Electrical Discharge Machining Manufacturers: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for electrical discharge machining manufacturers

In today’s competitive manufacturing landscape, sourcing reliable electrical discharge machining (EDM) manufacturers can be a daunting challenge for international B2B buyers. The precision and versatility of EDM processes are essential for producing intricate components across various industries, yet the complexities of supplier selection, cost considerations, and varying regional standards can create significant barriers. This comprehensive guide aims to navigate these challenges by providing a detailed overview of the EDM market, including types of machining services, applications across sectors such as aerospace, automotive, and medical devices, and critical insights into supplier vetting processes.

By exploring key factors such as technological capabilities, certifications, and customer service excellence, buyers from Africa, South America, the Middle East, and Europe—including markets like Germany and Nigeria—will be equipped to make informed purchasing decisions. Additionally, this guide addresses cost implications, ensuring that buyers can identify manufacturers that not only meet their precision requirements but also align with their budgetary constraints.

Ultimately, this resource empowers B2B buyers to confidently engage with EDM manufacturers, facilitating partnerships that enhance product quality and drive operational efficiency. With the right knowledge, organizations can leverage EDM technology to gain a competitive advantage in their respective markets.

Understanding electrical discharge machining manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

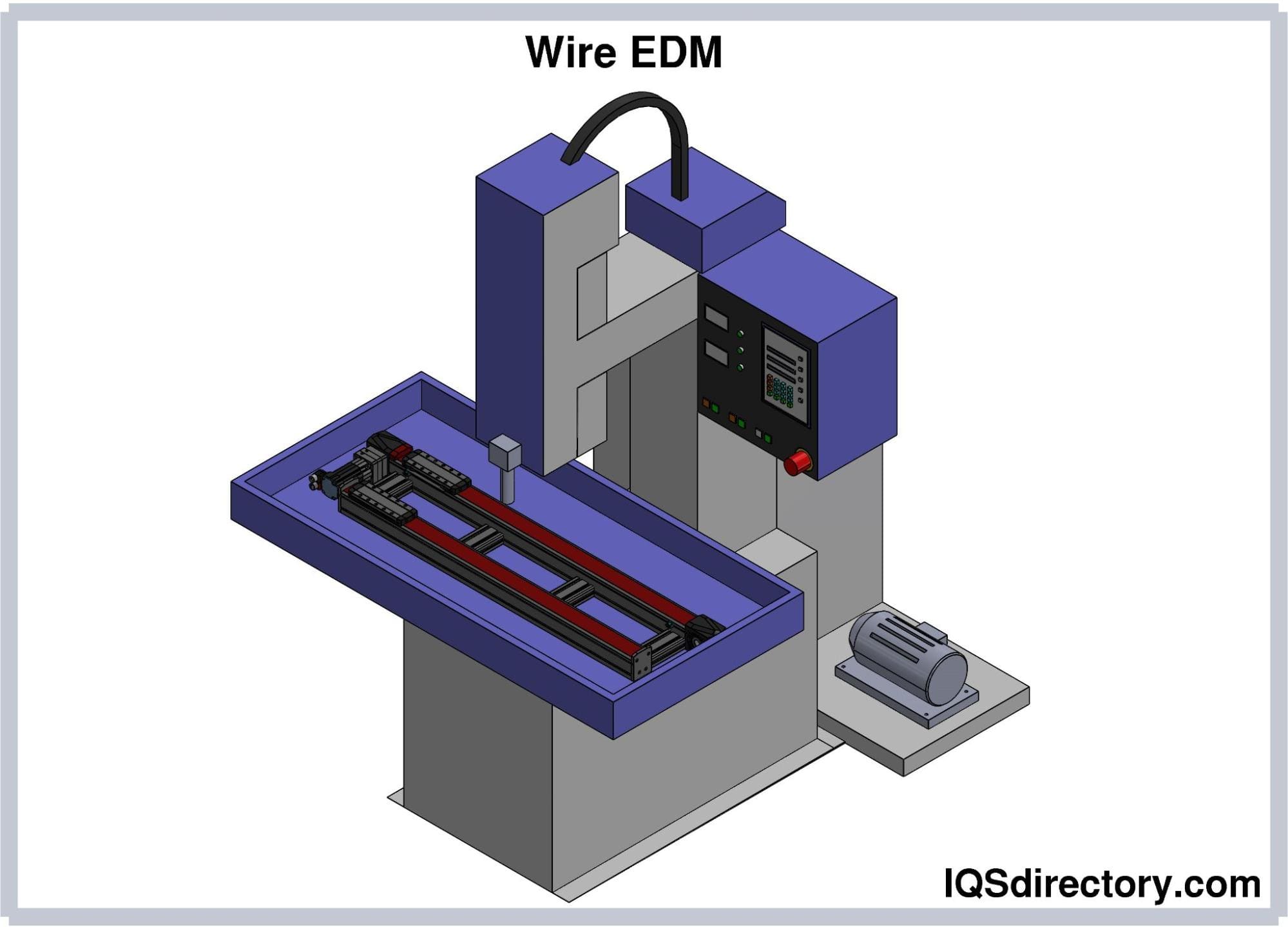

| Wire EDM | Utilizes a thin wire electrode to cut materials. | Aerospace, automotive, and medical device manufacturing. | Pros: High precision, complex shapes. Cons: Slower than other methods for large volumes. |

| Sinker EDM | Employs a shaped electrode to create cavities. | Tool and die making, aerospace components, and molds. | Pros: Excellent for intricate designs. Cons: Limited to specific geometries. |

| Hole Drilling EDM | Specializes in creating small holes with high precision. | Electronics, automotive, and medical devices. | Pros: High accuracy for micro-components. Cons: Limited to small hole applications. |

| Fast Hole EDM | Focuses on rapid drilling of larger holes. | Aerospace and defense industries for component production. | Pros: Quick turnaround for larger holes. Cons: May sacrifice some precision. |

| Micro EDM | Targets ultra-fine machining for micro-components. | Medical devices, electronics, and precision instruments. | Pros: Exceptional detail and precision. Cons: Higher costs and complexity in setup. |

What Are the Key Characteristics of Wire EDM Manufacturers?

Wire EDM (Electrical Discharge Machining) is characterized by its use of a thin, electrically charged wire as an electrode to cut through conductive materials. This method is particularly suitable for producing complex geometries and intricate designs, making it highly valuable in industries such as aerospace and automotive, where precision is critical. B2B buyers should consider the manufacturer’s capability to handle specific materials and thicknesses, as well as their experience in the relevant industry sectors.

How Do Sinker EDM Manufacturers Operate?

Sinker EDM, also known as cavity or plunge EDM, utilizes a shaped electrode to create detailed cavities in the workpiece. This method is ideal for tool and die making, as well as for crafting molds used in various manufacturing processes. Buyers should assess the manufacturer’s technology level, including CNC capabilities, to ensure they can produce the required intricate designs. The ability to work with a range of materials is also a key consideration.

What Makes Hole Drilling EDM Manufacturers Unique?

Hole Drilling EDM is specialized for creating precise holes, often at micro scales. This variation is essential for industries such as electronics and medical devices, where accuracy in small components is paramount. When evaluating suppliers, buyers should focus on their expertise in micro-hole applications and the technology they employ to ensure high precision and quality. Additionally, understanding the turnaround times for production can be crucial for project timelines.

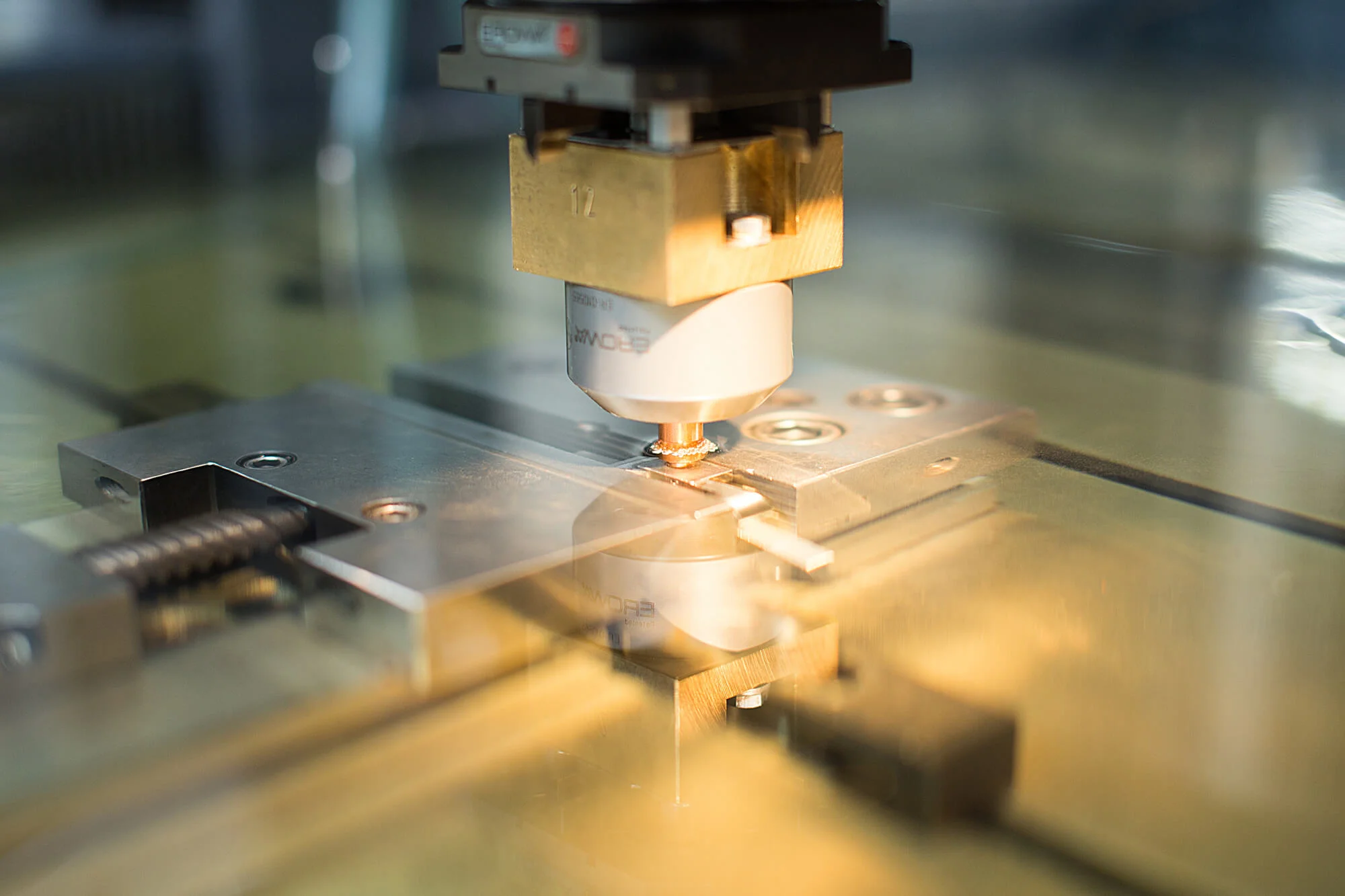

Illustrative image related to electrical discharge machining manufacturers

What Are the Advantages of Fast Hole EDM Manufacturers?

Fast Hole EDM is designed for quick drilling of larger holes, making it suitable for applications in aerospace and defense sectors where efficiency is vital. This method can significantly reduce lead times for component production. Buyers should consider the balance between speed and precision, as some manufacturers may prioritize rapid output over the finest tolerances. Evaluating the supplier’s past performance and customer feedback can provide insights into their reliability.

Why Choose Micro EDM Manufacturers for Precision Needs?

Micro EDM focuses on machining ultra-fine components, making it indispensable for high-tech industries such as medical devices and electronics. The precision offered by Micro EDM allows for the creation of intricate parts that conventional methods struggle to achieve. Buyers must weigh the higher costs associated with this technology against the benefits of superior detail and accuracy. Understanding the manufacturer’s capabilities in terms of tooling and material handling is essential for ensuring project success.

Key Industrial Applications of electrical discharge machining manufacturers

| Industry/Sector | Specific Application of electrical discharge machining manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of turbine blades and engine components | Ensures extreme precision and reliability in critical applications | Look for ISO certifications and experience with aerospace standards. |

| Automotive | Production of high-precision dies for transmission parts | Reduces manufacturing time and improves part quality | Assess the manufacturer’s capabilities in producing complex geometries. |

| Medical Device Manufacturing | Creation of surgical instruments and implants | Guarantees biocompatibility and precise fit for patient safety | Verify compliance with medical industry regulations and quality assurance processes. |

| Electronics and Semiconductor | Fabrication of microelectromechanical systems (MEMS) | Enables miniaturization and high performance in electronic devices | Seek manufacturers with expertise in micro-machining and advanced technologies. |

| Defense and Military Applications | Production of components for weapons systems and military vehicles | Ensures durability and functionality under extreme conditions | Consider suppliers with a proven track record in defense contracts and precision machining. |

How is Electrical Discharge Machining Used in Aerospace Manufacturing?

In the aerospace sector, electrical discharge machining (EDM) is crucial for producing turbine blades and engine components that require extreme precision and tight tolerances. The non-contact nature of EDM allows for the effective machining of superalloys and hard metals, which are commonly used in aerospace applications. International B2B buyers, particularly from Europe and the Middle East, should prioritize manufacturers with ISO certifications and experience in meeting aerospace industry standards to ensure compliance and reliability in critical applications.

What Role Does EDM Play in Automotive Production?

In automotive manufacturing, EDM is employed to create high-precision dies and molds for complex transmission parts and other components. This process is vital for reducing manufacturing time while improving the quality and performance of automotive parts. Buyers from Africa and South America should evaluate manufacturers’ capabilities in producing intricate geometries and their flexibility to adapt to evolving automotive technologies, ensuring they meet stringent industry requirements.

Why is EDM Important in Medical Device Manufacturing?

EDM is extensively utilized in medical device manufacturing for the creation of surgical instruments and implants. The precision achieved through EDM ensures that these components are biocompatible and fit accurately, which is critical for patient safety and successful medical procedures. International buyers, especially from regions like Europe, should verify that manufacturers comply with medical industry regulations and have robust quality assurance processes in place to maintain high standards.

How Does EDM Benefit the Electronics and Semiconductor Sector?

In the electronics and semiconductor industry, EDM is essential for fabricating microelectromechanical systems (MEMS) and intricate connectors. This process enables the production of miniature components that are crucial for next-generation electronic devices. B2B buyers, particularly from Africa and South America, should seek manufacturers with expertise in micro-machining and advanced EDM technologies to ensure high performance and reliability in their electronic products.

What is the Significance of EDM in Defense Manufacturing?

Electrical discharge machining plays a vital role in producing components for weapons systems and military vehicles, where durability and functionality are paramount. The precision provided by EDM ensures that these critical components can withstand extreme conditions. Buyers from the Middle East and Europe should consider suppliers with a proven track record in defense contracts, as well as those who specialize in precision machining to meet the rigorous demands of military applications.

3 Common User Pain Points for ‘electrical discharge machining manufacturers’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision Tolerances for Complex Components

The Problem: B2B buyers, particularly in industries like aerospace and medical device manufacturing, often face challenges in sourcing EDM services that can meet stringent precision tolerances. These components are critical for ensuring the reliability and safety of end products. A buyer may find that many manufacturers lack the advanced technology or expertise to handle specific materials or complex geometries, leading to costly reworks or delays in production schedules. This can be especially problematic when tight deadlines are involved, and the stakes are high regarding product performance and regulatory compliance.

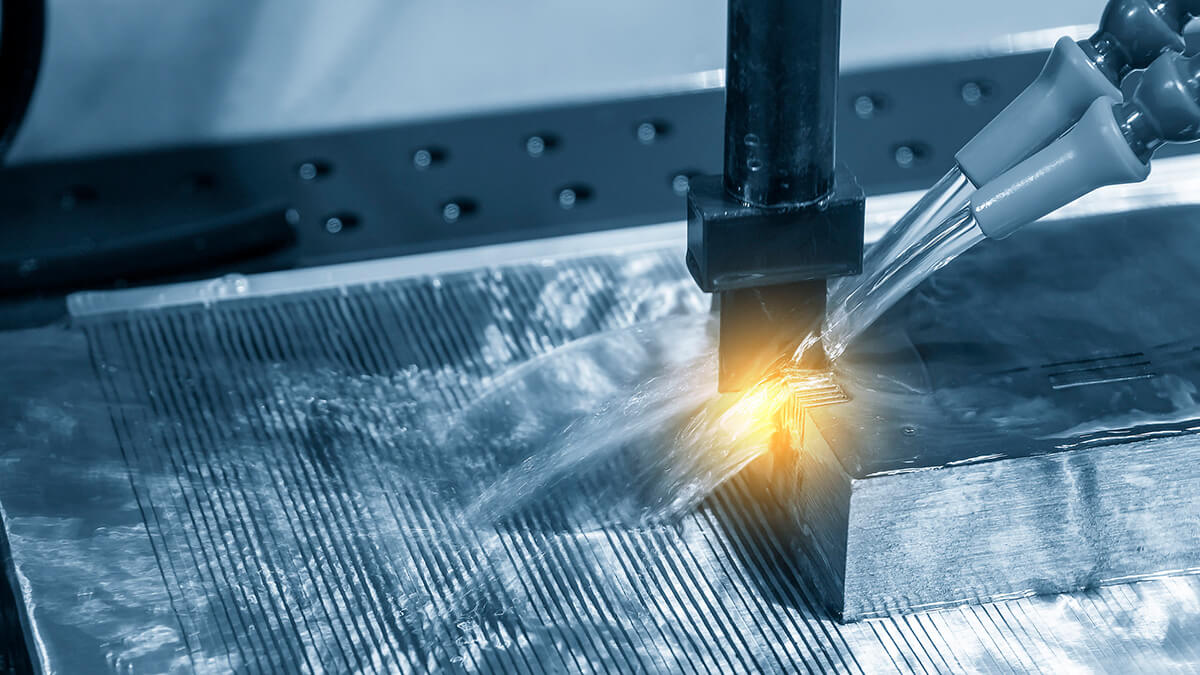

Illustrative image related to electrical discharge machining manufacturers

The Solution: To navigate this challenge, buyers should conduct thorough research into potential EDM manufacturers’ capabilities before making a selection. Look for manufacturers with ISO certifications, as these indicate adherence to international quality standards. Additionally, engage in discussions about past projects that required similar precision levels and request detailed case studies or references from the manufacturer. It is also beneficial to specify the exact tolerances and materials in the initial request for quotes, as this will help manufacturers assess their ability to meet your requirements accurately. Establishing a collaborative relationship with the chosen manufacturer can facilitate better understanding and execution of complex projects, ensuring that precision is maintained throughout the manufacturing process.

Scenario 2: High Production Costs Due to Inefficient EDM Processes

The Problem: Many B2B buyers discover that the cost of production can be significantly higher than anticipated due to inefficient EDM processes. This can stem from outdated machinery, poor workflow management, or inadequate planning, resulting in longer lead times and increased operational costs. For companies aiming to remain competitive in price-sensitive markets, these unplanned expenses can erode profit margins and hinder growth prospects.

The Solution: Buyers should prioritize manufacturers that utilize modern EDM technologies and have a reputation for operational efficiency. It’s advisable to request a detailed breakdown of production costs and inquire about their process optimization strategies. Consider asking manufacturers how they leverage automation, CNC technology, and real-time monitoring to enhance efficiency. Additionally, exploring partnerships with manufacturers who offer flexible production runs can help buyers scale operations without incurring unnecessary costs. Lastly, maintaining open lines of communication throughout the production process can help identify potential inefficiencies early, allowing for timely adjustments that can keep costs in check.

Illustrative image related to electrical discharge machining manufacturers

Scenario 3: Limited Access to Specialized EDM Expertise

The Problem: As industries evolve, the demand for specialized EDM expertise has grown, particularly in sectors like defense and electronics, where unique materials and intricate designs are common. B2B buyers may find themselves struggling to locate manufacturers that possess the necessary technical knowledge and experience in these specialized applications. This gap can lead to subpar manufacturing outcomes, increased risk of product failure, and challenges in meeting specific regulatory requirements.

The Solution: To overcome this limitation, buyers should actively seek out manufacturers with a proven track record in their specific industry applications. This can be achieved by participating in industry trade shows, networking events, and online forums dedicated to EDM technologies. Additionally, buyers can leverage platforms that showcase manufacturer capabilities, such as industry directories and review sites, to identify potential partners with relevant expertise. Engaging in initial consultations and asking targeted questions about the manufacturer’s experience with similar projects can also provide insights into their capabilities. Establishing a partnership with a manufacturer that understands the unique challenges of your industry will not only improve product quality but also foster innovation and adaptability in the long run.

Strategic Material Selection Guide for electrical discharge machining manufacturers

What are the Key Properties of Common Materials Used in Electrical Discharge Machining?

Electrical discharge machining (EDM) relies on specific materials that enhance the precision and efficiency of the machining process. Understanding the properties and applications of these materials is crucial for manufacturers, especially for international B2B buyers who must navigate diverse market needs and compliance standards.

1. Copper

Key Properties: Copper is known for its excellent electrical conductivity and thermal conductivity, making it an ideal choice for EDM electrodes. It has a melting point of approximately 1,984°F (1,085°C) and offers good corrosion resistance.

Pros & Cons: The primary advantage of copper is its high conductivity, which facilitates faster machining speeds and better surface finishes. However, it can wear out quickly during the EDM process, leading to shorter tool life and potentially higher replacement costs. Additionally, copper is relatively expensive compared to other materials.

Impact on Application: Copper is particularly effective in applications requiring high precision and fine details, such as in the aerospace and electronics sectors. However, its performance can be affected by the dielectric fluid used, necessitating careful selection.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM B152/B152M for copper. The fluctuating costs of copper can also impact budgeting, especially in emerging markets like Nigeria and South Africa, where sourcing may vary.

2. Graphite

Key Properties: Graphite has a high melting point (around 3,600°F or 2,000°C) and is chemically stable, making it resistant to oxidation. It also exhibits good thermal conductivity and is lightweight.

Pros & Cons: Graphite is favored for its long tool life and ability to produce intricate shapes with minimal wear. However, it can be brittle, making it prone to chipping during machining. Cost-wise, graphite is generally more affordable than copper but may require specialized handling due to its dust production.

Impact on Application: Its durability and precision make graphite suitable for complex molds and dies in the automotive and aerospace industries. The material’s compatibility with various dielectric fluids enhances its versatility across different applications.

Considerations for International Buyers: Buyers should be aware of the need for compliance with environmental regulations regarding graphite dust in regions like Europe, where stringent health and safety standards apply. Additionally, understanding the material’s sourcing can be vital for buyers in South America, where local availability may influence costs.

3. Tungsten

Key Properties: Tungsten is characterized by its high melting point (6,192°F or 3,422°C) and exceptional hardness. It is highly resistant to wear and has a low thermal expansion coefficient.

Pros & Cons: The primary advantage of tungsten is its durability, making it ideal for high-precision applications in harsh environments. However, its high cost and machining complexity can deter some manufacturers. Tungsten also requires specialized equipment for EDM due to its hardness.

Illustrative image related to electrical discharge machining manufacturers

Impact on Application: Tungsten is particularly suitable for industries that demand extreme precision and durability, such as defense and aerospace. Its compatibility with high-performance components is crucial for applications that involve high temperatures and pressures.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should consider the availability of tungsten and its compliance with international standards like ASTM F288. The high cost may also necessitate careful planning and budgeting.

Summary Table of Material Selection for EDM

| Material | Typical Use Case for electrical discharge machining manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Ideal for high-precision electrodes in aerospace and electronics | Excellent electrical and thermal conductivity | Short tool life due to rapid wear | High |

| Graphite | Suitable for complex molds and dies in automotive and aerospace | Long tool life and minimal wear | Brittle and prone to chipping | Medium |

| Tungsten | Used in high-precision applications in defense and aerospace | Exceptional durability and high melting point | High cost and machining complexity | High |

By understanding these materials’ properties, advantages, and limitations, international B2B buyers can make informed decisions that align with their specific manufacturing needs and regional compliance requirements.

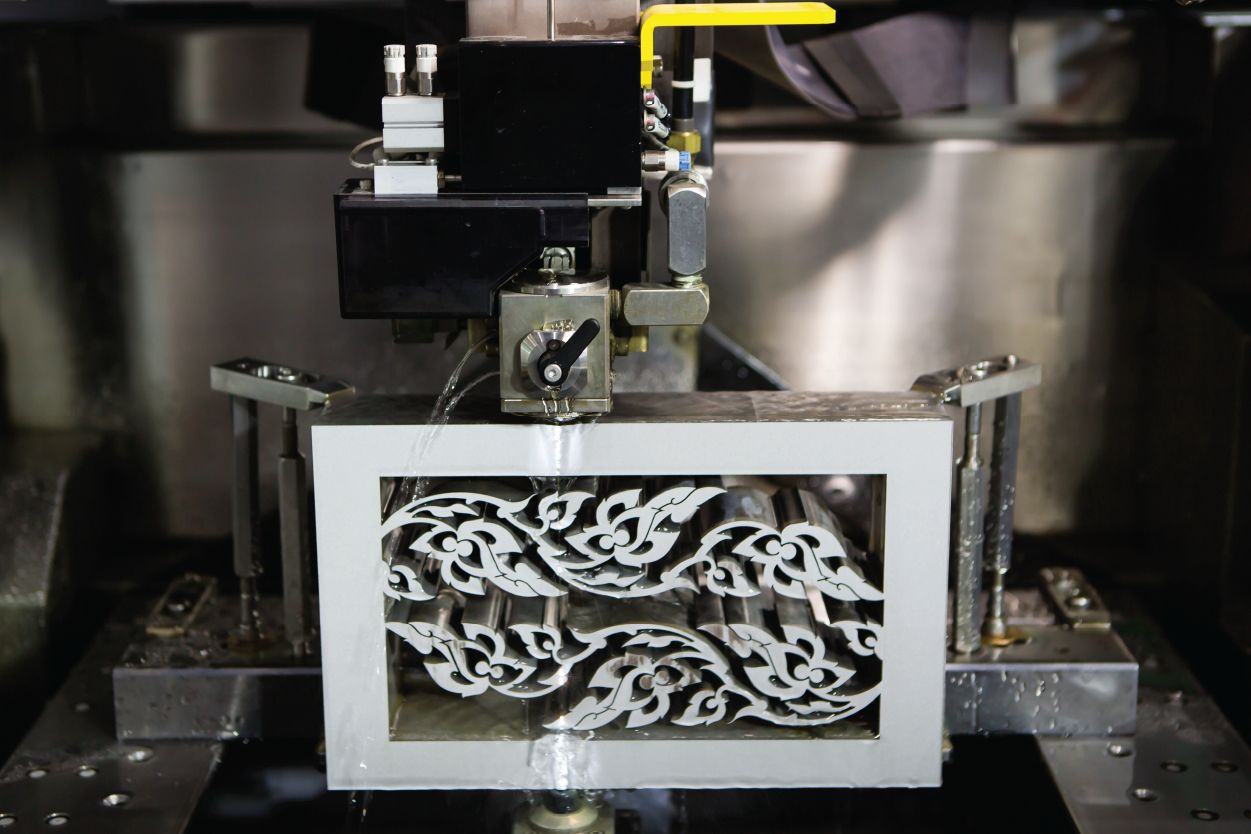

Illustrative image related to electrical discharge machining manufacturers

In-depth Look: Manufacturing Processes and Quality Assurance for electrical discharge machining manufacturers

What Are the Key Stages in the Manufacturing Process of Electrical Discharge Machining?

The manufacturing process of electrical discharge machining (EDM) is intricate and consists of several critical stages that ensure high precision and quality in the final products. Understanding these stages is essential for B2B buyers looking to source EDM components from reliable manufacturers.

1. Material Preparation: How Is Material Selected and Prepared for EDM?

Material selection is paramount in EDM, as the process is suited for hard metals and alloys that are difficult to machine using conventional methods. Common materials include tool steels, titanium, and superalloys. The preparation phase involves cutting the raw material into manageable sizes and ensuring that it is free from contaminants. This often includes cleaning the surface and checking for any pre-existing defects that might affect the EDM process.

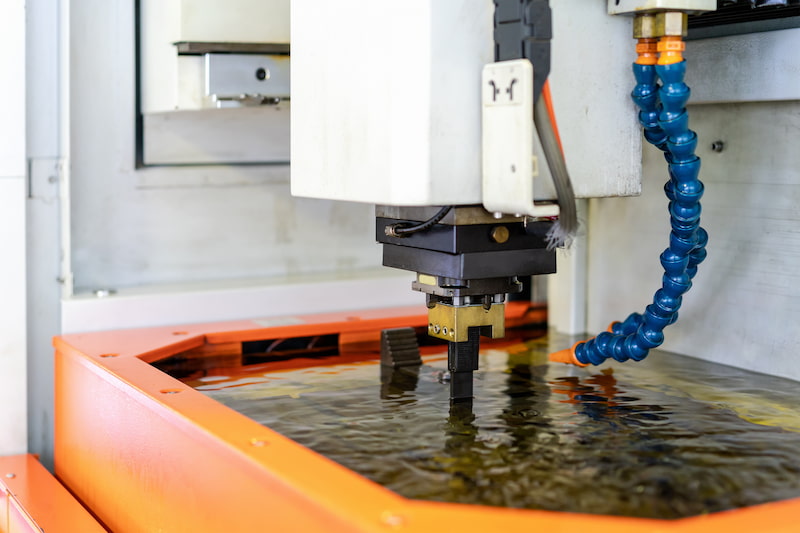

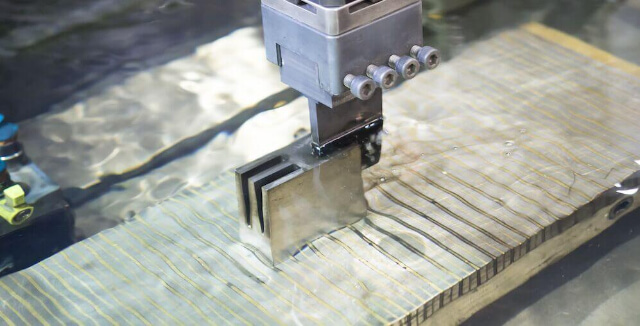

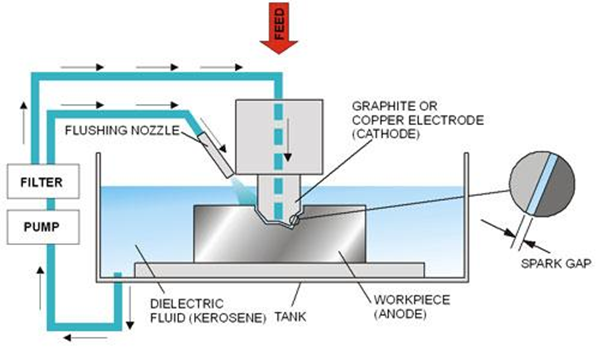

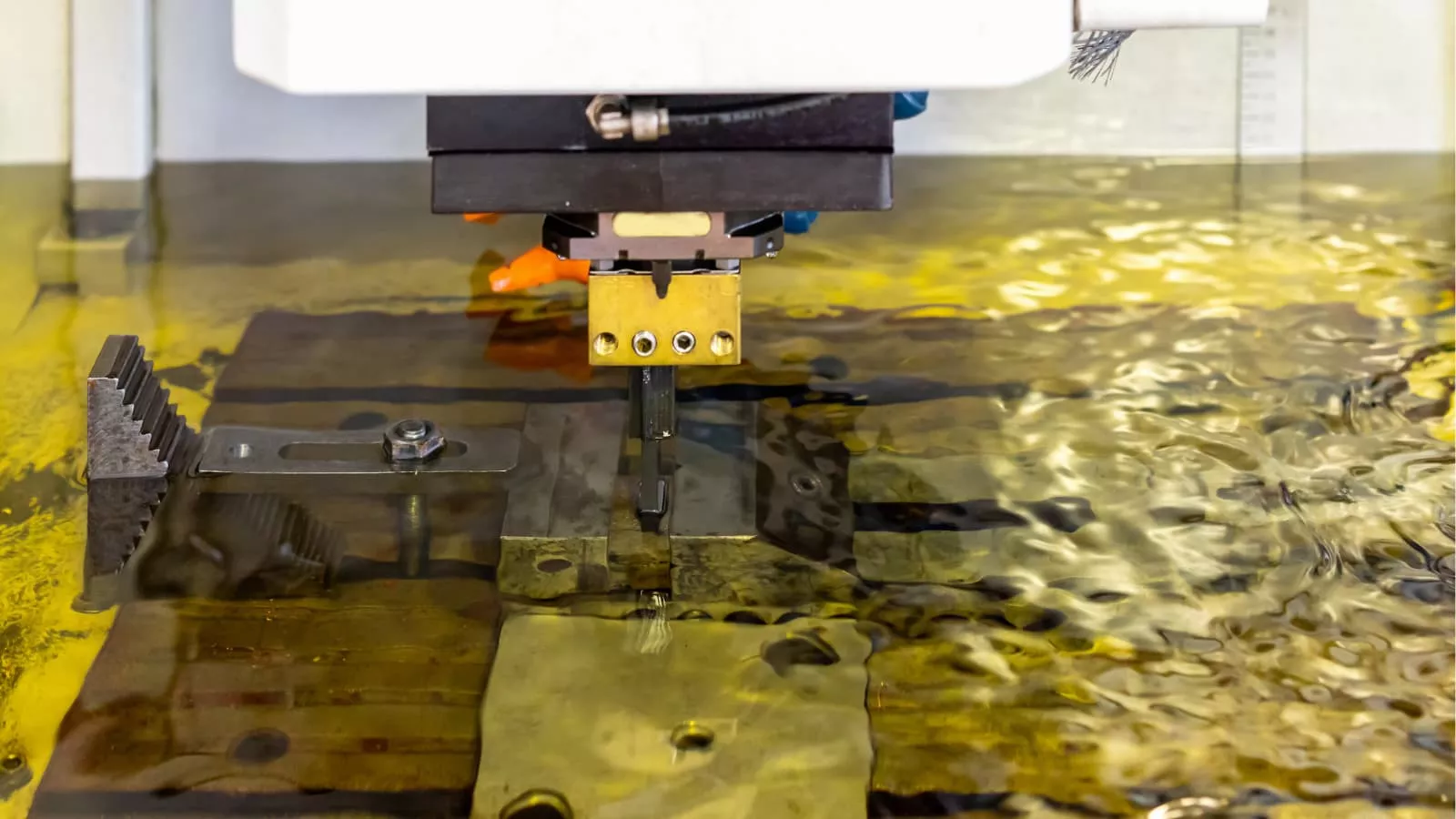

2. Forming: What Techniques Are Used in the EDM Process?

The core of the EDM process involves creating a desired shape through controlled electrical discharges. This is typically executed using either wire EDM or sinker EDM techniques. In wire EDM, a thin wire serves as the electrode, cutting through the material with high precision to create intricate shapes. Sinker EDM, on the other hand, uses a shaped electrode to erode material, allowing for complex geometries that are difficult to achieve with traditional machining. Both methods require careful programming and setup to ensure optimal results.

3. Assembly: How Are Components Joined in EDM Manufacturing?

Post-EDM, components may require assembly, especially when they are part of larger systems or assemblies. Techniques such as welding, soldering, or adhesive bonding are often utilized, depending on the materials involved and the application requirements. The assembly process must be carried out with precision to maintain the integrity and performance of the machined components.

Illustrative image related to electrical discharge machining manufacturers

4. Finishing: What Are the Final Steps in EDM Manufacturing?

Finishing processes are critical in achieving the desired surface quality and tolerances. This can include polishing, surface hardening, or applying protective coatings. The choice of finishing techniques depends on the specific application of the EDM component and the requirements for surface roughness and wear resistance.

How Do Electrical Discharge Machining Manufacturers Ensure Quality Control?

Quality assurance in EDM manufacturing is vital to meet the stringent requirements of various industries, such as aerospace, automotive, and medical devices. Manufacturers adhere to international standards and implement robust quality control processes.

Relevant International Standards: What Certifications Should B2B Buyers Look For?

EDM manufacturers often seek certifications such as ISO 9001, which establishes a framework for quality management systems. Additionally, industry-specific certifications like CE for products sold in Europe and API for oil and gas applications ensure compliance with safety and quality standards. Buyers should look for these certifications to verify that the manufacturer maintains high-quality standards.

What Are the Key Quality Control Checkpoints in EDM Manufacturing?

Quality control in EDM involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step verifies the quality of raw materials before they enter production. It ensures that materials meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor critical parameters and ensure adherence to specifications. This may include checking electrode wear, machining accuracy, and surface finish.

-

Final Quality Control (FQC): After the components are manufactured and assembled, a thorough inspection is performed to confirm that they meet all design specifications and quality standards before shipment.

What Common Testing Methods Are Used in EDM Quality Control?

Testing methods commonly employed in EDM quality control include:

-

Dimensional Inspection: Utilizing coordinate measuring machines (CMM) to verify that components meet dimensional tolerances.

-

Surface Roughness Testing: Employing profilometers to measure the surface finish and ensure it meets the required specifications.

-

Material Testing: Conducting hardness tests and metallurgical analysis to confirm the material properties and integrity.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need assurance that their EDM suppliers implement effective quality control measures. Here are several strategies to verify supplier quality:

Illustrative image related to electrical discharge machining manufacturers

What Role Do Audits Play in Verifying Quality Control?

Conducting supplier audits is an effective way for buyers to assess the quality control processes of EDM manufacturers. Audits can include reviewing documentation, observing manufacturing practices, and evaluating compliance with international standards. This proactive approach helps buyers identify potential risks and ensure that suppliers maintain high-quality standards.

How Can Buyers Request Quality Reports and Documentation?

Buyers should request quality reports and documentation from suppliers, including inspection reports, certifications, and compliance documents. These records provide valuable insights into the supplier’s quality assurance processes and help establish trust in their capabilities.

What Is the Importance of Third-Party Inspections in Quality Assurance?

Engaging third-party inspection services can further enhance confidence in the quality of EDM components. Independent inspectors can evaluate manufacturing processes, conduct product testing, and provide unbiased reports, ensuring that the products meet the required standards before delivery.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances:

-

Cultural Differences: Understanding the cultural context can impact communication and expectations regarding quality. It is essential to establish clear quality standards and ensure that both parties are aligned.

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should verify that suppliers can comply with local regulations and international standards relevant to their industry.

-

Logistics and Supply Chain Considerations: The logistics of international shipping can introduce challenges in maintaining quality. Buyers must ensure that suppliers have robust logistics processes to prevent damage or quality degradation during transport.

In conclusion, understanding the manufacturing processes and quality assurance practices of electrical discharge machining manufacturers is crucial for B2B buyers. By focusing on the detailed stages of manufacturing and implementing effective quality control strategies, buyers can make informed decisions and establish successful partnerships with EDM suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electrical discharge machining manufacturers’

In today’s competitive landscape, sourcing reliable electrical discharge machining (EDM) manufacturers is critical for businesses seeking precision components. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively, ensuring that they select the right partners for their manufacturing needs.

Illustrative image related to electrical discharge machining manufacturers

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. This includes the materials you plan to machine, the desired tolerances, and specific geometries. Having well-defined specifications will help you communicate effectively with potential suppliers and ensure they have the capability to meet your needs.

- Identify key attributes: Consider aspects like part size, complexity, and surface finish requirements.

- Document your needs: Create a detailed specification sheet to share with potential manufacturers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential EDM manufacturers that align with your technical specifications. Utilize industry directories, trade shows, and online platforms to compile a list of candidates.

- Look for industry experience: Focus on suppliers with a proven track record in your specific industry, such as aerospace, automotive, or medical devices.

- Check their capabilities: Ensure they offer the specific EDM processes you require, such as wire EDM, sinker EDM, or micro EDM.

Step 3: Evaluate Supplier Certifications

Certifications can provide assurance of a manufacturer’s quality management practices. Verify that the suppliers hold relevant certifications, such as ISO 9001, which indicates adherence to quality standards.

- Request documentation: Ask for copies of their certifications and any recent audit reports.

- Understand their quality control processes: Inquire about their inspection methods and quality assurance protocols to gauge their commitment to excellence.

Step 4: Request Samples and Quotes

Once you have narrowed down your list of potential suppliers, request samples of their work along with detailed quotes. This step allows you to assess the quality of their machining and compare pricing structures.

- Specify your requirements: Clearly communicate the exact parts or prototypes you want them to produce.

- Evaluate their responsiveness: Take note of how quickly and thoroughly they respond to your requests, as this can be indicative of their customer service.

Step 5: Conduct On-site Visits

If feasible, arrange to visit the manufacturing facilities of your top candidates. An on-site visit provides invaluable insights into their operations, capabilities, and overall quality culture.

- Observe their equipment: Check if they utilize advanced EDM technology and maintain their machines properly.

- Meet the team: Engage with engineers and technicians to assess their expertise and willingness to collaborate on your projects.

Step 6: Check References and Reviews

Before making a final decision, verify the reputation of your shortlisted suppliers by checking references and reading reviews from previous clients. This feedback can help you gauge their reliability and performance.

- Ask for case studies: Request examples of past projects that are similar to yours.

- Look for testimonials: Seek out reviews on third-party platforms to get an unbiased view of their service quality.

Step 7: Negotiate Terms and Finalize Contracts

After selecting the right supplier, negotiate terms that align with your business objectives. This includes pricing, delivery timelines, and payment terms.

- Clarify expectations: Ensure that all agreed-upon specifications, quality standards, and timelines are documented in the contract.

- Establish communication protocols: Set up regular check-ins and updates to maintain transparency throughout the production process.

By following this checklist, B2B buyers can confidently navigate the sourcing process for electrical discharge machining manufacturers, ensuring they select a partner that meets their precision manufacturing needs.

Comprehensive Cost and Pricing Analysis for electrical discharge machining manufacturers Sourcing

What Are the Key Cost Components in Electrical Discharge Machining Manufacturing?

Understanding the cost structure of electrical discharge machining (EDM) is crucial for international B2B buyers. The primary cost components include:

Illustrative image related to electrical discharge machining manufacturers

-

Materials: The selection of materials significantly impacts pricing. EDM commonly utilizes hard metals and alloys, which can be expensive. The cost fluctuates based on market conditions and material availability.

-

Labor: Skilled labor is essential for operating EDM machines and performing quality checks. Labor costs can vary widely depending on the region and the skill level of the workforce. In regions like Europe, higher wages may be a factor compared to other areas, such as Africa or South America.

-

Manufacturing Overhead: This includes costs associated with the maintenance of machinery, utilities, and facility expenses. Efficient manufacturing processes can help minimize overhead, impacting overall pricing.

-

Tooling: Custom tooling can be required for specific projects, which adds to the upfront costs. Buyers should inquire about tooling costs when evaluating quotes.

-

Quality Control (QC): Rigorous QC processes ensure that parts meet specifications and certifications. The cost of quality assurance can be a significant factor, particularly for industries such as aerospace and medical devices where precision is critical.

-

Logistics: Shipping and handling costs can vary based on distance, shipping terms (Incoterms), and the nature of the product. International buyers need to account for these logistics costs in their total budget.

-

Margin: Manufacturers will include a profit margin in their pricing. Understanding the typical margins in the EDM sector can help buyers gauge the fairness of quotes.

How Do Pricing Influencers Affect EDM Costs?

Several factors can influence the pricing of EDM services, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes can lead to bulk pricing discounts. Buyers should negotiate for better rates based on their purchasing power.

-

Specifications and Customization: Complex geometries and tight tolerances can increase costs. Providing detailed specifications early in the sourcing process can help suppliers give more accurate quotes.

-

Materials: The choice of materials directly affects pricing. Rare or specialized materials will increase costs, so it’s advisable to explore alternatives if budget constraints are an issue.

-

Quality and Certifications: Certifications such as ISO 9001 can influence pricing. Manufacturers with higher quality standards may charge more due to the additional processes involved.

-

Supplier Factors: The supplier’s location, reputation, and experience level can impact costs. Established suppliers may charge a premium for their expertise and reliability.

-

Incoterms: The chosen Incoterms can alter the total cost of ownership. Buyers should understand terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to evaluate the true cost of procurement.

What Are Effective Buyer Tips for Negotiating EDM Prices?

When sourcing EDM services, buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing and terms. Highlighting long-term relationships can sometimes yield better pricing.

-

Focus on Cost-Efficiency: Evaluate not just the initial price but the total cost of ownership, including maintenance, potential downtime, and logistics. This broader perspective can lead to more informed decisions.

-

Understand Pricing Nuances for International Purchases: Different regions may have varying pricing structures due to local market conditions, labor costs, and material availability. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these dynamics.

-

Request Multiple Quotes: Obtaining quotes from several suppliers can provide a better understanding of market rates and help identify competitive pricing.

-

Be Mindful of Currency Fluctuations: For international transactions, currency exchange rates can affect pricing. Buyers should stay informed about currency trends to mitigate potential losses.

Disclaimer

The prices and cost estimates mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Always obtain updated quotes tailored to your unique needs.

Alternatives Analysis: Comparing electrical discharge machining manufacturers With Other Solutions

Understanding Alternative Solutions to Electrical Discharge Machining

In the world of precision manufacturing, electrical discharge machining (EDM) is renowned for its ability to create intricate and high-tolerance components. However, various alternative methods exist that can also achieve similar goals, depending on the specific requirements of a project. Evaluating these alternatives can help B2B buyers make informed decisions based on performance, cost, and application needs.

Comparison Table

| Comparison Aspect | Electrical Discharge Machining Manufacturers | Alternative 1 Name: Laser Cutting | Alternative 2 Name: CNC Machining |

|---|---|---|---|

| Performance | High precision for complex geometries | Excellent for flat shapes and cutting | Versatile for various materials and shapes |

| Cost | Generally higher due to specialized equipment | Moderate, varies with material thickness | Often lower for simpler designs |

| Ease of Implementation | Requires skilled operators and setup | Easier to set up and program | Requires CAD design but widely accessible |

| Maintenance | High maintenance due to precision needs | Low maintenance; fewer moving parts | Moderate; regular maintenance needed |

| Best Use Case | Aerospace, medical devices, intricate tooling | Sheet metal fabrication, signage | Prototyping, mass production of parts |

What Are the Pros and Cons of Laser Cutting?

Laser cutting is a popular alternative that utilizes focused light beams to melt or vaporize material. The primary advantage of laser cutting is its speed and efficiency, especially for flat materials. It is ideal for creating intricate designs in sheet metal and is often more cost-effective for larger production runs. However, laser cutting may not achieve the same level of precision on complex 3D geometries as EDM, and the heat-affected zone can affect material properties, which is crucial in sensitive applications like aerospace or medical manufacturing.

How Does CNC Machining Compare?

CNC (Computer Numerical Control) machining is another viable alternative that employs computer-controlled tools to shape materials. It offers versatility across a wide range of materials and can produce parts with high accuracy. CNC machining is particularly effective for mass production and can handle larger volumes at a lower cost than EDM for simpler designs. However, it may struggle with the same level of complexity as EDM, especially for intricate shapes that require fine details. Additionally, the setup time for CNC machining can be longer due to the need for CAD designs.

Choosing the Right Solution for Your Needs

When selecting between EDM and its alternatives, B2B buyers should carefully consider their specific manufacturing needs. Factors such as the complexity of the part, required tolerances, material types, production volume, and budget constraints will guide the decision-making process. For highly intricate and precise components, EDM remains unparalleled, while laser cutting may be favored for flat materials requiring quick turnaround times. CNC machining offers a balance for those needing versatility and cost-effectiveness in production. Ultimately, understanding these alternatives will empower buyers to make decisions that best align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for electrical discharge machining manufacturers

What Are the Key Technical Properties in Electrical Discharge Machining?

Electrical discharge machining (EDM) is distinguished by several critical technical properties that influence its effectiveness and suitability for various applications. Understanding these specifications is essential for B2B buyers looking to make informed decisions.

1. Material Grade

Material grade refers to the specific type of metal or alloy used in the EDM process. Common materials include tool steels, titanium, and superalloys. The material grade impacts the machining parameters, such as the required voltage and current settings, influencing the quality of the finished product. For manufacturers, selecting the right material grade ensures compatibility with the intended application, whether it be in aerospace, automotive, or medical device sectors.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. In EDM, tolerances can be as tight as ±0.001 mm, making it an ideal process for components requiring high precision. Understanding tolerance specifications helps B2B buyers ensure that the parts produced will meet their operational standards and fit seamlessly into their assembly processes.

3. Surface Finish

Surface finish refers to the texture and smoothness of the machined part’s surface. EDM can achieve finishes as fine as Ra 0.2 microns. A superior surface finish is critical in applications where contact surfaces affect functionality, such as in medical devices or aerospace components. Buyers should prioritize manufacturers who can meet their specific surface finish requirements to enhance the performance of their products.

4. Electrode Material

The choice of electrode material significantly affects the machining process. Common materials include copper, graphite, and brass, each offering different conductivity and wear characteristics. Selecting the appropriate electrode material is crucial for optimizing machining efficiency and achieving desired outcomes. B2B buyers should inquire about the electrode materials used by manufacturers to ensure they align with their production needs.

5. Wire Diameter (for Wire EDM)

Wire diameter plays a vital role in wire EDM processes, impacting the level of detail and complexity achievable in the machined part. Common wire diameters range from 0.1 mm to 0.3 mm. A finer wire allows for tighter curves and intricate designs, which is essential for applications in fields such as electronics and precision tooling. Buyers should assess manufacturers’ capabilities concerning wire diameter to meet their specific design requirements.

What Are Common Trade Terms in Electrical Discharge Machining?

Familiarity with industry terminology is crucial for effective communication and negotiation in the EDM sector. Here are some common trade terms relevant to B2B buyers:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the OEM relationship helps buyers identify potential partners and assess the quality and reliability of the components they are purchasing.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory costs and production schedules effectively, ensuring they can meet their production requirements without incurring excess costs.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain price quotes for specific products or services. This process is critical for buyers to compare costs and negotiate terms effectively, ensuring they receive competitive pricing for their EDM needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities, ensuring smoother cross-border transactions.

5. CMM (Coordinate Measuring Machine)

CMM refers to a device used for measuring the physical geometrical characteristics of an object. In EDM, CMM ensures that the machined components meet precise specifications. Buyers should ensure that their manufacturers utilize advanced CMM technology for quality assurance.

Understanding these essential technical properties and trade terms equips B2B buyers with the knowledge needed to make informed purchasing decisions in the electrical discharge machining sector, facilitating smoother transactions and better partnerships.

Illustrative image related to electrical discharge machining manufacturers

Navigating Market Dynamics and Sourcing Trends in the electrical discharge machining manufacturers Sector

What Are the Key Trends Shaping the Electrical Discharge Machining Market?

The electrical discharge machining (EDM) sector is witnessing significant transformation driven by technological advancements and shifting market demands. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (e.g., Germany, Nigeria) navigate this landscape, understanding key trends is essential. The increasing complexity of components across industries—especially aerospace, automotive, and medical—fuels demand for EDM’s unparalleled precision. Additionally, the trend towards automation and Industry 4.0 is propelling manufacturers to adopt smart technologies, such as IoT-enabled machines and advanced data analytics, to enhance operational efficiency and reduce lead times.

Emerging sourcing trends also reflect a growing preference for suppliers who can provide customized solutions and agile manufacturing capabilities. The rise of just-in-time (JIT) manufacturing practices, particularly in Europe and parts of Africa, demands that EDM manufacturers adapt quickly to fluctuating order sizes without compromising quality. Moreover, as global supply chains become increasingly interconnected, B2B buyers are prioritizing suppliers with robust logistics networks that can ensure timely delivery and mitigate risks associated with geopolitical uncertainties.

How Can Sustainability and Ethical Sourcing Be Integrated into EDM Manufacturing?

Sustainability and ethical sourcing are becoming paramount in the EDM manufacturing sector, driven by both regulatory pressures and customer expectations. The environmental impact of traditional machining processes—such as waste generation and energy consumption—highlights the need for greener alternatives. EDM, with its precise material removal capabilities, can minimize waste and energy use, making it an attractive option for environmentally conscious manufacturers.

B2B buyers should seek suppliers committed to ethical supply chains and sustainable practices. This includes sourcing materials from certified suppliers who adhere to environmental standards and utilize eco-friendly processes. Certifications such as ISO 14001 for environmental management systems can serve as benchmarks for evaluating a manufacturer’s commitment to sustainability. Furthermore, the adoption of green materials and technologies, such as biodegradable dielectric fluids and energy-efficient machinery, is gaining traction. Buyers who prioritize these factors not only contribute to environmental preservation but also enhance their brand reputation in increasingly eco-aware markets.

What is the Evolution of Electrical Discharge Machining and Its Impact on B2B Buyers?

The evolution of electrical discharge machining (EDM) has significantly shaped its application in modern manufacturing. Originating in the 18th century, the technology advanced rapidly during the 20th century, particularly with the introduction of computer numerical control (CNC) systems in the 1970s. This evolution has expanded EDM’s capabilities, allowing for the precise machining of complex geometries in hard materials, which are essential in industries such as aerospace and medical device manufacturing.

Illustrative image related to electrical discharge machining manufacturers

For B2B buyers, understanding this historical context is crucial, as it illustrates EDM’s adaptability and relevance in meeting contemporary manufacturing challenges. The continuous improvement in EDM technologies—such as increased automation and integration with digital workflows—provides buyers with opportunities to enhance production efficiency and product quality. As the sector continues to innovate, staying informed about these advancements enables buyers to make strategic sourcing decisions that align with their operational goals.

Frequently Asked Questions (FAQs) for B2B Buyers of electrical discharge machining manufacturers

-

How can I ensure the quality of electrical discharge machining (EDM) parts from manufacturers?

To ensure the quality of EDM parts, request detailed documentation of the manufacturer’s quality assurance processes, including certifications like ISO 9001. Ask for samples of previous work to assess their precision and tolerance levels. Additionally, consider visiting the facility or arranging third-party inspections to verify their capabilities. Establishing clear quality benchmarks and performance metrics in your contract can also safeguard your interests. -

What factors should I consider when selecting an EDM manufacturer?

Key factors include the manufacturer’s experience in your specific industry, their technological capabilities, and the range of services offered. Look for a manufacturer with expertise in producing components similar to your requirements. Additionally, consider their lead times, scalability, and customer service responsiveness. Reviews and testimonials from other clients can provide insights into their reliability and overall satisfaction. -

What are the common applications of electrical discharge machining in various industries?

EDM is widely used in aerospace for precision components like turbine blades, in automotive for dies and molds, and in medical device manufacturing for surgical tools and implants. Its ability to produce complex geometries and tight tolerances makes it indispensable in sectors requiring high precision, such as defense, electronics, and energy. Understanding your specific industry needs can help you identify the most suitable EDM solutions. -

What is the minimum order quantity (MOQ) for EDM services?

The MOQ for EDM services can vary significantly among manufacturers. Some may accept small orders for prototyping, while others may have higher minimums for cost-effectiveness. When sourcing, inquire about MOQs upfront and ensure they align with your project needs. If you anticipate larger orders in the future, negotiating flexible terms can be beneficial. -

What payment terms are typically offered by EDM manufacturers?

Payment terms can vary, but common practices include a deposit upfront (often 30-50%) with the balance due upon completion or delivery. Some manufacturers may offer net payment terms depending on the buyer’s creditworthiness. It’s crucial to discuss payment methods, currency considerations, and any potential for financing options during negotiations to avoid future misunderstandings. -

How do I verify the reliability of an international EDM supplier?

To verify an EDM supplier’s reliability, conduct thorough due diligence by checking their business credentials, certifications, and industry reputation. Request references from previous clients and review case studies to gauge their performance. Utilizing platforms that specialize in supplier vetting can also provide valuable insights. Establishing a clear communication channel and setting expectations can further enhance the partnership’s success. -

What logistics considerations should I keep in mind when sourcing EDM services internationally?

When sourcing EDM services internationally, consider shipping times, customs regulations, and import duties that may affect delivery schedules and costs. Evaluate the manufacturer’s ability to handle logistics, including packaging and transportation. Clear communication regarding timelines and responsibilities can help mitigate risks. Additionally, explore options for local representation or partnerships to streamline the process. -

Can EDM manufacturers accommodate custom designs and specifications?

Most reputable EDM manufacturers can accommodate custom designs, as the process is inherently flexible for producing intricate parts. When discussing your project, provide detailed specifications and any CAD drawings to facilitate accurate quotes. Ensure that the manufacturer has experience with similar custom projects and inquire about their prototyping capabilities to validate designs before full-scale production.

Top 8 Electrical Discharge Machining Manufacturers Manufacturers & Suppliers List

1. Electrical Discharge Machining – Key Services

Domain: electricaldischargemachining.com

Registered: 2000 (25 years)

Introduction: Electrical Discharge Machining (EDM) is a highly accurate machining process that utilizes electrical discharges to shape a workpiece by removing material. Key services include EDM Drilling, EDM Machining, Micro EDM, Plunge EDM, Ram EDM, Sinker EDM, Small Hole EDM, and Wire EDM. Leading companies in the field include Xact Wire EDM Corporation, Twin City EDM, Sematool Precision Mfg. Inc., National J…

2. Mitsubishi – Wire EDM Machines

Domain: xometry.com

Registered: 2015 (10 years)

Introduction: 1. Mitsubishi: Five lines of wire EDM machines including MX600 (highest accuracy, smallest part size), FA40V and FA50V (least precise). Features linear drive and automatic wire threading.

2. ONA: Four series – compact (maximal precision), modular (flexibility), hole-drilling, and custom models.

3. Makino: 14 wire EDM machines ranging from compact micromachining (0.5-micron accuracy, 150 x 150 mm) …

3. Makino – Electrical Discharge Machining Solutions

Domain: makino.com

Registered: 1996 (29 years)

Introduction: Makino Electrical Discharge Machining (EDM) offers solutions for multiple industries including die/mold, medical, aerospace, electronics, military, and manufacturing. Key types of EDM include: 1. Sinker EDMs – Ideal for hardened materials and complex part details, suitable for difficult machining tasks. 2. Wire EDMs – Used for precise removal of excess material without strong cutting force, common…

4. Methods Machine Tools – Wire-Cut EDM Solutions

Domain: methodsmachine.com

Registered: 1996 (29 years)

Introduction: Methods Machine Tools offers wire-cut electrical discharge machining (EDM) solutions that provide high accuracy, efficiency, and throughput for drilling precise holes and cutting complex shapes. Key features include: 1. High reliability and performance with automatic wire feeding systems. 2. Ball screw positioning systems for accuracy and smooth operation. 3. Predictable maintenance schedules and …

5. Oscarmax – Electric Discharge Machines

Domain: oscaredm.com

Registered: 2006 (19 years)

Introduction: Oscarmax is a leading manufacturer of Electric Discharge Machines (EDMs) based in Taiwan, known for high-quality wire EDMs, sinking EDMs, and EDM drilling machines. Their products emphasize superior quality, precision, reliability, and accuracy, catering to various industries. Oscarmax focuses on research and development, offering innovative machines that meet the increasing demands of the manufac…

6. Hamill Manufacturing – Electrical Discharge Machining (EDM) Services

Domain: hamillmfg.com

Registered: 1997 (28 years)

Introduction: Hamill Manufacturing offers Electrical Discharge Machining (EDM) services, specializing in hard metals and exotic materials like titanium and Inconel®. They utilize three EDM machines: 1) Charmilles Robofil 640CC (wire EDM) with a five-axis CNC head, max part size 51.25″ x 39.4″ x 20.1″, max weight 6,600 lbs, and max output 1,200 amps; 2) ONA H600 (RAM EDM) with a three-axis CNC head, max part siz…

7. ONA EDM – Die-Sinking & Wire-Cut EDM Solutions

Domain: onaedm.com

Registered: 2002 (23 years)

Introduction: ONA EDM offers a range of Electrical Discharge Machining (EDM) products including: 1. Die-Sinking EDM – Features the highest power digital generator in the market, an ecological filter, and the option for a second head to reduce erosion times. 2. Wire-Cut EDM – High efficiency machines with precision and cutting speed, reducing rework and improving surface finish by up to 30%. 3. Additive Technolo…

8. Micro-Tronics – Electrical Discharge Machining Services

Domain: micro-tronics.com

Registered: 1998 (27 years)

Introduction: Micro-Tronics, Inc. offers Electrical Discharge Machining (EDM) services, including CNC EDM, CNC Wire EDM, and CNC Fast Hole EDM. EDM utilizes electrical discharges between two electrodes to remove material from conductive workpieces, making it ideal for machining extremely hard metals. The process allows for the creation of fine details and polished finishes, suitable for precision dies and molds…

Strategic Sourcing Conclusion and Outlook for electrical discharge machining manufacturers

As the demand for precision components escalates across diverse industries, electrical discharge machining (EDM) stands out as a pivotal technology for manufacturers. Strategic sourcing of EDM services enables businesses to leverage advanced capabilities, ensuring the production of intricate geometries and high-tolerance parts that traditional machining methods struggle to achieve. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the unique advantages of EDM is essential for maintaining a competitive edge.

Investing in reliable EDM suppliers not only enhances product quality but also fosters innovation in manufacturing processes. By aligning with experienced EDM providers, companies can access tailored solutions that meet specific industry needs, from aerospace to medical devices. This strategic partnership allows for improved operational efficiency and reduced lead times, critical factors in today’s fast-paced market.

Looking ahead, the EDM landscape is poised for growth, driven by technological advancements and increasing applications across sectors. International buyers are encouraged to explore partnerships with leading EDM manufacturers to harness these innovations, positioning themselves at the forefront of their industries. Embrace the future of manufacturing by prioritizing strategic sourcing in your procurement strategy today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to electrical discharge machining manufacturers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.