Dot Peen: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for dot peen

In the competitive landscape of global manufacturing, sourcing reliable and efficient marking solutions like dot peen technology presents a significant challenge for B2B buyers. The ability to ensure product traceability while maintaining high production throughput is paramount, particularly for businesses in regions such as Africa, South America, the Middle East, and Europe. This guide delves into the multifaceted world of dot peen marking, offering insights into various types of systems, their diverse applications across industries, and essential factors for supplier vetting.

As you navigate the complexities of selecting the right dot peen marking system, this comprehensive resource empowers you with the knowledge needed to make informed purchasing decisions. From understanding the advantages of dot peen over other marking methods to evaluating cost-effectiveness and integration capabilities, we cover every aspect crucial for your business’s operational efficiency.

Whether you’re in the automotive, aerospace, or heavy equipment manufacturing sectors, this guide aims to equip you with actionable insights that enhance your procurement strategy. By leveraging the information contained herein, international buyers can confidently invest in dot peen marking solutions that not only meet their immediate needs but also align with long-term growth objectives.

Understanding dot peen Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Integrated Systems | Fully automated, in-line marking systems | Automotive, Electronics, Heavy Equipment | Pros: High efficiency, real-time marking. Cons: Higher initial investment. |

| Benchtop Systems | Complete workstations for stationary marking | Manufacturing, Aerospace, Medical | Pros: Versatile for various tasks. Cons: Limited mobility. |

| Portable Systems | Hand-held, mobile units for large parts | Construction, Field Services | Pros: Flexibility and ease of use. Cons: Battery life may vary. |

| Tag Marking Machines | Dedicated systems for marking tags and plates | Logistics, Inventory Management | Pros: Specialized for tags. Cons: Limited to tag size and format. |

| Intelligent Impact Systems | Patented marking technology for uneven surfaces | Aerospace, Automotive, Defense | Pros: Consistent quality on irregular surfaces. Cons: May require training. |

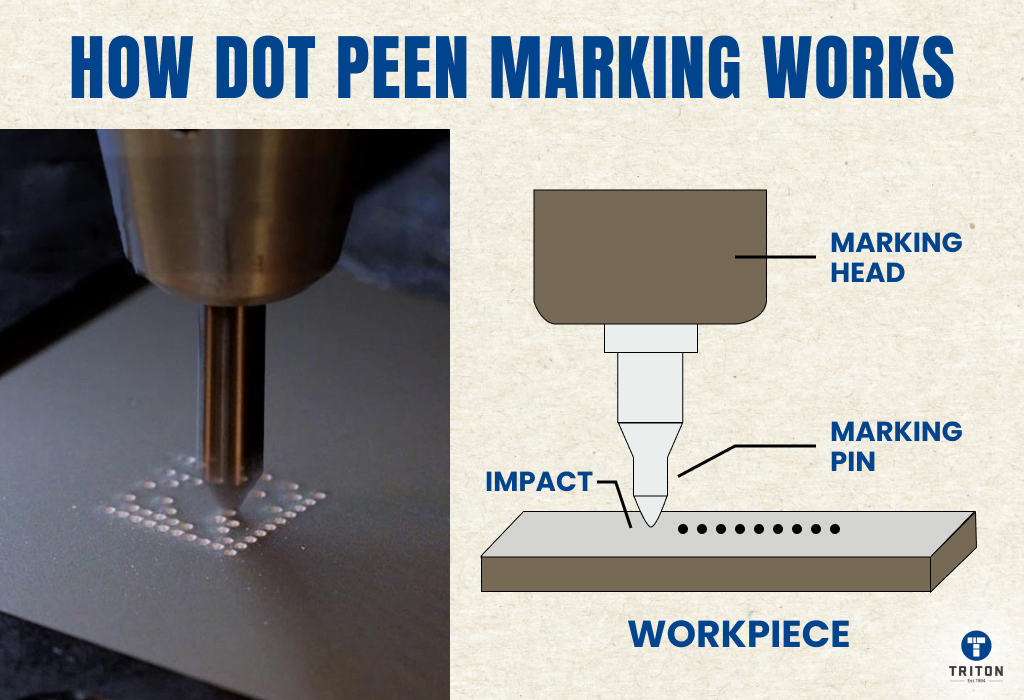

What are Integrated Dot Peen Marking Systems?

Integrated dot peen marking systems are designed for seamless integration into automated production lines. These systems offer real-time marking capabilities, which significantly enhance production efficiency. They are particularly suited for industries such as automotive and electronics, where high throughput and precision are critical. Buyers should consider the upfront investment against the long-term productivity gains and labor savings these systems can deliver.

How Do Benchtop Dot Peen Marking Systems Operate?

Benchtop dot peen marking systems provide a stationary solution for part marking, allowing manufacturers to handle various tasks from a single workstation. These systems are versatile, making them ideal for applications in aerospace and medical industries where precision is paramount. Buyers should evaluate their specific marking needs and consider the potential for increased operational efficiency against the limited mobility of these systems.

What Advantages Do Portable Dot Peen Marking Systems Offer?

Portable dot peen marking systems are hand-held devices that offer flexibility for marking large or irregularly shaped parts in various environments. Ideal for construction and field services, these systems allow for marking on-site, enhancing convenience and reducing downtime. Buyers should consider factors such as battery life and ease of use when selecting portable solutions to ensure they meet operational demands.

What are the Unique Features of Tag Marking Machines?

Tag marking machines are specialized systems designed for marking tags and plates used in logistics and inventory management. They provide precise and permanent markings, which are crucial for traceability. While these machines are efficient for specific applications, buyers should be aware of their limitations regarding tag size and format to ensure they align with their operational needs.

How Do Intelligent Impact Systems Enhance Marking Quality?

Intelligent Impact systems utilize patented technology to maintain consistent marking quality on uneven surfaces. This feature is particularly beneficial in industries such as aerospace and defense, where component integrity is vital. Buyers should assess the training requirements and operational adaptations needed to fully leverage this advanced technology, balancing the quality benefits against potential learning curves.

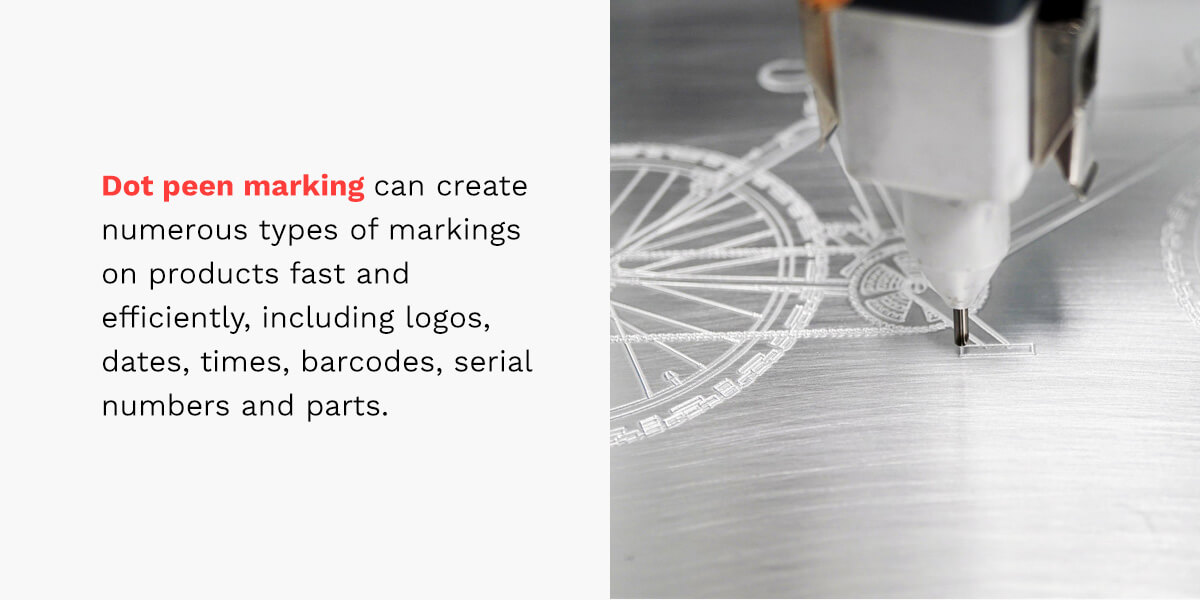

Key Industrial Applications of dot peen

| Industry/Sector | Specific Application of dot peen | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Marking VINs and part numbers on components | Enhances traceability, reduces rework, and improves compliance with regulations | Need for high-speed, automated systems for production lines |

| Aerospace | Engraving serial numbers on aircraft components | Ensures compliance with safety regulations and traceability | Equipment must handle a variety of materials, including alloys |

| Medical Devices | Marking surgical instruments and implants | Guarantees patient safety through traceability and regulatory compliance | Requires precision and the ability to mark on small, complex surfaces |

| Heavy Equipment | Marking equipment specifications and safety labels | Increases equipment lifespan through proper identification and reduces liability | Durability and adaptability to harsh environments are crucial |

| Electronics | Marking circuit boards and components | Facilitates quality control and inventory management | Systems must be flexible enough to handle various materials and sizes |

How is Dot Peen Marking Applied in the Automotive Industry?

In the automotive sector, dot peen marking is essential for engraving Vehicle Identification Numbers (VINs) and part numbers directly onto components. This method enhances traceability and compliance with industry regulations, significantly reducing the risk of counterfeit parts entering the supply chain. For B2B buyers, sourcing dot peen systems that can integrate seamlessly into high-speed production lines is critical, ensuring that marking processes do not disrupt overall manufacturing efficiency.

What Role Does Dot Peen Play in Aerospace Applications?

In aerospace, dot peen marking is used to engrave serial numbers on critical components, ensuring compliance with stringent safety regulations. This technology offers precise, permanent markings on various materials, including high-strength alloys. Buyers in this sector should prioritize equipment that can handle complex geometries and provide reliable marking under rigorous quality standards, as any failure in traceability could have dire consequences.

Why is Dot Peen Important for Medical Devices?

Dot peen marking technology is vital in the medical device industry for marking surgical instruments and implants. It ensures that each item can be traced back to its production batch, which is crucial for patient safety and regulatory compliance. B2B buyers must consider the precision of the marking systems, especially when dealing with small and intricate parts, to maintain the highest standards of quality and reliability.

How Does Dot Peen Enhance Heavy Equipment Identification?

In the heavy equipment sector, dot peen marking is used to inscribe equipment specifications and safety labels directly onto machinery. This practice not only improves equipment traceability but also aids in compliance with safety regulations, reducing liability for manufacturers. Buyers should look for robust marking solutions that can withstand harsh environmental conditions and provide clear, durable markings to ensure long-term visibility and legibility.

What Benefits Does Dot Peen Offer in the Electronics Industry?

In electronics, dot peen marking is employed to mark circuit boards and various components, facilitating quality control and inventory management. The technology allows for high precision and the ability to mark on a range of materials, including plastics and metals. For international B2B buyers, sourcing adaptable systems that can accommodate different sizes and materials is essential for maintaining efficiency in production and ensuring accurate identification throughout the supply chain.

3 Common User Pain Points for ‘dot peen’ & Their Solutions

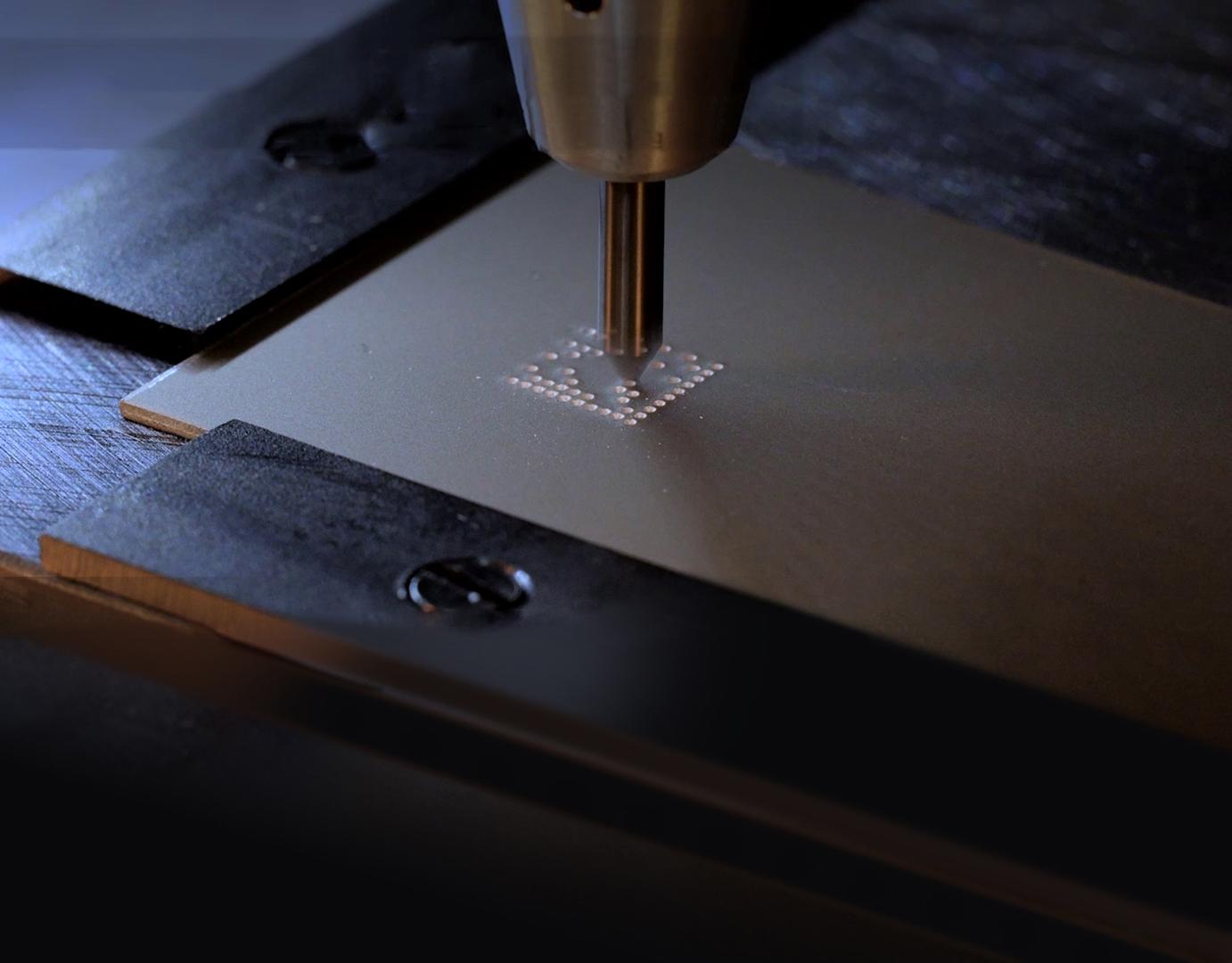

Scenario 1: Inconsistent Mark Quality Complicating Production

The Problem: Many manufacturers face the issue of inconsistent mark quality when using various part marking technologies. For instance, if a buyer has transitioned from manual marking methods to dot peen systems, they may experience difficulties in achieving uniformity across different materials and surfaces. This inconsistency can lead to misidentification during quality checks, resulting in delays, potential scrap, and costly rework. Furthermore, issues can arise when marking on uneven or coated surfaces, where other technologies might falter, resulting in subpar markings that fail to meet traceability standards.

The Solution: To resolve these challenges, B2B buyers should consider investing in advanced dot peen marking systems equipped with features like adjustable marking depth and Intelligent Driving Impact (IDI) technology. This technology allows for marking on a variety of surfaces without compromising the mark quality, even on uneven or coated parts. When sourcing a dot peen system, buyers should look for machines that offer programmable settings for various materials, ensuring that they can achieve consistent results regardless of surface conditions. Additionally, conducting trials on sample materials before full-scale implementation can help identify the optimal settings for each specific application, thus ensuring a seamless transition and preventing future inconsistencies.

Scenario 2: High Labor Costs Due to Inefficient Marking Processes

The Problem: In industries where labor costs are a significant concern, inefficient marking processes can lead to increased operational expenses. For example, companies that rely on manual marking methods may find that workers spend excessive time marking parts, leading to bottlenecks in production. This inefficiency can also increase the risk of human error, resulting in additional costs associated with rework and lost productivity. Buyers in sectors like automotive or aerospace, where precision and speed are critical, often struggle to balance quality with labor costs.

Illustrative image related to dot peen

The Solution: To address these labor cost challenges, businesses should consider integrating automated dot peen marking systems into their production lines. These systems can significantly enhance productivity by allowing for faster, error-free marking without the need for extensive manual intervention. Buyers should look for solutions that offer in-line marking capabilities, enabling seamless integration with existing production workflows. Furthermore, investing in training for personnel on the new automated systems can maximize their effectiveness, ensuring that workers can quickly adapt and that the transition minimizes disruptions. By automating the marking process, companies can not only reduce labor costs but also improve overall production efficiency.

Scenario 3: Difficulty in Data Management and Integration

The Problem: As industries increasingly rely on smart technologies and data-driven decision-making, B2B buyers often encounter challenges with integrating marking systems into their existing data management frameworks. For instance, manufacturers may struggle to connect their dot peen marking equipment with PLCs or host systems, leading to inefficiencies in tracking and traceability. This lack of integration can hinder the ability to maintain accurate records of marked parts, complicating compliance with industry regulations and quality standards.

The Solution: To overcome data management issues, buyers should prioritize dot peen marking systems that offer robust integration capabilities with existing software and hardware. When selecting a marking solution, it’s essential to verify compatibility with their current PLCs, barcode scanners, and data management systems. Additionally, manufacturers should consider investing in training sessions for their IT and operational teams to facilitate smooth integration processes. By ensuring that the marking system can seamlessly communicate with other data sources, companies can enhance their traceability efforts and maintain compliance more efficiently. Investing in technology that supports Industry 4.0 standards can also future-proof their operations, ensuring they remain competitive as data management needs evolve.

Illustrative image related to dot peen

Strategic Material Selection Guide for dot peen

What Are the Key Properties of Common Materials for Dot Peen Marking?

When selecting materials for dot peen marking, it’s essential to consider their properties, suitability for various applications, and how they align with the specific needs of international B2B buyers. Below are analyses of four common materials used in dot peen marking.

Aluminum: A Lightweight and Versatile Option

Key Properties: Aluminum is known for its excellent corrosion resistance, lightweight nature, and good thermal conductivity. It can withstand moderate temperatures and pressures, making it suitable for various industrial applications.

Pros & Cons: The primary advantage of aluminum is its low weight, which facilitates easier handling and transportation. It is also relatively inexpensive compared to other metals. However, it can be more susceptible to scratches and dents, which may affect the quality of the marking if not handled properly.

Impact on Application: Aluminum is commonly used in the automotive and aerospace industries, where weight reduction is crucial. It is compatible with various media, including paints and coatings, which can be marked through during the dot peen process.

Illustrative image related to dot peen

Considerations for International Buyers: Buyers from regions like Europe and South America should ensure compliance with standards such as ASTM B117 for corrosion testing. In Germany, for example, adherence to DIN standards is critical for quality assurance.

Stainless Steel: Durability and Corrosion Resistance

Key Properties: Stainless steel is renowned for its high corrosion resistance and mechanical strength. It can withstand high temperatures and pressures, making it a preferred choice in demanding environments.

Pros & Cons: The durability of stainless steel ensures that markings remain clear and legible over time, even in harsh conditions. However, it is generally more expensive than aluminum and can be challenging to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel is frequently used in the medical and food industries, where hygiene and durability are paramount. Its compatibility with various cleaning media ensures that markings remain intact through rigorous cleaning processes.

Illustrative image related to dot peen

Considerations for International Buyers: Compliance with international standards such as ISO 9001 for quality management systems is essential. Buyers should also be aware of local regulations regarding food safety and medical device manufacturing.

Titanium: High Strength and Lightweight

Key Properties: Titanium is known for its exceptional strength-to-weight ratio and excellent corrosion resistance. It can withstand extreme temperatures, making it ideal for aerospace and military applications.

Pros & Cons: The key advantage of titanium is its durability and lightweight nature, which is beneficial for applications requiring high performance. However, it is one of the more expensive materials and can be difficult to machine, leading to increased production costs.

Impact on Application: Titanium is often used in high-performance applications such as aerospace components and medical implants. Its ability to maintain the integrity of markings under extreme conditions is a significant benefit.

Considerations for International Buyers: Buyers should consider compliance with aerospace standards such as AS9100 and medical device regulations like ISO 13485. Understanding local market demands for titanium products is also crucial for successful procurement.

Polyamide: A Cost-Effective Alternative

Key Properties: Polyamide, commonly known as nylon, exhibits good chemical resistance and flexibility. It can withstand moderate temperatures but is less durable than metals.

Pros & Cons: The primary advantage of polyamide is its cost-effectiveness and ease of processing. It is lightweight and can be molded into complex shapes. However, its lower mechanical strength and temperature resistance may limit its applications.

Illustrative image related to dot peen

Impact on Application: Polyamide is often used in the automotive and consumer goods industries for components that require flexibility and lightweight properties. Dot peen marking on polyamide can produce clear and legible markings, although care must be taken with heat-sensitive applications.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties is important. Buyers should also consider regional preferences for materials, especially in markets where lightweight components are favored.

Summary Table of Material Selection for Dot Peen Marking

| Material | Typical Use Case for dot peen | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive, aerospace components | Lightweight and cost-effective | Susceptible to scratches | Low |

| Stainless Steel | Medical, food processing | High durability and corrosion resistance | Higher cost and machining complexity | High |

| Titanium | Aerospace, military applications | Exceptional strength-to-weight ratio | Expensive and difficult to machine | High |

| Polyamide | Automotive, consumer goods | Cost-effective and easy to process | Lower mechanical strength | Low |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for dot peen marking, helping them make informed decisions that align with industry standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dot peen

What Are the Key Stages in the Manufacturing Process of Dot Peen Marking Systems?

The manufacturing process of dot peen marking systems encompasses several critical stages, each designed to ensure the final product meets stringent quality and performance standards.

Illustrative image related to dot peen

Material Preparation

The first stage involves sourcing high-quality materials that can withstand the rigors of industrial marking. Common materials include various metals such as aluminum, stainless steel, and carbide, as well as plastics like ABS and polypropylene. Suppliers should ensure that the materials meet industry standards for durability and compatibility with dot peen technology.

Forming Techniques

Once the materials are prepared, they undergo forming processes that shape them into components suitable for dot peen marking systems. This may include machining operations like turning and milling to create precise parts, such as marking heads and housings. Advanced techniques like laser cutting may also be employed to ensure high accuracy and minimal waste.

Assembly Process

The assembly stage is where the various components come together. Skilled technicians or automated systems piece together the marking machines, ensuring that all parts fit correctly and function as intended. Quality checks are integral during this phase, with assembly line workers trained to spot any discrepancies or defects immediately.

Illustrative image related to dot peen

Finishing Touches

Finishing processes enhance the durability and aesthetic appeal of the marking systems. This may include anodizing or coating the metal parts to resist corrosion and wear. Additionally, final adjustments are made to calibrate the marking depth and precision, ensuring that each machine can produce the required quality of marks.

How Is Quality Assurance Implemented in Dot Peen Marking Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for dot peen marking systems. It involves various international standards and checkpoints that guarantee the reliability and performance of the marking systems.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with several international quality standards that dot peen marking manufacturers may adhere to, including:

-

ISO 9001: This standard outlines the criteria for a quality management system (QMS). Companies certified to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: Particularly relevant for buyers in Europe, CE marking indicates that a product complies with EU safety, health, and environmental protection standards.

-

API Standards: For industries such as oil and gas, American Petroleum Institute (API) standards ensure that products meet industry-specific quality requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints play a vital role in maintaining the standards of dot peen marking systems. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial inspection checks the quality of raw materials upon arrival at the manufacturing facility. It ensures that only materials meeting specified standards are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor the quality of components. This ensures that any defects are identified and rectified before the final assembly.

-

Final Quality Control (FQC): The final inspection occurs after assembly, where the complete marking systems are tested for functionality and quality. This includes checking the precision of marks, operational consistency, and adherence to performance specifications.

What Common Testing Methods Are Used in Dot Peen Marking Systems?

To ensure that the dot peen marking systems meet quality standards, several testing methods are commonly employed:

-

Performance Testing: This involves running the marking machines to verify their operational capabilities, including speed, accuracy, and the quality of marks on various materials.

-

Durability Testing: Manufacturers may subject the marking systems to stress tests to assess their longevity and resistance to wear over time.

-

Environmental Testing: Given that marking systems may operate in diverse conditions, environmental tests simulate factors such as temperature fluctuations, humidity, and exposure to dust or chemicals.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control processes of suppliers is crucial to ensure that they receive reliable products. Here are some strategies:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. This includes reviewing their adherence to international standards and their internal QC protocols.

-

Quality Reports: Requesting documentation on quality control processes, including IQC, IPQC, and FQC reports, can help buyers assess the thoroughness of a supplier’s quality assurance practices.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s products and processes. This is especially important for international transactions, where local regulations and standards may differ.

What Are the QC Considerations for International B2B Buyers?

When sourcing dot peen marking systems from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should consider the following QC nuances:

-

Regulatory Compliance: Different regions have varying regulations concerning product safety and quality. Understanding local compliance requirements is crucial for avoiding costly delays and ensuring product acceptance in the target market.

-

Cultural and Communication Barriers: Language differences and cultural practices can affect the clarity of quality expectations. Establishing clear communication channels and documentation practices can mitigate misunderstandings.

-

Logistical Challenges: International shipping can introduce risks such as damage or loss. Buyers should ensure that suppliers have robust packaging and shipping processes to protect products during transit.

By understanding the manufacturing processes and quality assurance measures involved in dot peen marking systems, B2B buyers can make informed decisions and establish partnerships with reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dot peen’

The following guide serves as a practical checklist for B2B buyers looking to procure dot peen marking systems. This technology is vital for ensuring product traceability and quality control across various industries. By following this checklist, you can make informed decisions that align with your operational needs and business objectives.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your dot peen marking system. Consider factors such as the materials you will mark (e.g., metals, plastics), the size and complexity of the markings (text, logos, Data Matrix codes), and the environment in which the system will operate (industrial, mobile, or stationary). Understanding these specifications will help you identify suitable suppliers and systems that meet your specific needs.

Illustrative image related to dot peen

Step 2: Research Available Technologies

Investigate the different dot peen marking technologies on the market. Focus on features such as automation capabilities, marking depth adjustment, and compatibility with various surfaces. Look for systems that offer programmable options and ease of integration with your existing production processes, as these can greatly enhance efficiency and reduce operational disruptions.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from other businesses in your industry or region. Pay attention to their experience and reputation in the market, as well as their ability to provide after-sales support and maintenance services, which are crucial for the longevity of your investment.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers you are considering comply with relevant industry standards and regulations. Check for certifications such as ISO 9001 for quality management and any specific certifications related to safety and environmental standards. Compliance is essential not only for legal reasons but also to ensure that you are sourcing high-quality equipment that meets international standards.

Illustrative image related to dot peen

Step 5: Request Demonstrations and Samples

Whenever possible, request product demonstrations or samples of the marking systems. This allows you to assess the quality and speed of the marking process firsthand. Pay attention to the ease of use, the clarity of the markings produced, and how well the equipment performs on different materials, as these factors can significantly impact your production quality.

Step 6: Discuss Warranty and Support Options

Inquire about the warranty terms and post-purchase support offered by the supplier. A comprehensive warranty can protect your investment, while responsive customer support can minimize downtime in case of technical issues. Look for suppliers who offer training services for your staff to ensure they can operate the equipment effectively.

Step 7: Compare Pricing and Total Cost of Ownership

Finally, evaluate the pricing of the systems you are considering, but do not focus solely on the initial purchase price. Calculate the total cost of ownership, including maintenance, consumables, and potential downtime. A higher upfront cost may be justified by lower operational costs and higher reliability in the long run, making it essential to analyze the overall value each option provides.

By following this checklist, you can systematically approach the procurement of dot peen marking systems, ensuring that your investment aligns with your operational goals and quality standards.

Comprehensive Cost and Pricing Analysis for dot peen Sourcing

Understanding the cost structure and pricing dynamics of dot peen marking systems is essential for international B2B buyers. This technology, known for its precision and efficiency in part marking, involves various cost components that can significantly influence the total investment.

What Are the Key Cost Components for Dot Peen Marking Systems?

-

Materials: The primary costs in dot peen marking come from the materials used in the machines, such as carbide marking pins and durable casings. The choice of materials impacts the longevity and effectiveness of the marking, especially when dealing with hard metals or specialized plastics.

-

Labor: While dot peen marking is designed to automate processes, labor costs still play a role, particularly in installation, maintenance, and operation. Skilled technicians may be required for setup and troubleshooting, especially in complex manufacturing environments.

-

Manufacturing Overhead: This encompasses costs related to the facilities, utilities, and indirect labor associated with the production of dot peen marking systems. Efficient manufacturing practices can help minimize overhead, contributing to more competitive pricing.

-

Tooling: The initial investment in tooling, including dies and fixtures specifically for dot peen marking, can be substantial. This cost is often amortized over the volume of parts marked, making it crucial to consider the expected production run when evaluating tooling expenses.

-

Quality Control (QC): Ensuring that marking meets industry standards requires a robust QC process. This includes testing for mark durability and legibility, which can add to the overall cost but is essential for compliance and traceability.

-

Logistics: Shipping and handling costs can vary significantly based on the geographical location of the supplier and buyer. For international transactions, customs duties and import taxes must also be factored into the logistics costs.

-

Margin: Suppliers typically apply a margin on top of their costs to ensure profitability. The margin can vary based on market demand, competition, and the supplier’s positioning within the industry.

What Factors Influence Dot Peen Marking Prices?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their production needs to optimize pricing.

-

Specifications and Customization: Custom features, such as specific marking depths or tailored software integration, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and compliance with industry certifications (e.g., ISO standards) can lead to increased prices. However, these factors also enhance the machine’s reliability and lifespan.

-

Supplier Factors: The supplier’s reputation, experience, and location can significantly affect pricing. Established suppliers may command higher prices due to their reliability and service levels.

-

Incoterms: Understanding the agreed-upon Incoterms (International Commercial Terms) is crucial. They dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk management, directly impacting the final price.

What Are the Best Practices for Buyers to Negotiate Dot Peen Marking Prices?

-

Effective Negotiation: Engage in discussions with multiple suppliers to compare prices and terms. Leverage competitive quotes to negotiate better deals.

-

Focus on Cost-Efficiency: Consider not just the purchase price but also the Total Cost of Ownership (TCO), which includes maintenance, operational costs, and potential downtime.

-

Pricing Nuances for International Buyers: Different regions may have varying price structures due to local regulations, tariffs, and market conditions. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these nuances.

-

Disclaimer on Indicative Prices: It’s important to note that prices can fluctuate based on market conditions and supplier negotiations. Always seek updated quotes and clarify all terms before finalizing any agreements.

By understanding these cost components and price influencers, B2B buyers can make informed decisions when sourcing dot peen marking systems, ultimately ensuring that their investment aligns with their operational needs and budgetary constraints.

Alternatives Analysis: Comparing dot peen With Other Solutions

Exploring Alternatives to Dot Peen Marking Technology

When considering marking solutions for parts and products, businesses often evaluate various methods to ensure optimal performance, cost-effectiveness, and ease of use. Dot peen marking, known for its precision and reliability, stands out among alternatives. However, understanding how it compares to other technologies is crucial for making informed decisions. Below, we examine two viable alternatives: laser marking and chemical etching.

| Comparison Aspect | Dot Peen | Laser Marking | Chemical Etching |

|---|---|---|---|

| Performance | High-quality, permanent marks; versatile with various materials | Excellent precision; ideal for intricate designs | Durable markings, but limited to conductive materials |

| Cost | Moderate initial investment; low operating costs | Higher initial costs; lower consumable costs | High consumable costs; additional chemical handling expenses |

| Ease of Implementation | Easy to integrate; programmable for automation | Requires specialized training; setup can be complex | Multi-step process; difficult to automate |

| Maintenance | Low maintenance; durable machines | Moderate maintenance; lens cleaning required | High maintenance; hazardous waste management |

| Best Use Case | General manufacturing, automotive, aerospace | High-detail applications, electronics | Specific industrial applications, metal parts |

Understanding Laser Marking: Advantages and Disadvantages

Laser marking utilizes focused light to engrave or etch designs onto various materials. Its primary advantage lies in its precision, making it ideal for intricate logos or barcodes. Laser systems can handle a wide range of surfaces, including metals and plastics. However, laser marking generates heat, which can be problematic for certain materials, leading to potential surface damage. Additionally, the initial setup costs can be higher than dot peen systems, and it often requires specialized training to operate effectively.

Evaluating Chemical Etching: Pros and Cons

Chemical etching involves using corrosive substances to remove layers from a material’s surface, creating a mark. While it can produce highly durable markings on metals, the process is complex and often requires a multi-step approach, which complicates automation. Moreover, chemical etching is limited to conductive surfaces, making it less versatile than dot peen marking. The ongoing costs for chemicals and the need for proper waste disposal also contribute to its higher operational expenses.

Conclusion: How to Choose the Right Marking Solution for Your Business Needs

Selecting the appropriate marking technology hinges on various factors, including the specific requirements of your manufacturing process, budget constraints, and desired marking quality. Dot peen marking offers a balanced solution with its reliability, cost-effectiveness, and versatility across materials. In contrast, laser marking excels in precision for intricate designs, while chemical etching serves niche applications but comes with higher costs and complexity. By assessing these alternatives in relation to your operational needs, you can make a strategic decision that enhances productivity and product traceability in your organization.

Essential Technical Properties and Trade Terminology for dot peen

What Are the Key Technical Properties of Dot Peen Marking?

When evaluating dot peen marking systems, it’s crucial to understand specific technical properties that directly impact operational efficiency, cost, and product quality. Here are some essential specifications:

-

Marking Depth

– Definition: This refers to how deep the marking pin can imprint on a material surface, which can be adjusted based on the application.

– B2B Importance: Proper marking depth ensures durability and legibility of the marks. For industries such as automotive and aerospace, where traceability is paramount, the ability to adjust depth can help meet stringent regulatory requirements. -

Material Compatibility

– Definition: The range of materials that can be marked, including metals (like steel and aluminum) and plastics (like ABS and polypropylene).

– B2B Importance: Understanding material compatibility allows businesses to ensure that their marking system can handle the specific materials used in their products, minimizing the risk of damage and ensuring consistent quality. -

Marking Speed

– Definition: This indicates how quickly the marking system can operate, often measured in marks per minute or per second.

– B2B Importance: Faster marking speeds contribute to increased production throughput. For manufacturers, this means higher efficiency and the ability to meet tight production schedules without compromising on quality. -

Integration Capabilities

– Definition: The ability of dot peen systems to connect with existing production line machinery, such as PLCs (Programmable Logic Controllers) and barcode scanners.

– B2B Importance: Seamless integration reduces downtime and enhances workflow efficiency. Companies looking to automate their processes can benefit from systems that easily connect to their current infrastructure. -

Impact Force

– Definition: This specifies the amount of force exerted by the marking pin during the marking process.

– B2B Importance: Low-impact force minimizes stress on the parts being marked, reducing the likelihood of warping or damage, especially for delicate components. This is particularly beneficial in industries where part integrity is crucial. -

Portability

– Definition: The ease with which a marking system can be moved or adapted for different marking environments, such as workshop or on-site applications.

– B2B Importance: Portable systems offer flexibility, allowing companies to mark large or heavy items without needing to transport them. This is advantageous for businesses in construction or heavy machinery sectors.

What Are Common Trade Terms Related to Dot Peen Marking?

Familiarizing yourself with industry terminology is vital for effective communication and decision-making in the B2B landscape. Here are several key terms related to dot peen marking:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can influence procurement strategies, particularly when sourcing marking systems that need to be compatible with existing machinery. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps businesses manage inventory and cost. For marking equipment, understanding MOQ can ensure that manufacturers order sufficient quantities to meet production needs without excess. -

RFQ (Request for Quotation)

– Definition: A business process wherein a company invites suppliers to submit price proposals for specific goods or services.

– Relevance: Using RFQs enables companies to compare pricing and specifications of different dot peen marking systems, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define responsibilities of sellers and buyers for the delivery of goods under sales contracts.

– Relevance: Understanding Incoterms is crucial when negotiating international purchases of marking equipment, as they clarify cost allocation and risk management during shipping. -

Traceability

– Definition: The ability to verify the history, location, or application of an item by means of documented recorded identification.

– Relevance: In industries like automotive or pharmaceuticals, traceability is critical for compliance and quality assurance. Dot peen marking systems enhance traceability through permanent, readable markings. -

Customization

– Definition: The ability to tailor products or services to meet specific customer requirements.

– Relevance: Customizable marking systems allow businesses to adapt their equipment to various marking needs, enhancing versatility and operational efficiency.

Understanding these properties and terms will empower international B2B buyers to make informed decisions regarding dot peen marking systems, ensuring they select the right solutions for their specific industrial applications.

Navigating Market Dynamics and Sourcing Trends in the dot peen Sector

What Are the Key Market Drivers for Dot Peen Marking Solutions?

The dot peen marking sector is witnessing significant growth driven by the increasing need for product traceability and compliance with stringent regulatory requirements. Industries such as automotive, aerospace, and electronics are under pressure to provide clear and durable identification of components, making dot peen marking an attractive solution due to its efficiency and reliability. Furthermore, the rise of Industry 4.0 is pushing manufacturers to adopt automated solutions that enhance productivity and reduce labor costs.

Illustrative image related to dot peen

Emerging technologies are facilitating the integration of dot peen marking systems into automated production lines, allowing for real-time data integration from various sources such as PLCs and host systems. This trend is particularly relevant for B2B buyers in regions like Africa and South America, where manufacturing capabilities are rapidly evolving. Buyers are increasingly seeking suppliers that offer versatile, portable, and customizable marking solutions that can adapt to different materials and production environments.

Moreover, as companies expand their global footprints, the demand for consistent quality across diverse markets is paramount. Dot peen marking systems, with their ability to maintain high-quality marks even on uneven surfaces, are well-positioned to meet these requirements, thereby enhancing supply chain efficiency and reducing the likelihood of errors.

How Can Sustainability and Ethical Sourcing Impact the Dot Peen Sector?

Sustainability is becoming a critical consideration for B2B buyers in the dot peen marking sector. As manufacturers strive to minimize their environmental footprint, the choice of marking technology plays a pivotal role. Dot peen marking is inherently eco-friendly, producing no hazardous waste or emissions, unlike some traditional marking methods such as chemical etching and laser marking, which can generate harmful byproducts.

Additionally, ethical sourcing of materials is gaining traction. Buyers are increasingly interested in suppliers that prioritize sustainable practices, such as utilizing recyclable or biodegradable materials in their products. Certifications like ISO 14001 for environmental management systems can serve as a benchmark for evaluating suppliers’ commitment to sustainability.

Investing in dot peen marking technology that adheres to these principles not only enhances a company’s reputation but also attracts environmentally conscious clients. This trend is particularly relevant for businesses operating in regions like Europe, where regulations around sustainability are stringent, and consumers are more likely to favor brands that demonstrate a commitment to ethical practices.

Illustrative image related to dot peen

What Is the Evolution of Dot Peen Marking Technology?

The evolution of dot peen marking technology has been marked by significant advancements in both hardware and software. Initially developed as a manual marking solution, the technology has transformed into sophisticated automated systems capable of high-speed, precise marking on a wide variety of materials.

The introduction of pneumatic-driven marking pins has enhanced the quality and depth of marks, while the development of programmable systems allows for greater flexibility and efficiency in production lines. Innovations such as Technomark’s Intelligent Driving Impact (IDI) feature have further improved the ability to mark uneven surfaces without compromising quality.

As industries continue to evolve, the demand for reliable, efficient, and sustainable marking solutions is only expected to grow. This trajectory highlights the importance of staying informed about the latest advancements and trends in the dot peen marking sector to ensure competitive advantage in the global market.

Illustrative image related to dot peen

Frequently Asked Questions (FAQs) for B2B Buyers of dot peen

1. How do I select the right dot peen marking machine for my needs?

When choosing a dot peen marking machine, consider factors such as the materials you will be marking (e.g., metals, plastics), the required marking depth and precision, and whether you need a portable or stationary unit. Assess your production volume and whether you require automated integration with existing systems. Additionally, evaluate features like wireless connectivity, ease of use, and the ability to mark complex codes or logos. Consulting with suppliers who can demonstrate their machines and provide samples can also help in making an informed decision.

2. What are the key advantages of dot peen marking over other methods?

Dot peen marking offers several advantages, including high-speed, precise marking with minimal surface stress, making it suitable for both rough and smooth surfaces. It can mark through coatings and is capable of creating permanent, scannable 2D Data Matrix codes. Unlike laser marking, dot peen does not generate heat or fumes, making it safer for operators. Additionally, it eliminates the debris often associated with traditional marking methods, maintaining the integrity of the marked parts without the need for post-processing.

3. How can I ensure the quality and reliability of a dot peen marking supplier?

To ensure the quality and reliability of a dot peen marking supplier, start by checking their industry reputation and customer reviews. Request case studies or references from previous clients to understand their experiences. Evaluate the supplier’s certifications and adherence to international quality standards. Additionally, inquire about their after-sales support, warranty terms, and maintenance services. A visit to their manufacturing facility can also provide insight into their production processes and quality control measures.

4. What customization options are available for dot peen marking systems?

Many manufacturers offer customization options for dot peen marking systems, including adjustable marking depths, various marking pin sizes, and the ability to create custom layouts for specific applications. Some systems can be tailored for specific industries, such as automotive or aerospace, with features designed to meet regulatory requirements. Additionally, software customization may be available to integrate with your existing production management systems, allowing for seamless data transfer and enhanced productivity.

5. What are the typical minimum order quantities (MOQs) for dot peen marking machines?

Minimum order quantities (MOQs) for dot peen marking machines can vary significantly based on the supplier and the specific product line. Some manufacturers may have MOQs for bulk orders to optimize production efficiency, while others may offer single units for smaller businesses. It’s advisable to discuss your needs with suppliers directly, as they may accommodate smaller orders or offer financing options to support your initial investment, especially for international buyers.

6. What payment terms should I expect when purchasing dot peen marking equipment?

Payment terms for dot peen marking equipment typically vary by supplier and can include options like upfront payment, partial payments, or financing plans. Common terms might involve a deposit upon order confirmation, with the balance due before shipment or installation. International buyers should clarify any additional fees related to shipping, customs duties, and currency exchange. It’s also prudent to negotiate terms that align with your budget and cash flow needs while ensuring security through escrow or letters of credit when necessary.

7. How do logistics and shipping impact the purchase of dot peen marking systems?

Logistics and shipping play a crucial role in the procurement of dot peen marking systems, especially for international buyers. Factors such as shipping costs, delivery timelines, and customs clearance can significantly affect the overall purchase experience. It’s important to discuss these aspects with your supplier to understand their shipping processes, including whether they handle customs documentation. Additionally, consider the location of the supplier and whether they offer localized support for installation and training, which can mitigate logistics challenges.

8. What industries commonly use dot peen marking technology?

Dot peen marking technology is widely used across various industries, including automotive, aerospace, energy, metallurgy, medical, and electronics. Its versatility makes it suitable for applications requiring permanent traceability, such as part identification, serialization, and compliance with industry regulations. Industries like heavy equipment manufacturing and public works also benefit from its durability and precision. Understanding the applications within your industry can help you determine the best solutions for your specific marking needs.

Top 1 Dot Peen Manufacturers & Suppliers List

1. CMT Home Products – Handy Andy X Dot-Peen Marking Machine

Domain: columbiamt.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Handy Andy X Dot-Peen Marking Machine”, “brand”: “CMT Home Products”, “model”: “Handy Andy X”, “price”: “$3,910.00”, “original_price”: “$4,600.00”, “marking_type”: “Dot-Peen”, “marking_speed”: “3-4 characters per second”, “marking_window”: “3.15” x 1.97″ (50 x 80mm)”, “marking_materials”: [“Plastic”, “Wood”, “Metals (up to 45RC)”], “power_requirements”: {“voltage”: “110 VAC”, “co…

Strategic Sourcing Conclusion and Outlook for dot peen

In the ever-evolving landscape of industrial marking, dot peen technology stands out as a robust solution for permanent traceability and efficiency. Its versatility allows for high-quality marks on various surfaces, including metals and plastics, while minimizing labor costs and reducing errors. By adopting dot peen marking systems, manufacturers can enhance productivity, improve product identification, and ultimately drive down costs associated with rework and scrap.

Strategic sourcing plays a critical role in optimizing the procurement of dot peen marking equipment. By partnering with reputable suppliers, businesses in Africa, South America, the Middle East, and Europe can ensure they acquire cutting-edge technology that aligns with their operational needs. Evaluating factors such as system capabilities, ease of integration, and after-sales support can lead to informed decisions that bolster production efficiency.

As industries continue to embrace automation and Industry 4.0 principles, the demand for innovative marking solutions will grow. Now is the time for international B2B buyers to explore dot peen marking technologies, positioning their organizations for success in an increasingly competitive market. Reach out to industry experts today to discover how dot peen marking can transform your operations and enhance your product traceability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.