Everything You Need to Know About 8.00 16 Sourcing in 2025

Introduction: Navigating the Global Market for 8.00 16

In today’s competitive landscape, sourcing the right 8.00 16 tires presents a significant challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The complexity arises not only from the variety of tire types and applications available but also from the need to ensure quality, cost-effectiveness, and reliability. This comprehensive guide aims to empower buyers by providing valuable insights into the diverse range of 8.00 16 tires, including their specifications, intended uses, and performance characteristics.

We delve into key topics such as the different tire types—ranging from agricultural to industrial applications—along with supplier vetting processes to identify trustworthy partners. Additionally, we will explore pricing strategies, shipping considerations, and warranty options to enhance your purchasing strategy. By equipping you with the necessary knowledge and tools, this guide enables informed decision-making that aligns with your business objectives.

Navigating the global market for 8.00 16 tires doesn’t have to be daunting. With a clear understanding of your options and a strategic approach, you can confidently source the right tires that meet your operational needs while optimizing your supply chain.

Understanding 8.00 16 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Titan Hi-Traction Lug R-1 | High traction lug design, 6 ply, tubeless, 28 PSI inflation | Agricultural machinery, tractors | Pros: Excellent grip on uneven terrain; durable. Cons: Higher cost compared to standard tires. |

| K9 Farm R1 | Robust construction, tube-type, 45 PSI inflation | Farming equipment, utility vehicles | Pros: Strong load capacity; versatile. Cons: Tube-type may require more maintenance. |

| Carlstar Farm Specialist R-1 | Bias ply construction, 8 ply, 19 MPH max speed | Tractors, combines | Pros: Enhanced stability; suitable for heavy loads. Cons: Limited speed rating may hinder performance. |

| BKT TR144 Rear Tractor R-1 | 6 ply, tubeless, designed for rear tractor applications | Agricultural tasks, fieldwork | Pros: Designed for heavy-duty use; good tread depth. Cons: Slightly heavier, impacting fuel efficiency. |

| Galaxy Agri Trac II R-1 | All-season capability, 6 ply, 31/32 tread depth | General agricultural use | Pros: Versatile for different conditions; good traction. Cons: May wear faster in extreme conditions. |

What are the Key Characteristics of Titan Hi-Traction Lug R-1 Tires?

The Titan Hi-Traction Lug R-1 tires are designed for optimal grip and durability in agricultural settings. With a robust lug pattern and a 6 ply construction, these tires can handle the rigors of uneven terrain and heavy loads. They operate efficiently at 28 PSI, making them suitable for various farming equipment. B2B buyers should consider their higher upfront cost against the long-term benefits of durability and performance.

How Does the K9 Farm R1 Tire Stand Out?

The K9 Farm R1 tire features a tube-type design with a strong load index, allowing it to support significant weights while maintaining stability. With a maximum inflation pressure of 45 PSI, it is built for demanding agricultural applications. Buyers should weigh the advantages of its robust construction against the potential for increased maintenance associated with tube-type tires.

What Makes the Carlstar Farm Specialist R-1 a Reliable Choice?

The Carlstar Farm Specialist R-1 is characterized by its bias ply construction and an 8 ply rating, which provides enhanced stability under heavy loads. It is suitable for tractors and combines, operating at a maximum speed of 19 MPH. While its speed rating may be a limitation for some, its ability to handle substantial weight makes it a dependable choice for agricultural professionals.

Why Choose BKT TR144 Rear Tractor R-1 Tires?

BKT TR144 Rear Tractor R-1 tires are engineered specifically for rear tractor applications, featuring a 6 ply, tubeless design that ensures durability and easy maintenance. With a tread depth of 31/32nds, they are well-suited for heavy-duty agricultural tasks. However, their weight can affect fuel efficiency, which is a consideration for B2B buyers focused on operational costs.

What are the Advantages of Galaxy Agri Trac II R-1 Tires?

Galaxy Agri Trac II R-1 tires offer all-season capabilities, making them versatile for various agricultural conditions. With a 6 ply rating and a tread depth of 31/32nds, they provide reliable traction and performance. While they are effective across multiple conditions, buyers should be aware that extreme environments may lead to faster wear, necessitating a balance between performance and longevity.

Key Industrial Applications of 8.00 16

| Industry/Sector | Specific Application of 8.00 16 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Tractor and Farm Equipment | Enhanced traction and stability on varied terrains | Load capacity, ply rating, tread design for specific soil types |

| Construction | Heavy Machinery and Equipment | Improved durability and performance in tough conditions | Compatibility with machinery specs, inflation pressure, and load index |

| Material Handling | Forklifts and Loaders | Increased efficiency in transporting goods | Tire weight, speed rating, and sidewall type for specific applications |

| Transportation & Logistics | Delivery Vehicles and Light Trucks | Optimal performance for regional deliveries | Cost-effectiveness, availability, and delivery times |

| Mining | Haulage and Dump Trucks | Superior traction in rugged environments | Resistance to wear, load capacity, and inflation requirements |

How is ‘8.00 16’ Used in Agriculture and What Problems Does It Solve?

In the agriculture sector, the 8.00 16 tire is primarily utilized on tractors and farm equipment. These tires provide excellent traction and stability, essential for navigating various terrains, including muddy or uneven fields. They help mitigate soil compaction, a common issue in farming, thereby promoting healthier crop growth. For international buyers, especially in regions like Africa and South America, sourcing tires that can withstand local conditions while offering a high load capacity is critical. Buyers must consider ply ratings and tread designs tailored for specific soil types.

What is the Role of ‘8.00 16’ in Construction?

In construction, the 8.00 16 tires are commonly fitted on heavy machinery and equipment, such as backhoes and excavators. These tires are designed to endure rugged terrains, providing enhanced durability and performance, which is vital for maintaining productivity on job sites. Construction businesses benefit from reduced downtime due to tire failures. When sourcing these tires, buyers need to ensure compatibility with their machinery specifications, paying close attention to inflation pressure and load index to optimize performance.

How Do ‘8.00 16’ Tires Enhance Material Handling Operations?

For material handling, 8.00 16 tires are used on forklifts and loaders, where they play a crucial role in improving efficiency during the transportation of goods. These tires facilitate smooth operations on various surfaces, which is essential in warehouses and distribution centers. The value lies in their ability to support heavy loads while providing stability. Buyers should evaluate tire weight, speed ratings, and sidewall types to ensure they meet the specific demands of their operations.

What Benefits Do ‘8.00 16’ Tires Provide in Transportation and Logistics?

In the transportation and logistics sector, 8.00 16 tires are fitted on delivery vehicles and light trucks, optimizing performance for regional deliveries. These tires help reduce fuel consumption and improve handling, which is essential for timely deliveries. Businesses benefit from the enhanced reliability and cost-effectiveness of these tires, which can lead to significant savings in operational costs. Buyers should focus on sourcing options that offer a balance of quality and affordability, alongside timely delivery.

How Are ‘8.00 16’ Tires Applied in Mining Operations?

In mining, the 8.00 16 tire is essential for haulage and dump trucks, where superior traction in rugged environments is critical. These tires are designed to handle heavy loads and harsh conditions, ensuring operational efficiency and safety. The mining sector benefits from reduced tire wear and the ability to navigate steep gradients and rough terrain. Buyers must prioritize sourcing tires that meet specific resistance to wear and load capacity, as well as inflation requirements, to ensure optimal performance in challenging environments.

3 Common User Pain Points for ‘8.00 16’ & Their Solutions

Scenario 1: Navigating Availability and Lead Times for 8.00 16 Tires

The Problem: B2B buyers, particularly those in agricultural sectors across diverse regions like Africa and South America, often face significant challenges in sourcing 8.00 16 tires due to fluctuating availability. This can lead to delays in machinery operations, resulting in lost productivity and increased costs. When a buyer needs tires urgently for critical farming equipment, the uncertainty around lead times can exacerbate the problem, causing frustration and operational inefficiencies.

The Solution: To mitigate these issues, buyers should establish relationships with multiple suppliers and leverage local distributors who have a better grasp of regional stock levels. Conducting a thorough market analysis can help identify suppliers with consistent inventory and favorable lead times. Additionally, implementing a just-in-time (JIT) inventory strategy can ensure that tire stock is replenished before it runs low, allowing for smoother operations. Buyers can also negotiate contracts that include guaranteed availability clauses, ensuring that they are prioritized during high-demand periods.

Scenario 2: Understanding Specifications and Load Ratings for 8.00 16 Tires

The Problem: Many B2B buyers may struggle to comprehend the technical specifications associated with 8.00 16 tires, such as load ratings, ply ratings, and tire types. This lack of understanding can lead to purchasing tires that do not meet the operational requirements of their equipment, potentially resulting in tire failure, accidents, and costly downtime. Buyers from regions with varying soil conditions and terrain also need to ensure they choose the right tread patterns for optimal performance.

The Solution: Buyers should invest time in educating themselves about tire specifications, particularly focusing on load indices and speed ratings relevant to their operations. Engaging with tire experts or consulting manufacturers’ representatives can provide valuable insights into the best options for their specific applications. Additionally, utilizing online resources and databases that outline the performance characteristics of different 8.00 16 tires can aid in making informed decisions. Implementing a checklist that includes equipment load requirements, expected terrain, and desired speed can streamline the selection process, ensuring that the tires purchased are suitable for their operational needs.

Scenario 3: Managing Cost vs. Quality in 8.00 16 Tire Purchases

The Problem: In a competitive market, B2B buyers often face the dilemma of balancing cost and quality when sourcing 8.00 16 tires. While lower-priced options might seem attractive, they can lead to higher long-term costs due to premature wear and increased maintenance needs. This is particularly critical in regions with challenging agricultural conditions, where tire durability directly impacts operational efficiency and cost-effectiveness.

The Solution: To navigate this challenge, buyers should adopt a value-based purchasing approach rather than simply focusing on upfront costs. This involves conducting a total cost of ownership (TCO) analysis that considers factors such as tire lifespan, performance, and maintenance needs. Buyers can also seek out tire brands known for their quality and durability, even if their initial price is higher. Engaging in bulk purchasing agreements can lead to discounts while ensuring that they are procuring tires that offer long-term reliability. Additionally, requesting samples or trials of different tire options can provide first-hand experience of performance, aiding in making more informed decisions about future purchases.

Strategic Material Selection Guide for 8.00 16

When selecting materials for 8.00 16 tires, it is essential to consider the specific requirements of agricultural and industrial applications. The materials used in tire construction significantly influence performance, durability, and overall cost. Below are analyses of four common materials used in the production of 8.00 16 tires, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Rubber in 8.00 16 Tires?

Rubber is the primary material used in tire manufacturing due to its excellent elasticity and resilience. It can withstand a wide range of temperatures and pressures, making it suitable for diverse environmental conditions. The rubber used in agricultural tires often features enhanced tread designs for improved traction on various terrains.

Pros: Rubber provides excellent grip and flexibility, ensuring a smooth ride and effective load-bearing capacity. It also offers good resistance to wear and tear, extending the tire’s lifespan.

Cons: The main drawback of rubber is its vulnerability to ozone and UV degradation, which can lead to cracking over time. Additionally, high-quality rubber can be costly, impacting overall production expenses.

Impact on Application: Rubber’s compatibility with various agricultural media makes it ideal for use in fields and rugged terrains. However, buyers must consider the local climate and environmental conditions, which may affect rubber performance.

How Does Steel Reinforcement Enhance 8.00 16 Tire Performance?

Steel belts are often incorporated into the tire structure to improve strength and puncture resistance. This material enhances the tire’s durability, allowing it to withstand heavy loads and rough surfaces.

Pros: Steel reinforcement significantly increases the tire’s load-bearing capacity and reduces the risk of punctures. It also improves stability during high-speed operations.

Cons: The addition of steel can increase the overall weight of the tire, which may affect fuel efficiency. Furthermore, manufacturing processes involving steel can be more complex and costly.

Impact on Application: Steel-reinforced tires are particularly beneficial for heavy-duty applications in agriculture and construction. International buyers should ensure compliance with local standards for steel quality and durability, as these can vary by region.

What Role Does Nylon Play in 8.00 16 Tire Construction?

Nylon is often used in the tire’s inner lining and sidewalls to enhance strength and flexibility. Its lightweight nature contributes to better fuel efficiency while maintaining structural integrity.

Pros: Nylon provides excellent resistance to abrasion and impacts, making it ideal for rough terrains. It also offers good heat dissipation, which is crucial during prolonged use.

Cons: Nylon can be more susceptible to chemical degradation compared to other materials, limiting its use in certain environments. Additionally, while it enhances performance, it may also increase manufacturing complexity.

Impact on Application: For international buyers, understanding the chemical compatibility of nylon with local agricultural chemicals is essential. Compliance with international standards for nylon quality can also influence selection.

How Does Natural vs. Synthetic Rubber Affect 8.00 16 Tires?

Natural rubber offers superior elasticity and resilience, while synthetic rubber provides better resistance to heat and aging. Many manufacturers use a blend of both to optimize performance.

Pros: Natural rubber is generally more durable and provides better traction, while synthetic rubber can withstand higher temperatures and resist degradation from environmental factors.

Cons: Natural rubber can be more expensive and less consistent in quality due to its dependence on agricultural factors. Synthetic rubber, while more stable, may not provide the same level of traction.

Impact on Application: Buyers should consider the specific agricultural practices in their region when selecting between natural and synthetic rubber. Different climates and soil types may dictate the best choice for tire performance.

Summary Table of Material Selection for 8.00 16 Tires

| Material | Typical Use Case for 8.00 16 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General agricultural applications | Excellent grip and flexibility | Vulnerable to UV degradation | Medium |

| Steel Reinforcement | Heavy-duty agricultural and industrial | Increased strength and puncture resistance | Increased weight and cost | High |

| Nylon | Inner lining and sidewalls | Good abrasion resistance and heat dissipation | Susceptible to chemical degradation | Medium |

| Natural/Synthetic Rubber | Diverse agricultural terrains | Optimal performance through blending | Cost variability and traction issues | Medium to High |

This guide serves as a valuable resource for international B2B buyers looking to make informed decisions about material selection for 8.00 16 tires, ensuring they meet both performance and compliance standards in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 8.00 16

What Are the Key Stages in the Manufacturing Process for 8.00 16 Tires?

The manufacturing process for 8.00 16 tires involves several critical stages, each designed to ensure high performance and durability.

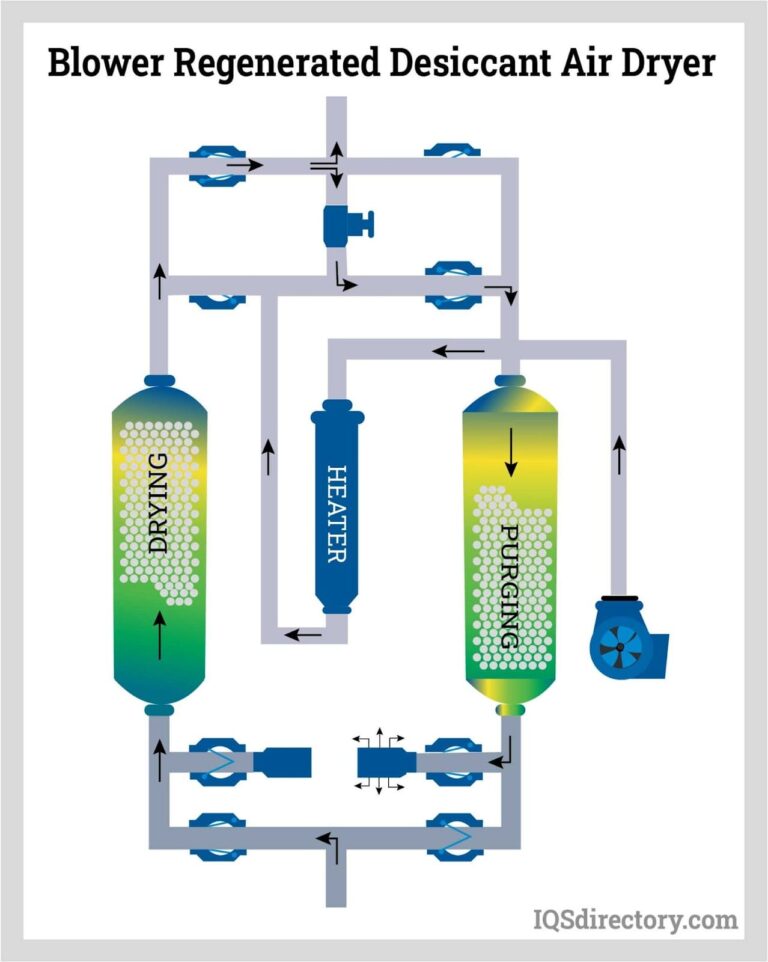

Material Preparation

The process begins with the selection of raw materials, including natural and synthetic rubber, steel belts, and fabric reinforcements. Each material is sourced based on specific performance characteristics, such as load capacity and weather resistance. Rubber compounds are created by mixing raw rubber with additives, such as carbon black and sulfur, to enhance strength and elasticity. This initial stage is crucial as it sets the foundation for the tire’s overall performance.

Forming

Once the materials are prepared, the next stage is forming, where the tire’s various components are shaped. This includes creating the tread, sidewalls, and inner linings. The rubber is heated and molded into the desired shapes using specialized machinery. This process often involves a series of presses and molds that ensure precise dimensions, crucial for maintaining tire performance under load.

Assembly

In the assembly stage, the formed components are combined to create the tire structure. This involves layering the tread, sidewalls, and steel belts. The layers are carefully aligned and bonded together using high-pressure techniques. The assembly process is vital for ensuring that the tire can withstand the stresses of heavy loads and rough terrain, particularly in agricultural and industrial applications.

Finishing

The final manufacturing stage is finishing, where the tires undergo curing. This process involves heating the assembled tire in a mold, allowing the rubber to vulcanize. This step is essential as it enhances the tire’s durability and performance characteristics. After curing, tires are inspected for defects and imperfections before they are ready for quality assurance testing.

What International Standards and Quality Assurance Practices Are Relevant to 8.00 16 Tires?

Quality assurance is paramount in tire manufacturing, particularly for B2B buyers looking for reliability and safety. Various international standards govern the production of tires, with ISO 9001 being one of the most recognized. This standard outlines a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

Industry-Specific Standards

In addition to ISO 9001, other industry-specific standards, such as the European CE marking and the American Petroleum Institute (API) standards, may apply. These certifications indicate that the tires meet specific safety and performance criteria, particularly for agricultural and industrial applications. For international buyers, especially those from regions like Africa, South America, and the Middle East, understanding these certifications is crucial for ensuring product quality.

What Are the Quality Control Checkpoints in Tire Manufacturing?

Quality control (QC) is an integral part of the tire manufacturing process, with several checkpoints established to ensure that each tire meets stringent performance standards.

Incoming Quality Control (IQC)

The first checkpoint is Incoming Quality Control (IQC), where raw materials are inspected upon arrival. This includes assessing the quality of rubber compounds, steel belts, and other components. Suppliers must provide certificates of compliance to verify that materials meet specified standards.

In-Process Quality Control (IPQC)

In-Process Quality Control (IPQC) is the next step, occurring throughout the manufacturing process. This involves regular inspections at various stages, such as after forming and assembly. Key metrics, including dimensions, weight, and visual defects, are monitored to ensure that each component adheres to quality specifications.

Final Quality Control (FQC)

Finally, Final Quality Control (FQC) is conducted before the tires are packaged and shipped. This comprehensive inspection includes dynamic testing for balance, uniformity, and performance under simulated conditions. Tires may undergo tests such as durability assessments and load capacity evaluations to ensure they meet the required standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in international markets, verifying a supplier’s quality control practices is essential for mitigating risk. Here are several methods to ensure that suppliers adhere to high-quality standards:

Audits and Certifications

Conducting supplier audits is one of the most effective ways to verify quality control practices. This can include on-site inspections where buyers assess the manufacturing processes, quality control measures, and compliance with international standards. Requesting certifications such as ISO 9001 or CE marking can also provide assurance that the supplier meets established quality benchmarks.

Quality Assurance Reports

B2B buyers should request regular quality assurance reports from suppliers. These reports should detail the results of IQC, IPQC, and FQC processes, including any defects found and corrective actions taken. Regular reporting fosters transparency and builds trust between buyers and suppliers.

Third-Party Inspections

Engaging third-party inspection agencies can further validate supplier quality. These independent organizations can conduct audits and testing, ensuring that products meet specified standards before shipment. This is particularly valuable for international buyers who may face challenges in assessing suppliers remotely.

What Quality Control Nuances Should International Buyers Consider?

International B2B buyers, especially from diverse regions like Europe, Africa, South America, and the Middle East, should be aware of specific nuances in quality control. Differences in regulatory requirements, testing standards, and cultural practices can impact product quality and compliance.

Understanding Regional Standards

Buyers should familiarize themselves with the regional standards that apply to tire manufacturing. For instance, European buyers may prioritize CE marking, while buyers in the Middle East may focus on compliance with local safety standards. Understanding these differences ensures that the products sourced meet local regulations and market expectations.

Language and Communication Barriers

Language barriers can also pose challenges in verifying quality control practices. Buyers should ensure clear communication with suppliers regarding quality expectations, testing procedures, and compliance documentation. Establishing a common language or utilizing translation services can help mitigate misunderstandings.

Conclusion

In conclusion, the manufacturing processes and quality assurance practices for 8.00 16 tires are complex yet essential for ensuring product reliability. By understanding these processes and actively engaging in quality verification, B2B buyers can make informed decisions that enhance their procurement strategies. Emphasizing quality assurance not only safeguards investments but also ensures that the tires perform optimally in demanding environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘8.00 16’

Introduction

This guide is designed to assist B2B buyers in sourcing 8.00-16 tires effectively. As an essential component for agricultural and industrial vehicles, ensuring you select the right tires can significantly impact operational efficiency and cost-effectiveness. This checklist outlines critical steps to streamline the procurement process, ensuring you make informed decisions.

Step 1: Define Your Technical Specifications

Establish clear technical requirements for the 8.00-16 tires you need. This includes load capacity, speed ratings, tread type, and whether you require tube-type or tubeless options. Defining these specifications upfront helps narrow down potential suppliers and ensures the tires meet your operational demands.

- Load Index: Consider the weight the tires need to support, typically indicated in pounds (e.g., 1356 lbs for load index 91).

- Speed Rating: Understand the maximum speed at which the tires can operate safely.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in 8.00-16 tires. Use online platforms, trade shows, and industry recommendations to compile a list of candidates. This step is crucial to ensure you are dealing with suppliers who have a proven track record.

- Supplier Reviews: Look for reviews or testimonials from other B2B buyers.

- Market Presence: Consider suppliers with a strong presence in your region, especially in Africa, South America, or Europe.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that potential suppliers have the necessary certifications and comply with industry standards. Certifications can indicate a commitment to quality and safety, which is vital for tire procurement.

- ISO Certifications: Look for ISO 9001 or similar certifications that demonstrate quality management.

- Safety Standards: Ensure compliance with local and international safety standards relevant to tire manufacturing.

Step 4: Request Samples and Specifications

Request samples or detailed specifications of the 8.00-16 tires you are considering. This allows you to assess the quality and suitability of the tires for your specific applications.

- Tread Design: Examine the tread design to ensure it aligns with your operational needs, such as traction and durability.

- Material Quality: Inquire about the materials used in the tire construction to ensure longevity and performance.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare pricing and payment terms. Look beyond the initial cost and consider total ownership costs, including shipping, warranties, and potential discounts for bulk purchases.

- Bulk Purchase Discounts: Ask about discounts for purchasing multiple tires.

- Financing Options: Explore financing options that may be available to ease cash flow.

Step 6: Negotiate Contract Terms

Before finalizing your order, negotiate the contract terms carefully. Ensure clarity on delivery timelines, payment terms, and return policies. A well-negotiated contract protects your interests and clarifies expectations.

- Delivery Schedules: Confirm delivery timelines and penalties for delays.

- Return Policies: Understand the conditions under which you can return or exchange tires.

Step 7: Monitor Delivery and Quality Assurance

Once the order is placed, closely monitor the delivery process and perform quality checks upon receipt. Ensuring the tires meet the agreed specifications is crucial to avoid future operational issues.

- Inspection Protocol: Develop a protocol for inspecting the tires upon delivery.

- Documentation: Keep all purchase documents and delivery receipts for record-keeping and future reference.

By following this checklist, B2B buyers can streamline the procurement of 8.00-16 tires, ensuring they select the right products that meet their operational needs and quality standards.

Comprehensive Cost and Pricing Analysis for 8.00 16 Sourcing

What Are the Key Cost Components for Sourcing 8.00 16 Tires?

When sourcing 8.00 16 tires, it is essential to consider the various cost components that contribute to the final price. The primary elements include:

- Materials: The cost of raw materials, such as rubber, fabric, and steel belts, plays a significant role. Fluctuations in the prices of these materials can directly impact the overall tire cost.

- Labor: Labor costs encompass wages for production workers involved in the manufacturing process. Regions with higher labor costs will naturally lead to increased pricing.

- Manufacturing Overhead: This includes indirect costs related to production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

- Tooling: Special tools and molds required for tire production represent a significant upfront investment. The cost of these tools is typically amortized over the volume produced, influencing the unit cost.

- Quality Control (QC): Implementing rigorous QC measures ensures that the tires meet safety and performance standards. While this adds to production costs, it is essential for long-term customer satisfaction and brand reputation.

- Logistics: Shipping and handling costs, especially for international transactions, must be factored in. These costs can vary widely based on distance, mode of transport, and shipping partner.

- Margin: Suppliers will add a profit margin on top of their costs, which can vary based on their business model and market conditions.

How Do Price Influencers Affect the Cost of 8.00 16 Tires?

Several factors can influence the pricing of 8.00 16 tires, particularly for international B2B buyers:

- Volume and Minimum Order Quantity (MOQ): Bulk purchases often result in lower per-unit costs. Negotiating higher volume orders can significantly improve pricing.

- Specifications and Customization: Customizing tires to meet specific requirements or certifications can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

- Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or DOT) can lead to increased prices but may also offer better performance and durability, impacting the total cost of ownership.

- Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products, reflecting their quality assurance and customer service.

- Incoterms: Understanding the terms of shipping and delivery is critical. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the final price and responsibility for logistics.

What Are the Best Buyer Tips for Negotiating 8.00 16 Tire Prices?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies for effective negotiation:

- Conduct Market Research: Understand current market rates and competitor pricing. This knowledge empowers buyers during negotiations and helps justify their expectations.

- Negotiate Terms: Beyond price, focus on securing favorable terms such as payment schedules, delivery timelines, and warranty conditions. These elements can greatly affect the overall cost-effectiveness of the purchase.

- Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with maintenance, performance, and potential downtime. Choosing higher-quality tires may involve a higher upfront cost but could save money in the long run through increased durability and efficiency.

- Consider Logistics and Delivery: International shipping can introduce significant costs and delays. Buyers should evaluate suppliers’ logistics capabilities and choose partners with reliable shipping options to avoid unexpected costs.

- Utilize Local Representatives: Engaging local representatives or consultants familiar with the regional market can provide insights into cost structures and negotiation practices, ultimately leading to better deals.

Disclaimer on Pricing

Prices for 8.00 16 tires can fluctuate based on market conditions, supplier changes, and other external factors. It is advisable to obtain multiple quotes and verify current pricing before making purchasing decisions.

Alternatives Analysis: Comparing 8.00 16 With Other Solutions

Understanding Alternatives to 8.00 16 Tires for B2B Buyers

When evaluating tire options for agricultural or industrial vehicles, the 8.00 16 tire offers a robust solution. However, several alternatives exist that may better suit specific operational needs or budget constraints. This section will compare the 8.00 16 tire against two viable alternatives: the 7.50-16 tire and the 9.50-16 tire. Each of these options has unique characteristics that may appeal to different segments of the market.

Comparison Table

| Comparison Aspect | 8.00 16 Tire | 7.50-16 Tire | 9.50-16 Tire |

|---|---|---|---|

| Performance | Good traction; load index of 91-95 | Moderate traction; load index of 88-91 | Superior traction; load index of 98 |

| Cost | $106.96 – $237.97 per tire | $95.00 – $150.00 per tire | $120.00 – $200.00 per tire |

| Ease of Implementation | Widely available; compatible with standard rims | Compatible with standard rims; moderate availability | Requires specific rim size; availability can vary |

| Maintenance | Low; regular inspections needed | Low; regular inspections needed | Moderate; more wear under heavy loads |

| Best Use Case | General agricultural use | Light agricultural tasks | Heavy-duty agricultural tasks |

Detailed Breakdown of Alternatives

7.50-16 Tire

The 7.50-16 tire is a suitable alternative for lighter agricultural tasks. It typically features a lower load index, which makes it ideal for lighter machinery or equipment. Its cost is generally lower than the 8.00 16, providing a budget-friendly option for businesses operating with limited resources. However, while it offers good performance for lighter loads, it may not provide the same level of traction or durability as the 8.00 16, especially in challenging terrains.

9.50-16 Tire

The 9.50-16 tire is designed for heavy-duty applications, offering superior traction and a higher load index. This makes it an excellent choice for more demanding agricultural tasks or for vehicles that regularly carry heavier loads. However, the cost can be higher than both the 8.00 16 and 7.50-16 tires, which might be a consideration for budget-conscious buyers. Additionally, the 9.50-16 may require specific rim sizes and have variable availability, which could complicate sourcing and replacement.

Conclusion: How to Choose the Right Tire for Your Needs

Selecting the right tire solution is critical for optimizing performance and cost-efficiency in agricultural and industrial applications. Buyers should carefully consider their specific operational needs, such as the types of vehicles they are using, the loads they typically carry, and their budget constraints. The 8.00 16 tire remains a strong contender for general use, but alternatives like the 7.50-16 and 9.50-16 tires offer unique benefits that could better align with particular operational requirements. By evaluating these factors, B2B buyers can make informed decisions that enhance their operational efficiency and financial sustainability.

Essential Technical Properties and Trade Terminology for 8.00 16

What are the Key Technical Properties of 8.00-16 Tires?

Understanding the technical specifications of 8.00-16 tires is crucial for international B2B buyers, especially those in agriculture and heavy machinery. Here are the essential properties to consider:

-

Load Index

The load index indicates the maximum weight a tire can support at its maximum inflation pressure. For 8.00-16 tires, typical load indices range from 88 to 95, equating to load capacities of approximately 1,235 to 1,521 pounds. This specification is vital for buyers to ensure that the tires can handle the loads required in agricultural or industrial applications without risk of failure. -

Speed Rating

The speed rating denotes the maximum speed a tire can safely maintain. Common ratings for 8.00-16 tires include A6 (up to 19 mph) and A8 (up to 25 mph). Understanding this rating is essential for operational efficiency, especially in agricultural settings where speed can impact productivity. -

Tread Depth

Tread depth affects traction and performance on different surfaces. In 8.00-16 tires, tread depths can vary, typically ranging from 26/32nds to 34/32nds. A deeper tread can provide better grip in muddy or uneven terrain, which is critical for agricultural tasks. -

Inflation Pressure

Proper inflation pressure is crucial for tire performance and longevity. For 8.00-16 tires, recommended pressures may vary from 28 to 45 PSI, depending on the load range and specific tire model. Incorrect inflation can lead to premature wear or tire failure, making this a key specification for maintenance planning. -

Load Range

The load range indicates the tire’s ply rating, which affects its strength and load-carrying capacity. For 8.00-16 tires, load ranges typically include C (6 Ply) and D (8 Ply). Understanding the load range helps buyers select the appropriate tire for their specific application needs, ensuring safety and performance. -

Sidewall Type

The sidewall type (e.g., tubeless or tube-type) impacts installation and maintenance. Tubeless tires are generally easier to maintain and less prone to punctures, while tube-type tires may offer certain advantages in specific agricultural applications. Knowing the sidewall type is essential for compatibility with existing equipment.

What are Common Trade Terms in the Tire Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to 8.00-16 tires:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the tire industry, OEM tires are those that come standard with vehicles or equipment. Understanding OEM specifications is important for buyers looking to replace tires on existing machinery. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For 8.00-16 tires, MOQs can vary significantly between suppliers and affect purchasing decisions. Buyers should assess their needs against MOQs to avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers, issuing an RFQ for 8.00-16 tires can facilitate competitive pricing and help identify the best supplier based on cost and delivery terms. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, delivery, and risk. Familiarity with these terms is crucial for B2B transactions involving 8.00-16 tires, as they clarify who is responsible for costs and liability at various stages of the shipping process. -

Tread Pattern

The tread pattern refers to the design on the tire’s surface that affects traction, performance, and handling. Different tread patterns are suited for various applications, such as agricultural or off-road use. Buyers should choose tires with appropriate tread patterns for their operational needs. -

Ply Rating

Ply rating indicates the strength and load capacity of a tire. Higher ply ratings generally mean greater load-carrying capabilities. Understanding ply ratings is essential for selecting the right tire for specific machinery and ensuring operational efficiency.

By grasping these technical specifications and industry terms, international B2B buyers can make informed decisions when purchasing 8.00-16 tires, optimizing their operations and ensuring safety in their applications.

Navigating Market Dynamics and Sourcing Trends in the 8.00 16 Sector

What Are the Key Market Dynamics and Trends Influencing the 8.00 16 Sector?

The global market for 8.00 16 tires, primarily used in agricultural applications, is witnessing significant transformation driven by various factors. As economies in Africa, South America, the Middle East, and Europe (notably Germany and Vietnam) evolve, so too does the demand for durable, high-performance tires that can withstand diverse environmental conditions. One key trend is the increasing preference for tires that offer enhanced traction and longevity, as agricultural activities expand and mechanization increases.

Digital transformation is also reshaping the sourcing landscape. B2B buyers are increasingly leveraging online platforms for tire procurement, seeking transparency in pricing, availability, and performance metrics. This shift not only streamlines the purchasing process but also fosters competition among suppliers, driving down costs and improving service delivery. Furthermore, the rise of data analytics in supply chain management enables buyers to make informed decisions based on predictive insights, enhancing inventory management and reducing lead times.

Emerging markets are prioritizing local sourcing to mitigate risks associated with global supply chain disruptions. This is particularly relevant for the 8.00 16 sector, where local suppliers are often better positioned to provide timely support and tailored solutions. The integration of sustainable practices in sourcing is also gaining traction, with buyers increasingly demanding eco-friendly products that align with their corporate social responsibility goals.

How Is Sustainability Shaping Sourcing Practices in the 8.00 16 Sector?

Sustainability is becoming a cornerstone of B2B procurement strategies, particularly in the agricultural tire sector. The environmental impact of tire production and disposal has prompted buyers to seek suppliers who prioritize sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and eco-friendly disposal methods.

Ethical sourcing is also gaining prominence, with businesses increasingly scrutinizing their supply chains to ensure compliance with environmental and labor standards. Certifications such as the Global Organic Textile Standard (GOTS) and ISO 14001 for environmental management are becoming essential credentials for suppliers. By partnering with certified manufacturers, B2B buyers can enhance their brand reputation and appeal to environmentally conscious consumers.

Moreover, the integration of ‘green’ technologies, such as biodegradable materials and advanced tire recycling processes, is becoming a competitive differentiator. Buyers who prioritize these innovations not only contribute to environmental sustainability but also position themselves as leaders in their respective markets. This alignment with sustainable practices is increasingly seen as a driver of profitability, as it opens doors to new customer segments and enhances brand loyalty.

What Is the Historical Context of the 8.00 16 Tire Market?

The evolution of the 8.00 16 tire market traces back to the early 20th century when agricultural mechanization began to take hold. Initially, tires were crafted from solid rubber, which offered limited performance on uneven terrains. As agricultural practices modernized, the demand for more versatile and durable tires led to the development of the bias-ply construction, which provided improved traction and load-bearing capabilities.

The introduction of radial tires in the latter half of the century further revolutionized the sector, offering enhanced durability and fuel efficiency. Today, the 8.00 16 tire category is synonymous with reliability and performance, catering to a diverse range of agricultural machinery. As market dynamics continue to evolve, the focus on innovation, sustainability, and ethical sourcing is expected to shape the future trajectory of the sector, providing ample opportunities for B2B buyers to engage with suppliers who align with their values and operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of 8.00 16

-

How do I select the right 8.00-16 tires for my agricultural equipment?

Choosing the right 8.00-16 tires involves considering the specific application of your equipment, load requirements, and terrain conditions. Focus on the tire’s load index, which indicates its load-carrying capacity, and the ply rating, which determines the tire’s strength and durability. For agricultural use, opt for tires designed for traction and stability, like R-1 or R-4 tread patterns. Additionally, consider the tire’s inflation pressure and tread depth, as these factors significantly impact performance and longevity. -

What factors should I consider when sourcing 8.00-16 tires internationally?

When sourcing 8.00-16 tires internationally, evaluate the supplier’s reputation, product quality, and compliance with international standards. Check for certifications and customer reviews to gauge reliability. Understand the logistics involved, including shipping times, customs duties, and potential delays. It’s also essential to verify the supplier’s capacity to meet your quantity needs and any specific tire specifications you might require. Engaging with suppliers who have experience in your target market can also provide insights into local regulations and preferences. -

What are the typical minimum order quantities (MOQ) for 8.00-16 tires?

Minimum order quantities for 8.00-16 tires can vary significantly based on the supplier and region. Generally, MOQs can range from 10 to 100 tires. Suppliers may offer more favorable pricing for larger orders, so it’s beneficial to inquire about bulk discounts. Always confirm the MOQ with your supplier before placing an order, as this can impact your overall budget and inventory management. Additionally, consider logistics and storage capabilities when determining the optimal order quantity. -

What payment terms are common for international tire purchases?

Common payment terms for international tire purchases include advance payment, letters of credit, and payment upon delivery. Suppliers may require a deposit upfront, typically 30% to 50% of the total order value, with the balance due before shipping or upon delivery. Establishing clear payment terms is crucial to avoid disputes and ensure smooth transactions. Consider using secure payment methods and platforms that provide buyer protection, especially when dealing with new suppliers. -

How can I ensure the quality of the 8.00-16 tires I am purchasing?

To ensure quality when purchasing 8.00-16 tires, request samples or product specifications from suppliers. Look for certifications such as ISO, DOT, or ECE, which indicate compliance with safety and performance standards. Conduct due diligence by researching supplier reviews and previous customer experiences. If feasible, arrange for third-party inspections to verify tire quality before shipment. Establishing a quality assurance process can help mitigate risks associated with subpar products. -

What are the logistics considerations when importing 8.00-16 tires?

Logistics considerations for importing 8.00-16 tires include selecting reliable shipping methods, understanding customs regulations, and planning for potential delays. Evaluate shipping options such as sea freight or air freight based on cost and urgency. Be aware of import duties and taxes that may apply in your country. Collaborating with a freight forwarder experienced in tire shipments can streamline the process and help navigate any logistical challenges. -

Can I customize my order of 8.00-16 tires?

Many suppliers offer customization options for 8.00-16 tires, including specific tread patterns, sidewall designs, and load ratings. Customization often requires larger minimum orders and may involve additional costs. Discuss your specific needs with potential suppliers to understand their capabilities and the lead times involved. Custom tires can enhance performance for specialized applications, so it’s worth exploring these options if you have unique requirements. -

What are the common applications for 8.00-16 tires in agriculture?

8.00-16 tires are commonly used in various agricultural applications, particularly in tractors, harvesters, and other farm equipment. They are designed for optimal traction on soft and uneven terrains, making them suitable for plowing, tilling, and transporting goods. These tires also provide stability and load-bearing capacity essential for heavy agricultural machinery. Understanding the specific demands of your equipment and operations will help you select the most appropriate tire model for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 8.00 16 Manufacturers & Suppliers List

1. Titan – Titan Hi-Traction Lug R-1 8.00-16 91G C

Domain: simpletire.com

Registered: 2009 (16 years)

Introduction: Tire Size: 8.00-16

Available Tires: 11

Tire Types: Farm & Agricultural

Free Shipping: Yes

Easy Returns: Yes (Unmounted tires within 30 days)

Discounts: Up to 40% off during Labor Day Sale

Key Products:

1. Titan Hi-Traction Lug R-1 8.00-16 91G C

– Price: $237.97

– Load Index: 1356 lbs (91)

– Max Speed: 56 MPH (G)

– Load Range: C (6 Ply)

– Tread Depth: 31/32nds

– Inflation Pressure…

2. Deestone – D413 Duramax AG

Domain: tiremart.com

Registered: 2000 (25 years)

Introduction: [{‘brand’: ‘Deestone’, ‘model’: ‘D413 Duramax AG’, ‘size’: ‘8-16’, ‘load_index’: ’91’, ‘load_range’: ‘6 Ply’, ‘tread_depth’: ’26/32′, ‘speed_rating’: ‘A6’, ‘price’: ‘$108.99’, ‘overall_diameter’: ‘31.1’, ‘load_capacity’: ‘1356 lbs’}, {‘brand’: ‘Carlisle’, ‘model’: ‘Farm Specialist Tractor Bias’, ‘size’: ‘8-16’, ‘load_index’: ’91’, ‘load_range’: ‘8 Ply’, ‘tread_depth’: ‘N/A’, ‘speed_rating’: ‘A8’, …

3. Carlstar – Carlisle Farm Specialist TB TL Tire

Domain: gallaghertire.com

Registered: 2000 (25 years)

Introduction: {“item_name”:”Carlisle Farm Specialist Tb TL Tire”,”size”:”8-16″,”item_number”:”6X17403″,”availability”:”6″,”type”:”TIRE ONLY”,”shipping”:”Free ground shipping”,”brand”:”CARLSTAR (FORMERLY CARLISLE)”,”construction”:”BIAS”,”industry_code”:”R1″,”load_index”:”95″,”load_speed_index”:”95A6″,”max_load_capacity_lbs”:”1520″,”max_psi”:”42″,”mounted_diameter_inch”:”31.1″,”ply_load_index_star_rating”:”8″,”ri…

4. Case Colt Ingersoll – 8×16 Rear Turf Tire Replacement

Domain: casecoltingersoll.com

Registered: 2010 (15 years)

Introduction: 8×16 Rear TURF Tire Replacement; Standard 8×16 turf tires are discontinued; Difficulty in direct comparisons due to different measurement standards; Concerns about tire plies affecting ride quality and bead retention at 8 PSI; Alternative size discussed: 245/75, but concerns about width; Closest size match suggested: 215/65R16 or 215/75R16; Measurements taken: Diameter of 31.12 inches, Width of 9….

5. Morrow Tire – GR/KR-16 Air-Loc Universal Inner Tube

Domain: morrowtire.com

Registered: 2000 (25 years)

Introduction: This company, Morrow Tire – GR/KR-16 Air-Loc Universal Inner Tube, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. BKT Tire – 8-16 BKT TR-144 Farm Tractor Tire

Domain: petestirestore.com

Registered: 2010 (15 years)

Introduction: {“Product Name”: “8-16 BKT TR-144 Farm Tractor Tire (6 Ply) (TT)”, “Part Number”: “94004720”, “Manufacturer”: “BKT Tire”, “Tread Design”: “R-1”, “Load Range”: “C”, “Ply Rating”: “6 Ply”, “Recommended Rim Width”: “6 Inches”, “Section Width”: “7.9 Inches”, “Overall Diameter”: “30.9 Inches”, “Static Loaded Radius”: “14.4 Inches”, “Rolling Circumference”: “92.9 Inches”, “Tread Depth”: “33 (32nds)”, “L…

Strategic Sourcing Conclusion and Outlook for 8.00 16

How Can Strategic Sourcing Enhance Your Tire Procurement Process?

In conclusion, strategic sourcing for 8.00 16 tires presents significant advantages for international B2B buyers. By understanding the specific needs of your agricultural or industrial applications, you can select from a diverse range of high-quality tires that cater to various load capacities, speed ratings, and tread designs. Utilizing platforms that offer competitive pricing, financing options, and easy return policies can streamline your procurement process, ensuring you get the best value.

Moreover, effective strategic sourcing enables you to build relationships with reliable suppliers, enhancing your supply chain resilience. This is particularly vital for businesses in regions such as Africa, South America, the Middle East, and Europe, where local market conditions can vary significantly.

As you look ahead, consider leveraging data-driven insights to inform your purchasing decisions. Embrace the opportunity to negotiate better terms and explore bulk buying options. By prioritizing strategic sourcing, you position your business for sustainable growth and operational efficiency. Take action today—review your tire procurement strategy and explore new partnerships that can drive your business forward.