Everything You Need to Know About 20000 Btu Air Conditioner Sourcing in 2025

Introduction: Navigating the Global Market for 20000 btu air conditioner

In today’s rapidly evolving global market, sourcing a 20,000 BTU air conditioner poses unique challenges for B2B buyers, particularly in regions with extreme climates like Africa, South America, the Middle East, and Europe. Whether you are seeking to cool industrial warehouses or provide comfort in large commercial spaces, understanding the diverse applications and types of air conditioning units is crucial. This guide delves into the multifaceted world of 20,000 BTU air conditioners, offering insights into various types—such as window, wall-mounted, and mini-split systems—alongside their specific applications across different sectors.

Navigating supplier vetting processes can be daunting, especially when considering factors like compliance with local regulations, energy efficiency ratings, and warranty offerings. By providing a thorough analysis of cost implications, potential suppliers, and installation considerations, this guide empowers international B2B buyers to make informed purchasing decisions. Key information on market trends and environmental factors will also be highlighted to ensure that your organization remains competitive and compliant with evolving standards.

With actionable insights tailored to the unique challenges faced in regions like Nigeria and Germany, this comprehensive guide serves as an invaluable resource for businesses looking to enhance their operational efficiency and comfort through strategic air conditioning solutions.

Understanding 20000 btu air conditioner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Window Air Conditioner | Easy installation, compact design, cost-effective | Small to medium-sized office spaces, retail | Pros: Affordable, easy to install. Cons: Limited cooling area, less efficient in larger spaces. |

| Ductless Mini-Split System | Flexible installation, energy-efficient, multi-zone cooling | Commercial buildings, hotels, residential units | Pros: Quiet operation, high efficiency. Cons: Higher initial cost, requires professional installation. |

| Through-the-Wall Air Conditioner | Permanent installation, space-saving design | Apartments, hotels, and small offices | Pros: Saves floor space, effective for smaller areas. Cons: Installation can be complex, less portable. |

| Portable Air Conditioner | Mobility, no permanent installation required | Temporary cooling needs, trade shows, events | Pros: Easy to move, no installation required. Cons: Limited cooling capacity, may require venting. |

| Enclosure Air Conditioner | Closed-loop cooling, designed for harsh environments | Data centers, industrial facilities | Pros: Protects sensitive equipment, efficient in extreme conditions. Cons: Higher cost, specialized installation needed. |

What Are the Key Characteristics of Window Air Conditioners?

Window air conditioners are a popular choice for businesses seeking cost-effective cooling solutions for small to medium-sized spaces. They are easy to install and typically come with a compact design that fits directly into a window frame. This type is ideal for retail shops or small offices where budget constraints are a concern. However, their cooling capacity is limited to smaller areas, making them less suitable for larger commercial spaces.

Why Consider Ductless Mini-Split Systems for Your Business?

Ductless mini-split systems offer flexibility and energy efficiency, making them ideal for various commercial applications, including hotels and multi-unit residential buildings. These systems allow for multiple indoor units connected to a single outdoor unit, enabling zoned cooling. While they have a higher initial cost and require professional installation, their quiet operation and efficiency can lead to significant energy savings over time, making them a worthwhile investment.

How Do Through-the-Wall Air Conditioners Benefit Commercial Spaces?

Through-the-wall air conditioners provide a permanent cooling solution that is particularly effective in apartments and small offices. Their design saves floor space and allows for efficient cooling without the need for bulky window units. However, installation can be complex, and they are not as portable as other options. Businesses should consider their long-term cooling needs when opting for this solution.

What Are the Advantages of Portable Air Conditioners?

Portable air conditioners are an excellent choice for businesses that require flexibility in their cooling solutions. These units can be easily moved from one location to another, making them ideal for temporary cooling needs at events or trade shows. While they are easy to set up and do not require permanent installation, they may have limitations in cooling capacity and often need venting, which can complicate their use in certain environments.

Illustrative image related to 20000 btu air conditioner

Why Are Enclosure Air Conditioners Essential for Sensitive Equipment?

Enclosure air conditioners are specifically designed to provide cooling for sensitive electronic equipment in harsh environments, such as data centers and industrial facilities. Their closed-loop cooling systems protect against dust and moisture while maintaining optimal temperatures. Although these units tend to have a higher cost and require specialized installation, their ability to safeguard critical equipment makes them invaluable for businesses that rely on technology for operations.

Key Industrial Applications of 20000 btu air conditioner

| Industry/Sector | Specific Application of 20000 BTU Air Conditioner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Cooling production lines and machinery in high-temperature areas | Enhances equipment longevity and reduces downtime due to overheating | Reliability of cooling systems; energy efficiency ratings; local support for maintenance |

| Data Centers | Maintaining optimal temperatures for server rooms | Prevents overheating, ensuring uninterrupted operations and data integrity | Compatibility with existing infrastructure; energy consumption; remote monitoring capabilities |

| Healthcare Facilities | Climate control in patient care areas and laboratories | Improves patient comfort and protects sensitive medical equipment | Compliance with health regulations; noise levels; ease of installation and maintenance |

| Food and Beverage Industry | Cooling storage areas and processing facilities | Extends shelf life of perishable goods and maintains quality standards | Durability in harsh environments; energy efficiency; availability of replacement parts |

| Commercial Spaces | Air conditioning in large retail and office spaces | Enhances customer and employee comfort, leading to increased productivity | Installation flexibility; aesthetic design; warranty and service agreements |

How is a 20000 BTU Air Conditioner Used in Manufacturing?

In manufacturing environments, 20000 BTU air conditioners are crucial for cooling production lines and machinery, particularly in high-temperature areas. These units help maintain optimal operating temperatures, which enhances the longevity of equipment and reduces the risk of overheating-related downtime. For international buyers, sourcing considerations include the reliability of cooling systems, energy efficiency ratings, and the availability of local support for maintenance, especially in regions with extreme climates like parts of Africa and the Middle East.

What Role Does a 20000 BTU Air Conditioner Play in Data Centers?

Data centers require precise climate control to maintain optimal temperatures for server operations. A 20000 BTU air conditioner is often employed to prevent overheating, which can compromise data integrity and lead to significant operational disruptions. Buyers from Europe and South America should focus on compatibility with existing infrastructure, energy consumption metrics, and remote monitoring capabilities to ensure effective cooling solutions that align with their operational requirements.

Why is Climate Control Essential in Healthcare Facilities?

In healthcare settings, maintaining a controlled environment is vital for patient care and the operation of sensitive medical equipment. A 20000 BTU air conditioner provides the necessary climate control in patient care areas and laboratories, improving patient comfort and protecting critical equipment from heat damage. Buyers must consider compliance with health regulations, acceptable noise levels, and the ease of installation and maintenance when sourcing these units, particularly in regions with stringent healthcare standards.

How Does the Food and Beverage Industry Benefit from 20000 BTU Air Conditioners?

The food and beverage industry relies on effective cooling solutions to maintain storage areas and processing facilities. A 20000 BTU air conditioner plays a key role in extending the shelf life of perishable goods and ensuring that quality standards are met. For B2B buyers, durability in harsh environments, energy efficiency, and the availability of replacement parts are crucial factors to consider, especially in countries with diverse climates and varying energy costs.

What are the Advantages of Using 20000 BTU Air Conditioners in Commercial Spaces?

In commercial spaces, such as large retail outlets and office environments, 20000 BTU air conditioners significantly enhance customer and employee comfort. This leads to increased productivity and improved customer satisfaction. When sourcing these units, considerations include installation flexibility, aesthetic design to match the environment, and comprehensive warranty and service agreements to ensure long-term reliability and support.

3 Common User Pain Points for ‘20000 btu air conditioner’ & Their Solutions

Scenario 1: Inconsistent Cooling Across Large Spaces

The Problem: B2B buyers, such as facility managers or business owners, often encounter difficulties with inconsistent cooling in large areas when using a 20000 BTU air conditioner. This issue can lead to uncomfortable work environments, affecting employee productivity and potentially damaging sensitive equipment. In regions with extreme temperatures, these inconsistencies can also result in increased energy costs as the unit struggles to maintain a uniform temperature.

The Solution: To address this problem, buyers should consider investing in a zoning system that allows for targeted cooling in specific areas. When sourcing a 20000 BTU air conditioner, opt for models that support multi-zone applications or those that can be paired with additional units for comprehensive coverage. Installing ductless mini-split systems alongside the main unit can further enhance temperature regulation across different zones. Additionally, regular maintenance, including cleaning filters and checking refrigerant levels, will ensure that the air conditioner operates at peak efficiency, thereby improving cooling consistency and lowering energy costs.

Illustrative image related to 20000 btu air conditioner

Scenario 2: High Energy Consumption and Operating Costs

The Problem: Many businesses face the challenge of high energy bills due to the inefficient operation of air conditioning units. A 20000 BTU air conditioner, if not chosen carefully, can consume excessive energy, leading to operational costs that strain budgets. This is particularly pertinent in regions with high electricity rates or where energy efficiency is a critical concern for sustainability-focused companies.

The Solution: Buyers should prioritize energy-efficient models that carry high Seasonal Energy Efficiency Ratio (SEER) ratings when selecting a 20000 BTU air conditioner. Look for units that utilize inverter technology, which adjusts the compressor speed based on the cooling demand, significantly reducing energy consumption. Furthermore, it is advisable to conduct a comprehensive energy audit of the facility before purchasing, as this will help in determining the exact cooling needs and prevent oversizing the unit, which can lead to wasted energy. Implementing smart thermostats that allow for programmable settings can also optimize energy use by aligning cooling cycles with actual occupancy patterns.

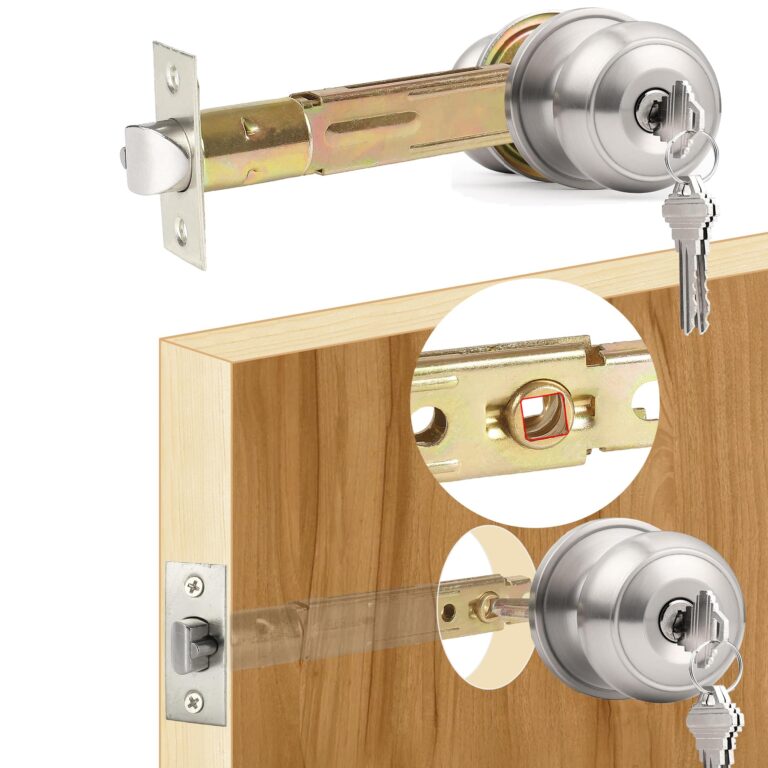

Scenario 3: Installation Challenges and Compatibility Issues

The Problem: B2B buyers, particularly those in facilities management, often encounter installation challenges when integrating a 20000 BTU air conditioner into existing infrastructure. Compatibility with current systems, structural constraints of the building, and local regulations can complicate the installation process. These issues not only delay project timelines but can also incur unexpected costs, creating frustration for buyers.

Illustrative image related to 20000 btu air conditioner

The Solution: To mitigate installation challenges, it is crucial to engage with HVAC professionals who can provide thorough assessments of the installation site before the purchase. This includes evaluating structural requirements, electrical capacities, and compliance with local building codes. When selecting a 20000 BTU air conditioner, consider models that are designed for flexibility in installation, such as those that can be mounted through walls or windows, or that feature compact designs for limited spaces. Additionally, utilizing support brackets and proper mounting kits can simplify the installation process. Establishing a clear communication channel with the installation team can ensure that any potential compatibility issues are addressed early in the project, preventing costly delays and ensuring a smooth integration into the existing HVAC system.

Strategic Material Selection Guide for 20000 btu air conditioner

What Are the Key Materials Used in 20000 BTU Air Conditioners?

When selecting materials for 20000 BTU air conditioners, it’s essential to consider their properties, advantages, and limitations. The choice of materials can significantly affect the performance, durability, and compliance of the units, especially for international B2B buyers operating in diverse environments such as Africa, South America, the Middle East, and Europe.

Which Metals Are Commonly Used in 20000 BTU Air Conditioners?

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It typically withstands temperatures up to 150°C and is suitable for various pressure ratings.

Pros & Cons: Its lightweight nature makes it easy to handle and install, while its resistance to corrosion is beneficial in humid or coastal environments. However, aluminum can be more expensive than some alternatives and may not be as durable under extreme mechanical stress.

Impact on Application: Aluminum is often used in heat exchangers and fins, where efficient heat transfer is crucial. Its compatibility with refrigerants makes it a preferred choice in air conditioning systems.

Considerations for International Buyers: Buyers in regions like Nigeria and Germany should ensure compliance with local standards such as DIN and ASTM for aluminum components, particularly regarding thickness and alloy specifications.

Steel

Key Properties: Steel is known for its strength and durability, with a high tensile strength rating. It can endure high pressures and temperatures, making it suitable for various applications.

Pros & Cons: Steel’s robustness provides excellent durability, making it ideal for outdoor units exposed to harsh conditions. However, it is heavier than aluminum and can be prone to rust if not properly coated or treated.

Impact on Application: Often used in the structural framework and casings of air conditioners, steel provides the necessary support and protection for internal components. Its compatibility with various coatings enhances its corrosion resistance.

Considerations for International Buyers: Buyers should consider the availability of high-quality steel that meets international standards for corrosion resistance, particularly in humid climates.

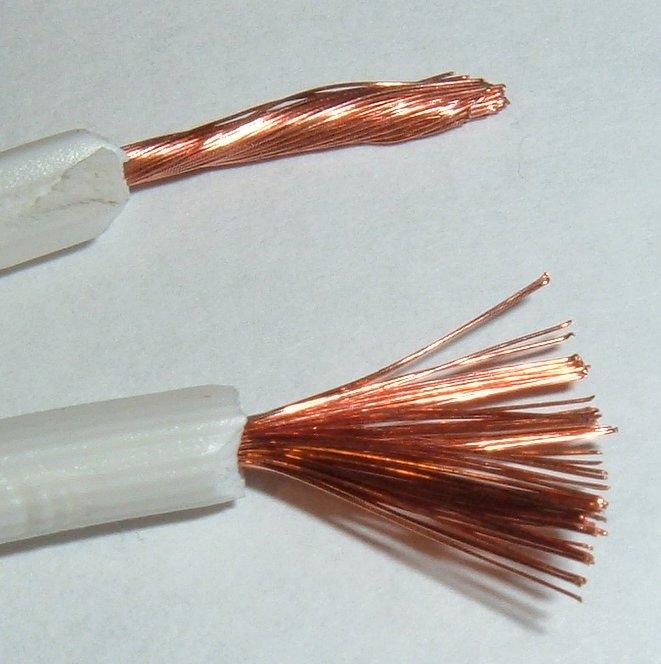

Copper

Key Properties: Copper has excellent thermal and electrical conductivity, making it ideal for heat exchangers and electrical connections. It can handle temperatures up to 200°C and is resistant to corrosion when properly treated.

Pros & Cons: Its superior conductivity enhances energy efficiency, but copper can be more expensive than aluminum and is susceptible to corrosion if exposed to certain environmental conditions.

Impact on Application: Copper is widely used in refrigerant lines and heat exchangers, where efficient heat transfer is vital. Its compatibility with various refrigerants makes it a staple in air conditioning systems.

Considerations for International Buyers: Compliance with international standards for copper quality and thickness is crucial, especially in regions with varying environmental conditions.

Plastic Composites

Key Properties: Plastic composites are lightweight, corrosion-resistant, and can be molded into complex shapes. They are typically rated for moderate temperatures and pressures.

Pros & Cons: Their lightweight nature and resistance to corrosion make them suitable for various applications. However, they may not offer the same strength and durability as metals, particularly in high-stress environments.

Impact on Application: Used in fan blades and housing components, plastic composites can reduce weight and improve energy efficiency. Their insulating properties also help in reducing energy loss.

Illustrative image related to 20000 btu air conditioner

Considerations for International Buyers: Buyers should ensure that plastic materials meet local regulations regarding fire resistance and environmental impact, especially in regions with strict compliance standards.

Summary Table of Material Selection for 20000 BTU Air Conditioners

| Material | Typical Use Case for 20000 BTU Air Conditioner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat exchangers and fins | Lightweight and corrosion-resistant | Higher cost than some alternatives | Med |

| Steel | Structural framework and casings | High durability and strength | Heavier and prone to rust | Med |

| Copper | Refrigerant lines and heat exchangers | Excellent thermal conductivity | More expensive and corrosion-prone | High |

| Plastic Composites | Fan blades and housing components | Lightweight and moldable | Lower strength and durability | Low |

This guide provides actionable insights into material selection for 20000 BTU air conditioners, helping B2B buyers make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 20000 btu air conditioner

What Are the Key Stages in the Manufacturing Process of a 20000 BTU Air Conditioner?

The manufacturing process for a 20000 BTU air conditioner involves several critical stages, each ensuring that the final product meets the required specifications and performance standards.

1. Material Preparation

The manufacturing journey begins with the preparation of raw materials, including metals, plastics, and refrigerants. Components such as compressors, evaporators, and condensers are sourced from certified suppliers who adhere to international quality standards. For instance, copper and aluminum are often used in heat exchangers due to their excellent thermal conductivity. Before production, materials undergo rigorous inspections to ensure they meet specifications, which helps prevent defects later in the manufacturing process.

2. Forming Processes

Once materials are prepared, they undergo various forming processes. This includes stamping and bending metal sheets to create chassis and housing components. Advanced techniques like CNC machining are often employed to ensure precision in creating complex parts. Additionally, injection molding is used for plastic components, allowing for efficient mass production while maintaining quality consistency.

3. Assembly

The assembly stage is critical, as it involves bringing together all the individual components. Automated assembly lines are common, where robots and skilled workers collaborate to install parts such as compressors, fans, and control systems. Each assembly line is designed to optimize efficiency and minimize errors. During this phase, manufacturers often implement lean manufacturing principles to streamline operations and reduce waste.

4. Finishing

Finishing processes enhance the aesthetic appeal and durability of the air conditioner. This includes powder coating for metal parts to prevent corrosion and improve appearance. Quality checks are performed at this stage to ensure that all components fit correctly and that there are no visible defects.

What International Standards Guide Quality Assurance in Air Conditioner Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of air conditioners, as it directly impacts product reliability and customer satisfaction. Several international standards guide these practices.

ISO 9001 Certification

ISO 9001 is a globally recognized standard for quality management systems (QMS). Manufacturers seeking this certification demonstrate their commitment to quality through defined processes and continuous improvement. For B2B buyers, an ISO 9001 certification indicates that the manufacturer has established a robust QA system, reducing the risk of defects in the final product.

Illustrative image related to 20000 btu air conditioner

CE Marking

In Europe, the CE mark signifies that products meet EU safety, health, and environmental requirements. For air conditioners, this includes adherence to energy efficiency standards, which is increasingly important for international buyers concerned with sustainability.

Industry-Specific Certifications

Depending on the market, manufacturers may also pursue industry-specific certifications. For example, the American Petroleum Institute (API) certification may be relevant for air conditioning units used in industrial settings. Buyers should inquire about these certifications to ensure compliance with local regulations and standards.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves systematic checks at various points in the manufacturing process to ensure that products meet established standards.

Incoming Quality Control (IQC)

The first checkpoint is IQC, where incoming materials are inspected for quality and compliance with specifications. This step is crucial for preventing defective components from entering the production line.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC checks are conducted at various stages of assembly. This includes inspections for proper installation of components and adherence to assembly protocols. Regular monitoring ensures that any deviations from quality standards are addressed promptly.

Final Quality Control (FQC)

FQC occurs after assembly, where the complete unit undergoes rigorous testing. This may include performance tests to verify cooling efficiency, noise levels, and energy consumption. Manufacturers typically conduct durability tests to simulate real-world conditions, ensuring that the product can withstand rigorous use.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability and compliance with standards.

Audits

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers can request an audit of the manufacturing facility to evaluate compliance with international standards and company policies.

Quality Reports

Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC. These documents should outline the methods used for testing and any corrective actions taken in case of defects.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality control processes. These inspections can occur at various stages of production, offering insights into compliance with industry standards.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control.

Regional Compliance

Different regions have varying compliance requirements, which can impact the certification process. Buyers should be aware of local regulations and ensure that suppliers can meet these standards.

Illustrative image related to 20000 btu air conditioner

Language and Communication Barriers

Language differences can complicate the communication of quality standards and requirements. Establishing clear communication channels and documentation in a common language can help mitigate misunderstandings.

Cultural Differences in Manufacturing Practices

Cultural differences may influence manufacturing practices and quality perceptions. Understanding these nuances can aid buyers in assessing supplier reliability and building stronger partnerships.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing 20000 BTU air conditioners, ensuring they acquire products that meet their quality and performance expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘20000 btu air conditioner’

To assist B2B buyers in sourcing a 20,000 BTU air conditioner effectively, this guide outlines essential steps to ensure a successful procurement process. Each step addresses critical factors that can influence the efficiency, cost, and reliability of your air conditioning solution.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the air conditioner meets your operational needs. Consider factors such as cooling capacity, energy efficiency ratings (like SEER), and noise levels. Additionally, determine whether you require features such as remote control, programmable settings, or Wi-Fi connectivity.

Step 2: Assess Your Installation Requirements

Understanding your installation environment is crucial before procurement. Evaluate the available space for the unit, whether it’s a window, wall, or ductless system. Consider factors like electrical requirements, which may differ by region, and ensure that the chosen model is compatible with your existing infrastructure.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with proven track records in reliability and customer support, especially in your geographical area, as local service capabilities can significantly impact maintenance and support.

Step 4: Verify Supplier Certifications and Standards

Ensure that your potential suppliers meet necessary industry certifications and standards. This includes looking for UL certification, energy efficiency certifications, and compliance with local regulations. Such certifications indicate that the products have been tested for safety and performance, reducing the risk of future issues.

Step 5: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to gain a comprehensive understanding of market pricing. When comparing prices, consider not only the upfront cost but also potential long-term operational costs, such as energy consumption and maintenance. Look for bulk purchase discounts or promotional offers that could provide additional savings.

Step 6: Review Warranty and Support Options

Before finalizing your purchase, carefully review the warranty and support options provided by the supplier. A robust warranty can protect your investment against defects and failures, while responsive customer support can be invaluable in case of issues post-installation. Ensure that support is readily available in your region, which can minimize downtime.

Step 7: Plan for Delivery and Installation

Once you’ve selected a supplier and finalized your order, coordinate the logistics for delivery and installation. Confirm the expected delivery timeline and ensure that the installation team is familiar with your specific requirements. Proper planning can help avoid delays and ensure that your air conditioning system is operational when you need it.

By following these steps, B2B buyers can navigate the complexities of sourcing a 20,000 BTU air conditioner with greater confidence, ensuring that they select the right product for their specific needs while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for 20000 btu air conditioner Sourcing

What Are the Key Cost Components for Sourcing a 20000 BTU Air Conditioner?

When sourcing a 20000 BTU air conditioner, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as steel, copper, and various plastics can vary significantly based on market fluctuations. High-quality components can increase the initial cost but may enhance performance and longevity.

-

Labor: Labor costs encompass both direct assembly labor and indirect costs associated with training, benefits, and overhead. Countries with lower labor costs may offer more competitive pricing, but this can impact the quality of workmanship.

-

Manufacturing Overhead: This includes costs associated with running the factory, such as utilities, rent, and equipment maintenance. Efficient production processes can help reduce these costs.

-

Tooling: Initial tooling costs for molds and assembly lines can be substantial, particularly for customized units. Buyers should consider whether they need standard models or if customizations are necessary for their specific applications.

-

Quality Control (QC): Investing in robust QC processes ensures that the air conditioners meet international standards. This can lead to higher upfront costs but may reduce warranty claims and enhance customer satisfaction in the long run.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and the volume of the order. Understanding the logistics involved can help buyers budget effectively for total expenses.

-

Margin: Supplier margins can differ widely based on the brand reputation, market demand, and competition. Buyers should evaluate the value offered against the margin to ensure they receive a fair deal.

How Do Price Influencers Affect the Cost of 20000 BTU Air Conditioners?

Several factors influence the pricing of 20000 BTU air conditioners, including:

-

Volume/MOQ: Bulk purchasing often leads to better pricing, as suppliers can reduce their per-unit costs. Establishing long-term contracts may also yield favorable terms.

-

Specifications and Customization: Customized units may incur additional costs due to unique specifications or features. Buyers must weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ENERGY STAR) can drive up costs but often result in greater energy efficiency and reliability, which can lower the Total Cost of Ownership (TCO).

-

Supplier Factors: The choice of supplier can significantly impact pricing. Established brands may command higher prices due to perceived reliability, while emerging suppliers may offer competitive rates to gain market share.

-

Incoterms: Understanding the terms of shipment can help buyers manage costs effectively. For example, choosing to handle logistics through DDP (Delivered Duty Paid) can simplify the process but may come with higher fees.

What Tips Can Help Buyers Negotiate Better Prices for 20000 BTU Air Conditioners?

Negotiating the best price for air conditioners requires a strategic approach:

-

Conduct Market Research: Understanding market trends, average pricing, and supplier capabilities can empower buyers during negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also operating costs, maintenance, and potential energy savings over time. A slightly higher upfront cost can be justified if it leads to lower operational expenses.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and access to exclusive deals.

-

Be Prepared to Walk Away: If negotiations do not meet your budget or quality expectations, being willing to explore other suppliers can provide leverage.

-

Factor in International Pricing Nuances: For buyers from regions like Africa, South America, the Middle East, and Europe, understanding local tariffs, taxes, and import duties is critical in calculating the final cost.

Conclusion

Sourcing a 20000 BTU air conditioner involves navigating a complex cost structure influenced by various factors. By understanding these components and employing effective negotiation strategies, B2B buyers can ensure they secure optimal pricing while maintaining product quality and reliability. Remember that indicative prices may vary based on market conditions, supplier relationships, and specific buyer requirements.

Alternatives Analysis: Comparing 20000 btu air conditioner With Other Solutions

When considering cooling solutions for large spaces, the 20,000 BTU air conditioner is a popular choice. However, it’s essential to evaluate alternative options that may better suit specific business needs, environmental conditions, or budget constraints. This analysis will compare the 20,000 BTU air conditioner against two viable alternatives: mini-split systems and enclosure air conditioners.

| Comparison Aspect | 20000 BTU Air Conditioner | Mini-Split System | Enclosure Air Conditioner |

|---|---|---|---|

| Performance | Cools up to 1,200 sq ft | Cools multiple zones; high SEER | Designed for sealed environments, efficient for electronics |

| Cost | Moderate initial cost | Higher upfront investment | Varies widely based on specs |

| Ease of Implementation | Easy installation (window or wall-mounted) | Requires professional installation | Typically straightforward for NEMA-rated environments |

| Maintenance | Regular filter cleaning | Minimal maintenance; easy access | Requires periodic checks; specialized filters |

| Best Use Case | Residential and small commercial spaces | Multi-zone cooling in homes and offices | Cooling sensitive electronic equipment in harsh environments |

What Are the Advantages and Disadvantages of Mini-Split Systems Compared to 20000 BTU Air Conditioners?

Mini-split systems provide an efficient alternative for cooling larger or multi-zone areas. They typically have a higher Seasonal Energy Efficiency Ratio (SEER), leading to lower energy bills over time. However, the initial investment can be significantly higher, and installation often requires a professional contractor, which may not be ideal for all businesses. Additionally, mini-splits offer flexibility in design and installation, allowing for aesthetic integration into modern spaces.

Illustrative image related to 20000 btu air conditioner

Why Are Enclosure Air Conditioners a Good Alternative for Specific Applications?

Enclosure air conditioners are specifically engineered for environments where sensitive electronic equipment must be protected from heat, dust, and moisture. Their closed-loop cooling systems ensure that outside air does not compromise the integrity of the equipment. While they excel in niche applications, their cost can vary widely based on specifications, and they may require specialized maintenance. For businesses in technology or manufacturing sectors, these units can be invaluable in safeguarding critical infrastructure.

How Should B2B Buyers Choose the Right Cooling Solution?

When selecting a cooling solution, B2B buyers should consider factors such as the specific cooling needs of their space, budget constraints, and the intended use of the cooled environment. For general cooling needs in residential or small commercial spaces, a 20,000 BTU air conditioner is often sufficient and cost-effective. Conversely, businesses requiring efficient multi-zone cooling or specialized environments for sensitive equipment may find mini-split systems or enclosure air conditioners to be more advantageous. Ultimately, understanding the unique requirements of the space and the long-term operational costs will guide buyers in making an informed decision that aligns with their business goals.

Essential Technical Properties and Trade Terminology for 20000 btu air conditioner

What Are the Key Technical Properties of a 20000 BTU Air Conditioner?

When considering a 20000 BTU air conditioner, it’s essential to understand various technical specifications that can impact performance, efficiency, and suitability for specific applications. Below are critical properties that every B2B buyer should evaluate:

-

Cooling Capacity (BTU/hr)

The cooling capacity, measured in British Thermal Units (BTU), indicates the amount of heat the air conditioner can remove from a space per hour. A 20000 BTU unit is designed for larger rooms, typically between 1,000 to 1,200 square feet, making it ideal for commercial spaces or larger residential areas. Understanding the cooling capacity helps businesses ensure they select a unit that adequately meets their cooling needs without excessive energy consumption. -

Energy Efficiency Ratio (EER)

EER is a measure of the air conditioner’s efficiency, calculated by dividing the cooling capacity (BTU/hr) by the power input (watts). A higher EER indicates a more efficient unit, which can lead to significant energy savings over time. This is particularly important for businesses looking to reduce operational costs while maintaining a comfortable environment. -

Seasonal Energy Efficiency Ratio (SEER)

Similar to EER, SEER measures efficiency over an entire cooling season rather than at peak conditions. It is crucial for understanding the long-term energy costs associated with running the air conditioner. B2B buyers should prioritize units with high SEER ratings, as they often qualify for energy rebates and incentives, improving the overall return on investment. -

Voltage Requirements

Air conditioners typically operate at different voltage levels, such as 115V, 220V, or 230V. Understanding the voltage requirement is vital for compatibility with existing electrical systems. Buyers should assess their facility’s electrical infrastructure to ensure it can support the chosen unit without requiring costly upgrades. -

Refrigerant Type

The type of refrigerant used in the air conditioner can affect both environmental impact and efficiency. Most modern units use environmentally-friendly refrigerants such as R-410A, which have a lower global warming potential compared to older refrigerants like R-22. Selecting a unit with a compliant refrigerant type is essential for businesses aiming to meet sustainability goals. -

Noise Level (dB)

Measured in decibels (dB), the noise level of an air conditioner is a critical consideration, especially in environments where quiet operation is necessary, such as offices or healthcare facilities. Units with lower dB ratings provide a more comfortable atmosphere for employees and clients alike.

Which Trade Terms Should B2B Buyers Know When Purchasing Air Conditioners?

Understanding industry-specific jargon can facilitate smoother transactions and negotiations. Here are some common terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. When sourcing air conditioners, buyers may encounter OEM products, which can offer reliability and brand assurance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects purchasing decisions, inventory management, and budgeting. Understanding MOQ helps companies negotiate better terms based on their needs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for a specific product. B2B buyers should prepare detailed RFQs for air conditioners to ensure they receive accurate and competitive quotes. -

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of sellers and buyers in the shipping process. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and the point at which ownership of the goods transfers. -

Warranty Period

This term refers to the duration that the manufacturer guarantees the air conditioner against defects or malfunctions. Understanding warranty terms is essential for businesses to assess the long-term viability and support options for their investment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing a 20000 BTU air conditioner, ensuring they select the best options for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 20000 btu air conditioner Sector

What Are the Current Market Dynamics and Key Trends in the 20000 BTU Air Conditioner Sector?

The global air conditioning market is undergoing significant transformation, driven by rising temperatures, urbanization, and an increasing emphasis on energy efficiency. Particularly in regions like Africa, South America, the Middle East, and Europe, the demand for high-capacity units such as the 20000 BTU air conditioner is surging. This growth is fueled by the need for reliable cooling solutions in both residential and commercial applications, especially in climates experiencing extreme heat.

Emerging technologies are reshaping the B2B landscape, with advancements in IoT (Internet of Things) and smart controls becoming increasingly prevalent. These technologies allow businesses to monitor and optimize energy use, leading to cost savings and improved operational efficiency. Additionally, the integration of energy-efficient systems is not only a response to regulatory pressures but also aligns with consumer preferences for sustainable products. For international buyers, particularly in markets like Nigeria and Germany, sourcing from manufacturers that prioritize innovation and energy efficiency can provide a competitive edge.

Market dynamics are also influenced by global supply chain challenges. The COVID-19 pandemic highlighted vulnerabilities in sourcing, prompting businesses to seek more localized supply chains. B2B buyers are advised to consider suppliers that can demonstrate resilience and adaptability in their operations, ensuring timely delivery and consistent product quality.

How Is Sustainability and Ethical Sourcing Reshaping the B2B Landscape for 20000 BTU Air Conditioners?

Sustainability is no longer a niche consideration; it has become a central pillar in the B2B procurement process. The environmental impact of air conditioning units, particularly those with higher BTU ratings, necessitates a focus on energy efficiency and eco-friendly refrigerants. International buyers should prioritize manufacturers that utilize HFC-free refrigerants and comply with global environmental standards.

Ethical sourcing practices are also gaining traction, with businesses increasingly seeking suppliers that maintain transparent supply chains and fair labor practices. Certifications such as ENERGY STAR and ISO 14001 are indicators of a manufacturer’s commitment to sustainability. By choosing to work with certified suppliers, businesses can mitigate risks associated with environmental compliance and enhance their brand reputation.

Moreover, the demand for sustainable products is influencing purchasing decisions, as end-users are more inclined to choose brands that align with their values. This shift presents an opportunity for B2B buyers to differentiate themselves in the marketplace by offering products that are not only high-performing but also environmentally responsible.

What Is the Historical Evolution of the 20000 BTU Air Conditioner Market?

The evolution of the air conditioning market can be traced back to the early 20th century when the first commercial systems were developed. Initially, air conditioning was seen as a luxury; however, post-World War II economic growth spurred widespread adoption, making cooling a standard requirement in homes and businesses.

As technology advanced, the introduction of more efficient compressor designs and refrigerants led to the development of units with higher BTU ratings, such as the 20000 BTU air conditioner. This evolution was further propelled by rising global temperatures and increasing energy costs, prompting manufacturers to innovate towards more energy-efficient models.

In recent years, the focus has shifted towards sustainability and smart technology integration, marking a new chapter in the air conditioning market. The current emphasis on energy efficiency and eco-friendly practices signifies a maturation of the industry, aligning with global efforts to combat climate change and reduce energy consumption. For B2B buyers, understanding this historical context can inform sourcing strategies that prioritize both performance and sustainability.

Illustrative image related to 20000 btu air conditioner

Frequently Asked Questions (FAQs) for B2B Buyers of 20000 btu air conditioner

-

How do I determine the right capacity for my cooling needs?

To determine the appropriate capacity for your cooling needs, consider the size of the space you wish to cool, insulation quality, and the number of occupants. A 20,000 BTU air conditioner is suitable for areas between 1,200 to 1,500 square feet, depending on these factors. Additionally, consider heat-generating appliances and direct sunlight exposure, which may require a higher capacity. It’s advisable to consult with HVAC professionals for precise calculations based on your specific environment. -

What are the key features to look for in a 20,000 BTU air conditioner?

When sourcing a 20,000 BTU air conditioner, prioritize energy efficiency ratings (SEER), noise levels, and additional features such as programmable thermostats, remote control, and energy-saving modes. Look for units with environmentally friendly refrigerants and easy maintenance options like accessible air filters. Durability and warranty terms are also critical, especially for B2B applications where reliability impacts operational efficiency. -

What are the typical payment terms for purchasing air conditioners in bulk?

Payment terms can vary significantly by supplier and region but often include options like net 30, net 60, or upfront payments. For bulk orders, negotiate terms that may include discounts for early payment or flexible financing options. Ensure clarity on currency, payment methods (like wire transfer or letters of credit), and potential escrow arrangements to safeguard both parties’ interests, especially in international transactions. -

How can I ensure the quality of the air conditioners I am sourcing?

To ensure product quality, request certifications such as ISO, CE, or UL, which indicate adherence to international standards. Conduct factory audits or utilize third-party inspection services to verify manufacturing processes. Additionally, review past customer feedback and request samples to assess performance and reliability. Establishing a strong relationship with your supplier can also facilitate better quality assurance processes. -

What logistics considerations should I keep in mind when importing air conditioners?

When importing air conditioners, consider shipping methods, lead times, and customs clearance processes. Ensure compliance with local regulations regarding import duties, taxes, and environmental standards. Partner with logistics providers experienced in handling HVAC equipment to minimize risks related to damage during transit. Discuss warehousing options to manage stock levels effectively and avoid stockouts upon arrival. -

Are there customization options available for commercial air conditioners?

Many manufacturers offer customization options for commercial air conditioners, such as tailored cooling capacities, specific voltage requirements, or additional features like heating elements. Discuss your specific needs with suppliers to understand the range of customization available and any implications on lead times or costs. Custom solutions can enhance operational efficiency and ensure that the units meet unique project specifications. -

What is the minimum order quantity (MOQ) for purchasing 20,000 BTU air conditioners?

The minimum order quantity (MOQ) for air conditioners can vary by supplier, typically ranging from a single unit to several dozen units for bulk pricing. Discuss your needs with potential suppliers to negotiate favorable MOQs that align with your business requirements. Some suppliers may offer flexibility based on the total value of the order or the potential for repeat business. -

How do I evaluate potential suppliers for reliability and trustworthiness?

To evaluate suppliers, conduct thorough research, including checking references, reading customer reviews, and verifying their business credentials. Look for suppliers with a proven track record in international trade and experience in your target market. Attend trade shows or industry conferences to meet suppliers in person and assess their products firsthand. Utilizing platforms that provide supplier ratings and reviews can also aid in your vetting process.

Top 1 20000 Btu Air Conditioner Manufacturers & Suppliers List

1. ROVSUN – 2 Zone 20000 BTU Mini Split Air Conditioner

Domain: rovsun.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “ROVSUN 2 Zone 20000 BTU Mini Split Air Conditioner with Heat Pump”, “features”: {“wifi_enabled”: true, “zones”: 2, “cooling_capacity_btu”: 20000, “heating_capacity_btu”: 20000, “energy_efficiency_ratio”: “20 SEER2”, “voltage”: “230V”, “install_kit_length”: “25Ft”}, “price”: {“sale_price”: 1549.99, “regular_price”: 1849.99}, “shipping”: {“free_shipping”: true, “shipping_time”: “Sh…

Strategic Sourcing Conclusion and Outlook for 20000 btu air conditioner

In the realm of strategic sourcing for 20,000 BTU air conditioners, international buyers must prioritize quality, efficiency, and adaptability to diverse environmental conditions. The growing demand for high-capacity cooling solutions in regions such as Africa, South America, the Middle East, and Europe underscores the necessity for suppliers to offer robust products that meet local regulatory standards while providing optimal performance.

Investing in energy-efficient models not only reduces operational costs but also aligns with global sustainability goals, making them a preferred choice among environmentally conscious businesses. Furthermore, leveraging suppliers that offer comprehensive support, including timely quotes and after-sales services, enhances the sourcing experience and builds long-term partnerships.

As the market evolves, buyers are encouraged to remain proactive in exploring innovative cooling technologies and trends. Engaging with manufacturers that prioritize R&D can lead to competitive advantages and improved operational efficiencies. By focusing on strategic sourcing, businesses can secure reliable air conditioning solutions that not only meet current needs but also adapt to future demands.

Illustrative image related to 20000 btu air conditioner

International B2B buyers are urged to assess their sourcing strategies critically and engage with trusted partners to ensure that their cooling solutions are both effective and sustainable.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.