Drill With Integral Bullseye Level: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for drill with integral bullseye level

In the competitive landscape of construction and manufacturing, sourcing a drill with an integral bullseye level presents a significant challenge for businesses striving for precision and efficiency. The ability to drill straight, regardless of orientation, is crucial for achieving high-quality results and minimizing costly errors. This comprehensive guide delves into the intricacies of the drill market, highlighting various types of drills equipped with advanced alignment technologies, their applications across multiple industries, and the essential factors to consider when selecting suppliers.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including Germany and Brazil—will find actionable insights into the procurement process, including supplier vetting, pricing structures, and compatibility with existing equipment. By equipping decision-makers with a thorough understanding of product specifications and market trends, this guide empowers businesses to make informed purchasing decisions that enhance operational efficiency and boost productivity.

With a focus on the latest innovations in drill technology, buyers will learn how to navigate the global market effectively, ensuring they invest in tools that meet their specific needs and drive long-term success.

Understanding drill with integral bullseye level Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Bullseye Core | Projects a single reference and alignment pattern | General construction and DIY projects | Pros: Easy to use, cost-effective. Cons: Limited operational range (2”-5”). |

| Extended Bullseye Core | Includes dual alignment patterns for enhanced versatility | Specialized drilling tasks, cabinetry | Pros: Greater flexibility for various drill lengths. Cons: Slightly higher cost. |

| Green Laser Bullseye | Utilizes a visible green laser for better visibility | Bright environments, outdoor projects | Pros: Enhanced visibility in daylight. Cons: Shorter battery life. |

| Red Laser Bullseye | Employs a red laser for improved battery efficiency | Indoor applications, lower light areas | Pros: Longer battery life. Cons: Less visible in bright conditions. |

| Specialty Bullseye Core | Adapts to various drill bit types (e.g., auger, spade) | Heavy-duty industrial applications | Pros: Versatile for different tasks. Cons: May require training for optimal use. |

What Are the Key Characteristics of Standard Bullseye Core?

The Standard Bullseye Core features a single reference and alignment pattern, designed for straightforward drilling tasks. It is particularly suitable for general construction and DIY projects where precision is required but the operational range is limited to 2”-5”. B2B buyers should consider this model for its affordability and ease of use, making it ideal for both seasoned professionals and novices. However, the limited range may restrict its application in specialized drilling tasks.

How Does the Extended Bullseye Core Enhance Functionality?

The Extended Bullseye Core offers dual alignment patterns, significantly enhancing its versatility for various drilling tasks. Suitable for specialized applications such as cabinetry and intricate installations, this model operates within an extended range of 2”-8”. B2B buyers should weigh the added functionality against the slightly higher cost, as the flexibility it provides can lead to improved accuracy and efficiency in complex projects.

Why Choose a Green Laser Bullseye Core?

The Green Laser Bullseye Core is designed for optimal visibility, utilizing a green laser that stands out even in bright conditions. This makes it particularly effective for outdoor projects or in well-lit environments. B2B buyers focused on visibility and precision in challenging lighting conditions will find this model advantageous, although it comes with a trade-off of reduced battery life. Understanding the operational context is crucial for maximizing its benefits.

What Advantages Does the Red Laser Bullseye Offer?

The Red Laser Bullseye features a red laser that is less power-hungry, resulting in longer battery life. This model is best suited for indoor applications or environments with lower light levels, where visibility is not a major concern. B2B buyers should consider this option for cost-effective solutions that do not compromise on functionality. However, its limitations in bright conditions may necessitate careful planning for usage.

How Does the Specialty Bullseye Core Cater to Diverse Needs?

The Specialty Bullseye Core is engineered to accommodate a variety of drill bit types, including auger and spade bits, making it ideal for heavy-duty industrial applications. This model is particularly beneficial for businesses that require versatility across different drilling tasks. While it provides significant advantages in adaptability, B2B buyers must consider the potential need for additional training to ensure optimal use, especially when integrating it into existing workflows.

Key Industrial Applications of drill with integral bullseye level

| Industry/Sector | Specific Application of drill with integral bullseye level | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Precision drilling for structural beams and supports | Ensures structural integrity and safety of constructions | Compatibility with various drill types and bit sizes |

| Manufacturing | Assembly line operations for machinery and equipment | Increases operational efficiency and reduces errors | Durability and ease of use in high-volume settings |

| Electrical Installation | Installing electrical fixtures and fittings | Guarantees accurate placement and reduces rework | Safety features and adaptability to various installation angles |

| Interior Design | Installing fixtures, cabinetry, and decorative elements | Enhances aesthetic appeal and client satisfaction | Non-marring features to protect surfaces |

| Oil & Gas | Drilling precision holes for equipment installation and maintenance | Improves operational reliability and safety standards | Compliance with industry regulations and environmental standards |

How is the drill with integral bullseye level used in the construction industry?

In the construction sector, the drill with integral bullseye level is essential for precision drilling into structural beams and supports. This tool allows contractors to ensure that holes are drilled straight and at the correct angles, which is crucial for maintaining the structural integrity of buildings. Buyers in this industry should prioritize compatibility with various drill types and bit sizes to accommodate diverse construction needs.

What benefits does the drill with integral bullseye level provide in manufacturing?

Within manufacturing, this drill assists in assembly line operations by enabling accurate and efficient drilling of components. The bullseye level feature minimizes the risk of misalignment, which can lead to costly errors and downtime. For international buyers, sourcing a drill that can withstand high-volume production settings while remaining user-friendly is vital for maintaining operational efficiency.

Why is the drill with integral bullseye level important for electrical installations?

In electrical installations, precise drilling is crucial for the accurate placement of fixtures and fittings. The drill with an integral bullseye level ensures that holes are drilled at the correct angles, reducing the need for rework and enhancing overall project efficiency. Buyers should look for safety features that accommodate various installation angles, ensuring compliance with local regulations and standards.

How does the drill with integral bullseye level enhance interior design applications?

Interior designers utilize the drill with integral bullseye level for installing fixtures, cabinetry, and decorative elements, ensuring that installations are both aesthetically pleasing and structurally sound. The tool’s non-marring features are particularly beneficial, as they prevent damage to surfaces during the drilling process. Buyers should consider tools that offer versatility in use across various materials to meet diverse design requirements.

What role does the drill with integral bullseye level play in the oil and gas industry?

In the oil and gas sector, precision drilling is critical for the installation and maintenance of various equipment. The drill with integral bullseye level enhances the accuracy of drilling operations, which is essential for ensuring operational reliability and adhering to safety standards. Buyers should focus on sourcing drills that meet industry regulations and environmental standards to ensure compliance and safety in their operations.

3 Common User Pain Points for ‘drill with integral bullseye level’ & Their Solutions

Scenario 1: Ensuring Precision in Diverse Drilling Conditions

The Problem:

B2B buyers often face challenges when drilling in varied orientations and conditions, such as walls, ceilings, or at odd angles. This versatility is crucial in many industries like construction and manufacturing, where misalignment can lead to costly mistakes and rework. Buyers may struggle with ensuring that their drills maintain accuracy across different surfaces, especially in projects where tight tolerances are required. For instance, a contractor working on a high-rise building might need to drill both horizontally and vertically, but without proper guidance, achieving consistent perpendicular holes can be daunting.

Illustrative image related to drill with integral bullseye level

The Solution:

To address this issue, sourcing a drill with an integral bullseye level, like the BullseyeBore Core, is essential. This tool is designed to project concentric circular patterns on the work surface, providing instant visual feedback on alignment. When sourcing, ensure compatibility with your existing drills by consulting the manufacturer’s compatibility guide. Implementing this tool means users can quickly assess alignment, even in challenging conditions, ensuring they maintain precision whether drilling overhead or at awkward angles. Train your team to leverage this visual alignment feature effectively, maximizing productivity and accuracy on-site.

Scenario 2: Minimizing Surface Damage During Drilling

The Problem:

In many industrial applications, maintaining the integrity of the work surface is paramount. Traditional drill guides can contact the surface, leading to scratches or dents, which are unacceptable in high-end applications such as cabinetry or fine furniture. B2B buyers must contend with the risk of damaging expensive materials while attempting to achieve precise drilling results. This concern is particularly relevant for businesses in sectors like luxury construction or bespoke furniture, where aesthetic quality is crucial.

The Solution:

Investing in a drill with an integral bullseye level addresses this pain point effectively. The BullseyeBore Core operates without making contact with the work surface, thereby eliminating the risk of damage. When specifying this tool, highlight its contactless operation in your procurement documentation. Additionally, provide training for your team on how to use the alignment patterns to drill accurately while safeguarding the surface. This proactive approach not only preserves the quality of the materials but also enhances the reputation of your business for delivering top-notch results without compromising on quality.

Scenario 3: Enhancing Safety in Drilling Operations

The Problem:

Safety is a paramount concern for B2B buyers, particularly in sectors like construction and manufacturing. Standard drill guides can present hazards, such as causing the drill to bind or malfunction if it encounters an obstruction. This can lead to accidents or injuries on the job site. Buyers may find it challenging to ensure that their drilling operations are both efficient and safe, especially when working in tight or complex environments.

The Solution:

The BullseyeBore Core offers a significant safety advantage through its unique magnetic connection, which disengages the tool if it encounters an obstruction. When considering this tool, ensure that safety features are highlighted during procurement discussions. Implement a safety training program that emphasizes the importance of using tools with built-in safety mechanisms. Encourage your team to perform regular safety audits to ensure that they are using the drill with the integral bullseye level correctly. By prioritizing safety and investing in advanced tools, businesses can create a safer work environment, reducing the risk of accidents and enhancing overall operational efficiency.

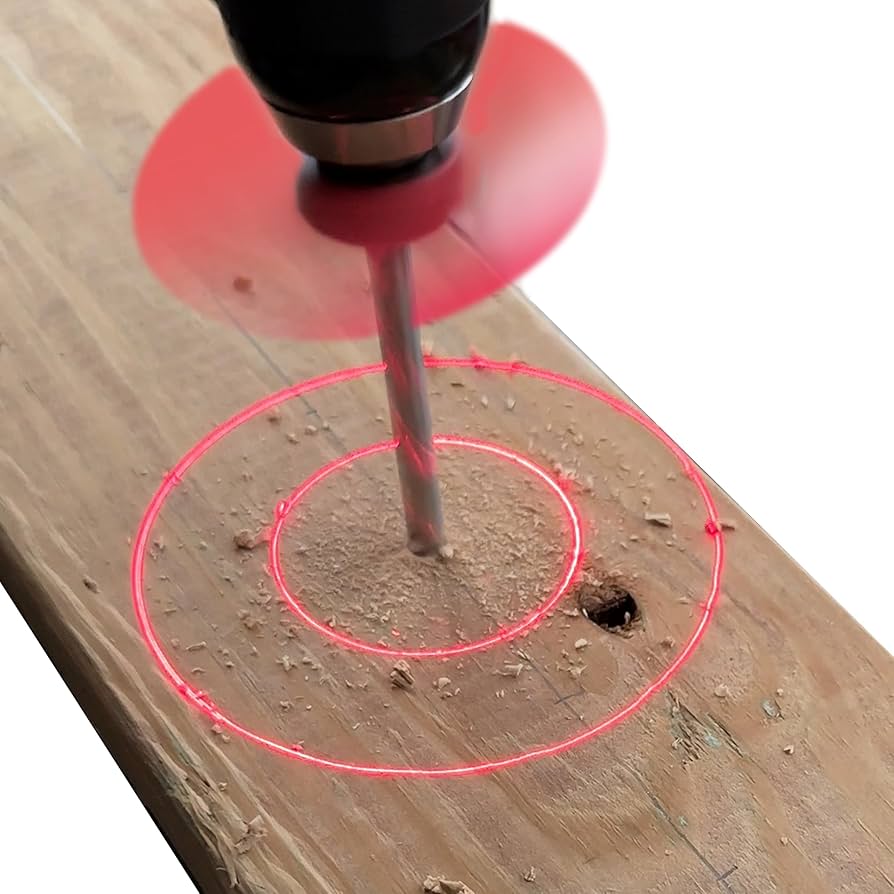

Illustrative image related to drill with integral bullseye level

Strategic Material Selection Guide for drill with integral bullseye level

What Materials are Commonly Used for Drills with Integral Bullseye Levels?

When selecting materials for drills equipped with integral bullseye levels, it’s essential to consider the performance characteristics, manufacturing complexities, and regional compliance standards. Below, we analyze four common materials used in the production of these tools.

1. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It typically withstands moderate temperatures and pressures, making it suitable for various drilling applications.

Pros & Cons:

Aluminum’s lightweight nature enhances user comfort and reduces fatigue during prolonged use. However, its lower strength compared to steel may limit its use in heavy-duty applications. Manufacturing aluminum components can be complex, requiring specialized machining and finishing processes, which can drive up costs.

Impact on Application:

Aluminum is compatible with a variety of media, including wood and soft metals, but may not be ideal for harder materials like steel. Its corrosion resistance makes it suitable for environments with moisture or chemicals.

Considerations for International Buyers:

In regions like Europe and South America, aluminum products must comply with standards such as EN 573. Buyers should also consider local sourcing to reduce costs and ensure compliance with regional regulations.

2. Stainless Steel

Key Properties:

Stainless steel is known for its exceptional strength, durability, and resistance to corrosion and oxidation. It can withstand high temperatures and pressures, making it ideal for demanding applications.

Pros & Cons:

The primary advantage of stainless steel is its longevity and ability to maintain performance in harsh environments. However, it is heavier than aluminum, which may affect user comfort. The cost of stainless steel is generally higher due to its complex manufacturing process and material properties.

Impact on Application:

This material is highly suitable for drilling into tougher materials, such as metal and concrete, due to its strength. Its resistance to corrosion makes it ideal for outdoor or humid applications.

Considerations for International Buyers:

International buyers should ensure compliance with standards like ASTM A240 or DIN 1.4301, particularly in regions like Germany, where strict quality controls are in place. The higher cost may also necessitate a thorough cost-benefit analysis for budget-conscious buyers.

3. High-Carbon Steel

Key Properties:

High-carbon steel offers a balance of hardness and toughness, making it suitable for tools that require sharp edges and durability. It can withstand moderate temperatures and is often treated to enhance its properties.

Pros & Cons:

The primary advantage of high-carbon steel is its cost-effectiveness and ability to maintain sharpness, making it ideal for drilling applications. However, it is prone to rust and corrosion, requiring protective coatings or regular maintenance.

Impact on Application:

High-carbon steel is particularly effective for drilling into wood and softer materials. Its susceptibility to corrosion limits its use in wet or humid environments unless adequately protected.

Illustrative image related to drill with integral bullseye level

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings to enhance durability. Compliance with standards such as JIS G4401 is essential in regions like Japan and South America, where quality assurance is critical.

4. Polycarbonate

Key Properties:

Polycarbonate is a durable thermoplastic known for its impact resistance and lightweight characteristics. It can operate effectively at moderate temperatures and offers good optical clarity.

Pros & Cons:

The key advantage of polycarbonate is its lightweight nature and resistance to shattering, making it safe for use in various applications. However, it may not withstand high temperatures or heavy loads as well as metals, limiting its use in certain drilling scenarios.

Impact on Application:

Polycarbonate is ideal for protective covers or components in drills that require visibility of the bullseye level without compromising safety. Its chemical resistance makes it suitable for environments with exposure to various substances.

Illustrative image related to drill with integral bullseye level

Considerations for International Buyers:

Buyers must ensure compliance with relevant safety standards, such as ASTM D635, especially in regions with stringent safety regulations. Its lower cost can be attractive for budget-conscious buyers looking for effective yet lightweight solutions.

Summary Table

| Material | Typical Use Case for drill with integral bullseye level | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General-purpose drilling in wood and soft metals | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Stainless Steel | Heavy-duty drilling in metal and concrete | Exceptional durability and strength | Heavier and higher cost | High |

| High-Carbon Steel | Drilling in wood and softer materials | Cost-effective and maintains sharpness | Prone to rust without protection | Low |

| Polycarbonate | Protective covers for visibility in drills | Lightweight and impact-resistant | Limited high-temperature performance | Medium |

This analysis provides B2B buyers with a comprehensive understanding of material options for drills with integral bullseye levels, enabling informed decision-making based on specific application needs and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for drill with integral bullseye level

What Are the Main Stages of Manufacturing a Drill with Integral Bullseye Level?

The manufacturing process for drills with integral bullseye levels involves several critical stages that ensure high-quality output. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The initial stage focuses on the selection of high-grade materials such as steel for drill bits and durable polymers for the bullseye level housing. Suppliers often source these materials from certified vendors to ensure quality. Incoming materials undergo inspection to confirm compliance with specified standards, including tensile strength and corrosion resistance. This initial quality check is vital for maintaining the integrity of the final product.

Forming Processes: How Are Components Shaped?

Once materials are prepared, the forming stage begins. This typically involves precision machining techniques such as CNC (Computer Numerical Control) milling and turning. For the drill bits, processes like heat treatment are also employed to enhance hardness and wear resistance. For the bullseye level, injection molding may be used to create the housing, ensuring consistent dimensional accuracy and surface finish.

How Are Components Assembled for Optimal Performance?

The assembly process is critical, as it determines the functionality of the drill with the bullseye level. Components are assembled in a controlled environment to minimize contamination and ensure precision fitting. This often involves:

- Magnetic Attachment: The bullseye level is designed to attach magnetically to the drill chuck. This requires precise engineering to ensure strong yet easily removable connections.

- Calibration: Each drill unit undergoes a calibration process to ensure that the bullseye level accurately projects alignment patterns. This is crucial for user accuracy and safety.

What Finishing Techniques Enhance Product Quality?

The finishing stage focuses on surface treatments and coatings that enhance performance and longevity. Processes may include:

- Surface Coating: Application of anti-corrosive coatings and lubricants to prevent wear and extend the drill’s lifespan.

- Quality Polishing: Polishing the drill bits for reduced friction, which improves drilling efficiency and prolongs service life.

What International Standards Govern Quality Assurance?

Quality assurance in the manufacturing of drills with integral bullseye levels is governed by several international standards. One of the most recognized is ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with this standard ensures that manufacturers consistently meet customer and regulatory requirements.

In addition to ISO 9001, industry-specific standards such as CE marking (for European markets) and API (American Petroleum Institute) standards may also apply, particularly if the drills are used in specialized applications like oil and gas drilling.

How Are Quality Control Checkpoints Established?

Quality control (QC) is a multi-stage process that includes several checkpoints throughout the manufacturing cycle:

-

Incoming Quality Control (IQC): This involves the inspection of raw materials and components upon arrival to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): During manufacturing, various checkpoints are established to monitor processes and ensure that any deviations from quality standards are addressed immediately. This might include visual inspections and measurements at different stages of assembly.

-

Final Quality Control (FQC): Once assembly is complete, the final product undergoes rigorous testing. This includes functionality tests to ensure the bullseye level accurately indicates alignment and durability tests to assess resistance to wear and tear.

What Common Testing Methods Are Used?

Testing methods for drills with integral bullseye levels may include:

- Performance Testing: Verifying that the bullseye level projects accurate alignment patterns under various drilling conditions.

- Durability Testing: Subjecting the drills to extreme conditions to ensure they can withstand rigorous use without failure.

- Safety Testing: Assessing the safety features, such as the automatic disconnection of the bullseye level upon encountering an obstruction.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of potential suppliers:

-

Supplier Audits: Conducting on-site audits can provide invaluable insight into a manufacturer’s quality control processes. This allows buyers to assess the implementation of quality standards and practices firsthand.

-

Quality Reports: Requesting documentation such as quality management system certifications, testing reports, and inspection records can help buyers evaluate a supplier’s commitment to quality.

-

Third-party Inspections: Engaging independent quality assurance firms to conduct inspections can provide unbiased assessments of product quality and compliance with international standards.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of specific nuances in quality control that may affect their purchasing decisions:

Illustrative image related to drill with integral bullseye level

-

Regulatory Compliance: Different regions have varying regulations regarding product safety and quality. Familiarizing oneself with these regulations, such as CE in Europe or ASTM in the United States, is essential for compliance.

-

Cultural Considerations: Quality standards may also be influenced by local practices and expectations. Understanding these cultural factors can help buyers navigate supplier relationships more effectively.

-

Logistics and Supply Chain: Quality assurance does not end at the factory. Buyers should consider the entire supply chain, including transportation and storage conditions, which can impact product quality upon delivery.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for drills with integral bullseye levels is essential for B2B buyers. By focusing on supplier verification and compliance with international standards, buyers can ensure they procure high-quality tools that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drill with integral bullseye level’

In this guide, we provide a step-by-step checklist for B2B buyers seeking to procure drills equipped with an integral bullseye level. This tool enhances drilling accuracy and efficiency, making it essential for various industries. Following this checklist will help ensure that your procurement process is effective and that you select a product that meets your operational needs.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the drill with integral bullseye level you require. Consider aspects such as drilling range, compatibility with existing drill bits, and orientation capabilities (e.g., vertical, horizontal, angled). A well-defined specification will guide your search and ensure that potential products meet your specific operational needs.

Step 2: Research Product Variants

Explore the different models and variants of drills with integral bullseye levels available in the market. Manufacturers may offer features such as laser color options (red vs. green), battery life, and operational drilling range. Understanding these variants will help you assess which model best fits your application and environmental conditions.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and references from previous clients, particularly those within your industry or region. A reliable supplier will provide transparency regarding their manufacturing processes and quality control measures.

- Look for certifications: Ensure the supplier holds relevant certifications (ISO, CE, etc.) to validate product quality and safety standards.

- Assess customer service: Evaluate their responsiveness and support services, as ongoing assistance may be critical post-purchase.

Step 4: Request Product Samples

Whenever possible, request samples of the drill with integral bullseye level before making a bulk purchase. Testing a sample allows you to evaluate its performance, durability, and ease of use in your specific working conditions. This hands-on assessment can prevent costly errors in procurement.

Step 5: Review Warranty and Support Terms

Examine the warranty and support terms provided by the supplier. A robust warranty indicates the manufacturer’s confidence in their product’s quality. Look for details on what the warranty covers, its duration, and the process for claiming repairs or replacements. Additionally, ensure that the supplier offers accessible customer support for troubleshooting and maintenance inquiries.

Step 6: Compare Pricing and Payment Terms

Conduct a thorough analysis of pricing and payment terms from multiple suppliers. While cost is a significant factor, consider the overall value, including product quality, support, and warranty terms. Negotiate favorable payment terms that align with your budget and cash flow needs.

Step 7: Finalize Your Purchase Decision

Once you have gathered all the necessary information and evaluated your options, finalize your purchase decision. Ensure that all terms, including delivery timelines and post-purchase support, are clearly outlined in the contract. A well-documented agreement will help mitigate misunderstandings and set expectations for both parties.

By following this checklist, you can streamline your procurement process and confidently select a drill with an integral bullseye level that meets your operational requirements.

Comprehensive Cost and Pricing Analysis for drill with integral bullseye level Sourcing

What Are the Key Cost Components for a Drill with Integral Bullseye Level?

When evaluating the cost structure for a drill with an integral bullseye level, several components come into play. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The quality of the materials used significantly affects the overall cost. High-grade metals, durable plastics, and advanced components such as laser systems for the bullseye functionality can elevate costs. Buyers should consider sourcing from suppliers who provide detailed material specifications to ensure quality without compromising on price.

-

Labor: Labor costs can vary depending on the location of manufacturing. Regions with lower labor costs may offer competitive pricing, but this must be balanced against quality control standards and skill levels.

-

Manufacturing Overhead: This includes expenses related to the factory operations, such as utilities, rent, and salaries for administrative staff. Efficient manufacturing processes can minimize overhead, allowing for more competitive pricing.

-

Tooling: Custom tooling for unique designs or specifications can be a significant upfront cost. Buyers looking for customized solutions should factor in these costs when negotiating prices.

-

Quality Control (QC): Ensuring that each drill meets safety and performance standards is critical. Investing in robust QC processes may increase initial costs but can lead to long-term savings through reduced returns and enhanced customer satisfaction.

-

Logistics: Shipping costs, including freight charges and customs duties, can greatly influence total costs, particularly for international buyers. Understanding the logistics involved is crucial for assessing overall pricing.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. This margin can vary widely based on market conditions, competition, and the perceived value of the product.

How Do Price Influencers Impact the Cost of Drills with Integral Bullseye Levels?

Several factors influence the pricing of drills with integral bullseye levels, and understanding these can help buyers make informed decisions.

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases can lead to significant discounts, making it financially viable for businesses with high demand. However, smaller companies should negotiate terms that allow for flexibility in order sizes.

-

Specifications and Customization: Custom features, such as specialized laser colors or additional functionalities, can increase costs. Buyers should assess the necessity of these features against their budget.

-

Material Choices: Different materials can drastically affect price points. For instance, opting for high-performance plastics versus standard materials can influence both cost and functionality.

-

Quality and Certifications: Products certified to international standards often command higher prices but also offer assurance of quality. Buyers should consider the long-term value of investing in certified products.

-

Supplier Factors: Supplier reputation, reliability, and customer service can impact pricing. Established suppliers may charge a premium, but they often provide better support and consistent quality.

-

Incoterms: Understanding shipping terms is crucial. Incoterms dictate the responsibilities of buyers and sellers in shipping and can significantly affect overall costs.

What Are Effective Buyer Tips for Negotiating Prices?

To secure the best pricing for a drill with an integral bullseye level, international buyers should consider the following strategies:

Illustrative image related to drill with integral bullseye level

-

Negotiate: Don’t hesitate to discuss pricing. Many suppliers expect negotiations, especially for larger orders. Highlighting long-term partnerships can incentivize better pricing.

-

Focus on Cost Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes maintenance, operational efficiency, and potential downtime due to product failure.

-

Understand Pricing Nuances: Different markets may exhibit varying pricing structures. For instance, buyers from Europe may face different tariffs compared to those in Africa or South America. Awareness of these differences can aid in budgeting.

-

Leverage Global Sourcing: Consider sourcing from different regions to find the best balance between quality and price. Engaging suppliers from various countries can also mitigate risks associated with supply chain disruptions.

-

Request Samples: Before committing to larger orders, request samples to assess quality and performance. This can prevent costly mistakes and ensure the product meets expectations.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing drill with integral bullseye level With Other Solutions

Exploring Alternative Solutions to the Drill with Integral Bullseye Level

When considering drilling solutions, it’s essential to evaluate various options that can enhance accuracy and efficiency. The “drill with integral bullseye level” is a specialized tool designed to ensure straight drilling through visual alignment cues. However, other alternatives also exist, each offering unique advantages and limitations. Below is a comparative analysis of the drill with an integral bullseye level against two viable alternatives: traditional drill guides and laser drill alignment systems.

| Comparison Aspect | Drill With Integral Bullseye Level | Traditional Drill Guides | Laser Drill Alignment Systems |

|---|---|---|---|

| Performance | High accuracy with concentric patterns for alignment | Moderate accuracy; reliant on user setup | Very high accuracy; visual laser guidance |

| Cost | Moderate; typically priced for accessibility | Low; basic models are inexpensive | High; advanced technology can be costly |

| Ease of Implementation | Simple to attach and use; minimal learning curve | Requires precise setup; can be cumbersome | Quick to set up but requires power source |

| Maintenance | Low; minimal wear and tear | Moderate; needs regular checks for alignment | Low; durable but requires battery or charging |

| Best Use Case | Ideal for DIY projects and professional use | Suitable for basic home projects | Best for precision work in industrial applications |

What Are the Pros and Cons of Traditional Drill Guides?

Traditional drill guides offer a straightforward approach to ensuring straight drilling. They typically consist of a stable frame that holds the drill in place, aligning it with the work surface. The primary advantage of these guides is their cost-effectiveness; they are widely available and can be purchased at a low price point. However, they require careful setup and can be cumbersome to use, which may lead to inaccuracies if not aligned correctly. Additionally, they often obstruct the user’s view of the drill bit, complicating the drilling process.

Illustrative image related to drill with integral bullseye level

How Do Laser Drill Alignment Systems Compare?

Laser drill alignment systems represent a more technologically advanced solution, projecting a laser line onto the work surface to indicate the drill’s alignment. This method offers exceptional accuracy, making it ideal for precision tasks in industrial or professional environments. The primary drawback is the cost; these systems can be significantly more expensive than both the drill with an integral bullseye level and traditional drill guides. Furthermore, they require a power source, which may limit their usability in remote locations. Despite these downsides, their quick setup and high visibility make them a preferred choice for professionals who demand accuracy.

Conclusion: Which Drilling Solution Is Right for Your Needs?

Choosing the right drilling solution depends on the specific requirements of your projects. If precision and ease of use are paramount, the drill with integral bullseye level stands out as an excellent option, offering a balance of accuracy and affordability. For budget-conscious buyers engaged in casual DIY projects, traditional drill guides may suffice, albeit with some limitations in performance. Conversely, for those in industrial settings requiring pinpoint accuracy, investing in a laser drill alignment system may be justified despite the higher costs. Evaluate your project needs, budget, and preferred level of precision to make the most informed decision.

Essential Technical Properties and Trade Terminology for drill with integral bullseye level

What are the Key Technical Properties of a Drill with Integral Bullseye Level?

1. Material Grade

The material grade of a drill with an integral bullseye level is crucial for its durability and performance. Typically, high-grade materials like carbon steel or high-speed steel (HSS) are used, which provide resistance to wear and heat. For B2B buyers, selecting a product made from superior materials ensures longevity and reduced maintenance costs, translating to better ROI over time.

2. Tolerances

Tolerances refer to the permissible limits of variation in dimensions and are essential for ensuring precision in drilling operations. A drill with a tolerance of ±0.5 mm, for instance, guarantees that holes are consistently straight and accurately positioned. For businesses that rely on precision manufacturing or construction, tight tolerances are non-negotiable, as they directly impact product quality and assembly efficiency.

3. Operational Range

The operational range defines the length of drill bits that can be effectively used with the bullseye level. Standard models might accommodate bits from 2 to 5 inches, while extended versions can range up to 8 inches. Understanding this property allows B2B buyers to assess compatibility with existing equipment and ensure that the tool can meet diverse drilling needs, enhancing versatility in various projects.

4. Laser Visibility

The visibility of the laser patterns projected by the bullseye level is another critical technical property. Green lasers, for instance, are generally more visible in bright conditions compared to red lasers. For buyers in regions with high ambient light, choosing a drill that offers superior laser visibility can significantly enhance operational efficiency, ensuring that alignment checks are quick and accurate.

5. Safety Features

Safety features, such as automatic disconnection upon contact with foreign objects, are paramount in minimizing workplace accidents. A drill that incorporates robust safety measures ensures compliance with industry standards and protects workers, which is a significant concern for B2B buyers prioritizing workplace safety.

6. Compatibility with Drill Types

The drill with an integral bullseye level should be compatible with various types of drill bits, including masonry, auger, and spade bits. This compatibility is vital for businesses that utilize a range of drilling techniques, as it eliminates the need for multiple tools and simplifies inventory management.

Which Trade Terms Should B2B Buyers Understand for Drills with Bullseye Levels?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that can be branded and sold by another company. In the context of drills, understanding OEM relationships can provide insights into product quality and reliability, as reputable OEMs often ensure rigorous testing and adherence to industry standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for inventory planning and budgeting. It helps in negotiating better terms and ensuring that purchases align with project timelines and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for a specific quantity of goods. Understanding how to prepare and submit an RFQ is crucial for B2B buyers seeking competitive pricing and clear specifications for drills with bullseye levels.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is vital for international B2B transactions, as they help clarify who bears the risk and cost at various stages of the shipping process.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for project planning, as delays can affect construction schedules and operational efficiency.

6. Certification Standards

Certification standards such as ISO or ANSI indicate that a product meets specific quality and safety benchmarks. For B2B buyers, ensuring that drills with integral bullseye levels comply with recognized certification standards can enhance credibility and reduce the risk of product failure in critical applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and enhance their competitive edge in the marketplace.

Navigating Market Dynamics and Sourcing Trends in the drill with integral bullseye level Sector

What Are the Current Market Dynamics and Key Trends in the Drill with Integral Bullseye Level Sector?

The drill with integral bullseye level sector is experiencing a notable transformation driven by advancements in technology and changing consumer preferences. A key trend is the growing demand for precision tools among both DIY enthusiasts and professionals. As construction and renovation projects surge in various regions—especially in Africa and South America—there’s an increased emphasis on tools that guarantee accuracy, such as those featuring integrated alignment technology. Additionally, the rise of e-commerce platforms, including Amazon, has made these tools more accessible to international B2B buyers, facilitating easier procurement processes.

Emerging technologies such as augmented reality (AR) are also influencing sourcing trends. Some manufacturers are exploring AR applications to enhance user experience and training, thereby increasing the efficiency of tool usage. Furthermore, the integration of smart features—like Bluetooth connectivity for performance tracking—is becoming increasingly prevalent. These innovations not only improve usability but also provide a competitive edge in the market.

For international buyers, understanding regional variations in demand is crucial. In Europe, particularly in Germany, there is a strong emphasis on durability and reliability due to stringent quality standards. Conversely, markets in Africa and South America are more price-sensitive, often prioritizing cost-effectiveness without compromising essential functionality. Thus, B2B buyers must tailor their sourcing strategies to meet these diverse market needs.

How Does Sustainability and Ethical Sourcing Impact the Drill with Integral Bullseye Level Sector?

Sustainability is becoming a central theme in the drill with integral bullseye level sector as buyers increasingly prioritize environmentally responsible products. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Consequently, many manufacturers are adopting sustainable practices, such as using recycled materials and minimizing packaging waste.

Ethical sourcing is equally important, as buyers are more inclined to engage with suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for wooden components can significantly influence purchasing decisions. These certifications not only demonstrate a commitment to sustainability but also enhance brand reputation in competitive markets.

Moreover, the demand for “green” products is spurring innovation within the sector. Manufacturers are exploring eco-friendly alternatives for materials used in drills and accessories, such as biodegradable plastics and sustainably sourced metals. B2B buyers should consider these factors when evaluating suppliers, as partnering with environmentally conscious companies can improve corporate social responsibility (CSR) profiles and attract a broader customer base.

What Is the Brief Evolution and History of the Drill with Integral Bullseye Level Technology?

The evolution of drill technology has been marked by significant milestones, reflecting broader trends in manufacturing and engineering. Initially, drills were simple mechanical devices, limited to manual operation. However, as industrialization progressed in the late 19th century, electric drills emerged, transforming the industry by enhancing efficiency and ease of use.

The introduction of alignment technologies, such as the bullseye level, represented a pivotal advancement. Early models relied on manual alignment techniques, which were often imprecise. The integration of laser-guided alignment systems in the late 20th century marked a turning point, providing users with real-time feedback on drill positioning. This innovation not only improved accuracy but also reduced the time spent on setup.

Today, products like the BullseyeBore Core exemplify the latest advancements, combining laser technology with user-friendly design. These developments cater to both professional contractors and DIY users, highlighting the continuous quest for precision and efficiency in the drilling sector. As technology progresses, the future may hold even more sophisticated solutions that integrate smart capabilities, further enhancing the user experience and operational effectiveness.

Illustrative image related to drill with integral bullseye level

Frequently Asked Questions (FAQs) for B2B Buyers of drill with integral bullseye level

-

How do I solve the issue of drilling misalignment with my current drill?

To address misalignment, consider integrating a drill with an integral bullseye level, such as the BullseyeBore Core. This tool projects visual patterns onto the work surface, allowing users to quickly assess alignment. By ensuring that the patterns are concentric, you can easily achieve straight, perpendicular holes. Additionally, training your team on its use can significantly enhance drilling accuracy and reduce errors, which is particularly valuable in high-stakes projects. -

What is the best drill with integral bullseye level for industrial applications?

For industrial applications, the BullseyeBore Core is highly recommended due to its compatibility with various commercial electric drills and drill bits. It functions effectively in any orientation, making it ideal for diverse drilling tasks, from vertical to horizontal. The ability to work without contact with the work surface prevents damage, which is essential in professional settings. Evaluate your specific operational needs, such as drilling depth and bit types, to select the most suitable model. -

How can I ensure the quality of the drill with integral bullseye level I purchase?

When sourcing drills, conduct thorough supplier vetting by checking their certifications, production processes, and customer reviews. Request samples to evaluate product quality before committing to larger orders. Additionally, inquire about quality assurance processes, including testing methods and materials used. Establishing a relationship with reliable suppliers can lead to better quality control and consistent supply. -

What customization options are available for bulk orders of drills?

Many manufacturers offer customization options for bulk orders, including branding, color variations, and specific features tailored to your operational needs. When negotiating with suppliers, clearly communicate your requirements and ask about minimum order quantities (MOQs) for customized products. This ensures that you receive drills that meet your specific application needs while also enhancing your brand visibility in the market. -

What are the typical payment terms for international B2B purchases of drills?

Payment terms can vary significantly by supplier and region, but common practices include a deposit upfront (usually 30% to 50%) and the balance upon shipment or delivery. Discussing payment methods such as letters of credit, PayPal, or bank transfers can provide security for both parties. Always ensure that the agreed terms are documented in your purchase contract to avoid misunderstandings. -

How do I manage logistics for shipping drills internationally?

Effective logistics management involves choosing a reliable freight forwarder experienced in handling tools and equipment. Discuss shipping options, including air and sea freight, to determine the most cost-effective and timely solution. Ensure you understand the customs regulations and duties in the destination country, as these can significantly affect delivery timelines and costs. Proper documentation is crucial to facilitate smooth customs clearance. -

What safety guidelines should I follow when using a drill with an integral bullseye level?

Adhering to safety guidelines is essential to prevent accidents. Always read the manufacturer’s safety instructions, wear appropriate personal protective equipment (PPE), and ensure the workspace is clear of obstacles. The BullseyeBore Core, for instance, is designed to disconnect safely if it encounters an obstruction, but operators should still remain vigilant and maintain focus while drilling. Regular training and safety drills can further enhance workplace safety. -

What factors should I consider when evaluating suppliers for drills with integral bullseye levels?

When evaluating suppliers, consider their industry experience, production capacity, and customer service reputation. Check for certifications that indicate quality standards and sustainability practices. Additionally, assess their ability to provide technical support and after-sales service. Building a partnership with a supplier that aligns with your values and business goals can lead to a more successful and sustainable procurement process.

Top 3 Drill With Integral Bullseye Level Manufacturers & Suppliers List

1. BullseyeBore – Core Drill Alignment Device

Domain: bullseyebore.com

Registered: 2015 (10 years)

Introduction: BullseyeBore Core is a drill alignment device designed to ensure straight (perpendicular) holes by projecting circular patterns on the worksurface. It works with a variety of common commercial electric drills and drill bits, including Standard, Hex Shank, Spade, Step, Masonry, and Auger bits. The device operates safely, disconnecting if an obstruction is encountered during drilling. It functions i…

2. Bulleye Bore – Straight Hole Drilling Tool

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The Bulleye Bore is a tool designed for drilling straight holes. It is currently in the Kickstarter phase and is not yet available for purchase. The product was first teased in 2015 and has a YouTube page showcasing its features. There are concerns about its availability and legitimacy, with some users expressing skepticism about it being ‘vaporware.’ The expected retail price is $129 for a set of…

3. Stahl – Drilling Machine Level

Domain: stahl-libellen.com

Registered: 2009 (16 years)

Introduction: Drilling machine level – Code no. 200 300; Easy to attach on all types of drilling machines; Suitable for both vertical and horizontal drilled holes; Designed for professionals and domestic use; Available on Amazon.de; Includes video instructions for attachment and use.

Strategic Sourcing Conclusion and Outlook for drill with integral bullseye level

In the competitive landscape of precision drilling tools, the drill with integral bullseye level represents a significant advancement in operational efficiency and accuracy. B2B buyers across Africa, South America, the Middle East, and Europe can leverage this technology to enhance productivity, reduce material waste, and ensure superior quality in their projects. The ability of tools like the BullseyeBore Core to provide real-time feedback on alignment empowers users to make informed adjustments quickly, saving both time and costs.

Strategic sourcing of these innovative drilling solutions not only strengthens supplier partnerships but also positions businesses to capitalize on the growing demand for high-quality, accurate drilling tools. By investing in products that enhance operational capabilities, buyers can differentiate themselves in a crowded marketplace, meeting the diverse needs of their clientele.

As the industry evolves, staying ahead means embracing technological advancements. We encourage international B2B buyers to explore these cutting-edge drilling solutions and consider how they can integrate them into their operations. By doing so, they can ensure they are equipped for future challenges while maximizing their competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.