Everything You Need to Know About Aluminium Extrusion Press Sourcing in 2025

Introduction: Navigating the Global Market for aluminium extrusion press

In today’s competitive landscape, sourcing an aluminium extrusion press that meets specific production needs while ensuring operational efficiency can be a daunting challenge for international B2B buyers. The global market for aluminium extrusion presses is diverse, featuring various types that cater to different applications, from energy-efficient hybrid presses to specialized systems for complex shapes. This guide offers a comprehensive overview of the aluminium extrusion press market, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

As you navigate this intricate landscape, you’ll gain insights into the latest advancements in extrusion technology, enabling you to make informed decisions tailored to your unique production requirements. Whether you are based in Africa, South America, the Middle East, or Europe, this guide equips you with the knowledge to identify reputable suppliers, assess the quality and efficiency of different press models, and ultimately enhance your procurement strategy.

By understanding the nuances of aluminium extrusion presses, you can optimize your manufacturing processes, reduce operational costs, and remain competitive in a rapidly evolving industry. Armed with this information, you will be better positioned to leverage the benefits of aluminium extrusion technology, paving the way for successful business outcomes.

Understanding aluminium extrusion press Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Extrusion | Utilizes hydraulic force to push the aluminum through the die. | General manufacturing, small batch sizes | Pros: Cost-effective, flexible for various shapes. Cons: Limited to softer alloys. |

| Indirect Extrusion | Reduces friction between billet and container, ideal for hard alloys. | Aerospace, automotive, high-strength applications | Pros: Optimized material flow, suitable for high-strength alloys. Cons: Higher initial investment. |

| Hybrid Extrusion | Combines electric and hydraulic systems for efficiency. | Energy-efficient production lines | Pros: Up to 55% less energy consumption, increased productivity. Cons: Requires higher technical expertise. |

| Tube Extrusion | Specialized for producing seamless tubes with precise tolerances. | Plumbing, automotive, structural applications | Pros: Excellent dimensional accuracy, suitable for complex profiles. Cons: Limited to tube shapes. |

| Front-Loading Presses | Allows for easy access and rapid setup changes. | Small to medium production runs | Pros: Fast changeovers, versatile for different profiles. Cons: May have lower production rates compared to back-loading presses. |

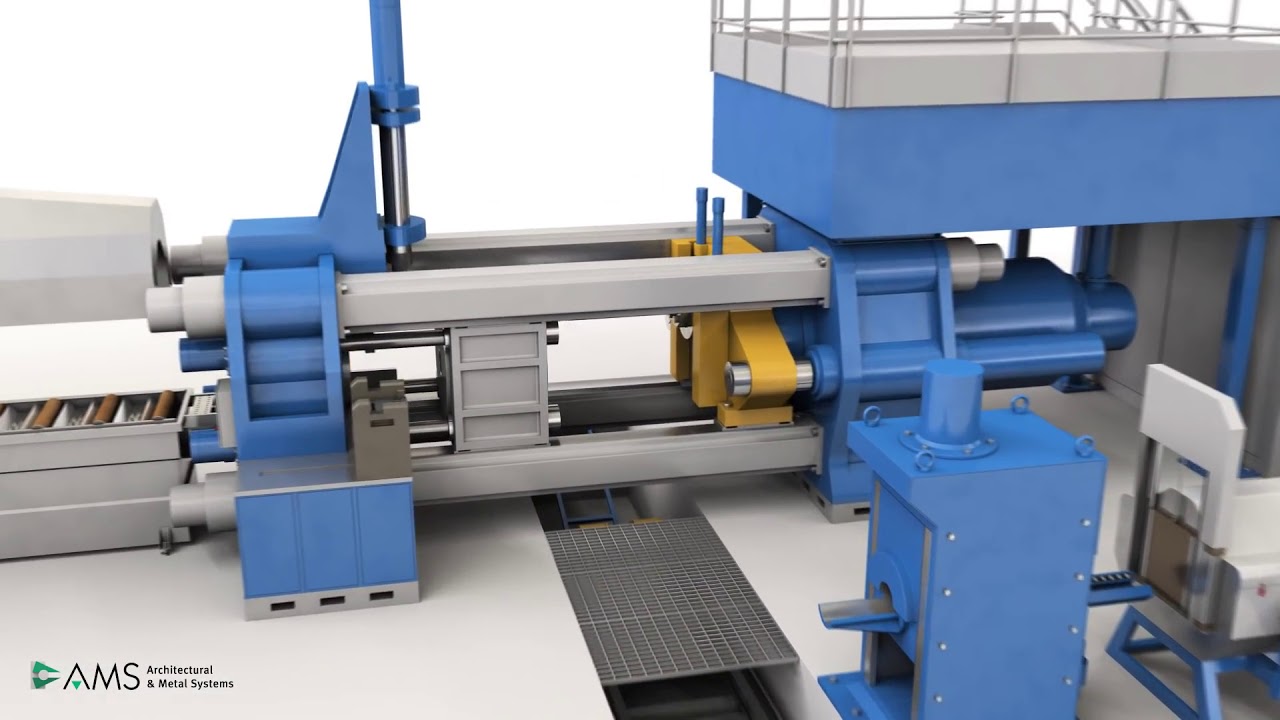

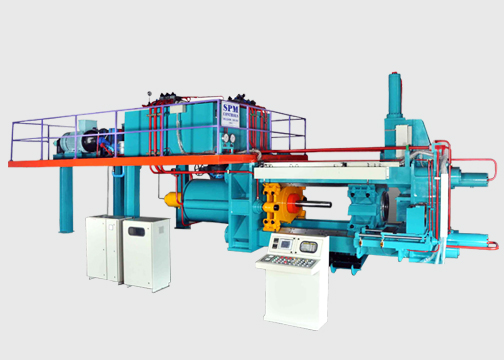

What are the Characteristics of Direct Extrusion Presses?

Direct extrusion presses are characterized by their straightforward design, where a hydraulic ram pushes a heated aluminum billet directly through a die. This method is particularly suitable for producing a variety of shapes and is favored in applications that require flexibility and lower production costs. For B2B buyers, the primary consideration is the ability to handle small batch sizes efficiently. However, it is essential to note that this method is generally limited to softer aluminum alloys, which may restrict the range of products that can be manufactured.

Illustrative image related to aluminium extrusion press

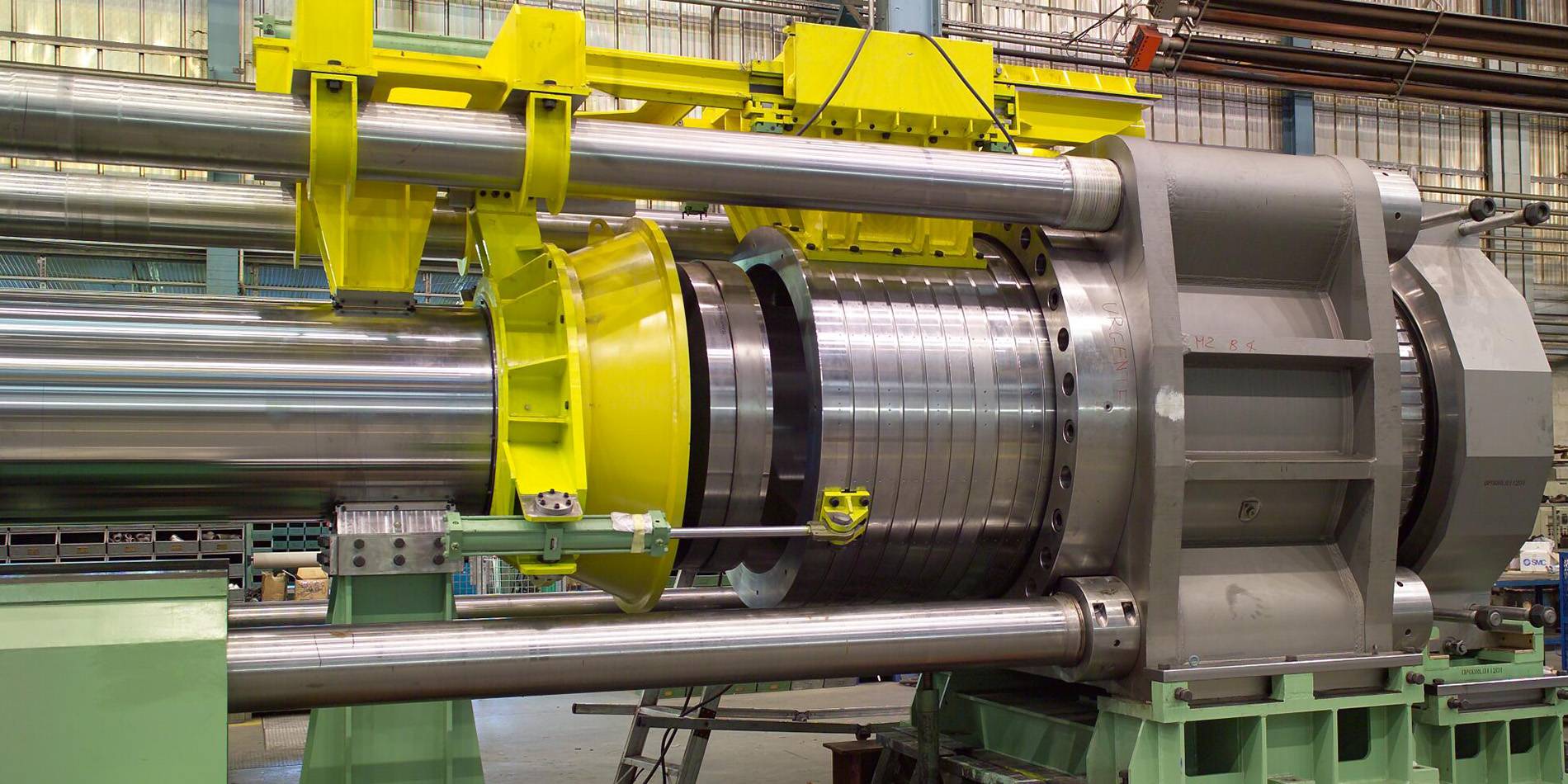

How Do Indirect Extrusion Presses Work for Hard Alloys?

Indirect extrusion presses differentiate themselves by minimizing friction between the aluminum billet and the container. This design is particularly advantageous when working with harder aluminum alloys, such as AA2xxx and AA7xxx, making it ideal for high-strength applications in industries like aerospace and automotive. Buyers should consider the initial investment required for these presses, as they tend to be more expensive than direct extrusion options. However, the benefits of optimized material flow and reduced extrusion force can lead to significant long-term savings and enhanced product quality.

What Makes Hybrid Extrusion Presses a Sustainable Choice?

Hybrid extrusion presses utilize a combination of electric servomotors and hydraulic systems, resulting in significant energy savings and increased productivity. With the ability to consume up to 55% less energy, these presses are particularly appealing to manufacturers focusing on sustainability and cost efficiency. Buyers should weigh the benefits of lower operational costs against the need for specialized training and maintenance. This technology is increasingly becoming a preferred choice for modern production lines aiming to balance productivity with ecological considerations.

Why Choose Tube Extrusion Presses for Specialized Needs?

Tube extrusion presses are specifically designed to produce seamless tubes with high precision, making them essential for industries such as plumbing and automotive. These presses often incorporate advanced features like internal piercing devices, which enhance the dimensional accuracy of the extruded products. For B2B buyers, the key consideration is the ability to meet stringent tolerance requirements for complex tube shapes. However, the specialization of these presses means they are less versatile compared to other types of extrusion presses, limiting their application scope.

Illustrative image related to aluminium extrusion press

What are the Advantages of Front-Loading Presses in Production?

Front-loading presses allow for easy access to the extrusion die and quick setup changes, making them ideal for small to medium production runs. This type of press is characterized by its versatility in producing various profiles and shapes, catering to diverse manufacturing needs. B2B buyers should consider the speed of changeovers and the flexibility offered by these presses when evaluating their production capabilities. However, potential downsides include lower production rates compared to back-loading presses, which may affect overall output in high-demand environments.

Key Industrial Applications of aluminium extrusion press

| Industry/Sector | Specific Application of aluminium extrusion press | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Structural components for vehicles | Reduces weight, enhances fuel efficiency, and improves safety | Look for precision in manufacturing and compliance with safety standards. |

| Construction | Window frames and architectural elements | Offers durability and aesthetic flexibility in building designs | Ensure compatibility with local building codes and environmental standards. |

| Aerospace | Aircraft fuselage and wing components | Provides lightweight yet strong materials, enhancing performance | Focus on high-strength alloys and stringent quality certifications. |

| Electronics | Heat sinks and enclosures for electronic devices | Improves thermal management and protects sensitive components | Seek suppliers with advanced extrusion technology and customization options. |

| Renewable Energy | Solar panel frames and wind turbine components | Supports lightweight designs and enhances energy efficiency | Consider sourcing from manufacturers with sustainable practices and materials. |

How is Aluminium Extrusion Press Used in the Automotive Industry?

In the automotive sector, aluminium extrusion presses are employed to manufacture structural components such as chassis, beams, and brackets. These extrusions are lightweight, which contributes to overall vehicle efficiency and performance. By reducing weight, manufacturers can enhance fuel economy and minimize emissions. Buyers should prioritize suppliers that adhere to stringent safety regulations and offer precision in their extrusions to meet the specific needs of automotive applications.

What Role Does Aluminium Extrusion Press Play in Construction?

Aluminium extrusion presses are vital in producing window frames, curtain walls, and other architectural elements. The versatility of aluminium allows for a variety of designs while maintaining strength and durability. This is particularly important in regions with extreme weather conditions. Buyers should ensure that their suppliers comply with local building codes and environmental regulations, as well as offer customization options to meet specific architectural demands.

How is Aluminium Extrusion Beneficial in Aerospace Applications?

In the aerospace industry, aluminium extrusion presses are used to create critical components like fuselage sections and wing structures. The lightweight nature of aluminium is crucial for enhancing fuel efficiency and overall aircraft performance. Additionally, the strength-to-weight ratio is vital for safety and operational effectiveness. Buyers should focus on sourcing high-strength alloys that meet rigorous quality standards and certifications, as well as suppliers with a proven track record in aerospace applications.

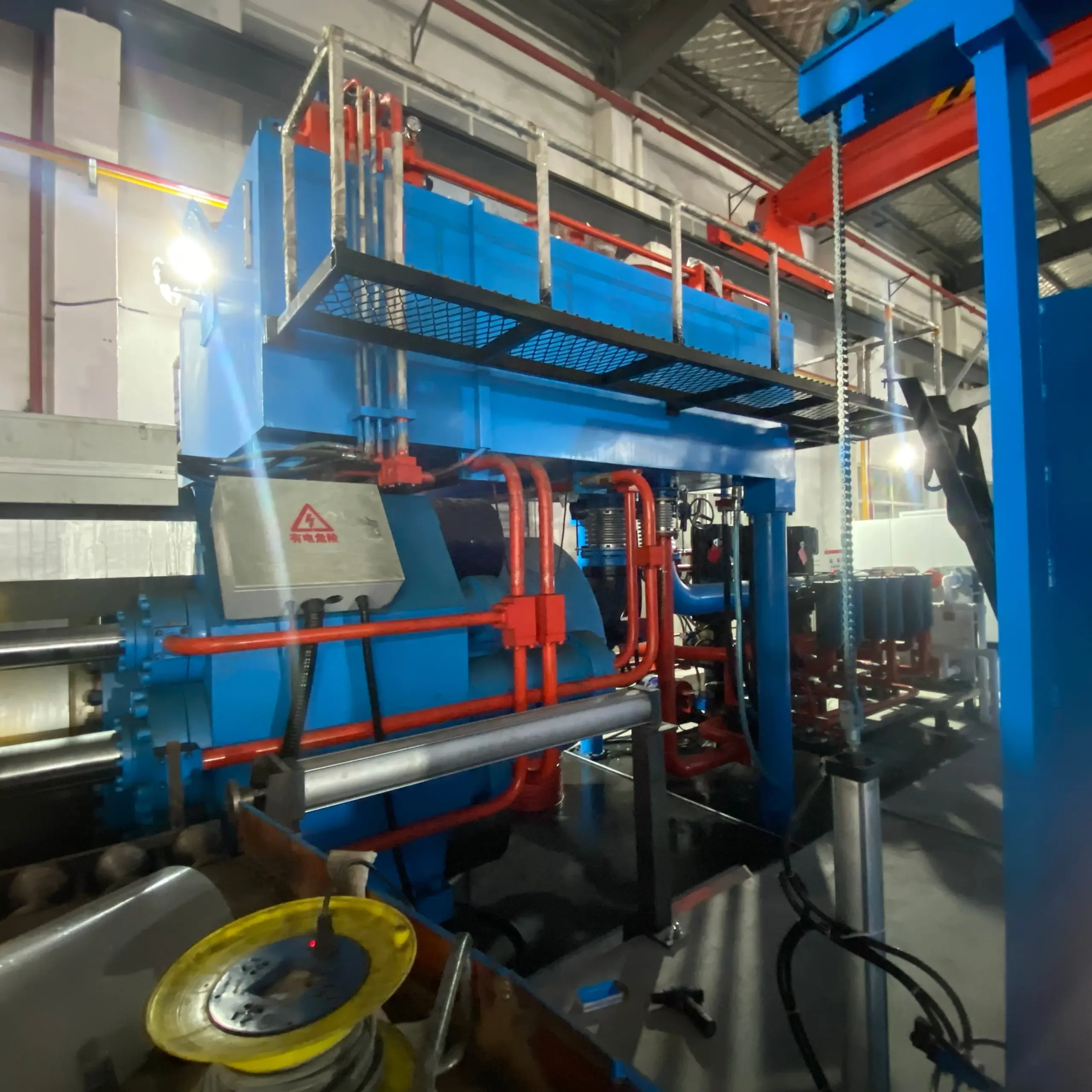

Illustrative image related to aluminium extrusion press

How Does Aluminium Extrusion Enhance Electronics Manufacturing?

Aluminium extrusion presses are essential for producing heat sinks, enclosures, and other components used in electronic devices. The excellent thermal conductivity of aluminium helps manage heat dissipation, protecting sensitive electronic parts. Buyers should look for suppliers with advanced extrusion technologies that can customize designs to meet specific thermal management requirements, ensuring reliability and performance in electronic applications.

What Advantages Does Aluminium Extrusion Provide in Renewable Energy?

In the renewable energy sector, aluminium extrusion presses are utilized to manufacture frames for solar panels and components for wind turbines. The lightweight properties of aluminium facilitate easier installation and transportation, while also improving energy efficiency. Buyers should consider sourcing from manufacturers that prioritize sustainable practices and materials, as this aligns with the overall goals of the renewable energy industry.

3 Common User Pain Points for ‘aluminium extrusion press’ & Their Solutions

Scenario 1: Managing Production Costs in Aluminum Extrusion

The Problem:

B2B buyers often face the challenge of rising production costs associated with aluminum extrusion presses. As energy prices fluctuate and raw material costs increase, manufacturers struggle to maintain profitability while ensuring high-quality output. For instance, traditional hydraulic presses can consume a significant amount of energy, which directly impacts operational costs. Additionally, inefficient machinery can lead to higher maintenance costs and production downtimes, further squeezing profit margins.

The Solution:

To mitigate these challenges, buyers should consider investing in energy-efficient aluminum extrusion presses, such as hybrid models that combine hydraulic and electric drives. These presses, like the HybrEx® series, are designed to reduce energy consumption by up to 55% while simultaneously increasing productivity by as much as 20%. When sourcing machinery, buyers should prioritize models with advanced energy-saving technologies, such as the ecoDraulic system, which intelligently manages hydraulic pump usage to minimize energy waste. Furthermore, implementing a predictive maintenance program can help identify potential issues before they lead to costly downtimes, ensuring continuous operation and optimized performance.

Scenario 2: Achieving Precision in Complex Profiles

The Problem:

As the demand for intricate and customized aluminum profiles increases, manufacturers often struggle with achieving the necessary precision during the extrusion process. This is particularly true for B2B buyers in industries like aerospace and automotive, where tolerances are critical. Inaccuracies can lead to defective products, wasted materials, and costly rework, ultimately affecting customer satisfaction and brand reputation.

The Solution:

To enhance precision in extruded profiles, buyers should focus on selecting presses that offer advanced die design capabilities and automation features. For example, investing in presses equipped with sophisticated die-casting technologies and precise temperature control systems can significantly improve the quality of the extrusions. Buyers should also consider sourcing extrusion presses that allow for real-time monitoring and adjustments during the extrusion process. This enables operators to make necessary tweaks on-the-fly, ensuring that the final product meets strict specifications. Collaborating with experienced suppliers who can provide technical support and training on best practices can further enhance operational outcomes.

Scenario 3: Flexibility to Adapt to Market Demands

The Problem:

In today’s rapidly changing market, B2B buyers often find themselves facing the challenge of needing to produce a variety of aluminum profiles in small batch sizes. This demand for flexibility can strain traditional aluminum extrusion presses, which are typically optimized for high-volume production runs. Consequently, manufacturers may face delays in fulfilling orders or incur excessive costs due to the need for frequent equipment adjustments and changeovers.

The Solution:

To address this pain point, buyers should seek out extrusion presses that offer versatility in production methods. For instance, presses that combine both direct and indirect extrusion capabilities can provide the flexibility needed to accommodate diverse product requirements without significant downtime. Additionally, investing in modular equipment allows for quicker changeovers between different profiles. Suppliers that offer comprehensive training and support for staff can also ensure that operators are adept at switching between different production setups efficiently. Ultimately, choosing machinery that aligns with the current and anticipated future demands of the market can empower manufacturers to respond swiftly to customer needs while maintaining operational efficiency.

Illustrative image related to aluminium extrusion press

Strategic Material Selection Guide for aluminium extrusion press

What Are the Key Materials Used in Aluminium Extrusion Presses?

When selecting materials for aluminium extrusion presses, it is crucial to consider their properties, advantages, and limitations. The right choice can significantly impact production efficiency, product quality, and operational costs. Below are analyses of four common materials used in aluminium extrusion presses, focusing on their performance characteristics and implications for international B2B buyers.

What Are the Key Properties of Steel in Aluminium Extrusion Presses?

Steel, particularly high-strength alloy steel, is commonly used in the construction of extrusion presses. It boasts excellent tensile strength and durability, making it suitable for high-pressure applications. Steel can withstand temperatures up to 500°C, which is essential during the extrusion process. Its corrosion resistance can be enhanced through coatings, though untreated steel may be prone to rust in humid environments.

Pros: Steel’s strength allows for the construction of robust press frames, ensuring longevity and reliability. It is also widely available and relatively cost-effective.

Cons: The weight of steel can complicate transport and installation. Additionally, if not properly treated, steel can corrode, particularly in regions with high humidity.

Impact on Application: Steel’s compatibility with high-pressure applications makes it ideal for producing a range of aluminium profiles, including complex shapes.

Considerations for International Buyers: Compliance with regional standards such as DIN (Germany) and ASTM (USA) is essential. Buyers should also consider local sourcing options to mitigate transportation costs.

How Does Aluminum Alloy Benefit Extrusion Processes?

Aluminum alloys, particularly those in the 6000 series, are frequently used for the extrusion dies themselves. These alloys offer a good balance of strength, corrosion resistance, and workability, making them ideal for various applications. They typically have a temperature rating of around 400°C.

Pros: Aluminum alloys are lightweight, which facilitates easier handling and installation. Their inherent corrosion resistance reduces maintenance needs.

Cons: While they are suitable for many applications, aluminum alloys may not withstand as high pressures as steel, which can limit their use in certain high-demand scenarios.

Impact on Application: Aluminum alloys are particularly effective for producing lightweight and corrosion-resistant profiles, making them ideal for automotive and architectural applications.

Considerations for International Buyers: Buyers should ensure that the selected aluminum alloys meet local standards such as JIS (Japan) or ASTM, especially for industries like automotive or aerospace.

What Role Do Copper Alloys Play in Extrusion Presses?

Copper alloys are sometimes used in components that require excellent thermal and electrical conductivity. They can handle high temperatures and pressures, making them suitable for specific parts of the extrusion process.

Illustrative image related to aluminium extrusion press

Pros: Copper alloys provide superior thermal conductivity, which can enhance the efficiency of the extrusion process. They also have excellent corrosion resistance.

Cons: The cost of copper alloys is typically higher than that of steel or aluminum, which may not be justifiable for all applications. Additionally, they are heavier, which can complicate handling.

Impact on Application: Copper alloys are particularly beneficial in applications where heat dissipation is critical, such as in electrical components.

Considerations for International Buyers: Compliance with international standards for electrical components is vital. Buyers should also consider the availability of copper alloys in their region to avoid supply chain disruptions.

How Do Composite Materials Enhance Extrusion Press Performance?

Composite materials, often combining metals with polymers, are increasingly used in specific components of extrusion presses. They can offer a balance of lightweight construction and high strength.

Illustrative image related to aluminium extrusion press

Pros: Composites can significantly reduce weight while maintaining strength, leading to lower energy consumption during operation. They also offer excellent corrosion resistance.

Cons: The manufacturing process for composites can be more complex and costly compared to traditional materials. Additionally, their performance can vary widely based on the specific formulation.

Impact on Application: Composites are ideal for non-structural components where weight savings are critical, such as in mobile or portable extrusion presses.

Considerations for International Buyers: Buyers should be aware of the specific performance characteristics of the composites used and ensure they meet relevant industry standards.

Summary Table of Material Selection for Aluminium Extrusion Presses

| Material | Typical Use Case for aluminium extrusion press | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Press frames and structural components | High strength and durability | Prone to corrosion if untreated | Medium |

| Aluminum Alloy | Extrusion dies and lightweight components | Lightweight and corrosion-resistant | Limited high-pressure applications | Medium |

| Copper Alloy | Heat exchangers and electrical components | Excellent thermal conductivity | Higher cost and weight | High |

| Composite | Non-structural components in portable presses | Lightweight and corrosion-resistant | Complex manufacturing process | Medium to High |

This guide provides a strategic overview of material selection for aluminium extrusion presses, enabling informed decisions that align with operational needs and regional compliance standards.

Illustrative image related to aluminium extrusion press

In-depth Look: Manufacturing Processes and Quality Assurance for aluminium extrusion press

What Are the Key Stages in the Manufacturing Process of Aluminium Extrusion Presses?

The manufacturing of aluminium extrusion presses involves several critical stages, ensuring that the final product meets stringent quality standards and operational efficiency. Understanding these stages is essential for B2B buyers who are considering investing in extrusion technology.

How Is Material Prepared for Aluminium Extrusion Presses?

The first stage in the manufacturing process is material preparation. Typically, this begins with selecting high-quality aluminium alloys, which are then cut into billets. These billets are preheated in an induction furnace to a temperature between 400-500 degrees Celsius, enhancing their malleability without reaching a molten state. This step is crucial, as the right temperature ensures optimal material flow during extrusion.

Additionally, lubricants are applied to both the billet and the extrusion ram to reduce friction, which is vital for the smooth operation of the press. This preparation phase is foundational, as it directly impacts the quality of the final extruded profiles.

Illustrative image related to aluminium extrusion press

What Techniques Are Used in the Forming Stage of Aluminium Extrusion?

The forming stage involves the actual extrusion process, where the preheated billet is loaded into the extrusion press. A powerful hydraulic ram applies significant pressure—up to 15,000 tons—to force the aluminium through a specifically designed die. This die determines the cross-sectional shape of the extruded product, whether it’s a simple rod or a complex architectural profile.

Different techniques can be employed during this stage, including direct and indirect extrusion methods. Direct extrusion pushes the billet directly through the die, while indirect extrusion uses a container, allowing for lower friction and better material flow, especially for harder alloys. The choice of technique depends on the specific requirements of the product being manufactured.

How Is Assembly Managed in Aluminium Extrusion Press Manufacturing?

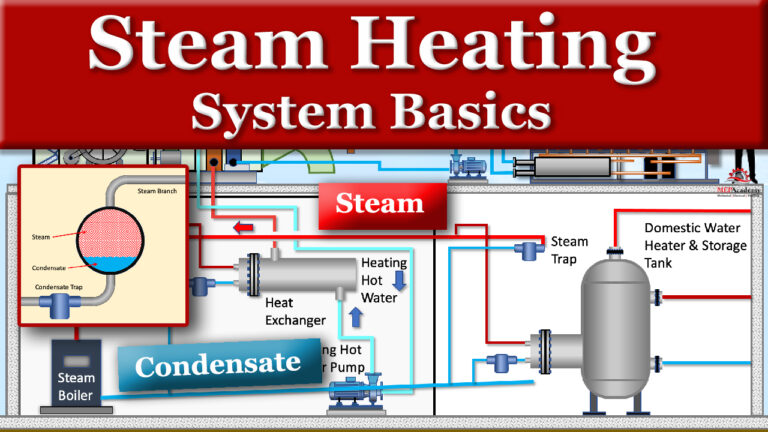

After the extrusion process, the next phase is assembly, which involves the integration of various components of the extrusion press. This includes the hydraulic systems, control panels, and any additional handling equipment, such as quenching systems and cooling tables.

Precision in assembly is critical, as any misalignment can lead to inefficiencies and defects in the extruded products. Manufacturers often utilize CAD software for design and simulation, ensuring that all components fit together seamlessly before physical assembly begins.

What Finishing Techniques Are Commonly Applied to Aluminium Extrusions?

Finishing techniques are essential for enhancing the aesthetic and functional properties of the extruded aluminium products. Common finishing processes include:

Illustrative image related to aluminium extrusion press

- Anodizing: This electrochemical process increases corrosion resistance and provides a decorative finish.

- Powder Coating: A dry finishing technique that offers a durable and colorful surface, ideal for architectural applications.

- Mechanical Finishing: Techniques such as sanding, polishing, and machining ensure that the profiles meet specific dimensional and surface quality requirements.

These finishing processes not only improve the product’s appearance but also its performance in various applications across different industries.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical aspect of the aluminium extrusion press manufacturing process. International standards, such as ISO 9001, provide frameworks for ensuring quality management systems are in place. These standards help manufacturers consistently deliver high-quality products and services.

In addition to ISO standards, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) may also be relevant, depending on the intended application of the extrusions. Compliance with these standards assures buyers that the products meet safety, health, and environmental protection requirements.

How Are Quality Control Checkpoints Implemented in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure each stage meets specified standards. Key QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify any issues in real time.

- Final Quality Control (FQC): After the extrusion and finishing processes, products undergo rigorous testing to ensure they meet quality standards before shipment.

Common testing methods include dimensional inspections, tensile strength tests, and surface quality assessments. These checks ensure that the final products are not only functional but also adhere to the required specifications.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, verifying a supplier’s quality assurance practices is crucial for ensuring reliability and product quality. Here are several methods to consider:

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes, quality control systems, and compliance with international standards.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the supplier’s QC methodologies and performance metrics.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s adherence to quality standards and specifications.

What Are the Nuances of Quality Control and Certification for International Buyers?

International B2B buyers must navigate various nuances related to quality control and certification. For instance, different regions may have specific regulatory requirements that impact product certification. Buyers from Europe, for example, should be familiar with CE marking requirements, while those in the Middle East may need to consider GSO standards.

Additionally, language barriers and differing documentation standards can pose challenges. Buyers should ensure that all certifications and reports are available in a language they understand and that they meet the specific regulatory requirements of their home country.

Illustrative image related to aluminium extrusion press

In conclusion, understanding the manufacturing processes and quality assurance practices related to aluminium extrusion presses is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, as well as establishing robust quality control measures, suppliers can ensure that they deliver high-quality products that meet global standards. Buyers must actively engage in verifying these practices to safeguard their investments and ensure the reliability of their supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminium extrusion press’

To assist B2B buyers in navigating the procurement of an aluminum extrusion press, this guide provides a structured checklist designed to streamline the sourcing process. By following these steps, buyers can ensure they make informed decisions that align with their operational needs and market demands.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right aluminum extrusion press. Consider the types of aluminum alloys you will be using, the required shapes (solid, hollow, or semi-hollow), and the production volume. Detailed specifications help narrow down options and ensure compatibility with your production requirements.

Step 2: Assess Energy Efficiency and Technology

Evaluate the energy efficiency of potential extrusion presses. Look for technologies such as hybrid drive systems that can reduce energy consumption significantly while enhancing productivity. For instance, presses like the HybrEx® can provide up to 55% energy savings, which is essential for lowering operational costs and meeting sustainability targets.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, case studies, and references from existing clients in similar industries or regions. Assess their manufacturing capabilities, customer support, and after-sales service to ensure they align with your operational needs.

Illustrative image related to aluminium extrusion press

Step 4: Verify Compliance and Certifications

Ensure that the suppliers’ products meet international safety and quality standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management systems. Compliance with environmental regulations is also important, especially if you are sourcing from regions with stringent eco-friendly policies.

Step 5: Request Proposals and Conduct Cost Analysis

Obtain detailed proposals from shortlisted suppliers, including pricing, warranty, and service agreements. Conduct a comprehensive cost analysis that considers not only the initial investment but also long-term operational costs, such as maintenance and energy consumption. This holistic view will aid in making a financially sound decision.

Step 6: Examine Technical Support and Training

Inquire about the technical support and training offered by suppliers. A reliable supplier should provide comprehensive training for your staff on operating the extrusion press, as well as ongoing support for troubleshooting and maintenance. This will help ensure smooth operation and minimize downtime during production.

Step 7: Negotiate Terms and Finalize Contract

Once you have selected a supplier, negotiate terms that suit both parties. Pay attention to delivery timelines, payment terms, and post-installation support. A well-structured contract should clearly outline responsibilities, warranties, and service agreements, ensuring that all parties are aligned for a successful partnership.

Illustrative image related to aluminium extrusion press

By adhering to this checklist, B2B buyers can effectively navigate the complexities of sourcing an aluminum extrusion press, ensuring that their investment supports their production needs while aligning with industry standards.

Comprehensive Cost and Pricing Analysis for aluminium extrusion press Sourcing

Understanding the cost structure and pricing dynamics of aluminum extrusion presses is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will break down the key cost components, price influencers, and provide actionable tips for buyers looking to optimize their sourcing strategies.

What Are the Key Cost Components in Aluminum Extrusion Press Sourcing?

-

Materials: The primary materials include aluminum alloys, which can vary significantly in price depending on the alloy type and market conditions. The cost of high-strength alloys, such as AA2xxx and AA7xxx, is typically higher due to their specialized properties. Additionally, the quality and sourcing of these materials can influence costs.

-

Labor: Labor costs encompass skilled technicians for operating extrusion presses and assembly personnel. Depending on the region, labor costs can fluctuate widely. For example, countries with lower labor costs may offer competitive pricing but might lack the same level of expertise found in more developed regions.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes, such as those offered by advanced hybrid extrusion presses, can reduce overhead by increasing production efficiency and lowering energy consumption.

-

Tooling: Tooling costs are associated with the dies and molds used in the extrusion process. Custom tooling can be expensive, but it is essential for producing specific profiles. Buyers should consider the longevity and reusability of dies when evaluating tooling costs.

-

Quality Control (QC): Ensuring that the extruded products meet industry standards requires investment in quality control processes. This may involve testing materials, monitoring production processes, and implementing certifications, which can add to the overall cost.

-

Logistics: Transportation and shipping costs are significant, especially for international buyers. Factors such as distance, mode of transport, and Incoterms (which define the responsibilities of buyers and sellers) play a crucial role in logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the typical margins within different regions can help buyers negotiate better prices.

How Do Price Influencers Affect Aluminum Extrusion Press Costs?

Several factors can influence pricing in the aluminum extrusion press market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider their production needs and negotiate MOQs that align with their operational capabilities.

-

Specifications and Customization: Custom specifications can significantly impact costs. While bespoke solutions may better meet specific needs, they often come with higher tooling and production costs.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO, ASTM) can affect pricing. Higher quality and certified products may command a premium but can lead to better long-term value.

-

Supplier Factors: The reputation, experience, and geographical location of the supplier can influence costs. Established suppliers may offer better reliability and support, albeit at a higher price point.

-

Incoterms: Understanding the shipping terms and responsibilities can help buyers manage logistics costs effectively. Different Incoterms can shift costs between buyers and suppliers, impacting the total landed cost.

What Are Some Buyer Tips for Sourcing Aluminum Extrusion Presses?

-

Negotiation: Leverage your buying power by negotiating terms and pricing. Suppliers may offer discounts for larger volumes or long-term contracts.

-

Cost-Efficiency Analysis: Conduct a Total Cost of Ownership (TCO) analysis, considering not just the purchase price but also long-term operational costs, maintenance, and energy consumption.

-

Understand Pricing Nuances: Be aware of regional pricing variations and market dynamics. For example, European suppliers may offer advanced technology but at a premium, while emerging markets may provide cost-effective solutions.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, improved service, and access to innovations.

-

Stay Informed: Regularly monitor market trends and material prices to make informed purchasing decisions. This can help you anticipate cost fluctuations and adjust your sourcing strategy accordingly.

Disclaimer on Indicative Prices

Pricing in the aluminum extrusion press market can vary significantly based on the factors outlined above. It is advisable for buyers to seek quotes from multiple suppliers and conduct thorough market research to ensure competitive pricing and value for their investment.

Illustrative image related to aluminium extrusion press

Alternatives Analysis: Comparing aluminium extrusion press With Other Solutions

Exploring Alternatives to Aluminium Extrusion Press Technology

In the world of manufacturing, particularly in the aluminum sector, selecting the right production technology is crucial. While aluminum extrusion presses are widely recognized for their efficiency and versatility, there are alternative methods that may better suit specific operational needs or financial constraints. Understanding these alternatives can empower international B2B buyers to make informed decisions aligned with their production goals.

| Comparison Aspect | Aluminium Extrusion Press | 3D Printing (Additive Manufacturing) | Roll Forming |

|---|---|---|---|

| Performance | High precision and consistency in profile production; capable of handling complex shapes. | Excellent for custom, low-volume parts; slower production speed for large runs. | Efficient for producing long sections with uniform cross-sections; limited to simpler shapes. |

| Cost | High initial investment; favorable for large-scale production due to lower per-unit costs. | Lower initial costs; cost-effective for small batches but higher per-unit costs for large volumes. | Moderate initial investment; economical for large, continuous runs. |

| Ease of Implementation | Requires significant setup, including die preparation and machinery installation. | Quick setup and flexibility in design changes; minimal tooling required. | Easier to set up for long runs; requires specific tooling for different profiles. |

| Maintenance | Regular maintenance needed; potential high costs associated with downtime. | Minimal maintenance; however, requires regular software updates and material handling. | Low maintenance costs; machinery is generally robust and reliable. |

| Best Use Case | Ideal for high-volume production of complex aluminum profiles in various industries. | Best for prototyping, custom parts, and low-volume production runs. | Suited for continuous production of standard shapes, such as channels and angles. |

3D Printing (Additive Manufacturing): Advantages and Disadvantages

3D printing technology has gained traction for its ability to create intricate designs without the need for complex tooling. Its major advantage lies in its flexibility, enabling manufacturers to produce customized parts quickly and cost-effectively for small batches. However, the slower production speeds and higher costs per unit when scaling up can be a significant drawback for large-scale operations.

Roll Forming: Pros and Cons

Roll forming is a continuous bending operation that produces long sections of metal with uniform cross-sections. This method is cost-effective for high-volume production and allows for quick changes in design with minimal tooling modifications. However, roll forming is limited to simpler shapes and may not meet the precision demands of more complex designs as effectively as extrusion presses.

Illustrative image related to aluminium extrusion press

Conclusion: Choosing the Right Solution for Your Production Needs

Selecting the optimal manufacturing technology requires a thorough understanding of your specific production requirements, including volume, complexity, and budget. Aluminium extrusion presses excel in high-volume scenarios with complex shapes, while 3D printing offers unmatched flexibility for custom designs. Roll forming stands out for its efficiency in producing standard shapes in long runs. By carefully evaluating these factors, B2B buyers can choose the solution that aligns best with their operational objectives, ensuring both cost-effectiveness and production efficiency.

Essential Technical Properties and Trade Terminology for aluminium extrusion press

What Are the Key Technical Properties of Aluminium Extrusion Presses?

When investing in aluminium extrusion presses, understanding specific technical properties is crucial for ensuring optimal performance and product quality. Here are the essential specifications to consider:

1. Material Grade

The material grade of aluminium alloys used in extrusion processes is vital. Common grades include 6060 and 6061, known for their good mechanical properties and corrosion resistance. Selecting the appropriate grade impacts the extruded product’s strength, weight, and durability. For B2B buyers, knowing the material grade ensures the final product meets industry standards and application requirements.

Illustrative image related to aluminium extrusion press

2. Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of an extruded profile. Tight tolerances are critical in applications where precision is paramount, such as in automotive or aerospace industries. A tolerance of ±0.1 mm may be acceptable for general applications, but specialized sectors may require tighter tolerances. Understanding tolerance requirements helps buyers ensure that their products fit seamlessly into their manufacturing processes.

3. Extrusion Ratio

The extrusion ratio is the ratio of the cross-sectional area of the billet to that of the final extruded profile. A higher extrusion ratio can lead to improved mechanical properties and surface finish. For buyers, knowing the extrusion ratio allows for better selection of machinery and process parameters, ultimately affecting production efficiency and product quality.

4. Production Rate

Production rate indicates the speed at which an extrusion press can produce profiles, typically measured in kilograms per hour. Higher production rates can significantly enhance operational efficiency, especially for businesses with large volume requirements. Understanding this metric helps buyers assess the press’s capability to meet their production demands.

5. Energy Consumption

Energy efficiency has become increasingly important in manufacturing. Modern extrusion presses, such as hybrid models, can consume significantly less energy than traditional hydraulic presses. For businesses looking to minimize operational costs and environmental impact, evaluating energy consumption is essential.

Illustrative image related to aluminium extrusion press

6. Cooling Systems

Effective cooling systems are vital for maintaining the integrity of the extruded profiles. They ensure that the material cools uniformly, which is crucial for achieving desired mechanical properties. A robust cooling system can also increase production efficiency and reduce cycle times, making it a key consideration for B2B buyers.

What Are Common Trade Terms in the Aluminium Extrusion Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the aluminium extrusion market. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In aluminium extrusion, OEMs often provide customized solutions tailored to specific industry needs. Understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of products that a supplier is willing to sell. This term is crucial for B2B buyers as it influences inventory management and cost. Knowing the MOQ helps businesses plan their procurement strategy effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers to request pricing and terms for specific products. It is a critical step in the procurement process, allowing buyers to compare offers and make informed purchasing decisions. Familiarity with RFQ processes can streamline negotiations and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers to manage shipping costs and liabilities effectively.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Shorter lead times can enhance a company’s responsiveness to market demands. For buyers, understanding lead times is critical for inventory planning and ensuring timely production schedules.

6. Die Design

Die design involves creating the specific shape through which the aluminium is extruded. The complexity of the die can impact production costs and lead times. Buyers should be aware of die design implications to optimize their extrusion processes and product offerings.

In summary, comprehending these technical properties and industry terms equips B2B buyers with the knowledge necessary to make informed purchasing decisions in the aluminium extrusion market.

Illustrative image related to aluminium extrusion press

Navigating Market Dynamics and Sourcing Trends in the aluminium extrusion press Sector

Market Overview & Key Trends

The global aluminum extrusion market is experiencing robust growth, driven by increasing demand across multiple sectors such as automotive, aerospace, construction, and electronics. Recent reports forecast a compound annual growth rate (CAGR) of nearly 4% from 2019 to 2023. Key market drivers include the lightweight and corrosion-resistant properties of aluminum, which make it an attractive alternative to traditional materials like steel. Additionally, advancements in extrusion technology, including hybrid and direct extrusion methods, are enhancing production efficiency and flexibility, catering to diverse product requirements.

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these market dynamics is crucial. The demand for custom aluminum profiles is rising, leading to increased investments in advanced extrusion presses that offer versatility in production. Sourcing trends are also evolving, with a shift towards suppliers who can provide energy-efficient solutions and automation capabilities, significantly reducing operational costs. Moreover, buyers are increasingly favoring suppliers that offer integrated solutions, encompassing everything from heating systems to handling equipment, which enhances the overall supply chain efficiency.

What Are the Sustainability & Ethical Sourcing Considerations in the Aluminium Extrusion Press Sector?

As sustainability becomes a central focus for industries worldwide, the aluminum extrusion sector is not exempt. The environmental impact of aluminum production is significant, with energy consumption and carbon emissions being primary concerns. However, advancements in production technology, such as the use of hybrid extrusion presses, are paving the way for greener manufacturing processes. These presses can reduce energy consumption by up to 55% while simultaneously boosting productivity.

Ethical sourcing is gaining prominence among B2B buyers, with a growing expectation for suppliers to adhere to responsible practices. Certifications for ‘green’ materials and processes are becoming key differentiators in supplier selection. Buyers are encouraged to seek partnerships with manufacturers who prioritize sustainable practices, such as using recycled aluminum and implementing energy-efficient technologies. This not only enhances brand reputation but also aligns with global sustainability goals, appealing to environmentally conscious consumers.

Illustrative image related to aluminium extrusion press

How Has the Aluminium Extrusion Press Sector Evolved Over Time?

The aluminum extrusion press sector has undergone significant transformation over the past few decades. Initially dominated by traditional hydraulic presses, the industry has embraced technological advancements, leading to the development of more efficient and versatile machines. The introduction of hybrid presses, such as the HybrEx® technology, has revolutionized production by combining hydraulic and electric systems, resulting in enhanced precision and reduced energy consumption.

The evolution of the sector is also characterized by a growing emphasis on automation and smart manufacturing. This includes the integration of advanced control systems and robotics in extrusion lines, allowing for greater flexibility and faster response times to market demands. As the industry continues to evolve, international B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminium extrusion press

-

How can I determine the right aluminium extrusion press for my production needs?

Selecting the appropriate aluminium extrusion press depends on various factors, including your product specifications, production volume, and material types. Evaluate whether you need direct or indirect extrusion based on the alloys you plan to use, as different presses cater to specific material properties. Additionally, consider energy efficiency, automation features, and the ability to handle small or large batch sizes. Consulting with manufacturers can provide insights tailored to your operational requirements, ensuring you choose a press that enhances productivity and meets quality standards. -

What is the best extrusion press for producing complex shapes?

For producing complex shapes, a hybrid extrusion press is often the best choice. These presses combine the benefits of hydraulic and electric drive systems, offering enhanced precision and energy efficiency. They are particularly effective for intricate profiles that require consistent quality across varying production runs. Additionally, ensure that the selected press can accommodate the necessary tooling and die configurations to achieve the desired complexity in your extruded products. -

What customization options are available for aluminium extrusion presses?

Most manufacturers offer a range of customization options for aluminium extrusion presses, including modifications to the press size, die design, and automation features. Depending on your production needs, you might request specific configurations that enhance efficiency or accommodate unique product designs. Discussing your requirements with suppliers can lead to tailored solutions, such as enhanced cooling systems or specialized handling equipment, which can significantly impact your production capabilities and product quality. -

What are the minimum order quantities (MOQ) for aluminium extrusion presses?

Minimum order quantities for aluminium extrusion presses can vary widely among manufacturers. Some suppliers may require a minimum order for the entire press system, while others might offer flexibility for smaller, modular components. It is essential to clarify MOQs early in the negotiation process, especially if you are a smaller manufacturer or are testing new products in your market. Understanding these parameters can help you plan your budget and production schedules more effectively. -

What payment terms should I expect when purchasing an aluminium extrusion press?

Payment terms can vary by supplier but generally include options such as upfront deposits, milestone payments, or full payment upon delivery. It’s crucial to negotiate terms that align with your cash flow capabilities and project timelines. Some suppliers may also offer financing options or payment plans, especially for larger capital investments. Always ensure that payment terms are clearly outlined in the contract to avoid any misunderstandings during the procurement process. -

How do I ensure quality assurance in my aluminium extrusion press procurement?

To ensure quality assurance, conduct thorough due diligence on potential suppliers. Check for certifications such as ISO 9001, which indicates adherence to quality management standards. Request samples or visit existing installations to assess performance and reliability. Additionally, establish clear quality metrics in your purchase agreement, including acceptable tolerances and testing procedures. Regular communication with the supplier throughout the manufacturing process can also help mitigate risks and ensure compliance with your quality standards. -

What logistics considerations should I keep in mind when sourcing an aluminium extrusion press?

Logistics play a critical role in the procurement of an aluminium extrusion press. Consider the shipping options available, including freight costs and delivery timelines, as these can significantly impact your project schedule. Evaluate the supplier’s ability to handle export documentation and customs clearance, particularly for international shipments. Additionally, assess the installation and commissioning support provided by the supplier, as this can facilitate a smoother transition into production once the equipment arrives. -

How can I vet suppliers for aluminium extrusion presses effectively?

Vetting suppliers involves several steps to ensure reliability and quality. Start by researching their industry reputation through reviews and testimonials from previous clients. Verify their experience in manufacturing aluminium extrusion presses and ask for case studies or references. Engaging in direct discussions regarding their production processes, quality control measures, and after-sales support can provide deeper insights into their capabilities. Consider visiting their facilities if possible, as this allows you to observe their operations firsthand and assess their commitment to quality and customer service.

Top 5 Aluminium Extrusion Press Manufacturers & Suppliers List

1. Ube Machinery – Extrusion Presses

Domain: ubemachinery.com

Registered: 1997 (28 years)

Introduction: This company, Ube Machinery – Extrusion Presses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Gabrian – Aluminum Extrusion Solutions

Domain: gabrian.com

Registered: 2000 (25 years)

Introduction: Aluminum Extrusion is a manufacturing process where aluminum alloy material is forced through a die with a specific cross-sectional profile. The process allows for the creation of various shapes, including solid, hollow, and semi-hollow profiles. Commonly extruded shapes include angles, channels, and round tubes. The aluminum extrusion process involves ten steps: preparing the extrusion die, prehe…

3. Presezzi Extrusion – Melting Technology

Domain: presezziextrusion.com

Registered: 2000 (25 years)

Introduction: Presezzi Extrusion S.p.A. is a leading manufacturer of extrusion presses, established in 1994, specializing in high-level technology and flexibility in design and construction of presses for aluminum, hard alloy, copper, and brass. Key products include:

1. Melting Technology: UBC Scrap Decoaters, Furnaces, L.E.C. Stirrer, Charging & Skimming Machine, Dross Cooler, Horizontal Casting Billet.

2. Ext…

4. Macrodyne – Hydraulic Extrusion and Vertical Presses

Domain: macrodynepress.com

Registered: 1998 (27 years)

Introduction: Macrodyne manufactures hydraulic extrusion and vertical presses for hot and cold extrusion applications for a wide range of profiles in ferrous and non-ferrous materials, including several grades of steel, aluminum, copper, zirconium, and more. Key specifications include: Bed Sizes: 42″ x 42″, 38″ x 36″, 48″ x 48″; Daylight: 152″, 7″, 80″; Stroke: 105″, 40″, 40″; Installed Power: 4 x 250 HP, 90 HP…

5. FSZhelu – 600-12000T Aluminum Extrusion Press Machine

Domain: fszhelu.com

Registered: 2022 (3 years)

Introduction: Product: 600-12000T Aluminum Extrusion Press Machine

Application: For Windows and industrial profiles

Working Principle: Physical deformation of heated aluminum rods, extruded through a die.

Heating Equipment: Electromagnetic heating furnace or coil induction heating furnace, heating to about 450 ℃.

Extrusion Process: Heated aluminum rod is pushed through an extrusion cylinder towards the mold, fo…

Strategic Sourcing Conclusion and Outlook for aluminium extrusion press

In conclusion, the strategic sourcing of aluminum extrusion presses is pivotal for manufacturers aiming to enhance productivity and sustainability. The growing demand for energy-efficient solutions, such as hybrid drive technology, indicates a shift towards eco-conscious manufacturing practices. Investing in advanced extrusion technology not only optimizes production processes but also significantly reduces operational costs, thereby providing a competitive edge in the global marketplace.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, aligning with reputable suppliers who offer tailored solutions can ensure that your production line meets diverse market demands. The ability to adapt to both small and large batch productions while maintaining high-quality standards is essential for success in various industries, from automotive to construction.

As the aluminum extrusion market continues to expand, now is the time to evaluate your sourcing strategies. Engage with suppliers who prioritize innovation and sustainability to future-proof your operations. By making informed decisions today, you position your business to thrive in an increasingly competitive landscape. Reach out to industry leaders and explore the advanced solutions that can propel your manufacturing capabilities forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.