Everything You Need to Know About Ac Unit Power Cord Sourcing in 2025

Introduction: Navigating the Global Market for ac unit power cord

In the ever-evolving landscape of global trade, sourcing the right AC unit power cord presents a critical challenge for international B2B buyers. With diverse electrical standards and varying application needs across regions such as Africa, South America, the Middle East, and Europe, ensuring compatibility and compliance is essential for seamless operations. This guide delves deep into the myriad types of AC unit power cords available in the market, exploring their specific applications and highlighting the importance of selecting the right product for your business needs.

From understanding different cord lengths and amperage ratings to identifying suitable suppliers and evaluating costs, this comprehensive resource equips you with the knowledge necessary to make informed purchasing decisions. By detailing the nuances of cord specifications and safety standards, we aim to empower buyers from diverse regions, including Brazil and Vietnam, to navigate their unique market landscapes confidently. Furthermore, we will provide actionable insights on supplier vetting practices, ensuring that you partner with reliable manufacturers who meet your quality requirements.

With this guide in hand, B2B buyers can streamline their procurement process, minimize risks associated with product compatibility, and ultimately enhance the operational efficiency of their air conditioning systems. Embrace the opportunity to optimize your sourcing strategy and unlock the full potential of your investments in AC unit power cords.

Understanding ac unit power cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Power Cord | Typically 120V or 240V, various lengths, NEMA connectors | Residential and light commercial AC units | Pros: Common availability; Cons: Limited to specific voltage ratings. |

| Heavy-Duty Power Cord | Rated for higher amperage (up to 30A), thicker gauge wire | Industrial and commercial HVAC systems | Pros: Durable and robust; Cons: Bulkier and potentially more expensive. |

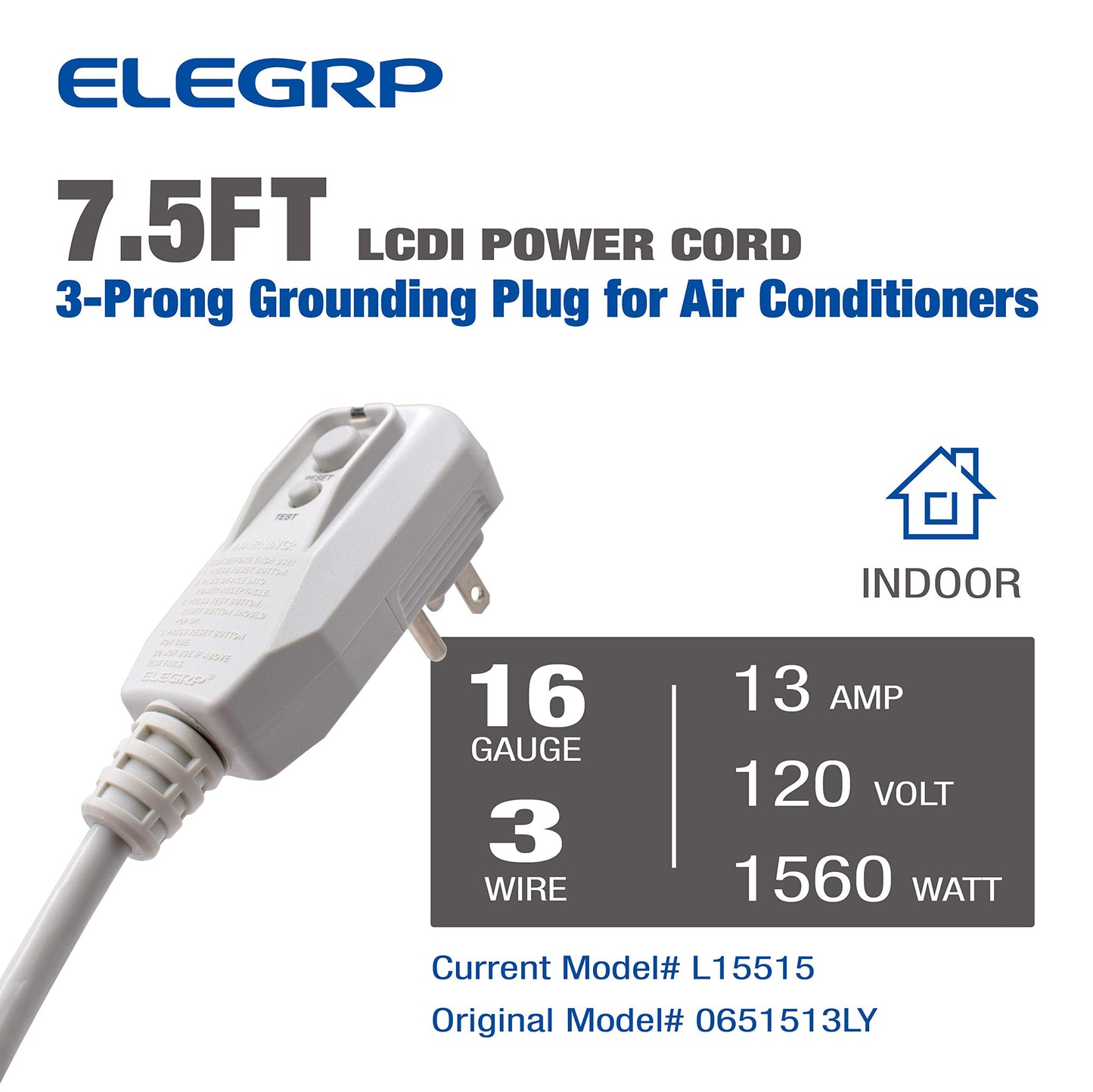

| LCDI Power Cord | Incorporates leakage current detection, often 15-20A | Air conditioning units with safety standards | Pros: Enhanced safety features; Cons: May be pricier than standard cords. |

| Twist-Lock Power Cord | Twist-lock mechanism for secure connection, 250V rated | Commercial and outdoor HVAC applications | Pros: Prevents accidental disconnection; Cons: Requires compatible outlets. |

| Extension Power Cord | Available in various lengths, designed for flexibility | Temporary setups, event HVAC needs | Pros: Increases reach; Cons: May not handle high loads effectively. |

What Are the Characteristics of Standard Power Cords for AC Units?

Standard power cords are typically designed for both 120V and 240V applications, featuring NEMA connectors that correspond to the voltage and amperage requirements of the air conditioning unit. These cords are widely used in residential and light commercial settings. When purchasing, businesses should consider the length required for their setup, as well as compatibility with existing electrical systems. These cords offer a balance of affordability and availability, making them a common choice for many buyers.

How Do Heavy-Duty Power Cords Stand Out in Industrial Applications?

Heavy-duty power cords are engineered to handle higher amperage, often rated up to 30A, making them suitable for industrial and commercial HVAC systems. The thicker gauge wire provides enhanced durability and reliability under heavy loads. B2B buyers should assess their specific power requirements and consider the environment where the cords will be used, as these cords may be bulkier and more expensive than standard options. Their robustness makes them ideal for demanding applications.

What Makes LCDI Power Cords Essential for Safety?

LCDI (Leakage Current Detection Interrupter) power cords are specifically designed for air conditioning units, incorporating safety features that detect leakage currents to prevent electrical hazards. They are usually rated for 15-20A, making them suitable for residential and light commercial applications. Buyers should prioritize these cords for installations where safety is a concern, especially in environments with high humidity. While they may come at a premium, the added safety benefits justify the investment.

Why Choose Twist-Lock Power Cords for Commercial HVAC Systems?

Twist-lock power cords feature a locking mechanism that ensures a secure connection, typically rated for 250V, making them ideal for commercial and outdoor HVAC applications. These cords prevent accidental disconnections, which is crucial in busy environments. When selecting twist-lock cords, businesses should ensure compatibility with their outlets and consider the potential need for additional adapters. Their reliability in high-demand settings makes them a preferred choice for many commercial operations.

How Do Extension Power Cords Provide Flexibility for Temporary Setups?

Extension power cords are designed to increase the reach of existing power supplies, available in various lengths to suit temporary setups such as events or construction sites. While they offer significant flexibility, B2B buyers must ensure that the cords can handle the load requirements of the connected devices. Although convenient, these cords may not be suitable for high-load applications, and businesses should evaluate their specific needs before making a purchase.

Key Industrial Applications of ac unit power cord

| Industry/Sector | Specific Application of ac unit power cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC (Heating, Ventilation, and Air Conditioning) | Powering residential and commercial AC units | Ensures efficient cooling and comfort in living and working spaces | Compliance with local electrical standards and safety certifications |

| Manufacturing | Supporting large-scale HVAC systems in factories | Maintains optimal temperature for machinery and products, enhancing productivity | Durability and resistance to industrial environments, such as moisture and heat |

| Hospitality | Connecting air conditioning units in hotels | Improves guest comfort, leading to better reviews and repeat business | Length and gauge of cords for different room layouts and electrical systems |

| Retail | Powering air conditioning in shopping centers | Enhances customer experience, encouraging longer shopping durations | Flexibility in cord length and compatibility with various AC models |

| Telecommunications | Supporting climate control in data centers | Protects sensitive electronic equipment from overheating, ensuring uptime | High amperage ratings and compliance with international electrical standards |

How is the AC Unit Power Cord Used in HVAC Applications?

In the HVAC industry, AC unit power cords are crucial for powering both residential and commercial air conditioning systems. These cords must comply with local electrical standards to ensure safety and efficiency. By providing reliable power, they help maintain comfortable indoor temperatures, which is essential for both occupant satisfaction and operational efficiency. Buyers in this sector should prioritize cords that are durable and meet specific safety certifications relevant to their region.

What Role Does the AC Unit Power Cord Play in Manufacturing?

In manufacturing environments, AC unit power cords are integral to large-scale HVAC systems that regulate temperature and humidity. Proper climate control is essential for machinery operation and product integrity, as extreme temperatures can affect both equipment performance and product quality. Businesses should consider sourcing heavy-duty cords that can withstand industrial conditions, including exposure to moisture and heat, ensuring longevity and reliability.

How is the AC Unit Power Cord Beneficial for the Hospitality Sector?

For the hospitality sector, connecting AC units in hotels is vital for enhancing guest comfort. A well-regulated environment contributes to positive experiences, leading to favorable reviews and repeat business. In this context, the flexibility of cord length and compatibility with various air conditioning models are essential. Buyers should ensure that the cords sourced can accommodate diverse room layouts and electrical configurations, optimizing installation efficiency.

What Importance Does the AC Unit Power Cord Have in Retail?

In retail settings, AC unit power cords are essential for powering air conditioning systems in shopping centers. A comfortable shopping environment encourages customers to spend more time in stores, directly impacting sales. Therefore, sourcing cords that offer flexibility in length and compatibility with different air conditioning units is crucial. Retailers should also consider the aesthetic aspect of cords to maintain a professional appearance in their establishments.

How Does the AC Unit Power Cord Support Telecommunications?

In telecommunications, AC unit power cords are vital for climate control in data centers, where overheating can lead to equipment failure and downtime. These cords must have high amperage ratings to support the significant power demands of cooling systems. Buyers in this sector should focus on sourcing cords that comply with international electrical standards, ensuring reliable operation and safeguarding critical infrastructure from temperature-related disruptions.

3 Common User Pain Points for ‘ac unit power cord’ & Their Solutions

Scenario 1: Inconsistent Power Supply Causing Operational Downtime

The Problem: Many B2B buyers in sectors such as manufacturing or construction face issues with unreliable power supply for air conditioning units. Frequent power fluctuations can lead to sudden shutdowns or failures of AC systems, causing discomfort for employees and negatively impacting productivity. For international buyers, particularly in regions with unstable power grids, this problem is exacerbated by the challenges of sourcing durable and reliable power cords that can withstand varying voltage conditions.

The Solution: To mitigate this issue, it is crucial to invest in high-quality, heavy-duty AC unit power cords designed to handle voltage fluctuations. Buyers should look for cords with features like surge protection and a higher amp rating to ensure they can handle unexpected spikes in electrical current. Additionally, consider cords with cold-weather ratings for regions experiencing extreme temperatures, which can affect performance. Establishing a relationship with reputable suppliers who understand local electrical standards can also ensure that the cords comply with necessary regulations, thus reducing the risk of failure.

Scenario 2: Compatibility Issues with Different AC Units

The Problem: Compatibility between air conditioning units and their power cords can be a significant pain point, especially for B2B buyers managing multiple installations across different locations. Units may require specific plug types or cord lengths, leading to frustration when cords do not match the equipment specifications. This issue is particularly prevalent among companies that may have older models alongside newer units, resulting in mismatched electrical requirements and potential safety hazards.

The Solution: Buyers should conduct a thorough assessment of all AC units in use to identify their specific power cord requirements. This includes examining the plug type, amperage, and voltage specifications. Sourcing from suppliers who offer a wide range of cord options, including different lengths and gauge ratings, can streamline procurement. Furthermore, consider investing in universal power cords with adjustable configurations or adapters to ensure compatibility across various models. Regularly reviewing and updating inventory based on new purchases can prevent compatibility issues from arising in the future.

Scenario 3: Poor Cord Quality Leading to Frequent Replacements

The Problem: Many businesses experience frequent power cord failures due to subpar quality, leading to operational disruptions and increased costs associated with replacements. This issue is particularly critical in industries like hospitality or healthcare, where consistent climate control is essential for comfort and compliance. B2B buyers may struggle to find cords that are not only durable but also cost-effective, leading to a cycle of purchasing low-quality cords that fail prematurely.

The Solution: It is essential to prioritize quality over price when sourcing AC unit power cords. Buyers should research manufacturers with a proven track record of producing high-quality electrical components that comply with safety standards. Look for cords made from robust materials that offer features such as kink resistance and UV protection, which can extend the lifespan of the product. Additionally, consider establishing a maintenance schedule to routinely inspect cords for wear and tear, allowing for proactive replacements before failure occurs. Implementing a centralized procurement process can also help in selecting trusted suppliers, ensuring that the quality of power cords is consistent across all locations.

Strategic Material Selection Guide for ac unit power cord

What Are the Key Materials Used in AC Unit Power Cords?

When selecting materials for AC unit power cords, it is essential to consider various properties that impact performance, durability, and compliance with international standards. Below, we analyze four common materials used in AC unit power cords, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. PVC (Polyvinyl Chloride)

Key Properties: PVC is known for its excellent electrical insulation properties and resistance to moisture and chemicals. It can typically withstand temperatures ranging from -15°C to 60°C, making it suitable for various environments.

Pros & Cons: PVC is relatively inexpensive and easy to manufacture, making it a popular choice for budget-conscious projects. However, it can become brittle over time, especially when exposed to extreme temperatures, which may limit its lifespan.

Impact on Application: PVC is compatible with a variety of media, including air and water, but may not perform well in extremely high-temperature applications.

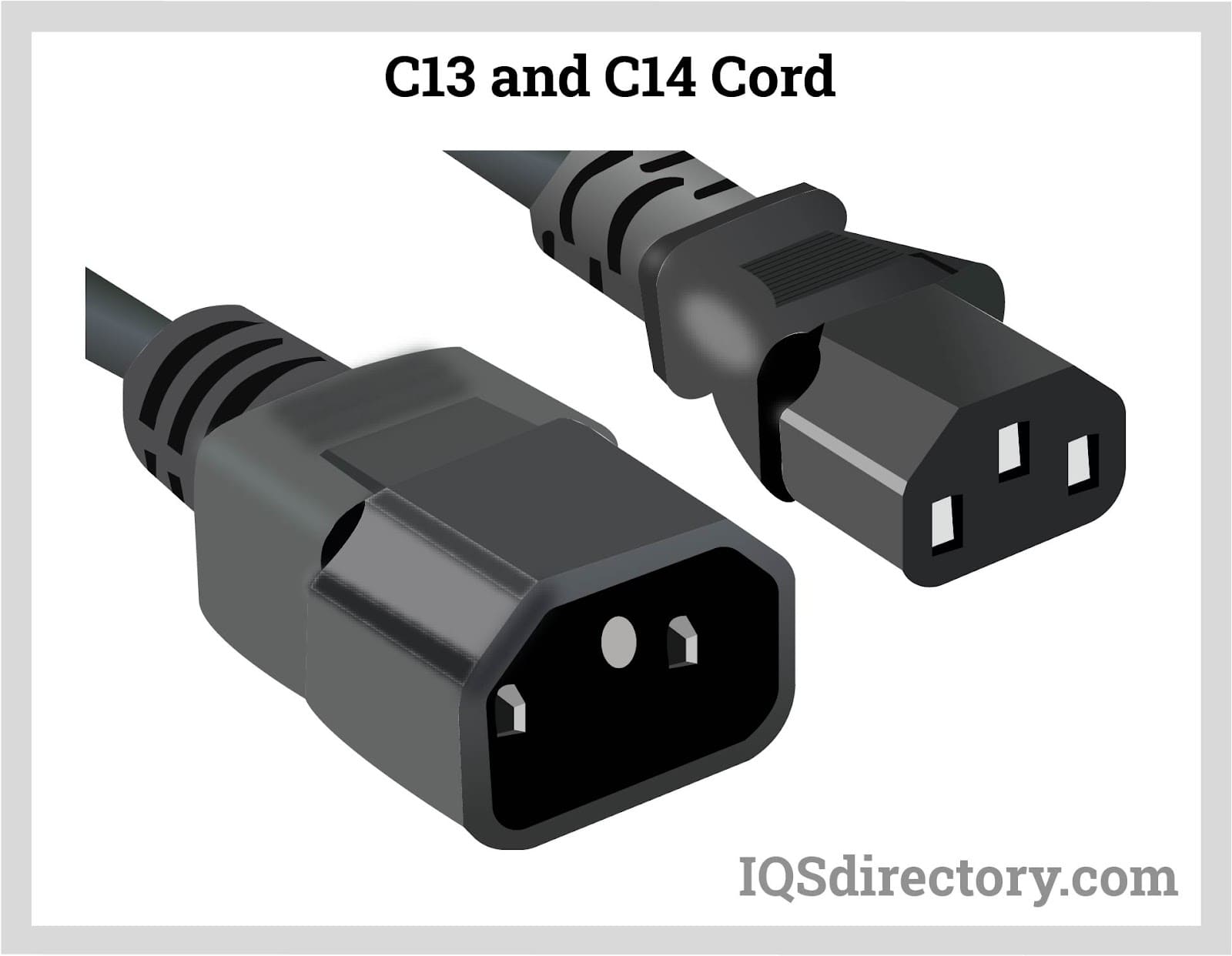

Illustrative image related to ac unit power cord

Considerations for International Buyers: Compliance with standards such as ASTM D3032 is crucial. Buyers in regions like Africa and South America should also consider local regulations regarding the use of PVC, especially in terms of environmental impact.

2. Silicone Rubber

Key Properties: Silicone rubber offers exceptional temperature resistance, typically functioning effectively between -60°C and 200°C. It also has excellent flexibility and resilience, even in extreme conditions.

Pros & Cons: The durability and flexibility of silicone make it ideal for high-performance applications. However, it is more expensive than PVC and may present manufacturing complexities due to its unique properties.

Illustrative image related to ac unit power cord

Impact on Application: Silicone is particularly well-suited for environments with high heat and humidity, making it a preferred choice for industrial applications.

Considerations for International Buyers: Buyers should ensure that silicone materials comply with international standards such as IEC 60245. In regions like Europe, there is a strong preference for materials that are environmentally friendly and compliant with RoHS directives.

3. Thermoplastic Elastomer (TPE)

Key Properties: TPE combines the properties of rubber and plastic, offering flexibility, durability, and excellent weather resistance. It can typically withstand temperatures ranging from -40°C to 90°C.

Pros & Cons: TPE is lightweight and offers good mechanical properties, making it suitable for various applications. However, it can be more costly than traditional materials like PVC, which may deter some buyers.

Impact on Application: TPE is compatible with a wide range of media, including air and water, and is particularly effective in outdoor applications due to its UV resistance.

Considerations for International Buyers: Compliance with local and international standards, such as UL and CE certifications, is essential. Buyers from the Middle East and Africa should also consider the material’s performance in high-temperature and humid conditions.

4. Neoprene

Key Properties: Neoprene is known for its excellent resistance to oil, chemicals, and weathering. It can typically operate within a temperature range of -40°C to 100°C.

Pros & Cons: Its durability and resistance to environmental factors make neoprene a reliable choice for harsh conditions. However, it is often more expensive than PVC and may not be as flexible.

Impact on Application: Neoprene is particularly suitable for applications exposed to oils and chemicals, making it a preferred choice in industrial settings.

Considerations for International Buyers: Buyers should be aware of compliance with ASTM D2000 standards. In Europe, the demand for environmentally friendly materials may affect the choice of neoprene, especially in light of regulations on hazardous substances.

Summary Table of Material Selection for AC Unit Power Cords

| Material | Typical Use Case for ac unit power cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General residential AC units | Cost-effective and easy to manufacture | Brittle at extreme temperatures | Low |

| Silicone Rubber | High-performance industrial AC units | Excellent temperature resistance | Higher cost and manufacturing complexity | High |

| Thermoplastic Elastomer (TPE) | Outdoor AC applications | Lightweight and UV resistant | More expensive than PVC | Med |

| Neoprene | Industrial applications with chemical exposure | Durable and weather resistant | Higher cost and less flexibility | High |

This strategic material selection guide serves as a comprehensive resource for international B2B buyers, enabling informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ac unit power cord

What Are the Key Stages in the Manufacturing Process of AC Unit Power Cords?

The manufacturing process of AC unit power cords involves several critical stages that ensure the final product meets quality and safety standards. Each stage is designed to optimize material usage, enhance durability, and ensure compliance with international regulations.

Material Preparation: What Materials Are Used?

The foundation of any AC unit power cord lies in the selection of high-quality materials. Typically, manufacturers utilize copper for the conductors due to its excellent electrical conductivity. The insulation is often made from thermoplastic elastomers (TPE) or polyvinyl chloride (PVC), which provide flexibility and resistance to heat and abrasion.

In addition to the core materials, connectors and plugs are crafted from durable plastics and metals that can withstand wear over time. The preparation stage also includes sourcing materials from certified suppliers to guarantee compliance with international standards.

How Is the Forming Process Executed?

Once materials are prepared, the next step is forming. This process involves several techniques, such as extrusion and molding. During extrusion, the copper wires are drawn and insulated with the chosen material, creating a continuous length of cable.

For connectors, injection molding is commonly used, where molten plastic is injected into a mold to form the desired shape. This ensures that the connectors fit securely and can handle the physical stresses during use. Precision in this stage is crucial, as any defects can lead to performance issues or safety hazards.

What Does the Assembly Process Involve?

The assembly stage is where the individual components come together to form a complete product. This typically includes:

- Cutting the Cable: The extruded cable is cut to specified lengths according to product requirements.

- Attaching Connectors: The ends of the cables are stripped, and connectors are crimped or soldered onto the wires, ensuring a secure connection.

- Quality Checks: Each assembly line should have checkpoints where workers inspect for visible defects, ensuring that only properly assembled cords proceed to the next stage.

What Finishing Techniques Are Used?

Finishing processes are essential for enhancing the durability and aesthetics of AC unit power cords. This may involve:

- Coating: Applying a protective coating to the cable to enhance its resistance to environmental factors.

- Marking: Clearly labeling cords with specifications, safety ratings, and compliance marks to ensure traceability and compliance with international standards.

- Packaging: Proper packaging is crucial for protecting the cords during transport and storage, often utilizing eco-friendly materials to appeal to environmentally-conscious buyers.

What International Standards Govern Quality Assurance for AC Unit Power Cords?

Quality assurance is paramount in the manufacturing of AC unit power cords. Various international standards guide manufacturers to ensure safety and reliability. Notably, ISO 9001 sets a benchmark for quality management systems, which many manufacturers adopt to streamline their processes and improve product quality.

In addition to ISO standards, compliance with industry-specific certifications such as CE (Conformité Européenne) and UL (Underwriters Laboratories) is critical. These certifications indicate that products have been tested for safety and performance in specific applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves a series of checkpoints to ensure that every power cord meets the required standards. Typical QC checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Any non-conforming materials are rejected or returned.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, operators perform checks at various stages to identify and rectify issues early. This includes verifying dimensions, electrical conductivity, and insulation integrity.

- Final Quality Control (FQC): Before products are packaged, they undergo a final inspection to ensure they meet all specifications and safety standards. This includes electrical testing and visual inspections for any physical defects.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are some actionable strategies:

-

Conduct Supplier Audits: Regularly auditing suppliers helps ensure compliance with quality standards. Buyers should assess manufacturing facilities, QC processes, and employee training programs.

-

Request Quality Reports: Suppliers should provide detailed reports on their QC processes, including results from IQC, IPQC, and FQC. These documents should outline testing methodologies and results.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. This can include pre-shipment inspections and random sampling of products.

What Are the Specific QC and Certification Nuances for International Buyers?

International buyers must be aware of the nuances in QC and certification requirements that can vary by region. For instance:

- Regional Regulations: Different countries may have specific regulations governing electrical products. Buyers should ensure that suppliers are aware of and compliant with local laws in their target markets.

- Cultural Considerations: Understanding cultural differences in business practices can also impact quality expectations. Establishing clear communication about quality standards and expectations is essential for successful partnerships.

By focusing on robust manufacturing processes and stringent quality assurance measures, B2B buyers can confidently source AC unit power cords that meet their operational needs and safety requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ac unit power cord’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of air conditioning unit power cords. Given the importance of reliable power connectivity in HVAC systems, this checklist will ensure that you navigate the sourcing process effectively, ensuring quality, safety, and compatibility with your specific equipment needs.

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, clearly outline the technical requirements for the AC unit power cords you need. This includes the voltage rating, amperage, wire gauge, and plug type.

– Voltage and Amperage: Ensure the cords match the electrical specifications of your AC units to prevent overheating and equipment failure.

– Wire Gauge: A lower gauge number indicates a thicker wire, which is crucial for high amperage applications.

Step 2: Research Regulatory Compliance

Verify that the power cords comply with local and international safety standards, such as UL, CE, or IEC certifications. Compliance is vital for ensuring safety and reliability.

– Documentation: Request relevant certificates from suppliers to confirm compliance.

– Market-Specific Requirements: Different regions may have specific regulations; be aware of these to avoid legal issues.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to ensure they meet your business needs. Look for established companies with a proven track record in supplying quality electrical components.

– Company Profiles: Examine their history, product range, and client testimonials.

– References: Ask for case studies or references from businesses in similar industries to gauge reliability.

Step 4: Request Samples for Testing

Before placing a bulk order, always request samples of the power cords to evaluate their quality and compatibility with your equipment. This step helps mitigate risks associated with faulty products.

– Testing for Performance: Assess the cords under operational conditions to ensure they meet your performance standards.

– Durability Assessment: Check for features such as cold weather ratings or fire resistance, which are essential for long-term use.

Step 5: Compare Pricing and Terms

Once you have a shortlist of suppliers, compare pricing and payment terms to find the best value for your investment. Remember that the lowest price may not always equate to the best quality.

– Total Cost of Ownership: Consider factors such as warranty, return policies, and shipping costs in your comparison.

– Negotiation: Be prepared to negotiate terms to achieve favorable conditions for your purchase.

Illustrative image related to ac unit power cord

Step 6: Finalize Your Order and Logistics

After selecting a supplier, finalize your order details, including quantities, delivery timelines, and shipping methods. Clear communication at this stage can prevent future issues.

– Documentation: Ensure all agreements are documented, including delivery schedules and payment terms.

– Logistics Coordination: Confirm the logistics arrangements, especially if shipping internationally, to avoid customs delays.

Step 7: Post-Purchase Evaluation

After receiving the power cords, conduct a post-purchase evaluation to assess the product quality and supplier performance. This feedback is crucial for future procurement decisions.

– Quality Checks: Inspect the cords for any defects or discrepancies with your order.

– Supplier Review: Provide feedback to the supplier based on your experience, which can help improve future transactions.

By following this checklist, B2B buyers can streamline the procurement process for AC unit power cords, ensuring that they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for ac unit power cord Sourcing

What Are the Key Cost Components in Sourcing AC Unit Power Cords?

When analyzing the cost structure for sourcing AC unit power cords, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The primary cost driver in the production of power cords is the raw materials, which often include copper wire, insulation, and various connectors. Higher quality materials can significantly increase costs but are essential for ensuring safety and durability.

-

Labor: Labor costs vary by region and are influenced by local wage standards and the complexity of the manufacturing process. Skilled labor is typically required for assembly and quality checks, impacting overall costs.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial setup costs for specialized tools and molds can be substantial, particularly for custom or high-volume orders. These costs are typically amortized over the production run.

-

Quality Control: Ensuring compliance with safety standards and certifications is crucial. This may involve additional testing and inspection, which adds to the overall cost.

-

Logistics: Shipping, warehousing, and handling costs can vary widely based on the destination. For international buyers, understanding Incoterms is essential to determining who bears these costs.

-

Margin: Suppliers will typically include a margin to cover their operational costs and profit. This margin can fluctuate based on market conditions and competition.

How Do Price Influencers Affect the Cost of AC Unit Power Cords?

Several factors influence the pricing of AC unit power cords, particularly for B2B buyers in diverse markets like Africa, South America, the Middle East, and Europe.

Illustrative image related to ac unit power cord

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Understanding a supplier’s MOQ can help negotiate better pricing.

-

Specifications and Customization: Customized cords with specific lengths, gauges, or connectors can increase costs. Buyers should weigh the necessity of customization against budget constraints.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as UL or CE) can enhance safety and reliability but will increase costs. Buyers should assess the total cost of ownership when considering these factors.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers may charge a premium for their brand reputation and service quality.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can affect overall costs by determining who pays for shipping, insurance, and customs duties. It is crucial for buyers to clearly understand these terms to avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of AC Unit Power Cords?

For international B2B buyers, particularly those operating in markets such as Brazil or Vietnam, several strategies can enhance cost-efficiency when sourcing AC unit power cords.

-

Negotiate Wisely: Leverage your purchasing volume and long-term potential to negotiate better terms. Establishing a relationship with suppliers can also lead to more favorable pricing and terms.

-

Assess Total Cost of Ownership: Consider not just the purchase price but also factors like shipping, tariffs, and potential maintenance costs. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

-

Understand Pricing Nuances: Be aware of regional pricing differences and market dynamics that can affect costs. For instance, suppliers in Europe may have different pricing structures compared to those in Asia due to labor and material costs.

-

Seek Multiple Quotes: Always obtain quotes from multiple suppliers to understand the market rate and ensure competitive pricing. This practice can also reveal valuable insights into different suppliers’ capabilities and reliability.

-

Stay Informed on Market Trends: Being aware of global supply chain trends, material shortages, or changes in regulations can provide leverage during negotiations and help anticipate price fluctuations.

In conclusion, a comprehensive understanding of the cost components and price influencers is essential for B2B buyers in the AC unit power cord market. By employing strategic negotiation tactics and considering the total cost of ownership, buyers can make informed decisions that align with their budget and operational needs.

Alternatives Analysis: Comparing ac unit power cord With Other Solutions

In today’s competitive market, B2B buyers must carefully assess their options when selecting solutions for powering air conditioning units. While the traditional AC unit power cord is a widely used solution, several alternatives may offer distinct advantages depending on specific needs. This analysis will explore alternative technologies and methods, providing insights to help buyers make informed decisions.

| Comparison Aspect | Ac Unit Power Cord | Alternative 1: Surge Protector Power Strip | Alternative 2: Smart Power Management System |

|---|---|---|---|

| Performance | Reliable for standard AC units | Protects against surges, multiple outlets | Monitors and controls energy consumption |

| Cost | Moderate ($10 – $50) | Low to moderate ($10 – $100) | Higher initial investment ($100 – $500) |

| Ease of Implementation | Plug-and-play installation | Simple setup, requires minimal effort | Requires installation and configuration |

| Maintenance | Low (occasional checks) | Low (replace if damaged) | Moderate (software updates, monitoring) |

| Best Use Case | Standard residential/commercial AC units | Environments with multiple devices needing surge protection | Facilities focused on energy efficiency and monitoring |

What Are the Benefits and Drawbacks of Using Surge Protector Power Strips?

Surge protector power strips offer a practical alternative for environments where multiple electrical devices are used alongside an AC unit. They protect against voltage spikes, which can be common in certain regions, ensuring longevity for both the AC unit and connected devices. The cost is generally low, making them accessible for many businesses. However, they may not provide the same level of direct power delivery as an AC unit power cord, and their reliance on a single outlet can lead to overloading if too many devices are connected.

How Does a Smart Power Management System Enhance AC Unit Operation?

Smart power management systems represent a more advanced solution for businesses looking to optimize energy consumption. These systems allow for real-time monitoring of electricity usage, enabling users to identify inefficiencies and reduce operational costs. They can also be programmed to turn off devices when not in use, providing additional energy savings. However, the initial investment and complexity of installation can be significant drawbacks for smaller businesses or those with limited technical expertise.

Conclusion: How Can B2B Buyers Choose the Right Power Solution?

Selecting the right power solution for AC units involves evaluating specific needs, including performance requirements, budget constraints, and ease of implementation. For businesses prioritizing reliability and straightforward functionality, the AC unit power cord remains a solid choice. Conversely, companies looking for enhanced protection and energy management may find surge protector power strips or smart power management systems more beneficial. Ultimately, understanding the unique demands of your operations will guide you in choosing the most suitable power solution.

Essential Technical Properties and Trade Terminology for ac unit power cord

What Are the Key Technical Properties of an AC Unit Power Cord?

When evaluating AC unit power cords, several technical specifications are critical for ensuring safety, efficiency, and compatibility with various air conditioning systems. Here are some essential properties to consider:

-

Wire Gauge: The wire gauge indicates the thickness of the wire within the power cord, typically measured in AWG (American Wire Gauge). A lower gauge number (e.g., 10 AWG) means a thicker wire capable of carrying higher currents without overheating. For air conditioning units, a wire gauge of 12 or 14 is common, as it balances current capacity and flexibility. B2B buyers should ensure the wire gauge meets the amperage requirements of their specific units to prevent electrical hazards.

-

Amperage Rating: This specification denotes the maximum amount of electrical current the cord can safely carry. Common ratings for AC unit power cords range from 10 A to 30 A, depending on the unit’s power requirements. Understanding the amperage rating is vital for compliance with local electrical codes and for ensuring the longevity of both the power cord and the air conditioning unit.

-

Voltage Rating: The voltage rating indicates the maximum voltage the power cord can handle, typically ranging from 120V to 250V for AC units. This rating is crucial for international buyers, as voltage standards vary by region. For instance, while North America predominantly uses 120V systems, many countries in Europe and Asia utilize 230V. Ensuring compatibility with local voltage standards helps prevent equipment damage and ensures safe operation.

-

Length: The length of the power cord impacts installation flexibility and convenience. Standard lengths range from 3 feet to over 15 feet. Buyers should consider the distance from the power source to the AC unit to avoid the need for extension cords, which can pose safety risks. It’s essential to choose a length that accommodates installation requirements without compromising safety.

-

Material Composition: The insulation and conductor materials affect the cord’s durability and performance. Common materials include PVC (Polyvinyl Chloride) and rubber, which provide flexibility and resistance to environmental factors like heat and moisture. For B2B buyers, selecting high-quality materials can reduce maintenance costs and improve safety in industrial or outdoor settings.

-

Certifications: Look for power cords that comply with international safety standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne). Certifications indicate that the product has been tested for safety and performance, providing peace of mind for buyers concerned about compliance and reliability.

What Are Common Trade Terms Associated with AC Unit Power Cords?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms relevant to AC unit power cords:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that may be marketed by another manufacturer. In the context of AC unit power cords, OEMs often supply parts that meet specific standards required by the air conditioning units they are designed to support.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units a supplier is willing to sell. This term is significant for B2B buyers as it affects purchasing decisions and inventory management. Understanding the MOQ helps businesses balance between cost-effectiveness and stock availability.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers requesting price estimates for specific products. For AC unit power cords, submitting an RFQ can help buyers compare costs, gauge supplier responsiveness, and negotiate better terms.

-

Incoterms (International Commercial Terms): These are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) are crucial for clarifying shipping responsibilities and costs, helping to prevent disputes.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for project planning and inventory management, particularly when dealing with international suppliers.

-

Surge Protection: This refers to devices or features designed to protect electrical equipment from voltage spikes. For AC unit power cords, surge protection can be critical in regions prone to electrical surges, ensuring the longevity and safety of the air conditioning units.

By familiarizing themselves with these properties and terms, B2B buyers can make informed decisions when sourcing AC unit power cords, ensuring compatibility, safety, and efficiency for their operations.

Navigating Market Dynamics and Sourcing Trends in the ac unit power cord Sector

What Are the Key Trends and Market Dynamics Affecting AC Unit Power Cord Sourcing?

The global market for AC unit power cords is shaped by several key drivers, including increasing demand for air conditioning systems across emerging economies and the growing emphasis on energy efficiency. In regions such as Africa, South America, the Middle East, and Europe, the rise in temperatures due to climate change is propelling the sales of air conditioning units, consequently increasing the demand for compatible power cords. Emerging trends in B2B sourcing include a shift towards online procurement platforms, allowing buyers to compare products and prices more efficiently. Additionally, the integration of smart technologies into air conditioning systems is influencing the design and specifications of power cords, with a growing preference for cords that support smart connectivity and energy management systems.

International buyers are also increasingly interested in customization options, as various regions have different electrical standards and requirements. For instance, countries in Europe often require cords with specific plug types and voltage ratings, while African nations may prioritize durability and resistance to extreme weather conditions. Additionally, the market is witnessing a trend towards shorter lead times and just-in-time inventory systems, allowing businesses to respond swiftly to fluctuating demands without incurring excess inventory costs.

Illustrative image related to ac unit power cord

How Does Sustainability and Ethical Sourcing Influence AC Unit Power Cord Procurement?

Sustainability is becoming a critical consideration in the procurement of AC unit power cords. The environmental impact of manufacturing processes, including resource consumption and waste generation, is under scrutiny. Buyers are increasingly seeking suppliers who prioritize eco-friendly practices, such as using recycled materials in their products or implementing energy-efficient manufacturing processes.

Ethical sourcing also plays a vital role in B2B relationships. Companies are looking for partners who adhere to fair labor practices and uphold human rights throughout their supply chains. Certifications such as RoHS (Restriction of Hazardous Substances) and Energy Star are becoming benchmarks for assessing the sustainability of power cords. These certifications not only ensure compliance with environmental regulations but also enhance brand reputation and consumer trust. For international buyers, especially in regions with stringent environmental regulations, sourcing products that meet these standards is not only a compliance issue but also a competitive advantage.

What Is the Historical Context Behind AC Unit Power Cords and Their Evolution?

The evolution of AC unit power cords can be traced back to the increasing reliance on electric power for household and commercial appliances in the early 20th century. Initially, power cords were relatively simple, primarily designed for basic electrical conductivity. However, as air conditioning technology advanced, the need for specialized cords that could handle higher voltage and current ratings emerged.

By the late 20th century, manufacturers began incorporating safety features such as grounded plugs and circuit interrupters to mitigate risks associated with electrical fires and equipment damage. Today, the focus has shifted towards enhancing energy efficiency and integrating smart technology, reflecting broader trends in the electrical and electronics sectors. This historical context informs current sourcing strategies, as international buyers seek products that not only meet modern safety and efficiency standards but also align with their sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of ac unit power cord

-

How do I solve compatibility issues with different AC unit power cords?

To address compatibility issues, it’s essential to verify the specifications of both the AC unit and the power cord. Check the voltage, amperage, and plug type required by your AC unit. Additionally, ensure the power cord meets local electrical standards. If you’re sourcing from international suppliers, inquire about product certifications that comply with your region’s regulations. Consider consulting with a technical expert if unsure, as using an incompatible cord can lead to performance issues or safety hazards. -

What is the best power cord length for my air conditioning unit?

The optimal power cord length depends on the distance between your AC unit and the power source. Generally, a cord that is too short can lead to strain and potential damage, while an excessively long cord may pose safety risks and reduce efficiency. For most residential and commercial applications, a length of 6 to 10 feet is common. Always measure the distance and consider the layout of your space when selecting the appropriate length. -

What are the key specifications to look for in an AC unit power cord?

When selecting an AC unit power cord, prioritize specifications such as wire gauge, amperage rating, voltage rating, and plug type. A lower wire gauge (e.g., 12 AWG) indicates a thicker wire that can handle more current, which is crucial for larger units. Ensure the cord is rated for the voltage of your AC unit, typically 120V or 240V. Additionally, verify that the plug type matches the outlet configuration in your region to ensure a secure fit. -

How can I ensure the quality and reliability of AC unit power cords from suppliers?

To guarantee quality, conduct thorough research on potential suppliers. Look for manufacturers with established reputations and positive reviews. Request product samples to evaluate the cord’s construction and materials. Confirm that the cords meet international safety standards, such as UL or CE certifications. Engaging in direct communication with suppliers regarding their quality control processes can also provide insights into their reliability. -

What is the minimum order quantity (MOQ) for AC unit power cords?

The MOQ for AC unit power cords can vary significantly between suppliers. Many manufacturers set an MOQ to cover production costs, which can range from 100 to 1,000 units. When negotiating with suppliers, clarify the MOQ and see if they offer flexibility for first-time orders or smaller businesses. Understanding the MOQ is crucial for budgeting and ensuring you have enough inventory to meet demand without overcommitting. -

What payment terms should I expect when sourcing AC unit power cords internationally?

Payment terms can differ widely depending on the supplier and the nature of the business relationship. Common options include full payment upfront, partial payment with the balance due upon shipment, or payment against documents. Ensure to discuss and agree on terms that suit both parties before finalizing an order. Utilizing secure payment methods, such as letters of credit or escrow services, can also mitigate risks in international transactions. -

How does shipping logistics affect the sourcing of AC unit power cords?

Shipping logistics play a crucial role in the timely delivery of AC unit power cords. Factors to consider include shipping method (air vs. sea), customs clearance processes, and potential tariffs or duties. Collaborate with suppliers to understand their shipping policies and timelines. It’s also beneficial to work with a freight forwarder familiar with international trade to navigate complexities and ensure smooth delivery to your location. -

What customization options are available for AC unit power cords?

Many suppliers offer customization options for AC unit power cords, including variations in length, gauge, plug types, and even branding. If you have specific requirements, discuss them upfront with your supplier to understand the available options and any associated costs. Custom cords can help in meeting unique electrical standards or aesthetic preferences, making your product offerings more competitive in the market.

Top 2 Ac Unit Power Cord Manufacturers & Suppliers List

1. C2G – AC Power Cords

Domain: cablestogo.com

Registered: 1995 (30 years)

Introduction: This company, C2G – AC Power Cords, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. GE Appliances – Genuine Parts & Accessories

Domain: geapplianceparts.com

Registered: 1999 (26 years)

Introduction: This company, GE Appliances – Genuine Parts & Accessories, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for ac unit power cord

As global demand for air conditioning continues to rise, particularly in regions experiencing extreme temperatures, the significance of high-quality AC unit power cords cannot be overstated. Strategic sourcing of these components not only ensures compliance with safety standards but also enhances operational reliability and efficiency. Buyers should focus on evaluating suppliers based on product durability, gauge specifications, and overall compatibility with various AC units. Understanding local market needs, including voltage requirements and environmental conditions, is essential for making informed purchasing decisions.

Investing in reliable power cords can prevent costly downtime and enhance customer satisfaction, making it a critical component of supply chain management. For international buyers from Africa, South America, the Middle East, and Europe, forming strategic partnerships with reputable manufacturers can lead to long-term benefits and competitive advantages in the marketplace.

Looking ahead, businesses should prioritize sourcing strategies that embrace innovation and sustainability in product offerings. By collaborating with suppliers that align with these values, B2B buyers can secure a robust supply chain that meets the evolving demands of the air conditioning sector. Now is the time to act—seek out partners who can provide the quality and reliability essential for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to ac unit power cord

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.