Electronic Leak Detection Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for electronic leak detection

In the dynamic landscape of construction and facility management, the need for effective electronic leak detection (ELD) solutions has never been more critical. As businesses across Africa, South America, the Middle East, and Europe grapple with the challenges of water damage and maintenance costs, sourcing reliable ELD systems can significantly mitigate risks associated with leaks in roofing and waterproofing membranes. This comprehensive guide serves as an essential resource for B2B buyers seeking to navigate the complexities of the global ELD market.

Within these pages, we delve into various ELD technologies, examining their applications across different environments—from commercial buildings to industrial sites. We will explore the methodologies behind ELD systems, including low-voltage and high-voltage testing, and the unique advantages they offer over traditional methods. Additionally, we provide insights on supplier vetting processes, helping buyers identify reputable manufacturers and service providers, while also addressing cost considerations that impact procurement decisions.

By equipping international B2B buyers with actionable insights and in-depth knowledge, this guide empowers organizations to make informed purchasing choices that enhance operational efficiency and safeguard investments. Whether you are based in Brazil, Vietnam, or elsewhere, understanding the nuances of electronic leak detection will position your business for success in an increasingly competitive market.

Understanding electronic leak detection Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Low-Voltage Scanning Platform | Uses a scanning platform with perimeter wire loops | Roofing quality control, waterproofing assessments | Pros: Accurate leak location, minimal water use. Cons: Requires conductive substrate. |

| Low-Voltage Vertical Roller Testing | Employs a roller system for vertical surfaces | Flashing inspections, vertical membrane testing | Pros: Effective for vertical applications. Cons: Limited to vertical surfaces. |

| Low-Voltage Electronic Field Vector Mapping | Utilizes electric fields to detect breaches | Comprehensive roof assessments, forensic investigations | Pros: Non-destructive, precise leak detection. Cons: Complexity in setup. |

| High-Voltage Spark Testing | Applies high-voltage charges to identify leaks | Industrial roofing, large-scale waterproofing | Pros: Rapid testing, effective on large areas. Cons: Safety concerns, potential for damage. |

| Permanently Embedded Monitoring Systems | Continuous monitoring with embedded sensors | Long-term building maintenance, proactive leak management | Pros: Real-time data, minimizes disruption. Cons: Higher initial investment. |

What are the characteristics of Low-Voltage Scanning Platform Testing?

Low-Voltage Scanning Platform Testing is characterized by its use of a portable scanning platform that incorporates perimeter wire loops to detect breaches in roofing membranes. This method is particularly effective for horizontal surfaces and complies with ASTM standards, making it suitable for quality control during installation. B2B buyers should consider the compatibility of their roofing materials with this system, as it requires a conductive substrate below the membrane to function effectively.

How does Low-Voltage Vertical Roller Testing work in practice?

Low-Voltage Vertical Roller Testing employs a specially designed roller that moves along vertical surfaces, such as flashings and walls. This method is ideal for inspecting vertical membranes and is also governed by ASTM standards. For businesses focusing on vertical installations, this testing method provides a reliable way to identify leaks without the need for extensive water usage. Buyers should evaluate the specific applications of their projects to determine the suitability of this method.

What makes Low-Voltage Electronic Field Vector Mapping a preferred choice?

Low-Voltage Electronic Field Vector Mapping (EFVM) utilizes electric fields to locate breaches in non-conductive membranes. This method is particularly beneficial for comprehensive roof assessments and forensic investigations, allowing for precise leak detection without damaging the membrane. B2B buyers should consider the complexity of the setup and the need for trained personnel, as this method may require a higher level of expertise compared to others.

What are the benefits and drawbacks of High-Voltage Spark Testing?

High-Voltage Spark Testing involves applying a high-voltage charge to the roofing membrane to identify leaks. This method is well-suited for industrial applications and large-scale waterproofing projects due to its rapid testing capabilities. However, safety concerns and the potential for damaging sensitive materials make it less favorable for smaller or more delicate installations. B2B buyers should weigh the speed of testing against the associated risks.

How do Permanently Embedded Monitoring Systems enhance leak detection?

Permanently Embedded Monitoring Systems consist of sensors that are embedded within the roofing membrane, providing continuous monitoring for leaks and moisture. This proactive approach is ideal for long-term building maintenance and can significantly reduce the disruption typically associated with leak detection. While the initial investment may be higher, the long-term benefits of real-time data and reduced maintenance costs make it an attractive option for businesses focused on sustainability and efficiency.

Illustrative image related to electronic leak detection

Key Industrial Applications of electronic leak detection

| Industry/Sector | Specific Application of Electronic Leak Detection | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Roofing | Quality control during roofing installation and maintenance | Minimizes potential water damage, ensuring long-term roof integrity | Equipment compatibility with various membrane types and local codes |

| Oil & Gas | Leak detection in pipelines and storage tanks | Prevents environmental hazards and costly product loss | Compliance with international safety standards and certifications |

| Manufacturing | Monitoring for leaks in cooling systems and hydraulic lines | Reduces downtime and maintenance costs, enhancing operational efficiency | Durability and reliability of detection systems in industrial settings |

| Water Treatment | Leak detection in water storage and treatment facilities | Ensures water quality and compliance with environmental regulations | Adaptability to different types of storage materials and conditions |

| Pharmaceutical | Monitoring for leaks in cleanroom environments and storage areas | Protects product integrity and compliance with health regulations | Precision and sensitivity of detection technology for sterile areas |

How is Electronic Leak Detection Used in Construction & Roofing?

In the construction and roofing industry, electronic leak detection (ELD) serves as a critical quality control measure during installation and maintenance of roofing systems. By utilizing low-voltage scanning methods, contractors can pinpoint breaches in roofing membranes without extensive water usage, which could damage newly installed roofs. This non-destructive testing method not only ensures the integrity of the roof but also helps avoid costly repairs and potential water damage in the future. Buyers in this sector must consider the compatibility of ELD systems with various roofing materials and compliance with local building codes, especially in regions with diverse climatic conditions, such as Africa and South America.

What Role Does Electronic Leak Detection Play in Oil & Gas?

In the oil and gas sector, electronic leak detection is vital for monitoring pipelines and storage tanks. ELD systems can detect minute leaks that may lead to environmental hazards or significant product loss. By implementing these systems, companies can enhance their safety protocols, reduce the risk of spills, and comply with stringent environmental regulations. For international buyers, especially in the Middle East where oil extraction is prevalent, it is crucial to source ELD equipment that adheres to international safety standards and certifications, ensuring reliability in harsh operational environments.

How is Electronic Leak Detection Beneficial in Manufacturing?

Manufacturing facilities benefit from electronic leak detection in various applications, including monitoring cooling systems and hydraulic lines. ELD technology helps identify leaks that could lead to equipment failure or production downtime, thus optimizing maintenance schedules and reducing operational costs. For manufacturers, especially in regions like Europe and Brazil, selecting durable and reliable detection systems that can withstand industrial conditions is essential. This ensures that the equipment can operate effectively in high-demand environments, maintaining productivity levels.

Why is Electronic Leak Detection Important in Water Treatment?

In water treatment facilities, electronic leak detection is crucial for ensuring the integrity of water storage systems and treatment processes. ELD can quickly identify leaks that could compromise water quality, thereby helping facilities maintain compliance with environmental regulations. For buyers in regions facing water scarcity, such as parts of Africa and the Middle East, sourcing adaptable ELD solutions that can handle various storage materials and conditions is essential to prevent water loss and ensure sustainability.

Illustrative image related to electronic leak detection

How Does Electronic Leak Detection Protect Pharmaceutical Environments?

In the pharmaceutical industry, electronic leak detection is employed to monitor cleanroom environments and storage areas for any leaks that could compromise product integrity. ELD systems provide precise and sensitive monitoring, ensuring compliance with health regulations and maintaining the sterility of products. International buyers in this sector should prioritize sourcing ELD technology that meets stringent industry standards and offers reliable performance in sterile conditions, particularly in regions with growing pharmaceutical markets like South America and Europe.

3 Common User Pain Points for ‘electronic leak detection’ & Their Solutions

Scenario 1: Difficulty in Accurately Locating Leaks

The Problem: B2B buyers often encounter significant challenges in pinpointing the exact location of leaks in roofing and waterproofing systems. Traditional methods like visual inspections can be misleading, leading to unnecessary repairs or costly replacements. This problem is exacerbated in large commercial properties or complex structures where access can be limited and the areas to inspect are extensive. The inability to accurately detect leaks can lead to prolonged water damage, increased repair costs, and potential safety hazards, all of which can strain budgets and timelines.

The Solution: To effectively address this challenge, B2B buyers should invest in advanced electronic leak detection (ELD) systems that utilize non-destructive testing methods. Opt for systems such as the IntegriScan, which employs low-voltage scanning technology to detect breaches with high precision. When specifying ELD systems, ensure that the equipment is compliant with ASTM standards and that it can work with various roofing materials. Furthermore, conducting regular training for staff on how to use this technology can enhance their ability to identify leaks quickly and accurately. Utilizing a system that allows for continuous monitoring, such as the PermaScan, can also help in early detection, minimizing potential damage and repair costs over time.

Scenario 2: High Costs Associated with Traditional Leak Testing Methods

The Problem: Many businesses are reliant on traditional leak testing methods, such as flood testing, which can be costly and time-consuming. This approach not only involves the risk of water damage to other building elements but also requires significant labor and resources. In regions prone to water scarcity or where water usage is heavily regulated, these methods can incur additional costs and compliance issues. Consequently, organizations may struggle to balance effective leak detection with budget constraints, leading to inadequate inspections.

The Solution: Transitioning to electronic leak detection methods can provide a more cost-effective and efficient alternative. For instance, low-voltage electronic field vector mapping (EFVM) offers a reliable means of detecting leaks without the extensive water usage associated with traditional methods. B2B buyers should look for ELD systems that minimize water consumption while still providing accurate results. Additionally, negotiating service contracts that include ELD as a standard procedure can reduce long-term costs and improve the overall quality of roofing inspections. By making this switch, companies can ensure compliance with environmental regulations and reduce operational costs associated with traditional testing methods.

Illustrative image related to electronic leak detection

Scenario 3: Challenges in Compliance and Industry Standards

The Problem: Ensuring compliance with industry standards and regulations can be a daunting task for B2B buyers in the electronic leak detection space. Different regions may have varying requirements, particularly in Africa, South America, the Middle East, and Europe. Buyers may struggle to keep up with these regulations, leading to potential liabilities or project delays. The complexity increases when dealing with multiple contractors or stakeholders who may not be familiar with the latest standards, such as ASTM Guide D7877 or FM Approval requirements.

The Solution: To navigate this challenge, B2B buyers should prioritize sourcing ELD systems that are not only compliant with local and international standards but also supported by thorough documentation and training resources. Investing in equipment that comes with a robust warranty and support from reputable manufacturers can ensure that your testing methods meet industry expectations. Additionally, establishing a compliance checklist that aligns with ASTM guidelines can help streamline the process. Collaborating with certified contractors who are knowledgeable about ELD systems and compliance can also mitigate risks. Regular audits of testing processes and contractor performance can further ensure that all stakeholders are aligned with the required standards, ultimately safeguarding the integrity of the project.

Strategic Material Selection Guide for electronic leak detection

What Are the Key Materials Used in Electronic Leak Detection Systems?

When selecting materials for electronic leak detection (ELD) systems, it is crucial to consider their properties, advantages, and limitations. This analysis will focus on four common materials: Conductive Primers, EPDM Membranes, Aluminized Coatings, and Conductive Substrates. Each material plays a significant role in the effectiveness and reliability of ELD systems.

Illustrative image related to electronic leak detection

How Do Conductive Primers Enhance Electronic Leak Detection?

Conductive primers, such as TruGround®, are essential for enabling ELD testing on non-conductive substrates. These primers create a conductive layer beneath roofing membranes, facilitating the detection of leaks.

Key Properties: Conductive primers are designed to withstand a wide range of temperatures and environmental conditions, ensuring consistent performance. They exhibit excellent adhesion and corrosion resistance.

Pros & Cons: The primary advantage of conductive primers is their ability to transform non-conductive surfaces into conductive ones, allowing for effective leak detection. However, they can add to the overall cost of the roofing system and may require specialized application techniques, increasing manufacturing complexity.

Impact on Application: Conductive primers are particularly effective for testing black EPDM membranes and other non-conductive materials. Their compatibility with various roofing systems makes them a versatile choice for international applications.

Considerations for International Buyers: Buyers in regions such as Africa and South America should ensure that the primers meet local compliance standards and consider the availability of skilled applicators familiar with these products.

What Role Do EPDM Membranes Play in ELD Systems?

Ethylene Propylene Diene Monomer (EPDM) membranes are widely used in roofing applications due to their excellent durability and weather resistance.

Key Properties: EPDM membranes are known for their high elasticity, temperature resistance, and UV stability, making them suitable for various climates.

Pros & Cons: The main advantage of EPDM is its longevity and low maintenance requirements. However, its initial cost can be higher than other roofing materials, which may deter some buyers.

Impact on Application: EPDM membranes are compatible with conductive testing methods, particularly when used with conductive primers. This compatibility enhances the effectiveness of ELD systems.

Considerations for International Buyers: Buyers should verify that the EPDM membranes meet local and international standards, such as ASTM, to ensure compliance and performance.

Illustrative image related to electronic leak detection

How Do Aluminized Coatings Contribute to Leak Detection?

Aluminized coatings are often applied to modified bituminous membranes to enhance their reflective properties and protect against UV damage.

Key Properties: These coatings provide a durable, weather-resistant barrier and improve the membrane’s overall lifespan.

Pros & Cons: The reflective nature of aluminized coatings can reduce energy costs by keeping buildings cooler. However, they may require additional maintenance and can be more expensive than standard coatings.

Impact on Application: Aluminized coatings can enhance the performance of ELD systems by providing a conductive surface for testing, especially when combined with low-voltage methods.

Illustrative image related to electronic leak detection

Considerations for International Buyers: Buyers should consider the availability of aluminized coatings in their region and ensure they comply with local building codes and standards.

What Are the Benefits of Using Conductive Substrates in ELD Systems?

Conductive substrates, such as steel or aluminum, are crucial for establishing an effective grounding system in ELD applications.

Key Properties: These substrates offer excellent conductivity and durability, making them ideal for leak detection.

Pros & Cons: The primary advantage of conductive substrates is their reliability in completing electrical circuits during leak detection. However, they may be susceptible to corrosion if not properly treated, which can impact their longevity.

Impact on Application: Conductive substrates are essential for various ELD testing methods, including low-voltage scanning and electronic field vector mapping.

Considerations for International Buyers: Buyers should ensure that conductive substrates are treated to resist corrosion, especially in humid or coastal regions, and comply with international standards.

Summary of Material Selection for Electronic Leak Detection

| Material | Typical Use Case for electronic leak detection | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Conductive Primers | Enhancing non-conductive surfaces for ELD | Enables effective leak detection | Adds cost and complexity | Medium |

| EPDM Membranes | Roofing applications with ELD compatibility | High durability and low maintenance | Higher initial cost | High |

| Aluminized Coatings | Protective layer for modified bituminous roofs | Reflective properties reduce energy costs | Requires maintenance and higher cost | Medium |

| Conductive Substrates | Grounding for ELD systems | Reliable conductivity | Susceptible to corrosion | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers looking to implement effective electronic leak detection systems tailored to their regional requirements and standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electronic leak detection

What Are the Main Stages in the Manufacturing Process of Electronic Leak Detection Equipment?

The manufacturing process for electronic leak detection (ELD) equipment is a meticulous operation that includes several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets stringent quality and performance standards.

Material Preparation: How Are Raw Materials Chosen and Processed?

The first step in manufacturing ELD equipment involves selecting high-quality raw materials. Conductive materials, such as metals for electrodes and non-conductive substrates for insulation, are typically sourced from reputable suppliers who adhere to international standards. Materials are then subjected to rigorous testing to ensure they meet specifications for conductivity, durability, and resistance to environmental factors.

Illustrative image related to electronic leak detection

Once selected, materials undergo preparation processes such as cutting, shaping, and treating. For instance, conductive primers like TruGround® are formulated to enhance the effectiveness of ELD systems when applied to non-conductive surfaces. This preparation ensures that the materials are ready for the next stages, where precision is key.

Forming: What Techniques Are Used to Create Components?

Forming is the next critical stage, where raw materials are transformed into components. Techniques such as stamping, molding, and machining are commonly employed to create the various parts of ELD systems, including sensors, probes, and testing platforms.

Advanced manufacturing technologies, including CNC machining and injection molding, may be used to achieve the precision required for electrical components. For example, the IntegriScan system incorporates a scanning platform that must fit exact specifications to ensure effective leak detection. Employing high-quality forming techniques minimizes defects and enhances the reliability of the final product.

Assembly: How Are Components Integrated into Final Products?

The assembly stage involves integrating various components into a cohesive ELD system. This process often requires skilled technicians who can ensure that each component is correctly aligned and connected. Automated assembly lines may also be utilized for efficiency and consistency.

During assembly, careful attention is paid to the electrical connections, ensuring that circuits are complete and functional. For instance, the placement of conductive wires and the sealing of connections are vital to the performance of ELD systems. This stage often includes testing components individually before full assembly to catch any issues early.

Finishing: What Quality Enhancements Are Applied?

Finishing processes enhance the durability and functionality of ELD equipment. This may include surface treatments such as coating, painting, or sealing to protect against environmental factors like moisture, UV rays, and chemicals.

Additionally, final inspection and testing are conducted to verify that the product meets performance specifications. This step ensures that the equipment is ready for use in various conditions and applications, from roofing to industrial leak detection.

How Is Quality Assurance Implemented in Electronic Leak Detection Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of electronic leak detection systems, as it ensures that the products meet both international standards and customer expectations. Several checkpoints and methods are employed throughout the manufacturing process to maintain high-quality standards.

Illustrative image related to electronic leak detection

What International Standards Are Relevant for ELD Manufacturing?

International standards such as ISO 9001 play a significant role in establishing a quality management framework for manufacturers. ISO 9001 focuses on ensuring consistent quality in products and services through systematic processes and continuous improvement. Compliance with this standard can enhance a manufacturer’s credibility, especially for B2B buyers looking for reliable suppliers.

In addition to ISO standards, industry-specific certifications such as CE marking and API (American Petroleum Institute) standards may be relevant, depending on the application of the ELD systems. CE marking indicates compliance with European health, safety, and environmental protection standards, while API standards ensure that equipment meets the needs of the oil and gas industry.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are implemented at various stages of the manufacturing process to ensure that products meet required specifications:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predetermined quality criteria. Any materials that do not meet specifications are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, components are regularly tested for conformity to specifications. This may involve testing electrical connections, verifying dimensions, and assessing surface finishes.

-

Final Quality Control (FQC): After assembly, the entire ELD system undergoes comprehensive testing. This includes functional tests to verify leak detection capabilities, ensuring that the equipment operates as intended.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to assess the performance and reliability of electronic leak detection systems:

-

Functional Testing: This verifies that the ELD system operates correctly under various conditions and accurately identifies leaks.

-

Environmental Testing: Equipment may be subjected to extreme conditions (temperature, humidity, etc.) to evaluate its durability and performance in real-world applications.

-

Calibration and Validation: Regular calibration of ELD systems ensures that they provide accurate readings. Validation against known standards helps confirm their reliability.

How Can B2B Buyers Verify the Quality Control of ELD Suppliers?

For B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential for ensuring product reliability.

What Steps Can Buyers Take to Ensure Supplier Quality?

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can help buyers assess whether suppliers adhere to international standards.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation of their quality control processes and testing results. Reviewing these reports can give buyers confidence in the supplier’s capabilities.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s manufacturing and quality control processes. This is particularly important for buyers who may not have the resources to conduct comprehensive audits themselves.

What Nuances Should International Buyers Be Aware Of?

International buyers should be aware of specific regulations and standards applicable in their regions. For instance, compliance with local certifications may differ from international standards, affecting product acceptance in various markets. Understanding these nuances can help buyers navigate the complexities of sourcing electronic leak detection equipment globally.

In summary, the manufacturing processes and quality assurance practices for electronic leak detection systems are critical for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful leak detection solutions for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electronic leak detection’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring electronic leak detection (ELD) systems. As the demand for effective leak detection solutions grows, understanding how to navigate the procurement process is essential. This checklist provides actionable steps to ensure you select the right equipment and supplier for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the ELD system meets your operational requirements. Consider factors such as the types of surfaces you will be testing (e.g., roofs, walls), the required testing methods (low-voltage vs. high-voltage), and compliance with relevant standards like ASTM Guide D7877.

- Surface Types: Identify if you need to test horizontal, vertical, or sloped surfaces.

- Testing Methods: Evaluate whether you require systems that use water or those that operate dry.

Step 2: Research Available Technologies

Different ELD technologies offer various advantages. Familiarize yourself with the types of systems available, including low-voltage scanning platforms and high-voltage testing methods. Understanding these technologies will help you identify the best fit for your specific application.

- Low-Voltage Scanning: Ideal for non-destructive testing with minimal water usage.

- High-Voltage Spark Testing: Suitable for more challenging environments but requires careful handling.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s vital to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. A reputable supplier should have a proven track record of successful installations and satisfied customers.

- Supplier Experience: Look for companies with extensive experience in ELD systems.

- Client Testimonials: Seek feedback from other businesses that have used their products.

Step 4: Verify Certifications and Compliance

Ensure that the ELD systems you are considering meet industry standards and have the necessary certifications. This is crucial for ensuring product reliability and compliance with local regulations, especially in international markets.

Illustrative image related to electronic leak detection

- ASTM Compliance: Check if the equipment adheres to ASTM standards for leak detection.

- Local Certifications: Confirm that the supplier has relevant certifications for your specific region (e.g., UL, FM).

Step 5: Assess Support and Training Services

An effective ELD system is only as good as the support that comes with it. Evaluate the training and technical support offered by the supplier to ensure your team can operate the equipment efficiently.

- On-Site Training: Determine if the supplier provides hands-on training sessions.

- Ongoing Support: Ensure there is a clear plan for technical support after the purchase.

Step 6: Request Demonstrations or Trials

Before finalizing your purchase, request demonstrations or trial periods for the ELD systems. This allows you to evaluate the equipment’s performance in real-world conditions and ensure it meets your expectations.

- Field Testing: Conduct trials on actual projects to assess effectiveness.

- User Feedback: Gather input from your team during the trial phase to understand usability and functionality.

Step 7: Compare Pricing and Total Cost of Ownership

Finally, while price is a significant factor, consider the total cost of ownership, including maintenance, training, and potential downtime. Compare quotes from multiple suppliers to ensure you receive the best value for your investment.

- Hidden Costs: Be aware of any additional fees related to training or support.

- Long-Term Value: Evaluate the longevity and durability of the equipment to minimize future expenses.

By following this checklist, B2B buyers can make informed decisions when sourcing electronic leak detection systems, ensuring they invest in reliable solutions that meet their unique needs.

Illustrative image related to electronic leak detection

Comprehensive Cost and Pricing Analysis for electronic leak detection Sourcing

What Are the Key Cost Components in Electronic Leak Detection Sourcing?

When sourcing electronic leak detection (ELD) systems, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: This encompasses the raw materials required for the equipment, such as conductive substrates, components for electrical systems, and testing apparatus. The quality of materials can significantly influence both the cost and effectiveness of the leak detection systems.

-

Labor: Labor costs cover the workforce involved in manufacturing, assembling, and testing the ELD systems. Skilled technicians are often necessary for precise assembly and quality assurance, which can raise labor costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, equipment maintenance, and other indirect costs that contribute to production. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tooling may be required for specialized equipment or modifications, impacting initial setup costs. Investing in advanced tooling can enhance production efficiency and reduce long-term costs.

-

Quality Control (QC): A robust QC process ensures that the systems meet industry standards and performance requirements. Although this adds to the initial cost, it minimizes the risk of failures and warranty claims later.

-

Logistics: Transportation, warehousing, and distribution costs are crucial, especially for international shipments. Consideration of logistics can lead to significant savings, particularly when optimizing shipping routes or methods.

-

Margin: Supplier margins vary widely based on market positioning, brand reputation, and the level of customer service provided. Understanding the typical margins in the ELD market can help buyers gauge fair pricing.

What Influences Pricing for Electronic Leak Detection Systems?

Several factors can influence the pricing of electronic leak detection systems:

-

Volume/MOQ: Bulk purchases often attract discounts, making it cost-effective for large-scale projects. Buyers should negotiate minimum order quantities (MOQs) to optimize their costs.

-

Specifications and Customization: Customized solutions tailored to specific requirements can lead to higher prices. However, they may also provide enhanced performance and reliability that justify the additional expense.

-

Material Quality and Certifications: Systems that meet higher quality standards or possess industry certifications (e.g., FM Approval, UL Listing) typically command higher prices. Buyers should weigh the benefits of certification against cost.

-

Supplier Factors: Supplier reputation, reliability, and the level of customer support can impact pricing. Established suppliers may charge a premium for their proven track record and comprehensive service offerings.

-

Incoterms: The terms of trade (Incoterms) affect the total landed cost of the products. Buyers should negotiate terms that minimize their risk and optimize cost efficiency, especially in international transactions.

How Can Buyers Optimize Costs in Electronic Leak Detection Sourcing?

To maximize cost efficiency, B2B buyers should consider the following tips:

-

Negotiate Pricing and Terms: Engage in negotiations to secure favorable pricing, especially when dealing with larger orders or long-term contracts. Leverage relationships and market insights to strengthen your position.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase costs, assess long-term operational costs associated with maintenance, repair, and warranty claims. A lower upfront cost may lead to higher TCO if the system is less reliable.

-

Understand Pricing Nuances for International Transactions: Different regions may have varying pricing strategies based on local market conditions, tariffs, and shipping costs. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to ensure competitive pricing.

-

Consider Alternative Suppliers: Explore multiple suppliers to identify the best combination of quality and price. Don’t hesitate to consider emerging suppliers who may offer innovative solutions at competitive rates.

Disclaimer for Indicative Prices

Pricing for electronic leak detection systems can fluctuate based on market dynamics, supplier negotiations, and specific project requirements. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure the best possible price.

Alternatives Analysis: Comparing electronic leak detection With Other Solutions

When evaluating leak detection solutions, it’s crucial for B2B buyers to consider various alternatives to electronic leak detection (ELD). Each method has its unique advantages and limitations, which can significantly influence operational efficiency, cost-effectiveness, and long-term reliability. Below, we compare ELD with two prominent alternatives: Flood Testing and Infrared Thermography.

| Comparison Aspect | Electronic Leak Detection | Flood Testing | Infrared Thermography |

|---|---|---|---|

| Performance | High accuracy in leak location; real-time monitoring possible | Good for detecting significant leaks but may miss small breaches | Effective in identifying temperature variations indicative of leaks |

| Cost | Moderate to high initial investment; cost-effective over time due to reduced repairs | Generally low initial cost; can incur higher costs due to water damage | Moderate cost; may require specialized training and equipment |

| Ease of Implementation | Requires trained personnel; initial setup can be complex | Simple to set up; requires water and time | Requires specialized equipment and expertise for accurate results |

| Maintenance | Low; systems can be permanently installed for ongoing monitoring | Moderate; requires drying out and inspections post-testing | Low; equipment needs regular calibration and maintenance |

| Best Use Case | Ideal for ongoing monitoring and precise leak detection in new and existing roofs | Best for initial leak detection in new installations | Effective for thermal imaging of existing roofs to locate hidden leaks |

What Are the Advantages and Disadvantages of Flood Testing?

Flood testing is a traditional method that involves covering a roof with water to check for leaks. While it is straightforward and cost-effective, it has notable downsides. The method can introduce large amounts of water, risking damage to newly installed roofs and potentially masking smaller leaks. Additionally, flood testing may not be feasible for roofs with complex structures or those that are already susceptible to moisture damage.

How Does Infrared Thermography Compare?

Infrared thermography uses thermal imaging to detect temperature differences in roofing materials, indicating potential leaks. This method is non-destructive and can assess large areas quickly. However, its effectiveness is contingent on environmental conditions, as temperature variations can be influenced by external factors such as sunlight and ambient temperature. Furthermore, while it can identify potential issues, it does not provide direct evidence of leaks, necessitating follow-up verification with other methods.

How Can B2B Buyers Choose the Right Solution?

Selecting the appropriate leak detection solution depends on several factors, including the specific use case, budget constraints, and operational requirements. Buyers should consider the type of roofing system they have, the complexity of their structures, and whether ongoing monitoring is necessary. For instance, ELD may be ideal for facilities requiring continuous monitoring and quick response times, while flood testing might suffice for straightforward installations. Infrared thermography serves well for preliminary assessments but should be complemented with direct testing methods for conclusive results.

In conclusion, understanding the strengths and weaknesses of electronic leak detection compared to alternatives like flood testing and infrared thermography will empower B2B buyers to make informed decisions. Each method offers unique benefits that can align with specific operational needs and budget considerations, paving the way for effective leak management strategies.

Essential Technical Properties and Trade Terminology for electronic leak detection

What Are the Key Technical Properties of Electronic Leak Detection Systems?

When considering electronic leak detection (ELD) systems, several technical properties are paramount for ensuring effective leak detection and long-term reliability. Understanding these properties is crucial for B2B buyers looking to invest in quality solutions.

-

Material Grade

The material grade of the ELD equipment, particularly the conductive components, is critical. High-grade materials, such as carbon black for membranes or aluminum for conductive pathways, ensure durability and conductivity. This is essential for achieving accurate leak detection results and prolonging the lifespan of the equipment. -

Voltage Specifications

ELD systems typically operate on low-voltage or high-voltage testing methods. Low-voltage systems are preferred for safety and ease of use, while high-voltage systems can detect smaller breaches more effectively. B2B buyers should evaluate the voltage requirements based on the specific applications and safety regulations in their region. -

Tolerance Levels

Tolerance levels refer to the acceptable variations in the specifications of ELD systems. For instance, the tolerance in the electrical resistance of the conductive pathways directly impacts the system’s sensitivity. Higher sensitivity allows for the detection of smaller leaks, which can prevent significant water damage and reduce overall repair costs. -

Testing Coverage Area

The coverage area determines how much surface area the ELD system can effectively test in one go. Systems like the IntegriScan offer a designated scanning platform that can cover significant areas quickly, which is advantageous for large installations. Efficient coverage minimizes labor costs and accelerates the testing process. -

Integration Capabilities

ELD systems should seamlessly integrate with existing building monitoring systems. Compatibility with other technologies, such as moisture sensors or structural health monitoring systems, enhances the value proposition by providing comprehensive solutions for building maintenance and safety. -

Durability and Environmental Resistance

ELD equipment must withstand various environmental conditions, including humidity, temperature fluctuations, and exposure to chemicals. Systems designed with robust, weather-resistant materials ensure reliability in diverse settings, particularly in regions prone to extreme weather.

What Are Common Trade Terminology and Jargon Used in Electronic Leak Detection?

Navigating the electronic leak detection industry requires familiarity with specific jargon and trade terms. Understanding these terms can facilitate smoother transactions and communications between buyers and suppliers.

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ELD systems, knowing the OEM can help buyers identify the quality and reliability of the equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For ELD systems, understanding MOQ is crucial for budgeting and inventory management, especially when considering large-scale projects. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process is vital for B2B buyers to compare costs and services among different ELD providers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and potential costs when importing ELD systems from different countries. -

Calibration

Calibration refers to the process of adjusting and validating the accuracy of ELD equipment. Regular calibration is essential to maintain the reliability of the leak detection results and is a key consideration for buyers concerned about compliance with industry standards. -

Field Testing

Field testing involves the practical application of ELD systems in real-world conditions to verify their effectiveness. Understanding the importance of field testing can help buyers ensure that the products they invest in have been rigorously evaluated for performance and reliability.

By grasping these essential properties and terminologies, B2B buyers can make more informed decisions when selecting electronic leak detection solutions that meet their specific needs and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the electronic leak detection Sector

What Are the Key Market Dynamics and Trends in the Electronic Leak Detection Sector?

The electronic leak detection (ELD) market is experiencing significant growth, driven by increasing regulatory standards for water damage prevention, heightened awareness of infrastructure integrity, and the rising cost of water-related damages. Internationally, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable leak detection solutions is surging as industries seek to enhance their operational efficiency and protect valuable assets. Emerging technologies such as low-voltage scanning and electronic field vector mapping are setting new benchmarks in accuracy and reliability, making ELD systems a preferred choice over traditional methods like flood testing.

In the current landscape, international B2B buyers are gravitating toward integrated solutions that offer real-time monitoring and continuous leak detection capabilities. The adoption of smart technologies, including IoT-enabled devices, is another key trend, allowing for proactive maintenance and timely interventions. This shift is particularly relevant for sectors such as construction, manufacturing, and facility management, where water ingress can lead to significant operational disruptions and financial losses. Buyers from emerging markets are also recognizing the value of investing in quality ELD equipment that complies with international standards, ensuring longevity and effectiveness.

How Are Sustainability and Ethical Sourcing Impacting the Electronic Leak Detection Market?

As global awareness of environmental sustainability increases, the electronic leak detection sector is also adapting by focusing on environmentally friendly practices and ethical sourcing. The use of sustainable materials and processes in the manufacturing of ELD equipment is becoming a crucial factor for B2B buyers, especially in regions with stringent environmental regulations. Buyers are encouraged to seek suppliers who prioritize sustainable practices, such as utilizing recyclable materials and minimizing waste during production.

Ethical sourcing in the electronic leak detection market entails not only the selection of eco-friendly materials but also ensuring that supply chains are transparent and socially responsible. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 for environmental management systems can provide buyers with assurances regarding the sustainability of their purchases. Furthermore, companies that commit to ethical practices often find themselves more competitive in the marketplace, appealing to a growing base of environmentally-conscious consumers and businesses.

What Is the Evolution of Electronic Leak Detection in the B2B Context?

The evolution of electronic leak detection technology has been marked by significant advancements in both methodology and application. Initially, leak detection was limited to rudimentary visual inspections and flood testing, which were labor-intensive and often ineffective. Over the past few decades, technological innovations have introduced ELD systems that utilize electrical currents to identify breaches in waterproofing membranes, significantly increasing the accuracy of leak detection.

The introduction of standards such as ASTM Guide D7877 has further professionalized the industry, providing a framework for the effective use of ELD methods. As a result, the market has shifted towards sophisticated, non-destructive testing techniques that not only detect leaks but also allow for the monitoring of roof integrity throughout its service life. This evolution has made ELD an essential tool in sectors ranging from construction to facility management, where the integrity of infrastructure is paramount. As technology continues to advance, the future of electronic leak detection looks promising, with ongoing innovations likely to enhance both performance and sustainability in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of electronic leak detection

1. How do I solve issues with water leaks in roofing systems?

To effectively address water leaks in roofing systems, implementing Electronic Leak Detection (ELD) is crucial. ELD utilizes low- or high-voltage electrical currents to identify breaches in roofing membranes without causing significant disruption. This technology allows for precise pinpointing of leaks, enabling targeted repairs rather than extensive replacements. Conducting regular ELD tests can help in early detection, thus minimizing potential damage and costs. When choosing a provider, ensure they are certified and experienced in ELD methods to guarantee accurate results and compliance with international standards.

2. What is the best Electronic Leak Detection system for commercial roofs?

The best ELD system for commercial roofs often depends on the roofing material and the specific application. For instance, the IntegriScan system is widely recognized for its effectiveness across various surfaces, including vertical and horizontal membranes. It complies with ASTM standards, ensuring reliability in testing. Additionally, systems like PermaScan offer continuous monitoring, which is beneficial for long-term maintenance. When selecting a system, consider factors such as the type of roofing, environmental conditions, and whether you need portable or permanently installed solutions.

3. How can I verify the credibility of Electronic Leak Detection suppliers?

Verifying the credibility of ELD suppliers involves several key steps. First, check for certifications and industry accreditations, such as ISO or ASTM compliance, which indicate adherence to quality standards. Seek testimonials or case studies from previous clients to understand their service quality. Additionally, assess their experience and expertise in specific regions, particularly if you’re sourcing from international suppliers. Engaging in direct communication to discuss your requirements can also provide insights into their customer service and technical knowledge.

4. What are the customization options available for Electronic Leak Detection systems?

Many ELD suppliers offer customization options tailored to specific project needs. This can include modifications in the testing equipment to suit different roofing materials or environmental conditions. Some manufacturers may also provide bespoke training programs for your staff to ensure effective use of the equipment. When negotiating with suppliers, clearly outline your requirements and inquire about their capability to customize systems, including software integration or additional monitoring features, to enhance your leak detection processes.

5. What is the minimum order quantity (MOQ) for Electronic Leak Detection equipment?

Minimum order quantities for ELD equipment can vary widely among suppliers, often depending on the type of equipment and the supplier’s production capabilities. Some manufacturers may have a MOQ as low as one unit for specialized equipment, while others may require larger orders for cost efficiency. When sourcing, it’s advisable to inquire about the MOQ upfront to ensure it aligns with your project scale and budget. Additionally, consider the implications of bulk purchasing, such as potential cost savings and inventory management.

6. What payment terms should I expect when purchasing Electronic Leak Detection systems internationally?

Payment terms for international purchases of ELD systems can vary based on the supplier and the country of origin. Common terms include upfront payments, letters of credit, or staggered payments based on milestones. It’s crucial to clarify these terms before finalizing any agreements. Additionally, consider the currency exchange rates and potential transaction fees. Establishing clear communication with the supplier regarding payment methods can prevent misunderstandings and ensure a smoother procurement process.

Illustrative image related to electronic leak detection

7. How do I ensure quality assurance for Electronic Leak Detection systems?

To ensure quality assurance for ELD systems, it is essential to choose suppliers who adhere to international quality standards such as ISO 9001. Request documentation of testing and compliance with relevant ASTM standards, which govern the use of ELD methods. Additionally, consider conducting on-site visits or audits of the supplier’s facilities if possible. Establish a clear agreement on warranty and service support terms, ensuring that you have recourse in case of defects or performance issues with the equipment.

8. What logistical considerations should I keep in mind when sourcing Electronic Leak Detection equipment?

When sourcing ELD equipment internationally, consider logistics factors such as shipping methods, lead times, and customs regulations. Evaluate the supplier’s ability to provide timely delivery and their experience with international shipping. Additionally, consider the implications of import duties and taxes on your overall budget. It may be beneficial to work with logistics providers who specialize in international trade to navigate these complexities efficiently, ensuring that your equipment arrives on time and in good condition.

Top 4 Electronic Leak Detection Manufacturers & Suppliers List

1. Detec Systems – IntegriScan

Domain: detecsystems.com

Registered: 2003 (22 years)

Introduction: Detec Systems offers three main products for Electronic Leak Detection (ELD): 1. **IntegriScan**: A portable low voltage ELD quality control test that identifies breaches in roofing or waterproofing assemblies by detecting a water path to building ground. It complies with ASTM Guide D7877 and is FM Approved. 2. **TruGround®**: A UL listed and FM approved conductive medium that can be added during …

2. Carlisle SynTec – Electronic Leak Detection Systems

Domain: carlislesyntec.com

Registered: 2002 (23 years)

Introduction: Electronic Leak Detection (ELD) Systems are non-destructive tests used to verify the watertightness of roofing membranes. ELD offers advantages over traditional flood testing, including the ability to detect leaks throughout the roofing’s life, precise leak location, and testing capability for sloped roofs and vertical walls. ELD methods include: 1. Low-Voltage Scanning Platform Testing (IntegriSc…

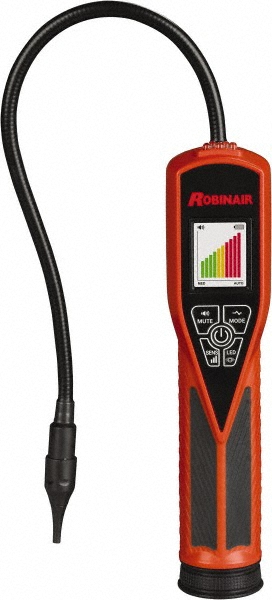

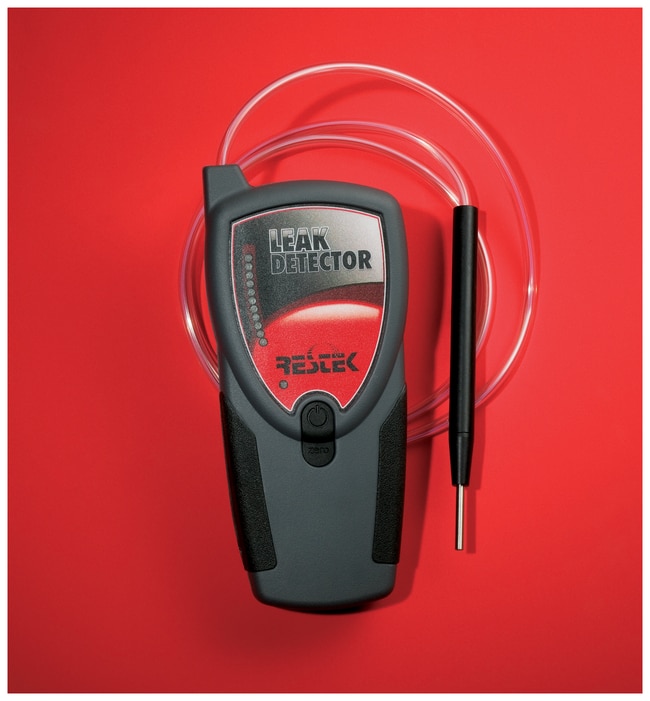

3. Restek – Electronic Leak Detector

Domain: restek.com

Registered: 1998 (27 years)

Introduction: {“Catalog No.”: “28500”, “Product Name”: “Restek Electronic Leak Detector”, “Price”: “$1,305.00”, “Overview”: “Prevent small leaks from causing big problems with a Restek leak detector. Detects a broad range of gases. Audible tone and LED display indicate the severity of a leak. Can be operated during charging or used up to 12 hours between charges. Ergonomic, handheld design. Rugged side grips fo…

4. WaterproofMag – Electronic Leak Detection

Domain: waterproofmag.com

Registered: 2007 (18 years)

Introduction: Electronic Leak Detection (ELD) methods can locate small leaks with pinpoint accuracy on vertical and horizontal surfaces. ELD has been used in North America for nearly two decades for testing leaks in roofs. It operates on the principle of using electrical current to locate membrane breaches. ELD is advantageous over alternatives like infrared thermography and nuclear moisture testing, as it can …

Strategic Sourcing Conclusion and Outlook for electronic leak detection

How Can Strategic Sourcing Enhance Your Electronic Leak Detection Solutions?

In conclusion, the strategic sourcing of electronic leak detection (ELD) systems offers significant advantages for businesses seeking reliable and efficient solutions to manage waterproofing integrity. By prioritizing high-quality ELD technologies, such as those compliant with ASTM standards, companies can not only ensure enhanced leak detection capabilities but also reduce long-term maintenance costs. The integration of innovative tools, like the IntegriScan and TruGround systems, empowers organizations to pinpoint breaches accurately, thereby minimizing unnecessary repairs and maximizing resource allocation.

Illustrative image related to electronic leak detection

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, investing in advanced ELD systems is not merely a technical upgrade—it’s a strategic move towards operational excellence. By collaborating with trusted suppliers and leveraging cutting-edge technologies, businesses can safeguard their assets and enhance their service offerings.

As the demand for effective waterproofing solutions continues to grow globally, now is the time to act. Embrace strategic sourcing to elevate your leak detection capabilities and position your business at the forefront of industry innovation. Explore partnerships that align with your goals and drive sustainable growth in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to electronic leak detection

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.