Everything You Need to Know About 5W High Power Led Chip Sourcing in 2025

Introduction: Navigating the Global Market for 5w high power led chip

In the rapidly evolving landscape of lighting technology, sourcing 5W high power LED chips presents both opportunities and challenges for international B2B buyers. With increasing demand for energy-efficient and sustainable lighting solutions across diverse sectors—such as industrial, commercial, and residential—companies must navigate a complex market filled with various product offerings, specifications, and suppliers. This guide serves as a comprehensive resource, addressing critical considerations like the types of 5W high power LED chips available, their applications, and best practices for supplier vetting.

Understanding the intricacies of the LED chip market is crucial for businesses looking to make informed purchasing decisions. This guide will delve into the specifications and performance metrics that matter most, helping you evaluate options based on lumens, voltage, and current requirements. Additionally, we will cover pricing structures, potential cost-saving strategies, and insights into the regulatory landscape affecting imports and exports in regions such as Africa, South America, the Middle East, and Europe, including Germany and Brazil.

By equipping you with actionable insights and expert knowledge, this guide empowers your organization to select the right 5W high power LED chips that align with your operational needs and sustainability goals. Navigate the global market with confidence, ensuring that your investments yield optimal performance and value.

Understanding 5w high power led chip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| COB LED Chip | Compact design, high luminous efficacy, low thermal resistance | Industrial lighting, street lights, downlights | Pros: High efficiency, space-saving. Cons: Requires specialized heat sinks. |

| SMD LED Chip | Surface mount technology, flexible designs, various color temperatures | Decorative lighting, signage, retail displays | Pros: Versatile, easy installation. Cons: Lower output compared to COB. |

| High-Voltage LED Chip | Operates at higher voltages, reduced current draw | Floodlights, outdoor lighting solutions | Pros: Reduced wiring complexity, energy-efficient. Cons: Higher initial cost. |

| Multi-Chip LED Module | Multiple chips combined for enhanced performance | Commercial lighting, architectural applications | Pros: High brightness, uniform light distribution. Cons: More complex installation. |

| Tunable White LED Chip | Adjustable color temperature, remote control options | Smart lighting, mood lighting | Pros: Customizable lighting environments, energy-saving. Cons: Requires compatible control systems. |

What are the characteristics of COB LED Chips?

COB (Chip-on-Board) LED chips are recognized for their compact design and high luminous efficacy, making them a popular choice in various lighting applications. They consist of multiple LED chips packed closely together on a single substrate, which allows for superior thermal management and higher light output. B2B buyers often favor COB chips for industrial lighting, street lights, and downlights due to their energy efficiency and space-saving advantages. However, it is crucial to consider that COB LEDs require specialized heat sinks to maintain optimal performance and longevity.

How do SMD LED Chips compare in versatility?

SMD (Surface-Mounted Device) LED chips stand out for their flexibility in design and application. They are widely used in decorative lighting, signage, and retail displays due to their ability to be mounted on various surfaces and available in multiple color temperatures. SMD chips are easy to install and can be adapted to different environments, making them an attractive option for many businesses. However, while they offer versatility, their light output is generally lower than that of COB chips, which may be a consideration for buyers seeking high-intensity lighting solutions.

What advantages do High-Voltage LED Chips offer?

High-Voltage LED chips operate at higher voltages, allowing for reduced current draw and less wiring complexity. This feature makes them ideal for applications such as floodlights and outdoor lighting solutions, where long runs of wiring can be cumbersome. B2B buyers appreciate these chips for their energy efficiency and lower operating costs over time. However, the initial investment may be higher compared to standard chips, which is an important factor to evaluate during the purchasing process.

Why consider Multi-Chip LED Modules for commercial applications?

Multi-Chip LED modules combine several chips to enhance performance and provide high brightness, making them suitable for commercial lighting and architectural applications. These modules ensure uniform light distribution, which is essential for creating visually appealing environments. While they deliver exceptional performance, the complexity of installation and potentially higher costs could be a drawback for some buyers, necessitating careful consideration of installation capabilities and budget constraints.

How do Tunable White LED Chips enhance lighting control?

Tunable White LED chips offer unique features that allow users to adjust color temperatures and create customized lighting environments. This adaptability is especially beneficial for smart lighting applications and mood lighting setups. B2B buyers value the energy-saving potential and the ability to create various atmospheres with a single lighting solution. However, it is essential to ensure that the necessary control systems are in place to fully leverage these capabilities, which may add to the overall project costs.

Key Industrial Applications of 5w high power led chip

| Industry/Sector | Specific Application of 5w high power led chip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Industrial Lighting | Used in high-efficiency industrial lighting systems for factories and warehouses. | Enhances visibility and safety, reducing accidents and improving productivity. | Ensure compliance with local regulations and energy efficiency standards. |

| Retail Lighting | Integrated into display and accent lighting for retail environments. | Attracts customers and enhances product visibility, driving sales. | Consider color rendering index (CRI) for optimal product display. |

| Road and Street Lighting | Implemented in streetlights and road illumination solutions. | Provides safer public spaces and reduces energy costs with long-lasting performance. | Check for durability against weather conditions and energy consumption metrics. |

| Architectural Lighting | Utilized in architectural features and façade lighting. | Enhances aesthetic appeal, allowing for creative design while improving night-time visibility. | Focus on customization options for color temperature and beam angle. |

| Medical Lighting | Employed in surgical and examination lighting. | Provides clear visibility for medical professionals, ensuring patient safety and precise procedures. | Prioritize low heat emission and energy efficiency to meet healthcare standards. |

How is the 5w High Power LED Chip Used in Industrial Lighting?

In industrial settings, the 5w high power LED chip is crucial for creating high-efficiency lighting systems that illuminate large areas such as factories and warehouses. These chips provide bright, consistent light that enhances visibility, thereby reducing the risk of workplace accidents and improving overall productivity. International buyers should focus on sourcing chips that comply with local energy efficiency regulations and standards to ensure long-term operational cost savings.

What Role Does the 5w LED Chip Play in Retail Lighting Solutions?

Retail environments benefit significantly from the integration of 5w high power LED chips in display and accent lighting. These chips enhance product visibility, making items more attractive to customers and ultimately driving sales. For businesses in regions like Europe and South America, it is essential to consider the color rendering index (CRI) when sourcing these chips, as a higher CRI can make products appear more vibrant and appealing.

How Can 5w LED Chips Improve Road and Street Lighting?

The implementation of 5w high power LED chips in road and street lighting solutions offers substantial benefits, including improved public safety and reduced energy costs. These chips provide bright, reliable lighting that enhances visibility on roads, helping to prevent accidents. Buyers should prioritize durability and energy consumption metrics when sourcing these chips, especially in regions with varying weather conditions, to ensure longevity and performance.

What Advantages Do 5w High Power LED Chips Offer in Architectural Lighting?

In the realm of architectural lighting, 5w high power LED chips are used to highlight structural features and façades, enhancing the aesthetic appeal of buildings. These chips allow for creative design possibilities while improving night-time visibility. Buyers should focus on customization options, such as color temperature and beam angle, to meet specific design needs and preferences in different markets, including Africa and the Middle East.

How are 5w High Power LED Chips Utilized in Medical Lighting?

5w high power LED chips are critical in medical lighting applications, particularly in surgical and examination settings. They provide bright, clear illumination that is essential for medical professionals during procedures, ensuring patient safety and precision. When sourcing for this application, it is vital to prioritize chips that emit low heat and meet energy efficiency standards, as these factors are crucial in healthcare environments.

3 Common User Pain Points for ‘5w high power led chip’ & Their Solutions

Scenario 1: Inconsistent Brightness and Quality Issues in LED Applications

The Problem: B2B buyers often encounter significant variations in brightness and quality when integrating 5W high power LED chips into their products. This inconsistency can stem from different manufacturing standards, leading to discrepancies in lumens output and color temperature. Such issues not only affect the performance of the final product but also tarnish the brand’s reputation, resulting in customer dissatisfaction and increased return rates. For manufacturers in regions such as Africa and South America, where quality assurance processes may not be as robust, this problem is particularly pronounced.

The Solution: To mitigate these issues, buyers should source 5W high power LED chips from reputable suppliers who adhere to stringent quality control measures and have certifications, such as CE or RoHS. Implementing a thorough supplier evaluation process can ensure consistency in quality. Additionally, conducting in-house testing of LED chips for brightness and color accuracy before mass integration is vital. This can include using colorimeters and lumen meters to assess performance under various operational conditions. Buyers should also consider establishing long-term partnerships with suppliers for better consistency and communication about product specifications.

Scenario 2: High Thermal Management Costs Affecting Profit Margins

The Problem: Another common challenge faced by B2B buyers is the high thermal management costs associated with 5W high power LED chips. These chips generate significant heat, which necessitates effective heat dissipation solutions to maintain performance and longevity. In many cases, inadequate thermal management can lead to premature failure of the LEDs, resulting in increased warranty claims and repair costs, ultimately impacting profit margins.

The Solution: To address this, buyers should prioritize the integration of high-quality heat sinks and thermal interface materials (TIM) when sourcing 5W high power LED chips. Selecting components that have been optimized for thermal conductivity can enhance heat dissipation significantly. Additionally, investing in thermal simulation software during the design phase can help identify potential hotspots and allow for effective redesign before production. Collaborating with thermal management experts can also lead to innovative solutions that minimize costs while ensuring the reliability of the LED products.

Scenario 3: Complicated Installation and Compatibility Issues

The Problem: B2B buyers often face complications during the installation of 5W high power LED chips, especially when integrating them into existing systems or fixtures. This can lead to increased labor costs and project delays, as installers may struggle with compatibility issues, whether related to the power supply, wiring configurations, or mounting solutions. Such challenges can be particularly detrimental for businesses aiming to meet tight deadlines or scale production efficiently.

The Solution: To streamline the installation process, it is crucial for buyers to choose 5W high power LED chips that come with detailed installation guidelines and compatibility specifications. Collaborating closely with manufacturers to understand the full range of compatible drivers and heat sinks can help simplify the installation process. Additionally, investing in modular systems or standardized components can reduce complexity. Training sessions for installation teams on best practices and common pitfalls can also enhance efficiency and reduce errors during implementation, leading to smoother project execution.

Strategic Material Selection Guide for 5w high power led chip

What Are the Most Common Materials for 5W High Power LED Chips?

The selection of materials for 5W high power LED chips is crucial for ensuring optimal performance, durability, and compliance with international standards. Below, we analyze four commonly used materials in the manufacturing of these LED chips, emphasizing their properties, advantages, disadvantages, and considerations for international buyers.

1. Silicon (Si)

Key Properties:

Silicon is a semiconductor material with excellent thermal conductivity and a wide bandgap, allowing it to operate efficiently at high temperatures. It has a melting point of about 1,414°C, making it suitable for high-power applications.

Pros & Cons:

Silicon is relatively inexpensive and widely available, which contributes to lower manufacturing costs. However, its brittleness can lead to challenges in handling and assembly. Additionally, while silicon is effective in many applications, it may not perform as well as other materials in extreme conditions.

Impact on Application:

Silicon is compatible with various electronic applications, including lighting and display technologies. However, it may not be suitable for environments with high humidity or corrosive elements.

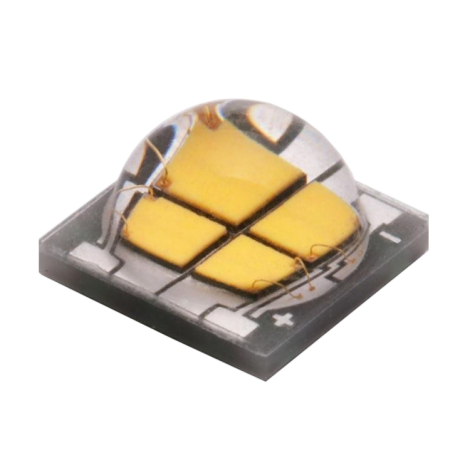

Illustrative image related to 5w high power led chip

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and JIS for semiconductor materials. This is particularly relevant in regions like Europe and the Middle East, where regulatory requirements can be stringent.

2. Gallium Nitride (GaN)

Key Properties:

Gallium Nitride is a wide-bandgap semiconductor that allows for high efficiency and high-temperature operation, with a thermal conductivity of about 1.5 W/mK. It can withstand high voltages and is resistant to radiation.

Pros & Cons:

GaN offers superior performance in terms of efficiency and thermal management, making it ideal for high-power applications. However, it is more expensive to produce compared to silicon and requires more complex manufacturing processes.

Impact on Application:

Due to its high efficiency and thermal stability, GaN is particularly suitable for applications in harsh environments, including outdoor lighting and industrial settings.

Considerations for International Buyers:

Buyers in regions like Africa and South America should consider the availability of GaN and its associated costs. Additionally, compliance with local and international standards is essential to ensure product reliability and safety.

3. Aluminum Nitride (AlN)

Key Properties:

Aluminum Nitride features excellent thermal conductivity (approximately 200 W/mK) and high thermal stability, making it suitable for high-power LED applications. It also has a high dielectric strength.

Pros & Cons:

AlN is highly effective in dissipating heat, which enhances LED performance and longevity. However, it is more costly than silicon and can be challenging to manufacture, leading to higher overall product costs.

Impact on Application:

The thermal management properties of AlN make it ideal for applications requiring efficient heat dissipation, such as automotive and aerospace lighting.

Considerations for International Buyers:

Buyers should be aware of the higher costs associated with AlN and ensure that suppliers can meet international material standards, particularly in Europe and Germany, where quality assurance is critical.

4. Copper (Cu)

Key Properties:

Copper is widely recognized for its excellent electrical conductivity and thermal management properties. It has a melting point of 1,085°C, making it suitable for high-temperature applications.

Pros & Cons:

Copper is relatively inexpensive and easy to work with, allowing for efficient manufacturing processes. However, it is prone to corrosion and oxidation, which can affect long-term performance.

Impact on Application:

Copper is commonly used in LED chip packaging and heat sinks, enhancing thermal performance. However, its susceptibility to corrosion may limit its use in certain environments.

Considerations for International Buyers:

International buyers should consider the corrosion resistance of copper in their specific applications, especially in humid or corrosive environments typical in regions like Africa and South America. Compliance with relevant standards is also essential for ensuring product quality.

Summary Table

| Material | Typical Use Case for 5W High Power LED Chip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon | General LED applications | Low cost, widely available | Brittle, less effective in extreme conditions | Low |

| Gallium Nitride | High-efficiency lighting | High efficiency, thermal stability | High production cost, complex manufacturing | High |

| Aluminum Nitride | Automotive and aerospace lighting | Excellent heat dissipation | Higher cost, challenging to manufacture | Medium |

| Copper | LED chip packaging and heat sinks | Excellent conductivity and low cost | Prone to corrosion and oxidation | Low |

This strategic material selection guide provides valuable insights for B2B buyers in diverse markets, helping them make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 5w high power led chip

What Are the Main Stages in the Manufacturing Process of 5W High Power LED Chips?

The manufacturing process for 5W high power LED chips is intricate and involves several stages, each critical to ensuring the final product meets industry standards for performance and reliability. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing is the preparation of raw materials, primarily semiconductor wafers, which are typically made from materials like gallium nitride (GaN). This stage involves the careful selection of high-quality materials to ensure optimal performance. The wafers undergo cleaning and etching processes to remove impurities and prepare them for the next stage.

Forming

In the forming stage, the cleaned wafers are processed through photolithography and etching to create the microstructures that will form the LED chip. This process involves applying a photosensitive material to the wafer, exposing it to light to create a pattern, and then etching away the unprotected areas. Techniques such as metal deposition are also employed to create the necessary electrical contacts.

Assembly

The assembly stage involves attaching the LED chips to substrates, often using techniques like die bonding and wire bonding. In die bonding, the chip is attached to a heat sink or PCB (printed circuit board) using a thermally conductive adhesive. Wire bonding connects the chip to the circuit board, ensuring electrical conductivity. This stage is crucial as it significantly affects thermal management and the overall efficiency of the LED.

Finishing

Finally, the finishing stage includes encapsulation, where a protective layer is applied to the chip to safeguard against environmental factors. This may involve the use of silicone or epoxy. The chips are then subjected to a series of tests to ensure they meet performance specifications before being packaged for shipment.

How Is Quality Assurance Implemented in the Manufacturing of 5W High Power LED Chips?

Quality assurance (QA) is a vital component of the manufacturing process for 5W high power LED chips, ensuring that the final products meet international standards and customer expectations.

What International Standards Govern Quality Assurance?

Manufacturers often adhere to international standards such as ISO 9001, which provides a framework for quality management systems. Compliance with CE certification is also common, particularly for products sold in Europe, indicating conformity with health, safety, and environmental protection standards. Other relevant certifications may include RoHS (Restriction of Hazardous Substances) and IEC (International Electrotechnical Commission) standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before they enter the production line.

- In-Process Quality Control (IPQC): Conducted during manufacturing, this phase includes regular checks at various stages, such as after forming and assembly, to identify defects or deviations in real-time.

- Final Quality Control (FQC): Before packaging, the final products undergo rigorous testing to validate their performance against specifications, including brightness, color temperature, and thermal management.

What Common Testing Methods Are Used?

Testing methods for LED chips include:

- Photometric Testing: Measures the light output and efficiency of the LED chip.

- Thermal Testing: Assesses the heat dissipation capability to ensure the chip operates within safe temperature limits.

- Electrical Testing: Verifies electrical performance, including voltage and current characteristics.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability and compliance with local regulations.

What Are Effective Ways to Verify Quality Control?

Buyers can employ several strategies to verify supplier QC:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, processes, and QC measures in place. This can include reviewing documentation and witnessing the production process firsthand.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, testing results, and any certifications obtained. These documents can help buyers evaluate the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing processes and product quality. This can be particularly useful for buyers unfamiliar with local suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is essential for international B2B buyers. Different regions may have specific regulatory requirements and standards that must be adhered to.

Regional Compliance Considerations

– Africa: Buyers should be aware of local certifications and standards that may differ significantly from those in Europe or the Americas. Ensuring compliance with regional regulations can help avoid legal issues and ensure smooth importation.

-

South America: Many countries in South America have unique import regulations and certification requirements. It’s crucial for buyers to understand these to ensure products can be marketed and sold without complications.

-

Middle East and Europe: Buyers in these regions often have stringent quality expectations. Ensuring that suppliers can meet ISO and CE certification requirements is vital for market entry.

By considering these factors and engaging in thorough due diligence, B2B buyers can ensure they partner with reputable suppliers that prioritize quality assurance in the manufacturing of 5W high power LED chips.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘5w high power led chip’

Introduction

In the rapidly evolving market of LED technology, sourcing high-quality 5W high power LED chips is crucial for manufacturers and distributors aiming to deliver efficient lighting solutions. This checklist serves as a practical guide to help B2B buyers navigate the sourcing process, ensuring they procure components that meet their specific needs and standards.

Illustrative image related to 5w high power led chip

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify the technical specifications required for your application. Consider factors such as brightness (measured in lumens), voltage, and current ratings. Having well-defined specifications helps streamline the selection process and ensures compatibility with existing systems.

- Example Specifications:

- Power: 5W

- Voltage: 15-17V

- Current: 240-260mA

Step 2: Identify Your Application Needs

Understanding the intended application of the 5W LED chips is essential. Different applications, such as industrial lighting, automotive, or consumer electronics, may have varying requirements regarding brightness, durability, and energy efficiency.

- Key Considerations:

- Will the LEDs be used indoors or outdoors?

- Are there specific environmental conditions (e.g., humidity, temperature) to consider?

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your quality and delivery requirements. Request company profiles, certifications, and references from other buyers in similar industries or regions. This assessment will help you gauge their reliability and commitment to quality.

- What to Look For:

- ISO certifications or other relevant quality standards.

- Positive customer reviews and case studies.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the 5W LED chips from shortlisted suppliers. Testing samples allows you to evaluate performance metrics such as brightness, heat dissipation, and color rendering index (CRI) under real-world conditions.

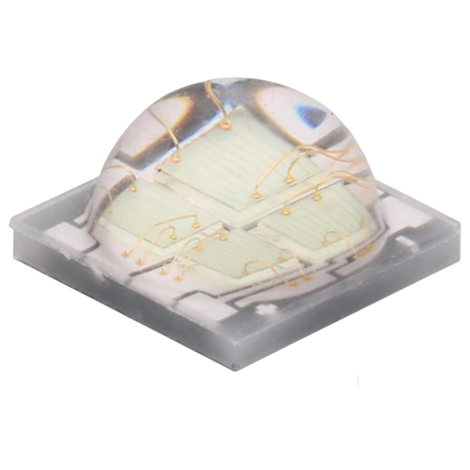

Illustrative image related to 5w high power led chip

- Testing Criteria:

- Measure lumens output against specifications.

- Assess thermal performance to prevent overheating.

Step 5: Check Compliance with Industry Standards

Ensure that the LED chips comply with relevant industry standards and regulations, such as CE, RoHS, or UL certifications. Compliance not only guarantees product safety but also enhances marketability in regions with strict regulations.

- Verification Steps:

- Request documentation proving compliance.

- Confirm that the supplier has a quality control process in place.

Step 6: Negotiate Terms and Pricing

Engage in discussions with potential suppliers about pricing, payment terms, and delivery timelines. Clear communication can lead to better deals and ensure that both parties have aligned expectations.

- Negotiation Tips:

- Inquire about bulk purchase discounts.

- Discuss warranty and return policies.

Step 7: Finalize the Order and Monitor Shipment

Once you’ve selected a supplier and agreed on terms, finalize the order. Monitor the shipment process to ensure timely delivery, and maintain open communication with the supplier to address any potential issues that may arise.

- Post-Order Actions:

- Confirm shipment tracking details.

- Prepare for receipt inspection upon delivery to ensure quality standards are met.

By following this checklist, B2B buyers can confidently navigate the sourcing process for 5W high power LED chips, ensuring they select the best products for their needs while establishing strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 5w high power led chip Sourcing

What Are the Key Cost Components in Sourcing 5W High Power LED Chips?

When sourcing 5W high power LED chips, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of semiconductor materials directly impacts the performance and longevity of LED chips. High-grade materials may lead to higher initial costs but can reduce failure rates and enhance efficiency in the long run.

-

Labor: Labor costs vary significantly across regions. In countries with lower labor costs, the overall pricing may be more competitive. However, the skill level required for manufacturing high-quality LED chips can also influence labor costs.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient factories may have lower overhead costs, which can translate into better pricing for buyers.

-

Tooling: The cost of molds and machinery for producing LED chips can be significant. Suppliers may pass these costs onto buyers, especially for custom designs or higher specifications.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability and compliance with international standards. However, extensive QC measures can increase overall costs.

-

Logistics: Shipping and handling costs fluctuate based on the origin of the product and the destination market. Buyers must account for these expenses, especially when sourcing from overseas suppliers.

-

Margin: Suppliers will add a margin to cover their expenses and profit. This margin can vary based on supplier reputation, market demand, and negotiation outcomes.

How Do Price Influencers Affect Sourcing Decisions for 5W High Power LED Chips?

Several factors can influence the pricing of 5W high power LED chips, making it essential for buyers to consider them during sourcing:

-

Volume/MOQ: Suppliers often provide better pricing for larger orders due to economies of scale. Understanding the minimum order quantity (MOQ) can help buyers negotiate more favorable terms.

-

Specifications and Customization: Customized chips with specific performance metrics or additional features typically command higher prices. Buyers should weigh the necessity of customization against potential cost increases.

-

Materials and Quality Certifications: Chips that meet stringent quality certifications (like CE, RoHS, or ISO) may be priced higher due to the assurance of performance and compliance. Buyers should assess whether these certifications are essential for their applications.

-

Supplier Factors: Reputation, reliability, and history of the supplier can significantly influence pricing. Established suppliers may charge more but offer better quality assurance and customer support.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is crucial. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect overall costs, shipping responsibilities, and risk management.

What Negotiation Strategies Can Enhance Cost-Efficiency for International Buyers?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can enhance cost-efficiency:

-

Leverage Volume Discounts: If feasible, consolidate purchases across multiple projects to meet higher MOQ thresholds, thus securing better pricing.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, consider long-term savings from energy efficiency, durability, and reduced maintenance needs.

-

Research Market Prices: Familiarize yourself with the standard pricing for 5W high power LED chips in different markets. This knowledge can provide leverage during negotiations.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and insights into upcoming promotions or bulk deals.

-

Be Open to Alternatives: If a supplier cannot meet your budget, consider alternatives that may offer similar specifications at a lower cost, or negotiate for phased deliveries to align with budget availability.

Conclusion: What Should Buyers Keep in Mind When Sourcing 5W High Power LED Chips?

Sourcing 5W high power LED chips involves a complex interplay of cost components and pricing influencers. By understanding these factors and employing strategic negotiation techniques, international buyers can enhance their sourcing outcomes. Always remember to seek out suppliers who can provide transparency in pricing and uphold quality standards, ensuring that your investment translates into reliable performance and value.

Disclaimer: Prices for 5W high power LED chips can vary widely based on market conditions, supplier practices, and specific buyer requirements. Always request quotes and conduct thorough market research before making purchasing decisions.

Alternatives Analysis: Comparing 5w high power led chip With Other Solutions

Introduction: Exploring Alternative Solutions to the 5W High Power LED Chip

In the rapidly evolving landscape of lighting technology, businesses often seek alternatives to traditional solutions to enhance efficiency, reduce costs, and meet specific application needs. The 5W high power LED chip is a popular choice due to its excellent performance and energy efficiency. However, various alternatives can also deliver comparable results, and understanding these options is crucial for B2B buyers in making informed decisions.

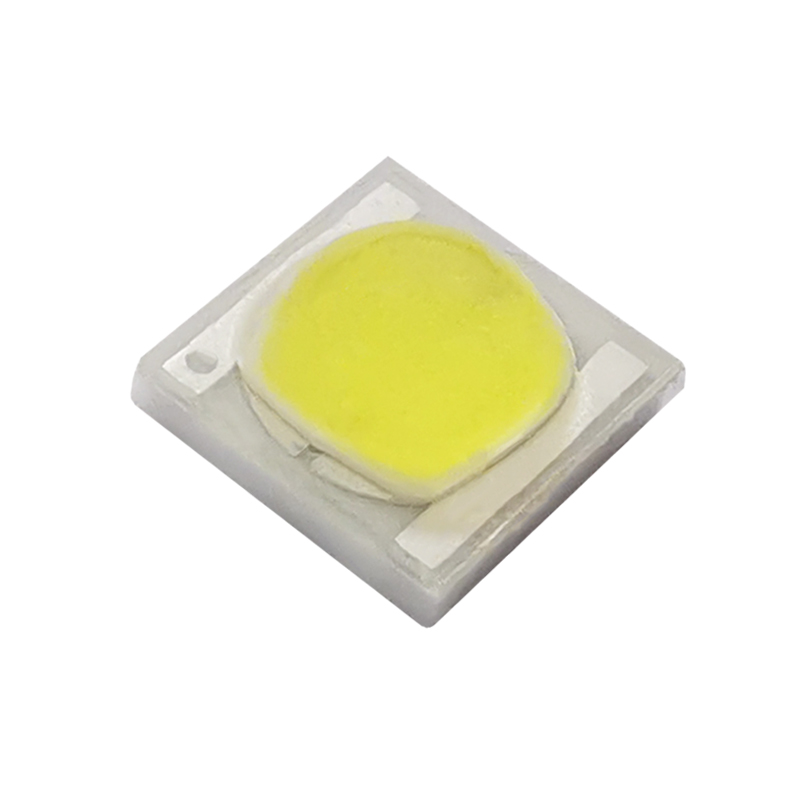

Illustrative image related to 5w high power led chip

Comparison Table

| Comparison Aspect | 5W High Power LED Chip | COB LED Chip (3W/5W/7W/10W) | Fluorescent Tube |

|---|---|---|---|

| Performance | High lumen output (90-100 lm/W) | High brightness, varying output | Moderate lumen output (50-70 lm/W) |

| Cost | Moderate initial investment | Competitive pricing for bulk | Lower upfront cost but higher energy cost |

| Ease of Implementation | Requires heat sink and driver | Easier integration, flexible designs | Straightforward installation, requires ballast |

| Maintenance | Long lifespan, minimal upkeep | Long lifespan, low maintenance | Shorter lifespan, more frequent replacements |

| Best Use Case | Industrial, commercial, and residential applications | Versatile, suitable for various lighting needs | Office spaces, retail, and general lighting |

Detailed Breakdown of Alternatives

COB LED Chip (3W/5W/7W/10W):

COB (Chip on Board) LED chips provide a high level of brightness and efficiency, similar to the 5W high power LED chip. They are designed for compact applications and can be easily integrated into various fixtures. The primary advantage of COB technology is its ability to produce a uniform light output, reducing the appearance of hotspots. However, while the initial costs may be competitive, the need for proper heat management and drivers can complicate implementation.

Fluorescent Tube:

Fluorescent tubes have been a staple in commercial lighting for decades, offering a lower upfront cost compared to LED solutions. They are straightforward to install, making them a go-to option for many businesses. However, fluorescent lights are less efficient, with a shorter lifespan and higher energy consumption than LED alternatives. Additionally, they contain hazardous materials, which can pose disposal challenges. Their application is best suited for environments where initial cost savings are prioritized over long-term efficiency.

Conclusion: Making the Right Choice for Your Lighting Needs

Selecting the right lighting solution involves evaluating specific operational requirements, budget constraints, and long-term goals. While the 5W high power LED chip offers excellent performance and longevity, alternatives like COB LED chips and fluorescent tubes may fit particular applications better based on installation complexity or initial cost. B2B buyers should consider their unique needs, including energy efficiency, maintenance, and application suitability, to make an informed choice that aligns with their business objectives. By analyzing these alternatives, companies can invest wisely in lighting solutions that enhance productivity and sustainability.

Illustrative image related to 5w high power led chip

Essential Technical Properties and Trade Terminology for 5w high power led chip

What Are the Key Technical Properties of a 5W High Power LED Chip?

Understanding the essential technical properties of a 5W high power LED chip is crucial for B2B buyers looking to make informed purchasing decisions. Here are the key specifications to consider:

-

Power Rating (5W)

The power rating indicates the maximum power the LED chip can handle. A 5W rating means it consumes 5 watts of electrical power, which affects brightness and energy efficiency. For buyers, this is important as it directly impacts operational costs and energy consumption. -

Voltage Range (15-17V)

The operating voltage specifies the range in which the LED chip functions optimally. A typical 5W high power LED chip operates at 15 to 17 volts. Knowing this helps buyers ensure compatibility with their existing power supply systems and can prevent damage due to voltage mismatches. -

Current (240-260mA)

The current rating indicates the amount of electrical current required for the LED to operate effectively. A 5W chip typically operates within a current range of 240 to 260 milliamps. Understanding this allows buyers to design appropriate circuits and select suitable drivers, enhancing the chip’s longevity and performance. -

Luminous Efficiency (90-100 lm/W)

Luminous efficiency measures how well the LED converts electrical power into visible light, expressed in lumens per watt (lm/W). A 5W LED chip with an efficiency of 90-100 lm/W is considered high-performing, making it a cost-effective choice for lighting applications. This metric is vital for buyers focused on maximizing light output while minimizing energy use. -

Chip Size and Configuration (9 x 22 mm)

The physical dimensions and arrangement of the LED chip influence heat dissipation and installation compatibility. A standard size of 9 x 22 mm is common for 5W chips. Buyers should consider these dimensions to ensure proper integration into their lighting systems. -

Heat Management

Effective heat management is essential for maintaining LED performance and longevity. Many 5W high power LED chips require a heat sink to dissipate heat generated during operation. Buyers need to account for this in their designs to prevent overheating, which can lead to reduced efficiency or failure.

What Are Common Trade Terminologies Related to 5W High Power LED Chips?

Familiarity with industry jargon can streamline the procurement process. Here are some common terms relevant to 5W high power LED chips:

-

OEM (Original Equipment Manufacturer)

This refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the LED industry, an OEM might design a lighting fixture that includes 5W high power LED chips. Understanding OEM relationships can help buyers secure reliable suppliers. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity a supplier is willing to sell. Knowing the MOQ for 5W high power LED chips allows buyers to budget appropriately and ensures they meet supplier requirements without overcommitting to inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers, submitting an RFQ for 5W high power LED chips can facilitate competitive pricing and better negotiation leverage. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is crucial for international buyers to understand shipping costs, risks, and obligations when sourcing LED chips from different regions. -

Lead Time

This term refers to the time it takes from placing an order to delivery. Understanding lead times is vital for B2B buyers to plan their projects effectively and ensure timely product availability. -

Certification Standards

These are compliance markers indicating that the product meets specific safety and performance standards. Certifications like CE, RoHS, or UL can influence buyer decisions, as they ensure product quality and regulatory compliance.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing 5W high power LED chips with confidence and precision.

Navigating Market Dynamics and Sourcing Trends in the 5w high power led chip Sector

What are the Key Market Trends Influencing the 5W High Power LED Chip Sector?

The 5W high power LED chip market is currently shaped by several global drivers, including the push for energy efficiency and advancements in lighting technology. As businesses and governments worldwide increasingly prioritize sustainability, the demand for energy-efficient lighting solutions continues to rise. This trend is particularly pronounced in regions such as Africa and South America, where energy costs are a significant concern, and in Europe, where regulatory frameworks favor low-energy consumption products.

Emerging technologies, such as smart lighting and IoT integration, are also influencing sourcing strategies for international B2B buyers. Companies are seeking LED chips that not only provide high luminosity but also integrate seamlessly with smart systems for enhanced control and energy management. This shift is driving innovation among manufacturers, leading to the development of chips with improved thermal management and longer lifespans, critical factors for B2B buyers focusing on total cost of ownership.

Market dynamics are characterized by increasing competition and a growing number of suppliers entering the space. Buyers are encouraged to explore multiple sourcing options to ensure they obtain the best quality and pricing. Additionally, geopolitical factors and supply chain disruptions are prompting businesses to diversify their supply chains, thereby enhancing their resilience against market fluctuations.

How is Sustainability and Ethical Sourcing Impacting the 5W High Power LED Chip Sector?

Sustainability is becoming a cornerstone of sourcing decisions in the 5W high power LED chip sector. The environmental impact of manufacturing processes, including the use of hazardous materials and energy consumption, has led many buyers to prioritize suppliers that demonstrate a commitment to sustainable practices. Ethical sourcing is not just a trend; it is increasingly viewed as a business necessity. Buyers are now looking for manufacturers that comply with international standards and certifications, such as RoHS (Restriction of Hazardous Substances) and ISO 14001 (Environmental Management).

Illustrative image related to 5w high power led chip

The importance of ‘green’ certifications extends to the materials used in the production of LED chips. Buyers are increasingly seeking suppliers who utilize recyclable or environmentally friendly materials in their products. This not only meets regulatory requirements but also resonates with end consumers who prefer sustainable products. Furthermore, companies that can provide transparent supply chains and demonstrate their commitment to social responsibility are more likely to gain the trust and loyalty of B2B buyers.

What is the Historical Evolution of the 5W High Power LED Chip Market?

The evolution of the 5W high power LED chip market can be traced back to the early days of LED technology, where initial applications were primarily limited to indicators and basic lighting. As technological advancements emerged, particularly in chip efficiency and luminosity, the use of LED technology expanded into more demanding applications, such as commercial and industrial lighting.

The introduction of COB (Chip on Board) technology marked a significant milestone, allowing for higher power outputs and better thermal management. This innovation paved the way for the development of the 5W high power LED chip, which now plays a critical role in various sectors, including automotive lighting, architectural illumination, and street lighting. Over the years, the market has seen a shift towards greater energy efficiency and sustainability, aligning with global trends that favor environmentally friendly lighting solutions.

As buyers navigate the complexities of this evolving market, understanding these historical contexts helps inform better sourcing decisions and anticipate future trends in the 5W high power LED chip sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 5w high power led chip

-

How do I choose the right 5W high power LED chip for my application?

When selecting a 5W high power LED chip, consider factors such as the intended application (e.g., industrial lighting, automotive, or residential), required brightness (measured in lumens), and color temperature (Kelvin). Ensure compatibility with your existing systems, including voltage and current specifications. Additionally, assess the heat dissipation needs, as proper thermal management is crucial for longevity. Reviewing technical datasheets and consulting with suppliers can provide insights into the best options for your specific requirements. -

What are the common applications for 5W high power LED chips?

5W high power LED chips are versatile and widely used in various applications, including spotlights, downlights, floodlights, and industrial lighting. They are also suitable for road lighting and decorative lighting in commercial spaces. Their energy efficiency and high luminosity make them ideal for both indoor and outdoor settings, contributing to significant energy savings over traditional lighting solutions. Understanding your project requirements will help in choosing the right LED chip for optimal performance. -

What should I consider regarding minimum order quantities (MOQ) when sourcing 5W high power LED chips?

Minimum order quantities (MOQ) can vary significantly between suppliers. It’s essential to confirm the MOQ with potential vendors, as this can impact your initial investment and inventory management. Some suppliers may offer lower MOQs for new buyers or specific product lines, while others might have strict requirements. If you are testing a new product line, seek suppliers who can accommodate smaller orders, allowing you to evaluate product performance before committing to larger purchases. -

What payment terms should I negotiate with suppliers for 5W high power LED chips?

When negotiating payment terms, consider factors such as your cash flow, the supplier’s reputation, and the overall cost of the order. Common terms include a percentage upfront, with the balance due upon delivery or after a specified period. For larger orders, you might negotiate extended payment terms or discounts for early payment. Always ensure that payment methods are secure, and consider using escrow services for high-value transactions to mitigate risks. -

How can I ensure the quality of 5W high power LED chips before purchase?

To ensure quality, request samples from suppliers to evaluate their performance in your specific applications. Additionally, inquire about the supplier’s quality assurance processes, certifications (such as ISO), and warranty policies. Conducting factory audits or third-party inspections can further validate the manufacturing standards. It’s also beneficial to review customer testimonials and case studies to gauge the reliability of the supplier’s products. -

What are the logistics considerations when importing 5W high power LED chips?

Logistics play a crucial role in the timely delivery of your LED chips. Factors to consider include shipping methods, customs regulations, and lead times. Work closely with your supplier to understand their shipping practices and packaging standards to minimize damage during transit. It’s also important to factor in potential delays due to customs clearance, especially when importing from international suppliers. Establishing a reliable logistics partner can help streamline the process. -

Can I customize 5W high power LED chips to meet specific needs?

Yes, many suppliers offer customization options for 5W high power LED chips, including variations in color temperature, brightness levels, and packaging configurations. Discuss your specific requirements with potential suppliers to see if they can accommodate your needs. Customization may involve additional costs and lead times, so be sure to factor these into your project planning. Collaborating early with suppliers can also yield the best results in terms of product development. -

What certifications should I look for when sourcing 5W high power LED chips?

When sourcing LED chips, look for certifications that indicate compliance with international safety and quality standards. Common certifications include CE (European Conformity), RoHS (Restriction of Hazardous Substances), and UL (Underwriters Laboratories). These certifications ensure that the products meet specific safety and environmental regulations, which is particularly important for B2B transactions in diverse markets. Always verify that the supplier can provide documentation for these certifications to ensure transparency and accountability.

Top 7 5W High Power Led Chip Manufacturers & Suppliers List

1. Super Lighting – COB LED Chip Light Source

Domain: superlightingled.com

Registered: 2014 (11 years)

Introduction: 3W/5W/7W/10W COB LED Chip Light Source Chip

2. High Power – LED Chip Light Bulb

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “High Power LED Chip Light Bulb”, “available_wattages”: [1, 3, 5, 10, 20, 50, 100], “colors”: [“Warm White (3000K – 3500K)”, “Natural White (4000K – 4500K)”, “Pure White (6000K – 6500K)”, “Cool White (10000K – 15000K)”], “condition”: “New”, “price”: “$4.40”, “shipping_cost”: “$5.82”, “estimated_delivery”: “Fri, Sep 19 – Thu, Sep 25”, “seller”: “Chanzon TopBrand Store”, “seller_fee…

3. Lumixtar – WL-5P5050EP120R-630 High Power LED

Domain: lumixtar.com

Registered: 2019 (6 years)

Introduction: {“Product Model”:”WL-5P5050EP120R-630″,”Wavelength”:”630nm”,”Power”:”5W”,”Type”:”SMD5050 Red High Power LED”,”Features”:”99.99% gold wire bonding, 1.2mil Ceramic substrate, Silicone Lens, Epistar/Epileds, 4pcs * 42mil Chips, CE and ROHS Compliant”,”Applications”:”Medical Instrument, Aquarium lighting, horticultural lighting, professional or commercial lighting”,”Beam Angle”:”60 degrees, 120 degree…

4. Raspberry Pi – High-Power LED Driver Solutions

Domain: forums.raspberrypi.com

Introduction: Raspberry Pi Zero WH, 5V power supply, High-Power LED with Forward Current: 1000mA, Forward Voltage: 2.9V, driven with a 4.3Ω resistor (5W) at 500mA. Recommended switching method: MOSFET for GPIO control. Alternative suggestions include using a PT4115 1.2A driver for 6-30V input or XL4001E1 DC-DC Buck converter for 5V input, though the latter lacks a dimming circuit. Efficiency considerations and …

5. Cree LED – InGaN-based LED Chips

Domain: cree-led.com

Registered: 2016 (9 years)

Introduction: Cree LED offers a diverse portfolio of InGaN-based LED chips for blue, green, and white-converted LEDs. Key product families include:

1. EZ: Low- to high-power 2D “top-emitters” with a Lambertian radiation pattern.

2. SA: High-power 3D “volume-emitters” for efficient, no wire packaging.

3. SR: Low- to mid-power LED chips for a wide range of applications.

4. SD: Low-power, vertical design repla…

6. Quartz Components – 5W Cool White COB LED Chip

Domain: quartzcomponents.com

Introduction: 5W LED chip, High Power, Cool White, COB Light, 300mA

7. Reddit – 10x 5W White LEDs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 10x 5W White LEDs, total power 50W, recommended operating voltage 6 Volts, current 700mA each, potential driver options include step-down modules with maximum output of 36 Volts and 5A.

Strategic Sourcing Conclusion and Outlook for 5w high power led chip

In the rapidly evolving market for high-power LED chips, particularly the 5W variants, strategic sourcing emerges as a critical element for international B2B buyers. By focusing on reliable suppliers that offer high-quality products, businesses can significantly enhance their operational efficiency and reduce overall costs. The 5W high-power LED chip is not only energy-efficient but also versatile, making it suitable for diverse applications ranging from industrial lighting to residential use.

As buyers from Africa, South America, the Middle East, and Europe seek to expand their product offerings, understanding the specifications and performance metrics of 5W LED chips becomes essential. Prioritizing suppliers that provide transparent information about their products, including lumens per watt and compatibility with various heat sinks, can help ensure optimal performance and longevity of LED lighting solutions.

Looking ahead, the demand for energy-efficient lighting solutions will continue to rise, driven by sustainability initiatives and technological advancements. By establishing solid relationships with manufacturers and distributors, buyers can stay ahead of market trends and secure a competitive edge. Take proactive steps today to enhance your sourcing strategy and maximize the potential of high-power LED chips in your product lineup.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.