Drum Fuel: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for drum fuel

In an increasingly competitive global market, sourcing drum fuel efficiently and reliably can present significant challenges for B2B buyers, particularly those operating across diverse regions such as Africa, South America, the Middle East, and Europe. With the rise in fuel prices and fluctuating regulations, understanding the intricacies of drum fuel types—ranging from gasoline and diesel to specialized racing fuels—is crucial for making informed purchasing decisions. This comprehensive guide delves into various fuel types, their applications across industries, and essential considerations for supplier vetting, cost analysis, and logistics management.

By providing detailed insights into the characteristics of different fuels, alongside practical advice on how to evaluate suppliers effectively, this guide aims to empower international buyers to navigate the complexities of the drum fuel market with confidence. Whether you are a distributor looking to expand your product offerings or a manufacturer seeking consistent fuel supply, the information contained herein is designed to streamline your procurement process.

Ultimately, this guide equips businesses with the knowledge necessary to optimize their fuel sourcing strategies, ensuring that they not only meet operational demands but also achieve cost efficiency and compliance with local regulations. Embrace the opportunity to enhance your purchasing strategies and fuel your business growth with informed decision-making.

Understanding drum fuel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Unleaded Gasoline | High octane, low emissions, suitable for various engines | Automotive, machinery, and industrial use | Pros: Widely available, lower cost. Cons: May require specific handling and storage protocols. |

| Ethanol Blends | Contains ethanol, promoting cleaner combustion | Racing, automotive, and renewable energy | Pros: Higher octane rating, eco-friendly. Cons: Potential for moisture absorption and system compatibility issues. |

| Diesel | High energy content, suitable for heavy-duty engines | Transportation, agriculture, and construction | Pros: Efficient fuel economy, robust supply chain. Cons: Higher emissions, regulatory concerns in some regions. |

| Methanol | High purity, used in racing and specific industrial applications | Racing, chemical production, and energy | Pros: High performance in racing, cost-effective. Cons: Toxicity concerns, specific handling requirements. |

| Nitromethane | Specialized fuel with high energy output for racing | Motorsports and specialized applications | Pros: Exceptional performance, high power output. Cons: Costly, requires specialized storage and handling. |

What Are the Characteristics of Unleaded Gasoline in Drum Fuel?

Unleaded gasoline is a staple in the fuel market, characterized by its high octane rating and low emissions. It is commonly used in a variety of engines, including automotive and industrial machinery. For B2B buyers, it’s crucial to consider the availability of this fuel type, as it is widely accessible and typically less expensive than other options. However, proper storage and handling procedures must be followed to prevent contamination and ensure compliance with environmental regulations.

How Do Ethanol Blends Differ from Traditional Fuels?

Ethanol blends, such as E85, contain a significant percentage of ethanol, making them a popular choice in racing and renewable energy sectors. These fuels offer higher octane ratings, enhancing engine performance and promoting cleaner combustion. B2B buyers should assess the compatibility of their equipment with ethanol blends, as moisture absorption can lead to operational issues. While these fuels are more eco-friendly, they may require adjustments to fuel systems for optimal performance.

What Are the Benefits of Using Diesel in Drum Fuel?

Diesel fuel is known for its high energy content, making it an ideal choice for heavy-duty applications in transportation, agriculture, and construction. B2B buyers appreciate the fuel’s efficiency and robust supply chain. However, they must also consider the environmental regulations that may affect diesel usage in certain regions. While diesel engines offer excellent fuel economy, the associated emissions can be a concern, prompting some businesses to explore cleaner alternatives.

Why Choose Methanol for Industrial and Racing Applications?

Methanol is a highly pure fuel that is often used in racing and chemical production. It provides excellent performance characteristics, making it a cost-effective option for high-speed applications. For B2B buyers, it’s essential to be aware of the toxicity concerns associated with methanol, necessitating stringent handling protocols. Despite these challenges, its affordability and performance advantages make it a viable option for businesses involved in competitive racing or specialized industrial processes.

What Makes Nitromethane a Specialized Choice for Motorsports?

Nitromethane is a specialized fuel that delivers exceptional performance and high power output, primarily used in motorsports. Its unique properties allow for rapid combustion, making it ideal for racing applications. However, B2B buyers must consider the higher costs associated with nitromethane and the need for specialized storage and handling solutions. This fuel type is not suitable for general use, which limits its market but enhances its appeal among serious racing teams looking for a competitive edge.

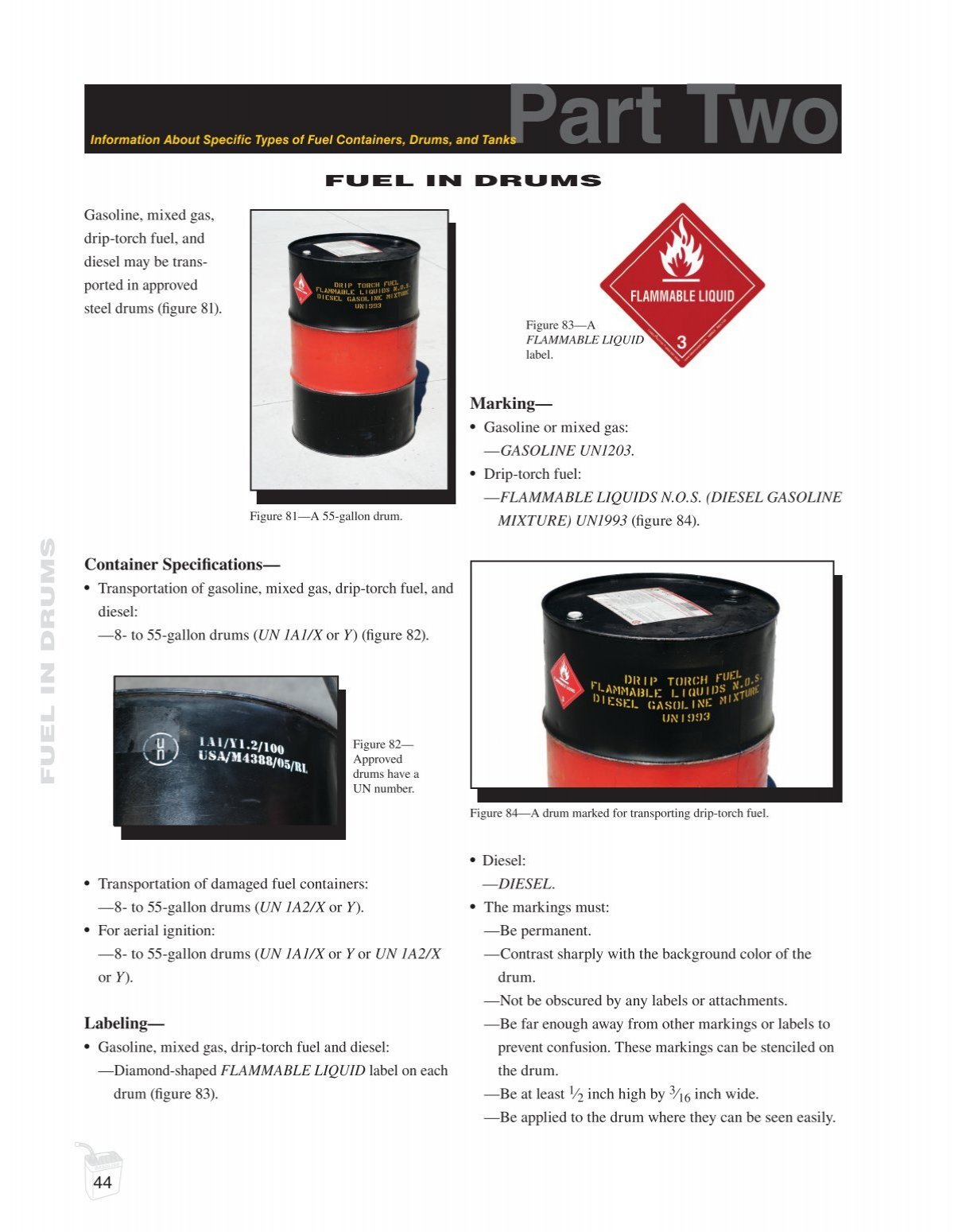

Illustrative image related to drum fuel

Key Industrial Applications of drum fuel

| Industry/Sector | Specific Application of drum fuel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Racing | High-performance racing fuel | Enhances engine performance and reliability in racing events | Consistency in fuel formulation, compliance with regulations |

| Agriculture | Fuel for farm machinery and equipment | Ensures efficient operation of tractors and harvesters | Availability of bulk supply, compatibility with equipment |

| Construction | Fuel for heavy machinery | Powers equipment like excavators and generators | Quality assurance, local sourcing options |

| Marine Transport | Fuel for commercial vessels | Supports long-distance travel and operational efficiency | Compliance with maritime fuel regulations, storage solutions |

| Power Generation | Fuel for backup generators | Provides reliable energy supply during outages | Delivery logistics, storage capacity, and safety measures |

How is Drum Fuel Used in Automotive Racing?

In the automotive racing sector, drum fuel plays a crucial role as high-performance racing fuel. This specialized fuel is designed to maximize engine output and efficiency, allowing vehicles to achieve optimal speeds during competitive events. The use of consistent formulations, such as those with high octane ratings, ensures that engines perform reliably under extreme conditions. Buyers in this sector must prioritize sourcing fuels that comply with racing regulations and provide detailed technical specifications to avoid performance issues.

What Role Does Drum Fuel Play in Agriculture?

In agriculture, drum fuel is essential for powering farm machinery, including tractors, harvesters, and irrigation systems. Reliable fuel supply ensures that these machines operate efficiently, directly impacting productivity and crop yields. Buyers should consider the availability of bulk fuel delivery options and the compatibility of the fuel with various machinery types. Additionally, sourcing from local suppliers can reduce transportation costs and ensure timely deliveries, particularly during critical planting and harvesting seasons.

How is Drum Fuel Utilized in Construction?

The construction industry relies heavily on drum fuel to power heavy machinery such as excavators, bulldozers, and generators. These machines require a steady supply of fuel to maintain operational efficiency on job sites. Businesses benefit from using high-quality fuels that minimize engine wear and reduce downtime. When sourcing drum fuel, construction companies should focus on quality assurance and consider local suppliers who can meet their logistical needs, ensuring that fuel is available when and where it is needed.

What is the Importance of Drum Fuel in Marine Transport?

In the marine transport sector, drum fuel is vital for commercial vessels, including cargo ships and fishing boats. It supports long-distance travel and operational efficiency, as ships require large quantities of fuel for extended voyages. Compliance with maritime fuel regulations, such as sulfur content limits, is critical for international shipping operations. Buyers should also evaluate storage solutions to manage the bulk fuel effectively, ensuring safety and adherence to environmental standards.

How Does Drum Fuel Support Power Generation?

Drum fuel is extensively used in backup generators for power generation, providing a reliable energy source during outages. This is particularly important for businesses that rely on continuous power supply to maintain operations. When sourcing drum fuel for power generation, companies must consider delivery logistics, storage capacity, and safety measures to prevent spills and leaks. Ensuring a consistent supply of high-quality fuel can significantly enhance the reliability of backup energy systems, safeguarding against potential business disruptions.

3 Common User Pain Points for ‘drum fuel’ & Their Solutions

Scenario 1: Inconsistent Quality of Drum Fuel Deliveries

The Problem: One major challenge faced by B2B buyers, especially in regions like Africa and South America, is the inconsistent quality of drum fuel deliveries. Buyers often receive fuel that does not meet the required specifications, leading to equipment malfunctions, reduced efficiency, and costly downtime. This inconsistency can stem from a lack of quality control during the production and transportation processes, leaving buyers frustrated and financially impacted.

The Solution: To mitigate this issue, it is essential to establish strong relationships with reputable suppliers who adhere to strict quality control standards. Conduct thorough research on potential suppliers, including checking for certifications and industry reputation. Additionally, buyers should request samples before placing large orders, allowing them to test for compliance with local regulations and performance benchmarks. Implementing a quality assurance protocol, including regular audits and feedback loops with suppliers, can further ensure that the drum fuel received consistently meets the required standards.

Scenario 2: Regulatory Compliance Challenges with Drum Fuels

The Problem: Navigating regulatory compliance is a significant pain point for businesses dealing with drum fuel, particularly in regions with stringent environmental regulations, like Europe and the Middle East. Buyers must ensure that the fuels they procure comply with local and international standards, which can be complex and time-consuming. Failure to comply can result in hefty fines, operational delays, and potential harm to the company’s reputation.

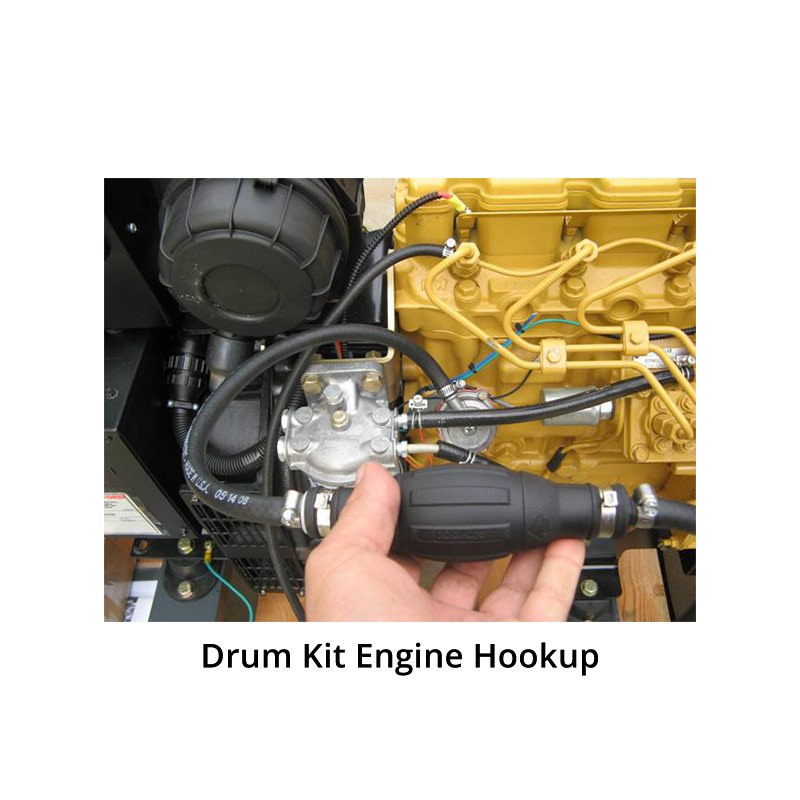

Illustrative image related to drum fuel

The Solution: To effectively manage compliance, buyers should stay informed about the latest regulations affecting their industry and region. This can be achieved by subscribing to relevant industry publications or joining professional associations. Additionally, working closely with suppliers who have a robust compliance track record can significantly ease the burden. Buyers should request documentation that proves the fuel’s compliance with local laws and consider utilizing third-party testing services for verification. Establishing a compliance checklist that outlines necessary documentation and periodic reviews can streamline the procurement process and reduce the risk of non-compliance.

Scenario 3: High Shipping Costs and Delivery Delays

The Problem: Many B2B buyers face the challenge of high shipping costs and delivery delays when sourcing drum fuel, particularly when dealing with international suppliers. These issues can disrupt operational timelines, leading to project delays and increased costs. Buyers in remote or underserved regions may experience even more significant delays, which can critically impact their business continuity.

The Solution: To address shipping costs and delays, buyers should explore multiple sourcing options, including local suppliers, to reduce transportation distances and costs. Establishing a network of suppliers across different regions can provide flexibility and backup options during peak demand times. Additionally, negotiating bulk purchasing agreements with suppliers can lead to better shipping rates. Implementing a robust inventory management system that tracks fuel usage and forecasts needs can also help in planning purchases more effectively, ensuring timely deliveries without incurring excess shipping costs. Finally, utilizing technology, such as GPS tracking for shipments, can provide real-time updates on delivery status, enabling proactive management of supply chain issues.

Strategic Material Selection Guide for drum fuel

When selecting materials for drum fuel, it is crucial to consider various factors that influence performance, compatibility, and regulatory compliance. Below is an analysis of four common materials used in drum fuel applications, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Steel Drums for Drum Fuel?

Steel drums are widely used for transporting and storing various types of fuels. They typically feature a high-temperature and pressure rating, making them suitable for volatile substances. Steel is inherently resistant to many chemicals, which enhances its durability in harsh environments.

Pros: Steel drums are robust and can withstand significant impact and pressure. They also offer excellent sealing capabilities, reducing the risk of leaks and contamination.

Cons: The primary drawback is susceptibility to corrosion if not properly coated or maintained, especially in humid or saline environments. Additionally, steel drums can be heavier and more expensive than alternatives like plastic.

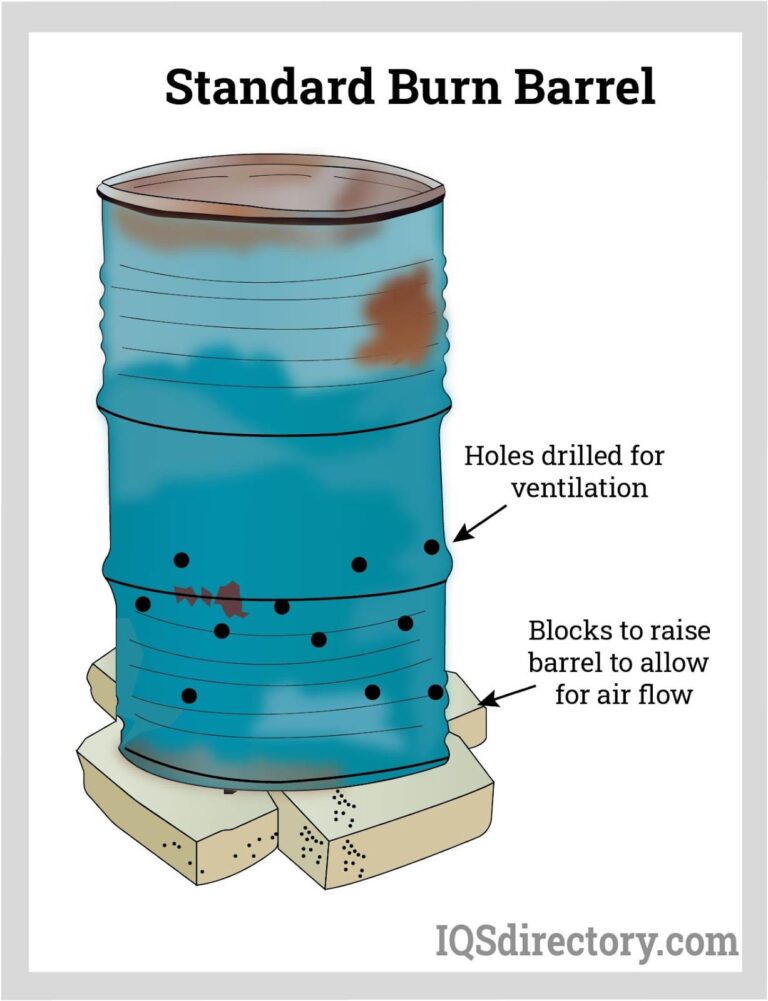

Illustrative image related to drum fuel

Impact on Application: Steel drums are compatible with a wide range of fuels, including diesel, gasoline, and ethanol blends. However, their weight can affect shipping costs and handling.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is essential. Buyers in regions with high humidity, like parts of Africa and South America, should ensure proper coatings to prevent corrosion.

How Do Plastic Drums Compare for Storing Drum Fuel?

Plastic drums, often made from high-density polyethylene (HDPE), are another popular option for drum fuel. They are lightweight and resistant to many chemicals, making them suitable for various fuel types.

Illustrative image related to drum fuel

Pros: The lightweight nature of plastic drums reduces shipping costs. They are also resistant to corrosion and do not rust, which is advantageous for long-term storage.

Cons: Plastic drums may not withstand high temperatures or pressures as well as steel. They can also be more susceptible to UV degradation, which can limit their lifespan if exposed to direct sunlight.

Impact on Application: Plastic drums are ideal for non-corrosive fuels and chemicals but may not be suitable for high-temperature applications.

Considerations for International Buyers: Buyers should check for compliance with local regulations regarding fuel storage. In regions like the Middle East, where temperatures can soar, it’s critical to ensure that the plastic can withstand extreme conditions.

What Are the Advantages of Fiber Drums for Drum Fuel Applications?

Fiber drums, often made from recycled materials, are a more eco-friendly option for storing drum fuel. They are lightweight and can be designed for specific applications.

Illustrative image related to drum fuel

Pros: Fiber drums are biodegradable and recyclable, making them an environmentally friendly choice. They are also lightweight, which can reduce transportation costs.

Cons: They generally have lower durability compared to steel or plastic drums and may not be suitable for all fuel types, especially those that are corrosive or volatile.

Impact on Application: Fiber drums are best suited for non-hazardous materials and less volatile fuels. Their permeability can be a concern for certain applications.

Considerations for International Buyers: Buyers should ensure that fiber drums meet local safety and environmental standards. In Europe, for example, compliance with DIN standards is crucial.

Why Are Stainless Steel Drums Preferred for Certain Drum Fuels?

Stainless steel drums are often used for high-value or sensitive materials, including specialty fuels. They provide superior corrosion resistance and durability.

Pros: Stainless steel drums are highly resistant to corrosion and can handle a wide range of temperatures and pressures. They are also easy to clean and maintain, making them suitable for repeated use.

Cons: The primary disadvantage is cost; stainless steel drums are significantly more expensive than their plastic or fiber counterparts.

Impact on Application: Their durability and chemical resistance make them ideal for storing high-purity fuels and chemicals.

Considerations for International Buyers: Buyers should consider the cost-benefit ratio, especially in regions with budget constraints. Compliance with international standards is also a must, particularly in regulated markets like Germany.

Summary Table of Material Selection for Drum Fuel

| Material | Typical Use Case for drum fuel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Diesel, gasoline, ethanol | High durability and pressure resistance | Susceptible to corrosion | Medium |

| Plastic | Non-corrosive fuels | Lightweight and corrosion-resistant | Limited high-temperature resistance | Low |

| Fiber | Non-hazardous materials | Eco-friendly and lightweight | Lower durability for volatile fuels | Low |

| Stainless Steel | High-value or sensitive fuels | Superior corrosion resistance | High cost | High |

This guide aims to assist international B2B buyers in making informed decisions regarding drum fuel material selection, taking into account the unique challenges and requirements of their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for drum fuel

What Are the Main Stages in the Manufacturing Process of Drum Fuel?

The manufacturing process for drum fuel involves several critical stages that ensure the product’s quality and compliance with international standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality raw materials, which may include hydrocarbons, alcohols, or other chemical compounds. Suppliers often utilize rigorous testing to ensure that the materials meet specified purity and performance standards. For instance, ethanol used in racing fuels should be of a specific grade to ensure consistent performance.

-

Forming: In this stage, the raw materials are combined according to precise formulations. Advanced blending techniques are employed to achieve the desired chemical properties, such as octane rating or oxygen content. This process may involve using specialized equipment that ensures accurate measurements and homogeneity in the final product.

-

Assembly: Once the fuel blend is prepared, it is transferred into drums. This process often includes automated filling systems that minimize human error and contamination. The drums are typically made of steel, plastic, or fiber, chosen based on the fuel type and intended use. Proper sealing and labeling are crucial at this stage to ensure compliance with safety regulations.

-

Finishing: The final stage includes quality checks and packaging. Drums are inspected for integrity, and any defects are addressed before they are shipped. This stage often involves stringent cleaning protocols to ensure that no residues affect the fuel quality.

How Is Quality Assurance Implemented in Drum Fuel Manufacturing?

Quality assurance (QA) is paramount in the drum fuel manufacturing process, especially for international B2B buyers who demand reliability and performance. Several international standards and industry-specific certifications guide the QA processes.

Illustrative image related to drum fuel

-

International Standards: Manufacturers often adhere to ISO 9001, which outlines the criteria for a quality management system. Compliance with this standard demonstrates a commitment to consistent quality and customer satisfaction. Additionally, certifications like API (American Petroleum Institute) and CE (Conformité Européenne) are essential for ensuring that products meet specific safety and performance criteria.

-

Quality Control Checkpoints: Various checkpoints are integrated into the production process to maintain quality. These include:

– Incoming Quality Control (IQC): Raw materials are tested upon arrival to ensure they meet quality standards.

– In-Process Quality Control (IPQC): Monitoring occurs during the manufacturing process to catch any deviations in real-time.

– Final Quality Control (FQC): The finished product undergoes comprehensive testing before it is released for distribution. -

Common Testing Methods: Depending on the fuel type, testing methods may include:

– Octane Rating Tests: Ensuring the fuel meets specified octane levels.

– Chemical Composition Analysis: Verifying the blend of components for consistency and performance.

– Physical Property Tests: Assessing properties such as viscosity, density, and flash point.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

-

Conduct Supplier Audits: Buyers should perform regular audits of suppliers’ manufacturing facilities to assess adherence to quality standards. This can include reviewing production processes, quality control measures, and compliance with international regulations.

-

Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC. These reports offer transparency and can help buyers make informed decisions.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can add an extra layer of assurance. These inspectors can evaluate both the manufacturing process and the final product against established standards.

-

Understand Certification Nuances: Different regions have varying certification requirements. For example, while CE certification is critical in Europe, buyers in the Middle East might look for compliance with local standards. Understanding these nuances can help buyers ensure that the products they source are compliant with regional regulations.

How Do Quality Control Practices Differ Across Regions?

Quality control practices in drum fuel manufacturing can vary significantly across different regions, influenced by local regulations and market demands.

-

Africa: In many African countries, regulatory frameworks may be less stringent, leading to variability in quality assurance practices. However, international buyers are increasingly demanding compliance with global standards, pushing local manufacturers to enhance their QA processes.

-

South America: The fuel market in South America is diverse, with varying standards across countries. Buyers should be aware of local regulations and ensure that suppliers meet both local and international quality benchmarks.

-

Middle East: The Middle East has a robust oil and gas sector, with strict quality control measures in place. Suppliers often have to comply with rigorous testing and certification processes, making it easier for buyers to find reliable sources.

-

Europe (e.g., Germany): European manufacturers are typically at the forefront of quality assurance, with stringent adherence to ISO and other certifications. Buyers in Europe can expect high-quality products, but they should still verify that suppliers are compliant with the latest regulations.

Conclusion

Understanding the manufacturing processes and quality assurance measures for drum fuel is essential for B2B buyers looking to source reliable products. By recognizing the key stages of manufacturing, the importance of quality control, and the steps to verify supplier practices, buyers can make informed decisions that align with their operational needs and regulatory requirements. This thorough approach not only ensures product quality but also fosters long-term partnerships with suppliers across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drum fuel’

To assist international B2B buyers in effectively sourcing drum fuel, this guide provides a comprehensive step-by-step checklist. Each step is designed to ensure that you procure the right fuel type, from reputable suppliers, while complying with safety and quality standards.

Step 1: Identify Your Fuel Requirements

Understanding your specific fuel needs is paramount. Determine the type of fuel required (e.g., unleaded, diesel, ethanol) based on your operational demands. Consider factors such as engine compatibility, performance requirements, and local regulations regarding fuel types.

- Fuel Characteristics: Research the properties of different fuel types, including octane ratings and additives.

- Usage Context: Define whether the fuel will be used for racing, industrial, or commercial purposes, as this influences the specifications.

Step 2: Verify Supplier Certifications

Before engaging with any supplier, ensure they have the necessary certifications and licenses. This not only ensures compliance with local regulations but also guarantees the quality and safety of the fuel you are purchasing.

- Quality Assurance: Look for certifications such as ISO standards or other industry-specific qualifications.

- Regulatory Compliance: Confirm that the supplier complies with environmental and safety regulations relevant to your region.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your requirements. Request company profiles, case studies, and references from buyers in similar industries or regions.

- Supplier Reputation: Research their track record in the industry and check reviews or testimonials from previous clients.

- Financial Stability: Assess the financial health of the supplier to ensure they can fulfill large orders without disruption.

Step 4: Request Samples and Specifications

Before finalizing your order, ask for product samples and detailed specifications. This allows you to evaluate the quality and compatibility of the fuel with your systems.

- Fuel Testing: Conduct tests to ensure the fuel meets your performance criteria.

- Documentation: Review technical data sheets and safety data sheets for comprehensive information on handling and storage.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, negotiate the pricing and terms of sale. Consider factors such as bulk purchase discounts, payment terms, and shipping costs.

- Transparent Pricing: Ensure that all costs, including hidden fees, are clearly outlined in the agreement.

- Flexible Terms: Look for suppliers that offer flexible payment and delivery options to accommodate your cash flow and operational needs.

Step 6: Establish a Logistics Plan

Plan how the fuel will be transported and stored once procured. This is critical for maintaining fuel quality and ensuring compliance with safety regulations.

Illustrative image related to drum fuel

- Storage Solutions: Assess your storage capabilities to prevent contamination and degradation of the fuel.

- Transportation Logistics: Confirm the reliability of the transportation method to avoid delays that could impact your operations.

Step 7: Monitor and Review Supplier Performance

After procurement, continuously monitor the performance of your supplier. Regular reviews can help identify issues early and ensure that the fuel quality remains consistent over time.

- Feedback Mechanism: Establish a communication channel for feedback and concerns regarding fuel quality or delivery.

- Performance Metrics: Track key performance indicators such as delivery times, fuel quality, and customer service responsiveness.

By following this checklist, B2B buyers can confidently navigate the sourcing process for drum fuel, ensuring they select the right products and suppliers for their operational needs.

Comprehensive Cost and Pricing Analysis for drum fuel Sourcing

What Are the Key Cost Components in Drum Fuel Sourcing?

When sourcing drum fuel, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of fuel (e.g., diesel, ethanol, methanol) significantly influences material costs. Specialty fuels, such as high-octane race fuels, can command higher prices due to their refined components and performance specifications.

-

Labor: Labor costs vary based on the region of production. Areas with higher wages may increase the overall cost, while regions with lower labor costs can offer competitive pricing.

-

Manufacturing Overhead: This encompasses facility costs, utilities, and equipment maintenance. Manufacturers that invest in efficient processes may reduce overhead, potentially passing savings to buyers.

-

Tooling and QC: Investments in tooling can affect initial costs but enhance production efficiency and quality assurance. Rigorous QC processes are vital for ensuring the fuel meets regulatory and performance standards, impacting the overall price.

-

Logistics: Transportation costs are a significant factor, particularly for international shipments. Factors like distance, mode of transport, and fuel prices can lead to variability in logistics costs.

-

Margin: Suppliers typically apply a markup to cover their costs and earn a profit. Understanding the expected margin can help buyers gauge fair pricing.

How Do Price Influencers Impact Drum Fuel Costs?

Several factors can influence the pricing of drum fuel, making it crucial for buyers to understand these dynamics:

-

Volume/MOQ: Many suppliers offer discounts for larger orders. Establishing a minimum order quantity (MOQ) can lead to significant cost savings.

-

Specifications and Customization: Custom formulations or specific quality certifications (e.g., environmental standards) can raise prices. Buyers should weigh the necessity of these specifications against their budget.

-

Material Quality and Certifications: Higher-quality fuels with certifications (like ASTM) often come at a premium. Buyers must consider the benefits of quality against the additional costs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer superior service and product consistency.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the shipping costs and risks. This can impact the total cost and should be clearly defined in contracts.

What Are Effective Buyer Tips for Negotiating Drum Fuel Prices?

-

Negotiation Strategies: Always negotiate based on comprehensive cost data. Understanding the supplier’s cost structure can provide leverage in discussions.

-

Focus on Cost-Efficiency: Look for suppliers that offer total cost of ownership (TCO) analyses. This approach considers not just the price per drum but also logistics, storage, and handling costs.

-

International Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and regional regulations that can affect pricing. Establishing long-term relationships with suppliers can help mitigate some of these risks.

-

Regular Market Research: Staying updated on market trends and competitor pricing can provide valuable insights during negotiations.

-

Consider Local Suppliers: Sourcing from local suppliers may reduce logistics costs and lead times, offering a competitive edge.

Disclaimer on Indicative Prices

While prices for drum fuels can be found online, they vary widely based on the factors discussed. Buyers are encouraged to request quotes tailored to their specific needs to ensure they receive accurate pricing and terms.

Illustrative image related to drum fuel

Alternatives Analysis: Comparing drum fuel With Other Solutions

Introduction: Exploring Alternatives to Drum Fuel

As businesses seek efficient and effective fuel solutions, understanding the alternatives to drum fuel becomes essential. Drum fuel, typically stored in large barrels, offers a convenient way to handle bulk fuel needs. However, other options may provide better performance, cost savings, or ease of use depending on specific operational requirements. This analysis will compare drum fuel with two viable alternatives: bulk fuel delivery and fuel tanks.

Comparison Table

| Comparison Aspect | Drum Fuel | Bulk Fuel Delivery | Fuel Tanks |

|---|---|---|---|

| Performance | Consistent quality; suitable for various applications | Varies with supplier; often high-quality | High capacity; suitable for large operations |

| Cost | Moderate upfront and storage costs | Variable based on delivery frequency and distance | Higher initial investment; lower long-term costs |

| Ease of Implementation | Requires storage space and handling | Easy; delivered directly to site | Requires installation and setup |

| Maintenance | Regular checks for leaks and integrity | Minimal maintenance required | Requires regular monitoring and maintenance |

| Best Use Case | Small to medium operations needing flexibility | Large operations with high consumption | Industries with consistent fuel needs |

Detailed Breakdown of Alternatives

1. Bulk Fuel Delivery

Bulk fuel delivery involves suppliers transporting fuel directly to a business site. This method is advantageous for companies with high fuel consumption, as it eliminates the need for storage space. The primary benefit is convenience; businesses can order fuel as needed, reducing the risks associated with storage, such as leaks or contamination. However, costs can vary significantly based on location, supplier reliability, and market fluctuations. Additionally, depending on the supplier, the quality of fuel may not always meet specific operational requirements.

2. Fuel Tanks

Fuel tanks provide a more permanent solution for businesses with substantial and consistent fuel needs. These tanks can store large quantities of fuel, which can be more cost-effective over time compared to purchasing smaller quantities of drum fuel. The main advantage of fuel tanks is their scalability; they can be integrated with fueling systems for ease of use. However, the initial investment for installation can be high, and ongoing maintenance is required to ensure safety and compliance with regulations. Additionally, businesses must consider the environmental impact and ensure proper containment measures to avoid spills.

Conclusion: How to Choose the Right Fuel Solution

When selecting the most suitable fuel solution, B2B buyers should assess their specific operational needs, including fuel consumption rates, budget constraints, and storage capabilities. Drum fuel remains a flexible option for smaller operations, while bulk fuel delivery may offer convenience for larger companies. Fuel tanks, though requiring a higher initial investment, could provide long-term savings for industries with consistent fuel demands. By carefully evaluating these alternatives, businesses can make informed decisions that align with their operational efficiency and cost management strategies.

Essential Technical Properties and Trade Terminology for drum fuel

What Are the Key Technical Properties of Drum Fuel?

When considering drum fuel, understanding its technical properties is essential for making informed purchasing decisions. Below are critical specifications that define the quality and usability of drum fuels:

1. Octane Rating

The octane rating measures a fuel’s ability to resist knocking during combustion. For high-performance applications, fuels with higher octane ratings (e.g., 99 for racing fuels) are preferred as they allow for more aggressive tuning and higher compression ratios. This specification is crucial for businesses involved in motorsports or high-performance engines, ensuring optimal performance and efficiency.

2. Specific Gravity

Specific gravity is the ratio of the density of a fuel to the density of water. It influences the fuel’s energy content and efficiency in combustion. A typical specific gravity for many fuels is around 0.79. Understanding this property helps businesses assess fuel storage needs and compatibility with existing equipment.

3. Reid Vapor Pressure (RVP)

RVP indicates the volatility of a fuel, which is essential for engine performance and emissions control. A lower RVP is typically preferred for fuels used in warmer climates to prevent vapor lock. For B2B buyers, knowing the RVP helps ensure that the selected fuel meets local regulations and operational requirements.

4. Lower Heating Value (LHV)

The LHV measures the amount of energy released when a fuel is burned. Fuels with higher LHV (e.g., 82,200 Btu/gallon for certain blends) provide more energy per volume, making them more economical for businesses that rely on bulk fuel consumption. This property is vital for calculating operational costs and efficiency.

5. Oxygen Content

In oxygenated fuels, the oxygen content affects combustion efficiency and emissions. For instance, E85 fuels contain about 30% oxygen by weight, enhancing combustion but also requiring adjustments in air-fuel ratios. Businesses should consider this when selecting fuel to comply with environmental standards while achieving performance goals.

What Are Common Trade Terms Related to Drum Fuel?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B fuel market. Here are some key terms:

Illustrative image related to drum fuel

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of drum fuel, understanding OEM specifications ensures compatibility with engines or machinery, which is crucial for maintaining operational efficiency.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For drum fuels, MOQs can affect inventory management and cost efficiency. Buyers need to negotiate MOQs to align with their operational demands and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific quantities and types of goods. It is a critical step in the procurement process, allowing businesses to compare prices and terms from multiple suppliers, ensuring they secure the best possible deal.

4. Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers as they dictate shipping, risk transfer, and cost responsibilities, which can significantly impact the total cost of procurement.

5. Bulk Fuel Supply

This term refers to the purchase of fuel in large quantities, typically for commercial use. Understanding bulk supply logistics is crucial for businesses aiming to optimize their fuel procurement processes, reduce costs, and ensure consistent supply.

Conclusion

Navigating the complexities of drum fuel requires a grasp of both its technical properties and industry jargon. By understanding these specifications and terms, B2B buyers can make informed decisions that enhance operational efficiency and align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the drum fuel Sector

What Are the Current Market Dynamics and Key Trends in the Drum Fuel Sector?

The drum fuel market is experiencing significant growth, driven by a combination of global energy demands, evolving regulations, and technological advancements. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing high-quality fuel products that meet stringent environmental and performance standards. Key drivers include the rise of e-commerce in fuel distribution, which facilitates easier access to diverse suppliers, and the growing demand for specialty fuels, including racing fuels and eco-friendly options.

Emerging technologies such as blockchain for supply chain transparency and advanced analytics for demand forecasting are reshaping sourcing strategies. B2B buyers are leveraging these technologies to enhance their procurement processes, ensuring better inventory management and cost efficiency. Moreover, the shift towards alternative fuels, including biofuels and ethanol-blended options, is becoming increasingly prominent. This trend aligns with global sustainability goals and offers buyers an opportunity to differentiate their offerings in competitive markets.

Furthermore, geopolitical factors, such as fluctuating oil prices and trade policies, are crucial in shaping market dynamics. Buyers need to stay informed about these variables to make strategic sourcing decisions that mitigate risks associated with price volatility and supply chain disruptions.

How Is Sustainability Shaping the Drum Fuel Industry?

Sustainability is becoming a cornerstone of the drum fuel sector, compelling B2B buyers to prioritize ethical sourcing and environmentally responsible practices. The environmental impact of fuel production and consumption is under intense scrutiny, prompting companies to adopt more sustainable practices in their operations. Ethical supply chains that focus on reducing carbon footprints and minimizing waste are not just a regulatory requirement but also a competitive advantage.

Illustrative image related to drum fuel

Buyers are increasingly seeking suppliers that can provide certifications and documentation demonstrating compliance with environmental standards. Green certifications, such as ISO 14001 for environmental management systems, are becoming essential for businesses looking to establish credibility in their sustainability efforts. Additionally, sourcing fuels that utilize renewable resources, such as biodiesel and ethanol, is gaining traction, aligning with global initiatives to combat climate change.

Moreover, the shift towards circular economy principles encourages the adoption of reconditioned and reusable drum products. This practice not only reduces environmental impact but also appeals to a growing segment of consumers who prioritize sustainability. B2B buyers who integrate these sustainable practices into their sourcing strategies can enhance their brand reputation and attract environmentally conscious customers.

How Has the Drum Fuel Sector Evolved Over Time?

The drum fuel sector has undergone significant evolution since its inception, adapting to technological advancements and changing consumer demands. Initially, the market was dominated by traditional fossil fuels, primarily sourced from large oil companies. However, the oil crises of the 1970s prompted a shift towards diversification in fuel types, including the introduction of biofuels and specialty fuels tailored for specific applications.

In recent decades, advancements in refining technology and increased regulatory focus on emissions have led to the development of cleaner, more efficient fuel products. The rise of e-commerce and digital platforms has further transformed the landscape, allowing small and medium-sized enterprises to enter the market and compete with established players. Today, the drum fuel sector is characterized by a diverse range of products, including high-performance racing fuels, environmentally friendly options, and advanced logistics solutions, reflecting the industry’s commitment to innovation and sustainability.

Illustrative image related to drum fuel

For international B2B buyers, understanding this evolution is crucial for navigating the complexities of the current market and making informed sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of drum fuel

-

How do I ensure the quality of drum fuel before purchasing?

To ensure the quality of drum fuel, request certificates of analysis (COAs) from suppliers, which verify the fuel’s specifications and composition. Conduct thorough research on the supplier’s reputation and track record in the industry. Additionally, consider ordering a sample for testing to assess its performance in your specific applications. Engaging third-party testing services can further validate the quality of the fuel. Establishing clear quality assurance criteria upfront can help mitigate risks associated with subpar products. -

What is the best type of drum fuel for my industry needs?

The best type of drum fuel depends on your specific applications and industry requirements. For instance, racing applications often benefit from high-octane fuels like methanol or ethanol blends, while heavy machinery may require diesel. It’s essential to evaluate factors such as engine compatibility, environmental regulations, and performance needs. Consulting with fuel experts or suppliers can provide insights tailored to your operational requirements, ensuring optimal performance and compliance with local regulations. -

What are the minimum order quantities (MOQ) for drum fuel?

Minimum order quantities for drum fuel can vary significantly by supplier and region. Typically, MOQs range from a single drum to several pallets, depending on the supplier’s policies and your specific needs. When sourcing internationally, consider discussing potential MOQs with suppliers to negotiate terms that suit your operational capacity and budget. It’s also beneficial to inquire about bulk pricing discounts if you’re able to commit to larger orders. -

How do I vet suppliers for international drum fuel sourcing?

Vetting suppliers for international drum fuel sourcing involves several key steps. Start by checking their certifications and compliance with international fuel standards. Evaluate their financial stability and industry reputation through reviews and references. Request detailed information about their sourcing practices, storage conditions, and quality control measures. Visiting their facilities, if feasible, or utilizing third-party verification services can provide additional assurance of their reliability and capability. -

What payment terms should I expect when purchasing drum fuel internationally?

Payment terms for international drum fuel purchases often vary based on supplier policies and the nature of the transaction. Common terms include letters of credit, advance payments, or net 30-60 days after delivery. It’s essential to clarify these terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers. Negotiating favorable terms can also help manage cash flow effectively. -

What logistics considerations should I keep in mind when importing drum fuel?

When importing drum fuel, logistics considerations include transportation methods, customs regulations, and storage facilities. Ensure that your logistics partner is experienced in handling hazardous materials and understands the regulations in your destination country. Plan for potential delays at customs and ensure compliance with all local laws regarding fuel storage and distribution. Establishing a reliable supply chain will help maintain consistent fuel availability while minimizing disruptions. -

Can I customize the drum fuel according to my specifications?

Yes, many suppliers offer customization options for drum fuel to meet specific performance or regulatory requirements. This may include blending fuels for particular octane ratings or formulations tailored to unique applications. When discussing customization, clearly outline your needs and any relevant testing or certification requirements. Keep in mind that customized fuels may have different lead times and costs, so plan accordingly. -

What are the environmental regulations I need to consider when sourcing drum fuel?

Environmental regulations concerning drum fuel vary by country and region, impacting its formulation, storage, and transportation. Familiarize yourself with local regulations regarding emissions, handling of hazardous materials, and disposal of used fuel. Ensure that your suppliers comply with these regulations to avoid legal issues and potential fines. Engaging with environmental consultants can provide valuable insights into best practices and help align your operations with sustainability goals.

Top 6 Drum Fuel Manufacturers & Suppliers List

1. Sunoco – E85-R 99 Octane Race Fuel

Domain: petroleumservicecompany.com

Registered: 2004 (21 years)

Introduction: {“Product Name”: “Sunoco E85-R 99 Octane Unleaded Race Fuel”, “SKU”: “”, “Weight”: “0.00 LBS”, “Product Size”: “5 Gallon Pail”, “Price”: “$86.80”, “Ethanol Content”: “85%”, “Octane Rating”: “99 (R+M)/2”, “Research Octane”: “104”, “Motor Octane”: “94”, “Specific Gravity”: “0.79”, “Weight (lbs/gallon)”: “6.6”, “Reid Vapor Pressure (PSI)”: “4.2”, “10% Evaporation (°F)”: “166”, “50% Evaporation (°F)”:…

2. Gasoline Storage – Key Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Gasoline storage options discussed include plastic 55-gallon drums and IBC containers. Key considerations for safe storage include using HDPE containers specifically made for gas, avoiding static buildup, and opting for smaller 5-gallon cans for easier handling and transport. Recommendations include storing fuel in a dedicated outbuilding, rotating fuel regularly to prevent degradation, and ensuri…

3. Drum Oil & Propane – Energy Services

Domain: drumoil.com

Registered: 1999 (26 years)

Introduction: Drum Oil & Propane offers a range of energy services including: 1. Fuel Delivery: – Propane Delivery – Heating Oil Delivery – Automatic Delivery 2. Heating Services: – Heating Installations – Heating Tune-Ups & Maintenance – Oil Tank Protection 3. Indoor Air Quality Products 4. Service Plans 5. Financing Options 6. Emergency Service 7. A/C Services: – A/C Installations – A/C Tune-Ups & Maintenance

4. Fill-Rite – 55 Gallon Barrel Fuel Station Setup

Domain: tractorbynet.com

Registered: 1999 (26 years)

Introduction: 55 gallon barrel fuel station setup includes: 115v 15GPM Fill-Rite transfer pump, water/particulate filter, auto stop fill nozzle. Steel drums typically have a 2″ bung and a 3/4″ bung; the pump fits in the 2″ bung. Concerns about using HDPE plastic barrels include the ability to support the weight of the pump and accessories in high temperatures. Users suggest alternatives like using metal drums o…

5. River Dave’s Place – 95 Octane Ethanol-Free Gas & Pumps

Domain: riverdavesplace.com

Registered: 2007 (18 years)

Introduction: 1. 55 Gallon Drum of 95 Octane, Ethanol-Free Gas – Used for boats, dirt bikes, generators, etc.

2. Plastic Siphon Pumps – Simple and effective but not robust.

3. Hand Crank Pump – Anti-static fuel hose; not rated for gasoline (only for diesel, kerosene, oils); requires proper anti-static ground strap.

4. Fill-Rite Electric Pump – 12V DC fuel transfer pump, 15 GPM, fast and efficient.

5. Bicos 12V …

6. VP Racing Fuels – LMP Advanced 54 Gallon Drum Race Fuel

Domain: vpracingfuels.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “VP LMP Advanced 54 Gallon Drum Race Fuel”, “price”: “$1,073.00”, “description”: “LMP Advanced delivers an upgrade in detonation protection and heat resistance compared to our highly successful Late Model+ fuel. Designed for super late model and off-road endurance-style desert racing with maximum compression ratios. Offers the same performance as Late Model+ and is stable under hi…

Strategic Sourcing Conclusion and Outlook for drum fuel

In the rapidly evolving landscape of drum fuel, strategic sourcing emerges as a critical component for international B2B buyers. Understanding the diverse types of drum fuels—ranging from unleaded and leaded fuels to ethanol and methanol—enables companies to make informed decisions tailored to their specific operational needs. Leveraging relationships with reliable suppliers ensures not only the quality and consistency of fuel but also cost-effectiveness in procurement.

Moreover, as global markets expand, the importance of compliance with regional regulations and standards cannot be overstated. Buyers from Africa, South America, the Middle East, and Europe, particularly in countries like Germany and Saudi Arabia, should prioritize partnerships that align with both local and international safety and environmental guidelines.

Looking ahead, the future of drum fuel sourcing is likely to be shaped by advancements in fuel technology and an increasing focus on sustainability. Businesses that proactively adapt to these changes will gain a competitive edge. We encourage B2B buyers to explore strategic sourcing options that not only meet their current fuel demands but also position them for future growth in an increasingly complex market. Engage with trusted suppliers today to ensure your operations are fueled for success tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to drum fuel

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.