Everything You Need to Know About Agitator Impeller Types Sourcing in 2025

Introduction: Navigating the Global Market for agitator impeller types

In the ever-evolving landscape of industrial manufacturing, sourcing the right agitator impeller types can present a significant challenge for B2B buyers. The complexities of various applications, from chemical processing to food production, demand a thorough understanding of the specific types of impellers available and their respective functionalities. This guide serves as a comprehensive resource, detailing the diverse range of agitator impeller types, their applications across different industries, and critical insights into supplier vetting and cost considerations.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—will find actionable insights tailored to their unique procurement needs. With a focus on practical solutions, this guide empowers decision-makers to navigate the complexities of the global market confidently. By understanding the nuances of agitator technologies, buyers can make informed purchasing decisions that enhance operational efficiency and product quality, ultimately driving business growth in competitive markets.

Whether you are seeking high shear mixers for emulsification or paddle agitators for viscous materials, our guide offers the essential knowledge to streamline your sourcing process, ensuring you choose the right equipment for your specific operational requirements.

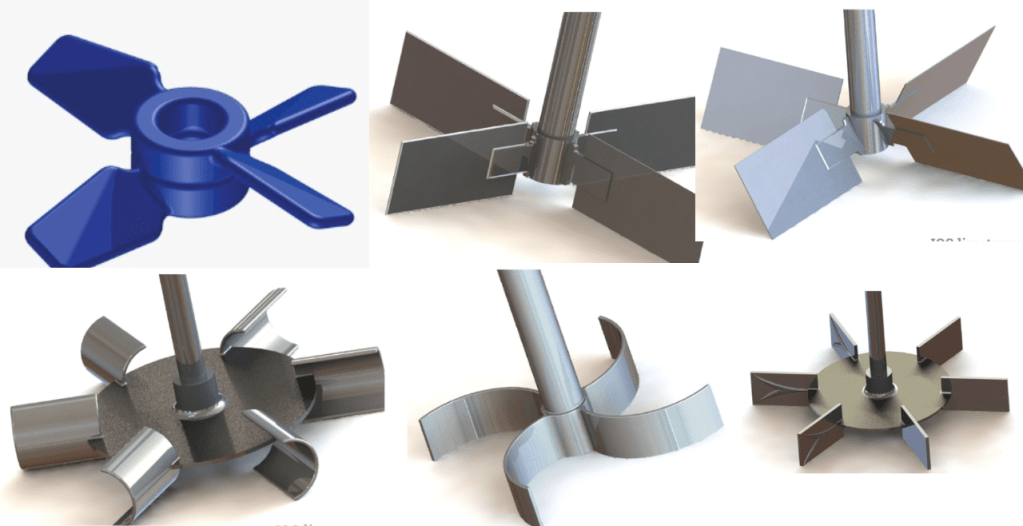

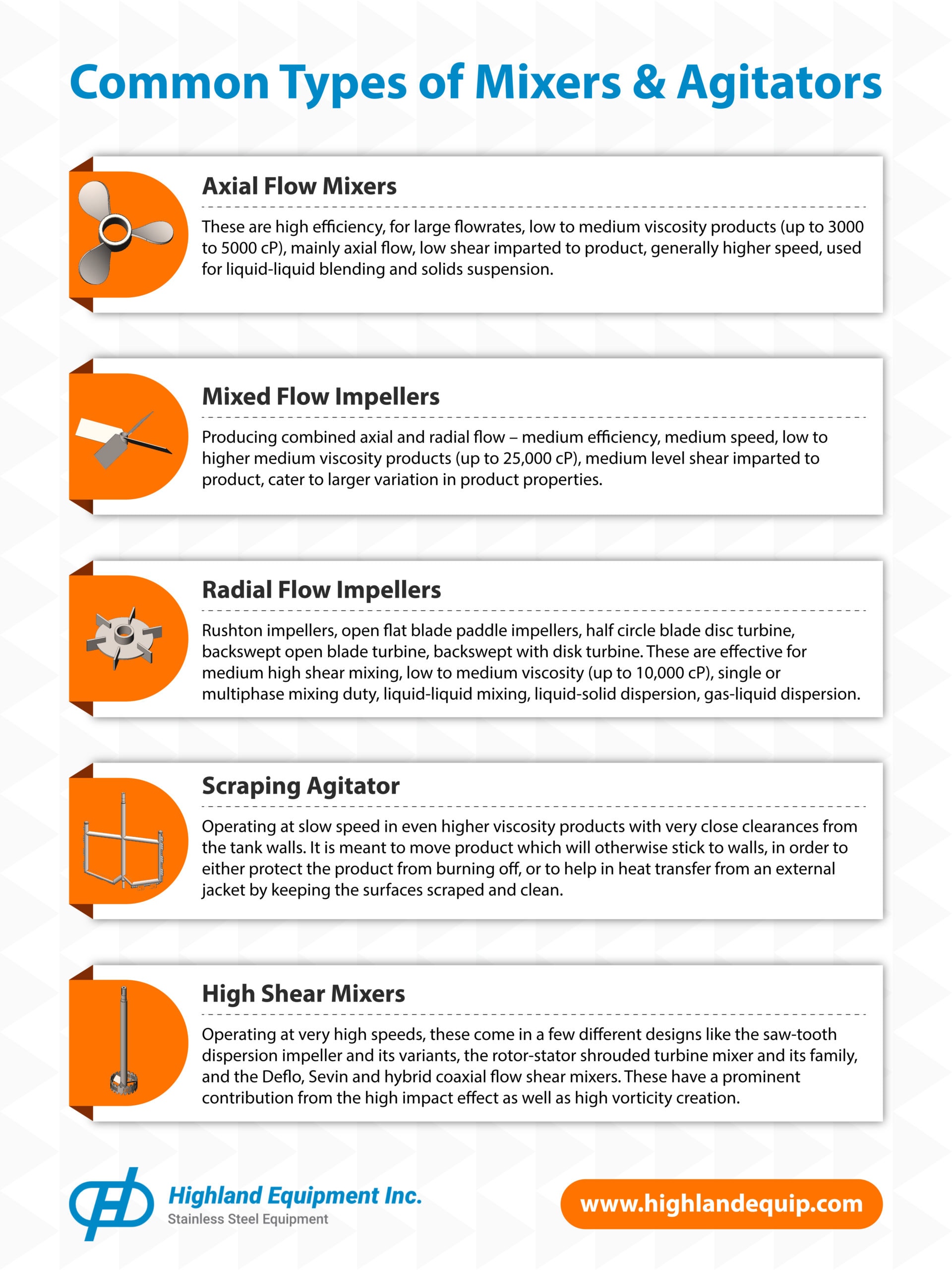

Understanding agitator impeller types Types and Variations

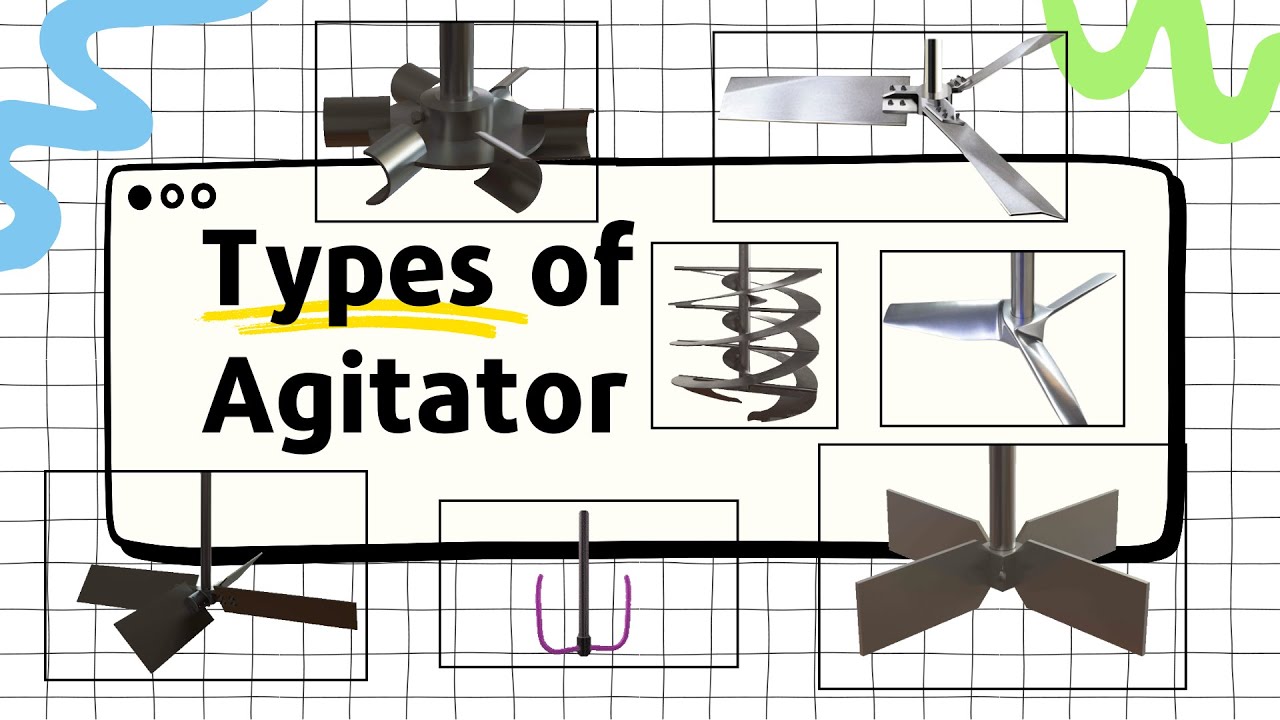

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

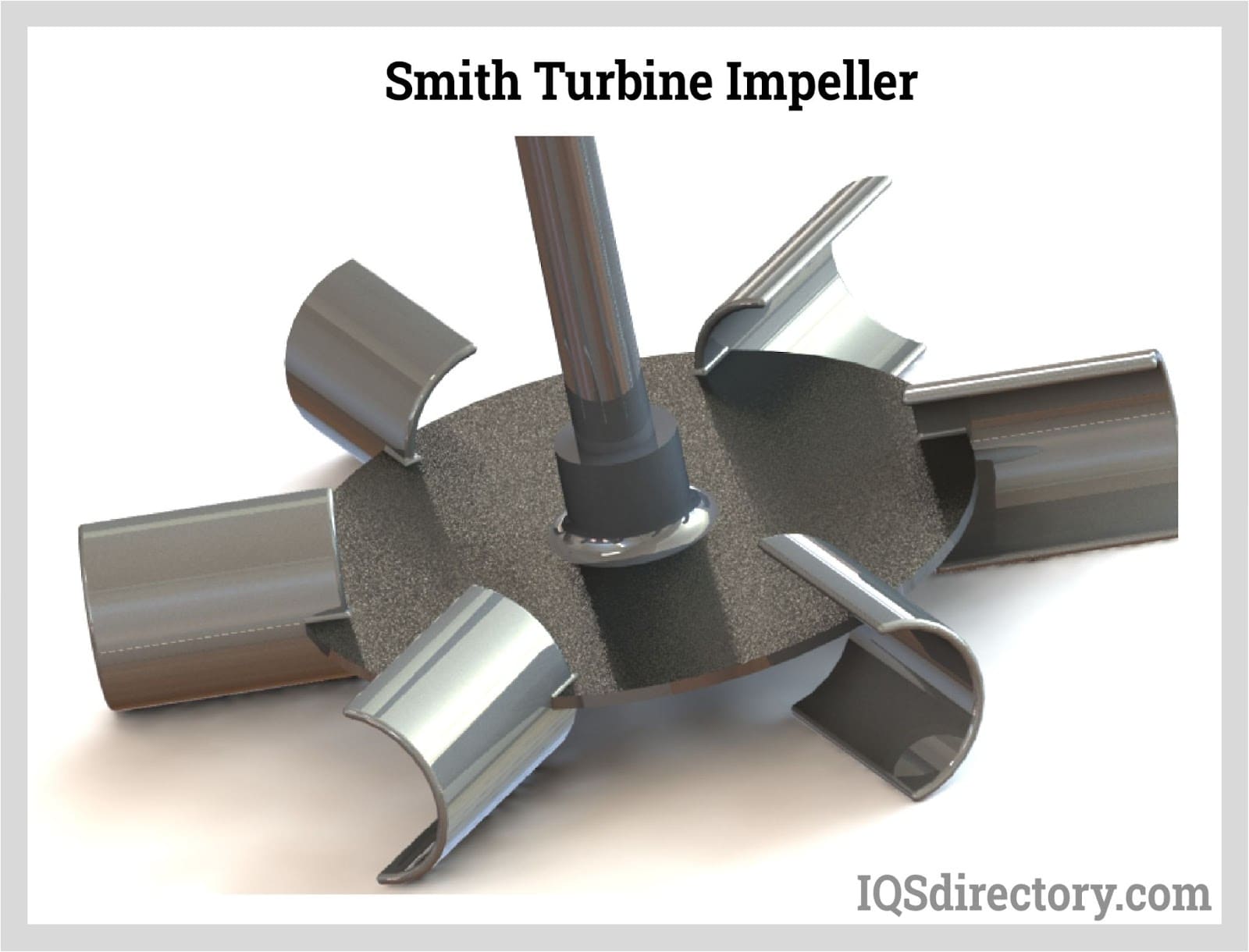

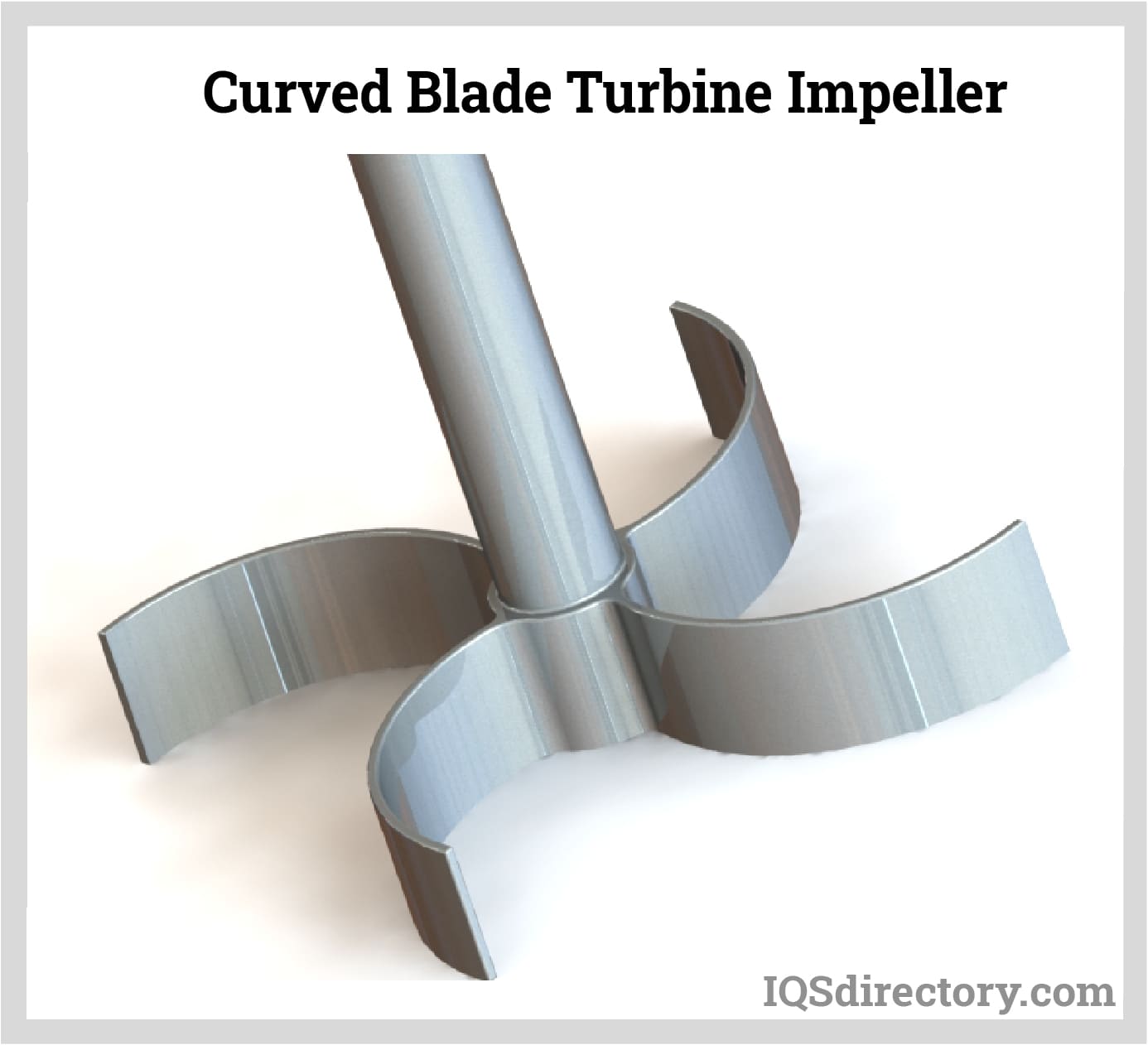

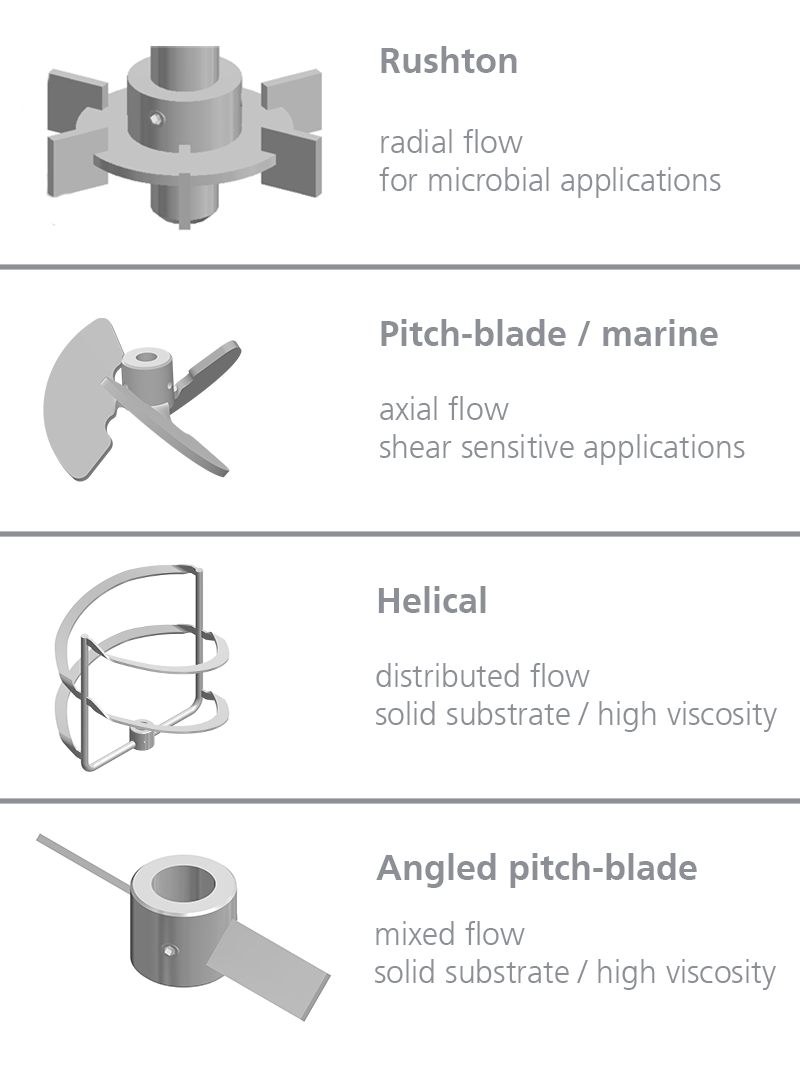

| Turbine Impellers | High blending efficiency with axial input and radial output. | Chemical, pharmaceutical, and metal extraction. | Pros: Versatile, efficient mixing in turbulent conditions. Cons: Can create excessive shear for sensitive materials. |

| Paddle Impellers | Paddle-shaped blades that create laminar flow, ideal for viscous materials. | Food processing, cosmetics, and wastewater treatment. | Pros: Gentle mixing, suitable for high-viscosity applications. Cons: Limited efficiency for low-viscosity fluids. |

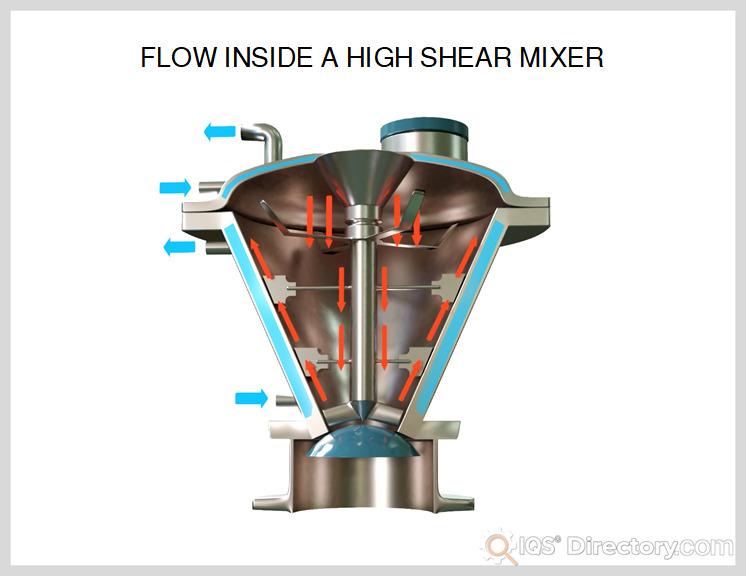

| High Shear Impellers | Designed for emulsification, dispersion, and homogenization. | Paint, pharmaceuticals, and food industries. | Pros: Effective for complex mixtures; quick processing. Cons: Higher energy consumption and potential heat generation. |

| Anchor Impellers | Fixed blades that scrape the vessel walls, promoting thorough mixing. | Adhesives, pastes, and other viscous materials. | Pros: Excellent for thick mixtures; minimizes dead zones. Cons: Slower mixing compared to turbine types. |

| Propeller Impellers | Simple design promoting axial flow, suitable for low-viscosity fluids. | Water treatment, chemical blending, and light food products. | Pros: Cost-effective and efficient for low-viscosity applications. Cons: Limited effectiveness in viscous or dense materials. |

What are the Characteristics and Suitability of Turbine Impellers?

Turbine impellers are known for their high blending efficiency, making them a popular choice in industries such as chemicals and pharmaceuticals. Their ability to create turbulent flow due to axial input and radial output allows for effective mixing of various materials. When considering turbine impellers, businesses should evaluate the viscosity of the materials they intend to mix, as excessive shear can be detrimental to sensitive substances.

How Do Paddle Impellers Benefit B2B Buyers in Viscous Applications?

Paddle impellers feature blades designed to create a gentle laminar flow, making them particularly effective for mixing viscous materials. Industries such as food processing and cosmetics often utilize paddle impellers for their ability to achieve uniform consistency without damaging delicate components. Buyers should consider the specific viscosity of their products, as paddle impellers may not perform efficiently with lower viscosity fluids.

Why Choose High Shear Impellers for Complex Mixtures?

High shear impellers excel in applications requiring emulsification, dispersion, or homogenization. They are widely used in industries such as paint and food processing due to their ability to handle complex mixtures quickly. However, potential buyers should be aware of their higher energy consumption and the heat they may generate during operation, which could affect temperature-sensitive materials.

What Are the Key Advantages of Anchor Impellers for Thick Mixtures?

Anchor impellers are designed with fixed blades that scrape against the vessel walls, ensuring thorough mixing of thick and viscous materials. This makes them ideal for applications in adhesives and pastes. While they provide excellent mixing for dense materials, buyers should note that anchor impellers may operate at slower speeds compared to turbine options, which could impact production timelines.

In What Scenarios Are Propeller Impellers Most Effective?

Propeller impellers offer a simple design that promotes efficient axial flow, making them suitable for low-viscosity fluids. Commonly used in water treatment and light chemical blending, they are cost-effective solutions for many applications. However, businesses should assess their material characteristics, as propeller impellers may not achieve the desired mixing efficiency with thicker substances.

Key Industrial Applications of agitator impeller types

| Industry/Sector | Specific Application of agitator impeller types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Use of turbine agitators for chemical reactions | Enhanced blending efficiency and uniformity of chemical mixtures | Impeller material compatibility with chemicals, energy efficiency |

| Food and Beverage | Paddle agitators for mixing viscous sauces and pastes | Consistent product quality and reduced processing time | Hygiene standards, ease of cleaning, and maintenance |

| Pharmaceutical | High shear mixers for emulsifying ointments and suspensions | Improved bioavailability and stability of formulations | Compliance with regulatory standards, precision in mixing |

| Oil and Gas | Gas-liquid reactors with specific impeller designs | Efficient gas dispersion in extraction processes | Durability under high pressure, material resistance |

| Wastewater Treatment | Dissolvers for mixing chemicals in treatment processes | Effective removal of contaminants, improving treatment efficiency | Chemical compatibility, energy consumption, and scalability |

How Are Agitator Impeller Types Utilized in Chemical Manufacturing?

In the chemical manufacturing sector, turbine agitators are commonly employed to facilitate chemical reactions through effective mixing. These impellers create turbulent flow, ensuring that reactants are uniformly blended, which enhances reaction rates and product consistency. For international buyers, especially in regions like Europe and the Middle East, it is crucial to consider the compatibility of the impeller material with aggressive chemicals, as well as the energy efficiency of the mixing system to minimize operational costs.

What Role Do Agitator Impeller Types Play in the Food and Beverage Industry?

Paddle agitators are particularly useful in the food and beverage industry for mixing viscous products like sauces and pastes. Their design enables uniform laminar flow, reducing shear and preserving the texture of sensitive ingredients. Businesses benefit from consistent product quality and reduced processing time. Buyers from Africa and South America should prioritize sourcing agitators that meet stringent hygiene standards and are easy to clean, ensuring compliance with food safety regulations.

How Are High Shear Mixers Applied in Pharmaceuticals?

In pharmaceuticals, high shear mixers are integral for emulsifying ointments and suspensions. These impellers generate high local shear forces, resulting in a homogeneous mixture that enhances the bioavailability and stability of active ingredients. For B2B buyers, particularly in Europe, compliance with strict regulatory standards is paramount. Sourcing mixers that provide precise control over mixing parameters can significantly impact product efficacy and regulatory approval.

Why Are Specialized Impellers Important in Oil and Gas Operations?

The oil and gas industry utilizes specialized impellers in gas-liquid reactors to optimize gas dispersion during extraction processes. Efficient mixing is critical for maximizing the conversion of raw materials into usable products. Buyers must consider the durability of the impeller under high-pressure conditions and the material’s resistance to corrosive substances. This ensures longevity and reliability in demanding operational environments, particularly in regions with extreme conditions.

How Do Dissolvers Contribute to Wastewater Treatment Processes?

Dissolvers are essential in wastewater treatment for mixing chemicals that aid in contaminant removal. Their design allows for effective dispersion of treatment agents, leading to improved process efficiency. B2B buyers should focus on the chemical compatibility of the dissolver materials, energy consumption, and scalability of the mixing system. These factors are critical for optimizing treatment processes and ensuring compliance with environmental regulations in diverse markets across Africa and the Middle East.

3 Common User Pain Points for ‘agitator impeller types’ & Their Solutions

Scenario 1: Inconsistent Mixing Performance in Viscous Materials

The Problem: B2B buyers in industries such as food processing or cosmetics often face challenges when mixing viscous materials. These materials can lead to inconsistent product quality if not properly mixed, resulting in variations in texture, flavor, or effectiveness. Buyers may invest in agitator impellers that fail to meet the specific viscosity requirements of their applications, leading to inadequate mixing and potential product recalls. This inconsistency can also affect customer satisfaction and brand reputation.

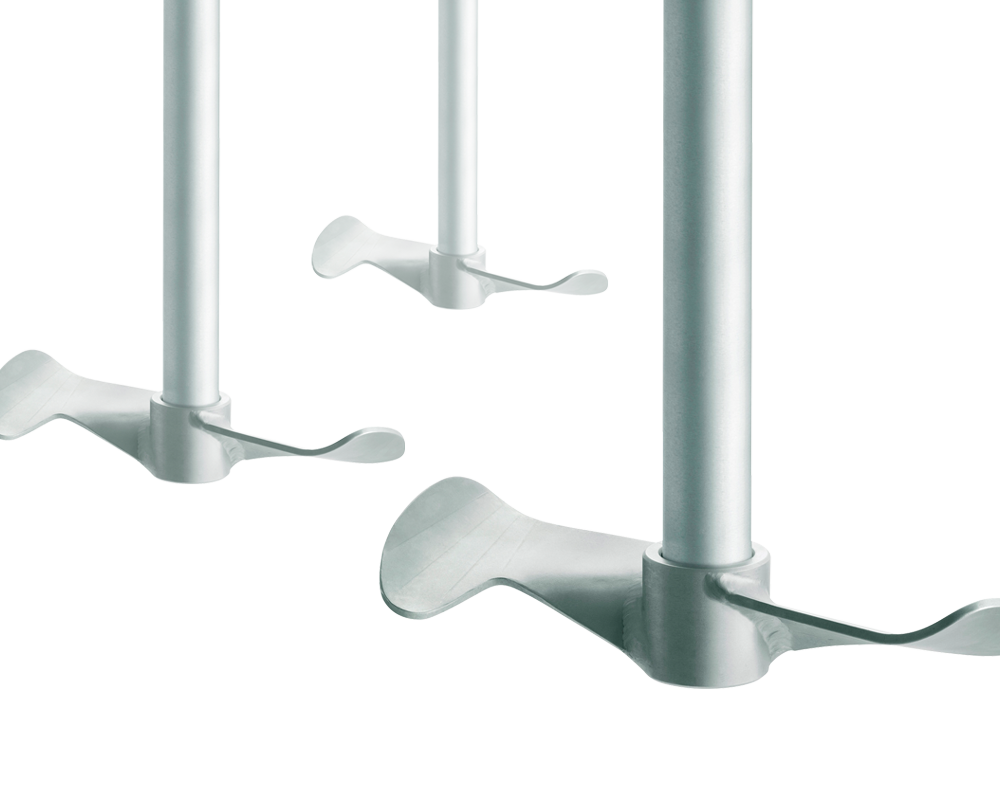

The Solution: To overcome this challenge, buyers should consider selecting high-performance impellers specifically designed for high-viscosity applications, such as the EKATO PARAVISC. This impeller features a unique blade geometry that enhances mixing efficiency without compromising the shear sensitivity of the product. When sourcing agitator impellers, it’s crucial to consult with manufacturers who can provide detailed specifications regarding the impeller’s performance in various viscosity ranges. Additionally, conducting pilot tests with different impeller designs can help in understanding how well they perform with specific materials, ensuring that the final choice leads to a consistent and high-quality product.

Scenario 2: Inefficient Gas-Liquid Mixing in Chemical Processes

The Problem: In chemical processing industries, achieving efficient gas-liquid mixing is crucial for reactions that require gas dispersion, such as fermentation or oxidation processes. Buyers often struggle with traditional impeller designs that do not provide adequate gas dispersion, resulting in poor reaction rates and lower yield. This inefficiency can lead to increased operational costs and delays in production schedules, ultimately affecting profitability.

Illustrative image related to agitator impeller types

The Solution: Buyers should look for specialized gas dispersing impellers like the EKATO GASJET or PHASEJET, designed to enhance gas-liquid interactions. These impellers optimize gas recirculation and minimize power consumption while maximizing dispersion efficiency. When specifying impellers for gas-liquid applications, it is advisable to analyze the specific gas flow rates and liquid properties to ensure compatibility. Engaging with suppliers who offer simulation software or modeling services can aid in selecting the right impeller configuration for specific reactor designs, ultimately leading to improved process efficiency and yield.

Scenario 3: Wear and Tear on Impellers Leading to Downtime

The Problem: Many B2B buyers encounter significant challenges related to the wear and tear of impellers, especially in harsh processing environments such as mining or chemical manufacturing. Over time, conventional impellers can degrade, leading to operational downtimes for maintenance and replacement. This not only disrupts production but also incurs additional costs associated with unplanned maintenance and equipment replacements.

The Solution: To mitigate wear issues, buyers should invest in impellers with advanced materials and wear-resistant coatings, such as ceramic or hardened steel options. For instance, the EKATO EPOX-R impeller is designed with unique wear-optimized blade geometry, making it ideal for applications involving abrasive materials. Buyers should also implement a regular maintenance schedule that includes inspections and performance assessments of the impellers to catch wear early. Partnering with suppliers who offer warranties or service agreements can further protect against unexpected costs and ensure that replacement parts are readily available, minimizing downtime and keeping production on track.

Strategic Material Selection Guide for agitator impeller types

What Are the Key Materials Used for Agitator Impeller Types?

When selecting agitator impellers, the choice of material significantly impacts performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of agitator impellers: stainless steel, polypropylene, carbon steel, and titanium. Each material presents unique properties, advantages, and limitations that can influence operational efficiency and cost-effectiveness.

How Does Stainless Steel Benefit Agitator Impeller Applications?

Stainless steel is a widely favored material for agitator impellers due to its excellent corrosion resistance and mechanical strength. It can withstand high temperatures and pressures, making it suitable for a variety of industrial applications, including food processing and pharmaceuticals. The key properties of stainless steel include a temperature rating of up to 800°F (427°C) and a pressure rating that can exceed 150 psi, depending on the specific alloy used.

Pros: Stainless steel is highly durable and resistant to rust and staining, ensuring a long lifespan even in harsh environments. Its smooth surface facilitates easy cleaning, which is crucial in industries requiring stringent hygiene standards.

Cons: The primary drawback is its cost, which is generally higher than other materials. Additionally, the manufacturing complexity can increase due to the need for specialized tooling and processes.

Impact on Application: Stainless steel impellers are compatible with a wide range of media, including corrosive liquids, making them ideal for chemical processing and food production.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, particularly in regions like Europe and the Middle East, where quality certifications are mandatory.

What Are the Advantages of Using Polypropylene for Agitator Impellers?

Polypropylene is a thermoplastic polymer known for its lightweight and chemical resistance, making it suitable for applications involving corrosive liquids. It typically operates effectively at temperatures up to 200°F (93°C) and pressures around 50 psi.

Pros: The primary advantage of polypropylene is its cost-effectiveness, offering a lower price point compared to metals. It is also easy to mold and manufacture, which simplifies production processes.

Cons: However, polypropylene is not as durable as metals and can degrade under prolonged exposure to UV light or high temperatures. Its mechanical strength is also lower, limiting its use in high-stress applications.

Impact on Application: Polypropylene impellers are ideal for mixing non-viscous liquids and are commonly used in the chemical and waste treatment industries.

Illustrative image related to agitator impeller types

Considerations for International Buyers: Buyers should ensure that the polypropylene complies with relevant chemical resistance standards, especially in regions with strict environmental regulations.

Why Choose Carbon Steel for Agitator Impeller Manufacturing?

Carbon steel is another common material used for agitator impellers, particularly in applications where strength is a priority. It can handle high pressure and temperature conditions, with ratings typically around 600°F (316°C) and 250 psi.

Pros: Carbon steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It is also relatively inexpensive compared to stainless steel.

Cons: The main limitation of carbon steel is its susceptibility to corrosion, which necessitates protective coatings or regular maintenance to prevent rusting.

Illustrative image related to agitator impeller types

Impact on Application: Carbon steel impellers are often used in the oil and gas industry, where robustness is essential, but their use in corrosive environments should be approached with caution.

Considerations for International Buyers: Buyers must consider the need for protective coatings and adherence to local standards, particularly in regions with high humidity or corrosive environments.

What Are the Benefits of Titanium in Agitator Impeller Design?

Titanium is a premium material known for its exceptional strength-to-weight ratio and outstanding corrosion resistance, particularly in aggressive environments. It can withstand temperatures up to 1,200°F (649°C) and pressures exceeding 300 psi.

Illustrative image related to agitator impeller types

Pros: The key advantage of titanium is its longevity and reliability, making it ideal for critical applications in aerospace, marine, and chemical processing industries.

Cons: Titanium is significantly more expensive than other materials, and its manufacturing processes can be complex and require specialized equipment.

Impact on Application: Titanium impellers are particularly suited for highly corrosive media, ensuring long-term performance without degradation.

Considerations for International Buyers: Compliance with international standards and certifications is vital, especially in high-stakes industries such as aerospace and pharmaceuticals.

Illustrative image related to agitator impeller types

Summary Table of Material Selection for Agitator Impellers

| Material | Typical Use Case for agitator impeller types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Polypropylene | Chemical processing, waste treatment | Cost-effective and lightweight | Lower durability and UV sensitivity | Low |

| Carbon Steel | Oil and gas industry | High tensile strength | Susceptible to corrosion | Medium |

| Titanium | Aerospace, marine applications | Exceptional strength and corrosion resistance | Very high cost and complex manufacturing | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on specific application needs and regional compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for agitator impeller types

What Are the Main Stages in the Manufacturing Process of Agitator Impellers?

The manufacturing process of agitator impellers involves several critical stages, each essential for producing high-quality components that meet specific industry demands. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in manufacturing agitator impellers is material preparation. Common materials include stainless steel, carbon steel, and specialized alloys, chosen for their strength, corrosion resistance, and suitability for high-temperature applications.

During this stage, raw materials undergo processes such as cutting, shaping, and surface treatment. Steel sheets are often sourced from reputable suppliers and subjected to quality checks to ensure they meet specified standards. This step is crucial, as the integrity of the materials directly affects the performance and lifespan of the impellers.

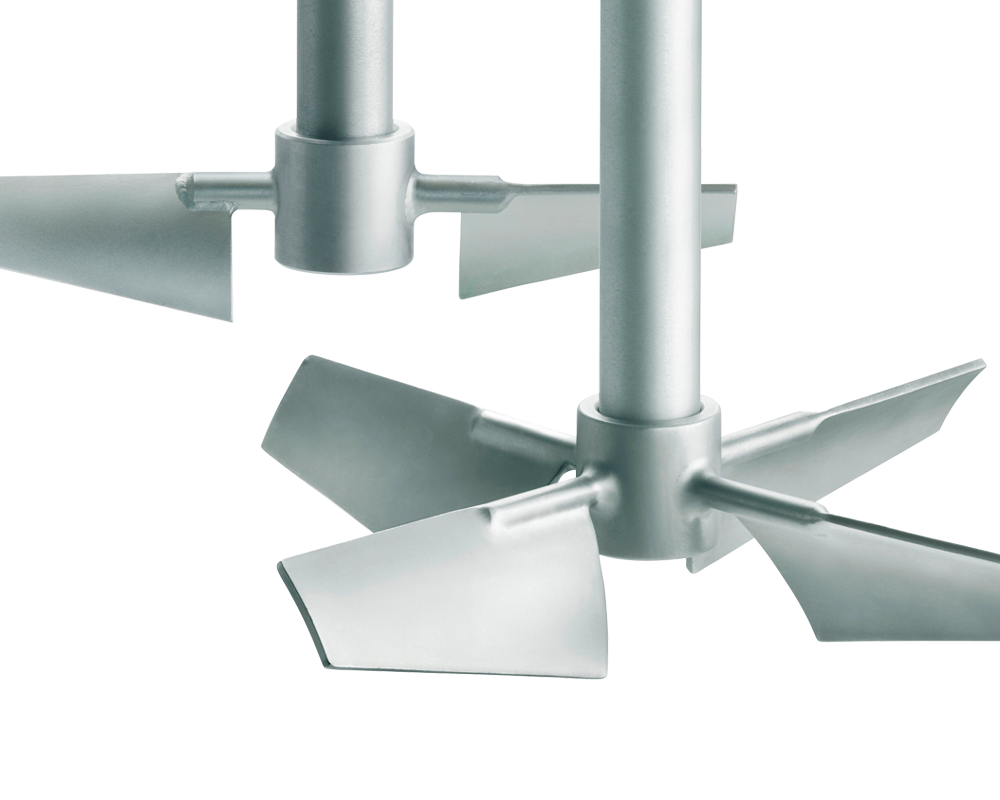

How Are Agitator Impellers Formed?

Once the materials are prepared, the next phase is forming. Techniques such as casting, forging, and machining are commonly used.

- Casting: This involves pouring molten metal into a mold to create the desired shape. It is beneficial for producing complex geometries, particularly for turbine and high-shear impellers.

- Forging: This process involves shaping the metal using compressive forces, enhancing its strength and durability. It is particularly useful for high-performance impellers.

- Machining: After initial forming, machining processes such as turning, milling, and grinding are employed to achieve precise dimensions and surface finishes. This step ensures that the impellers fit perfectly within their applications and maintain operational efficiency.

What Is the Assembly Process for Agitator Impellers?

The assembly stage involves integrating various components, such as the impeller blades and shaft, to create the final product. This stage often includes welding, bolting, or using adhesives, depending on the design requirements.

Illustrative image related to agitator impeller types

Quality control measures are critical at this point, as improper assembly can lead to operational failures. Manufacturers may use jigs and fixtures to ensure accuracy during assembly.

What Are the Key Finishing Techniques Applied to Agitator Impellers?

Finishing techniques play a vital role in enhancing the performance and durability of agitator impellers. Common finishing processes include:

- Surface Treatment: Processes like anodizing, plating, or powder coating can improve corrosion resistance and reduce wear. This is particularly important for impellers used in aggressive chemical environments.

- Polishing: This technique is employed to achieve a smooth surface finish, which is essential for minimizing turbulence and improving mixing efficiency.

- Inspection: Before the final product leaves the factory, it undergoes thorough inspections to ensure it meets design specifications.

What Quality Control Standards Are Relevant for Agitator Impellers?

Quality assurance is crucial in the manufacturing of agitator impellers, ensuring they meet international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is the leading international standard for quality management systems. It emphasizes consistent quality in products and services, making it a benchmark for many manufacturers. Additionally, specific industries may require adherence to other standards, such as:

- CE Marking: Required for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for manufacturers supplying the oil and gas industry, ensuring that products meet stringent safety and performance criteria.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Common QC methodologies include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified criteria before processing.

- In-Process Quality Control (IPQC): Conducted at various stages of production, IPQC ensures that processes are being executed correctly and that any deviations are addressed immediately.

- Final Quality Control (FQC): This final inspection involves a comprehensive assessment of the finished product against design specifications and quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers adhere to rigorous quality control practices. Here are several strategies for verification:

- Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control measures, and compliance with industry standards.

- Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, inspection results, and certifications. This transparency is vital for building trust.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices and product reliability.

What Are the QC and Certification Nuances for International B2B Buyers?

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, it’s essential to consider specific nuances in quality control and certification.

Different regions may have varying standards and regulations, which can affect the certification process. For instance, while European suppliers may prioritize CE marking, suppliers in other regions may focus on local standards. B2B buyers should familiarize themselves with these regional standards to ensure compliance and product safety.

Additionally, language barriers and cultural differences may impact communication regarding quality expectations. Establishing clear guidelines and maintaining open lines of communication can mitigate misunderstandings and enhance collaboration.

Illustrative image related to agitator impeller types

Conclusion: Why Understanding Manufacturing Processes and Quality Assurance Is Crucial for B2B Buyers

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for agitator impeller types is vital for B2B buyers. By familiarizing themselves with material preparation, forming, assembly, finishing techniques, and relevant quality control standards, buyers can make informed decisions when selecting suppliers. Ultimately, prioritizing quality and compliance ensures that the impellers will perform effectively in their intended applications, safeguarding investments and operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘agitator impeller types’

Introduction

When sourcing agitator impeller types, it’s essential to approach the process methodically to ensure that you select the right equipment for your specific industrial needs. This guide offers a step-by-step checklist that will help international B2B buyers navigate the complexities of procuring agitator impellers, ensuring compatibility, efficiency, and reliability.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your agitator impeller. This includes factors such as the type of materials being mixed, viscosity levels, and the desired mixing speed. Defining these specifications helps in narrowing down the options and ensures that the selected impeller will meet your operational needs effectively.

Illustrative image related to agitator impeller types

- Key Considerations:

- Material compatibility (e.g., corrosive substances may require stainless steel impellers).

- Required mixing action (e.g., axial vs. radial flow).

Step 2: Research Different Impeller Types

Familiarize yourself with various agitator impeller types available in the market. Each type, such as turbine, paddle, or high shear impellers, has distinct advantages depending on the application. Understanding these differences allows you to make informed decisions about which impeller type is best suited for your processes.

- Focus Areas:

- Application-specific requirements (e.g., emulsification, homogenization).

- Efficiency and energy consumption metrics.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request company profiles, product catalogs, and client references to gauge their credibility and experience in your industry. This due diligence can prevent future complications and ensure that you partner with a reliable supplier.

- What to Look For:

- Case studies showcasing previous successful implementations.

- Testimonials from clients in similar industries or geographical regions.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers adhere to relevant industry standards and certifications. This is especially important for international transactions, where compliance with regulations can vary widely. Checking for certifications such as ISO or CE can provide assurance of quality and safety.

- Important Certifications:

- ISO 9001 for quality management.

- CE marking for compliance with European safety standards.

Step 5: Request Samples and Conduct Testing

Before making a bulk purchase, request samples of the agitator impellers to conduct testing. This step is critical to verify that the impeller performs as expected in your specific application. Testing can help identify any potential issues before they become costly problems.

- Testing Considerations:

- Performance under actual operating conditions.

- Compatibility with existing systems.

Step 6: Compare Pricing and Terms of Sale

Once you have identified suitable suppliers and verified their products, it’s time to compare pricing and terms. Look beyond the initial cost; consider factors such as warranties, after-sales support, and delivery timelines. A comprehensive understanding of the total cost of ownership will aid in making the best financial decision.

- Cost Factors to Evaluate:

- Maintenance and operating costs.

- Availability of spare parts and service support.

Step 7: Make an Informed Purchase Decision

With all the information gathered, you can now make a well-informed purchase decision. Ensure that your final choice aligns with both your operational needs and budget. Clear communication with the supplier regarding expectations and requirements can further facilitate a smooth procurement process.

- Final Checks:

- Confirm lead times and shipping arrangements.

- Clarify return policies and warranty conditions.

By following this structured checklist, B2B buyers can effectively source the right agitator impeller types, ensuring they meet their operational requirements while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for agitator impeller types Sourcing

What Are the Key Cost Components for Sourcing Agitator Impeller Types?

When sourcing agitator impeller types, understanding the cost structure is crucial for effective budgeting and procurement strategies. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for impellers include stainless steel, which offers durability and resistance to corrosion, and various plastics for more economical options. Specialty materials like high-performance alloys or coatings for specific applications can lead to higher costs.

-

Labor: Labor costs encompass the wages of skilled workers involved in the manufacturing process. This includes assembly, welding, and finishing processes. Labor rates can vary significantly based on geographic location and local labor laws, impacting overall pricing.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production processes can lower overhead costs, which is a crucial factor for suppliers aiming to remain competitive.

-

Tooling: Initial tooling costs for custom designs can be substantial. This includes the expense of molds, dies, and specialized equipment needed for the production of unique impeller types. Buyers may need to consider these costs in relation to their specific design requirements.

-

Quality Control (QC): Implementing stringent QC measures ensures that the impellers meet required specifications and certifications. The cost associated with quality assurance can vary based on the complexity of the product and the certifications needed (e.g., ISO, FDA).

-

Logistics: Transportation and handling costs play a vital role in the total cost structure. These costs can fluctuate based on the distance from the supplier, shipping methods, and any tariffs or duties applicable for international shipments.

-

Margin: Supplier margins can vary widely based on market demand, competition, and the uniqueness of the impeller design. Understanding typical margins in the industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Agitator Impeller Costs?

Several factors influence the pricing of agitator impeller types:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often lead to volume discounts, making it beneficial for buyers to consolidate their purchases.

-

Specifications and Customization: Customized impellers tailored to specific applications can incur additional costs. Buyers should assess whether the added functionality justifies the investment.

-

Materials and Quality: Higher quality materials and specialized designs typically lead to increased costs. Buyers must balance the need for quality with budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge a premium for their reliability and support services.

-

Incoterms: The terms of sale (Incoterms) dictate responsibilities for shipping, insurance, and tariffs. Choosing the right Incoterm can impact overall costs, particularly for international transactions.

What Are the Best Buyer Tips for Cost-Efficiency in Agitator Impeller Sourcing?

To maximize cost-efficiency when sourcing agitator impeller types, consider the following tips:

-

Negotiate Effectively: Leverage your purchasing power to negotiate better terms and pricing. Establishing long-term relationships with suppliers can lead to more favorable conditions.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider maintenance, operational efficiency, and potential downtime costs associated with lower-quality products.

-

Understand Pricing Nuances for International Sourcing: For buyers from regions like Africa, South America, and the Middle East, fluctuations in currency exchange rates and geopolitical factors can impact costs. It’s essential to account for these variables in pricing discussions.

-

Research Local and International Suppliers: Diversifying your supplier base can lead to better pricing options. Evaluate both local manufacturers and international suppliers for comparative pricing and quality.

-

Stay Informed on Market Trends: Monitoring trends in the agitator impeller market can provide insights into pricing strategies and help buyers anticipate shifts in costs.

Disclaimer on Indicative Prices

Prices for agitator impeller types can vary significantly based on the factors mentioned above. Buyers are encouraged to conduct thorough market research and engage directly with suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing agitator impeller types With Other Solutions

Understanding Alternatives to Agitator Impeller Types

In the realm of industrial mixing, selecting the right technology is crucial for achieving desired outcomes efficiently. While agitator impeller types are widely used for their versatility in mixing applications, several alternative solutions can also meet similar needs. This section will explore these alternatives, comparing their performance, cost, ease of implementation, maintenance requirements, and best use cases.

Comparison Table

| Comparison Aspect | Agitator Impeller Types | High Shear Mixers | Emulsifiers | Industrial Blenders |

|---|---|---|---|---|

| Performance | High mixing efficiency, suitable for various viscosities | Excellent for emulsifying and homogenizing | Effective for creating stable emulsions | Good for large batch mixing |

| Cost | Moderate initial investment; long-term savings through efficiency | Higher initial cost; cost-effective in high-volume applications | Moderate cost; can be expensive for specialized emulsions | Varies widely based on capacity and features |

| Ease of Implementation | Requires careful installation and setup | Can be complex; needs skilled operators | Simple for standard applications; complex for specialized emulsions | Generally straightforward; easy to scale |

| Maintenance | Regular maintenance needed; parts subject to wear | Requires frequent maintenance; high wear parts | Low maintenance if properly managed | Moderate; depends on usage frequency |

| Best Use Case | Chemical, food, pharmaceuticals, and more | Food processing, cosmetics, pharmaceuticals | Cosmetics, food, and pharmaceuticals | Large-scale manufacturing and batch processes |

Analyzing High Shear Mixers as an Alternative

High shear mixers excel in applications requiring intense emulsification and homogenization. Their design allows for the rapid processing of materials, making them ideal for industries like food and pharmaceuticals. However, they come with a higher initial investment and may require skilled operators to manage effectively. While they deliver exceptional performance, the maintenance needs can be significant due to wear on high-stress components. For businesses focused on producing emulsions or homogenous mixtures at scale, high shear mixers represent a powerful alternative.

Exploring Emulsifiers for Mixing Solutions

Emulsifiers are specialized devices designed to create stable emulsions by combining immiscible liquids. They are particularly advantageous in applications like cosmetics and food production, where product stability is paramount. The cost of emulsifiers can vary based on their complexity, but they generally provide a moderate investment. While they are relatively easy to implement for standard emulsification tasks, specialized emulsifiers may require more intricate setups. Maintenance is usually low, making them an attractive option for businesses looking for consistent results with minimal downtime.

Evaluating Industrial Blenders as a Competitive Option

Industrial blenders are versatile machines used for large-scale mixing operations. They can effectively handle bulk materials, making them suitable for various industries, including food processing and chemical manufacturing. The cost of industrial blenders varies widely based on capacity and features, but they tend to offer a cost-effective solution for high-volume production. Implementation is generally straightforward, although scaling up can involve additional considerations. Maintenance requirements are moderate and depend on usage frequency, making them a solid choice for businesses focused on batch processing.

How Can B2B Buyers Choose the Right Mixing Solution?

When selecting a mixing solution, B2B buyers should consider their specific needs, including the type of materials being mixed, production volume, and desired consistency. Understanding the nuances of each technology, including the pros and cons highlighted in this analysis, is crucial. Companies should also evaluate their budget, maintenance capabilities, and operational expertise. By aligning the chosen solution with their unique requirements, buyers can enhance efficiency, reduce costs, and ensure product quality in their manufacturing processes.

Essential Technical Properties and Trade Terminology for agitator impeller types

What Are the Critical Specifications of Agitator Impeller Types?

When selecting agitator impeller types, understanding key technical specifications is essential for ensuring optimal performance and longevity in industrial applications. Here are some critical specifications to consider:

-

Material Grade

The material used for impellers can significantly impact durability and performance. Common materials include stainless steel for corrosion resistance, plastic for lightweight applications, and specialized alloys for high-temperature environments. Choosing the right material is crucial for maintaining the integrity of the mixing process and ensuring compliance with industry standards. -

Blade Design and Geometry

The configuration of the impeller blades—such as the number of blades, angle, and shape—affects mixing efficiency and flow patterns. For example, turbine agitators are designed for turbulent mixing, while paddle agitators are suitable for gentle stirring. Understanding the implications of blade design helps buyers select the right impeller for their specific application, ensuring effective mixing and energy efficiency. -

Diameter and Length of Impeller

The dimensions of the impeller must match the size of the vessel in which it operates. A larger diameter may enhance mixing efficiency but could also lead to increased energy consumption. Conversely, a smaller impeller might not provide sufficient mixing for larger volumes. Buyers should evaluate their vessel specifications to determine the appropriate size for optimal performance. -

Tolerance Levels

Precision in manufacturing tolerances is vital for the effective operation of agitator impellers. Tolerances refer to the allowable variations in dimensions, which affect the fit and function of the impeller within the agitator system. High tolerance levels ensure that the impeller operates smoothly, reducing wear and maintenance needs, which can lead to lower overall operational costs. -

Operating Speed

The speed at which an impeller operates can influence the mixing process. Different applications may require varying speeds to achieve the desired results, such as emulsification or homogenization. Understanding the operational speed requirements helps buyers select an impeller that meets their process needs while optimizing energy consumption.

What Are Common Trade Terms in Agitator Impeller Purchases?

Navigating the procurement process for agitator impellers involves understanding specific industry jargon. Here are several key terms that B2B buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in the manufacturing of another company’s product. When sourcing impellers, buyers may seek OEM parts to ensure compatibility and maintain the quality of their mixing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and cost-effectiveness. Buyers should negotiate MOQs based on their operational needs and production schedules. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing, specifications, and terms for a particular product or service. Using RFQs allows buyers to compare offers from different suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce, which are widely used in international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and risks during the purchasing process. -

Lead Time

This term refers to the total time it takes from placing an order to receiving the goods. Understanding lead times is vital for planning production schedules and inventory management. Buyers should consider lead times when sourcing impellers to avoid disruptions in their operations.

By grasping these technical specifications and trade terms, B2B buyers can make more informed decisions, ultimately enhancing operational efficiency and reducing costs in their mixing processes.

Navigating Market Dynamics and Sourcing Trends in the agitator impeller types Sector

What are the Key Market Trends in the Agitator Impeller Types Sector?

The global market for agitator impeller types is witnessing significant growth, driven by increasing industrial activities across various sectors including chemicals, pharmaceuticals, food and beverages, and wastewater treatment. In particular, the demand for high shear mixers and specialized impellers, such as gas dispersing and homogenizing impellers, is on the rise. This trend is largely due to the need for enhanced mixing efficiency and precision in processes that require the combination of immiscible liquids or solids with liquids.

Emerging technologies such as digital monitoring and automation are transforming the sourcing landscape. B2B buyers are increasingly looking for suppliers that can offer smart mixing solutions integrated with IoT capabilities, allowing for real-time monitoring and optimization of mixing processes. Additionally, the focus on customization is gaining momentum, with businesses seeking tailored impeller designs that meet specific operational requirements, particularly in diverse markets like Africa and South America where industrial needs can vary widely.

Illustrative image related to agitator impeller types

As international buyers evaluate suppliers, considerations such as lead times, production capacity, and after-sales support are becoming critical factors influencing purchasing decisions. Furthermore, as companies aim to enhance their competitive edge, sourcing from regions that offer cost-effective production without compromising quality is becoming a strategic priority, especially in Europe and the Middle East.

How is Sustainability Shaping the Sourcing of Agitator Impeller Types?

Sustainability is increasingly influencing the sourcing strategies of B2B buyers in the agitator impeller types sector. Companies are recognizing the environmental impact of their supply chains and are actively seeking partners who prioritize sustainable practices. This includes the use of recyclable materials and energy-efficient manufacturing processes, which not only reduce carbon footprints but also align with the growing consumer demand for environmentally responsible products.

Ethical sourcing is becoming a critical criterion, particularly for buyers from Europe and the Middle East, where regulations and consumer expectations regarding corporate responsibility are stringent. Suppliers that can demonstrate compliance with sustainability certifications, such as ISO 14001 for environmental management or other green certifications, are likely to gain a competitive advantage.

Moreover, the trend towards ‘green’ materials is noteworthy. Buyers are increasingly interested in impeller designs that utilize biodegradable or less harmful materials, particularly in industries such as food and pharmaceuticals where product safety is paramount. This shift not only aids in reducing environmental impact but also enhances brand reputation among eco-conscious consumers.

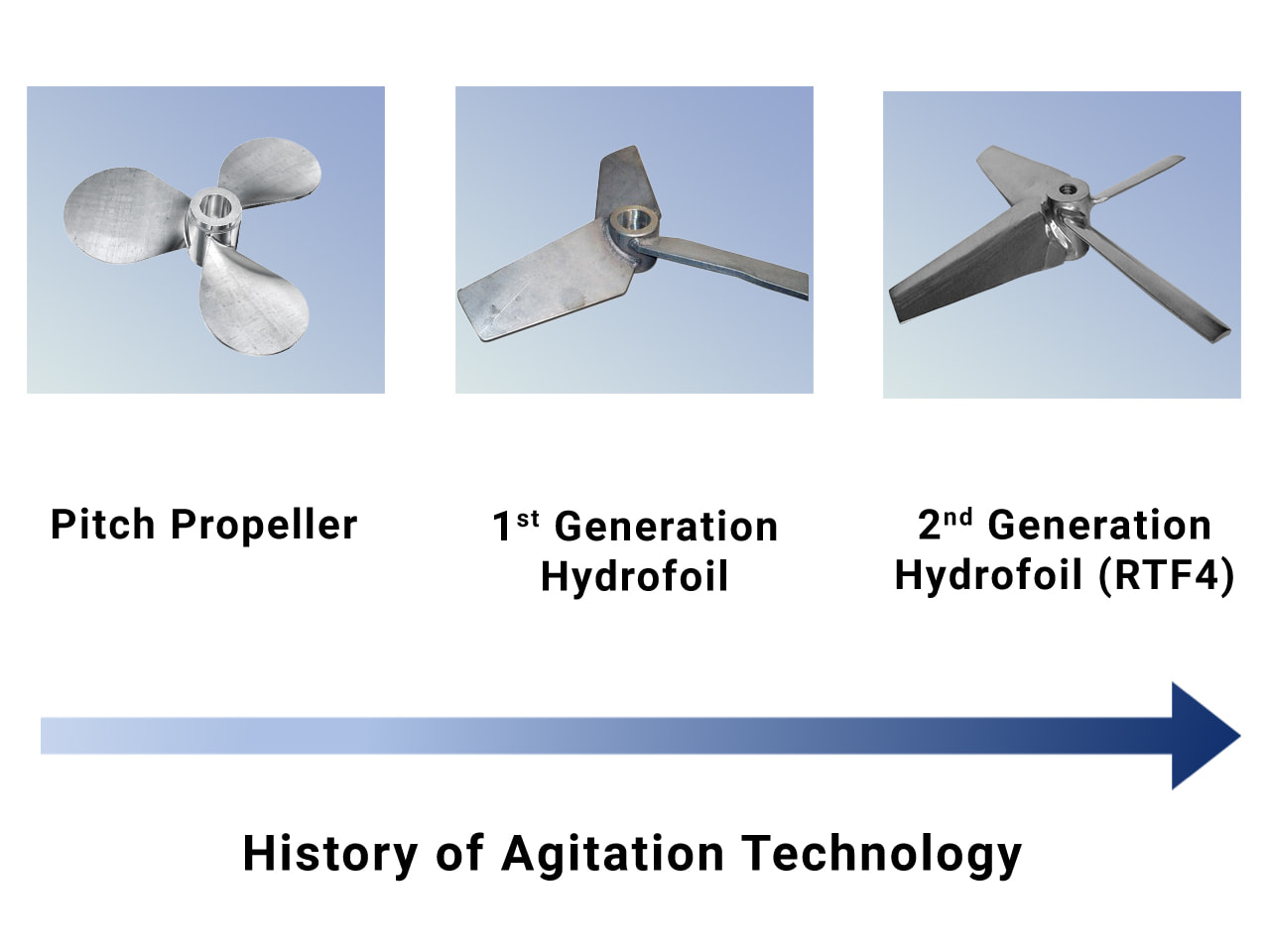

What is the Evolution of Agitator Impeller Types?

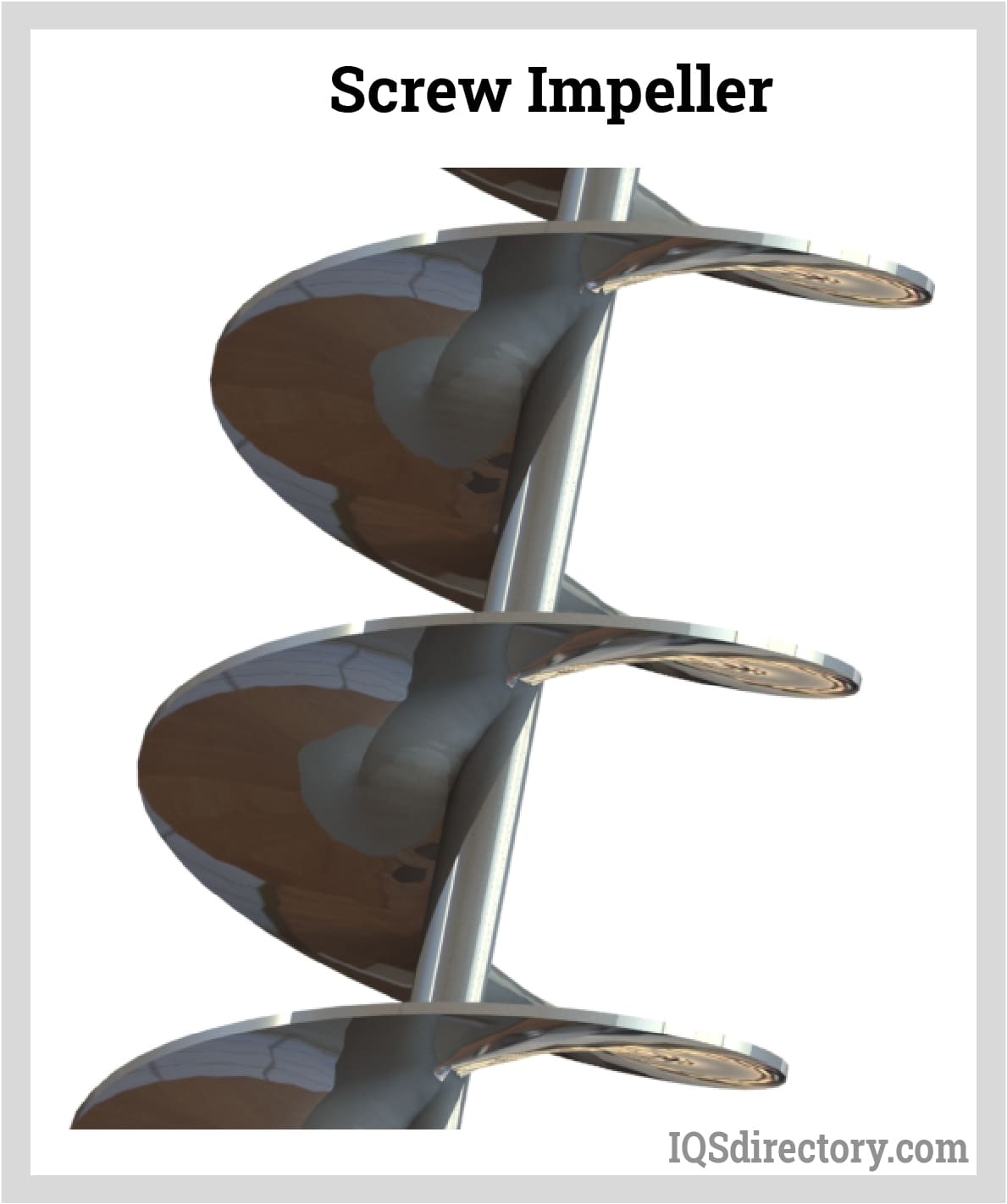

The evolution of agitator impeller types can be traced back to the industrial revolution when the need for efficient mixing solutions emerged in various manufacturing processes. Initially, basic designs dominated the market, focusing primarily on functionality. However, as industries expanded and technology advanced, the design and application of impellers became more sophisticated.

In recent decades, innovations have led to the development of specialized impellers tailored for specific applications, such as high shear mixers for emulsifying and dispersing, and gas dispersing impellers for reactions involving gases. This evolution is not just about performance; it also reflects a broader trend towards customization and efficiency, enabling businesses to optimize their production processes and improve product quality.

Today, the market is characterized by a diverse range of impeller designs that cater to unique industrial needs, reflecting the growing complexity of manufacturing processes across sectors. As the industry continues to innovate, the focus on automation, sustainability, and efficiency will likely shape the next chapter in the evolution of agitator impeller types.

Frequently Asked Questions (FAQs) for B2B Buyers of agitator impeller types

1. How do I select the right agitator impeller type for my application?

Choosing the right agitator impeller type involves understanding your specific mixing needs, such as the viscosity of the materials, the required shear forces, and the desired mixing speed. For low-viscosity fluids, high shear mixers or turbine agitators are often ideal. Conversely, paddle or anchor agitators may be more suitable for viscous materials. Additionally, consider the material compatibility and any specific chemical processes involved. Collaborating with suppliers who can provide data on performance and efficiency will further assist in making an informed decision.

2. What is the best agitator impeller for emulsifying liquids?

For emulsifying liquids, high shear mixers, particularly those equipped with rotor-stator designs, are highly effective. These impellers create intense shear forces that break down droplets and promote uniform dispersion of immiscible liquids. Additionally, emulsifiers like the ISOJET and VARIOBLADE can facilitate low-shear mixing while maintaining product integrity. When selecting an impeller, ensure it aligns with your specific viscosity requirements and the nature of the materials being mixed.

Illustrative image related to agitator impeller types

3. How can I ensure the quality of agitator impellers from suppliers?

To ensure quality, conduct thorough vetting of suppliers by checking their certifications, production processes, and quality control measures. Request samples or detailed product specifications, including material grades and performance data. It’s also beneficial to read reviews or seek testimonials from other clients, particularly those in similar industries. Engaging in direct communication with suppliers can clarify any concerns about quality standards and lead to a more reliable partnership.

4. What are typical minimum order quantities (MOQs) for agitator impellers?

Minimum order quantities for agitator impellers can vary widely depending on the supplier and the specific type of impeller required. Generally, MOQs can range from a few units to several hundred. Custom designs may have higher MOQs due to the complexity of production. It’s advisable to discuss your specific needs with suppliers to negotiate terms that suit your project requirements and ensure that you are not overcommitting to inventory you may not need.

5. What payment terms should I expect when sourcing agitator impellers internationally?

Payment terms can vary by supplier and region, but common practices include a deposit upfront (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or payment upon receipt as options for international transactions. It’s crucial to clarify these terms early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods that provide buyer protection, especially in international dealings.

Illustrative image related to agitator impeller types

6. How do logistics and shipping affect the sourcing of agitator impellers?

Logistics and shipping play a critical role in sourcing agitator impellers, particularly for international buyers. Factors such as shipping methods, delivery times, and customs clearance can impact your overall timeline and costs. Collaborate with suppliers who have experience with international shipping to ensure they can navigate these complexities. It’s also wise to factor in potential delays and plan accordingly to avoid interruptions in your production schedule.

7. Are there customization options available for agitator impellers?

Yes, many suppliers offer customization options for agitator impellers to meet specific application needs. Customizations may include alterations in size, blade design, material selection, and performance characteristics. When discussing customization, provide clear specifications and requirements to the supplier. Engaging in a dialogue about your unique challenges can lead to tailored solutions that enhance efficiency and effectiveness in your mixing processes.

8. What industries commonly use agitator impellers, and how can I identify suitable suppliers?

Agitator impellers are utilized across various industries, including chemical processing, pharmaceuticals, food and beverage, cosmetics, and wastewater treatment. To identify suitable suppliers, research those who specialize in your industry and have a proven track record of quality and performance. Utilize industry directories, attend trade shows, and leverage online platforms like LinkedIn to connect with potential suppliers. Ensure that they have experience with the specific applications relevant to your operations for the best results.

Top 5 Agitator Impeller Types Manufacturers & Suppliers List

1. IQS Directory – Agitators

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Agitators are devices designed to blend media uniformly within a tank, functioning by spinning submerged impellers at specific speeds (RPM). They ensure consistent texture, avoid concentration differences, facilitate gas dispersion, enhance chemical reactions, stabilize temperature levels, and improve heat exchange. Agitators handle various media types, including liquids, gases, solids, slurries, …

2. EKATO – High-Performance Impellers

Domain: ekato.com

Registered: 1996 (29 years)

Introduction: Impellers offered by EKATO include: VISCOPROP (high mixing performance, versatile blade angles), ISOJET (efficient for axial pumping in turbulent systems), ISOJET B (low shear widefoil for suspending and homogenizing), PHASEJET (gas dispersing for gas-liquid reactions), COMBIJET (efficient for fermenters and gas-liquid reactors), GASJET (self-aspirating for gas recirculation), ORION (maximizes gas…

3. Chemical Engineering World – Agitators

Domain: chemicalengineeringworld.com

Registered: 2019 (6 years)

Introduction: Agitators are devices used to stir liquids or semi-solids, consisting of a shaft and an impeller/propeller, driven by motors. They are used in various industries such as chemical, food, pharmaceuticals, and cosmetics for mixing, promoting chemical reactions, and heat transfer. Types of agitators include: 1. Turbine Agitators: Versatile, handle various mixing operations, create turbulent fluid move…

4. AFX Holdings – Impellers

Domain: afxholdings.com

Registered: 2014 (11 years)

Introduction: Impellers are critical components in various applications, designed to enhance fluid movement and efficiency. AFX Holdings offers a range of impellers tailored for different industries, ensuring optimal performance and reliability. Key features include customizable designs, high durability, and compatibility with various pump systems. The impellers are engineered to meet specific operational requi…

5. VISMEC – Agitator Impellers

Domain: vismecmixer.com

Registered: 2018 (7 years)

Introduction: Agitator Impeller manufactured by VISMEC CO.,LTD. offers a wide range of standard and custom impellers in various sizes and configurations. Types of agitator impellers include: 1. Marine Propeller: Suitable for low to medium viscosity media, typically with three blades and a pitch to diameter ratio of 1.0 or 1.5. 2. Beam: Features two skewed surfaces, with angles of 45 degrees and 30 or 60 degrees…

Strategic Sourcing Conclusion and Outlook for agitator impeller types

In the rapidly evolving landscape of industrial mixing, understanding the diverse types of agitator impellers is crucial for optimizing operational efficiency and enhancing product quality. Key takeaways for B2B buyers emphasize the importance of selecting the right impeller type—whether it’s turbine, paddle, or high shear mixers—tailored to specific applications such as chemical reactions, emulsification, or blending of viscous materials. Strategic sourcing allows companies to leverage competitive advantages by aligning their procurement processes with suppliers who offer innovative, high-performance mixing solutions.

Illustrative image related to agitator impeller types

Moreover, as industries in Africa, South America, the Middle East, and Europe continue to grow, the demand for specialized agitator systems will likely rise. International buyers should prioritize partnerships with manufacturers that not only provide advanced technology but also offer tailored support and expertise to navigate local market needs.

Looking ahead, investing in the right agitator impeller type can significantly impact production efficiency and product consistency. By fostering relationships with reliable suppliers and staying informed about technological advancements, companies can position themselves for success in their respective markets. Engage with industry experts today to explore the best solutions for your mixing challenges and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.