Elastic Chord: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for elastic chord

In the dynamic landscape of global trade, sourcing high-quality elastic chord can pose significant challenges for international B2B buyers. Whether you are looking for durable solutions for outdoor equipment, crafting materials, or industrial applications, understanding the diverse types of elastic chords available is crucial. This comprehensive guide will delve into the various applications, materials, and specifications of elastic chord, equipping you with the knowledge to make informed purchasing decisions.

From the resilience of nylon and polyester options to the flexibility required for specific projects, our guide covers essential factors such as supplier vetting, cost analysis, and best practices for procurement. Buyers from Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—will find tailored insights that address regional demands and market trends.

By exploring the intricacies of elastic chord sourcing, you will be empowered to navigate the complexities of the global market effectively. This resource aims not only to simplify your purchasing process but also to enhance your product offerings, ensuring you meet the varied needs of your clientele. Whether you are in the crafting, outdoor, or industrial sectors, our guide serves as your roadmap to successful procurement strategies in the elastic chord market.

Understanding elastic chord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bungee Cord | High elasticity, durable nylon or polyester sheath | Cargo securing, outdoor sports gear | Pros: Strong, versatile, weather-resistant. Cons: May stretch over time with heavy loads. |

| Round Elastic Cord | Circular cross-section, ideal for garments | Apparel manufacturing, accessories | Pros: Comfortable stretch, easy to sew. Cons: Limited load capacity compared to bungee cords. |

| Flat Elastic Cord | Flat profile, offers even distribution of tension | Crafts, sewing, and DIY projects | Pros: Excellent for wider applications, less bulk. Cons: Not suitable for heavy-duty use. |

| Polyester Elastic Cord | Made from polyester, resistant to UV and rot | Industrial applications, outdoor gear | Pros: Long-lasting, UV resistant. Cons: Can be less flexible than rubber-based cords. |

| Specialty Elastic Cord | Customizable features (color, thickness) | Niche markets like fashion and design | Pros: Tailored to specific needs, unique aesthetics. Cons: Higher cost, longer lead times. |

What are the Key Characteristics of Bungee Cords for B2B Buyers?

Bungee cords are renowned for their high elasticity and robust durability, typically featuring a nylon or polyester sheath that protects the inner elastic core. They are ideal for securing cargo in transportation and outdoor sports gear, making them a preferred choice for businesses in logistics and recreation. When considering bungee cords, buyers should evaluate their load capacity and potential for stretching over time, especially under heavy loads. This ensures that the product meets the specific demands of their applications.

How Do Round Elastic Cords Benefit Apparel Manufacturing?

Round elastic cords feature a circular cross-section, providing excellent stretch and comfort, making them particularly suitable for the apparel industry. They are commonly used in clothing production, such as pants and blouses, as well as accessories like bags. For B2B buyers in fashion, the ease of sewing and the ability to maintain shape are significant advantages. However, it’s essential to consider their limited load capacity, which may not be suitable for applications requiring heavy-duty support.

What Makes Flat Elastic Cords Ideal for Crafting and DIY Projects?

Flat elastic cords offer a unique flat profile that allows for even distribution of tension, making them an excellent choice for crafts, sewing, and DIY projects. Their versatility is a significant selling point for businesses involved in retail and handmade goods. Buyers should appreciate the reduced bulkiness, which can be advantageous for intricate designs. However, flat cords may not hold up under heavy-duty applications, so understanding the intended use is crucial.

Why Choose Polyester Elastic Cords for Industrial Applications?

Polyester elastic cords are crafted from durable polyester, providing superior resistance to UV rays and rot, making them ideal for outdoor applications. Industries that require long-lasting, weather-resistant products, such as construction and outdoor gear manufacturing, will find these cords particularly beneficial. Buyers should weigh the longevity and UV resistance against the potential trade-off of flexibility compared to rubber-based options, ensuring they select the right material for their needs.

How Do Specialty Elastic Cords Cater to Niche Markets?

Specialty elastic cords can be customized in terms of color, thickness, and material properties, catering to niche markets such as fashion and design. This customization allows businesses to differentiate their products and meet specific customer preferences. While the tailored features can be a significant advantage, buyers should be aware of the potentially higher costs and longer lead times associated with custom orders. Understanding market demand and timing is essential for making informed purchasing decisions.

Key Industrial Applications of elastic chord

| Industry/Sector | Specific Application of Elastic Chord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Securing cargo in transport vehicles | Reduces damage during transit, enhancing customer satisfaction | Durability against UV and weather, load capacity requirements |

| Outdoor Recreation | Gear attachment in camping and hiking equipment | Increases reliability and safety of outdoor gear | Weather-resistant materials, elasticity specifications |

| Textile and Apparel | Waistbands and garment closures | Provides comfort and flexibility in clothing | Material composition, compliance with safety regulations |

| Construction | Temporary securing of tarps and equipment | Ensures job site safety and organization | Tensile strength, resistance to environmental factors |

| Medical Supplies | Use in face masks and medical garments | Enhances comfort and fit for users | Biocompatibility, stretchability, and durability requirements |

How is Elastic Chord Used in the Automotive Industry?

In the automotive sector, elastic chord is widely utilized for securing cargo in transport vehicles. This application is crucial for preventing damage during transit, which can lead to costly claims and dissatisfaction among customers. Buyers in this industry must prioritize sourcing durable elastic chord that can withstand varying weather conditions and UV exposure, ensuring longevity and effectiveness. Additionally, load capacity specifications are essential to accommodate different types of cargo securely.

What Role Does Elastic Chord Play in Outdoor Recreation?

Elastic chord is integral to outdoor recreation, particularly in camping and hiking equipment. It is used for attaching gear, securing tents, and even in backpacks, enhancing the reliability and safety of outdoor activities. For B2B buyers in this sector, sourcing elastic chord that is resistant to weather elements and UV rays is vital, as it directly affects the performance and safety of outdoor gear. Buyers should also consider the elasticity and stretch capabilities to meet diverse application needs.

How is Elastic Chord Beneficial in Textile and Apparel Manufacturing?

In the textile and apparel industry, elastic chord is commonly used in waistbands and closures for garments. Its ability to provide comfort and flexibility enhances the wearer’s experience, making it a preferred choice for manufacturers. When sourcing elastic chord for this application, businesses should focus on the material composition to ensure compliance with safety regulations, as well as the specific stretch characteristics required for different garment types. This attention to detail can significantly impact product quality and marketability.

What is the Importance of Elastic Chord in Construction?

Elastic chord finds significant applications in the construction industry, particularly for temporarily securing tarps and equipment on job sites. This usage ensures safety and organization, reducing the risk of accidents and improving operational efficiency. Buyers in this sector need to prioritize tensile strength and resistance to environmental factors when sourcing elastic chord, as these attributes determine its effectiveness in demanding conditions. Additionally, understanding the specific requirements for different construction applications is crucial for optimal performance.

How is Elastic Chord Utilized in Medical Supplies?

In the medical field, elastic chord is employed in face masks and medical garments to enhance comfort and fit. This application is particularly important in ensuring that medical supplies are both functional and user-friendly. For international B2B buyers, sourcing elastic chord that meets biocompatibility standards and offers the necessary stretchability and durability is essential. Compliance with health regulations is also a critical consideration, as it impacts the safety and effectiveness of medical products.

3 Common User Pain Points for ‘elastic chord’ & Their Solutions

Scenario 1: Ensuring Durability in Outdoor Applications

The Problem: Many B2B buyers in sectors such as construction, logistics, and outdoor events face challenges with elastic cords that fail prematurely in harsh environmental conditions. The cords may degrade due to UV exposure, moisture, or extreme temperatures, leading to unexpected failures. This not only disrupts operations but can also pose safety risks if securing critical loads or equipment.

The Solution: To mitigate these issues, buyers should prioritize sourcing elastic cords with UV-resistant and weatherproof materials, such as those coated with a durable nylon or polyester sheath. When specifying these products, look for cords that are explicitly labeled as suitable for outdoor use. Additionally, consider the environmental conditions where the cords will be used and choose products with a higher denier count for added strength and durability. For example, a 5mm nylon elastic cord may perform better in outdoor settings compared to a thinner option. Regularly inspect the cords for signs of wear and replace them proactively to ensure ongoing safety and reliability.

Scenario 2: Difficulty in Sizing and Compatibility for Custom Projects

The Problem: Buyers often struggle with the challenge of selecting the right diameter and elasticity of the cord for specific applications, especially in custom manufacturing or crafting. Choosing an incorrect size can lead to inadequate performance, where the cord either does not provide enough stretch or is too loose, compromising the integrity of the final product.

The Solution: To address sizing issues, buyers should conduct thorough assessments of the intended application before purchasing elastic cords. Measure the required length and consider the specific stretch requirements of the project. For instance, when working on apparel or fabric goods, it’s beneficial to test different diameters (e.g., 2mm vs. 4mm) to determine the best fit. Additionally, buyers can request samples from suppliers to evaluate elasticity and strength in real-world conditions before committing to larger orders. Collaborating with manufacturers who offer customizable options, such as varying lengths and diameters, can also provide tailored solutions that meet unique project specifications.

Scenario 3: Managing Supply Chain and Quality Control Issues

The Problem: Supply chain disruptions can lead to delays in receiving elastic cords, which impacts production schedules and project timelines. Furthermore, inconsistencies in quality can arise from different suppliers, resulting in variability in performance and reliability, which is particularly concerning for B2B buyers who rely on uniformity across their products.

The Solution: To enhance supply chain reliability, buyers should establish partnerships with reputable manufacturers known for consistent quality and timely delivery. It is advisable to conduct thorough due diligence, including assessing supplier certifications and past performance metrics. Implementing a just-in-time inventory system can help manage stock levels effectively and reduce the risk of over-purchasing or stockouts. Additionally, consider integrating quality control measures such as third-party inspections or testing of batches upon arrival to ensure that the cords meet the required specifications. Regular communication with suppliers can also facilitate better management of any potential disruptions, allowing for proactive solutions.

Strategic Material Selection Guide for elastic chord

What Are the Key Materials for Elastic Chord and Their Properties?

When selecting elastic chords for various applications, understanding the properties and suitability of different materials is crucial for B2B buyers. Here, we analyze four common materials used in the manufacturing of elastic chords: rubber, polyester, nylon, and latex. Each material has unique characteristics that influence performance, durability, and cost.

How Does Rubber Perform in Elastic Chord Applications?

Rubber is a traditional choice for elastic chords due to its excellent elasticity and flexibility. It can withstand a wide range of temperatures, typically from -40°C to 70°C, making it suitable for both indoor and outdoor applications. However, rubber is susceptible to degradation from UV exposure and ozone, which can limit its lifespan in outdoor environments.

Pros: Rubber is highly elastic and provides good tensile strength, making it ideal for applications requiring significant stretch. It is also relatively inexpensive compared to other materials.

Cons: The main drawback is its susceptibility to environmental factors, which can lead to premature failure. Additionally, rubber can be less durable than synthetic alternatives, particularly in harsh conditions.

Illustrative image related to elastic chord

For international buyers, compliance with ASTM standards is essential, particularly in regions like Europe and North America, where quality assurance is paramount.

What Advantages Does Polyester Offer for Elastic Chord Manufacturing?

Polyester is increasingly popular for elastic chords due to its high resistance to UV light and moisture. It maintains its strength and elasticity over time, withstanding temperatures from -20°C to 100°C. Polyester chords are often used in applications like outdoor gear, automotive, and industrial settings.

Pros: The durability of polyester against environmental factors makes it a reliable choice for long-term use. It is also resistant to abrasion and has a lower tendency to stretch out over time.

Illustrative image related to elastic chord

Cons: Polyester can be more expensive than rubber and may require more complex manufacturing processes. In addition, while it is moisture-resistant, it can absorb some water, which may affect performance in certain applications.

B2B buyers should be aware of compliance with international standards such as DIN and ISO, particularly in Europe, where quality and safety are heavily regulated.

How Does Nylon Compare as a Material for Elastic Chord?

Nylon is another strong contender for elastic chords, known for its high tensile strength and resistance to abrasion. It performs well in a temperature range of -40°C to 90°C and is particularly valued for its resilience in demanding applications.

Pros: Nylon’s strength and flexibility make it suitable for heavy-duty applications, including industrial and outdoor uses. It also has good resistance to chemicals and can handle varying loads effectively.

Cons: The main disadvantage of nylon is its susceptibility to UV degradation, which can limit its use in prolonged outdoor applications without proper treatment. Additionally, nylon can be more expensive than rubber and polyester.

International buyers should consider the specific compliance requirements in their regions, as different countries may have varying standards for nylon products.

What Role Does Latex Play in Elastic Chord Applications?

Latex is often used in specialized applications where high elasticity and stretchability are required. It is capable of withstanding temperatures from -20°C to 60°C but is sensitive to UV exposure and ozone, similar to rubber.

Pros: Latex offers exceptional elasticity and is ideal for applications needing significant stretch, such as in medical and fitness products. It is also relatively cost-effective.

Cons: The main limitation of latex is its reduced durability in outdoor environments, as it can degrade quickly when exposed to sunlight and harsh weather conditions.

For B2B buyers, understanding the specific regulations regarding latex products, especially in medical applications, is crucial, as compliance with health and safety standards is mandatory.

Illustrative image related to elastic chord

Summary Table of Material Properties for Elastic Chord

| Material | Typical Use Case for elastic chord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General-purpose applications, indoor/outdoor use | High elasticity and flexibility | Susceptible to UV degradation | Low |

| Polyester | Outdoor gear, automotive, industrial applications | Durable, UV and moisture resistant | More expensive, complex manufacturing | Medium |

| Nylon | Heavy-duty applications, industrial uses | High tensile strength and abrasion resistance | UV degradation, higher cost | Medium |

| Latex | Medical products, fitness equipment | Exceptional elasticity | Limited outdoor durability | Low |

This comprehensive analysis of materials for elastic chords provides B2B buyers with the insights needed to make informed purchasing decisions, ensuring that they select the most suitable product for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for elastic chord

What Are the Main Stages in the Manufacturing Process of Elastic Cord?

The manufacturing process of elastic cord involves several critical stages that ensure the final product meets the necessary performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in manufacturing elastic cord is the selection and preparation of raw materials. Typically, a combination of natural and synthetic fibers, such as rubber, polyester, or nylon, is used. These materials are sourced based on their elasticity, durability, and resistance to environmental factors like UV radiation and moisture. Before the manufacturing process begins, the materials undergo testing to confirm they meet specific quality standards.

-

Forming: In this stage, the prepared materials are transformed into elastic strands. The rubber core, which provides the elasticity, is surrounded by a woven sheath made of polyester or nylon. This sheath protects the core from external damage while also providing additional strength. Techniques such as braiding or twisting the fibers are often employed to enhance the structural integrity of the cord.

-

Assembly: Once the forming process is complete, the elastic strands are cut to the desired lengths and assembled into coils or spools. This stage may also include adding specific features, such as hooks or loops, depending on the intended use of the elastic cord. Attention to detail during assembly is crucial to ensure consistency in product dimensions and performance.

-

Finishing: The final stage involves treating the elastic cord to enhance its performance characteristics. This may include applying coatings to improve resistance to rot, UV light, and chemicals, as well as conducting further quality checks. The finishing process is essential to ensure that the elastic cord is ready for diverse applications, from outdoor activities to industrial uses.

How is Quality Assurance Implemented in Elastic Cord Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that the final product meets both international standards and customer expectations. The QA process typically involves adherence to recognized standards, multiple checkpoints, and thorough testing methods.

-

International Standards Compliance: Manufacturers of elastic cord often adhere to international quality standards such as ISO 9001, which focuses on quality management systems, and industry-specific standards like CE marking for European markets. Compliance with these standards assures B2B buyers that the products are manufactured consistently and meet safety requirements.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are established throughout the manufacturing process, typically categorized as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC: At this stage, raw materials are inspected upon receipt to ensure they meet specifications before production begins.

- IPQC: During manufacturing, various parameters such as dimensions, elasticity, and tensile strength are monitored. This ensures any deviations from quality standards are detected early.

- FQC: The final product undergoes rigorous testing before shipping. This may include evaluating elasticity, durability, and environmental resistance.

- Common Testing Methods for Quality Assurance: Manufacturers employ various testing methods to verify the quality of elastic cord. These include:

- Tensile Testing: Measures the maximum load the elastic cord can withstand before breaking.

- Elongation Testing: Assesses how much the cord can stretch before it reaches its breaking point.

- UV Resistance Testing: Determines how well the cord withstands exposure to ultraviolet light over time.

- Rot Resistance Testing: Evaluates the cord’s durability in humid or wet conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers maintain rigorous quality control processes. Here are several actionable steps to verify supplier QC:

-

Conducting Audits: Regular audits of the manufacturing facilities can provide insights into the supplier’s adherence to quality standards. Buyers should request access to audit reports and verify the supplier’s compliance with ISO certifications.

-

Requesting Quality Control Reports: Suppliers should be able to provide detailed QC reports that outline testing procedures, results, and any corrective actions taken for non-conformities. These documents serve as proof of the supplier’s commitment to quality.

-

Engaging Third-party Inspectors: In some cases, hiring third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control processes. These agencies can perform inspections at various stages of production and provide detailed reports on compliance with quality standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of several nuances when it comes to quality control for elastic cord:

-

Cultural Differences: Understanding the cultural context of suppliers can influence communication and expectations regarding quality. Buyers should be prepared to navigate different business practices and standards across regions.

-

Regulatory Variations: Each region may have specific regulatory requirements that affect the quality standards for elastic cord. Buyers must ensure their suppliers comply with local regulations, which may differ significantly from international standards.

-

Supply Chain Transparency: Ensuring transparency within the supply chain can help buyers assess the quality of materials and processes used in production. Buyers should prioritize suppliers who are willing to share information about their sourcing and manufacturing practices.

-

Flexibility in Specifications: Given the diverse applications of elastic cord, B2B buyers should communicate their specific quality requirements clearly. This includes discussing any industry-specific standards that may apply to their intended use.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing elastic cord, ensuring they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘elastic chord’

To assist B2B buyers in successfully sourcing elastic chord, this guide outlines a systematic approach that ensures you make informed decisions while procuring this versatile product. Elastic chord, commonly used in various applications, requires careful consideration of technical specifications, supplier capabilities, and compliance standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical to ensure that the elastic chord meets your project requirements. Consider factors such as diameter, material composition (e.g., nylon or polyester), elasticity, and intended use (e.g., for crafting, outdoor activities, or industrial applications). Specificity in these areas will help you communicate effectively with suppliers and avoid costly mistakes.

Step 2: Research Market Trends and Applications

Understanding current market trends and applications for elastic chord can provide insights into your procurement strategy. Investigate how different industries utilize elastic chord, from textiles to outdoor equipment, and identify any emerging applications. This knowledge can help you position your business competitively and ensure you are sourcing products that meet market demand.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is essential to conduct a thorough evaluation. Request company profiles, production capabilities, and references from other businesses in your sector. Look for suppliers who have experience with your specific application of elastic chord and verify their reputation through customer reviews and case studies.

Illustrative image related to elastic chord

- Check Certifications: Ensure that suppliers have relevant certifications that demonstrate compliance with international quality and safety standards, such as ISO or ASTM.

- Assess Production Capacity: Confirm that the supplier can meet your order quantities and delivery timelines, especially if you anticipate fluctuating demand.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the elastic chord to test its performance. This step is crucial to ensure that the product meets your specifications in real-world applications. Evaluate the samples for elasticity, durability, and resistance to environmental factors such as UV exposure and moisture.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, enter into negotiations regarding pricing and terms. Discuss minimum order quantities, payment terms, and shipping costs. Ensure that you understand all aspects of the pricing structure, including any additional fees for customization or expedited shipping.

- Consider Long-Term Partnerships: If you anticipate ongoing needs, discuss the potential for long-term contracts, which can lead to better pricing and reliability in supply.

Step 6: Finalize the Contract and Place Your Order

After agreeing on terms, finalize the contract with clear stipulations regarding quality standards, delivery schedules, and penalties for non-compliance. This legal document serves as protection for both parties and ensures accountability. Once the contract is signed, proceed to place your order.

Step 7: Monitor Delivery and Quality Control

Upon receiving your order, conduct a thorough inspection of the elastic chord to ensure it meets the agreed-upon specifications. Implement quality control measures to verify that the product performs as expected in your applications. Address any discrepancies immediately with the supplier to resolve issues effectively.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing elastic chord efficiently and confidently, ensuring that their procurement decisions align with their business needs and market demands.

Comprehensive Cost and Pricing Analysis for elastic chord Sourcing

Analyzing the cost structure and pricing for elastic chord sourcing is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. Understanding the various cost components and price influencers can significantly enhance negotiation strategies and cost-efficiency.

What are the Key Cost Components in Elastic Chord Manufacturing?

The cost structure for elastic chords typically comprises several components:

-

Materials: The primary materials used in elastic chords include rubber, polyester, and nylon. The choice of material significantly affects the overall cost, with premium materials yielding higher durability and resistance to environmental factors like UV radiation and rot.

-

Labor: Labor costs can vary based on the region and the complexity of the manufacturing process. In regions with higher labor costs, such as Western Europe, the overall price may be impacted, while lower labor costs in countries like Vietnam may offer price advantages.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can help minimize overhead costs, which in turn can influence pricing.

-

Tooling: Initial investments in tooling for specialized production can be substantial. For custom or specialized elastic chords, these costs are amortized over the production volume, impacting unit pricing.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes adds to production costs. Certifications for quality (e.g., ISO standards) can also influence pricing, as suppliers may charge a premium for certified products.

-

Logistics: Transportation costs, including shipping and handling, play a crucial role in the total cost structure. This is particularly relevant for international buyers, where freight costs and customs duties can vary significantly.

-

Margin: Suppliers typically add a profit margin to cover their business costs and ensure sustainability. This margin can vary based on market conditions and competition.

What Influences Pricing for Elastic Chords?

Several factors can influence the pricing of elastic chords:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often attract discounts. Suppliers may offer better pricing for larger quantities, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Custom designs or specifications can lead to higher prices due to additional material and labor costs. Buyers should weigh the benefits of customization against their budget.

-

Materials and Quality Certifications: Higher-quality materials and certifications can justify a higher price point. Buyers should evaluate the trade-off between cost and product longevity.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more, while emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: The terms of trade (e.g., FOB, CIF) can significantly affect the total landed cost. Understanding these terms is crucial for accurately calculating the overall expense.

What Buyer Tips Can Enhance Cost-Efficiency in Elastic Chord Sourcing?

-

Negotiate Wisely: Leverage volume purchases and long-term relationships to negotiate better pricing. Don’t hesitate to ask for discounts based on order size or recurring business.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial price but the long-term costs associated with maintenance, replacement, and performance. A slightly higher upfront cost for better quality can lead to savings over time.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local taxes that can impact the final cost. Keeping abreast of market trends in the supplier’s region can also provide negotiation leverage.

-

Request Samples: Before placing large orders, request samples to assess quality and ensure that the product meets specifications. This can prevent costly mistakes down the line.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. A reliable supplier may be more willing to accommodate specific needs and provide favorable pricing structures over time.

Disclaimer

Pricing for elastic chords can vary widely based on the aforementioned factors. The information provided serves as a general guideline and should not be considered as fixed prices. Buyers are encouraged to conduct thorough market research and supplier assessments to obtain accurate and up-to-date pricing information.

Alternatives Analysis: Comparing elastic chord With Other Solutions

When evaluating solutions for elastic needs in various applications, it’s essential to consider alternatives that can offer similar benefits. This analysis compares elastic chord against two viable alternatives: bungee cords and polyester elastic bands. Each option presents distinct features that can cater to different requirements in the B2B space.

| Comparison Aspect | Elastic Chord | Bungee Cord | Polyester Elastic Band |

|---|---|---|---|

| Performance | High elasticity, durable, versatile for various uses | Excellent stretch and hold, ideal for heavy-duty tasks | Good stretch, designed for lighter applications |

| Cost | Moderate cost per meter | Generally higher due to robust construction | Low cost, budget-friendly option |

| Ease of Implementation | Simple to use in various projects | Requires proper anchoring for effectiveness | Easy to sew or attach in crafts |

| Maintenance | Low maintenance, resistant to UV and rot | Requires periodic inspection for wear | Minimal maintenance needed, but can degrade over time |

| Best Use Case | Ideal for crafts, light-duty tasks | Perfect for securing heavy loads, outdoor activities | Best for sewing, crafting, and lightweight applications |

What are the Advantages and Disadvantages of Bungee Cords Compared to Elastic Chord?

Bungee cords are renowned for their heavy-duty capabilities, making them suitable for securing larger items such as tarps or luggage during transport. Their construction typically allows for greater stretch and load-bearing capacity, which is beneficial for outdoor applications. However, their bulkier design may not be ideal for smaller, intricate projects where precision is needed. Additionally, bungee cords require proper anchoring, which may complicate their use in some scenarios.

How Do Polyester Elastic Bands Compare to Elastic Chord?

Polyester elastic bands are often favored for sewing and crafting due to their lightweight nature and affordability. They can be easily integrated into fabric projects, making them an excellent choice for apparel and accessories. However, they may not provide the same level of durability or stretch as elastic chords or bungee cords, limiting their use to lighter applications. Furthermore, while they are low-maintenance, their lifespan may be shorter under heavy use or exposure to harsh conditions.

How Can B2B Buyers Choose the Right Elastic Solution?

When selecting the appropriate elastic solution, B2B buyers should assess their specific application needs. Consider factors such as the weight of the items being secured, the environment in which the product will be used, and the level of durability required. For heavy-duty applications, bungee cords may be the best option, while elastic chords offer versatility for a range of lighter tasks. Polyester elastic bands are an excellent choice for cost-effective crafting needs. By carefully evaluating these elements, businesses can make informed decisions that align with their operational requirements and budget constraints.

Illustrative image related to elastic chord

Essential Technical Properties and Trade Terminology for elastic chord

What Are the Key Technical Properties of Elastic Chord?

Understanding the essential technical properties of elastic chord is vital for B2B buyers looking to select the right product for their applications. Below are critical specifications that influence performance, durability, and suitability for various uses.

1. Material Composition

Elastic cords are typically made from a blend of rubber and synthetic fibers like polyester or nylon. This combination ensures flexibility and strength, making the cord resistant to wear and environmental factors such as UV light and moisture. For B2B buyers, selecting the right material is crucial for ensuring longevity and reliability in end-use applications.

2. Diameter and Tolerance

Elastic cords come in various diameters ranging from 1mm to over 10mm. The diameter affects the cord’s strength and stretchability; smaller diameters are suitable for lightweight applications, while larger ones are used for heavy-duty tasks. Tolerance specifications indicate the allowable deviation from the stated diameter, which can impact the performance and fit in specific applications, especially in manufacturing and assembly processes.

3. Elasticity and Load Capacity

The elasticity of a cord refers to its ability to stretch and return to its original length. This property is crucial for applications requiring flexibility, such as in securing loads or providing tension. Load capacity, often measured in pounds or kilograms, indicates how much weight the cord can handle without breaking. For B2B buyers, understanding these metrics ensures that the selected elastic chord can withstand the intended use without failure.

4. Weather Resistance and Durability

Elastic cords designed for outdoor use are often treated to resist rot, UV degradation, and extreme temperatures. This durability is important for applications in harsh environments, such as construction, camping, or marine uses. Selecting weather-resistant materials can significantly reduce replacement costs and improve overall operational efficiency.

5. Color and Finish

While it may seem superficial, the color and finish of elastic chords can play a role in branding and aesthetics, particularly for consumer products. Additionally, certain finishes can enhance durability or provide additional resistance to abrasion or chemicals. B2B buyers should consider these aspects to align with their branding strategies and product requirements.

What Are Common Trade Terms Associated with Elastic Chord?

Familiarity with industry-specific jargon is essential for effective communication in B2B transactions. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing elastic chord, understanding whether the supplier is an OEM can help buyers ensure they are getting authentic, high-quality products designed for specific applications.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for B2B buyers to manage inventory and costs effectively. A lower MOQ can be advantageous for smaller businesses or those looking to test products before committing to larger orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. When purchasing elastic chord, submitting an RFQ helps buyers compare prices, terms, and delivery options across multiple suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps B2B buyers manage shipping costs, risks, and responsibilities effectively, ensuring smooth logistics when sourcing elastic chord from global suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Knowing the lead time is critical for B2B buyers to plan production schedules and manage inventory effectively, minimizing disruptions in their supply chain.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right elastic chord for their specific needs while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the elastic chord Sector

What Are the Key Trends Driving the Elastic Cord Market?

The elastic cord market is experiencing significant growth driven by several global factors. The increasing demand for versatile materials in various industries, including outdoor gear, fashion, and construction, is a primary driver. As urbanization rises, particularly in regions like Africa and South America, the need for robust and flexible materials for transportation and logistics is on the rise. Additionally, advancements in manufacturing technologies are enabling the production of high-quality elastic cords with enhanced durability and performance characteristics.

Emerging trends such as the rise of e-commerce are reshaping sourcing strategies for international buyers. B2B platforms are becoming essential for connecting manufacturers with buyers globally, streamlining the procurement process. Companies are increasingly leveraging data analytics to forecast demand and optimize inventory management, allowing for more responsive supply chains. This shift not only improves efficiency but also enables businesses to meet the diverse needs of customers across different regions, including the Middle East and Europe.

Furthermore, the focus on customization is growing, with buyers seeking tailored solutions that cater to specific applications, from crafting to industrial uses. This trend emphasizes the importance of supplier relationships, as manufacturers must be agile and responsive to meet evolving customer demands.

How Is Sustainability Influencing Elastic Cord Sourcing?

Sustainability is becoming a pivotal concern in the elastic cord sector, driving buyers to prioritize ethical sourcing practices. The environmental impact of materials used in elastic cords, particularly synthetic options like polyester and nylon, is under scrutiny. Buyers are increasingly looking for suppliers who utilize eco-friendly materials and sustainable manufacturing processes.

The importance of ethical supply chains cannot be overstated. B2B buyers are now more aware of the social implications of their sourcing decisions, seeking partners who adhere to fair labor practices and contribute positively to local communities. This shift is particularly pronounced in markets like Europe, where regulatory frameworks are evolving to support sustainable business practices.

To align with these values, suppliers are beginning to offer products certified by recognized green standards. These certifications not only enhance brand reputation but also provide buyers with confidence in the sustainability claims of their suppliers. By prioritizing ‘green’ materials and ethical sourcing, businesses can not only meet regulatory requirements but also cater to the growing consumer demand for environmentally responsible products.

What Is the Historical Context of Elastic Cord Development?

The evolution of elastic cord technology has been marked by significant advancements since its inception. Originally used in simple applications, elastic cords have expanded into a wide array of industries due to their versatility. The development of synthetic materials in the mid-20th century transformed the market, enabling manufacturers to produce stronger and more durable cords that resist environmental factors such as UV exposure and rot.

Illustrative image related to elastic chord

As consumer preferences shifted towards more functional and aesthetically pleasing products, innovations in design and material composition emerged. Modern elastic cords are now available in various diameters, colors, and compositions, catering to diverse applications from crafting to heavy-duty industrial use. This evolution reflects a broader trend towards customization and specialization, allowing B2B buyers to find products that meet their specific needs more effectively.

Understanding these dynamics is essential for international buyers looking to navigate the complexities of the elastic cord market successfully. By leveraging insights into market trends, sustainability practices, and historical context, businesses can make informed sourcing decisions that align with both operational goals and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of elastic chord

-

How do I solve issues with elastic cord durability?

To enhance the durability of elastic cords, consider sourcing products with a nylon or polyester outer sheath, as these materials provide resistance against UV rays and rot. It’s essential to inquire about the specific manufacturing processes and quality standards upheld by your suppliers. Conducting regular quality assurance checks during production can also help mitigate issues. Additionally, ensure that the cords are suitable for the intended application, whether for outdoor use or crafting, as this influences their longevity. -

What is the best type of elastic cord for outdoor applications?

For outdoor applications, bungee cords made from nylon or polyester are ideal due to their strength and resistance to environmental factors. Look for cords with a thicker diameter, as they typically offer greater tensile strength and durability. Additionally, verify that the cords are UV-resistant and have a robust construction to withstand varying weather conditions. Request samples from suppliers to assess performance before making a bulk purchase. -

How can I vet suppliers for elastic cords?

When vetting suppliers, start by researching their industry reputation and experience. Request references from previous clients to gauge reliability and quality. Verify their certifications and compliance with international quality standards, such as ISO 9001. Conduct site visits if possible, or ask for virtual tours of their manufacturing facilities to assess their production capabilities and quality control processes. Additionally, consider suppliers who offer transparent communication and responsive customer service. -

What customization options are available for elastic cords?

Many suppliers offer customization options for elastic cords, including variations in diameter, color, and material composition. You can also request specific lengths or packaging methods tailored to your business needs. Discuss your requirements with potential suppliers and request samples to ensure they can meet your specifications. It’s advisable to confirm minimum order quantities (MOQs) for customized products, as these may differ from standard offerings. -

What are typical minimum order quantities (MOQs) for elastic cords?

Minimum order quantities (MOQs) for elastic cords can vary significantly by supplier and product type. Generally, MOQs may range from 100 meters to several thousand, depending on the customization and materials required. When negotiating with suppliers, clarify the MOQs upfront to avoid unexpected costs. Some suppliers may be flexible with MOQs for first-time orders or trial runs, so it’s worth discussing your specific needs. -

What payment terms should I expect when sourcing elastic cords internationally?

Payment terms can differ widely among suppliers, but common practices include payment in advance, a 30% deposit with the balance due before shipping, or net 30 to 60 days after delivery. When engaging with suppliers, ensure that you discuss and agree upon the payment terms that align with your cash flow needs. Using secure payment methods like letters of credit or escrow services can provide additional protection for international transactions. -

How do I ensure quality assurance for my elastic cord orders?

To ensure quality assurance, establish clear specifications and standards before placing orders. Request samples to evaluate the materials and elasticity of the cords. Implement a third-party inspection service to conduct quality checks during and after production. Additionally, maintain open communication with your supplier throughout the manufacturing process to address any potential issues promptly. Document all quality standards and agreements to hold suppliers accountable. -

What logistics considerations should I keep in mind when importing elastic cords?

When importing elastic cords, consider factors such as shipping methods, lead times, and customs regulations in your country. Choose reliable freight forwarders experienced in handling your type of goods. Understand the incoterms (e.g., FOB, CIF) that will dictate shipping responsibilities. It’s also crucial to prepare for potential tariffs and taxes that may apply to your import. Collaborating with logistics experts can help streamline the import process and reduce delays.

Top 6 Elastic Chord Manufacturers & Suppliers List

1. Paracord Planet – High Quality Elastic Cords

Domain: paracordplanet.com

Registered: 2011 (14 years)

Introduction: High Quality Elastic Cords in Various Sizes; Free Standard Shipping on Orders of $8.99+ (US ONLY); Available Sizes: 1/32″ Elastic Cord, 1/16″ Elastic Cord; Price Range: $3.99 – $72.99; Variations include multiple colors such as White, Black, Royal Blue, Neon Yellow, Camo Green, Silver Gray, Charcoal Gray, Federal Standard Navy Blue, Purple, Goldenrod, Neon Pink, Imperial Red, Red, Orange, Brown; E…

2. Rope and Cord – Bungee Cord

Domain: ropeandcord.com

Registered: 2017 (8 years)

Introduction: Bungee Cord is designed for flexibility, stretch, and versatility, suitable for various projects such as tying down tarps, tents, or objects in a truck bed. Ideal for camping, fishing, hiking, and home use in garages or shops. The nylon jacket provides resistance against rot and UV fade, ensuring durability. Available sizes include: 1/8″ Nylon Shock Cord (20 Inner Rubber Strands) – $0.48, 3/16″ Ny…

3. Paracord.shop – Elastic Cord Solutions

Domain: paracord.shop

Introduction: Elastic cord is a versatile and durable material used for various applications. It is available in different sizes and strengths, making it suitable for crafting, outdoor activities, and securing items. The cord is stretchable, allowing for flexibility and ease of use. It can be used in projects such as making bracelets, securing tarps, or creating custom bungee cords. The elastic cord is often so…

4. Hobby Lobby – Round Elastic Cord

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Round Elastic Cord”, “SKU”: “794958”, “Original Price”: “$1.99”, “Color”: “Black”, “Length”: “5 Yards”, “Content”: “50% Polyester & 50% Rubber”, “Description”: “Stretch your creativity with Round Elastic Cord! Perfect for adding to pants, blouses, skirts, bags, and more, this elastic will add stretch and comfort to your creations. This light, stretchy elastic cord can be used for…

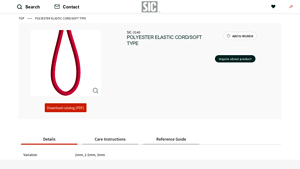

5. SICEN – POLYESTER ELASTIC CORD/SOFT TYPE

Domain: sicen.shindo.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “POLYESTER ELASTIC CORD/SOFT TYPE”, “model”: “SIC-3140”, “material”: “100% Polyester (with rubber thread)”, “processing_method”: “Yarn Dyeing”, “available_sizes”: [“2mm”, “2.5mm”, “3mm”], “minimum_lot”: “ROLL: 50m”, “care_instructions”: {“washing_temperature_limit”: “30℃”, “machine_wash”: “weak operation”, “bleach”: “non-chlorine bleach”, “tumble_dry”: “not allowed”, “drying_metho…

6. West Coast Paracord – Black 1/16 Elastic Cord

Domain: westcoastparacord.com

Registered: 2014 (11 years)

Introduction: {‘name’: ‘Black – 1/16 Elastic Cord’, ‘brand’: ‘West Coast Paracord’, ‘price’: ‘$2.99’, ‘sku’: ‘116EC-BLACK’, ‘upc’: ‘719574453302’, ‘maximum_purchase’: ’10 units’, ‘available_lengths’: [’10 Feet’, ’25 Feet’, ’50 Feet’, ‘100 Feet’, ‘1300 Feet’], ‘description’: ‘1/16″ elastic cord has a braided sleeve and an elastic inner core. It\’s perfect if you\’re looking for a smaller bungee shock cord that a…

Strategic Sourcing Conclusion and Outlook for elastic chord

What Are the Key Benefits of Strategic Sourcing for Elastic Cord?

In the dynamic landscape of global trade, effective strategic sourcing of elastic cord is essential for businesses seeking to optimize cost, quality, and supply chain efficiency. By leveraging strong supplier relationships and understanding regional market variations, international buyers from Africa, South America, the Middle East, and Europe can secure high-quality elastic cords that meet diverse application needs—from crafting and apparel to industrial uses.

How Can International Buyers Enhance Their Sourcing Strategies?

Investing in strategic sourcing not only enhances product quality but also fosters innovation and sustainability. With a variety of materials and specifications available, businesses can customize their procurement processes to align with operational requirements. Collaborating with suppliers who prioritize durability and resistance to environmental factors will ensure long-term reliability and performance of elastic cord products.

Illustrative image related to elastic chord

What is the Future Outlook for the Elastic Cord Market?

Looking ahead, the elastic cord market is poised for growth, driven by increasing demand across multiple sectors. Buyers are encouraged to stay informed about emerging trends and technological advancements that could influence sourcing decisions. By engaging in proactive sourcing strategies and embracing flexibility, businesses can navigate market shifts and capitalize on new opportunities.

Take the next step in optimizing your sourcing strategy for elastic cord—connect with reliable suppliers today and position your business for success in the evolving global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to elastic chord

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.