Electrical Wire Brush: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for electrical wire brush

In the increasingly competitive landscape of industrial cleaning and maintenance, sourcing the right electrical wire brush can be a formidable challenge for international B2B buyers. With applications ranging from conductor cleaning in electrical utilities to surface preparation in manufacturing, the demand for specialized wire brushes is on the rise. This comprehensive guide addresses the complexities of navigating the global market for electrical wire brushes, offering insights into various types, applications, and essential considerations for supplier vetting.

The guide delves into the diverse range of electrical wire brushes available, including twisted steel, stainless steel, and nylon options, highlighting their specific uses across different industries. Additionally, it provides actionable strategies for evaluating suppliers, understanding cost implications, and ensuring compliance with international standards. By equipping buyers with detailed knowledge about product specifications, market trends, and logistical considerations, this guide empowers decision-makers from regions such as Africa, South America, the Middle East, and Europe—specifically Brazil and Germany—to make informed purchasing choices.

Whether you are looking to enhance cleaning efficiency, ensure product longevity, or maintain safety standards, this guide serves as a vital resource to streamline your procurement process and optimize your operational performance.

Understanding electrical wire brush Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Twisted Steel Wire Brush | Heavy-duty bristles for aggressive cleaning | Metal fabrication, automotive maintenance | Pros: Durable, effective on tough surfaces. Cons: Can damage softer materials. |

| Stainless Steel Wire Brush | Corrosion-resistant, suitable for various surfaces | Electrical maintenance, marine applications | Pros: Long-lasting, versatile. Cons: Higher cost compared to other materials. |

| Nylon Wire Brush | Non-scratch bristles, ideal for delicate surfaces | Electronics, woodworking | Pros: Safe for sensitive surfaces, effective cleaning. Cons: Less aggressive than metal brushes. |

| Brass Wire Brush | Softer than steel, ideal for cleaning without scratching | Automotive, jewelry, and delicate components | Pros: Non-damaging, effective on soft metals. Cons: Less durable than steel options. |

| Conductor Cleaning Brush | Designed specifically for electrical conductor cleaning | Electrical utilities, telecommunications | Pros: Optimized for conductor maintenance. Cons: Niche use may limit versatility. |

What are the Characteristics of Twisted Steel Wire Brushes?

Twisted steel wire brushes are designed with heavy-duty bristles that provide aggressive cleaning capabilities. They are particularly effective for removing rust, paint, and heavy deposits from metal surfaces. This type is commonly used in metal fabrication and automotive maintenance, where durability and cleaning power are paramount. B2B buyers should consider the potential for surface damage when using these brushes on softer materials.

Why Choose Stainless Steel Wire Brushes for B2B Applications?

Stainless steel wire brushes are known for their corrosion resistance and versatility across various applications. They are suitable for cleaning a range of surfaces, including electrical components and marine equipment. B2B buyers appreciate their longevity and performance, although the initial investment may be higher compared to other materials. It is essential to evaluate the specific cleaning requirements and surface compatibility before making a purchase.

When Should You Use Nylon Wire Brushes?

Nylon wire brushes are an excellent choice for cleaning delicate surfaces without the risk of scratching. They are ideal for applications in electronics and woodworking, where preserving the integrity of the surface is critical. Buyers should consider the specific cleaning tasks at hand, as nylon brushes are less aggressive than metal alternatives but offer effective cleaning for sensitive applications.

What are the Benefits of Brass Wire Brushes?

Brass wire brushes provide a softer alternative to steel brushes, making them suitable for cleaning soft metals and delicate components. They are commonly used in automotive and jewelry applications where avoiding scratches is crucial. While brass brushes are effective, B2B buyers should be aware that they may not last as long as steel options, making them a less durable choice for heavy-duty tasks.

How Do Conductor Cleaning Brushes Stand Out in the Market?

Conductor cleaning brushes are specifically designed for maintaining electrical conductors, making them essential for electrical utilities and telecommunications. These brushes optimize cleaning efficiency and ensure proper contact in electrical applications. B2B buyers should consider the specialized nature of these brushes, as their niche application may limit broader use but provides significant benefits for specific cleaning tasks.

Key Industrial Applications of electrical wire brush

| Industry/Sector | Specific Application of electrical wire brush | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Utilities | Cleaning electrical conductors and connectors | Ensures optimal conductivity and reduces maintenance costs | Durability, corrosion resistance, and bristle material |

| Automotive Manufacturing | Surface preparation for paint and coating applications | Enhances adhesion of coatings, reducing rework and waste | Compatibility with various materials and surface types |

| Metal Fabrication | Deburring and surface finishing of metal parts | Improves surface quality, leading to higher product standards | Brush type and size for specific applications |

| Aerospace Industry | Maintenance of aircraft electrical systems | Enhances safety and reliability of electrical components | Compliance with industry standards and specifications |

| Construction & Infrastructure | Cleaning and preparing surfaces for electrical installations | Ensures safety and efficiency in electrical setups | Brush strength and flexibility for different surfaces |

How is Electrical Wire Brush Used in Electrical Utilities?

In the electrical utilities sector, electrical wire brushes are essential for cleaning conductors and connectors. This process removes corrosion, dirt, and oxidation, which can hinder electrical conductivity. By maintaining clean connections, utilities can prevent outages and reduce the frequency of maintenance. Buyers in this sector should prioritize brushes made from durable materials that resist corrosion to ensure longevity and effectiveness in harsh environments.

What Role Does Electrical Wire Brush Play in Automotive Manufacturing?

In automotive manufacturing, electrical wire brushes are used for surface preparation before painting and coating processes. This application is crucial as it enhances the adhesion of paints, ensuring a high-quality finish that withstands wear and tear. Businesses benefit from reduced rework and material waste, leading to cost savings. Buyers should consider brushes that are compatible with various automotive materials, ensuring they meet the specific requirements of each application.

Illustrative image related to electrical wire brush

How is Electrical Wire Brush Beneficial in Metal Fabrication?

Metal fabrication relies heavily on electrical wire brushes for deburring and surface finishing tasks. These brushes help eliminate sharp edges and surface imperfections, improving the overall quality of metal parts. This not only enhances aesthetic appeal but also ensures that components meet stringent quality standards. When sourcing brushes for this application, it is essential to select the right type and size to match the specific materials and processes used in fabrication.

Why is Electrical Wire Brush Important in the Aerospace Industry?

In the aerospace industry, the maintenance of electrical systems is critical for safety and reliability. Electrical wire brushes are used to clean and maintain connectors and wiring, ensuring that all components function optimally. This application is vital for preventing electrical failures that could compromise aircraft safety. Buyers must ensure that the brushes comply with industry standards and specifications, as the stakes are significantly high in aerospace applications.

How Does Electrical Wire Brush Aid in Construction & Infrastructure?

Within the construction and infrastructure sectors, electrical wire brushes are used for cleaning and preparing surfaces prior to electrical installations. This step is crucial for ensuring the safety and efficiency of electrical setups, as contaminants can lead to poor connections and potential hazards. For international buyers, sourcing brushes with the right strength and flexibility to accommodate various surfaces is important, as it ensures effective cleaning without damaging underlying materials.

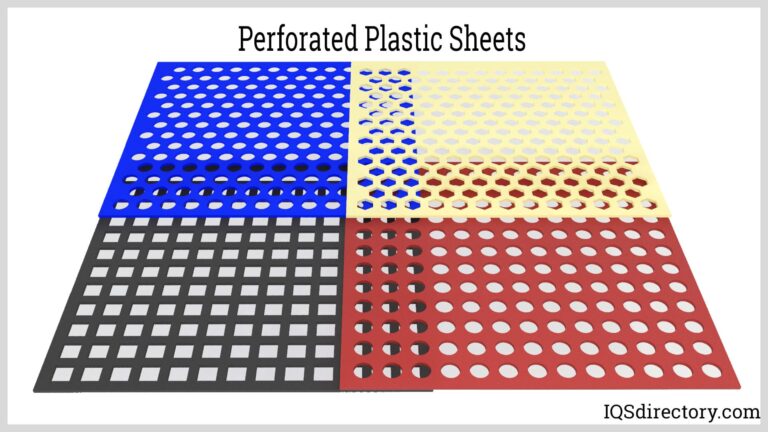

Illustrative image related to electrical wire brush

3 Common User Pain Points for ‘electrical wire brush’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Brush for Different Applications

The Problem: One common issue faced by B2B buyers is selecting the appropriate electrical wire brush for various applications. Different tasks—such as cleaning conductors, preparing surfaces for welding, or removing rust—require brushes with specific materials and bristle types. Buyers often find themselves overwhelmed by the numerous options available, leading to potential mistakes that can result in subpar performance or damage to equipment. This can particularly be challenging in regions like Africa and South America, where access to expert advice may be limited.

The Solution: To effectively address this issue, buyers should first conduct a thorough needs assessment to determine the specific requirements of their tasks. Understanding the material composition of the electrical wire brush is crucial; for instance, stainless steel brushes are ideal for heavy-duty applications, while brass brushes are better suited for softer materials. Buyers should also consider the bristle stiffness—hard bristles are effective for tough scrubbing, but may damage delicate surfaces. It is advisable to consult product specifications or seek recommendations from suppliers who can provide insights based on industry experience. Furthermore, investing in a variety of brushes for different applications can enhance efficiency and ensure the right tool is available when needed.

Scenario 2: Managing Brush Wear and Longevity

The Problem: Another pain point for B2B buyers is the rapid wear and tear of electrical wire brushes, which can lead to increased costs and operational downtime. Brushes that degrade quickly require frequent replacements, impacting the overall productivity of maintenance or manufacturing operations. This issue is particularly pertinent in sectors with high cleaning demands, such as electrical utilities and manufacturing plants, where consistent performance is crucial.

The Solution: To mitigate brush wear, buyers should implement a maintenance schedule that includes regular inspections of the brushes. Using brushes suited to specific tasks, such as avoiding overly aggressive cleaning when not necessary, can prolong the lifespan of the brushes. Additionally, sourcing high-quality brushes from reputable suppliers who offer durability guarantees can provide peace of mind and reduce long-term costs. Educating staff on proper usage techniques—such as using the right amount of pressure and cleaning at optimal angles—can also significantly enhance brush longevity. Finally, consider bulk purchasing options to lower costs over time while ensuring that adequate supplies are on hand for uninterrupted operations.

Scenario 3: Ensuring Safety and Compliance in Usage

The Problem: B2B buyers often struggle with ensuring safety and compliance when using electrical wire brushes, especially in environments that require adherence to strict safety regulations. This is especially critical in industries such as construction and electrical maintenance, where improper use can lead to accidents or injuries. The challenge is compounded in regions with varying safety standards and practices, making it crucial for buyers to navigate these complexities effectively.

The Solution: To ensure safety and compliance, buyers should prioritize sourcing brushes that meet international safety standards and are designed with user safety in mind. This includes selecting brushes with ergonomic handles and ensuring they are compatible with protective equipment such as gloves and goggles. Training employees on safe handling practices is essential; this can include workshops on the correct techniques for using wire brushes to minimize risks. Additionally, staying updated on local and international safety regulations can help organizations avoid legal issues and promote a culture of safety. Regular audits of equipment and practices can further enhance compliance and safety awareness within the organization.

Strategic Material Selection Guide for electrical wire brush

What Are the Key Materials Used in Electrical Wire Brushes?

When selecting materials for electrical wire brushes, it is essential to consider their properties, performance, and suitability for specific applications. The following analysis covers four common materials used in the manufacturing of electrical wire brushes: stainless steel, carbon steel, brass, and nylon. Each material has distinct characteristics that can impact performance, durability, and cost.

How Does Stainless Steel Perform in Electrical Wire Brushes?

Stainless steel is a popular choice for electrical wire brushes due to its excellent corrosion resistance and durability. It can withstand high temperatures and is less prone to rusting compared to other metals. This makes it suitable for applications in humid or corrosive environments, such as marine or industrial settings.

Illustrative image related to electrical wire brush

Pros: Stainless steel brushes are highly durable and maintain their structural integrity over time. They are ideal for cleaning applications where rust or corrosion could compromise performance.

Cons: The primary drawback is the higher cost compared to carbon steel. Manufacturing stainless steel brushes can also be more complex, which may affect lead times.

Impact on Application: Stainless steel brushes are compatible with a wide range of cleaning media, including solvents and abrasives, making them versatile for various industries.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial, particularly for buyers in Europe and the Middle East. Buyers should ensure that the stainless steel used meets the required specifications for their applications.

What Are the Benefits of Carbon Steel in Electrical Wire Brushes?

Carbon steel is another common material used in electrical wire brushes, known for its strength and affordability. It is effective for heavy-duty cleaning tasks and can handle tough materials.

Pros: Carbon steel brushes are generally less expensive than stainless steel, making them a cost-effective choice for bulk purchases. They offer good durability and are suitable for applications requiring aggressive scrubbing.

Cons: The primary limitation is their susceptibility to rust and corrosion, especially in wet environments. This can lead to a shorter lifespan compared to stainless steel brushes.

Impact on Application: Carbon steel brushes are best used in dry conditions or with protective coatings to extend their life. They are often used in automotive and construction applications.

Considerations for International Buyers: Buyers should be aware of the need for proper storage and maintenance to prevent rusting, particularly in humid climates like those found in Africa and South America.

Illustrative image related to electrical wire brush

How Does Brass Compare in Electrical Wire Brushes?

Brass wire brushes are less common but serve specific applications where gentleness is required. They are softer than steel brushes and are often used for cleaning delicate surfaces.

Pros: Brass brushes are non-sparking, making them suitable for use in explosive environments. They are also effective for cleaning without scratching sensitive surfaces.

Cons: The main disadvantage is their reduced durability compared to steel brushes. They may wear out faster in heavy-duty applications.

Illustrative image related to electrical wire brush

Impact on Application: Brass brushes are ideal for cleaning electrical contacts and delicate components, where avoiding damage is critical.

Considerations for International Buyers: Compliance with safety standards is vital, especially in industries where flammability is a concern. Buyers should ensure that brass brushes meet relevant regulations.

What Role Does Nylon Play in Electrical Wire Brushes?

Nylon brushes are synthetic and offer a unique combination of flexibility and durability. They are often used for cleaning applications that require gentleness, such as on painted or coated surfaces.

Pros: Nylon brushes are resistant to chemicals and do not rust, making them suitable for various cleaning agents. They are also less abrasive than metal brushes, reducing the risk of damage to surfaces.

Cons: The primary limitation is that nylon brushes may not be as effective for heavy-duty scrubbing tasks compared to metal options.

Impact on Application: Nylon brushes are commonly used in the electronics and automotive industries for cleaning delicate components and surfaces.

Considerations for International Buyers: Buyers should consider the chemical compatibility of nylon brushes with their specific cleaning agents, particularly in diverse markets like Africa and South America.

Summary Table of Material Selection for Electrical Wire Brushes

| Material | Typical Use Case for Electrical Wire Brush | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty industrial cleaning | Excellent corrosion resistance | Higher cost | High |

| Carbon Steel | Automotive and construction cleaning | Cost-effective for bulk purchases | Susceptible to rust | Medium |

| Brass | Cleaning delicate surfaces | Non-sparking and gentle | Reduced durability | Medium |

| Nylon | Electronics and automotive applications | Chemical resistance and flexibility | Less effective for heavy scrubbing | Low |

This strategic material selection guide provides valuable insights for B2B buyers, enabling informed decisions tailored to specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical wire brush

What Are the Key Stages in the Manufacturing Process of Electrical Wire Brushes?

The manufacturing process of electrical wire brushes involves several critical stages, each designed to ensure that the final product meets the rigorous demands of various applications. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in manufacturing electrical wire brushes is selecting the appropriate materials. Commonly used materials include carbon steel, stainless steel, and brass, each offering unique benefits in terms of durability and corrosion resistance.

Once the materials are selected, they undergo preparation processes such as cutting to length and surface treatment. For steel wires, processes like annealing may be employed to enhance flexibility and durability. In some cases, wires may also be coated with protective materials to prevent rust and improve lifespan.

How Are Electrical Wire Brushes Formed?

Forming is the next stage, where the prepared materials are shaped into their final form. Techniques such as wire drawing are used to create wire of specific diameters suitable for brush bristles. This is often followed by the twisting or crimping of wires to create bristle tufts, which are essential for the brush’s cleaning effectiveness.

Once the bristles are formed, they are attached to the brush body, which can be made from materials like plastic or wood. This assembly can be performed through methods such as crimping or inserting bristles into pre-drilled holes, ensuring a secure fit.

What Finishing Processes Enhance the Quality of Electrical Wire Brushes?

The finishing stage involves several processes designed to enhance the product’s performance and appearance. Common finishing techniques include polishing, coating, and packaging. Polishing helps to remove any burrs or rough edges, ensuring a smooth surface that is safe for handling.

Coatings may involve electroplating or powder coating, which can provide additional corrosion resistance and improve the brush’s longevity. Finally, the brushes are packaged according to international standards, ensuring they are protected during transport and ready for market.

What Quality Assurance Measures Are Essential in the Manufacturing of Electrical Wire Brushes?

Quality assurance (QA) is critical in the manufacturing process to ensure that electrical wire brushes meet both international and industry-specific standards. This involves multiple checkpoints throughout the production process.

Which International Standards Are Relevant for Electrical Wire Brush Manufacturing?

One of the most recognized international standards is ISO 9001, which outlines criteria for a quality management system. Compliance with this standard demonstrates a commitment to quality and consistency, making it a key requirement for B2B buyers.

Illustrative image related to electrical wire brush

In addition to ISO standards, specific industry certifications such as CE marking (for products sold in the European Economic Area) and API standards (for applications in the oil and gas industry) may also apply. These certifications ensure that products meet safety and performance criteria relevant to their intended use.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) in the manufacturing process typically includes several key checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to ensure they meet specified standards. Any non-conforming materials are rejected or returned to the supplier.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor the production process. This includes verifying dimensions, inspecting bristle attachment, and ensuring that finishing processes are applied correctly.

-

Final Quality Control (FQC): After assembly and finishing, a final inspection is performed. This includes testing the brushes for functionality, durability, and compliance with relevant standards. Any defective products are discarded or reworked.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. This can be achieved through several methods:

-

Supplier Audits: Conducting regular audits of potential suppliers allows buyers to assess their manufacturing processes and quality control measures firsthand. During an audit, buyers can evaluate compliance with international standards and industry-specific requirements.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, including results from IQC, IPQC, and FQC stages. This transparency can build trust and confidence in the supplier’s capabilities.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s manufacturing processes and quality control. This is particularly valuable for international transactions, where buyers may not have direct access to the supplier’s facilities.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is critical. Different regions may have varying standards and expectations regarding product quality. For instance, buyers from Europe may place a higher emphasis on CE compliance, while those in Africa and South America may focus on cost-effectiveness and local certifications.

Additionally, cultural differences can impact how quality control is perceived. In some regions, there may be a greater emphasis on personal relationships, while in others, formal documentation and compliance may take precedence. Buyers should be aware of these differences and tailor their approach accordingly.

Illustrative image related to electrical wire brush

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for electrical wire brushes is vital for B2B buyers. By focusing on material selection, forming techniques, and quality control checkpoints, buyers can ensure they partner with reputable suppliers that meet their standards for quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electrical wire brush’

Introduction

This guide serves as a comprehensive checklist for B2B buyers aiming to procure electrical wire brushes. Whether you are sourcing for maintenance, manufacturing, or cleaning applications, following this structured approach will ensure you make informed decisions, select quality products, and partner with reliable suppliers.

Step 1: Define Your Technical Specifications

Before initiating your procurement process, it’s essential to outline your technical requirements for the electrical wire brush. Consider the brush type (e.g., twisted wire, cup brushes), bristle material (stainless steel, brass, nylon), and the intended application (cleaning, texturing, or stripping).

- Application Suitability: Different applications may require varying stiffness and durability of brushes.

- Compatibility: Ensure the brush fits with your existing tools or machinery.

Step 2: Research Market Trends and Pricing

Understanding market trends is crucial to making competitive purchasing decisions. Research current pricing ranges across different suppliers and regions, particularly focusing on emerging markets in Africa and South America.

- Price Comparisons: Use platforms like Home Depot or specialized B2B marketplaces to benchmark prices.

- Trends in Demand: Identify if there are seasonal fluctuations or increasing demand for specific types of brushes.

Step 3: Evaluate Potential Suppliers

A thorough evaluation of potential suppliers is vital to ensure reliability and quality. Request detailed company profiles, product catalogs, and customer references.

- Certifications and Compliance: Verify if the suppliers meet international quality standards (ISO, CE certifications).

- Reputation Assessment: Look for reviews and testimonials from other buyers in similar industries or regions.

Step 4: Request Samples for Testing

Before making a bulk purchase, requesting samples allows you to assess the quality and performance of the electrical wire brushes firsthand.

- Performance Testing: Check for durability, effectiveness in cleaning, and ease of use.

- Material Verification: Ensure that the materials used meet your specifications, especially if you require specific bristle types.

Step 5: Negotiate Terms and Conditions

Once you identify a suitable supplier, engage in negotiations to establish favorable terms and conditions. This includes pricing, delivery timelines, payment terms, and warranty conditions.

- Volume Discounts: Inquire about discounts for bulk purchases, which can significantly reduce overall costs.

- After-Sales Support: Ensure that the supplier offers support for any issues that may arise post-purchase.

Step 6: Finalize Your Order and Monitor Delivery

After agreeing on terms, finalize your order while keeping a close eye on the delivery process.

- Order Confirmation: Ensure all specifications and quantities are confirmed in writing.

- Tracking: Monitor shipment progress to mitigate any potential delays and ensure timely receipt of goods.

Step 7: Evaluate Post-Purchase Performance

After receiving the electrical wire brushes, assess their performance in real-world applications.

- Feedback Loop: Gather feedback from your team on the brushes’ effectiveness and durability.

- Supplier Review: Based on your experience, consider providing feedback to the supplier, which can help improve future transactions.

By following this structured checklist, B2B buyers can streamline the procurement process for electrical wire brushes, ensuring they make informed and strategic purchasing decisions.

Comprehensive Cost and Pricing Analysis for electrical wire brush Sourcing

What Are the Key Cost Components in Electrical Wire Brush Production?

When sourcing electrical wire brushes, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. Common materials for wire brushes include stainless steel, carbon steel, and brass. Stainless steel brushes tend to be more expensive due to their corrosion resistance and durability, while carbon steel options are often more budget-friendly but may wear out faster.

-

Labor: Labor costs can vary widely depending on the region of production. In regions with lower labor costs, such as parts of Asia and Eastern Europe, manufacturers can offer more competitive pricing. Conversely, higher labor costs in Western Europe or North America can drive prices up.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and administrative costs. Efficient manufacturing processes can help minimize overhead, allowing suppliers to offer better prices.

-

Tooling: The setup and maintenance of specialized tools for manufacturing wire brushes can be a significant investment. Custom brushes may require unique tooling, which can increase initial costs but may be offset by lower per-unit costs at higher volumes.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection processes is vital. The associated costs can vary based on certification requirements, such as ISO standards, which are particularly valued in international markets.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. These costs can fluctuate based on shipping methods, distances, and customs duties.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding the average margins in the industry can provide leverage during negotiations.

How Do Price Influencers Affect Electrical Wire Brush Sourcing?

Several factors can influence the pricing of electrical wire brushes:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to discounts. Suppliers may offer lower prices per unit for larger orders, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Customized brushes that meet specific requirements (e.g., size, bristle type) generally incur higher costs due to the additional manufacturing processes involved.

-

Quality and Certifications: High-quality brushes with certifications (such as ISO or ANSI) may command a premium price. Buyers should weigh the benefits of these certifications against their budget and application needs.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers may charge more due to their proven track record and customer service capabilities.

-

Incoterms: The chosen Incoterms can significantly influence total costs. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, Freight) dictate who bears shipping costs, insurance, and risks during transit.

What Are the Best Buyer Tips for Cost-Efficiency?

To achieve cost-efficiency in sourcing electrical wire brushes, consider the following strategies:

-

Negotiate Effectively: Always initiate negotiations with suppliers. Having a clear understanding of the market price can empower buyers to negotiate better terms and prices.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the total cost of ownership, including maintenance, lifespan, and performance. A higher-quality brush may have a higher upfront cost but lead to savings over time due to reduced replacement frequency.

-

Understand Pricing Nuances for International Transactions: For buyers in regions like Africa, South America, the Middle East, and Europe, be aware of additional costs such as tariffs, taxes, and currency fluctuations. These factors can significantly alter the final cost.

-

Leverage Local Suppliers: Whenever possible, consider sourcing from local suppliers to minimize shipping costs and lead times, and to support regional economies.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific order requirements. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing electrical wire brush With Other Solutions

In today’s industrial landscape, businesses often seek effective and efficient tools for cleaning and maintenance tasks. The electrical wire brush is a popular choice for its ability to clean surfaces, remove rust, and prepare metal for further treatment. However, it is essential to consider alternative solutions that may offer comparable or even superior performance for specific applications. This analysis will compare the electrical wire brush with two viable alternatives: pneumatic wire brushes and manual wire brushes.

| Comparison Aspect | Electrical Wire Brush | Pneumatic Wire Brush | Manual Wire Brush |

|---|---|---|---|

| Performance | High efficiency; effective for heavy-duty tasks | Very high efficiency; suitable for large surfaces | Moderate efficiency; best for small, detailed tasks |

| Cost | Moderate ($55 – $229) | Higher ($150 – $500) | Low ($3 – $50) |

| Ease of Implementation | Requires minimal setup | Requires air compressor and setup | Simple to use; no setup needed |

| Maintenance | Low; occasional brush replacement | Moderate; regular maintenance of air tools needed | Low; easy to clean and replace bristles |

| Best Use Case | Heavy-duty industrial cleaning | Large-scale industrial applications | Detail work and light cleaning |

What are the Benefits and Drawbacks of Using a Pneumatic Wire Brush?

Pneumatic wire brushes are powered by compressed air, offering exceptional speed and efficiency, especially for large surfaces and heavy-duty applications. Their high performance makes them ideal for industrial settings where time is critical. However, they require an air compressor and may involve a higher initial investment. Additionally, the need for regular maintenance of pneumatic tools can be a drawback for some businesses. Overall, pneumatic wire brushes are best suited for environments where high efficiency and power are paramount.

How Does a Manual Wire Brush Compare to Electrical Options?

Manual wire brushes are simple, cost-effective tools that require no power source, making them easy to use in various settings. They are particularly useful for detailed work and light cleaning tasks, such as preparing surfaces for painting or finishing. The low cost of manual wire brushes makes them accessible to businesses of all sizes. However, they lack the efficiency and speed of electrical or pneumatic options, which can be a limitation in larger operations. Manual brushes are best for smaller projects or as a supplementary tool in combination with powered options.

How Should B2B Buyers Choose the Right Cleaning Solution?

When selecting the appropriate cleaning tool, B2B buyers should consider the specific requirements of their operations. Factors such as the scale of the cleaning task, budget constraints, and available resources for maintenance should guide their decision. For heavy-duty industrial applications, an electrical or pneumatic wire brush may be necessary to ensure efficiency and effectiveness. Conversely, for smaller, more detailed tasks, a manual wire brush might be a more practical choice. Ultimately, understanding the unique needs of the business will lead to a more informed and strategic purchase decision.

Essential Technical Properties and Trade Terminology for electrical wire brush

What Are the Key Technical Properties of Electrical Wire Brushes?

When selecting electrical wire brushes, understanding their technical specifications is crucial for ensuring optimal performance and longevity. Here are some essential properties to consider:

-

Material Composition

Electrical wire brushes are typically made from materials such as stainless steel, carbon steel, brass, or nylon. Stainless steel offers corrosion resistance and durability, making it suitable for harsh environments, while carbon steel is known for its strength and effectiveness in heavy-duty applications. Brass is often used for softer surfaces to prevent scratching, and nylon brushes are ideal for cleaning delicate surfaces without causing damage. -

Bristle Stiffness

The stiffness of the bristles significantly affects the brush’s cleaning ability. Brushes with hard or stiff bristles provide aggressive scrubbing power, making them suitable for tough grime and heavy debris. Conversely, medium or soft bristles are better for sensitive applications where surface protection is paramount. Understanding bristle stiffness helps buyers choose the right brush for their specific cleaning tasks. -

Brush Size and Shape

The dimensions and configuration of a wire brush are critical to its effectiveness. Brushes come in various sizes, ranging from handheld options to larger industrial brushes. The shape—such as flat, round, or cup—determines the brush’s application area and effectiveness in reaching tight spaces. For instance, a cup brush is ideal for cleaning cylindrical surfaces, while a flat brush is more suited for broader areas. -

Grit Rating

Grit rating refers to the coarseness of the brush, typically measured by the size of the abrasive particles. A higher grit number indicates a finer brush, while a lower number denotes a coarser brush. This specification is vital for buyers, as it dictates the brush’s intended use; coarser brushes are used for heavy material removal, while finer brushes are suited for finishing work or polishing. -

Operating Speed and RPM Rating

Each electrical wire brush has a recommended operating speed, usually expressed in revolutions per minute (RPM). Exceeding this rating can lead to premature wear or damage to both the brush and the equipment. Buyers should ensure that the chosen brush matches their tool’s specifications to maintain safety and efficiency.

What Are Common Trade Terms Used in the Electrical Wire Brush Industry?

Familiarity with industry jargon helps streamline communication and negotiations among B2B buyers and suppliers. Here are some critical terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electrical wire brushes, buyers may seek OEM products for consistency and quality assurance, ensuring that they fit seamlessly with existing equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory effectively and to negotiate better pricing. This term is particularly significant for B2B transactions where bulk purchasing can lead to cost savings. -

RFQ (Request for Quotation)

An RFQ is a formal request by a buyer to suppliers for price quotes on specific products or services. This document typically includes detailed specifications and quantities, allowing suppliers to provide accurate pricing. For B2B buyers, issuing an RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, which is vital for international transactions. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is crucial for B2B buyers to plan their inventory and ensure timely project execution. Longer lead times may require advanced planning, while shorter lead times can enhance responsiveness to market demands. -

Certification Standards

Many electrical wire brushes are subject to certification standards that ensure they meet safety and quality requirements. Familiarity with relevant certifications (e.g., ISO, ANSI) is important for buyers to ensure compliance with industry regulations and to guarantee product reliability.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring electrical wire brushes, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the electrical wire brush Sector

What Are the Current Market Dynamics Affecting the Electrical Wire Brush Sector?

The global market for electrical wire brushes is experiencing significant growth, driven by the increasing demand for efficient cleaning solutions in various industries such as manufacturing, automotive, and electrical maintenance. In regions like Africa, South America, the Middle East, and Europe, there is a noticeable trend towards automation and the adoption of advanced cleaning technologies. This shift is largely influenced by the need for improved productivity and reduced labor costs. Consequently, B2B buyers are increasingly looking for suppliers that offer innovative products, such as cordless and brushless wire brushes, which enhance operational efficiency and reduce downtime.

Emerging technologies are reshaping sourcing trends, particularly in the context of Industry 4.0. Manufacturers are integrating IoT (Internet of Things) capabilities into their products, allowing for real-time monitoring and predictive maintenance. Buyers from international markets are now prioritizing suppliers who can provide these technologically advanced solutions, along with the traditional wire brushes. Furthermore, the rise of e-commerce platforms is facilitating easier access to global suppliers, enabling B2B buyers to compare products, prices, and customer reviews more efficiently.

Illustrative image related to electrical wire brush

How Are Sustainability and Ethical Sourcing Addressed in the Electrical Wire Brush Industry?

Sustainability is becoming a critical factor in the procurement process for electrical wire brushes. Buyers are increasingly aware of the environmental impact associated with the manufacturing and disposal of these products. Consequently, there is a growing demand for suppliers who adhere to sustainable practices, such as using recycled materials and minimizing waste during production. Additionally, ‘green’ certifications are becoming essential in the purchasing decision, as they provide assurance of a product’s environmental credentials.

Ethical sourcing is equally vital, as businesses strive to maintain their corporate social responsibility (CSR) commitments. This includes ensuring that suppliers follow fair labor practices and operate within a transparent supply chain. International buyers, particularly from Europe and North America, often require documentation and audits to verify compliance with these standards. As a result, suppliers who can demonstrate a commitment to sustainability and ethical sourcing are likely to gain a competitive advantage in the marketplace.

What Is the Historical Context of the Electrical Wire Brush Industry?

The electrical wire brush industry has evolved significantly over the past few decades. Initially, wire brushes were primarily used in manual cleaning applications, with limited innovation in design and materials. However, as industrial demands grew, manufacturers began to develop specialized brushes tailored for specific applications, such as cleaning electrical components and removing rust or corrosion from metal surfaces.

The introduction of advanced materials, such as stainless steel and nylon bristles, has enhanced the performance and durability of wire brushes. Moreover, technological advancements have led to the development of powered wire brushes that offer greater efficiency and consistency in cleaning tasks. This evolution reflects a broader trend in the manufacturing sector towards automation and precision, aligning with the needs of modern B2B buyers who prioritize efficiency and quality in their sourcing decisions.

In summary, the electrical wire brush sector is poised for continued growth, driven by technological innovation, sustainability, and evolving buyer expectations. International B2B buyers must stay informed of these trends to make strategic sourcing decisions that align with their operational goals and ethical commitments.

Illustrative image related to electrical wire brush

Frequently Asked Questions (FAQs) for B2B Buyers of electrical wire brush

-

How do I choose the right electrical wire brush for my application?

Choosing the right electrical wire brush depends on several factors including the type of material you need to clean, the size of the brush, and the specific application (e.g., surface preparation, rust removal, or polishing). For heavy-duty tasks, consider twisted steel brushes, while stainless steel brushes are ideal for softer materials like wood or aluminum. Always evaluate the bristle stiffness and size to ensure optimal cleaning without damaging the surface. Consulting with suppliers for recommendations based on your specific needs can also help streamline the selection process. -

What are the most common types of wire brushes used in electrical applications?

In electrical applications, the most common types of wire brushes include twisted steel wire brushes for aggressive cleaning, stainless steel wire brushes for softer materials, and nylon brushes for delicate surfaces. Each type serves different purposes; for instance, twisted brushes are effective for heavy rust and paint removal, while nylon brushes are suitable for cleaning sensitive components without scratching. Understanding the material compatibility and intended use will guide you in selecting the most effective brush for your project. -

What is the minimum order quantity (MOQ) for electrical wire brushes?

Minimum order quantities (MOQs) for electrical wire brushes vary by supplier and product type. Typically, MOQs can range from 50 to several hundred units, depending on the brush specifications and supplier policies. It’s advisable to discuss your requirements with potential suppliers to negotiate MOQs that align with your purchasing capacity, especially when sourcing for large projects or multiple locations. Some suppliers may offer flexibility for first-time buyers or bulk orders. -

How can I vet suppliers for electrical wire brushes?

To effectively vet suppliers for electrical wire brushes, consider their industry experience, product quality, and customer reviews. Request samples to assess the quality of their brushes firsthand. Additionally, check for certifications that indicate adherence to international standards, such as ISO or ASTM. Engaging in direct communication can also provide insights into their responsiveness and customer service. Finally, consider visiting their facilities if possible, to gain confidence in their manufacturing processes. -

What payment terms should I expect when sourcing wire brushes internationally?

Payment terms for international orders of wire brushes typically include options such as upfront payment, net 30/60 days, or letters of credit. Many suppliers may require a deposit (often 30-50%) upon order confirmation, with the balance due before shipping. It’s crucial to clarify payment methods accepted (e.g., bank transfer, PayPal) and ensure that the terms align with your financial processes. Establishing clear agreements upfront helps avoid disputes and ensures a smoother transaction. -

What quality assurance measures should I look for in wire brushes?

Quality assurance (QA) measures in the manufacturing of wire brushes include inspections at various production stages, adherence to industry standards, and certification from recognized bodies. Ask suppliers about their QA processes, including testing for bristle strength, durability, and safety. Look for products that come with warranties or guarantees, as these reflect the supplier’s confidence in their quality. Regular audits and customer feedback can also be indicators of a supplier’s commitment to maintaining high standards. -

What logistics considerations should I keep in mind for importing wire brushes?

When importing wire brushes, logistics considerations include shipping methods, customs regulations, and lead times. Determine whether air freight or sea freight is more cost-effective for your needs. Familiarize yourself with customs duties and taxes applicable to your order, as these can significantly impact overall costs. Additionally, communicate with your supplier about packaging and labeling requirements to ensure compliance and smooth customs clearance. Establishing a reliable logistics partner can help streamline the entire import process. -

Can I customize the wire brushes to meet specific needs?

Yes, many suppliers offer customization options for wire brushes, including variations in bristle material, size, shape, and handle design. Customization allows you to tailor the brushes to specific applications, enhancing their effectiveness. When discussing customization, be clear about your requirements and any specific performance characteristics you need. Be aware that custom orders may involve higher MOQs and longer lead times, so it’s best to plan accordingly.

Top 4 Electrical Wire Brush Manufacturers & Suppliers List

1. Restorer – Wire Brush Machine

Domain: restorertools.com

Registered: 2020 (5 years)

Introduction: Product Name: Restorer Wire Brush Machine

1. RESTORER HOT NEW SELLER – 20V WR520DC – Price: $229.00

2. RESTORER STRIP | SAND WR351K1 – Price: $129.00

3. RESTORER & Systainer STRIP | SAND WR351K1-SYS-V – Price: $228.00

4. Twisted Steel Wire Brush EXTREME TEXTURING WRTS01 – Price: $59.00

5. Wire Brush, Stainless Steel CLEAN/TEXTURE HARDWOOD WRSS01 – Price: $55.00

6. 80 Grit Nylon Brush CLEAN/TEXTURE…

2. Jharlen – Hastings Conductor Cleaning Brush

Domain: jharlen.com

Introduction: Hastings Conductor Cleaning Brush 10-178 – $54.90

Speedi-Spreader Midspan Installing Tool SS75G – $27.90

MADI Mini FlatRound™ Wire Brush MFRWB-1 – $31.90

MADI Replacement 1000MCM Brush For BrushBlade™ WB-1 – $3.90

MADI Safety BrushBlade™ Knife BB-2S – $34.90

MADI Hand J-Wire Brush HJWB1 – $29.90

Hastings Easy-Grip Curved Conductor Brush 10-175 – $38.90

MADI Replacement 1590MCM Brush For FlatRound™…

3. Weiler – Wire Wheels/Brushes for Rotary Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: User is looking for wire wheels/brushes for rotary tools that are safe and do not shed bristles. They prefer small sizes (no larger than 1 inch) and are concerned about quality and safety over low cost. Recommendations include Weiler brushes, which are noted for shedding less and being better than cheaper alternatives. The user also mentions using nylon brush wheels as a potential option.

4. Pelican Parts – Tiny Wire Brushes for Electrical Contacts

Domain: forums.pelicanparts.com

Registered: 1999 (26 years)

Introduction: Tiny wire brushes for cleaning electrical contacts, specifically designed for small female pin contacts that accept pins about 1mm in diameter. Users suggest alternatives like needle files and CAIG’s electrical contact cleaner, as well as Deoxit D5 for cleaning and maintaining connections.

Strategic Sourcing Conclusion and Outlook for electrical wire brush

As the demand for high-quality electrical wire brushes continues to grow across various industries, strategic sourcing emerges as a crucial factor for success. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with reliable suppliers who can provide durable and effective wire brushes tailored to specific needs. Understanding the diverse range of products—from twisted steel to nylon and stainless steel brushes—enables businesses to select the right tools for their applications, ensuring optimal performance and longevity.

Moreover, leveraging data-driven insights into market trends and supplier capabilities can streamline procurement processes, reduce costs, and enhance product availability. By fostering strong relationships with manufacturers and distributors, B2B buyers can secure better pricing and access to innovative solutions that meet evolving market demands.

Looking ahead, international buyers are encouraged to stay proactive in sourcing strategies. Embrace the opportunities presented by the expanding global market and invest in quality tools that enhance operational efficiency. Now is the time to engage with trusted suppliers and elevate your sourcing approach to ensure your business remains competitive in the fast-paced landscape of electrical wire brushes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to electrical wire brush

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.