Everything You Need to Know About Airline Cable Sourcing in 2025

Introduction: Navigating the Global Market for airline cable

Navigating the complexities of sourcing airline cable can be a daunting task for international B2B buyers, particularly those in dynamic markets such as Africa, South America, the Middle East, and Europe. With a plethora of options available—from galvanized to stainless steel variants, and various constructions like 7×7 and 7×19—understanding the right specifications is crucial for ensuring safety, reliability, and cost-effectiveness in your applications. This guide aims to demystify the global market for airline cable by exploring different types, their applications in various industries, and essential considerations for supplier vetting.

In this comprehensive resource, you will find detailed insights into the characteristics of different cable types, which are vital for making informed decisions. Additionally, we will cover practical aspects such as pricing structures, shipment logistics, and compliance with international standards. Our goal is to equip B2B buyers with the knowledge and tools necessary to navigate their procurement processes confidently.

By leveraging this guide, businesses can streamline their sourcing strategies, minimize risks associated with subpar products, and ultimately enhance operational efficiency. Whether you’re in Brazil, Vietnam, or anywhere in between, understanding the nuances of airline cable procurement will empower you to make strategic purchasing decisions that align with your organizational goals.

Understanding airline cable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 7×19 Galvanized Aircraft Cable | Composed of 7 strands with 19 wires each, offering flexibility and strength. | Suspension systems, rigging, and lifting applications. | Pros: Good corrosion resistance; Cons: Limited lifespan in harsh environments. |

| 7×7 Stainless Steel Aircraft Cable | Made of 7 strands with 7 wires each, providing moderate flexibility and high tensile strength. | Marine applications, architectural rigging, and safety systems. | Pros: Excellent corrosion resistance; Cons: Less flexibility than 7×19 cables. |

| Rotation-Resistant Wire Rope | Designed to minimize rotation during lifting, enhancing safety and stability. | Heavy lifting and construction applications where load stability is critical. | Pros: Improved load control; Cons: Typically more expensive. |

| Swaged & Compacted Wire Rope | Features a compact structure, increasing strength and reducing the diameter. | Use in cranes, elevators, and high-load applications. | Pros: High strength-to-weight ratio; Cons: Requires specialized fittings. |

| Cable Laid Wire Rope | Constructed with a unique cable-laid design for added flexibility and strength. | Ideal for marine and industrial applications requiring flexibility. | Pros: Enhanced flexibility; Cons: More complex installation process. |

What are the characteristics of 7×19 Galvanized Aircraft Cable?

The 7×19 galvanized aircraft cable is widely recognized for its versatility and strength, making it a preferred choice in various industries. Its construction consists of 7 strands, each containing 19 wires, which provides a balance of flexibility and load-bearing capacity. This type of cable is particularly suitable for applications such as suspension systems and rigging, where both strength and flexibility are crucial. Buyers should consider the environmental conditions, as while galvanized steel offers decent corrosion resistance, its lifespan may be limited in harsh environments.

How does 7×7 Stainless Steel Aircraft Cable compare?

The 7×7 stainless steel aircraft cable, featuring 7 strands of 7 wires, is known for its moderate flexibility and high tensile strength. This cable type is particularly advantageous in marine applications, architectural rigging, and safety systems, where exposure to moisture and corrosion is common. The primary consideration for B2B buyers is its excellent resistance to corrosion, making it suitable for long-term use in challenging environments. However, it may offer less flexibility compared to the 7×19 variant, which could impact its application in certain scenarios.

Why choose Rotation-Resistant Wire Rope?

Rotation-resistant wire rope is engineered to minimize rotation during lifting operations, thereby enhancing safety and stability. This feature is especially important in heavy lifting and construction applications where load control is critical. The design typically involves a combination of inner and outer strands that counteract rotation forces. While this type of wire rope generally comes with a higher price tag, the investment is justified by the enhanced operational safety and efficiency it provides, making it a smart choice for businesses focusing on safety and reliability.

What are the benefits of Swaged & Compacted Wire Rope?

Swaged and compacted wire rope is characterized by its compact structure, which increases strength while reducing the overall diameter. This type of cable is ideal for use in cranes, elevators, and high-load applications where maximizing strength while minimizing weight is essential. B2B buyers should note that while this wire rope offers a high strength-to-weight ratio, it requires specialized fittings for installation, which may add to the overall cost. Understanding the specific application needs will help determine if this cable type is the right choice.

When to use Cable Laid Wire Rope?

Cable laid wire rope features a unique design that enhances both flexibility and strength, making it ideal for marine and industrial applications where maneuverability is required. This type of cable is constructed by laying cables together, which allows for greater flexibility compared to traditional wire ropes. However, the installation process can be more complex, and B2B buyers should be prepared for potential additional labor costs. It’s crucial to evaluate the specific requirements of the application to determine if the benefits of cable laid wire rope align with operational needs.

Key Industrial Applications of airline cable

| Industry/Sector | Specific Application of airline cable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aviation & Aerospace | Cable assemblies for aircraft rigging | Ensures safety and reliability in aircraft operations | Compliance with aviation standards; tensile strength ratings |

| Construction & Rigging | Lifting and hoisting equipment | Enhances operational efficiency and safety | Corrosion resistance; compatibility with existing systems |

| Marine & Offshore | Mooring and anchoring systems | Provides secure and reliable mooring solutions | Material selection (stainless vs. galvanized); load capacity |

| Entertainment & Events | Suspension of lighting and stage equipment | Supports heavy loads safely in dynamic environments | Weight distribution; ease of installation |

| Telecommunications | Cable support for aerial and underground lines | Improves infrastructure reliability and durability | Environmental resistance; tensile strength and flexibility |

How is airline cable used in the aviation and aerospace sector?

In the aviation and aerospace industry, airline cable is critical for rigging and safety applications. It is used in various cable assemblies that support aircraft components, ensuring that vital systems operate safely during flight. Buyers from this sector must prioritize compliance with stringent aviation standards and select cables with appropriate tensile strength ratings. This ensures that they meet safety regulations while minimizing the risk of failure during operations.

What role does airline cable play in construction and rigging?

Airline cable serves a vital role in construction and rigging by providing lifting and hoisting capabilities for heavy materials. Its strength and reliability enhance operational efficiency, allowing construction teams to lift materials safely and effectively. International buyers in this sector should consider factors such as corrosion resistance and compatibility with existing rigging systems to ensure seamless integration and long-term performance on job sites.

How is airline cable utilized in marine and offshore applications?

In marine and offshore environments, airline cable is essential for mooring and anchoring systems. It provides secure connections that withstand harsh weather conditions and heavy loads. When sourcing airline cables for marine applications, buyers must focus on material selection, opting for stainless steel or galvanized options based on their resistance to corrosion and environmental factors. Load capacity is also a critical consideration to ensure safety and reliability in these demanding settings.

Illustrative image related to airline cable

How does airline cable support the entertainment and events industry?

The entertainment and events industry relies on airline cable for the safe suspension of lighting and stage equipment. These cables support heavy loads in dynamic environments, ensuring that installations are both secure and visually appealing. Buyers should evaluate weight distribution capabilities and ease of installation when sourcing airline cable for events, as these factors significantly impact setup efficiency and safety during performances.

What are the benefits of airline cable in telecommunications?

In telecommunications, airline cable is used to support aerial and underground lines, contributing to the reliability and durability of infrastructure. This application is crucial for maintaining service quality in various environments. International buyers should prioritize environmental resistance, tensile strength, and flexibility when sourcing airline cable for telecommunications to ensure it withstands the rigors of installation and long-term use.

3 Common User Pain Points for ‘airline cable’ & Their Solutions

Scenario 1: Inconsistent Quality Standards in Airline Cable Products

The Problem: For B2B buyers, particularly those in regions with emerging markets, sourcing airline cables that meet international quality standards can be a significant challenge. Variability in manufacturing processes across suppliers often leads to inconsistent product quality. This inconsistency can jeopardize the safety and performance of critical applications, leading to costly downtimes and potential liability issues. Buyers may find themselves receiving cables that do not meet the required tensile strength or corrosion resistance, causing frustration and potential safety hazards.

The Solution: To mitigate these risks, B2B buyers should prioritize suppliers who provide clear certifications and quality assurance processes. It’s advisable to request detailed product specifications, including material certifications (like ASTM or ISO standards), and to conduct thorough due diligence on the supplier’s manufacturing practices. Additionally, establishing a robust vendor management system that includes regular audits and performance reviews can help ensure that suppliers consistently meet quality standards. Buyers can also consider engaging third-party testing services to verify the integrity of the cables before they are put into use. This proactive approach not only ensures reliability but also builds long-term relationships with reputable suppliers.

Scenario 2: Difficulty in Selecting the Right Type of Airline Cable

The Problem: Many B2B buyers struggle with selecting the appropriate type of airline cable for their specific applications. With various constructions (like 7×7 or 7×19), materials (such as galvanized or stainless steel), and coatings available, the decision-making process can be overwhelming. Misjudgments in choosing the wrong type can lead to operational inefficiencies, increased maintenance costs, and even failures in critical systems, resulting in both financial losses and reputational damage.

The Solution: To tackle this issue, buyers should invest time in understanding the specific requirements of their applications. This includes assessing load capacities, environmental conditions (such as exposure to moisture or corrosive elements), and the intended use of the cable. Engaging with technical experts or engineers who specialize in rigging and cable applications can provide valuable insights. Additionally, creating a detailed comparison chart of the different types of airline cables available, along with their respective advantages and limitations, can facilitate informed decision-making. Suppliers that offer customization options or consultation services can also be invaluable partners in helping buyers identify the most suitable cable solutions for their needs.

Scenario 3: Challenges with Installation and Maintenance of Airline Cable

The Problem: Once the correct airline cable is sourced, many buyers face challenges during installation and ongoing maintenance. Improper installation can lead to cable wear and tear, reduced load capacity, and increased risk of failure. Moreover, lack of knowledge about appropriate maintenance practices can significantly shorten the lifespan of the cable, leading to costly replacements and project delays.

The Solution: To enhance installation practices, buyers should provide comprehensive training for their teams on the correct installation techniques specific to airline cables. This training should cover the use of proper tools, techniques for securing cable ends, and understanding the load limits. Additionally, developing a maintenance schedule that includes regular inspections and preventive measures can significantly improve the longevity of the cables. Buyers should also consider leveraging suppliers that offer installation guides, maintenance resources, and support services. This collaborative approach not only ensures the effective use of airline cables but also fosters a culture of safety and efficiency within the organization. By prioritizing education and ongoing support, businesses can greatly reduce the risks associated with cable failure.

Strategic Material Selection Guide for airline cable

What Are the Key Properties of Galvanized Steel for Airline Cable?

Galvanized steel is a popular choice for airline cables due to its excellent corrosion resistance and strength. The galvanization process involves coating the steel with a layer of zinc, which protects it from rust and degradation when exposed to moisture. This material typically has a temperature rating of up to 200°C, making it suitable for various environmental conditions.

Pros and Cons: The primary advantage of galvanized steel is its durability and cost-effectiveness. It is relatively inexpensive compared to stainless steel, making it a go-to choice for many applications. However, it may not perform well in highly corrosive environments, such as coastal areas, where the zinc coating can wear off over time.

Impact on Application: Galvanized steel is suitable for general-purpose applications, including rigging and lifting. However, it may not be ideal for applications involving chemicals that can degrade the zinc coating.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM A123 for hot-dip galvanized coatings. Understanding the local climate and potential corrosive elements is crucial for selecting the appropriate material.

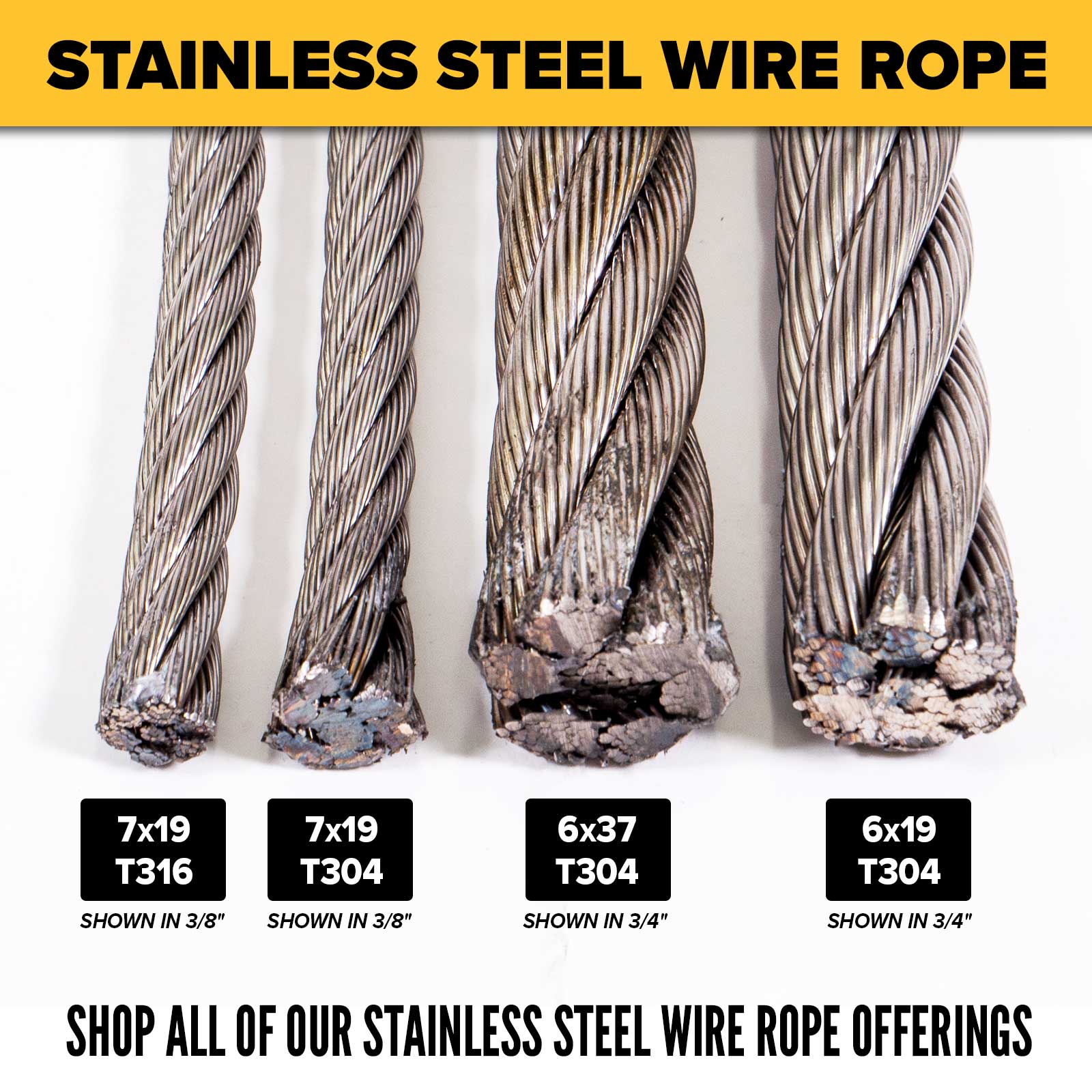

How Does Stainless Steel Compare for Airline Cable Applications?

Stainless steel, particularly grades 304 and 316, is highly regarded for its superior corrosion resistance and aesthetic appeal. It can withstand extreme temperatures and pressures, making it suitable for demanding applications. The typical temperature rating can exceed 500°C, depending on the specific grade.

Pros and Cons: The main advantage of stainless steel is its longevity and resistance to rust, making it ideal for marine and industrial environments. However, it is more expensive than galvanized steel, which may be a limiting factor for cost-sensitive projects.

Impact on Application: Stainless steel is particularly effective in applications where exposure to harsh chemicals or saltwater is a concern. Its compatibility with various media makes it versatile for different industries.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel required for their applications and ensure compliance with international standards like ASTM A313. In regions like the Middle East, local suppliers may prefer certain grades based on environmental conditions.

Illustrative image related to airline cable

What Are the Benefits of Using Plastic Coated Cable for Airline Applications?

Plastic-coated cables offer an additional layer of protection against abrasion and corrosion. The coating can be made from various materials, including PVC or polyurethane, which enhances the cable’s durability and flexibility. These cables typically perform well in temperatures ranging from -20°C to 70°C.

Pros and Cons: The key advantage of plastic-coated cables is their resistance to wear and tear, making them suitable for outdoor applications. However, the coating can add to the overall cost and may not be as strong as bare steel cables.

Impact on Application: These cables are ideal for applications requiring a softer touch, such as in the entertainment industry for rigging and suspension systems. The coating also provides a non-slip surface, which can be beneficial in certain settings.

Considerations for International Buyers: Buyers should check for compliance with local regulations regarding plastic materials, especially in Europe, where environmental standards are stringent. Understanding the specific applications and environments will help in selecting the right coating.

How Do Synthetic Fiber Cables Fit into the Airline Cable Market?

Synthetic fiber cables, such as those made from Kevlar or nylon, are gaining traction due to their lightweight and high-strength properties. These cables can withstand significant loads while being much lighter than metal counterparts, making them easier to handle. They typically have a temperature rating of up to 200°C.

Illustrative image related to airline cable

Pros and Cons: The main advantage of synthetic fiber cables is their high tensile strength and flexibility, which makes them suitable for various applications, including aerospace and maritime. However, they may not be as durable as metal cables in harsh environments.

Impact on Application: Synthetic cables are ideal for applications where weight is a critical factor. They are often used in aerospace applications where reducing weight can lead to significant fuel savings.

Considerations for International Buyers: Buyers should consider the specific performance characteristics required for their applications and ensure compliance with relevant standards, such as ISO 9001. In regions like South America, understanding the local market’s acceptance of synthetic materials is crucial.

Summary Table of Material Selection for Airline Cable

| Material | Typical Use Case for Airline Cable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | General rigging and lifting | Cost-effective and durable | Limited corrosion resistance | Low |

| Stainless Steel | Marine and industrial applications | Superior corrosion resistance | Higher cost compared to galvanized | High |

| Plastic Coated Cable | Outdoor rigging and suspension | Enhanced abrasion resistance | Added cost and lower strength | Medium |

| Synthetic Fiber Cables | Aerospace and lightweight applications | Lightweight and high strength | Less durable in harsh environments | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for airline cable

What Are the Main Stages in the Manufacturing Process of Airline Cable?

The manufacturing process of airline cable is intricate and involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring the final product meets the rigorous demands of the aviation industry.

Illustrative image related to airline cable

-

Material Preparation: The primary materials used in airline cables are galvanized and stainless steel. These materials are selected based on their strength, corrosion resistance, and flexibility. The steel is often sourced from reputable suppliers and undergoes preliminary testing to confirm its tensile strength and durability. This stage may also include cutting the materials to the required lengths and diameters.

-

Forming: The forming stage involves the actual creation of the cable. This is typically done using advanced machinery that twists the steel wires into various configurations, such as 7×7 or 7×19 constructions. The choice of construction influences the cable’s flexibility and strength. Techniques such as swaging, where metal terminals are compressed onto the cable ends, are also employed to ensure secure connections.

-

Assembly: Once the cable strands are formed, they are assembled into the final product. This may include integrating additional components such as thimbles and clips, which are essential for the cable’s functionality. In this stage, the assembly is often customized to meet specific customer requirements, which can vary greatly across different markets, such as Africa, South America, and Europe.

-

Finishing: The finishing stage includes processes such as coating or galvanizing to enhance corrosion resistance. Depending on the end-use, additional treatments may be applied to improve wear resistance or aesthetic appeal. The finished cables undergo a final inspection to ensure they meet all specifications and quality standards before packaging and shipment.

How Is Quality Assurance Integrated into the Manufacturing of Airline Cable?

Quality assurance (QA) in the production of airline cable is vital, especially given the safety-critical nature of aviation. Manufacturers implement a robust QA system that adheres to international standards and industry-specific regulations.

-

International Standards: Many manufacturers comply with ISO 9001 standards, which ensure a consistent quality management system. This certification indicates that the manufacturer has the processes in place to consistently produce products that meet customer and regulatory requirements. Additionally, CE marking may be required for products sold in the European market, affirming compliance with health, safety, and environmental protection standards.

-

Industry-Specific Certifications: Other relevant certifications may include API (American Petroleum Institute) for cables used in oil and gas applications or AS9100, which is specific to the aerospace industry. These certifications involve rigorous audits and assessments that verify the manufacturer’s commitment to quality.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are established throughout the manufacturing process. Key checkpoints include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing stages help identify any issues early, minimizing waste and rework.

– Final Quality Control (FQC): The finished products undergo thorough testing, including tensile strength tests, corrosion resistance evaluations, and dimensional checks to ensure they meet all technical specifications.

What Testing Methods Are Commonly Used for Airline Cable Quality Assurance?

Testing is a critical component of the quality assurance process for airline cables. Various methods are employed to validate the integrity and performance of the cables:

-

Tensile Testing: This method measures the maximum amount of tensile (pulling) force the cable can withstand before failing. It is essential for determining the cable’s strength and is typically performed in accordance with ASTM (American Society for Testing and Materials) standards.

-

Fatigue Testing: Fatigue tests simulate the cyclical loading that cables experience in real-world applications. This testing helps predict the lifespan of the cable and its ability to withstand repeated stress without failure.

-

Corrosion Testing: Given the critical nature of corrosion resistance in aviation applications, various corrosion tests, such as salt spray testing, are conducted to ensure the cable’s longevity under harsh environmental conditions.

-

Dimensional Inspection: This includes verifying that the cable dimensions, including diameter and length, meet specified tolerances. It is crucial for ensuring compatibility with fittings and other components.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from regions like Africa, South America, and the Middle East, verifying a supplier’s quality control processes is essential to mitigate risks associated with product quality.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control practices. During these audits, buyers can assess compliance with international standards, review documentation, and observe manufacturing practices firsthand.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the QC measures in place. These reports should include results from various tests performed, certifications obtained, and any incidents of non-conformance.

-

Third-Party Inspections: Utilizing third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate the manufacturing processes, conduct testing, and verify compliance with international standards.

-

Certification Verification: Buyers should verify the authenticity of any claimed certifications. This can typically be done through the issuing organizations’ websites or through direct communication with the certifying bodies.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control in different regions is crucial for B2B buyers looking to procure airline cables. Buyers should be aware of:

-

Regional Standards: Different regions may have varying standards and regulations governing manufacturing practices. Familiarizing oneself with these requirements is crucial for compliance and successful market entry.

-

Cultural Factors: Cultural differences can influence manufacturing practices and quality perceptions. Building strong relationships with suppliers and understanding local practices can facilitate better communication and quality outcomes.

-

Logistical Considerations: The logistics of shipping and handling can impact product quality. Buyers should ensure that suppliers have adequate measures in place to protect products during transportation, especially for delicate or high-value items like airline cables.

In conclusion, understanding the manufacturing processes and quality assurance protocols for airline cables is vital for B2B buyers. By focusing on the intricacies of production and verification techniques, buyers can make informed decisions that ensure safety, compliance, and reliability in their procurement processes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘airline cable’

Introduction

This guide is designed to assist international B2B buyers in sourcing airline cable effectively. With a focus on key considerations and actionable steps, this checklist will help ensure that you procure the right product to meet your operational needs while minimizing risks associated with quality and compliance.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of effective sourcing. Determine the type of airline cable required, including material (galvanized or stainless steel), construction (7×7 or 7×19), and any specific size or strength requirements. This clarity will streamline communication with suppliers and ensure you receive products that meet your operational demands.

- Considerations:

- Break strength requirements based on your application.

- Environmental factors that may influence material choice (corrosion resistance, etc.).

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to ensure they can meet your specifications and quality standards. Look for suppliers with a strong track record in the industry, positive reviews, and solid references.

- Key Actions:

- Review their company profiles and product offerings.

- Check for certifications that validate their compliance with international standards.

Step 3: Evaluate Product Quality and Compliance

Quality assurance is critical when sourcing airline cable. Request samples if possible, and inquire about the manufacturing processes to ensure they adhere to industry standards.

Illustrative image related to airline cable

- Quality Indicators:

- Certifications such as ISO or ASTM.

- Details on the testing methods used for their products.

Step 4: Verify Supplier Certifications

Before finalizing any deals, verify that your suppliers hold necessary certifications. This step is crucial for ensuring that the airline cable meets safety and regulatory requirements in your region.

- What to Check:

- Compliance with local and international standards.

- Any additional certifications that may be relevant to your industry.

Step 5: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotes that outline pricing, delivery timelines, and payment terms. This transparency is essential for making informed comparisons and negotiations.

- Important Factors:

- Breakdown of costs (material, shipping, duties).

- Terms regarding bulk discounts or long-term contracts.

Step 6: Assess Customer Support and After-Sales Service

The level of customer support provided by a supplier can significantly impact your sourcing experience. Ensure that they offer comprehensive support and a clear return or warranty policy.

- What to Look For:

- Responsiveness to inquiries.

- Availability of technical support for installation or maintenance.

Step 7: Negotiate and Finalize the Contract

Once you have evaluated all aspects, engage in negotiations to finalize the contract. Ensure all terms are clearly defined, including delivery schedules, payment terms, and penalties for non-compliance.

- Key Points:

- Include clauses for quality assurance and inspection rights.

- Clearly outline the dispute resolution process.

By following this checklist, B2B buyers can navigate the complexities of sourcing airline cable, ensuring they make informed decisions that align with their operational requirements and business goals.

Comprehensive Cost and Pricing Analysis for airline cable Sourcing

What Are the Key Cost Components in Airline Cable Sourcing?

Understanding the cost structure of airline cable sourcing is critical for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to airline cable

-

Materials: The choice between galvanized steel, stainless steel, or other materials significantly impacts pricing. High-quality materials that comply with international standards typically command a premium. The specific type of cable construction, such as 7×19 or 7×7, also influences material costs.

-

Labor: Labor costs can vary based on the manufacturing location. Countries with lower labor costs might offer more competitive pricing, but this can sometimes affect quality. Skilled labor is essential for ensuring the proper assembly and quality assurance of the cables.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, depreciation of equipment, and facility maintenance. Buyers should inquire about the manufacturing processes and facilities to gauge overhead costs.

-

Tooling: Custom tooling for specialized cable configurations can add to initial costs. However, once established, this can lead to efficiencies in production.

-

Quality Control: Rigorous QC measures ensure product reliability and compliance with aviation standards. Buyers should consider the costs associated with QC processes, as they can vary significantly between suppliers.

-

Logistics: Shipping and handling costs can fluctuate based on the distance from the supplier to the buyer, as well as the chosen shipping method. Understanding Incoterms is vital for clarifying who bears these costs.

-

Margin: Finally, suppliers will include a margin to cover their risk and profit. Buyers should be aware that margins can vary widely based on supplier reputation, market demand, and the complexity of the cable.

What Influences Pricing for Airline Cables?

Several factors can influence pricing beyond the basic cost structure. These include order volume, specifications, customization, material quality, certifications, supplier reliability, and Incoterms.

-

Volume/MOQ: Purchasing in larger quantities often leads to volume discounts. Buyers should assess their needs carefully to negotiate better pricing based on minimum order quantities (MOQs).

-

Specifications and Customization: Custom specifications typically increase costs. Buyers should clarify their requirements upfront to avoid unexpected charges during production.

-

Material Quality and Certifications: Premium materials and recognized certifications (like ISO or AS9100) can lead to higher prices but also ensure product reliability and safety. Buyers should weigh the long-term benefits of investing in high-quality products.

-

Supplier Factors: A supplier’s market position, reputation, and service level can influence pricing. Established suppliers may offer better guarantees and support, which can justify a higher price.

-

Incoterms: Understanding Incoterms is essential for determining who is responsible for shipping, insurance, and tariffs. This knowledge can help buyers avoid hidden costs that could inflate the total price.

What Tips Can Help Buyers Negotiate Better Prices for Airline Cables?

When negotiating prices for airline cables, international B2B buyers should consider several strategies to enhance cost-efficiency.

-

Research and Benchmarking: Conducting thorough market research and benchmarking prices across multiple suppliers can provide leverage during negotiations. Understanding the average market price for specific types of cables can help identify outliers.

-

Total Cost of Ownership (TCO): Buyers should evaluate the TCO rather than just the upfront cost. This includes considering potential maintenance costs, lifespan, and the reliability of the cable. A slightly higher initial investment may lead to significant savings over time.

-

Flexibility in Specifications: Being flexible with specifications may allow buyers to take advantage of more cost-effective options. Discussing alternative materials or constructions with suppliers can yield savings.

-

Long-term Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Loyal customers often receive preferential pricing and improved service.

-

Understand Pricing Nuances for Different Regions: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences influenced by local demand, supply chain dynamics, and import tariffs. Understanding these nuances can aid in more informed negotiations.

Disclaimer on Indicative Prices

Prices for airline cables can vary significantly based on specifications, supplier location, and market conditions. Buyers are encouraged to request detailed quotations from multiple suppliers to obtain the most accurate pricing information tailored to their specific needs.

Alternatives Analysis: Comparing airline cable With Other Solutions

Introduction to Alternative Solutions for Airline Cable

In the context of rigging and suspension applications, airline cable is a popular choice due to its strength and versatility. However, buyers should consider alternative solutions that may offer specific advantages depending on their unique requirements. In this analysis, we will compare airline cable with two viable alternatives: Wire Rope and Synthetic Rope. Each solution has distinct features that may better suit certain applications.

Comparison Table of Airline Cable and Alternatives

| Comparison Aspect | Airline Cable | Wire Rope | Synthetic Rope |

|---|---|---|---|

| Performance | High tensile strength; flexible | Very high load capacity; durable | Lightweight; good shock absorption |

| Cost | Moderate pricing | Generally higher cost | Lower initial cost |

| Ease of Implementation | Easy to handle and install | Requires specialized tools | Simple to work with; lightweight |

| Maintenance | Minimal maintenance required | Regular inspections needed | Low maintenance; resistant to abrasion |

| Best Use Case | Suspension systems in aircraft | Heavy lifting and industrial applications | Marine, climbing, and rescue operations |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Wire Rope?

Wire rope is a robust alternative to airline cable, renowned for its exceptional load-bearing capabilities. It is often used in heavy lifting applications, such as cranes and industrial machinery. One of its key advantages is its durability, which allows it to withstand harsh environmental conditions. However, wire rope can be heavier and may require more specialized installation techniques compared to airline cable. Additionally, regular inspections and maintenance are necessary to ensure safety and performance, which can lead to increased operational costs.

How Does Synthetic Rope Compare?

Synthetic rope is another alternative that has gained popularity, especially in marine and climbing applications. It is significantly lighter than both airline cable and wire rope, making it easier to handle and transport. Synthetic rope also offers excellent shock absorption, which can be beneficial in dynamic loads. However, it may not match the tensile strength of steel options, limiting its use in extremely heavy applications. Furthermore, while it requires less maintenance, synthetic materials can be more susceptible to UV damage and abrasion over time, necessitating careful consideration of the environment in which it will be used.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between airline cable, wire rope, and synthetic rope, B2B buyers should assess their specific needs based on application, budget, and environmental conditions. Airline cable may be the best choice for aviation-related applications where flexibility and lightweight characteristics are essential. Conversely, wire rope excels in heavy-duty industrial applications that demand maximum load capacity. Synthetic rope is ideal for lighter tasks where portability and shock absorption are priorities. By carefully considering these factors, buyers can make informed decisions that align with their operational requirements and budget constraints.

Illustrative image related to airline cable

Essential Technical Properties and Trade Terminology for airline cable

What Are the Key Technical Properties of Airline Cable?

Understanding the essential technical properties of airline cable is crucial for B2B buyers to ensure they select the right product for their specific applications. Here are some critical specifications to consider:

1. Material Grade

Airline cables are typically made from galvanized or stainless steel. The material grade affects the cable’s strength, corrosion resistance, and suitability for various environments. For instance, stainless steel cables (like 304 or 316 grades) provide better corrosion resistance, making them ideal for marine or humid conditions. Choosing the appropriate material grade can significantly enhance the longevity and reliability of the cable in demanding applications.

2. Construction Type

Common constructions include 7×7 and 7×19 configurations. The numbers refer to the number of strands and wires within each strand. For example, a 7×19 cable has 19 wires in each of its 7 strands, providing increased flexibility and strength compared to a 7×7 cable. Understanding construction types allows buyers to match the cable’s mechanical properties to the intended use, whether it be for lifting, rigging, or suspension.

3. Break Strength

This specification indicates the maximum load that a cable can withstand before failing. Break strength is often expressed in pounds or tons and is a critical factor in safety calculations. Buyers should always consider the break strength in relation to the expected load to ensure that safety margins are maintained. For example, a cable with a break strength of 2,000 lbs should ideally be used in applications that do not exceed 50% of that capacity for optimal safety.

4. Diameter

The diameter of airline cables varies, typically from 1/8 inch to 1 inch or more. A larger diameter generally translates to higher strength but may also affect flexibility. For applications requiring tight bends or intricate rigging, a smaller diameter may be advantageous. Buyers must evaluate their specific application requirements to determine the appropriate diameter.

5. Tolerance

Tolerance refers to the allowable deviation from specified dimensions and is critical in ensuring compatibility with fittings and other hardware. A tighter tolerance can lead to a better fit, reducing the risk of failure due to slippage or improper alignment. This is especially important in high-stakes applications such as aerospace or heavy lifting.

What Are Common Trade Terms Associated with Airline Cable?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of airline cables, buyers often seek OEM suppliers to ensure high-quality components that meet specific industry standards.

Illustrative image related to airline cable

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for buyers to avoid overstocking or underordering, which can affect cash flow and storage capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. Including detailed specifications in the RFQ helps ensure that quotes are accurate and comparable, making it easier for buyers to make informed decisions.

4. Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities, which are crucial for budgeting and logistics planning.

5. SWL (Safe Working Load)

SWL indicates the maximum load that a cable can safely handle during normal operations. It is typically set at a fraction of the break strength to account for dynamic forces and other variables. Knowing the SWL helps buyers select cables that will perform reliably under expected conditions without risking failure.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing airline cables, ensuring safety, compliance, and operational efficiency in their projects.

Illustrative image related to airline cable

Navigating Market Dynamics and Sourcing Trends in the airline cable Sector

Market Overview & Key Trends: What Should International B2B Buyers Know About Airline Cable?

The airline cable market is witnessing significant growth, driven by the increasing demand for lightweight and high-strength materials in various industries, particularly aviation, construction, and maritime sectors. The global shift towards more efficient transportation systems and infrastructure development has led to a surge in the need for durable and reliable cable solutions. Emerging B2B technologies, such as advanced manufacturing techniques and digital sourcing platforms, are reshaping how buyers engage with suppliers, allowing for more streamlined procurement processes.

In regions like Africa, South America, the Middle East, and Europe, international buyers are increasingly focused on sourcing high-quality airline cable that meets stringent safety and performance standards. The rise of e-commerce platforms facilitates access to global suppliers, enabling buyers to compare product specifications, pricing, and certifications easily. Additionally, the growing emphasis on custom solutions and tailored cable assemblies is reshaping market dynamics, as buyers seek products that can meet specific project requirements.

Furthermore, the trend towards automation in manufacturing processes is leading to innovations in cable design and production, enhancing product reliability and performance. Buyers should also be aware of fluctuating raw material prices, which can impact sourcing strategies and overall procurement costs. Building strong supplier relationships and leveraging technology for supply chain visibility will be key to navigating these market dynamics effectively.

How Are Sustainability and Ethical Sourcing Influencing the Airline Cable Market?

As the global focus on sustainability intensifies, the airline cable sector is increasingly prioritizing environmentally friendly practices and ethical sourcing. Buyers are now more conscious of the environmental impact of their procurement choices, prompting manufacturers to adopt greener production methods and materials. This shift is particularly relevant for international buyers from regions like Africa and South America, where environmental regulations and consumer expectations are evolving rapidly.

Ethical supply chains are essential not only for compliance with local and international regulations but also for enhancing brand reputation. Many suppliers are now seeking certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety, which can provide assurance to buyers regarding their commitment to sustainable practices. Additionally, the use of recycled materials in the production of airline cables is gaining traction, offering buyers a way to reduce their carbon footprint.

Investing in ‘green’ certifications and materials is becoming a competitive advantage for suppliers. International buyers should prioritize partnerships with suppliers who demonstrate a commitment to sustainability, as this can positively impact their own corporate responsibility goals. By choosing ethically sourced airline cable, buyers contribute to a more sustainable future while also enhancing their brand’s credibility in the marketplace.

What is the Historical Context of the Airline Cable Industry?

The airline cable industry has evolved significantly over the past century, initially emerging from the need for reliable and strong materials in aviation. Early developments focused on the use of steel cables for supporting aircraft structures, which paved the way for advancements in cable technology. Over the years, innovations in materials such as stainless steel and synthetic fibers have led to the creation of lighter, stronger, and more durable cables, catering to the growing demands of the aviation and construction sectors.

Illustrative image related to airline cable

In recent decades, the industry has witnessed a paradigm shift towards automation and digitalization, transforming manufacturing processes and supply chain dynamics. This evolution has enabled suppliers to offer customized solutions that meet specific client needs while maintaining high safety and performance standards. As the market continues to adapt to technological advancements and sustainability imperatives, the airline cable sector remains poised for growth, providing a wealth of opportunities for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of airline cable

-

How do I choose the right airline cable for my application?

Selecting the appropriate airline cable involves understanding your specific requirements, such as load capacity, environmental conditions, and application type. Consider factors like cable construction (e.g., 7×7 or 7×19), material (galvanized vs. stainless steel), and breaking strength. Review product specifications and consult with suppliers to ensure the cable meets safety standards and performance criteria for your industry. Additionally, taking into account local regulations and certifications can prevent compliance issues. -

What is the best material for airline cable in humid environments?

For humid or corrosive environments, stainless steel cable is generally the best choice due to its superior resistance to rust and corrosion. Specifically, 316 stainless steel is ideal for marine or coastal applications where exposure to saltwater is a concern. If cost is a factor, galvanized steel can also be used, but it may require more frequent maintenance to prevent corrosion. Always evaluate the long-term costs associated with maintenance versus initial material costs to make an informed decision. -

What are the minimum order quantities (MOQs) for airline cable?

Minimum order quantities for airline cable can vary significantly based on the supplier and the type of cable required. Generally, MOQs can range from as little as 100 feet to several thousand feet for bulk orders. It’s advisable to communicate directly with suppliers to negotiate terms that fit your business needs. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so it’s worth exploring various options before finalizing your order. -

How can I vet suppliers for airline cable purchases?

To vet suppliers effectively, start by researching their reputation through customer reviews and industry ratings. Request references from previous clients and inquire about their experience with product quality and service. Assess their certifications and compliance with international standards, as well as their ability to meet your specific requirements. Additionally, consider visiting their facility if possible, or request product samples to evaluate quality firsthand before committing to a larger order. -

What payment terms should I expect when sourcing airline cable internationally?

Payment terms can vary widely among suppliers, particularly in international trade. Common terms include payment in advance, net 30, or letters of credit. It’s essential to clarify payment expectations upfront to avoid misunderstandings. Some suppliers may offer discounts for early payment or bulk orders. Always ensure that payment methods are secure and consider using an escrow service for significant transactions to protect both parties during the exchange. -

What quality assurance measures should I look for in airline cable?

Quality assurance is critical when sourcing airline cable. Look for suppliers that provide detailed product specifications, including breaking strength, tensile strength, and corrosion resistance. Ask about their quality control processes, such as third-party testing and certifications like ISO or ASTM compliance. Suppliers should be willing to share test results or certifications to ensure that their products meet industry standards. Regular audits of their quality processes can also be a good indicator of reliability. -

How do I handle logistics for international shipments of airline cable?

Logistics for international shipments can be complex, involving customs clearance, shipping regulations, and potential tariffs. Work with suppliers who have experience in international shipping and can guide you through the necessary documentation. It’s advisable to use a freight forwarder to manage transportation and ensure that all import/export regulations are met. Additionally, consider insurance options to protect your investment during transit, and factor in delivery timelines to avoid disruptions in your supply chain. -

Can I customize airline cable to meet specific project requirements?

Many suppliers offer customization options for airline cables, including specific lengths, materials, and fittings. When seeking customization, communicate your exact requirements clearly, including any technical specifications or load capacities needed for your project. Inquire about lead times for custom orders, as these may differ from standard products. Keep in mind that while customization can provide tailored solutions, it may also impact pricing and delivery schedules.

Top 4 Airline Cable Manufacturers & Suppliers List

1. Rigging Warehouse – Aircraft Cable & Wire Rope

Domain: riggingwarehouse.com

Registered: 2006 (19 years)

Introduction: Aircraft Cable & Wire Rope products include: 1″ 6×37 XIP Steel Core (IWRC) Bright Wire Rope, 3/16″ 1X7 Common Galvanized Strand, 3/16X1000′ 7X7 Stainless Steel Aircraft Cable T304, 3/16X500′ 7X7 Stainless Steel Aircraft Cable T304, 3/32″ x 500′ 7×19 Galvanized Aircraft Cable, 1″ 19×7 Rotation-Resistant Wire Rope, and various sizes of XIP Steel Core (IWRC) Bright and Galvanized Wire Rope. Categorie…

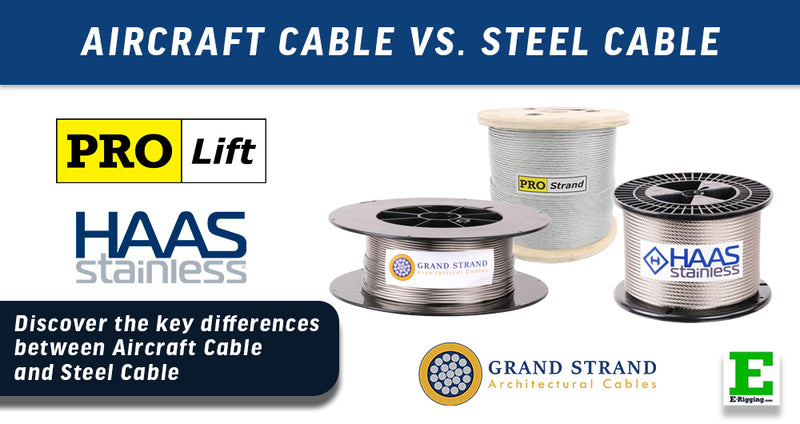

2. Griplock® Systems – Wire Rope Aircraft Cable

Domain: griplocksystems.com

Registered: 1998 (27 years)

Introduction: Wire Rope Aircraft Cable from Griplock® Systems is available in galvanized or stainless steel. Cable assemblies come in 7×7 or 7×19 configurations, offering medium-to-high tensile strength. The assemblies are factory fitted with various terminals including die-cast zinc, swaged aluminum, swaged copper, or swaged steel. Griplock terminals guarantee the full published break-strength of the cable unl…

3. US Cargo Control – Aircraft Cable Options

Domain: uscargocontrol.com

Registered: 2005 (20 years)

Introduction: Aircraft Cable options include: 7×19 Galvanized Aircraft Cable, 7×19 304 Stainless Steel Aircraft Cable, 7×19 316 Stainless Steel Aircraft Cable, 7×19 Galvanized Aircraft Cable – Vinyl-Coated, 7×19 304 Stainless Steel Aircraft Cable – Vinyl-Coated. Break Strengths range from 920 lbs. to 14400 lbs. Various products available for different applications.

4. Bulk Ropes – Aircraft Cable Options

Domain: bulkropes.com

Registered: 2007 (18 years)

Introduction: Aircraft Cable options include: Galvanized Aircraft Cable and Stainless Steel Aircraft Cable. Available sizes for Stainless Steel Aircraft Cable: 1/4″ ($741.00), 7/32″ ($614.24), 3/16″ ($485.76), 1/8″ ($253.52), 3/32″ ($179.50), 1/16″ ($120.96). Available sizes for 7×7 Galvanized Aircraft Cable: 1/16″ ($21.80), 3/16″ ($51.66), 5/32″ ($37.12), 1/8″ ($26.36), 3/32″ ($16.40). Available sizes for 7×19…

Strategic Sourcing Conclusion and Outlook for airline cable

In navigating the complexities of sourcing airline cable, international B2B buyers must prioritize strategic sourcing to ensure they acquire high-quality products that meet their operational needs. With a variety of options available, including galvanized and stainless steel cables in different constructions like 7×7 and 7×19, it’s essential to understand the specifications and performance characteristics that best suit your applications. Effective sourcing not only facilitates cost savings but also enhances supply chain resilience, particularly in regions like Africa, South America, the Middle East, and Europe.

As the global market evolves, staying informed about emerging trends and innovations in cable technology will be crucial. Buyers should consider partnerships with reputable suppliers who offer customization options and robust support services. Engaging in strategic sourcing now will position your business to leverage future opportunities and mitigate risks associated with fluctuating supply chains.

Looking ahead, it is imperative for B2B buyers to take proactive steps in refining their sourcing strategies. By doing so, you can ensure a steady supply of reliable airline cable that enhances your operational efficiency and competitiveness in the marketplace. Embrace the future of sourcing—connect with trusted suppliers today to explore the best solutions for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.