Emf Hat Protection: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for emf hat protection

In an increasingly interconnected world, the challenge of sourcing effective EMF hat protection has become paramount for businesses seeking to safeguard their employees and clientele from potential electromagnetic radiation exposure. As awareness of EMF-related health concerns grows, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe (including Saudi Arabia and Germany), are faced with the task of identifying reliable suppliers and high-quality products that meet stringent safety standards. This comprehensive guide is designed to equip buyers with essential insights into the diverse types of EMF protection hats available on the market, their applications across various industries, and effective strategies for vetting suppliers.

From understanding the science behind EMF shielding materials to exploring the cost implications of different product options, this guide empowers businesses to make informed purchasing decisions. It delves into critical factors such as compliance with international standards, product certifications, and user feedback, ensuring that buyers can confidently invest in solutions that align with their organizational needs. By navigating the complexities of the global EMF hat protection market with this resource, B2B buyers will not only enhance workplace safety but also contribute to the overall well-being of their workforce and customers.

Understanding emf hat protection Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Baseball Cap Style | Casual design, often lined with Faraday fabric for discreet shielding. | Everyday wear, corporate gifting | Pros: Comfortable, stylish. Cons: Limited EMF coverage. |

| Hooded Protection | Encompasses head and neck, providing more extensive coverage with Faraday material. | Outdoor workers, health-conscious individuals | Pros: Enhanced protection, versatile. Cons: Bulkier design. |

| Fashion-Forward Designs | Trendy styles that integrate EMF shielding while maintaining aesthetic appeal. | Fashion retailers, wellness brands | Pros: Attractive, encourages usage. Cons: Higher price point. |

| Adjustable Fit Models | Features adjustable sizing for comfort across various head sizes. | Retailers catering to diverse demographics | Pros: Versatile fit, increases market reach. Cons: May lack custom sizing. |

| Testing-Enabled Options | Includes a Faraday testing pouch to verify signal-blocking capabilities. | Tech companies, EMF safety consultants | Pros: Assurance of effectiveness, educative tool. Cons: Additional cost. |

What are the Key Characteristics of Baseball Cap Style EMF Hats?

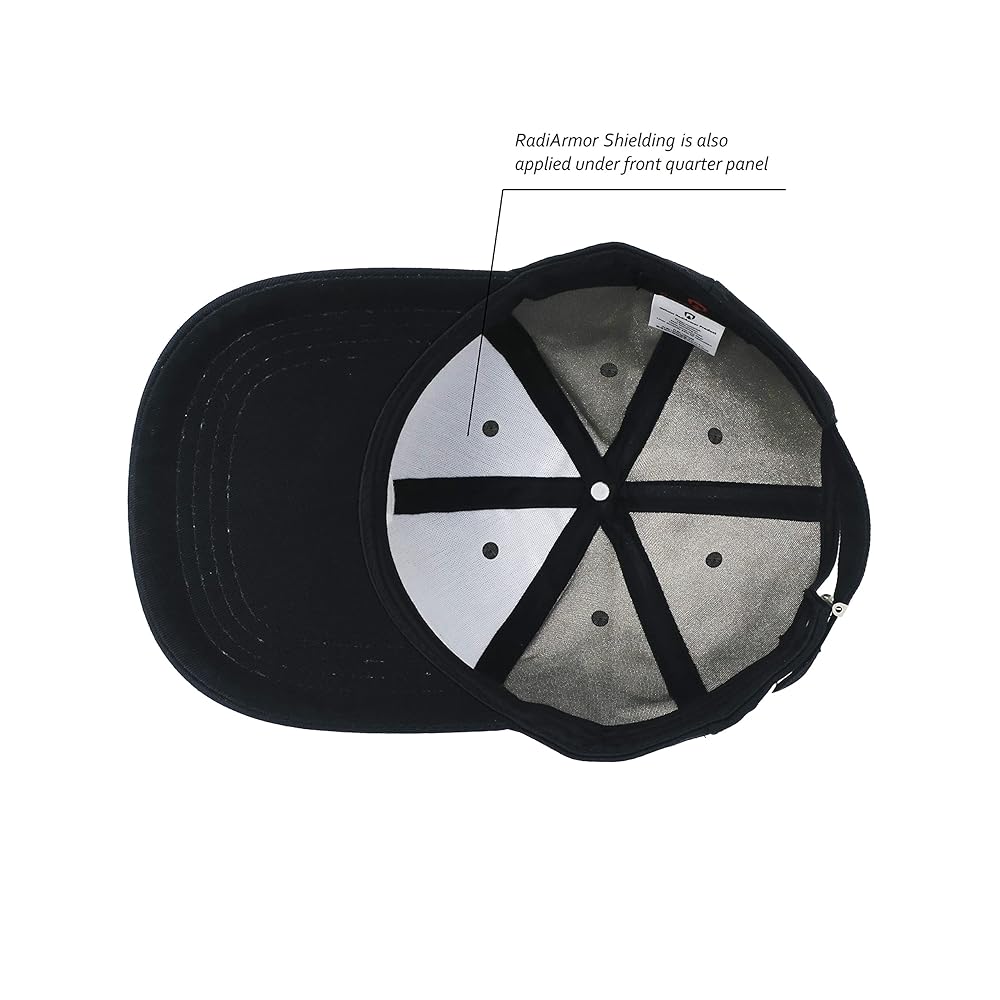

Baseball cap style EMF hats are designed for casual wear, appealing to a broad audience seeking protection without sacrificing style. Typically lined with Faraday fabric, these hats provide a barrier against electromagnetic radiation from devices such as cell phones and Wi-Fi routers. They are particularly suitable for everyday use and can serve as effective corporate gifts, promoting health awareness within organizations. Buyers should consider the balance between style and protection, as these hats may offer limited EMF coverage compared to more comprehensive designs.

How Do Hooded Protection Hats Enhance EMF Safety?

Hooded protection hats are engineered to cover not just the head but also the neck, offering increased shielding from electromagnetic frequencies. This design is especially beneficial for outdoor workers and individuals with heightened sensitivity to EMF exposure. The versatility of hooded hats makes them suitable for various environments, from construction sites to outdoor events. While they provide superior protection, buyers should be aware of the bulkier design, which may not appeal to all users.

Why Choose Fashion-Forward Designs for EMF Hats?

Fashion-forward EMF hats integrate modern trends with shielding technology, appealing to consumers who prioritize aesthetics alongside health. These hats are ideal for fashion retailers and wellness brands looking to attract a style-conscious demographic. While they encourage regular usage due to their attractive designs, buyers should consider the potential for a higher price point, which may limit market accessibility.

What Advantages Do Adjustable Fit Models Offer?

Adjustable fit EMF hats cater to a wide range of head sizes, making them ideal for retailers focused on inclusivity. By accommodating diverse demographics, these hats can enhance market reach and customer satisfaction. However, buyers should keep in mind that while adjustable options are versatile, they may not provide the same level of custom sizing as specialized designs.

How Do Testing-Enabled Options Benefit B2B Buyers?

Testing-enabled EMF hats come equipped with a Faraday testing pouch, allowing users to verify the hat’s signal-blocking capabilities. This feature is particularly valuable for tech companies and EMF safety consultants, as it provides assurance of product effectiveness and serves as an educational tool for clients. Although these options may come at an additional cost, the benefits of verified performance can enhance buyer confidence and support informed purchasing decisions.

Key Industrial Applications of emf hat protection

| Industry/Sector | Specific Application of emf hat protection | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Protection for technicians working near cell towers and antennas | Reduces health risks associated with prolonged EMF exposure | Compliance with international safety standards, bulk purchasing options |

| Construction | Use by workers in proximity to smart meters and electrical equipment | Enhances worker safety and productivity by minimizing EMF exposure | Durability in various weather conditions, adjustable sizing for comfort |

| Healthcare | EMF protection for medical professionals in diagnostic imaging areas | Improves staff well-being and reduces potential health issues | Certifications for shielding effectiveness, comfort for long shifts |

| Transportation | Use by drivers and crew in vehicles equipped with high-frequency devices | Protects against fatigue and health concerns from EMF exposure | Lightweight materials for comfort, style options for professional appearance |

| Research and Development | Protection for researchers working with EMF-sensitive equipment | Ensures accurate results by minimizing interference from EMF | Quality assurance and lab-testing certifications, custom branding options |

How is EMF Hat Protection Used in Telecommunications?

In the telecommunications sector, technicians frequently work in close proximity to cell towers and antennas that emit high levels of electromagnetic fields (EMF). Wearing EMF hats provides a protective barrier against potential health risks linked to prolonged exposure to these frequencies. For international buyers, particularly from regions with stringent health regulations, sourcing hats that comply with safety standards like IEEE 299-2006 is critical. Additionally, bulk purchasing options can help companies manage costs while ensuring their workforce is adequately protected.

What Role Does EMF Hat Protection Play in Construction?

Construction workers often operate near smart meters and electrical equipment, which can emit harmful EMF. By utilizing EMF hats, these workers can minimize their exposure, thereby enhancing both safety and productivity on-site. Buyers in this sector should consider hats that are durable enough for harsh environments and offer adjustable sizing for comfort. Ensuring that the product can withstand various weather conditions is also essential for outdoor applications, especially in diverse climates across Africa and South America.

How Can Healthcare Professionals Benefit from EMF Hat Protection?

In healthcare settings, especially in areas involving diagnostic imaging, professionals are exposed to various EMF sources. EMF hats can help mitigate potential health risks, ensuring that staff members remain healthy and focused. For international healthcare buyers, it is important to source hats that come with certifications verifying their shielding effectiveness. Comfort is also a key factor, as healthcare professionals often work long shifts, necessitating gear that can be worn for extended periods without discomfort.

Why is EMF Hat Protection Important for Transportation?

In the transportation industry, drivers and crew members are increasingly surrounded by vehicles equipped with high-frequency devices, leading to heightened EMF exposure. EMF hats can help protect these individuals from fatigue and associated health concerns, ultimately contributing to safer travel conditions. Buyers in this sector should look for lightweight materials that provide comfort without sacrificing protection. Additionally, style options that align with professional appearances can be beneficial for brand image.

How Does EMF Hat Protection Support Research and Development?

Researchers working with EMF-sensitive equipment must mitigate interference from electromagnetic fields to ensure accurate results. EMF hats provide a practical solution for this challenge. For B2B buyers in research and development, sourcing hats with quality assurance and lab-testing certifications is vital to guarantee effectiveness. Custom branding options can also be a consideration for organizations looking to maintain a professional image while prioritizing employee safety.

3 Common User Pain Points for ’emf hat protection’ & Their Solutions

Scenario 1: Navigating Compliance and Quality Standards for EMF Hat Protection

The Problem:

B2B buyers often face the challenge of ensuring that the EMF protection products they source meet stringent quality and compliance standards. In regions like Europe and the Middle East, regulations concerning electromagnetic exposure and product safety can be particularly rigorous. Buyers may find it difficult to verify whether the products adhere to standards such as IEEE 299-2006, which is essential for demonstrating the effectiveness of EMF shielding materials. This uncertainty can lead to potential liabilities and decreased customer trust.

Illustrative image related to emf hat protection

The Solution:

To navigate these compliance hurdles, B2B buyers should prioritize suppliers who provide clear documentation of their products’ testing and certification. Look for EMF hats that include lab test reports confirming their shielding effectiveness against specified frequencies. Consider establishing a checklist for compliance that includes the following: certification details, testing laboratory credentials, and customer testimonials regarding the product’s effectiveness. By sourcing from reputable manufacturers who are transparent about their compliance processes, buyers can mitigate risks and enhance their credibility in the market.

Scenario 2: Addressing Employee Health Concerns in High-EMF Environments

The Problem:

In sectors such as telecommunications and IT, employees are often exposed to high levels of electromagnetic fields (EMF) from devices like cell towers and Wi-Fi routers. This exposure can lead to health concerns, including headaches, fatigue, and other symptoms associated with EMF sensitivity. As a result, businesses may struggle to maintain employee productivity and morale, ultimately affecting their bottom line.

The Solution:

To effectively address these health concerns, companies should consider implementing an EMF protection policy that includes the use of protective apparel, such as EMF hats. When sourcing these hats, look for options that are designed for comfort and extended wear, ensuring they are suitable for everyday use in the workplace. Additionally, provide training sessions for employees to educate them on the importance of EMF protection and how to properly use the hats. By fostering a culture of health and safety, organizations can not only protect their employees but also boost overall workplace satisfaction and productivity.

Illustrative image related to emf hat protection

Scenario 3: Overcoming Skepticism About EMF Protection Efficacy

The Problem:

Many businesses encounter skepticism from employees or clients regarding the efficacy of EMF protection products, including hats. This skepticism can stem from a lack of understanding about EMF radiation and how protective gear works. If stakeholders do not believe in the benefits of wearing EMF hats, they may resist their adoption, leading to poor implementation and wasted resources.

The Solution:

To combat skepticism, B2B buyers should focus on providing educational resources that clearly outline the science behind EMF radiation and the protective properties of their products. This can include case studies, scientific articles, and testimonials from users who have experienced positive outcomes. Additionally, consider offering a demonstration or trial period for the EMF hats, allowing employees to experience the benefits firsthand. Engaging with industry experts to host informational webinars can also help build credibility and foster a more informed understanding among stakeholders. By bridging the knowledge gap, businesses can enhance acceptance and encourage the adoption of EMF protection measures.

Strategic Material Selection Guide for emf hat protection

What Materials Are Commonly Used for EMF Hat Protection?

When selecting materials for EMF protection hats, it is essential to consider their shielding effectiveness, durability, and overall performance. Here are four common materials used in the production of EMF hats, along with their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. TitanRF™ Flex Faraday Fabric

Key Properties:

TitanRF™ Flex Faraday Fabric is composed of a flexible blend of nickel and copper, providing high electromagnetic shielding effectiveness. It has been lab-tested to meet IEEE 299-2006 standards, ensuring reliable performance against a wide frequency range (1.5GHz to 40GHz).

Pros & Cons:

This material is lightweight and breathable, making it suitable for extended wear. However, it can be more expensive than other options due to its advanced manufacturing processes and material composition.

Impact on Application:

TitanRF™ fabric is particularly effective against RF signals from mobile devices, Wi-Fi, and 5G networks. Its flexibility allows for comfortable use in various hat designs.

International Considerations:

For buyers in regions like Europe and the Middle East, compliance with local safety standards and certifications is crucial. Buyers should verify that the product meets ASTM and DIN standards applicable to EMF protection.

Illustrative image related to emf hat protection

2. Silver-Infused Fabric

Key Properties:

Silver-infused fabrics leverage the natural conductive properties of silver to provide EMF shielding. These fabrics typically exhibit antimicrobial properties, adding an extra layer of functionality.

Pros & Cons:

The primary advantage of silver-infused fabric is its effectiveness in blocking EMF while also being lightweight and comfortable. However, silver can be prone to tarnishing and may require special care, which could complicate manufacturing and maintenance.

Impact on Application:

These fabrics are well-suited for everyday wear, particularly in environments with moderate EMF exposure. However, they may not perform as effectively against higher frequency signals compared to specialized materials like TitanRF™.

Illustrative image related to emf hat protection

International Considerations:

Silver-infused fabrics may face scrutiny regarding their antimicrobial claims. Buyers should ensure that any health claims are substantiated by relevant certifications, especially in markets like Germany, where consumer protection laws are stringent.

3. Copper Mesh

Key Properties:

Copper mesh is a highly conductive material known for its excellent shielding capabilities. It is typically used in applications requiring high-frequency EMF protection.

Pros & Cons:

Copper mesh is durable and can be easily shaped into various forms. However, it is heavier than fabric options, which may affect comfort. Additionally, its cost can be higher due to material sourcing and processing.

Impact on Application:

Copper mesh is particularly effective in environments with high EMF exposure, such as near cell towers or industrial settings. However, its visibility and weight may limit its use in casual wear like hats.

International Considerations:

For B2B buyers in Africa and South America, sourcing copper mesh may involve navigating fluctuating metal prices. Buyers should also consider local regulations regarding metal products and their environmental impact.

4. Conductive Polyester

Key Properties:

Conductive polyester blends incorporate conductive materials into traditional polyester fabric, offering a balance between comfort and EMF shielding.

Pros & Cons:

This material is lightweight, machine washable, and suitable for mass production, making it a cost-effective option. However, its shielding effectiveness may not match that of specialized fabrics like TitanRF™.

Impact on Application:

Conductive polyester is suitable for casual wear and is often used in mass-produced EMF protection apparel. Its versatility makes it appealing for various applications, although it may not be ideal for high-exposure environments.

International Considerations:

Buyers should ensure that the conductive polyester meets international textile standards, such as Oeko-Tex certification, to guarantee safety and environmental compliance.

Summary Table

| Material | Typical Use Case for emf hat protection | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| TitanRF™ Flex Faraday Fabric | Everyday wear, high-frequency shielding | High shielding effectiveness | Higher manufacturing cost | High |

| Silver-Infused Fabric | Casual wear, moderate EMF exposure | Antimicrobial properties | Prone to tarnishing | Med |

| Copper Mesh | High EMF exposure environments | Excellent shielding capabilities | Heavier and less comfortable | High |

| Conductive Polyester | Mass-produced EMF protection apparel | Lightweight and machine washable | Lower shielding effectiveness | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to invest in EMF protection hats, helping them make informed decisions based on material properties, advantages, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for emf hat protection

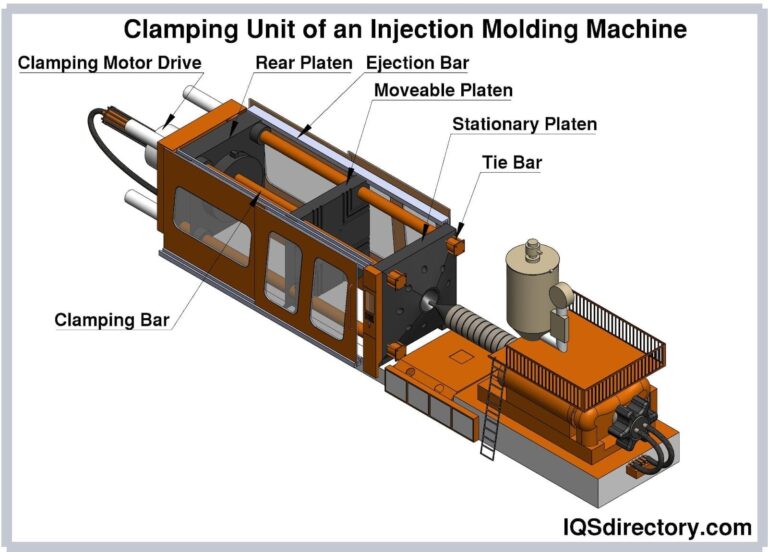

What Are the Main Stages of Manufacturing EMF Protection Hats?

The manufacturing of EMF protection hats involves several key stages that ensure the final product meets high standards of quality and effectiveness. Understanding these stages is crucial for B2B buyers looking to source reliable products.

1. Material Preparation

The first stage in the manufacturing process involves sourcing and preparing materials. For EMF protection hats, this typically includes high-shielding fabrics such as TitanRF™ Flex Faraday Fabric, which is composed of metals like copper and nickel. Suppliers must ensure that these materials are lab-tested for electromagnetic shielding effectiveness, adhering to standards such as IEEE 299-2006. Material preparation also involves pre-treatment processes to enhance fabric properties, including durability and comfort.

2. Forming

Once materials are prepared, they are cut and shaped into the components of the hat. This stage often utilizes automated cutting machines to ensure precision and consistency in sizing. The forming process may also involve techniques such as weaving or knitting to create the shielding fabric, ensuring that it maintains its protective qualities while remaining flexible and breathable.

Illustrative image related to emf hat protection

3. Assembly

The assembly phase is where individual components are stitched together to form the final product. This may include sewing the shielded fabric into the hat’s structure, adding adjustable features like snapback closures, and integrating any additional elements such as linings or tags. Quality control during assembly is critical, as any defects can compromise the hat’s effectiveness in shielding against EMF.

4. Finishing

The final stage of manufacturing involves finishing processes, which may include washing, pressing, and packaging the hats. Each hat is inspected for aesthetic and functional quality. The packaging is designed not only for protection during transport but also to enhance the product’s presentation for retail, which is particularly important for B2B buyers targeting consumer markets.

How Is Quality Assurance Implemented in EMF Hat Production?

Quality assurance is a vital aspect of the manufacturing process for EMF protection hats, ensuring that each product meets international standards and customer expectations.

Relevant International Standards for EMF Protection Hats

B2B buyers should look for manufacturers that comply with international quality standards such as ISO 9001, which focuses on maintaining quality management systems. For EMF protection products, specific industry standards such as CE marking in Europe indicate compliance with health, safety, and environmental protection legislation. Additionally, for markets in the Middle East and Africa, buyers should be aware of local regulations that may affect product acceptance.

What Are the Key Quality Control Checkpoints?

Quality control is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves testing raw materials upon arrival to ensure they meet specified standards. For EMF hats, this means verifying the electromagnetic shielding capability of the fabric.

-

In-Process Quality Control (IPQC): During assembly, manufacturers should conduct regular inspections to catch defects early in the production process. This includes checking stitching quality and ensuring that the hat retains its shielding properties.

-

Final Quality Control (FQC): Once the hats are completed, they undergo rigorous testing to confirm their shielding effectiveness and overall quality. This may include lab tests for electromagnetic shielding and visual inspections for defects.

What Common Testing Methods Are Used for EMF Protection Hats?

Testing methods are crucial for verifying the performance and safety of EMF protection hats. Common practices include:

-

Electromagnetic Shielding Tests: Manufacturers typically conduct tests according to the IEEE 299-2006 standard, which measures the effectiveness of the shielding fabric against specific frequency ranges (1.5GHz to 40GHz). Buyers can request test reports to validate claims made by suppliers.

-

Durability Tests: These tests assess the fabric’s resistance to wear and tear, ensuring that the hats maintain their protective qualities over time.

-

Flammability Tests: Given that EMF hats are made with conductive materials, they must undergo flammability testing to meet safety standards, particularly in markets with stringent regulations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, ensuring that suppliers adhere to quality control practices is essential for maintaining product integrity. Here are some strategies:

-

Audits: Conducting on-site audits of manufacturing facilities can provide insights into the supplier’s quality management processes. This includes checking for compliance with international standards and evaluating their testing protocols.

-

Requesting Reports: Buyers should ask for documentation detailing testing results, including electromagnetic shielding effectiveness, durability, and safety tests. This transparency is critical for establishing trust in the supplier’s capabilities.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. This is particularly beneficial for international buyers who may face challenges in verifying supplier claims.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from diverse markets like Africa, South America, the Middle East, and Europe, must navigate specific challenges in quality control:

-

Cultural Differences: Understanding local manufacturing practices and quality expectations is vital. Suppliers in different regions may have varying levels of adherence to international standards.

-

Regulatory Compliance: Buyers need to ensure that products meet the regulatory requirements of their home markets. This may involve additional testing or certification, particularly in regions with strict import laws.

-

Logistical Considerations: Quality control can also be affected by shipping and handling practices. Buyers should evaluate how suppliers manage product integrity during transport and whether additional inspections are necessary upon arrival.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing EMF protection hats, ensuring they receive products that meet their operational standards and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ’emf hat protection’

Introduction

This practical sourcing guide provides B2B buyers with a step-by-step checklist to procure effective EMF hat protection solutions. As concerns about electromagnetic radiation (EMR) rise globally, especially in regions like Africa, South America, the Middle East, and Europe, ensuring the quality and effectiveness of EMF protective gear is paramount. This guide will help streamline your procurement process, ensuring that you make informed decisions that align with your organization’s health and safety standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure that the EMF hats meet your organization’s needs. Consider the type of EMF exposure prevalent in your target market, such as frequencies from 5G networks or everyday electronic devices. Specific attributes to define include:

– Material Composition: Look for hats made from high-shielding fabrics, such as those incorporating nickel and copper for effective EMF protection.

– Shielding Standards: Ensure products meet recognized standards like IEEE 299-2006 for electromagnetic shielding effectiveness.

Step 2: Research Potential Suppliers

Identifying reputable suppliers is vital in sourcing quality EMF hats. Conduct thorough research on potential vendors to assess their credibility and experience in the industry. Key actions include:

– Check Reviews and Testimonials: Seek feedback from previous clients, focusing on reliability and product performance.

– Request Case Studies: Ask for examples of successful partnerships, particularly with businesses in your region or industry.

Step 3: Verify Supplier Certifications

Before finalizing any procurement, verifying supplier certifications is essential to ensure compliance with safety and quality standards. Look for:

– Lab Testing Certifications: Confirm that the materials used in the hats are tested for shielding effectiveness by accredited laboratories.

– Quality Assurance Standards: Suppliers should adhere to industry-specific quality standards, ensuring consistent product quality.

Illustrative image related to emf hat protection

Step 4: Evaluate Product Features

Assess the specific features of the EMF hats to ensure they align with user comfort and functionality. Key features to consider include:

– Design and Comfort: Hats should be designed for everyday wear, with breathable materials and adjustable fittings to accommodate various head sizes.

– Additional Protection: Look for added features such as UV protection, which enhances the overall utility of the hat.

Step 5: Request Samples for Testing

Before committing to a bulk order, it’s prudent to request samples for hands-on testing. This step allows you to:

– Assess Comfort and Fit: Ensure the hats are comfortable for extended use by potential wearers within your organization.

– Test Shielding Effectiveness: Utilize any provided testing pouches or equipment to verify the EMF shielding capabilities of the materials.

Step 6: Analyze Pricing and Terms

Understanding the pricing structure and contractual terms is vital for budget alignment. Ensure you:

– Compare Quotes: Obtain quotes from multiple suppliers to gauge competitive pricing.

– Review Terms of Sale: Pay attention to shipping costs, return policies, and warranty options to protect your investment.

Illustrative image related to emf hat protection

Step 7: Finalize Purchase and Monitor Performance

Once you’ve selected a supplier, finalize your purchase while ensuring you have a plan in place to monitor the performance of the EMF hats over time. Consider:

– Collecting User Feedback: After distribution, gather feedback from users to assess comfort and effectiveness.

– Regularly Reviewing Supplier Performance: Maintain a relationship with the supplier to address any issues that may arise and to explore future procurement opportunities.

By following this checklist, B2B buyers can ensure they make informed decisions when sourcing EMF hat protection, ultimately safeguarding the health and safety of their workforce.

Comprehensive Cost and Pricing Analysis for emf hat protection Sourcing

What Are the Key Cost Components in EMF Hat Protection Sourcing?

When sourcing EMF protection hats, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to emf hat protection

-

Materials: High-quality shielding materials, such as TitanRF™ Flex Faraday Fabric, are pivotal for effective EMF protection. The composition, often involving metals like nickel and copper, significantly influences the material cost. Prices for advanced shielding fabrics can vary widely based on their shielding effectiveness and durability.

-

Labor: Labor costs can fluctuate based on the production location. Regions with lower labor costs may offer competitive pricing, but this might affect quality. Skilled labor is necessary for the precise assembly of EMF hats to ensure their shielding capabilities are not compromised.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial investments in tooling for production can be substantial. Custom designs or unique specifications often require specialized tooling, which adds to the upfront cost but can enhance product differentiation.

-

Quality Control (QC): Ensuring that each hat meets the required shielding standards, such as IEEE 299-2006, involves rigorous testing and quality checks, which can impact overall costs. Buyers should prioritize suppliers with robust QC processes to ensure product reliability.

-

Logistics: Shipping costs vary significantly based on the destination, shipping method, and volume of the order. International buyers should account for potential delays and additional fees associated with customs clearance.

-

Margin: Suppliers typically apply a profit margin based on their operational costs, market demand, and competition. Understanding the average margins in the industry can help buyers assess fair pricing.

How Do Price Influencers Affect EMF Hat Protection Costs?

Several factors influence the pricing of EMF hats, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may offer discounts for large orders, making it advantageous for businesses to plan their needs effectively.

-

Specifications and Customization: Custom designs or unique specifications can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Premium materials and certification for shielding effectiveness generally result in higher prices. Buyers must balance their budget with the need for quality to ensure adequate protection.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may command higher prices due to their proven track record but may also offer superior quality and service.

-

Incoterms: The choice of Incoterms can significantly impact the total cost. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who bears responsibility for shipping costs and risks, influencing the overall expenditure.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

To maximize cost efficiency when sourcing EMF protection hats, consider the following strategies:

-

Conduct Market Research: Understanding the market rates for EMF hats can provide leverage during negotiations. Knowledge of competitor pricing can also help establish a reasonable price range.

-

Leverage Volume Discounts: Communicate your purchasing plans and inquire about volume discounts. Suppliers are often willing to negotiate better rates for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also long-term costs, such as shipping, customs, and potential returns. This holistic view can guide better purchasing decisions.

-

Build Relationships with Suppliers: Establishing a strong relationship with suppliers can lead to better pricing and terms over time. Regular communication can foster trust and collaboration.

-

Be Aware of Pricing Nuances for International Buyers: International transactions may involve fluctuating currency rates and additional tariffs. Ensure that all potential costs are accounted for in your budget.

Conclusion: Understanding Pricing Dynamics for EMF Hat Protection

Buyers in regions such as Africa, South America, the Middle East, and Europe should approach EMF hat sourcing with a comprehensive understanding of the cost structure and pricing influencers. By leveraging negotiation strategies and focusing on total cost considerations, businesses can make informed purchasing decisions that align with their budgetary constraints while ensuring quality protection against electromagnetic radiation.

Alternatives Analysis: Comparing emf hat protection With Other Solutions

When evaluating solutions for electromagnetic field (EMF) protection, it’s essential to consider various alternatives that can effectively minimize exposure. EMF hat protection is one option, but other technologies and methods exist that may also suit the needs of businesses and individuals seeking safety from electromagnetic radiation.

| Comparison Aspect | Emf Hat Protection | Alternative 1 Name: EMF Shielding Clothing | Alternative 2 Name: EMF Shielding Room |

|---|---|---|---|

| Performance | High shielding effectiveness; lab-tested | Good protection, but varies by garment type | Excellent protection; can shield entire space |

| Cost | Moderate ($80 per hat) | Varies widely ($50-$300 per item) | High ($2,000-$10,000 for setup) |

| Ease of Implementation | Simple; wear like regular clothing | Requires selection of specific items; practical | Complex; requires construction or retrofitting |

| Maintenance | Low; occasional cleaning | Low; regular washing as per fabric guidelines | Moderate; periodic checks on shielding integrity |

| Best Use Case | Individual use in various environments | Suitable for individuals needing ongoing protection | Best for dedicated spaces like offices or homes |

How Does EMF Shielding Clothing Compare to EMF Hat Protection?

EMF shielding clothing offers a broader range of protection compared to a hat, covering larger areas of the body. These garments utilize specialized fabrics that block EMF radiation and can be worn daily. However, the effectiveness can vary significantly based on the specific garment and the frequency range it targets. Costs for these items can range widely, making it vital for businesses to assess their needs and budgets when choosing this alternative.

What are the Benefits of EMF Shielding Rooms?

Creating an EMF shielding room is an effective way to protect individuals from pervasive radiation sources. This method involves installing shielding materials in walls, windows, and ceilings, creating a Faraday cage effect. While this solution provides excellent protection, the initial investment is significantly higher than wearing a hat or clothing. Additionally, it requires a more complex implementation process, making it less feasible for businesses seeking immediate solutions. However, for organizations that prioritize EMF protection in specific areas, such as medical or high-tech environments, this can be a valuable investment.

How Can B2B Buyers Choose the Right EMF Protection Solution?

When selecting the appropriate EMF protection method, B2B buyers should consider their unique operational environment and specific exposure levels. For those who need individual protection while on the go or in varied locations, EMF hats offer a practical and affordable solution. Conversely, businesses with a focus on long-term safety in static environments might find that investing in EMF shielding clothing or dedicated shielding rooms meets their needs more effectively. Evaluating factors such as performance, cost, ease of implementation, and maintenance will guide buyers in making informed decisions that align with their safety requirements and budget constraints.

Illustrative image related to emf hat protection

Essential Technical Properties and Trade Terminology for emf hat protection

Understanding the technical specifications and trade terminology related to EMF hat protection is crucial for B2B buyers seeking to invest in effective shielding solutions. This section outlines the key properties and terms relevant to the industry, enabling informed purchasing decisions.

What Are the Key Technical Properties of EMF Hats?

1. Material Composition

EMF hats are typically constructed from specialized fabrics, such as TitanRF™ Flex Faraday Fabric, which often contains a blend of metals like nickel and copper. This composition is pivotal as it determines the hat’s ability to shield against electromagnetic radiation (EMR) and radio frequencies (RF). For B2B buyers, understanding the material composition ensures they select products that meet their specific shielding needs.

2. Shielding Effectiveness

The effectiveness of an EMF hat is quantified through testing against established standards, such as IEEE 299-2006. This standard measures how well materials block various frequencies, typically ranging from 1.5 GHz to 40 GHz. For businesses, verifying shielding effectiveness through lab certifications can assure compliance with safety regulations and enhance product credibility.

3. Size and Fit Tolerance

The adjustable nature of EMF hats, accommodating a range of head sizes (e.g., 21.5″ to 23.6″), is crucial for comfort and usability. A proper fit ensures maximum coverage and protection from EMF exposure. For B2B buyers, offering a product that can fit a diverse customer base can enhance marketability and customer satisfaction.

Illustrative image related to emf hat protection

4. Breathability and Comfort

High-quality EMF hats are designed to be breathable and comfortable for extended wear. This property is essential for everyday use, especially in varying climates. B2B buyers should prioritize products that not only provide protection but also ensure comfort, as this can influence customer loyalty and repeat purchases.

5. Durability and Maintenance

Durability refers to the hat’s resistance to wear and tear, as well as its ability to maintain shielding capabilities over time. Maintenance considerations, such as washing instructions, also play a role in the product’s lifespan. For businesses, selecting durable products reduces the frequency of replacements and enhances overall value.

What Are Common Trade Terms in EMF Hat Protection?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand name. In the context of EMF hats, partnering with an OEM can streamline production processes and enhance product variety for B2B buyers looking to expand their offerings.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory effectively and optimize order costs. Low MOQs can facilitate testing new products in the market without significant financial commitment.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. For B2B buyers, issuing RFQs for EMF hats allows for competitive pricing, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers involved in cross-border transactions, as they clarify liability and reduce the risk of misunderstandings.

5. EMF (Electromagnetic Fields)

EMF refers to the invisible fields of energy produced by electrical devices, which can have varying effects on health. Understanding EMF and its implications is crucial for B2B buyers focused on health and safety, helping them select products that mitigate potential risks.

By comprehending these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they procure EMF hat protection solutions that align with their business needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the emf hat protection Sector

What Are the Current Market Dynamics and Key Trends in the EMF Hat Protection Sector?

The EMF hat protection sector is witnessing significant growth, driven by increasing awareness of electromagnetic radiation (EMR) and its potential health impacts. This heightened concern is particularly prevalent among consumers in regions like Africa, South America, the Middle East, and Europe, where urbanization and technological advancements are prevalent. The proliferation of 5G networks and smart devices has amplified public sensitivity to EMF exposure, leading to a surge in demand for protective apparel, including EMF hats.

Emerging B2B tech trends are also influencing sourcing practices within this sector. Buyers are increasingly looking for products that incorporate advanced shielding materials, such as TitanRF™ Flex Faraday Fabric, which has been lab-tested for effectiveness against a wide range of frequencies. Moreover, the integration of smart technologies into protective clothing is gaining traction. For instance, hats equipped with sensors that monitor EMF exposure levels can provide users with real-time data, enhancing their safety and comfort.

Illustrative image related to emf hat protection

In addition, the market is evolving towards customization and personalization. B2B buyers are seeking options that cater to specific demographics or industries, such as health care professionals or individuals with heightened sensitivity to EMF. This trend underscores the importance of understanding regional preferences and regulatory standards when sourcing products for international markets.

How Does Sustainability and Ethical Sourcing Impact the EMF Hat Protection Sector?

Sustainability and ethical sourcing are becoming increasingly critical in the EMF hat protection sector. As consumers become more environmentally conscious, B2B buyers must consider the environmental impact of their sourcing decisions. The production of EMF hats often involves materials like copper and nickel, which require responsible mining and manufacturing practices to minimize ecological damage.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are now favoring suppliers who adhere to fair labor practices and demonstrate transparency in their sourcing processes. Certifications such as OEKO-TEX® and Global Organic Textile Standard (GOTS) are gaining traction as indicators of quality and sustainability. These certifications assure buyers that the materials used are free from harmful substances and produced under socially responsible conditions.

Incorporating sustainable practices not only enhances brand reputation but also opens doors to new market segments that prioritize ethical consumption. For businesses looking to expand their footprint in the EMF hat protection market, aligning with sustainable practices can be a compelling differentiator.

Illustrative image related to emf hat protection

What Is the Brief Evolution of the EMF Hat Protection Market?

The evolution of the EMF hat protection market can be traced back to the increasing reliance on electronic devices and the subsequent rise in public awareness regarding EMF exposure. Initially, protective gear was primarily limited to specialized industries such as telecommunications and healthcare. However, as concerns about EMF effects on health became mainstream, the market expanded to include everyday consumer products.

The introduction of advanced materials, such as Faraday fabrics, has revolutionized the sector, enabling the creation of stylish and functional protective wear. Today, EMF hats are not only seen as safety gear but also as fashion statements, appealing to a broader demographic. This evolution reflects a growing understanding of the need for EMF protection in various environments, from urban settings to workplaces, thereby driving innovation and growth within the sector.

As the market continues to mature, B2B buyers must stay informed about technological advancements and consumer preferences to capitalize on emerging opportunities in this dynamic landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of emf hat protection

-

How do I determine the effectiveness of EMF protection hats?

To assess the effectiveness of EMF protection hats, look for products that use certified materials like TitanRF™ Flex Faraday Fabric, which has been tested according to IEEE standards. Request lab test reports from suppliers to ensure the hats meet specific shielding effectiveness criteria. Additionally, consider user testimonials and independent reviews to gauge real-world performance. Finally, test the hats yourself using a Faraday testing pouch included with the product, which can help you verify the material’s signal-blocking capabilities. -

What is the best EMF protection hat for sensitive individuals?

The ideal EMF protection hat for sensitive individuals is one that combines comfort with high shielding effectiveness. Look for hats that are lined with advanced materials like Faraday fabric, which effectively blocks a wide range of frequencies, including those emitted by mobile devices and 5G networks. Ensure the hat is breathable and designed for everyday wear, making it suitable for various environments. Additionally, check for adjustable sizing options to cater to different head sizes for maximum comfort. -

What are the minimum order quantities (MOQs) for EMF hats when sourcing internationally?

Minimum order quantities (MOQs) for EMF hats can vary significantly depending on the supplier and production capabilities. Generally, MOQs range from 100 to 500 units for bulk orders. It’s crucial to communicate directly with potential suppliers to negotiate terms that align with your business needs. Some manufacturers may offer lower MOQs for first-time buyers or allow flexibility based on the total value of the order, so exploring multiple suppliers can yield better options. -

How can I vet suppliers for EMF protection hats?

To vet suppliers for EMF protection hats, start by researching their reputation in the industry through online reviews and ratings. Request references from previous clients and check their production capabilities, including certifications for materials used in the hats. Conduct a factory visit or a virtual tour to assess their manufacturing processes and quality control measures. Additionally, ensure they comply with international trade regulations and have a robust customer service framework to address any concerns promptly. -

What payment terms should I expect when sourcing EMF hats?

Payment terms for sourcing EMF hats can vary by supplier, but common arrangements include a deposit (usually 30-50%) upfront, with the balance due upon delivery or before shipment. Some suppliers may also offer net terms, allowing payment within a specified period after receipt of goods. Always clarify payment methods accepted (e.g., bank transfer, credit card, or escrow services) and ensure that you have a clear agreement to protect your investment and mitigate financial risks. -

What logistics considerations should I keep in mind when importing EMF hats?

When importing EMF hats, consider shipping methods, customs regulations, and potential tariffs or import taxes applicable in your country. Choose reliable logistics partners who can handle international shipments efficiently. Ensure all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate customs clearance. Additionally, evaluate lead times for production and shipping to avoid delays in stock availability, especially if you are planning for seasonal demand. -

Can I customize EMF hats for branding purposes?

Yes, many suppliers offer customization options for EMF hats, allowing you to add your logo or branding elements. Customization can include embroidery, screen printing, or even color variations to match your corporate identity. Be sure to discuss the specifics with your supplier, including minimum quantities required for customization and any additional costs involved. This can enhance your brand visibility while promoting health and safety in your target market. -

What quality assurance (QA) measures should be in place for EMF hats?

Quality assurance measures for EMF hats should include rigorous testing of materials for shielding effectiveness and durability. Suppliers should conduct regular inspections during production to ensure compliance with safety standards. Request documentation of quality control processes, including any third-party certifications. Additionally, consider implementing a return policy for defective items and establish a feedback loop with your supplier to address any quality concerns that may arise post-delivery.

Top 2 Emf Hat Protection Manufacturers & Suppliers List

1. HAVN – WaveStopper™ Beanie

Domain: havnwear.com

Registered: 2023 (2 years)

Introduction: Product Name: WaveStopper™ Beanie

Brand: HAVN

Key Features:

– EMF Protection: Blocks over 99.7% of EMF radiation (cell phone, 4G, 5G, Wi-Fi, Bluetooth)

– 360-degree coverage

– Independently Certified: Tested using IEEE-299 and EN 62209-2 standards

– Naturally Antimicrobial: Pure silver fibers help fight odors

– UPF-50+: Blocks 99% of harmful UV rays

– Premium comfort and warmth

– HSA/FSA Eligible

…

2. MOSEquipment – Mission Darkness EMF Blackout Hat

Domain: mosequipment.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Mission Darkness EMF Blackout Hat”, “features”: [“Blocks electromagnetic fields (EMF)”, “Stylish design”, “Comfortable fit”, “Lightweight material”], “usage”: “Ideal for individuals seeking protection from EMF exposure”, “material”: “High-quality fabric with EMF shielding technology”, “sizes_available”: [“Small”, “Medium”, “Large”], “color_options”: [“Black”], “care_instructions”…

Strategic Sourcing Conclusion and Outlook for emf hat protection

In navigating the burgeoning market for EMF hat protection, strategic sourcing emerges as a pivotal approach for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Understanding the unique characteristics and compliance standards of products, such as the Mission Darkness™ EMF Blackout Hat, equips buyers with the knowledge to select high-quality, effective solutions that meet the demands of health-conscious consumers. The integration of certified materials like TitanRF™ Flex Faraday Fabric ensures that your offerings not only protect users from electromagnetic radiation but also align with international safety standards.

Investing in EMF protection apparel is not merely a response to rising health concerns; it represents a proactive commitment to customer well-being and market differentiation. As EMF awareness continues to grow globally, there is a significant opportunity for businesses to position themselves as leaders in this niche market.

We encourage international B2B buyers to explore partnerships with reputable manufacturers and distributors to expand their product lines and meet the increasing demand for EMF protection solutions. By leveraging strategic sourcing, businesses can enhance their competitive edge while contributing to a safer, healthier future for consumers worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to emf hat protection

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.