, possesses several critical technical properties that influence its performance and suitability for various applications. Understanding these specifications is crucial for B2B buyers to ensure they select the right products for their operational needs.

1. Material Grade

Aviation cables are typically manufactured from high-strength steel, which is either galvanized or stainless steel. Galvanized steel provides a cost-effective option with decent corrosion resistance, making it suitable for moderate environments. In contrast, stainless steel variants, particularly Type 304 and Type 316, offer superior resistance to corrosion and are ideal for marine or high-moisture applications. Buyers must consider the environment in which the cable will be used to choose the appropriate material grade.

2. Construction Type

The construction of aviation cables generally follows specific patterns, such as 7×19 or 7×7 configurations. The first number indicates the number of strands, while the second indicates the number of wires in each strand. A 7×19 construction, for example, offers greater flexibility and is commonly used in applications requiring dynamic movement, such as rigging. Understanding the construction type helps buyers determine the cable’s flexibility, strength, and load-bearing capacity.

3. Diameter and Breaking Strength

Aviation cables come in various diameters, typically ranging from 1/32″ to 3/8″. The diameter directly affects the cable’s breaking strength, which is the maximum load the cable can withstand before failure. For instance, a 3/8″ cable may have a breaking strength of around 14,400 lbs, making it suitable for heavy-duty applications. Buyers should assess their load requirements to select a cable with an appropriate diameter and breaking strength.

4. Coating and Finish

The finish of the aviation cable can significantly influence its durability and performance. Options include vinyl-coated, galvanized, and various grades of stainless steel. Vinyl coatings provide additional protection against wear and corrosion, making them ideal for outdoor applications. Buyers should consider the specific conditions their cables will face, such as exposure to chemicals or extreme weather, to select the most suitable finish.

5. Tolerance and Certification

Tolerance refers to the allowable deviation from specified dimensions and properties. Aviation cables must meet specific industry standards such as ASTM A1023 or federal specifications like RR-W-410. This ensures reliability and safety in applications where failure is not an option. Buyers should verify that their chosen cables are certified to the relevant standards to ensure compliance and quality.

What Common Trade Terms Should B2B Buyers Know?

Navigating the aviation cable market involves familiarity with specific trade terminology that can impact procurement and negotiations. Understanding these terms helps buyers communicate effectively and make informed purchasing decisions.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of aviation cables, knowing the OEM can help buyers assess product quality and compatibility with their existing systems.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and ensure they meet supplier requirements without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal document that solicits pricing and terms from suppliers for specific products. It allows buyers to compare offers and negotiate terms, making it a vital step in the procurement process for aviation cables.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs and responsibilities, ensuring smoother transactions.

5. Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. Understanding lead times is crucial for B2B buyers to align their supply chains and avoid delays in project timelines.

Illustrative image related to aviation cable

By grasping these essential technical properties and trade terms, B2B buyers can navigate the complexities of the aviation cable market more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the aviation cable Sector

What Are the Key Trends Driving the Aviation Cable Market?

The aviation cable sector is experiencing robust growth, driven by several global trends. Firstly, the increasing demand for lightweight, high-strength materials in the aerospace industry is propelling innovation in aviation cables. As manufacturers strive for fuel efficiency and enhanced performance, the need for advanced materials, such as stainless steel and galvanized cables, has surged. Additionally, the global push towards modernization and expansion of airport infrastructure, particularly in emerging markets such as Africa and South America, is creating new opportunities for suppliers.

Another significant trend is the integration of technology in sourcing and supply chain management. The rise of digital platforms enables B2B buyers to access a broader range of suppliers and products, fostering competition and driving down costs. International buyers are increasingly utilizing data analytics and AI-driven tools to make informed purchasing decisions, assess supplier reliability, and optimize inventory management. This shift towards tech-enabled sourcing is especially relevant in regions like Europe and the Middle East, where procurement processes are becoming more streamlined and efficient.

Furthermore, sustainability is becoming a critical focus within the aviation cable industry. As environmental regulations tighten, buyers are seeking suppliers who prioritize eco-friendly practices, from production to distribution. This trend is not only about compliance but also about meeting consumer expectations for corporate responsibility, particularly in markets where environmental consciousness is rising.

How Is Sustainability Influencing Sourcing Decisions for Aviation Cables?

Sustainability and ethical sourcing are increasingly pivotal in the aviation cable market, reflecting a broader shift towards responsible business practices. The environmental impact of production processes is under scrutiny, prompting manufacturers to adopt greener practices. This includes utilizing recycled materials and minimizing waste, which not only reduces the carbon footprint but also enhances brand reputation among environmentally conscious buyers.

Ethical supply chains are essential for fostering trust and transparency in business relationships. Buyers from diverse regions, including Africa and Latin America, are prioritizing suppliers who demonstrate a commitment to ethical labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and LEED for sustainable manufacturing are becoming vital for suppliers looking to differentiate themselves in a competitive marketplace.

Moreover, the demand for ‘green’ materials is on the rise. Buyers are increasingly favoring aviation cables made from sustainable sources, such as biodegradable coatings or recyclable materials, to align with their corporate sustainability goals. This trend not only helps mitigate environmental impact but also positions businesses as leaders in sustainability, appealing to a growing segment of eco-conscious consumers.

How Has the Aviation Cable Sector Evolved Over Time?

The evolution of the aviation cable sector reflects broader advancements in technology and materials science. Initially, aviation cables were primarily made from simple steel wires, which provided basic functionality but lacked the durability and strength required for modern aviation demands. Over the decades, innovations such as the introduction of galvanized and stainless steel cables have significantly enhanced the performance characteristics of aviation cables, making them more resilient to environmental stressors.

Illustrative image related to aviation cable

As the aviation industry expanded, so did the complexity of its needs. The introduction of multi-strand cables, such as the 7×19 configuration, allowed for increased flexibility and strength, addressing the challenges of modern aircraft design. Today, the sector is not only focused on mechanical performance but also on integrating advanced technologies that improve safety and efficiency.

In summary, the aviation cable market is at a pivotal point, shaped by technological advancements, sustainability imperatives, and evolving buyer expectations. International B2B buyers must navigate these dynamics to effectively source quality aviation cables that meet both operational and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of aviation cable

-

How do I determine the right type of aviation cable for my project?

Selecting the appropriate aviation cable involves understanding your specific application requirements. Key factors include the cable’s diameter, construction type (such as 7×19 or 7×7), and material (galvanized or stainless steel). Assess the environmental conditions, such as exposure to moisture or corrosive elements, to choose the right finish. Additionally, consult with manufacturers or suppliers who can provide technical data sheets and recommendations based on industry standards to ensure compliance and safety. -

What is the best material for aviation cable in humid environments?

For humid or marine environments, Type 316 stainless steel aviation cable is often the best choice due to its superior corrosion resistance. This material contains molybdenum, enhancing its ability to withstand rust in high-moisture conditions. While galvanized cables offer some corrosion protection, they may not perform as well as stainless steel in challenging environments. Always evaluate the specific environmental factors of your project to make an informed decision. -

What are the minimum order quantities (MOQs) for aviation cables?

Minimum order quantities for aviation cables can vary significantly by supplier and product type. Some manufacturers may offer MOQs as low as 100 feet, while others may require orders in the thousands of feet for custom products. It’s essential to communicate your needs with potential suppliers early in the sourcing process to negotiate terms that align with your project requirements, ensuring you get the right amount without excess inventory. -

How can I vet suppliers of aviation cables effectively?

To vet suppliers, start by checking their industry certifications and compliance with international standards, such as ASTM and ISO. Request references from previous clients, especially those in your region or industry. Assess their production capabilities, lead times, and quality assurance processes. Additionally, consider visiting their facilities if possible or arranging a video call to discuss your needs and evaluate their responsiveness and expertise. -

What payment terms should I expect when sourcing aviation cables internationally?

Payment terms for international sourcing can vary widely, but common practices include upfront payments, letters of credit, or net payment terms (e.g., 30, 60, or 90 days). Discuss payment methods that offer security for both parties, such as escrow services or trade finance options. Ensure that the terms are clearly outlined in the purchase agreement to avoid misunderstandings and protect your investment. -

How do I ensure quality assurance for aviation cables?

Quality assurance can be maintained through several steps, including specifying industry standards in your purchase order, requesting certificates of compliance, and conducting third-party inspections. Ask suppliers for their quality control processes and any testing they perform on their products. Additionally, consider requesting samples before placing a large order to evaluate the cable’s performance and specifications firsthand. -

What logistics considerations should I keep in mind when importing aviation cables?

Logistics for importing aviation cables involve understanding shipping methods, customs regulations, and potential tariffs in your country. Choose a reliable freight forwarder who can navigate these complexities on your behalf. Ensure that all shipping documentation is accurate and complete to prevent delays at customs. Also, factor in lead times for production and shipping to align with your project schedules. -

Can aviation cables be customized for specific applications?

Yes, many manufacturers offer customization options for aviation cables, including variations in diameter, construction type, material, and length. When seeking customization, clearly outline your specific requirements and intended application to the supplier. Discuss the technical specifications and any relevant industry standards to ensure the final product meets your needs effectively. Be prepared for potential lead times associated with custom orders.

Top 6 Aviation Cable Manufacturers & Suppliers List

1. Rigging Warehouse – Aircraft Cable & Wire Rope

Domain: riggingwarehouse.com

Registered: 2006 (19 years)

Introduction: Aircraft Cable & Wire Rope includes various subcategories such as General Purpose Wire Rope, Rotation-Resistant Wire Rope, Strand, Swaged & Compacted Wire Rope, Cable Laid Wire Rope, Wire Rope Winch Lines, and Wire Rope Lubricants. The product offerings include different sizes and constructions, such as 1″ 19×7 Rotation-Resistant Wire Rope, 1″ 6×25 XIP Steel Core (IWRC) Bright Wire Rope, and vario…

2. US Cargo Control – Aircraft Cable Solutions

Domain: uscargocontrol.com

Registered: 2005 (20 years)

Introduction: Aircraft Cable options include: 7×19 Galvanized Aircraft Cable, 7×19 304 Stainless Steel Aircraft Cable, 7×19 316 Stainless Steel Aircraft Cable, 7×19 Galvanized Aircraft Cable – Vinyl-Coated, 7×19 304 Stainless Steel Aircraft Cable – Vinyl-Coated. Break Strengths range from 920 lbs to 14400 lbs, with multiple products available at each strength level.

3. Griplock® Systems – Art Aircraft Cable

Domain: griplocksystems.com

Registered: 1998 (27 years)

Introduction: Product Name: Art Aircraft Cable

Brand: Griplock® Systems

Material: Stainless Steel

Cable Types: Extra-Fine, Standard, Medium, Heavy

Cable Diameters:

– Extra-Fine: 1.0mm (17 lbs SWL)

– Standard: 3/64″ (22 lbs SWL)

– Medium: 1/16″ (50 lbs SWL)

– Heavy: 3/32″ (87 lbs SWL)

Cable Lengths: Standard lengths are 36, 48, 60, 72, 84, 96, and 120 inches.

Price Range:

– Extra-Fine Cable: $2.21 – $3.66

– St…

4. e-Rigging – Aircraft Cable Solutions

Domain: e-rigging.com

Registered: 2004 (21 years)

Introduction: This company, e-Rigging – Aircraft Cable Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

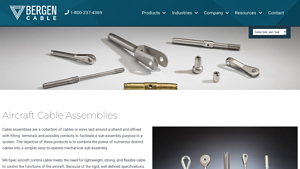

5. Bergen Cable – Aircraft Safety Cable™

Domain: bergencable.com

Registered: 1999 (26 years)

Introduction: Aircraft Cable Assemblies are custom cable assemblies designed for aerospace applications, combining multiple cables into a simpler mechanical sub-assembly. Key products include:

1. **Aircraft Safety Cable™**: Introduced in 1988, it replaces lockwire and is adopted by aviation OEMs and MROs. Specifications: Length: 6″ to 24″, Diameter: 20mm to 60mm, Materials: 321 stainless steel, 304 stainless s…

6. Elite Sales Inc – Aircraft Cable

Domain: elitesalesinc.com

Registered: 1997 (28 years)

Introduction: Aircraft cable is a wire rope made of steel wires stranded together, typically between 8 and 28 strands, providing strength and flexibility for various applications. It is commonly used in aerospace for control cables, rigging, and suspension systems, but also in marine, fitness equipment, garage doors, cargo securing, stage rigging, winching, and ziplines. The cable is available in four finishes:…

Strategic Sourcing Conclusion and Outlook for aviation cable

In the evolving landscape of aviation cable sourcing, international buyers must prioritize strategic procurement to ensure not only compliance with industry standards but also to enhance operational efficiency. The diversity of aviation cables—ranging from galvanized to stainless steel options—demands a nuanced understanding of material properties and application suitability. Buyers from regions such as Africa, South America, the Middle East, and Europe should leverage this knowledge to select products that align with their specific environmental conditions and operational requirements.

Establishing strong relationships with reliable suppliers can yield significant advantages, including better pricing, customized solutions, and timely delivery. The importance of quality assurance cannot be overstated; investing in high-quality aviation cables is essential for safety and longevity, ultimately reducing long-term costs.

Looking ahead, the global demand for aviation cables is expected to rise, driven by increasing air travel and infrastructure developments. B2B buyers are encouraged to remain proactive in their sourcing strategies, embracing innovations and sustainability practices. By aligning procurement processes with market trends, organizations can position themselves competitively in this dynamic sector. Engage with trusted suppliers today to secure the quality aviation cables your operations demand for a successful future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.