Electric Motor Applications: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for electric motor applications

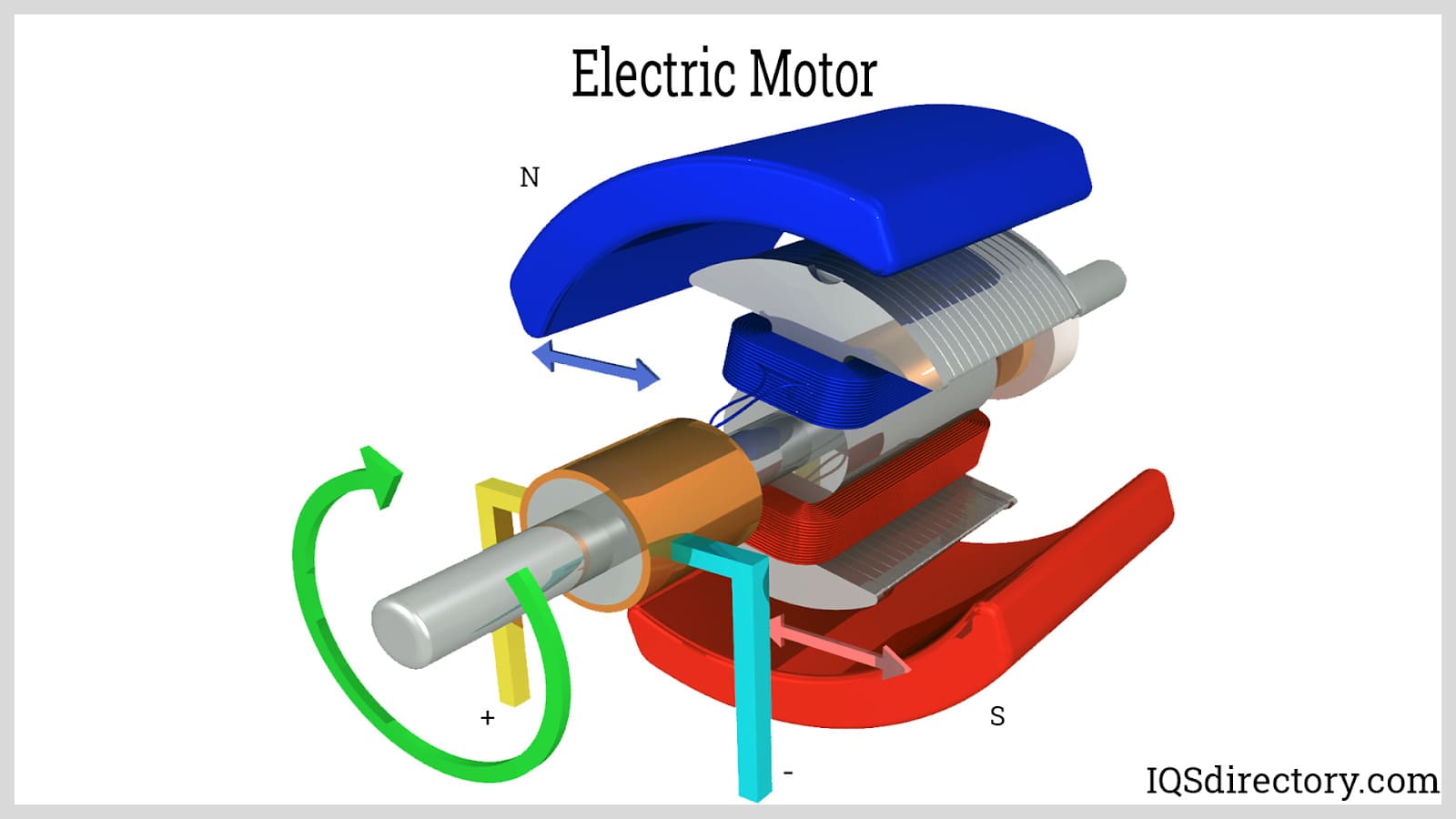

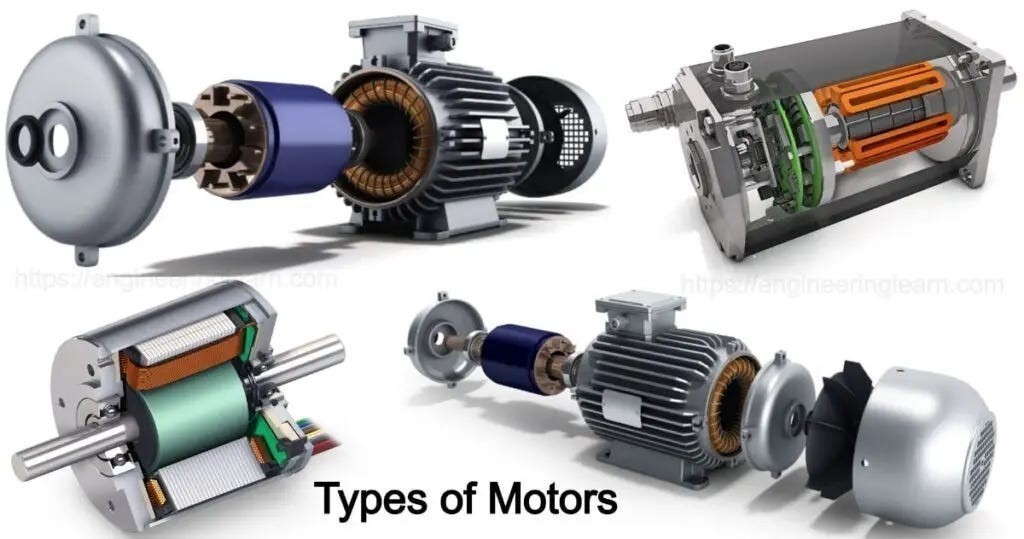

In an increasingly interconnected global marketplace, B2B buyers face the significant challenge of sourcing the right electric motor applications to meet their operational needs. With diverse options ranging from AC and DC motors to fractional horsepower and specialized variants, the complexity of decision-making can be overwhelming. This guide serves as a comprehensive resource, offering insights into various types of electric motors, their applications across industries, and essential criteria for supplier vetting.

By delving into the multifaceted world of electric motors, this guide empowers international buyers, particularly those from Africa, South America, the Middle East, and Europe—such as Nigeria and Saudi Arabia—to make informed purchasing decisions. It highlights critical factors such as cost considerations, performance metrics, and compliance standards, ensuring that businesses can select motors that enhance efficiency and reliability.

Whether you’re in need of motors for industrial machinery, HVAC systems, or innovative robotics, this guide equips you with the knowledge to navigate the global market effectively. By understanding the nuances of electric motor applications, buyers can streamline their procurement processes, reduce operational costs, and foster long-term partnerships with reputable suppliers.

Understanding electric motor applications Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Motors | Operate on alternating current; typically robust and efficient | HVAC systems, industrial machinery, fans | Pros: High efficiency, durable; Cons: More complex control systems. |

| DC Motors | Run on direct current; offer high torque at low speeds | Robotics, medical equipment, automotive | Pros: Simple control, high starting torque; Cons: Maintenance can be higher. |

| Fractional Horsepower Motors | Produce less than one horsepower; compact design | Consumer appliances, small tools | Pros: Cost-effective, space-saving; Cons: Limited power output. |

| Servo Motors | Provide precise control of angular position and velocity | Robotics, CNC machinery, automation | Pros: High precision, feedback capabilities; Cons: Higher initial cost. |

| Stepper Motors | Divide a full rotation into equal steps for accurate positioning | 3D printers, CNC machines, robotics | Pros: Excellent positional accuracy; Cons: Can be less efficient at high speeds. |

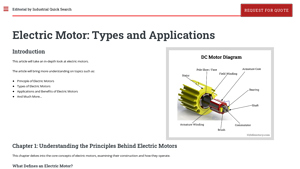

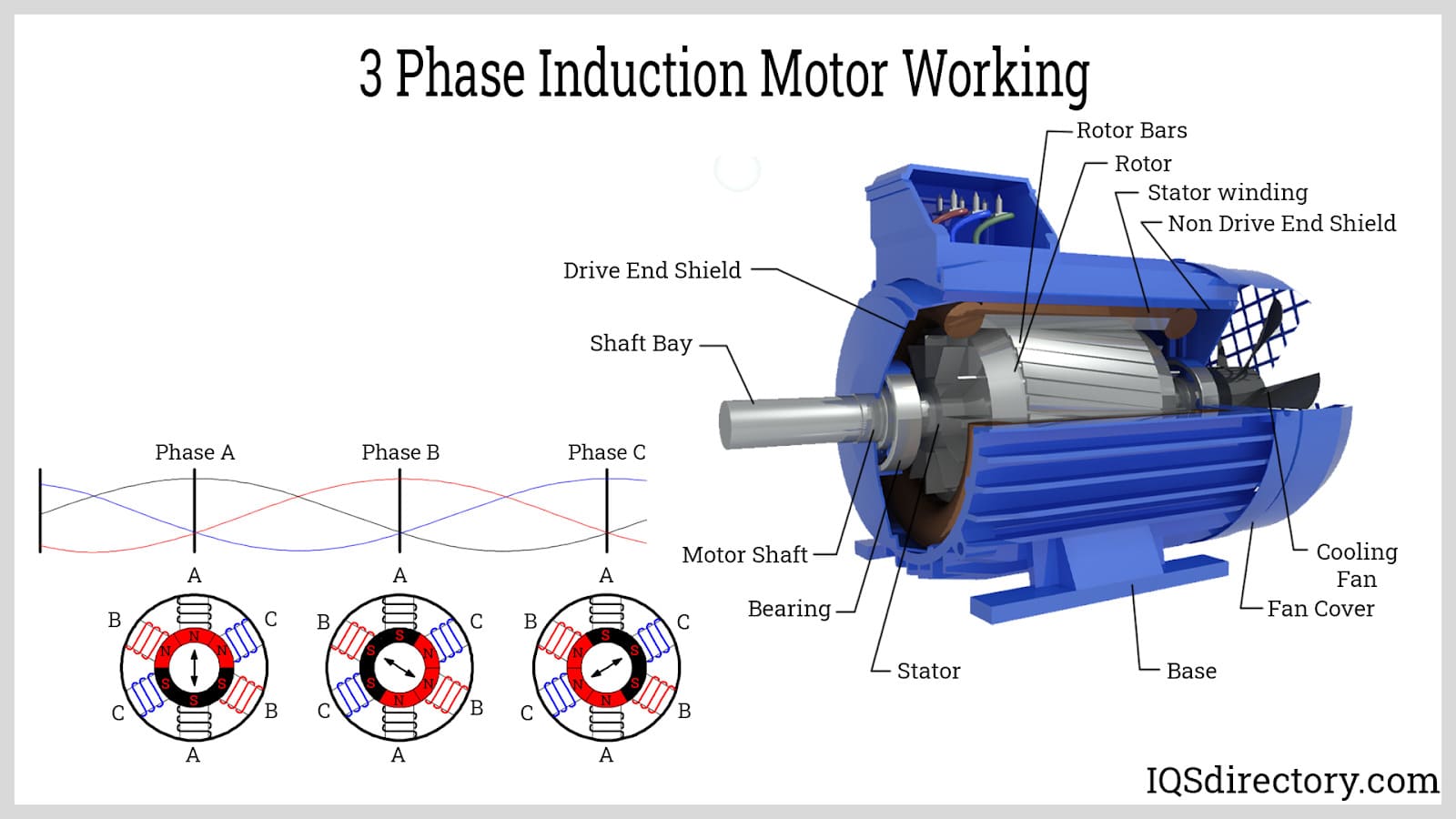

What Are AC Motors and Their B2B Applications?

AC motors utilize alternating current to produce mechanical energy, making them ideal for applications requiring constant speed and efficiency. They are widely used in HVAC systems, industrial machinery, and fans, where their robustness and durability are crucial. When considering AC motors, B2B buyers should evaluate their efficiency ratings, maintenance needs, and compatibility with existing systems, as these factors can significantly impact operational costs and system reliability.

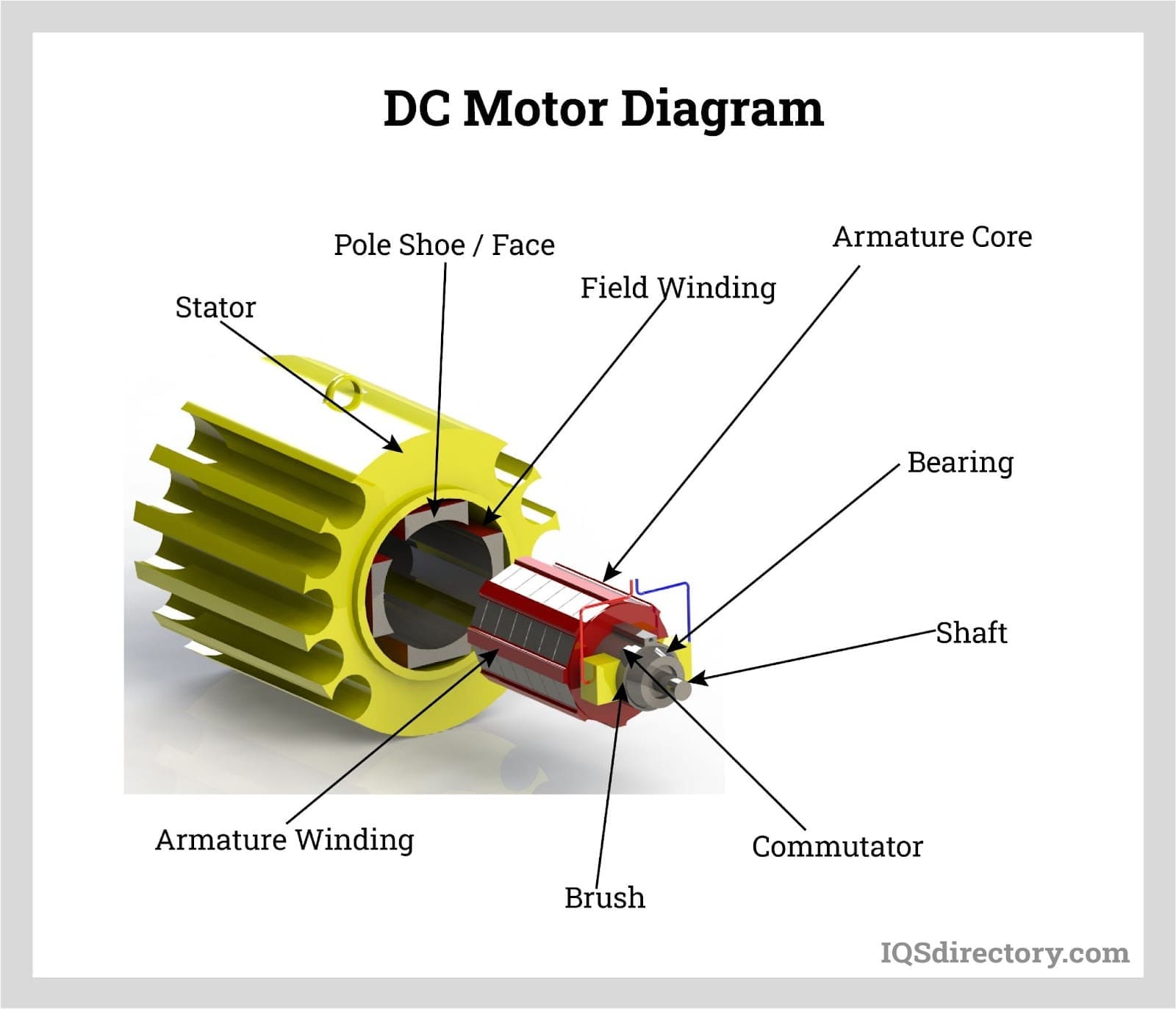

How Do DC Motors Fit into Various Industries?

DC motors operate on direct current and are known for their high starting torque and ease of speed control, making them suitable for applications like robotics and medical equipment. Their straightforward design allows for easier integration into systems that require precise control. Buyers should consider the total cost of ownership, including maintenance and potential downtime, as these motors may require more frequent servicing compared to their AC counterparts.

Why Choose Fractional Horsepower Motors for Small Applications?

Fractional horsepower motors are designed to produce less than one horsepower, making them perfect for consumer appliances and small tools. Their compact size and cost-effectiveness make them attractive options for businesses looking to optimize space and budget. When purchasing fractional horsepower motors, B2B buyers should assess the motor’s performance specifications and compatibility with the intended application to ensure it meets operational demands.

What Advantages Do Servo Motors Offer in Precision Applications?

Servo motors are designed for applications requiring precise control of angular position and velocity, such as in robotics and CNC machinery. Their feedback capabilities enable high accuracy and responsiveness, critical for automation processes. However, buyers should weigh the higher initial investment against long-term efficiency and operational improvements, ensuring the return on investment justifies the upfront costs.

How Are Stepper Motors Used in Automation and Precision Control?

Stepper motors excel in providing accurate positioning by dividing a full rotation into equal steps, making them ideal for 3D printers, CNC machines, and other automated systems. Their ability to maintain position without feedback systems is a significant advantage for certain applications. Buyers should consider the operational environment and load requirements, as stepper motors may not perform optimally at high speeds or under heavy loads.

Illustrative image related to electric motor applications

Key Industrial Applications of electric motor applications

| Industry/Sector | Specific Application of Electric Motor Applications | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering conveyor systems and assembly lines | Increases efficiency and reduces labor costs | Motor durability, power requirements, and compatibility |

| Agriculture | Electric motors in irrigation systems and automated farming equipment | Enhances crop yield and reduces water usage | Energy efficiency, weather resistance, and maintenance support |

| HVAC | Motors in heating, ventilation, and air conditioning systems | Improves energy efficiency and indoor air quality | Energy ratings, size specifications, and noise levels |

| Healthcare | Motors in medical devices such as MRI machines and surgical robots | Ensures precision and reliability in patient care | Compliance with medical standards, customization options, and reliability |

| Food and Beverage | Motors in food processing and packaging equipment | Increases production speed and maintains product quality | Hygiene standards, temperature tolerance, and energy efficiency |

How Are Electric Motors Used in Manufacturing and What Problems Do They Solve?

In the manufacturing sector, electric motors are essential for powering conveyor systems and assembly lines. They streamline production processes, significantly enhancing efficiency while reducing labor costs. For international buyers, especially in regions like Africa and South America, sourcing robust motors that can handle heavy loads and operate continuously is crucial. Buyers should consider factors such as motor durability and compatibility with existing machinery to ensure seamless integration into their operations.

What Role Do Electric Motors Play in Agriculture and How Do They Benefit Farmers?

Electric motors are increasingly utilized in modern irrigation systems and automated farming equipment, leading to improved crop yields and optimized water usage. This technology is particularly beneficial for farmers in regions like the Middle East, where water conservation is critical. Buyers should focus on energy-efficient motors that can withstand outdoor conditions and require minimal maintenance. Additionally, compatibility with smart farming technologies can provide further operational advantages.

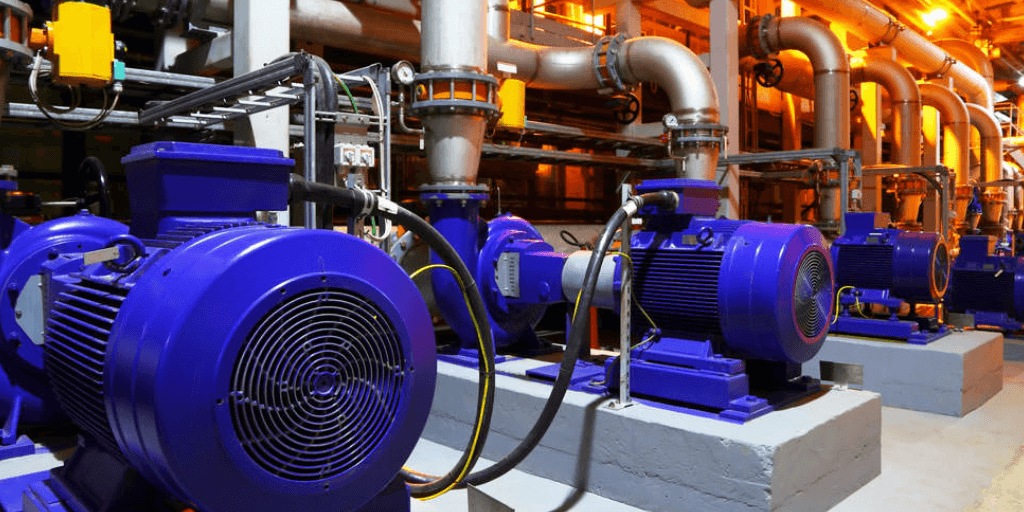

How Are Electric Motors Enhancing HVAC Systems for Better Energy Efficiency?

In HVAC systems, electric motors drive fans, blowers, and pumps, playing a vital role in regulating temperature and air quality in buildings. By enhancing energy efficiency, these motors help businesses reduce operational costs while ensuring a comfortable environment. Buyers from Europe and the Middle East should prioritize motors with high energy ratings and consider size specifications to match their system requirements. Noise levels are also a significant factor, particularly in residential or commercial spaces.

Why Are Electric Motors Critical in Healthcare Applications?

Electric motors are integral to various medical devices, including MRI machines and surgical robots, where precision and reliability are paramount. These motors facilitate controlled movements, ensuring the safety and effectiveness of medical procedures. For B2B buyers in the healthcare sector, compliance with medical standards is essential, along with customization options to meet specific device requirements. Reliability is also a key consideration, as any failure can have serious implications for patient care.

Illustrative image related to electric motor applications

How Do Electric Motors Contribute to the Food and Beverage Industry?

In the food and beverage sector, electric motors power processing and packaging equipment, significantly increasing production speed while maintaining product quality. This is crucial for businesses looking to scale operations and meet consumer demands efficiently. Buyers should ensure that the motors comply with hygiene standards and can operate under varying temperature conditions. Energy efficiency is also a vital consideration to minimize operational costs in this competitive industry.

3 Common User Pain Points for ‘electric motor applications’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Electric Motors for Specialized Applications

The Problem: B2B buyers often struggle to find reliable electric motors that meet specific performance criteria for specialized applications, such as medical equipment or industrial machinery. This challenge is exacerbated in regions with limited access to quality suppliers or where regulatory compliance is crucial. Buyers may face issues like inconsistent quality, lack of technical support, or inadequate customization options, leading to project delays and increased costs.

The Solution: To overcome sourcing difficulties, buyers should conduct thorough research on suppliers with a proven track record in their specific industry. It’s essential to prioritize suppliers who offer comprehensive technical support and customization options. Engaging in direct communication with potential suppliers can clarify product specifications and ensure that motors meet the exact requirements. Additionally, requesting samples or prototypes can help assess quality before making a larger investment. Leveraging online platforms that aggregate supplier ratings and customer feedback can also aid in making informed decisions.

Scenario 2: Inefficient Electric Motor Performance Leading to Increased Operating Costs

The Problem: Many businesses experience inefficient electric motor performance, which can result in higher energy consumption and increased operational costs. This issue often arises from the use of outdated motors that do not comply with modern efficiency standards. For companies in energy-sensitive markets, such as manufacturing or agriculture, this inefficiency can significantly impact profitability and sustainability efforts.

Illustrative image related to electric motor applications

The Solution: Buyers should consider investing in energy-efficient electric motors that comply with international standards, such as IE3 or IE4 classifications. Conducting an energy audit can identify underperforming motors and provide insight into potential savings from upgrading to more efficient models. Additionally, implementing regular maintenance schedules can ensure that motors operate optimally and prolong their lifespan. Collaborating with suppliers that offer energy management solutions can also help track performance and optimize motor usage over time, ultimately reducing operational costs.

Scenario 3: Challenges in Integrating Electric Motors with Existing Systems

The Problem: Integrating new electric motors with existing machinery or control systems can be a complex task, often leading to compatibility issues and system failures. B2B buyers may find themselves in a predicament when their new motor does not match the specifications or interfaces of their current systems, resulting in additional costs and project delays.

The Solution: To mitigate integration challenges, buyers should prioritize compatibility during the selection process. This includes verifying that the motor’s voltage, phase, and control requirements align with existing systems. Involving engineers in the early stages of the selection process can facilitate better alignment with operational needs. Additionally, buyers can explore modular motor solutions that allow for flexibility and easier integration. Working with suppliers who provide detailed technical documentation and support for integration can also streamline the process, reducing the risk of unforeseen issues. By ensuring that the new motors are compatible with existing infrastructure, buyers can save time and resources while enhancing overall operational efficiency.

Strategic Material Selection Guide for electric motor applications

What Are the Key Materials Used in Electric Motor Applications?

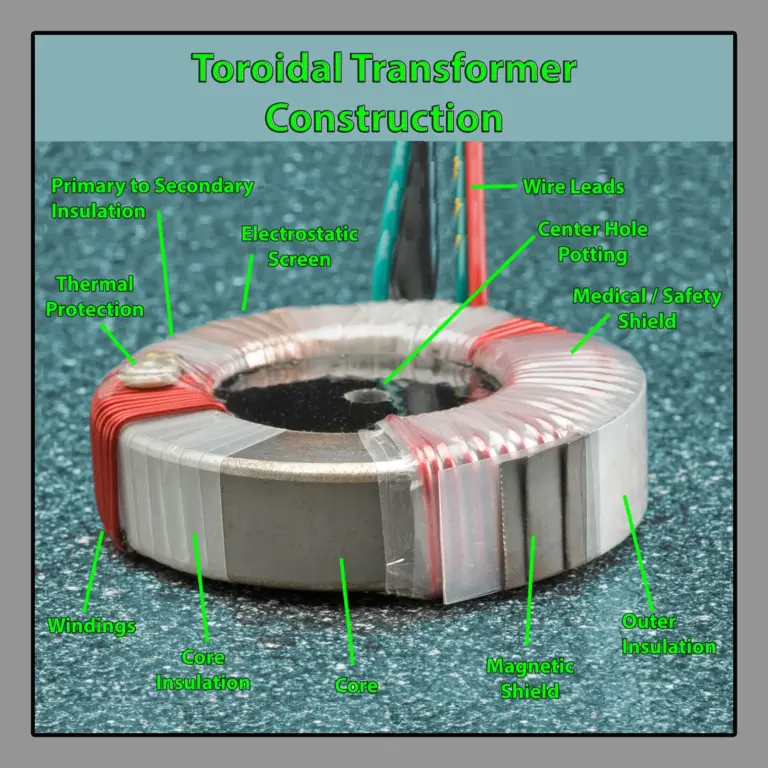

When selecting materials for electric motor applications, understanding the properties, advantages, and limitations of various materials is crucial for optimizing performance and ensuring compliance with international standards. Here, we analyze four common materials: Copper, Aluminum, Steel, and Plastic.

How Does Copper Benefit Electric Motor Applications?

Copper is widely regarded for its excellent electrical conductivity, making it a preferred choice for windings in electric motors. It has a high melting point (approximately 1,984°F or 1,085°C) and offers good corrosion resistance, which is essential for longevity in various environments.

Pros: Copper’s high conductivity allows for efficient energy transfer, reducing energy losses and improving motor performance. It is also relatively easy to work with, facilitating manufacturing processes.

Cons: The primary drawback of copper is its cost, as it is more expensive than alternatives like aluminum. Additionally, copper is heavier, which may not be suitable for applications where weight is a critical factor.

Impact on Application: Copper’s compatibility with high-temperature applications makes it ideal for motors used in industrial settings, such as HVAC and manufacturing.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM B170 and DIN 17671. In regions like Africa and the Middle East, where copper mining is prevalent, local sourcing may reduce costs.

What Role Does Aluminum Play in Electric Motors?

Aluminum is another popular material, particularly for motor casings and some winding applications. It has a lower density than copper, making it lightweight and suitable for applications where weight is a concern.

Illustrative image related to electric motor applications

Pros: Aluminum is cost-effective and offers good corrosion resistance, making it ideal for outdoor applications. Its lightweight nature can lead to energy savings in transport and installation.

Cons: While aluminum conducts electricity well, it is not as efficient as copper. Additionally, it has a lower melting point (approximately 1,221°F or 660°C), which may limit its use in high-temperature environments.

Impact on Application: Aluminum is often used in smaller motors, such as those found in household appliances and automotive applications, where weight and cost are significant factors.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B221 and JIS H4000. In South America, where aluminum production is robust, local sourcing can be advantageous.

Illustrative image related to electric motor applications

Why Is Steel Important in Electric Motor Manufacturing?

Steel is commonly used for the motor frame and rotor due to its strength and durability. It has excellent magnetic properties, which enhance the efficiency of magnetic circuits within the motor.

Pros: Steel’s high strength-to-weight ratio makes it suitable for heavy-duty applications. It is also relatively inexpensive compared to copper and aluminum.

Cons: Steel can be prone to corrosion if not properly treated, and its weight can be a disadvantage in applications requiring lightweight materials.

Impact on Application: Steel is ideal for large industrial motors used in manufacturing and material handling, where strength and durability are paramount.

Considerations for International Buyers: Compliance with standards such as ASTM A36 and DIN EN 10025 is essential. Buyers in Europe and the Middle East should consider the availability of high-quality steel products.

How Does Plastic Contribute to Electric Motor Applications?

Plastic is often used for insulation, housing, and components in electric motors. It offers good electrical insulation properties and is lightweight.

Pros: Plastics are cost-effective and can be molded into complex shapes, allowing for innovative designs. They also provide excellent resistance to moisture and chemicals.

Cons: Plastics generally have lower thermal stability compared to metals, which may limit their use in high-temperature applications. They can also be less durable under mechanical stress.

Impact on Application: Plastic is particularly useful in small motors for consumer electronics and appliances, where insulation and lightweight properties are critical.

Considerations for International Buyers: Compliance with standards such as ASTM D638 and ISO 527 is crucial. Buyers in regions with strict environmental regulations should also consider the recyclability of the plastics used.

Summary Table of Material Selection for Electric Motor Applications

| Material | Typical Use Case for electric motor applications | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings in industrial motors | Excellent conductivity | High cost and weight | High |

| Aluminum | Casings and small motor windings | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Steel | Frames and rotors in industrial motors | High strength and durability | Prone to corrosion | Low |

| Plastic | Insulation and housing for small motors | Cost-effective and lightweight | Lower thermal stability | Low |

This strategic material selection guide provides actionable insights for B2B buyers, enabling informed decisions that align with their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electric motor applications

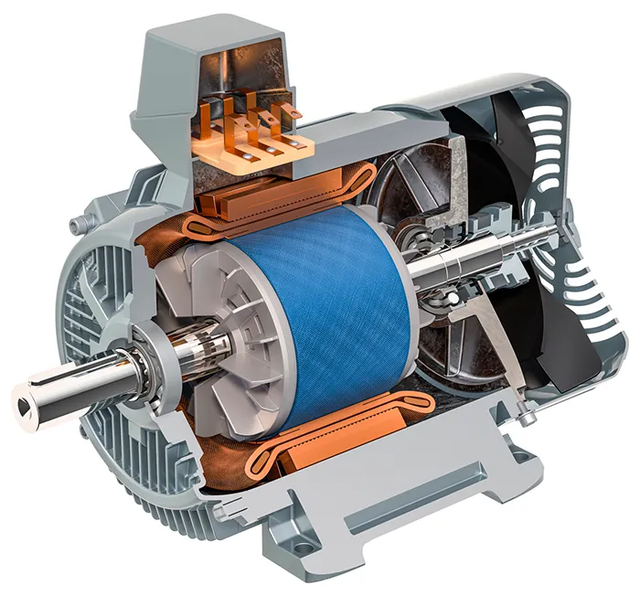

What Are the Main Stages of Electric Motor Manufacturing?

The manufacturing of electric motors is a multi-step process that involves various stages, each critical for ensuring the quality and performance of the final product. Here, we break down the primary stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Motor Production?

The first stage in electric motor manufacturing is material preparation. This involves sourcing high-quality raw materials such as copper for windings, silicon steel for laminations, and various polymers for insulation. The quality of these materials directly impacts the motor’s efficiency and longevity. Suppliers often provide certifications to ensure that materials meet industry standards, which is crucial for international buyers who may have specific compliance requirements.

What Forming Techniques Are Used in Electric Motor Manufacturing?

Once materials are prepared, the forming stage begins. This includes techniques such as stamping, machining, and winding.

-

Stamping: The silicon steel sheets are stamped into specific shapes to form the core of the motor. Precision in this step is vital, as any inaccuracies can affect magnetic performance.

-

Machining: Components like shafts and housings are machined to precise dimensions. This step often employs CNC (Computer Numerical Control) technology to achieve high accuracy.

-

Winding: The copper wire is wound into coils, which will later generate the magnetic field necessary for motor operation. This process requires skilled labor and automated machinery to ensure consistency and reliability.

How Is the Assembly Process Conducted?

The assembly stage involves bringing together all the individual components into a complete motor. This process can vary based on the motor type but generally includes:

- Coil Insertion: The wound coils are inserted into the stator or rotor.

- Mechanical Assembly: Components such as bearings, end shields, and housings are assembled. This often requires specialized tools and fixtures to maintain alignment and fit.

- Electrical Connections: Wiring is connected to ensure proper electrical flow. This step often involves meticulous testing to prevent short circuits or failures.

What Finishing Processes Are Important for Electric Motors?

The final stage is finishing, which ensures that the motor is ready for operation. This includes:

- Insulation: Applying varnish or resin to coils to protect against moisture and other environmental factors.

- Painting: Protective coatings are applied to prevent corrosion, especially for motors intended for outdoor or industrial use.

- Final Assembly: Any last components are added, and the motor undergoes a final inspection.

What Quality Assurance Processes Are Followed in Electric Motor Manufacturing?

Quality assurance (QA) is crucial in electric motor manufacturing to ensure reliability and performance. Manufacturers typically adhere to international standards such as ISO 9001, which outlines quality management principles.

What International Standards Are Relevant for Electric Motor Quality Assurance?

In addition to ISO 9001, various industry-specific standards apply, including:

- CE Certification: Required for products sold in the European market, ensuring they meet safety and environmental protection standards.

- API Standards: Relevant for motors used in oil and gas applications, focusing on reliability and safety.

These certifications not only enhance product credibility but also ensure that the manufacturer meets the necessary regulatory requirements for international markets.

What Are the Key QC Checkpoints in Electric Motor Production?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is the first step where raw materials are inspected upon arrival. Suppliers must provide certificates of conformity to ensure compliance with quality standards.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes such as stamping, winding, and assembly. This helps catch defects early in the production cycle.

-

Final Quality Control (FQC): After assembly, the complete motor undergoes rigorous testing, including electrical testing, thermal performance, and vibration analysis. Only motors that meet all specifications are packaged for shipment.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several actionable steps:

-

Supplier Audits: Conducting on-site audits of the manufacturing facility can provide insights into the production and QC processes. This allows buyers to assess compliance with international standards firsthand.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports and certifications that outline the testing and inspection processes they follow.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased evaluations of the supplier’s quality management system and product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers often face unique challenges regarding quality assurance and certification. For example:

- Regulatory Variations: Different regions may have varying regulatory requirements, making it essential for buyers to understand local compliance standards.

- Cultural Differences: Communication styles and expectations regarding quality can differ significantly across cultures, necessitating clear agreements and understanding between buyers and suppliers.

By being proactive in these areas, B2B buyers can ensure they partner with reputable manufacturers who prioritize quality in electric motor applications. This not only protects their investment but also enhances the reliability of the products they offer to their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric motor applications’

Introduction

Sourcing electric motors for various applications can be a complex process, particularly for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist to help you navigate the procurement process effectively, ensuring you select the right motor for your specific needs while minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the electric motor you need. This includes factors like the type of motor (AC or DC), power rating, torque, speed, and environmental conditions. Understanding these specifications is crucial as it directly impacts performance and compatibility with your existing systems.

- Consider application-specific needs: For instance, motors for medical equipment might require precise control, while those for HVAC systems need to handle varying loads.

- Assess energy efficiency requirements: High-efficiency motors can lead to significant energy savings and lower operational costs.

Step 2: Research Market Trends and Innovations

Stay updated on the latest advancements in electric motor technology and market trends. This knowledge can inform your sourcing decisions and provide insights into which suppliers are leading in innovation.

- Explore industry reports and publications: These resources often highlight emerging technologies and applications, helping you identify potential new suppliers.

- Attend industry conferences: Networking at these events can provide firsthand insights into the latest products and technologies.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Look for established companies with a solid reputation in the industry, and request company profiles, case studies, and references from buyers in similar sectors.

Illustrative image related to electric motor applications

- Check for industry certifications: Ensure the supplier adheres to relevant quality and safety standards, which can be critical for applications in sectors like healthcare and foodservice.

- Assess production capabilities: Understand their manufacturing processes and capacity to meet your volume and delivery timelines.

Step 4: Request Samples and Conduct Testing

Obtaining samples is a vital step to verify that the motor meets your specifications. Testing the samples under real-world conditions can reveal performance issues that may not be apparent from specifications alone.

- Evaluate performance metrics: Look at parameters such as efficiency, noise levels, and thermal management during your tests.

- Assess compatibility: Ensure that the motor integrates seamlessly with your existing systems and components.

Step 5: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, it’s time to discuss pricing and terms. Effective negotiation can lead to better pricing, payment terms, and warranty conditions.

- Consider total cost of ownership: Factor in not just the initial purchase price but also installation, maintenance, and energy costs over the motor’s lifespan.

- Request bulk pricing options: If you’re planning to order in large quantities, inquire about discounts or favorable payment terms.

Step 6: Verify Logistics and Support Services

Ensure that the supplier can provide adequate logistics support, including timely delivery and after-sales service. This is particularly important for international buyers who may face additional challenges.

- Assess shipping options: Confirm that the supplier can meet your delivery schedules, especially if you’re operating in regions with logistical challenges.

- Understand warranty and support services: Ensure that the supplier offers comprehensive support, including installation assistance and troubleshooting.

Step 7: Finalize Contracts and Place Orders

Once all terms are agreed upon, finalize the contracts and place your order. Ensure all specifications, pricing, and delivery terms are clearly documented to avoid misunderstandings.

- Review contract details carefully: Pay close attention to clauses related to warranties, liability, and dispute resolution.

- Maintain open communication: Keep lines of communication open with your supplier to address any issues that may arise during the order fulfillment process.

By following this checklist, you can streamline your sourcing process and make informed decisions that align with your business goals and operational needs.

Comprehensive Cost and Pricing Analysis for electric motor applications Sourcing

Understanding the cost structure and pricing dynamics for sourcing electric motors is crucial for international B2B buyers. This analysis delves into the components that contribute to the total cost, the influencers of pricing, and practical tips for effective negotiation and sourcing.

What Are the Key Cost Components in Electric Motor Sourcing?

When evaluating the cost of electric motors, several components should be considered:

-

Materials: The primary materials used in electric motor production, such as copper, steel, and magnets, significantly impact costs. Variations in global commodity prices can lead to fluctuations in motor pricing.

-

Labor: Labor costs can vary widely depending on the region of production. Countries with lower labor costs may offer more competitive pricing, but it’s essential to consider the skill level and expertise of the workforce.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and operational expenses of the manufacturing facility. Efficient production processes can help lower these overheads.

-

Tooling: Custom tooling for specific motor designs can add to initial costs. Buyers should weigh the need for custom tooling against the potential benefits of tailored solutions.

-

Quality Control (QC): Rigorous QC processes ensure that motors meet required specifications. However, these processes add to the overall cost. Certifications, such as ISO or UL, can enhance the quality assurance but may also increase expenses.

-

Logistics: Shipping costs, particularly for international orders, can be substantial. Factors such as distance, shipping method, and customs duties should be factored into the total cost.

-

Margin: Suppliers will typically include a margin that reflects their business model and the level of competition in the market. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Affect Electric Motor Costs?

Several factors can influence pricing beyond the basic cost structure:

-

Volume/MOQ: Purchasing in larger quantities often results in lower per-unit costs. Establishing Minimum Order Quantities (MOQs) can help buyers negotiate better pricing.

-

Specifications and Customization: Customized motors tailored to specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality: Higher-quality materials and stringent quality certifications generally lead to increased prices. However, investing in quality can reduce long-term operational costs.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers may charge a premium for reliability and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions, as they define responsibilities for shipping, insurance, and tariffs, impacting overall costs.

What Negotiation Strategies Can B2B Buyers Employ?

-

Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, consider the TCO, which includes maintenance, operational efficiency, and longevity of the electric motors. A higher initial price may yield lower long-term costs.

-

Leverage Volume Discounts: If your company has the potential for repeat orders or bulk purchases, use this leverage to negotiate better pricing.

-

Explore Alternative Suppliers: Engaging multiple suppliers can foster competitive pricing and provide options for different quality levels.

-

Be Clear About Specifications: Clearly defined requirements can minimize miscommunication and help avoid unexpected costs due to redesigns or adjustments.

-

Understand Regional Pricing Nuances: International buyers should be aware of regional price variations, influenced by local economic conditions and currency fluctuations. For instance, sourcing from suppliers in Nigeria or Saudi Arabia may offer different pricing dynamics compared to European suppliers.

Conclusion

In the complex landscape of electric motor sourcing, understanding the cost components and pricing influencers is essential for making informed purchasing decisions. By leveraging negotiation strategies and considering the total cost of ownership, B2B buyers can optimize their sourcing process and achieve cost-effective solutions tailored to their specific applications. It is important to note that prices can vary widely based on market conditions, supplier capabilities, and regional factors, so maintaining flexibility and adaptability in sourcing strategies will be beneficial.

Alternatives Analysis: Comparing electric motor applications With Other Solutions

Exploring Alternatives to Electric Motor Applications

In the quest for efficient power and motion solutions, businesses often consider various technologies beyond electric motors. Understanding these alternatives can help international B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Electric Motor Applications | Hydraulic Systems | Pneumatic Systems |

|---|---|---|---|

| Performance | High efficiency and torque, suitable for continuous operation | High power-to-weight ratio; excellent for heavy lifting | Quick response and high speed; ideal for repetitive tasks |

| Cost | Moderate initial investment with low operating costs | Higher initial costs, but lower operational costs in specific applications | Lower initial costs, but higher operational costs due to air supply |

| Ease of Implementation | Generally straightforward, with widespread support | Requires extensive installation and maintenance | Simple to set up, but requires an air compressor |

| Maintenance | Low maintenance; robust and long-lasting | Regular maintenance needed for fluid leaks and contamination | Regular maintenance for compressor and hoses; risk of air leaks |

| Best Use Case | Ideal for applications requiring precise control and efficiency | Best for heavy machinery and construction | Best for assembly lines and tools needing rapid actuation |

What Are the Pros and Cons of Hydraulic Systems as an Alternative?

Hydraulic systems utilize pressurized fluid to transmit power, making them highly effective for heavy lifting and machinery operation. Their primary advantage lies in their ability to generate substantial force relative to their size, which is invaluable in construction and manufacturing settings. However, hydraulic systems come with higher initial costs and require meticulous maintenance to prevent leaks and ensure system integrity. For industries focused on heavy-duty applications, the investment may be justified, but it may not be suitable for every operational context.

How Do Pneumatic Systems Compare to Electric Motors?

Pneumatic systems, powered by compressed air, are renowned for their rapid actuation capabilities, making them ideal for tasks requiring speed and repetitive motion, such as in assembly lines. Their initial setup costs are generally lower than hydraulic systems, and they can be easier to implement due to their simpler designs. However, the ongoing operational costs can be significant due to the need for continuous air supply and maintenance of the air compressor and hoses. While they excel in specific applications, pneumatic systems may not match the efficiency and precision of electric motors in more controlled environments.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting between electric motors and alternative solutions like hydraulic and pneumatic systems, B2B buyers should carefully consider their specific application requirements, budget constraints, and maintenance capabilities. Electric motors offer versatility, efficiency, and lower operational costs, making them suitable for a wide range of industries. Conversely, hydraulic systems are better suited for heavy lifting, while pneumatic systems excel in speed. Ultimately, the right choice hinges on aligning the technology’s strengths with the operational demands and financial considerations of the business.

Illustrative image related to electric motor applications

Essential Technical Properties and Trade Terminology for electric motor applications

What Are the Key Technical Properties of Electric Motors for B2B Buyers?

When sourcing electric motors for various applications, understanding essential technical properties is crucial. Here are some of the most significant specifications that B2B buyers should consider:

1. Power Rating (Horsepower or Watts)

The power rating indicates the motor’s ability to perform work. It is expressed in horsepower (HP) or watts (W). Selecting the appropriate power rating is essential for ensuring that the motor can handle the intended load without overheating or failing. B2B buyers must align the motor’s power rating with the specific needs of their applications to maximize efficiency and longevity.

2. Efficiency Rating

Efficiency refers to how effectively an electric motor converts electrical energy into mechanical energy, often expressed as a percentage. Higher efficiency ratings lead to lower operational costs and reduced energy consumption. For buyers in regions with high energy costs, selecting a motor with a high efficiency rating can result in significant savings over time.

Illustrative image related to electric motor applications

3. Torque Characteristics

Torque is the rotational force generated by the motor, typically measured in pound-feet (lb-ft) or Newton-meters (Nm). Understanding the torque characteristics is vital for applications requiring specific starting or running torque levels. For instance, motors used in conveyor systems may need high starting torque to overcome inertia, while others may require consistent running torque for steady operations.

4. Operating Temperature Range

The operating temperature range defines the conditions under which the motor can function effectively. This is particularly important for applications in extreme environments, such as those found in the Middle East or Africa. Motors with a wider temperature range can operate reliably across various climates, reducing the risk of thermal damage and prolonging service life.

5. Material Grade

The materials used in electric motors, including housing, windings, and bearings, can significantly impact performance and durability. Common materials include aluminum and steel for housings, while copper is typically used for windings due to its excellent conductivity. Buyers should assess material grades to ensure they meet industry standards and are suitable for their specific applications.

6. IP Rating (Ingress Protection)

The IP rating indicates the motor’s resistance to dust and water ingress. An IP rating of IP65, for example, means the motor is dust-tight and protected against water jets. This is crucial for applications in harsh environments, such as outdoor installations or industrial settings. Selecting a motor with an appropriate IP rating ensures reliability and reduces maintenance costs.

What Are Common Trade Terms Used in Electric Motor Procurement?

Understanding trade terminology is equally important for B2B buyers when negotiating and purchasing electric motors. Here are some commonly used terms:

Illustrative image related to electric motor applications

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In electric motors, OEMs often provide custom solutions tailored to specific application requirements. B2B buyers may engage with OEMs to ensure compatibility and performance in their unique projects.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs to align with their project needs and avoid excess stock or insufficient supply.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. B2B buyers should prepare detailed RFQs that include technical specifications and quantities to receive accurate quotes, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers clarify shipping costs, risks, and responsibilities. Familiarity with relevant Incoterms can prevent misunderstandings and ensure smooth logistics.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. It is a critical factor for project planning and inventory management. Buyers should communicate lead time expectations with suppliers to ensure timely delivery and avoid project delays.

Incorporating these technical properties and trade terms into procurement strategies can enhance decision-making and ensure that electric motors meet specific application requirements effectively.

Navigating Market Dynamics and Sourcing Trends in the electric motor applications Sector

What Are the Key Trends Shaping the Electric Motor Applications Market?

The electric motor applications market is experiencing significant growth driven by several global factors. The increasing demand for energy-efficient solutions across various sectors is propelling the adoption of electric motors, particularly in emerging markets such as Africa, South America, and the Middle East. Industries are rapidly transitioning from traditional mechanical systems to electric alternatives, which are not only cost-effective but also offer better performance and reliability. For example, the automotive sector is seeing a shift towards electric vehicles, which require advanced electric motor systems, creating a lucrative opportunity for B2B buyers.

Emerging technologies such as IoT and AI are transforming electric motor applications. The integration of smart technologies in electric motors allows for real-time monitoring and predictive maintenance, enhancing operational efficiency. B2B buyers are increasingly looking for suppliers who offer motors with integrated sensors and connectivity features, enabling seamless data collection and analysis. Moreover, the rise of automation in manufacturing and material handling is driving demand for specialized electric motors that can support complex applications.

In international markets, particularly in regions like Nigeria and Saudi Arabia, there is a growing emphasis on localized production and sourcing. Buyers are seeking suppliers who can deliver customized solutions tailored to regional needs, while also ensuring compliance with local regulations. This trend is prompting manufacturers to establish partnerships with local businesses to improve supply chain efficiency and reduce lead times.

How Is Sustainability Influencing B2B Sourcing in Electric Motor Applications?

Sustainability has become a core consideration for B2B buyers in the electric motor applications sector. The environmental impact of electric motors, particularly in terms of energy consumption and waste generation, is prompting companies to seek more sustainable sourcing options. Buyers are increasingly prioritizing suppliers who utilize eco-friendly materials and manufacturing processes. This shift is not just about compliance; it’s about enhancing brand reputation and meeting consumer demand for greener products.

Ethical sourcing is also gaining traction, with an emphasis on transparency in supply chains. B2B buyers are more inclined to partner with suppliers who can demonstrate responsible sourcing practices, including fair labor conditions and minimized environmental impact. Certifications such as ISO 14001 for environmental management and ISO 50001 for energy management are becoming essential criteria for supplier selection. By choosing partners with these certifications, buyers can ensure that their sourcing decisions align with their corporate sustainability goals.

Furthermore, innovations in materials such as recyclable components and energy-efficient designs are increasingly favored. Electric motor manufacturers are investing in research and development to create motors that not only meet performance standards but also contribute to a circular economy. This approach not only reduces environmental impact but also appeals to a growing segment of eco-conscious consumers.

What Is the Historical Context of Electric Motors in B2B Applications?

The evolution of electric motors dates back to the early 19th century, with the invention of the first practical electric motor by Michael Faraday and Joseph Henry. Initially, electric motors were limited to niche applications due to high costs and technological constraints. However, the 20th century marked a turning point with the advent of mass production techniques and the expansion of electrical infrastructure. This allowed electric motors to penetrate various industries, from manufacturing to transportation.

In recent decades, the push for automation and energy efficiency has further accelerated the adoption of electric motors. The global energy crisis of the 1970s spurred interest in electric motors as a means to reduce reliance on fossil fuels. Today, advancements in materials science and electronic controls have led to the development of more efficient and versatile electric motors, expanding their applications in sectors such as renewable energy and electric mobility.

For B2B buyers, understanding the historical context of electric motors is crucial for recognizing the technological advancements that have shaped current sourcing trends. This knowledge helps buyers make informed decisions when selecting suppliers who are not only technologically adept but also aligned with the future trajectory of electric motor applications.

Frequently Asked Questions (FAQs) for B2B Buyers of electric motor applications

-

How do I select the right electric motor for my application?

Selecting the right electric motor involves understanding the specific requirements of your application, such as power, torque, speed, and operational environment. Begin by evaluating the load characteristics and any constraints such as size, weight, and energy efficiency. Consider the type of motor (AC, DC, or specialized) that best fits your needs. Collaborate with suppliers to discuss custom solutions if standard options do not meet your specifications. Additionally, reviewing motor performance curves and obtaining prototypes for testing can be beneficial in making an informed decision. -

What is the best type of electric motor for industrial applications?

For industrial applications, AC induction motors are typically the best choice due to their reliability, efficiency, and lower maintenance requirements. They are suitable for various tasks, including driving pumps, fans, and conveyors. In contrast, DC motors may be preferable for applications requiring precise speed control or high starting torque. Evaluate the specific demands of your application, such as load type and operational conditions, to determine the ideal motor type. Consulting with motor specialists can also provide insights tailored to your industry. -

What customization options are available for electric motors?

Customization options for electric motors can include variations in voltage, power output, speed, and physical dimensions to fit specific applications. Additionally, manufacturers may offer features such as enhanced insulation for extreme temperatures, specific mounting configurations, or integrated controls for automation. It’s essential to communicate your exact requirements to potential suppliers, as they can often accommodate custom requests or design solutions that meet unique operational needs. -

What are the typical minimum order quantities (MOQs) for electric motors?

Minimum order quantities (MOQs) for electric motors can vary widely based on the supplier and the complexity of the motor design. Standard motors may have lower MOQs, often starting at 10 to 50 units, while custom-designed motors might require larger quantities to justify the production costs. When negotiating with suppliers, discuss your volume needs and explore options for smaller orders, especially if you are testing a new application or market. -

How can I ensure quality assurance when sourcing electric motors?

To ensure quality assurance when sourcing electric motors, it is crucial to partner with reputable manufacturers who adhere to international quality standards, such as ISO 9001. Request detailed product specifications, certifications, and test reports to validate the motor’s performance and reliability. Conducting factory audits or third-party inspections can also be beneficial. Additionally, consider trial orders to evaluate the motor’s performance in real-world conditions before committing to larger purchases. -

What payment terms should I expect when sourcing electric motors internationally?

Payment terms for international sourcing of electric motors can vary significantly based on the supplier, region, and order size. Common arrangements include advance payment, letter of credit, or net payment terms (e.g., net 30 or net 60 days). It’s essential to negotiate terms that align with your cash flow and risk management strategies. Ensure that all agreements are documented in the purchase contract to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing electric motors?

When importing electric motors, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with international shipping and customs processes to streamline the importation. Evaluate the total landed cost, including tariffs, taxes, and insurance. Additionally, ensure that the supplier provides proper documentation to facilitate smooth customs clearance, and plan for any potential delays in transit. -

How do I vet potential suppliers of electric motors?

Vetting potential suppliers of electric motors requires thorough research and due diligence. Start by checking their company credentials, certifications, and industry reputation through reviews and references. Assess their production capabilities, quality control processes, and compliance with international standards. Engaging in direct communication can provide insights into their customer service and responsiveness. If possible, request samples or visit their facilities to evaluate their operations firsthand before making a commitment.

Top 6 Electric Motor Applications Manufacturers & Suppliers List

1. IQS Directory – Electric Motors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Electric motors convert electrical energy into mechanical energy, generating torque through a magnetic field created by electric current in wire coils. They can be powered by DC or AC sources and categorized by power supply type, usage, construction, and output type. Key components include the stator (stationary part), rotor (moving part), field magnets, armature, bearings, and commutator. Motors …

2. Electronics For You – Electric Motors

Domain: electronicsforu.com

Registered: 1997 (28 years)

Introduction: This company, Electronics For You – Electric Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Electric Motors – Types and Applications

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: Electric Motors Types and Applications: 1. AC Motors: Overview – Simple, reliable, cost-effective. Types – Induction Motors (household appliances, industrial machinery, HVAC systems), Synchronous Motors (precise control in robotics, conveyor systems). Applications – Fans, pumps, compressors, conveyors. 2. DC Motors: Overview – Speed control and efficiency. Types – Brushed DC Motors (small applianc…

4. Aspina Group – Electric Motors

Domain: us.aspina-group.com

Registered: 2019 (6 years)

Introduction: Electric motors are devices that convert electrical energy into mechanical energy, typically in the form of rotational motion. They are categorized into various types based on current flow, coil design, and magnetic field generation. Key types include:

1. DC Motors: Driven by a DC power supply, can be brushed or brushless.

2. AC Motors: Driven by an AC power supply, can be single-phase (capacito…

5. Nature – Electric Motor Advancements

Domain: nature.com

Registered: 1994 (31 years)

Introduction: Title: The Electric Motor and its Applications

Author: Silvanus P. Thompson

Published: 03 March 1887

Publisher: Johnson, New York

Volume: 35

Pages: 410-411

Key Features:

– Discusses the rapid advancements in the industrial application of electric motors over the past six years.

– Highlights the advantages of electric motors over steam and gas engines, including lower maintenance, space efficiency…

6. TVT America – Linear Actuators

Domain: tvtamerica.net

Registered: 2010 (15 years)

Introduction: This company, TVT America – Linear Actuators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for electric motor applications

How Can Strategic Sourcing Enhance Your Electric Motor Supply Chain?

In the rapidly evolving landscape of electric motor applications, strategic sourcing emerges as a critical component for businesses seeking to optimize their operations. With a diverse range of applications—from medical equipment to industrial machinery—understanding the specific needs of your sector is paramount. By leveraging strategic sourcing, companies can not only reduce costs but also enhance product quality and reliability, ensuring that they stay competitive in their respective markets.

Illustrative image related to electric motor applications

As international B2B buyers in regions such as Africa, South America, the Middle East, and Europe increasingly demand efficient and durable electric motors, it is essential to partner with suppliers who can offer customized solutions tailored to local market conditions. This approach fosters innovation and drives operational efficiency, enabling businesses to harness the full potential of electric motors in various applications.

Looking ahead, the demand for electric motors is poised for significant growth, driven by advancements in technology and increasing automation across industries. Now is the time to evaluate your sourcing strategies and align with suppliers who can meet your evolving needs. Engage with us to explore how we can support your sourcing requirements and drive your business forward in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to electric motor applications

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.