Everything You Need to Know About 徐工 钻套管 Sourcing in 2025

Introduction: Navigating the Global Market for 徐工 钻套管

In today’s competitive landscape, sourcing high-quality 徐工 钻套管 (XCMG casing pipes) presents a significant challenge for international B2B buyers, particularly those operating in emerging markets such as Africa, South America, the Middle East, and Europe. As industries strive for efficiency and reliability in their drilling operations, the demand for robust and versatile casing solutions is paramount. This guide provides a comprehensive overview of 徐工 钻套管, detailing the various types available, their applications across different sectors, and essential criteria for supplier vetting.

Understanding the nuances of 徐工 钻套管 is crucial for making informed purchasing decisions. This guide empowers buyers by outlining key factors such as cost considerations, performance specifications, and potential suppliers, ensuring that they can navigate the complexities of the global market effectively. Whether you are looking to enhance your drilling capabilities or secure reliable suppliers, this resource equips you with the knowledge needed to optimize your procurement strategy.

By addressing the specific needs of buyers in regions like Brazil and Saudi Arabia, this guide not only simplifies the sourcing process but also enhances the potential for successful partnerships with leading manufacturers. Dive into the details and unlock the full potential of 徐工 钻套管 for your business success.

Understanding 徐工 钻套管 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| XRT2100 Full Rotation Casing Rig | Full rotation capability, high drilling efficiency | Oil & gas exploration, geothermal wells | Pros: High efficiency, versatile. Cons: Higher initial investment. |

| XSL720 Crawler Deep Well Drill | Compact design, various drilling methods available | Deep well drilling for water, geothermal | Pros: Versatile, energy-efficient. Cons: Limited depth compared to larger models. |

| XSM2250 Modular Deep Well Drill | Modular design for easy transport and setup | Mining, water extraction | Pros: Easy to transport, flexible. Cons: May require additional setup time. |

| XSL1000 Crawler Well Drilling Rig | High reliability, advanced safety features | Agriculture, industrial water supply | Pros: Safe operation, durable. Cons: Heavier machinery may limit mobility. |

| XSC1500 Crawler Mounted Rig | Enhanced automation, dual power options | Urban construction, environmental drilling | Pros: Automated processes, eco-friendly. Cons: Higher maintenance costs. |

What are the Key Characteristics of the XRT2100 Full Rotation Casing Rig?

The XRT2100 is designed for high efficiency in drilling operations, particularly in oil and gas exploration. Its full rotation capability allows for faster drilling speeds and improved hole quality. This rig is suitable for international buyers seeking reliable equipment for challenging drilling environments. However, its higher initial cost may require careful financial planning and budget considerations.

How Does the XSL720 Crawler Deep Well Drill Stand Out?

The XSL720 crawler deep well drill is known for its compact design and adaptability to various drilling methods, including air hammer and mud drilling. It is primarily used in the extraction of water and geothermal resources. Buyers appreciate its energy efficiency and the ability to operate in diverse geological conditions, but they should note its limitations in depth compared to larger models.

Why Choose the XSM2250 Modular Deep Well Drill?

The XSM2250 features a modular design that simplifies transportation and setup, making it ideal for projects that require mobility. This drill is commonly used in mining and water extraction applications. While its flexibility is a significant advantage, potential buyers should consider the time needed for assembly and disassembly, which may impact project timelines.

What Benefits Does the XSL1000 Crawler Well Drilling Rig Offer?

The XSL1000 crawler well drilling rig is recognized for its durability and advanced safety features, making it a reliable choice for agricultural and industrial water supply projects. Buyers can benefit from its robust construction, which ensures long-term performance. However, its weight may limit mobility in certain terrains, which is an important consideration for logistics.

How Does the XSC1500 Crawler Mounted Rig Enhance Operations?

The XSC1500 crawler mounted rig is equipped with enhanced automation features and dual power options, making it suitable for urban construction and environmental drilling. Its automated processes reduce labor costs and improve efficiency, appealing to buyers focused on productivity. However, potential maintenance costs should be factored into the overall budget, as they can be higher due to the advanced technology involved.

Key Industrial Applications of 徐工 钻套管

| Industry/Sector | Specific Application of 徐工 钻套管 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Drilling for oil and gas extraction | Enhanced drilling efficiency and reduced costs | Equipment durability, local service support, and compliance with international standards |

| Water Resource Management | Installation of deep water wells for agriculture | Improved access to water resources for irrigation | Availability of spare parts and adaptability to local geological conditions |

| Mining | Exploration and extraction of minerals | Increased productivity and reduced operational risks | Supplier reputation, after-sales service, and technological support |

| Geothermal Energy | Drilling geothermal wells for energy production | Sustainable energy solution and reduced carbon footprint | Expertise in geothermal applications and environmental compliance |

| Construction | Foundation drilling for large structures | Enhanced structural integrity and safety | Project-specific customization and adherence to local regulations |

How is 徐工 钻套管 Used in the Oil and Gas Industry?

In the oil and gas sector, 徐工 钻套管 is critical for drilling operations aimed at extracting hydrocarbons. These casings provide structural integrity to the borehole, ensuring safety and efficiency during drilling. The robust design allows for high-pressure environments, minimizing the risk of blowouts. For international buyers, especially in regions like the Middle East, understanding local regulations and securing reliable service support for maintenance and repairs is vital to maximize operational uptime.

What Role Does 徐工 钻套管 Play in Water Resource Management?

徐工 钻套管 is extensively used in the installation of deep wells for agricultural and municipal water supply. This application is particularly crucial in regions facing water scarcity, as it enables access to groundwater resources. The ability to customize the casing size and material based on local geological conditions is essential for ensuring longevity and effectiveness. Buyers from Africa and South America should consider the availability of spare parts and local service capabilities to support ongoing operations.

Illustrative image related to 徐工 钻套管

How is 徐工 钻套管 Beneficial for Mining Operations?

In mining, 徐工 钻套管 is utilized for exploration and the extraction of minerals. The casing enhances drilling accuracy and stability, which is critical in reducing operational risks and improving productivity. Given the challenging conditions often present in mining environments, buyers must prioritize suppliers with a strong reputation for durability and reliability. Additionally, after-sales service and technical support can significantly impact the success of mining projects.

Can 徐工 钻套管 Support Geothermal Energy Initiatives?

徐工 钻套管 is also instrumental in drilling geothermal wells, facilitating the harnessing of renewable energy. This application contributes to sustainable energy solutions, reducing reliance on fossil fuels. Buyers interested in geothermal projects should look for suppliers with expertise in this field, ensuring compliance with environmental regulations and standards. The adaptability of the equipment to varying geological conditions is a key consideration for successful project implementation.

How Does 徐工 钻套管 Enhance Construction Projects?

In construction, 徐工 钻套管 is essential for foundation drilling, providing stability and safety for large structures. The casings ensure that the boreholes maintain their integrity, which is crucial for load-bearing applications. For international buyers, particularly in Europe, understanding local building codes and project-specific requirements is necessary to ensure compliance and successful project execution. Customization options offered by suppliers can further enhance the suitability of the equipment for specific construction needs.

3 Common User Pain Points for ‘徐工 钻套管’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Specifications for Project Needs

The Problem: B2B buyers often encounter challenges when trying to select the appropriate specifications for ‘徐工 钻套管’ that align with their specific project requirements. For instance, a construction firm in Brazil might need to drill in varied geological conditions ranging from soft clay to hard rock. The lack of clear understanding about which drill pipe diameter, material, or design would perform best under these conditions can lead to costly project delays and increased operational risks.

The Solution: To effectively select the right specifications, it is crucial to conduct a thorough assessment of the geological conditions and operational requirements. Buyers should engage with technical experts from 徐工 who can provide detailed consultations based on the project scope. Utilizing simulation software to model the drilling process can also help predict performance under different conditions. Furthermore, buyers should request detailed product catalogs and case studies from 徐工 that showcase the performance of various drilling tools in similar environments. This proactive approach ensures that the selected ‘徐工 钻套管’ not only meets the project demands but also enhances efficiency and safety during operations.

Scenario 2: Managing Downtime Due to Equipment Failure

The Problem: Equipment failures can lead to significant downtime, impacting project timelines and budgets. For instance, a mining company in Saudi Arabia using ‘徐工 钻套管’ may experience breakdowns due to inadequate maintenance or the use of subpar components, which are not designed for extreme conditions. The resulting delays can affect not only productivity but also client relationships and financial outcomes.

The Solution: To mitigate the risk of downtime, it’s essential to implement a robust maintenance schedule tailored to the specific operational environment. Buyers should work closely with 徐工 to establish a service agreement that includes regular inspections and timely replacement of wear components. Additionally, investing in training for operators on proper usage and maintenance techniques can help identify potential issues before they result in failure. Utilizing data analytics tools can also aid in predictive maintenance, allowing for timely interventions based on real-time performance metrics. By prioritizing maintenance and operator training, companies can significantly reduce downtime and enhance overall productivity.

Scenario 3: Navigating Regulatory Compliance and Environmental Standards

The Problem: B2B buyers in regions like Africa and South America often face stringent regulatory compliance and environmental standards when utilizing drilling equipment such as ‘徐工 钻套管’. A drilling company may struggle to ensure that their operations meet local regulations concerning environmental impact, noise levels, and waste management, risking fines or project shutdowns.

The Solution: To navigate regulatory compliance effectively, buyers should conduct a comprehensive review of local regulations before commencing operations. Engaging with environmental consultants can provide insights into the necessary permits and compliance measures required for using ‘徐工 钻套管’. Additionally, 徐工 offers equipment that is designed with environmental considerations in mind, such as noise-reduction technologies and options for managing drilling waste. Buyers should also consider implementing an environmental management system (EMS) to monitor and report compliance, which not only helps in adhering to regulations but also enhances the company’s reputation. By taking these steps, buyers can ensure that their drilling operations are compliant and environmentally responsible, ultimately leading to smoother project execution and better stakeholder relationships.

Illustrative image related to 徐工 钻套管

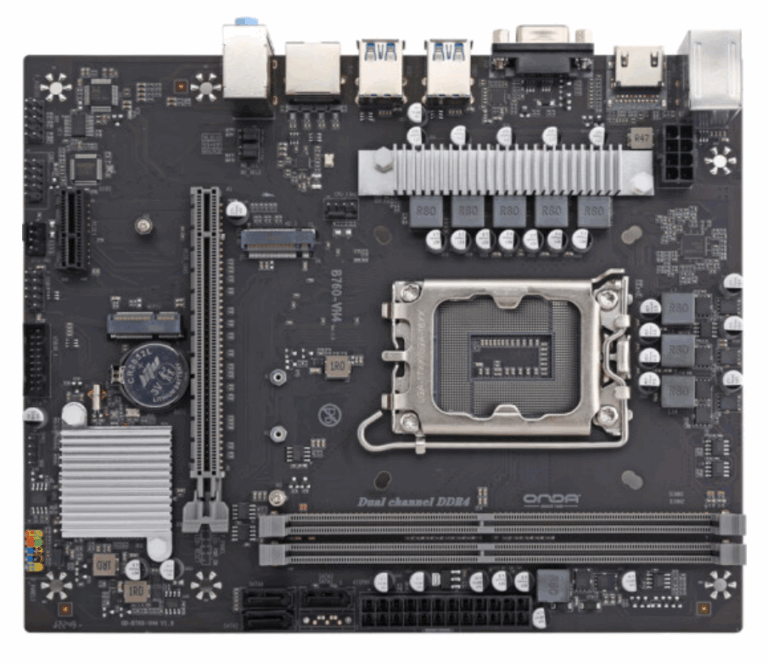

Strategic Material Selection Guide for 徐工 钻套管

What Are the Common Materials Used in 徐工 钻套管?

Selecting the right materials for 徐工 钻套管 is crucial for ensuring optimal performance and longevity in various drilling applications. Below, we analyze four common materials used in the manufacturing of these casings, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

How Does Steel Perform in 徐工 钻套管 Applications?

Key Properties: Steel is known for its high tensile strength and excellent durability. It typically has a temperature rating up to 500°C and can withstand high pressures, making it suitable for deep drilling applications.

Pros & Cons: Steel offers exceptional durability and resistance to deformation under stress. However, it is susceptible to corrosion, especially in saline or acidic environments, which can lead to premature failure. The manufacturing complexity is moderate, requiring specific processes like heat treatment.

Impact on Application: Steel’s compatibility with various drilling media, including water and oil, makes it a versatile choice. However, its corrosion susceptibility necessitates protective coatings or alloying with materials like chromium or nickel.

Considerations for International Buyers: Compliance with international standards such as ASTM A53 or API 5CT is essential. Buyers from regions like Africa and the Middle East should consider local environmental conditions that may affect steel’s longevity.

What Role Does PVC Play in 徐工 钻套管?

Key Properties: PVC (Polyvinyl Chloride) is lightweight and offers excellent chemical resistance, with a temperature rating typically up to 60°C.

Pros & Cons: The primary advantage of PVC is its resistance to corrosion and chemical degradation, making it ideal for applications involving aggressive fluids. However, its lower tensile strength compared to metals can limit its use in high-pressure scenarios. PVC is also easier to manufacture, resulting in lower production costs.

Impact on Application: PVC is suitable for shallow drilling applications where chemical exposure is a concern. It is not recommended for deep drilling due to its lower pressure tolerance.

Considerations for International Buyers: Compliance with standards like ASTM D1784 is crucial. Buyers in regions like South America should ensure that the PVC used meets local regulations regarding chemical safety.

Illustrative image related to 徐工 钻套管

How Does Composite Material Enhance Performance in 徐工 钻套管?

Key Properties: Composite materials, often a combination of fiberglass and resin, provide high strength-to-weight ratios and excellent corrosion resistance, with temperature ratings up to 120°C.

Pros & Cons: Composites are lightweight and resistant to corrosion, making them suitable for various drilling environments. However, they are typically more expensive to manufacture and can be less durable than metals in high-stress applications.

Impact on Application: Composites are ideal for specialized applications, such as geothermal drilling, where corrosion resistance is paramount. Their lightweight nature also allows for easier handling and installation.

Considerations for International Buyers: Compliance with standards like ASTM D3299 is essential. Buyers should consider the availability of composite materials in their region and any additional costs associated with their use.

Illustrative image related to 徐工 钻套管

What Are the Benefits of Using Stainless Steel in 徐工 钻套管?

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand high temperatures (up to 800°C) and pressures, making it suitable for various challenging environments.

Pros & Cons: The main advantage of stainless steel is its durability and resistance to rust, which enhances the lifespan of the drilling equipment. However, it is more expensive than regular steel and can be more complex to manufacture due to its alloying elements.

Impact on Application: Stainless steel is particularly beneficial in environments with high salinity or acidic conditions, ensuring the integrity of the casing over time.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A312. In regions like Europe and the Middle East, where stringent quality standards are enforced, stainless steel is often preferred despite its higher cost.

Summary Table of Material Selection for 徐工 钻套管

| Material | Typical Use Case for 徐工 钻套管 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Deep drilling applications | High tensile strength | Susceptible to corrosion | Medium |

| PVC | Shallow drilling applications | Excellent chemical resistance | Lower pressure tolerance | Low |

| Composite | Geothermal drilling | Lightweight and corrosion-resistant | Higher manufacturing costs | High |

| Stainless Steel | Harsh environments | Superior corrosion resistance | Higher cost and complexity | High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 徐工 钻套管

What Are the Key Stages in the Manufacturing Process of 徐工 钻套管?

The manufacturing process for 徐工 钻套管 (XCMG casing pipes) involves several critical stages designed to ensure high-quality output that meets international standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing of 徐工 钻套管 is the selection and preparation of raw materials. Typically, high-strength steel or alloy materials are chosen for their durability and resistance to corrosion. The materials undergo rigorous quality checks to confirm their mechanical properties, ensuring they meet the required specifications.

Once selected, the raw materials are cut to size using advanced cutting technologies, including laser and plasma cutting. This precise cutting is crucial for minimizing waste and ensuring that the components fit together seamlessly in subsequent stages.

What Forming Techniques Are Used in the Production of 徐工 钻套管?

After material preparation, the next phase is forming. 徐工 employs a combination of techniques such as hot rolling and cold forming, depending on the specific requirements of the casing pipes. Hot rolling is particularly beneficial for achieving desired shapes and dimensions while enhancing material properties through thermal treatment.

Advanced machinery, including CNC machines and hydraulic presses, are utilized to shape the pipes accurately. The forming process is closely monitored to maintain tolerances and ensure that the structural integrity of the pipes is not compromised.

How Are 徐工 钻套管 Assembled and Finished?

The assembly stage involves joining various components of the casing pipes. This is typically achieved through welding, which is carried out using automated welding machines to ensure consistent quality. The welding process is critical as it affects the overall strength and reliability of the finished product.

Following assembly, the finishing process takes place. This includes surface treatments such as galvanizing or coating to enhance corrosion resistance and improve the aesthetic appeal of the pipes. Quality assurance protocols are put in place to inspect the finished products for defects and adherence to specifications.

What Quality Assurance Standards Are Relevant for 徐工 钻套管?

Quality assurance is paramount in the manufacturing of 徐工 钻套管, especially for international markets. Compliance with recognized international standards such as ISO 9001 is essential, as it ensures that the manufacturing processes are continually improved and that customer satisfaction is prioritized.

In addition to ISO 9001, industry-specific certifications like CE marking and API (American Petroleum Institute) standards are crucial for products intended for oil and gas applications. These certifications indicate that the products meet strict safety and quality requirements, which is particularly important for B2B buyers operating in regions with varying regulatory landscapes.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated into every stage of the manufacturing process for 徐工 钻套管. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Any non-compliant materials are rejected and returned to the supplier.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the processes and ensure adherence to specifications. This includes checking the dimensions, tolerances, and weld integrity at various stages.

-

Final Quality Control (FQC): After the completion of manufacturing, a comprehensive inspection is performed on the finished products. This includes testing for mechanical properties, pressure tests, and visual inspections to identify any defects.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers can take several steps to verify the quality control measures of their suppliers. One effective method is conducting audits of the manufacturing facilities. This allows buyers to assess the processes and standards in place firsthand.

Buyers can also request quality assurance reports and documentation, which should include details of the testing methods used, results from various QC checkpoints, and information on any certifications obtained.

Additionally, engaging third-party inspection services can provide an unbiased assessment of the manufacturing quality. These organizations can perform random checks and provide certification that the products meet specified standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different markets may have distinct regulatory requirements and quality expectations.

Illustrative image related to 徐工 钻套管

Buyers should be aware of the documentation needed for customs clearance, including certificates of conformity and quality assurance documentation. It’s also important to consider the logistics of shipping and handling, as these can impact the product integrity during transit.

Moreover, establishing a clear communication line with suppliers regarding quality expectations and standards is crucial. This proactive approach can help mitigate risks associated with product non-compliance and ensure that the final products meet the buyer’s needs.

Conclusion

The manufacturing processes and quality assurance protocols for 徐工 钻套管 are designed to meet high industry standards and cater to the specific needs of international B2B buyers. By understanding these processes and the associated quality control measures, buyers can make informed decisions, ensuring they receive reliable products that meet their operational requirements.

Illustrative image related to 徐工 钻套管

Practical Sourcing Guide: A Step-by-Step Checklist for ‘徐工 钻套管’

This practical sourcing guide is designed to assist B2B buyers in effectively procuring ‘徐工 钻套管’ (XCMG drill casing). By following this step-by-step checklist, you can ensure a successful procurement process, minimizing risks and maximizing value from your investment.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to outline your technical requirements for the drill casing. Consider factors such as material composition, dimensions, and compatibility with existing equipment. A clear specification will help you communicate your needs effectively to potential suppliers and ensure that you receive products that meet your operational requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of 徐工 钻套管. Look for companies with a solid track record in the industry, particularly those with experience supplying to markets similar to yours, such as Africa, South America, or Europe. Utilize online platforms, industry reports, and trade shows to gather information about potential suppliers.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers possess the necessary certifications and quality assurance standards relevant to your industry. This may include ISO certifications, safety standards, and compliance with local regulations. Certifications serve as a testament to the supplier’s commitment to quality and reliability, ensuring that their products will meet your expectations.

Step 4: Request Product Samples

Before finalizing a purchase, it is advisable to request samples of the 徐工 钻套管. Assess the quality, durability, and suitability of the samples for your specific applications. This step allows you to make an informed decision and gauge the supplier’s ability to meet your quality standards.

Step 5: Check Customer References and Reviews

Reach out to previous customers or seek online reviews to gain insights into the supplier’s reliability and customer service. Inquire about their experiences regarding product quality, delivery times, and post-purchase support. Positive feedback from other buyers can significantly influence your decision and provide assurance of the supplier’s credibility.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in discussions to negotiate pricing, payment terms, and delivery schedules. Ensure that all agreements are documented in a formal contract to protect both parties. Clear communication during this phase is crucial to avoid misunderstandings and ensure a smooth procurement process.

Step 7: Plan for After-Sales Support and Maintenance

Consider the after-sales services offered by the supplier, including warranty provisions, maintenance support, and training for your staff. A supplier that provides comprehensive support can enhance the longevity and performance of the 徐工 钻套管, ultimately contributing to the efficiency of your operations.

By following these steps, B2B buyers can navigate the procurement process for 徐工 钻套管 with confidence, ensuring they make informed decisions that align with their operational needs and business objectives.

Comprehensive Cost and Pricing Analysis for 徐工 钻套管 Sourcing

What Are the Key Cost Components in Sourcing 徐工 钻套管?

When considering the sourcing of 徐工 钻套管, understanding the cost structure is essential. The primary cost components include:

-

Materials: The quality and type of materials used significantly impact the cost. High-grade steel or specialized alloys will drive up expenses but can enhance durability and performance.

-

Labor: Skilled labor is necessary for manufacturing and quality assurance. Labor costs can vary widely based on the region and the level of expertise required.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The initial investment in molds and tools can be substantial, especially for customized solutions. This cost is amortized over the production volume, making it crucial to consider order sizes.

-

Quality Control (QC): Implementing rigorous QC measures ensures the integrity of the products but adds to the overall costs. Certifications and compliance with international standards can also influence pricing.

-

Logistics: Transportation and warehousing costs can vary based on the destination. For international buyers, understanding Incoterms is vital to manage these costs effectively.

-

Margin: Supplier margins will depend on market conditions, competition, and the perceived value of the product. A higher margin may indicate a strong brand reputation or superior quality.

How Do Price Influencers Affect the Cost of 徐工 钻套管?

Several factors influence the pricing of 徐工 钻套管 in the international market:

-

Volume/MOQ: Larger orders typically result in lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can also lead to better pricing.

-

Specifications and Customization: Custom specifications may require additional resources, impacting the cost. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (such as ISO or CE) can justify increased costs but may be necessary for certain applications, particularly in regulated markets.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can influence pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is essential for managing logistics costs and risk allocation. These terms dictate who is responsible for shipping, insurance, and tariffs.

What Negotiation Strategies Can International Buyers Use for Cost Efficiency?

For international buyers from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can yield significant savings:

-

Research and Benchmarking: Understand market prices and competitor offerings. This knowledge empowers buyers during negotiations and helps identify fair pricing.

-

Volume Commitments: Offering to place larger orders can leverage discounts. Suppliers may be more willing to negotiate favorable terms for guaranteed long-term business.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, operation, and potential downtime. A lower initial price may lead to higher TCO if quality is compromised.

-

Flexible Payment Terms: Propose various payment options, such as staggered payments or early payment discounts, which can be attractive to suppliers and beneficial for cash flow management.

-

Building Relationships: Establishing a strong relationship with suppliers can lead to better terms and pricing over time. Trust and loyalty can often result in preferential treatment during negotiations.

What Should Buyers Be Aware of Regarding Indicative Prices?

While it is essential to have a ballpark figure for budgeting, buyers should be cautious with indicative prices. Fluctuations in raw material costs, labor rates, and currency exchange rates can lead to significant changes in pricing. Always confirm final pricing before placing orders and consider including clauses in contracts that account for potential price adjustments due to unforeseen circumstances.

By understanding these cost components and influencers, international B2B buyers can make informed decisions, negotiate effectively, and ultimately achieve better value in their sourcing of 徐工 钻套管.

Alternatives Analysis: Comparing 徐工 钻套管 With Other Solutions

Understanding the Importance of Alternatives in B2B Equipment Selection

In the competitive landscape of construction and resource extraction, selecting the right equipment is crucial for maximizing efficiency and reducing costs. For international B2B buyers, understanding various alternatives to a specific product, such as the 徐工 钻套管, can provide valuable insights into making informed purchasing decisions. This section compares 徐工 钻套管 with two viable alternatives, highlighting their respective advantages and drawbacks.

Illustrative image related to 徐工 钻套管

Comparison Table

| Comparison Aspect | ‘徐工 钻套管’ | Alternative 1: XSL720履带式深井钻机 | Alternative 2: Traditional Rotary Drilling |

|---|---|---|---|

| Performance | High drilling speed, versatile techniques | Excellent for deep wells, multiple configurations | Moderate speed, limited to specific applications |

| Cost | Competitive pricing | Higher initial investment, but cost-effective over time | Generally lower cost, but may incur higher operational costs |

| Ease of Implementation | Requires skilled operators | User-friendly with automated options | Simple setup, but requires extensive manual labor |

| Maintenance | Regular maintenance needed | Low maintenance due to robust design | High maintenance due to wear and tear |

| Best Use Case | Versatile for various drilling needs | Ideal for deep oil and gas wells | Best for shallow applications and small projects |

Detailed Breakdown of Alternatives

Alternative 1: XSL720履带式深井钻机

The XSL720 is designed specifically for deep well drilling, making it an excellent choice for sectors like oil and gas extraction. Its high adaptability and multiple configurations allow for efficient operation in various environments, including harsh conditions. While it comes with a higher initial investment, its advanced features such as automated operations significantly reduce labor costs and enhance productivity. However, its complexity may require specialized training for operators.

Alternative 2: Traditional Rotary Drilling

Traditional rotary drilling methods are widely recognized for their simplicity and cost-effectiveness. These systems are less expensive initially and can be deployed quickly for small-scale projects. However, they often involve higher operational costs due to slower drilling speeds and greater wear on equipment. Additionally, the manual labor requirement can lead to increased safety risks and potential delays in project timelines. They are best suited for shallow drilling applications, limiting their versatility compared to the 徐工 钻套管 and XSL720.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between 徐工 钻套管 and its alternatives, B2B buyers should evaluate their specific project requirements, including depth, soil type, and budget constraints. The 徐工 钻套管 offers a balanced solution with high performance and versatility, making it suitable for a wide range of applications. Alternatively, if deep drilling is the primary focus, the XSL720 may provide superior efficiency, albeit at a higher cost. For smaller projects or limited budgets, traditional rotary drilling could be an appropriate choice, despite its limitations. Ultimately, understanding the strengths and weaknesses of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for 徐工 钻套管

What Are the Essential Technical Properties of 徐工 钻套管?

Understanding the technical properties of 徐工 钻套管 is crucial for international buyers looking to invest in high-quality drilling equipment. Here are some of the key specifications that define the performance and suitability of these products:

-

Material Grade

The material grade of the drilling casing is vital as it determines the strength and durability of the pipe under various environmental conditions. High-grade steel, such as API 5CT, is commonly used, offering excellent resistance to corrosion and mechanical stress. Buyers should prioritize material specifications to ensure longevity and reliability in demanding drilling environments. -

Tolerance Levels

Tolerance levels refer to the permissible limits of variation in the dimensions of the drill casing. Precise tolerances are essential for ensuring proper fit and function during assembly and operation. Inaccurate tolerances can lead to operational inefficiencies and increased wear on drilling equipment, impacting overall productivity. -

Wall Thickness

The wall thickness of the drilling casing affects its load-bearing capacity and resistance to external pressures. Thicker walls provide enhanced strength, making them suitable for deep drilling applications where high pressures are encountered. Buyers should assess the wall thickness in relation to the specific drilling conditions to ensure optimal performance. -

Length and Diameter Specifications

Casing length and diameter are critical for compatibility with various drilling rigs and geological conditions. Standard lengths and diameters allow for easier handling and installation, while customized options can be tailored to meet specific project requirements. Understanding these dimensions is vital for project planning and execution. -

Coating and Corrosion Resistance

Protective coatings can significantly enhance the lifespan of drilling casings by preventing corrosion caused by harsh environmental conditions. Options such as epoxy or hot-dipped galvanization offer varying levels of protection, which are important considerations for buyers operating in corrosive environments. -

Connection Types

The type of connections (e.g., threaded or welded) used in drill casings can influence installation efficiency and leak prevention. Understanding the different connection types allows buyers to select the most appropriate solution for their specific drilling applications.

What Are Common Trade Terms in the Drilling Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B market. Here are some common trade terms relevant to 徐工 钻套管:

Illustrative image related to 徐工 钻套管

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the drilling industry, buyers often engage with OEMs to ensure they receive high-quality components that meet their specific needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers, as it affects inventory management and purchasing decisions. It can also influence pricing and shipping costs. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. This is particularly important in the drilling industry, where costs can vary significantly based on specifications and order size. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers navigate shipping logistics and costs associated with their purchases. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the drilling sector, lead times can be critical, especially for projects with tight schedules. Buyers should inquire about lead times to ensure timely delivery of equipment. -

Warranty

A warranty is a promise from the manufacturer regarding the condition of the product and the terms of repair or replacement. A strong warranty can provide buyers with peace of mind regarding the longevity and reliability of their drilling equipment.

By understanding these technical properties and trade terms, international buyers can make informed decisions when sourcing 徐工 钻套管, ensuring they choose the right products for their drilling needs.

Navigating Market Dynamics and Sourcing Trends in the 徐工 钻套管 Sector

What Are the Key Market Dynamics and Trends Influencing the 徐工 钻套管 Sector?

The 徐工 钻套管 sector is witnessing a dynamic transformation driven by global demand for infrastructure development and resource extraction. Key markets in Africa, South America, the Middle East, and Europe are increasingly investing in drilling technologies to meet the growing needs for energy and mineral resources. The push towards automation in drilling processes, including the adoption of advanced machinery like the XSL720 deep well drilling rig, has been a notable trend. These machines not only enhance drilling efficiency but also improve safety and reduce labor costs, making them highly appealing to international buyers.

Moreover, the integration of digital technologies, such as IoT and AI, is reshaping sourcing strategies. Buyers are now looking for equipment that not only meets traditional performance metrics but also incorporates smart features for predictive maintenance and real-time data analytics. This shift is particularly relevant for markets in Brazil and Saudi Arabia, where operational efficiency and cost-effectiveness are paramount. Additionally, as global supply chains become more complex, strategic partnerships with reliable manufacturers like 徐工 can provide buyers with competitive advantages in terms of quality and responsiveness.

Illustrative image related to 徐工 钻套管

How Are Sustainability and Ethical Sourcing Shaping the 徐工 钻套管 Industry?

Sustainability is increasingly becoming a cornerstone of business strategy in the 徐工 钻套管 sector. With heightened awareness of environmental issues, companies are prioritizing eco-friendly practices in their sourcing and manufacturing processes. This includes using sustainable materials and technologies that minimize environmental impact. For instance, 徐工’s initiatives to develop energy-efficient drilling equipment reflect a commitment to reducing carbon footprints.

Ethical sourcing is also gaining traction among B2B buyers. Companies are expected to ensure that their supply chains are transparent and responsible, adhering to international labor standards and environmental regulations. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications are becoming critical factors for buyers when evaluating suppliers. This trend is especially significant in regions like Europe, where regulatory frameworks are stringent and consumers demand accountability.

By focusing on sustainability and ethical sourcing, companies can not only comply with regulatory requirements but also enhance their brand reputation, attract environmentally-conscious investors, and ultimately drive long-term profitability.

What Is the Evolution of the 徐工 钻套管 Sector and Its Relevance to B2B Buyers?

The 徐工 钻套管 sector has evolved significantly over the past few decades, transitioning from traditional drilling methods to advanced technology-driven solutions. Established in the early 1980s, 徐工 has consistently innovated its product line, adapting to the changing needs of the global market. The introduction of high-efficiency drilling rigs and automated systems has allowed 徐工 to establish itself as a leader in the construction and drilling equipment industry.

This evolution is relevant for B2B buyers as it signifies a shift towards more reliable and efficient drilling solutions. Modern equipment not only increases productivity but also aligns with the global trend towards sustainability. Buyers looking for durable and efficient drilling solutions can benefit from partnering with established manufacturers like 徐工, ensuring they are equipped with the latest technology to meet their operational needs.

Illustrative image related to 徐工 钻套管

Frequently Asked Questions (FAQs) for B2B Buyers of 徐工 钻套管

-

How do I ensure the quality of 徐工 钻套管 before purchasing?

To ensure the quality of 徐工 钻套管, request detailed product specifications, certifications, and quality assurance documentation from the supplier. Conduct a thorough supplier vetting process that includes checking references and reviewing past performance. If possible, arrange for a factory visit or third-party inspection to assess manufacturing processes and materials used. This proactive approach helps mitigate risks and guarantees that you receive a product that meets your operational standards. -

What customization options are available for 徐工 钻套管?

徐工 offers various customization options for 钻套管 to meet specific project requirements. These may include adjustments in size, material specifications, and design features tailored to different drilling conditions. Engage directly with the supplier to discuss your needs, as they can provide insights on feasible modifications and potential impacts on performance and pricing. Be prepared to share detailed project requirements to facilitate the customization process. -

What are the minimum order quantities (MOQ) for 徐工 钻套管?

Minimum order quantities (MOQ) for 徐工 钻套管 can vary based on the model and supplier policies. Typically, larger orders may qualify for better pricing and terms. It’s essential to discuss your specific needs with the supplier to understand their MOQ requirements and explore options for smaller trial orders if necessary. This can help you assess product performance before committing to larger quantities. -

What payment terms should I expect when purchasing 徐工 钻套管?

Payment terms for 徐工 钻套管 typically include options like upfront payments, letters of credit, or payment upon delivery. The specific terms will depend on your negotiation with the supplier and your relationship history. Be sure to clarify payment structures, including any deposits required, timelines for payment, and acceptable payment methods. Establishing clear terms can help prevent misunderstandings and ensure a smooth transaction process. -

How can I verify the reliability of a supplier for 徐工 钻套管?

To verify a supplier’s reliability for 徐工 钻套管, conduct comprehensive due diligence. This includes checking their business licenses, certifications, and industry reputation. Look for reviews and testimonials from previous clients, and consider engaging with third-party verification services. Additionally, assess their production capacity and supply chain stability to ensure they can meet your demands consistently. -

What logistics considerations should I keep in mind when importing 徐工 钻套管?

When importing 徐工 钻套管, consider logistics factors such as shipping methods, customs regulations, and lead times. Work with experienced freight forwarders who understand international shipping protocols, especially for heavy machinery. Ensure all necessary documentation, such as invoices and shipping certificates, is in order to avoid delays at customs. Planning ahead for transportation can help mitigate unforeseen issues and ensure timely delivery. -

What after-sales support is available for 徐工 钻套管?

徐工 typically offers robust after-sales support, including installation assistance, maintenance training, and access to spare parts. Confirm the details of the support package with your supplier, as this can vary by region and purchase agreement. Establishing a clear understanding of after-sales services can enhance your operational efficiency and help address any issues that may arise after the purchase. -

How do I handle potential disputes with a supplier of 徐工 钻套管?

In the event of a dispute with a supplier of 徐工 钻套管, first attempt to resolve the issue amicably through direct communication. Clearly outline your concerns and seek a mutually agreeable solution. If necessary, consult the terms of your purchase agreement regarding dispute resolution processes, which may include mediation or arbitration. Maintaining documentation of all communications and agreements can be invaluable if the situation escalates and requires formal resolution.

Top 6 徐工 钻套管 Manufacturers & Suppliers List

1. XCMG – XRT2100 Full Rotation Casing Drilling Rig

2. 徐工集团 – XRS1050 旋挖钻机

Domain: m.machmall.com

Registered: 2005 (20 years)

Introduction: {‘model_name’: ‘XRS1050’, ‘type’: ‘旋挖钻机’, ‘power’: ‘298 kW’, ‘origin’: ‘江苏徐州’, ‘engine_type’: ‘康明斯 QSM11-C400’, ‘brand’: ‘徐工集团’, ‘dimensions’: ‘10265×4800×27520 mm’, ‘weight’: ‘180 t’, ‘max_bore_diameter’: ‘2500 mm’, ‘max_bore_depth’: ‘105 m’, ‘safety_bore_range’: ‘4350 ~ 4650 mm’, ‘max_working_pressure’: ’35 MPa’, ‘max_torque’: ‘390 kN•m’, ‘rotation_speed’: ‘7 ~ 18 r/min’, ‘max_pressure_cylinder’…

3. 徐工 – XR280D旋挖钻机

Domain: product.d1cm.com

Registered: 2006 (19 years)

Introduction: 徐工XR280D旋挖钻机

– 更新时间:2025-09-08

– 关注人数:103032

– 在线询价:431份

– 综合评分:75

– 参与评价人数:3

– 评分细分:

– 外观:80分

– 质量:90分

– 性能:80分

– 售后:80分

– 价格:80分

– 物流:80分

– 性价比:40分

– 产品特点:

1. 专用液压伸缩式履带底盘,大直径回转支承,超强稳定性和运输便捷性。

2. 康明斯涡轮增压发动机,先进电液控制技术,动力强劲。

3. 后置单排绳主卷扬结构,延长钢丝绳寿命,降低使用成本。

4. 多种钻杆配置可选,最大钻深88米,适合大孔深桩硬地层施工。

5. 可选多功能配置:支腿油缸,套管驱动,扩展性好。

6. 动力头选配入岩模式,提高施工效率。

4. 徐工 – 水平定向钻 XZ2860Plus

Domain: zj.lmjx.net

Registered: 2003 (22 years)

Introduction: 品牌: 徐工, 类别: 水平定向钻, 型号: XZ2860Plus, 性能特点: 1. 数字式仪表,自动显示施工中的实际扭矩、推拉力等施工主参数,操作简单;电子传感技术反应灵敏,能及时反馈瞬时超载,可靠地保护钻机。 2. 钻架滑移依靠油缸推拉,结合前摇臂结构,入土角度调节操作简单、方便、安全;钻架后限位使用三重无撞限位,安全性高。 3. 双动力系统,任一发动机启动可完成钻机的全部动作,适用范围广,燃油消耗少,施工成本低。 4. 全程浮动式虎钳,卸扣扭矩大,方便下套管施工;技术的可旋转虎牙座,实现钻杆自动定心,夹紧可靠。 5. 过载保护技术,钻机旋转扭矩、推拉力及虎钳夹紧力均可调且采用数字式调压技术,调整方便、简单,能精确预设。 6. 旋转采用闭式液压系统、推拉采用负荷敏感控制等多项先进的控制技术,关键液压、电器、传动元件均选用国际著名产品,质量可靠。

5. 徐工 – 岩巷掘进机与工程机械模型

Domain: taobao.com

Registered: 2003 (22 years)

Introduction: 原厂 徐工 集团 EBZ200 岩巷掘进机旋挖 钻机 工程机械合金车模型1:35 ¥ 339.00; 原厂 徐工 迷你系列 XE490DK挖掘机 起重机平地机旋挖 钻机 模型 1:87 ¥ 59.00; 原厂 徐工 1:35 XCMG XR220 旋挖 钻机 钻地机车合金工程机械模型 ¥ 338.00; 徐工 XR220D旋挖 钻机 流浪地球联名款 限量版 ¥ 899.00; 徐工 350打井机气动 钻机 租赁 ¥ 100.00; 徐工 350工程 钻机,康明斯发动机,154kw. ¥ 45000.00; 徐工 非开挖水平定向钻 ¥ 396005.00; 徐工 大型气动可定制水井光伏地质勘探XSL520履带式 钻机 大吨位煤矿 ¥ 700000.00; 徐工 68/75挖掘机打孔机打桩机挖改装螺旋 钻机 光伏打桩厂家现货 ¥ 199.00; 徐工 矿工矿钻井设备大型深水井全套家用大型履带气…

6. HD Engineering – Specialized Drilling Tools

Domain: hdengineering.com

Registered: 1997 (28 years)

Introduction: 漢機公司提供特殊系列的鑽具,用於與鑽孔同步下套管。大直徑套管普遍採用潛孔鑽進,小直徑套管用液壓衝擊鑽。這系列鑽具適用的套管直徑範圍從 100毫米(4吋)到 800毫米(32吋)。

Strategic Sourcing Conclusion and Outlook for 徐工 钻套管

As international markets continue to evolve, the strategic sourcing of 徐工 钻套管 presents significant opportunities for B2B buyers, particularly in emerging regions such as Africa, South America, the Middle East, and Europe. With 徐工’s commitment to high-quality, reliable drilling solutions, businesses can leverage these advanced technologies to enhance operational efficiency and reduce costs.

Investing in 徐工’s products not only ensures access to cutting-edge drilling machinery but also provides the advantage of tailored solutions that meet specific regional needs. The adaptability of these drilling systems, such as the XSL series, allows for diverse applications in oil and gas, geothermal energy, and water well drilling, making them indispensable assets for resource extraction in varied environments.

Looking ahead, it is crucial for buyers to engage with reputable distributors and explore the full range of 徐工’s offerings. By forging strong partnerships and investing in robust sourcing strategies, businesses can position themselves favorably in competitive markets. We encourage prospective buyers to reach out for inquiries and to discover how 徐工’s innovative solutions can drive their projects forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to 徐工 钻套管

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.