Door Lock Parts Names Diagram: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for door lock parts names diagram

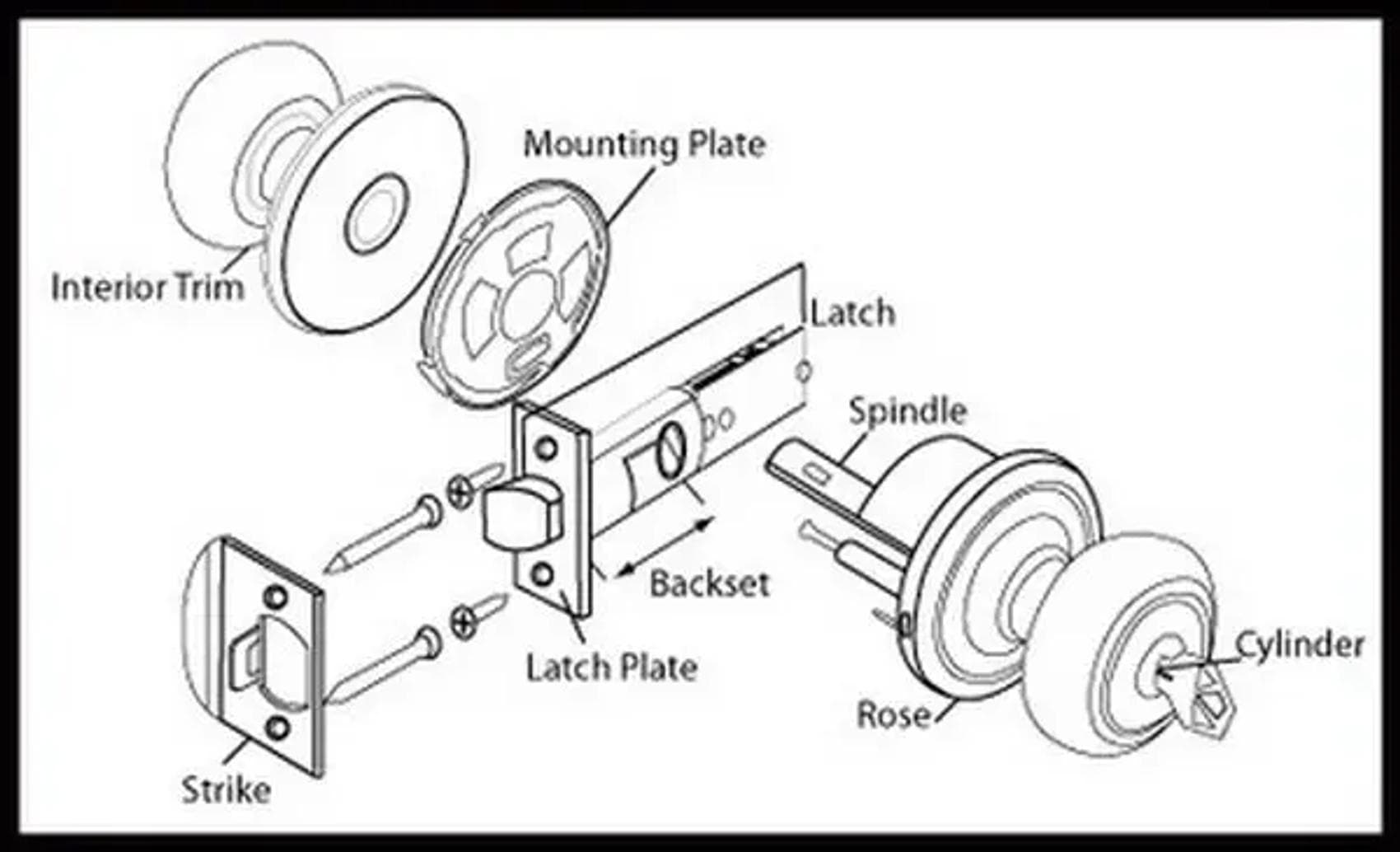

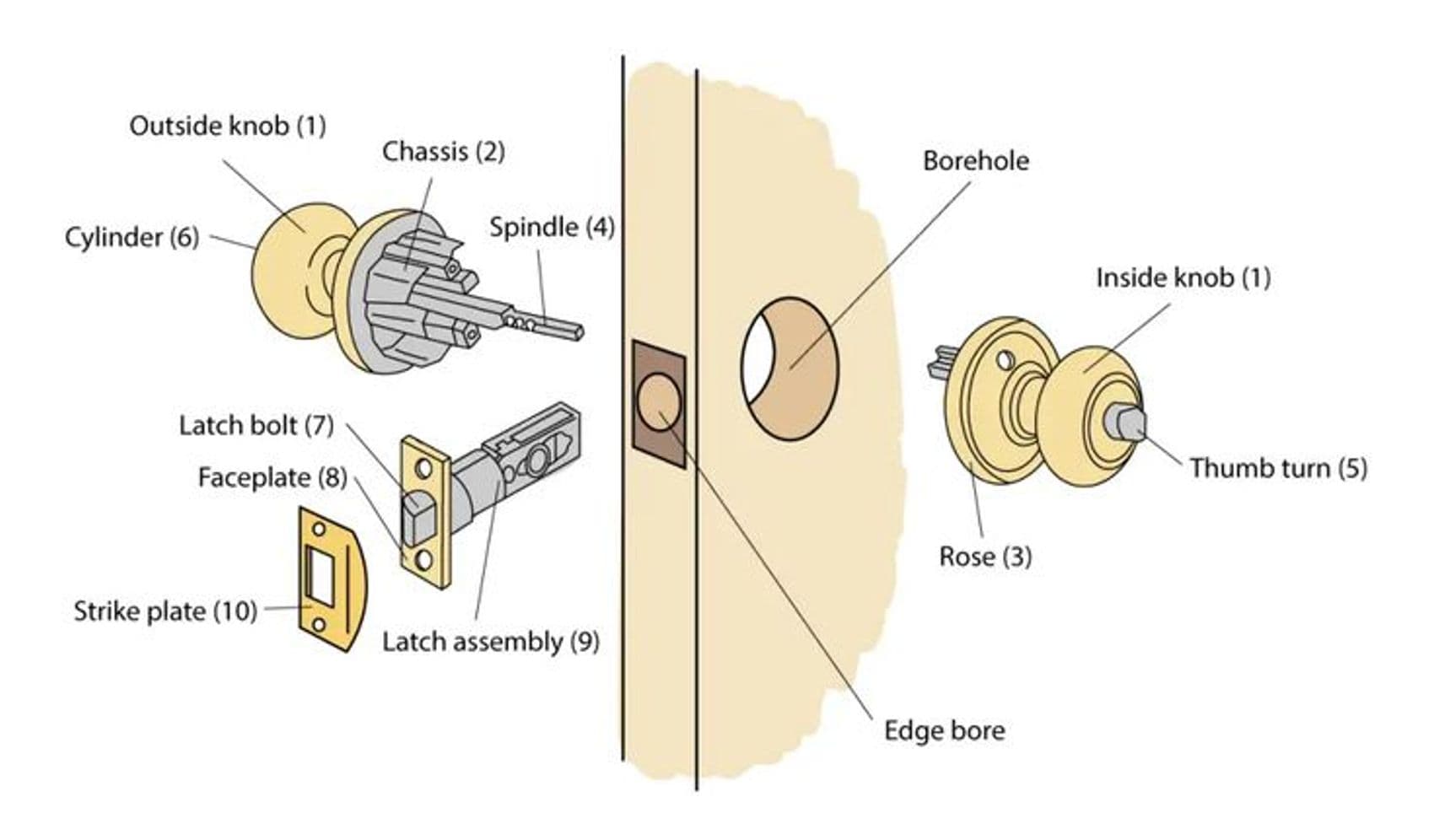

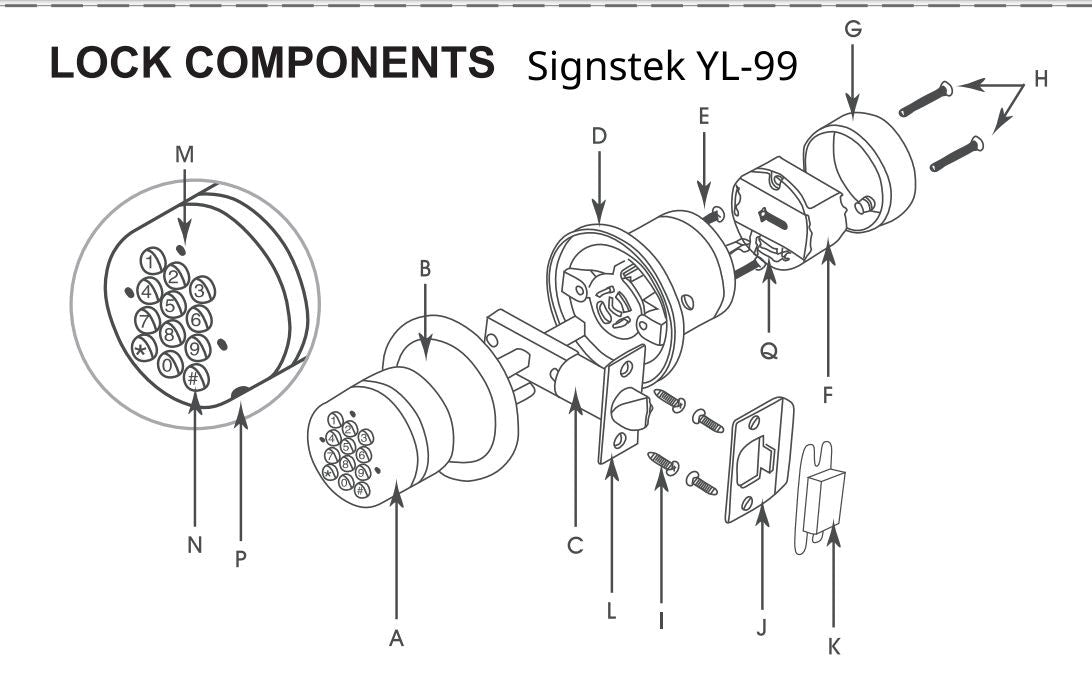

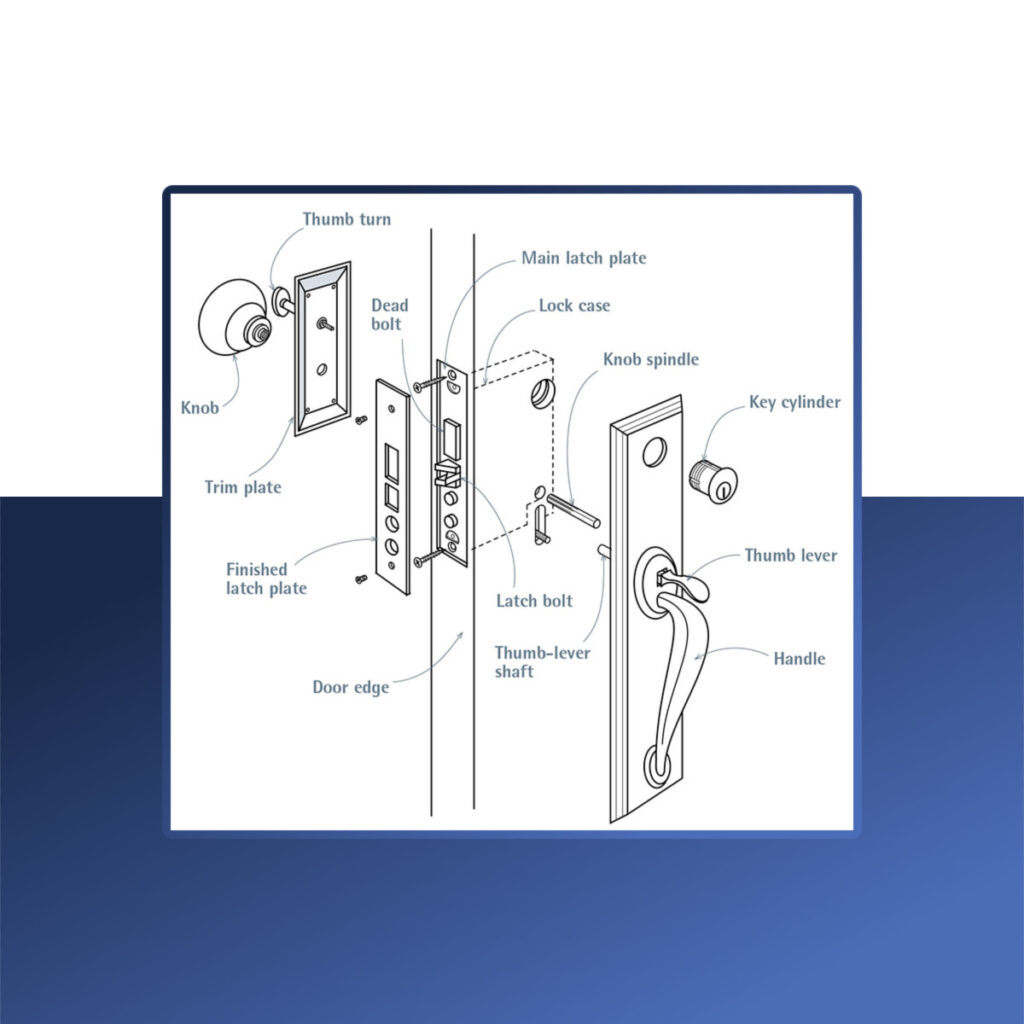

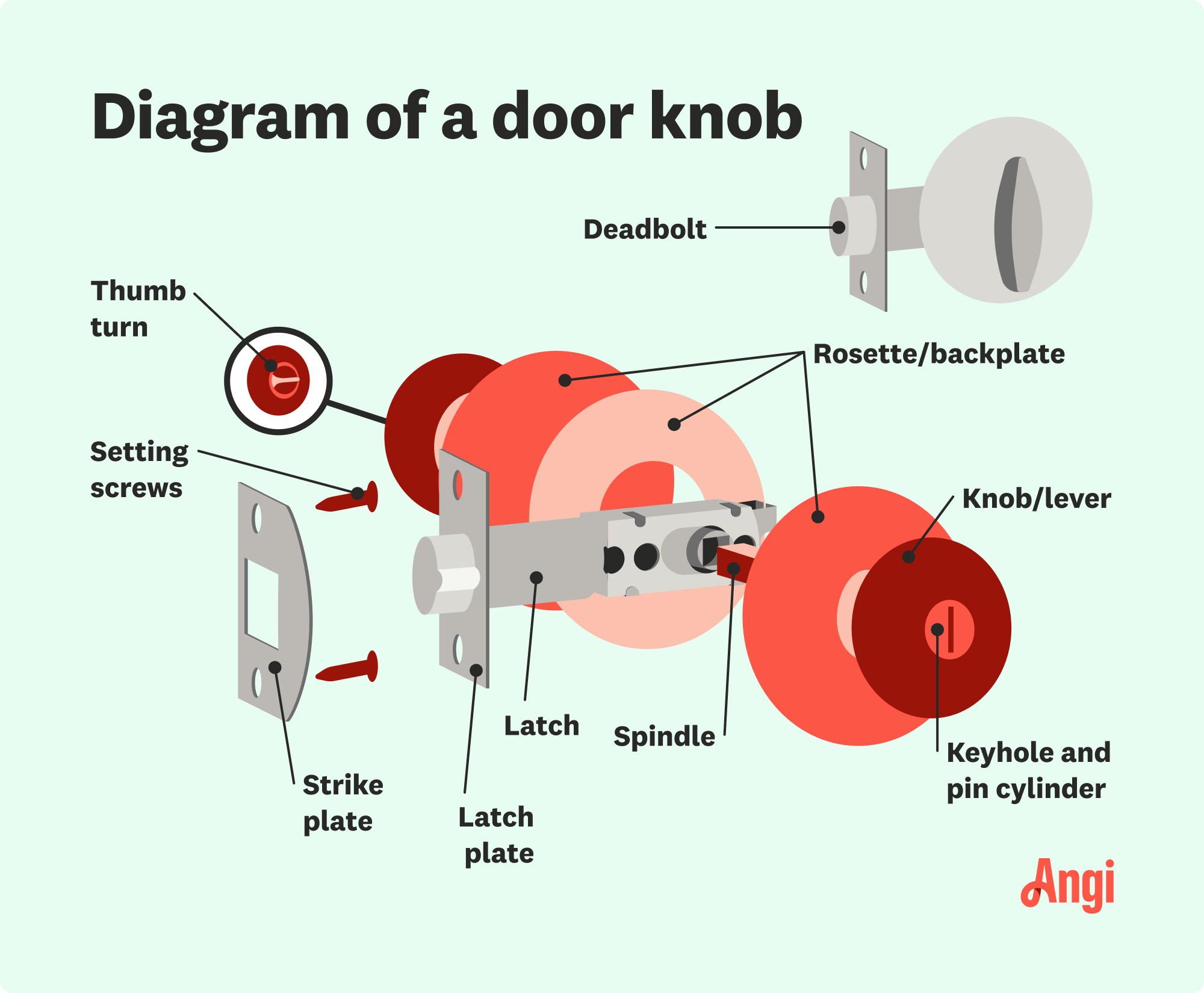

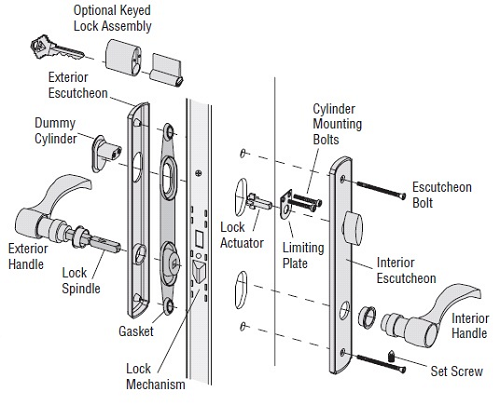

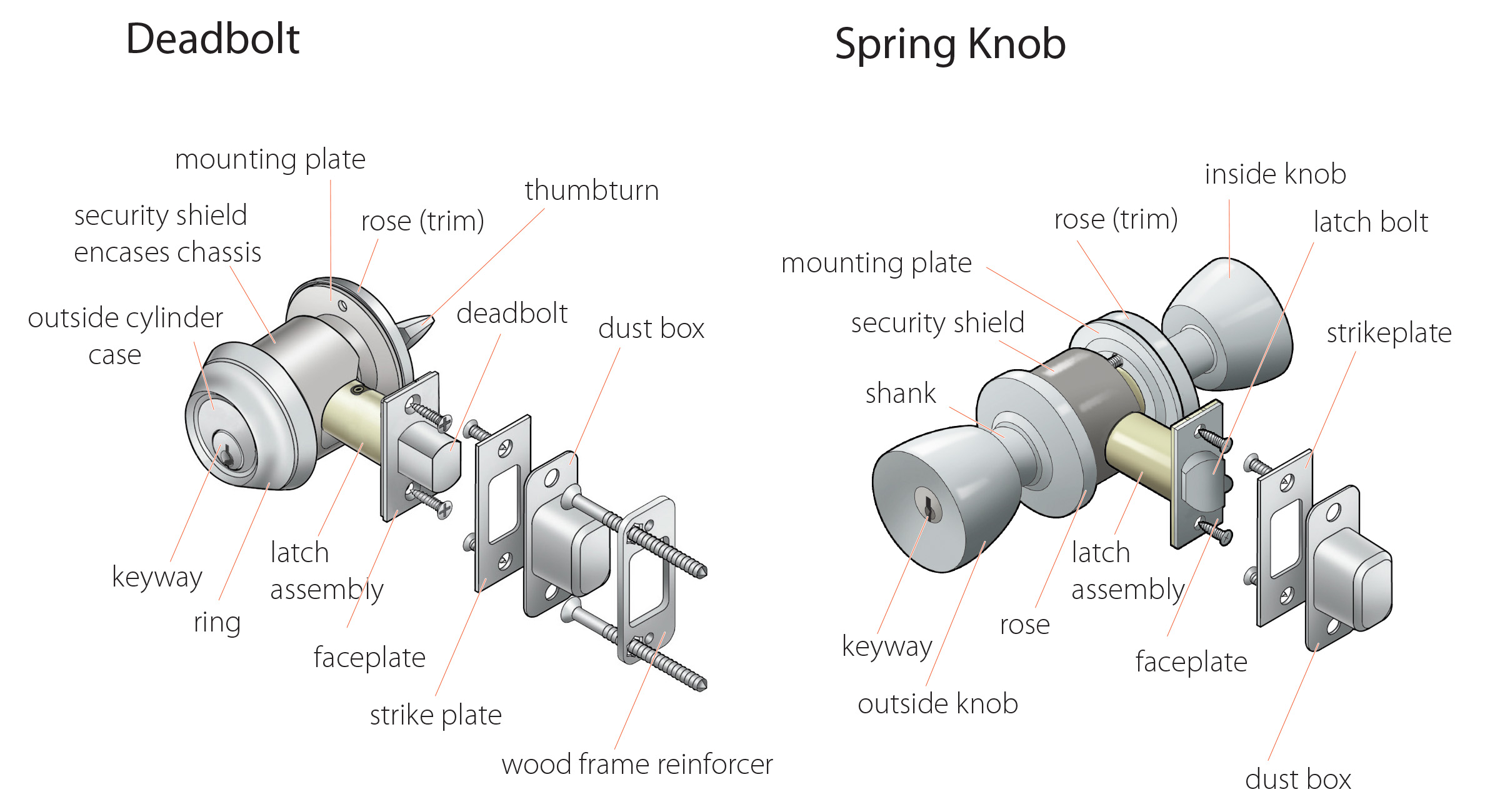

In the ever-evolving global market, international B2B buyers face the critical challenge of sourcing reliable door lock parts names diagrams that align with regional security needs and standards. Understanding the intricate components of door locks—such as cylinders, bolts, and strike plates—can significantly enhance decision-making processes. This comprehensive guide delves into the various types of door lock mechanisms, their applications across different industries, and the essential factors to consider when selecting suppliers.

Moreover, it addresses the nuances of cost evaluation and supplier vetting, ensuring that buyers from Africa, South America, the Middle East, and Europe—such as Nigeria and Brazil—can make informed purchasing decisions. With a detailed overview of the essential parts of door locks and their functionalities, this guide empowers businesses to enhance security measures effectively while optimizing budget allocations. By equipping B2B buyers with the knowledge to navigate this complex landscape, we aim to facilitate a smoother procurement process and ultimately contribute to safer environments across diverse markets.

As you explore the contents of this guide, you will gain valuable insights into not only the parts of door locks but also the broader implications of their selection and implementation in various settings.

Understanding door lock parts names diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Deadbolt Locks | High security, requires a key to operate, robust design | Commercial buildings, external doors | Pros: Superior security, difficult to pick. Cons: Can be more expensive; installation may require professional help. |

| Smart Locks | Keyless entry, remote access, often app-controlled | Residential and commercial properties | Pros: Convenience, enhanced security features. Cons: Dependence on technology; potential cybersecurity risks. |

| Knob Locks | Simple design, typically used on interior doors | Residential homes, offices | Pros: Affordable, easy to install. Cons: Lower security; often not suitable for external use. |

| Lever Handle Locks | Ergonomic design, easy operation | Commercial spaces, accessibility-focused areas | Pros: User-friendly, ideal for high-traffic areas. Cons: Less secure than deadbolts; may be easier to manipulate. |

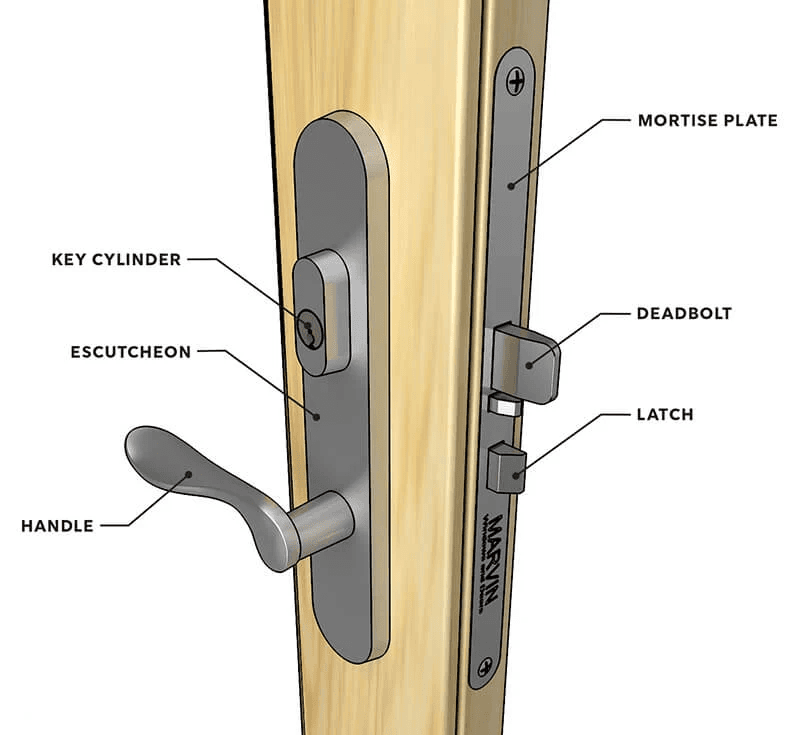

| Mortise Locks | Heavy-duty, built into the door, complex mechanism | High-security commercial applications | Pros: Durable, high security. Cons: More expensive; requires skilled installation. |

What Are the Key Characteristics of Deadbolt Locks and Their B2B Suitability?

Deadbolt locks are renowned for their robust security features, making them ideal for external doors in commercial buildings and residential properties. They operate with a key and are typically resistant to picking and forced entry, which is critical for businesses that prioritize safety. When considering deadbolt locks, B2B buyers should evaluate the level of security required, potential installation costs, and whether the lock meets local building codes.

How Do Smart Locks Enhance Security for B2B Buyers?

Smart locks are increasingly popular among B2B buyers due to their convenience and advanced security features. These locks can be controlled via smartphones or keypads, allowing for remote access and monitoring, which is particularly beneficial for property managers and businesses with multiple entry points. However, buyers must consider the potential cybersecurity risks and ensure they select reputable brands with strong encryption protocols.

Why Choose Knob Locks for Interior Applications?

Knob locks are a cost-effective solution primarily used in residential settings and offices for interior doors. Their simple design allows for easy installation, making them attractive to budget-conscious buyers. However, their lower security features make them unsuitable for external doors. B2B buyers should assess the specific needs of their facilities when considering knob locks, ensuring they are used in appropriate applications.

What Benefits Do Lever Handle Locks Offer in Commercial Spaces?

Lever handle locks are designed for ease of use, making them a popular choice in commercial settings, especially in areas requiring accessibility. Their ergonomic design allows for quick operation, which is essential in high-traffic environments. While they provide convenience, B2B buyers should weigh their security level against other options, as lever locks may be easier to manipulate than deadbolts.

Why Are Mortise Locks Considered a High-Security Option?

Mortise locks are built into the door itself, providing a strong, secure locking mechanism that is difficult to tamper with. They are commonly used in high-security commercial applications, such as banks and government buildings. The complexity of their installation often requires professional expertise, which can increase costs. B2B buyers should consider their security needs and budget when exploring mortise locks, as they offer unparalleled durability and protection.

Key Industrial Applications of door lock parts names diagram

| Industry/Sector | Specific Application of door lock parts names diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Specification for residential and commercial buildings | Ensures compliance with security standards and enhances safety | Availability of varied lock types, compliance with local regulations, and durability against environmental factors |

| Hospitality | Security solutions for hotels and resorts | Protects guests and property, enhancing customer trust | Customization options, compatibility with smart lock systems, and ease of installation and maintenance |

| Retail | Access control systems for storefronts and warehouses | Prevents theft and unauthorized access, safeguarding inventory | High-security features, aesthetic appeal, and ease of integration with existing systems |

| Government and Defense | Lock mechanisms for secure facilities and military bases | Provides high-level security to protect sensitive information | Compliance with security protocols, resistance to tampering, and ability to withstand extreme conditions |

| Automotive | Locking mechanisms for vehicle doors and compartments | Enhances vehicle security and user convenience | Lightweight materials, compatibility with various vehicle models, and resistance to wear and tear |

How Do Different Industries Utilize the Door Lock Parts Names Diagram?

In the construction industry, the door lock parts names diagram serves as a crucial reference for architects and builders. It provides detailed specifications for various lock types, ensuring that all installations meet security and safety standards. This is particularly important in regions with high crime rates, where robust security measures are essential. Buyers in this sector must consider the durability of materials and compliance with local regulations, especially in diverse markets like Nigeria and Brazil.

In the hospitality sector, hotels and resorts rely heavily on the door lock parts names diagram for selecting security solutions that protect both guests and property. Understanding the components allows facility managers to choose locks that are not only secure but also user-friendly, enhancing guest experiences. For B2B buyers, customization options and compatibility with smart lock systems are key considerations, especially in modern markets in Europe and the Middle East.

Illustrative image related to door lock parts names diagram

The retail industry utilizes the door lock parts names diagram to implement effective access control systems in storefronts and warehouses. By ensuring that the right locking mechanisms are in place, businesses can prevent theft and unauthorized access, thereby protecting their inventory. Buyers should focus on high-security features and aesthetic appeal to align with their brand identity, which is especially relevant in competitive markets across South America.

In government and defense, the door lock parts names diagram is critical for securing sensitive facilities and military bases. Understanding the specific components that provide high-level security can help in selecting locks that are resistant to tampering and can withstand extreme conditions. Buyers in this sector must ensure compliance with stringent security protocols, making sourcing from reputable manufacturers essential.

Finally, in the automotive industry, the diagram aids in the design and selection of locking mechanisms for vehicle doors and compartments. This enhances vehicle security and user convenience, addressing the growing concerns around automotive theft. Buyers need to consider lightweight materials and compatibility with various vehicle models, ensuring that they meet industry standards while catering to diverse consumer needs.

3 Common User Pain Points for ‘door lock parts names diagram’ & Their Solutions

Scenario 1: Understanding Complex Components of Door Locks

The Problem: Many B2B buyers, particularly those new to the hardware industry or those expanding their product lines, struggle to grasp the intricate parts and functions of door locks. This lack of understanding can lead to miscommunication with suppliers, incorrect specifications, and ultimately, product failures. For example, a buyer may order a specific type of cylinder lock without realizing it requires a compatible strike plate, leading to delays and additional costs.

The Solution: To address this issue, buyers should invest time in familiarizing themselves with a comprehensive door lock parts names diagram. This diagram should detail each component—such as the cylinder, latch, bolt, and strike plate—along with their functions and interdependencies. Buyers can enhance their knowledge through training sessions or workshops hosted by suppliers or industry experts. Additionally, establishing a standard reference guide within their organization can streamline communication and ensure everyone involved in procurement is on the same page. By doing so, businesses can minimize errors and improve the efficiency of their purchasing processes.

Scenario 2: Sourcing the Right Components for Security Needs

The Problem: In regions like Africa and South America, where security concerns are paramount, B2B buyers often face challenges in selecting door lock components that meet specific security standards. The market is flooded with various lock types, but without a clear understanding of the parts involved, buyers may inadvertently choose subpar locks that compromise safety.

The Solution: Buyers should utilize detailed door lock parts names diagrams as a foundational tool for evaluating security options. It is essential to look for locks featuring robust components such as deadbolts and high-security cylinders, which are often illustrated in these diagrams. Collaborating with trusted suppliers who can provide insights into the security features of different lock systems is crucial. Buyers should also consider conducting risk assessments for the environments where the locks will be installed, enabling them to specify components that offer maximum protection. By aligning the selection process with actual security needs, businesses can significantly enhance their safety measures.

Illustrative image related to door lock parts names diagram

Scenario 3: Troubleshooting and Maintenance Challenges

The Problem: Regular maintenance of door locks is crucial, yet many B2B buyers encounter difficulties in identifying the exact components that require attention or replacement. This issue is exacerbated when buyers lack a clear understanding of the various parts of a door lock, leading to costly downtimes and disruptions in operations.

The Solution: Implementing a systematic approach to maintenance can alleviate these challenges. Buyers should reference a door lock parts names diagram to familiarize themselves with the critical components that require regular checks, such as the latch assembly and strike plate. Establishing a routine inspection schedule can help identify issues like misalignment or wear and tear before they escalate. Additionally, buyers can create maintenance checklists tailored to specific lock types, ensuring that all necessary parts are evaluated. Collaborating with locksmiths or security professionals for periodic assessments can also provide an extra layer of expertise, helping buyers maintain the integrity and functionality of their lock systems over time.

Strategic Material Selection Guide for door lock parts names diagram

What Are the Key Materials Used in Door Lock Parts?

When selecting materials for door lock parts, understanding the properties, advantages, and limitations of each option is crucial for B2B buyers. This analysis focuses on four common materials: steel, brass, zinc alloy, and plastic. Each material has unique characteristics that can significantly impact the performance and suitability of door locks in various environments.

How Does Steel Perform in Door Lock Applications?

Steel is a widely used material in door lock manufacturing, particularly for components like bolts and strike plates. Its key properties include high tensile strength, excellent durability, and resistance to wear and tear. Steel can withstand significant pressure and is less prone to deformation under stress, making it ideal for high-security applications.

Pros: Steel’s durability ensures a long lifespan, and it offers exceptional resistance to forced entry. It can be coated to enhance corrosion resistance, which is especially beneficial in humid or coastal environments.

Cons: The primary drawback of steel is its weight, which can complicate installation and may not be suitable for lightweight door designs. Additionally, untreated steel can rust over time, necessitating protective coatings that can increase manufacturing complexity.

Impact on Application: Steel is compatible with various media, including moisture and temperature fluctuations, making it suitable for diverse climates.

Considerations for International Buyers: Compliance with international standards such as ASTM A36 for structural steel is vital. Buyers from regions like Africa and South America should consider local environmental conditions and corrosion resistance requirements.

What Role Does Brass Play in Door Lock Manufacturing?

Brass is another popular material, especially for lock cylinders and knobs. Its key properties include good corrosion resistance, malleability, and a pleasing aesthetic finish. Brass is less likely to corrode than other metals, which enhances its longevity in various environments.

Pros: The aesthetic appeal of brass makes it a preferred choice for decorative locks. Its malleability allows for intricate designs, and it is relatively easy to machine.

Cons: Brass is softer than steel, making it more susceptible to wear and tear under heavy use. It may also be more expensive than other materials, impacting overall project budgets.

Impact on Application: Brass locks perform well in dry environments but may not be ideal for areas with high humidity unless treated with protective finishes.

Considerations for International Buyers: Compliance with standards such as ASTM B453 for brass is essential. Buyers should also be aware of regional preferences for aesthetics and security features.

How Do Zinc Alloys Compare for Door Lock Components?

Zinc alloy is frequently used for door lock parts like knobs and levers due to its lightweight and cost-effectiveness. Key properties include good corrosion resistance and ease of casting, which allows for complex shapes.

Pros: Zinc alloys are less expensive to produce than brass or steel, making them an attractive option for budget-conscious projects. They also offer decent durability and can be finished in various colors.

Cons: While zinc alloys are resistant to corrosion, they are not as strong as steel or brass, which may limit their application in high-security scenarios. They can also be prone to wear over time.

Impact on Application: Zinc alloys are suitable for indoor applications but may require additional treatments for outdoor use to enhance durability.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B86 for zinc alloys. Understanding local market preferences for material strength and cost will also guide purchasing decisions.

What Are the Benefits and Limitations of Plastic in Door Locks?

Plastic is increasingly used in door lock components, particularly in smart locks and interior applications. Key properties include lightweight, resistance to corrosion, and ease of manufacturing.

Pros: Plastic is highly versatile and can be molded into intricate designs. It is also resistant to moisture and does not rust, making it suitable for various environments.

Illustrative image related to door lock parts names diagram

Cons: Plastic is generally less durable than metal options and may not withstand high-pressure applications. It can also be less aesthetically pleasing for high-end installations.

Impact on Application: Plastic is best suited for low-security applications or as part of a composite lock system where metal components provide strength.

Considerations for International Buyers: Compliance with safety and quality standards, such as ISO 9001, is crucial. Buyers should consider the environmental impact of plastic and local preferences for sustainable materials.

Summary of Material Selection for Door Lock Parts

| Material | Typical Use Case for door lock parts names diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-security locks, bolts, strike plates | Exceptional durability | Heavy and may rust without treatment | High |

| Brass | Decorative knobs, cylinders | Aesthetic appeal and corrosion resistance | Softer, more expensive | Medium |

| Zinc Alloy | Knobs, levers | Cost-effective and lightweight | Less durable than metal options | Low |

| Plastic | Smart locks, interior components | Lightweight and moisture-resistant | Less durable than metals | Low |

This material selection guide provides B2B buyers with the insights needed to make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for door lock parts names diagram

What Are the Main Stages in the Manufacturing Process of Door Lock Parts?

The manufacturing process for door lock parts involves several critical stages, ensuring that each component meets stringent quality and security standards. Understanding these stages is vital for B2B buyers looking to source reliable products.

Illustrative image related to door lock parts names diagram

1. Material Preparation

The first step in manufacturing door lock parts is the selection and preparation of raw materials. Common materials include stainless steel, brass, and zinc alloys, chosen for their durability and resistance to corrosion. Suppliers typically conduct material inspections to ensure compliance with international standards. This may involve checking for material certifications, such as ASTM or EN standards, which guarantee that the materials can withstand wear and tear over time.

2. Forming Techniques: How Are Door Lock Parts Shaped?

Once the materials are prepared, they undergo forming processes. The most common techniques include:

- Casting: This method involves pouring molten metal into molds to create specific shapes, such as lock bodies and bolts.

- Machining: Precision machining is often used for components like cylinders and spindles, where exact dimensions are crucial. Techniques such as CNC (Computer Numerical Control) milling and turning ensure high accuracy.

- Stamping: This is employed for creating flat parts like strike plates and latch assemblies, where sheets of metal are cut or shaped using dies.

These processes ensure that each part not only fits perfectly together but also meets the functional requirements of a secure locking mechanism.

Illustrative image related to door lock parts names diagram

3. Assembly: How Are Door Lock Parts Put Together?

The assembly stage involves combining the various components into a complete lock system. This typically includes integrating the cylinder, bolt, latch, and handle. Automation plays a significant role in this stage, with robotic assembly lines increasing efficiency and consistency. Manual assembly may also be employed for high-quality or custom products, allowing for meticulous attention to detail.

4. Finishing: What Techniques Enhance Durability and Aesthetics?

Finishing is the final stage of manufacturing, where products undergo treatments to enhance their appearance and durability. Common finishing techniques include:

- Plating: Nickel or chrome plating is often applied to improve corrosion resistance and provide an attractive finish.

- Anodizing: For aluminum components, anodizing increases resistance to wear and corrosion while allowing for color options.

- Powder Coating: This technique provides a durable finish for various materials, adding both protection and aesthetic appeal.

These finishing processes not only ensure the longevity of the locks but also enhance their marketability to B2B buyers.

What Quality Assurance Measures Are Critical for Door Lock Components?

Quality assurance (QA) is paramount in the manufacturing of door lock parts, especially given the security implications. B2B buyers must understand the QA processes that suppliers employ to guarantee product reliability.

Relevant International Standards: What Should Buyers Look For?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that the manufacturer has established procedures to ensure consistent quality.

Illustrative image related to door lock parts names diagram

In addition to ISO standards, industry-specific certifications may be relevant, such as:

- CE Marking: Required for products sold within the European Economic Area, ensuring compliance with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for locks used in industrial applications, these standards ensure that products can withstand harsh environments.

B2B buyers should verify that suppliers hold these certifications, as they reflect a commitment to quality and safety.

Key QC Checkpoints: How Are Door Lock Parts Tested?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. Key checkpoints include:

- Incoming Quality Control (IQC): This stage inspects raw materials to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): During manufacturing, random samples are taken to verify that processes are being followed and that products are meeting dimensional and functional standards.

- Final Quality Control (FQC): Once products are assembled, they undergo thorough testing, which may include functional tests, stress tests, and visual inspections to detect any surface defects.

Testing methods may include:

- Dimensional Inspection: Utilizing calipers and gauges to ensure parts meet specified tolerances.

- Functional Testing: Simulating actual use to ensure locks operate smoothly and securely.

- Durability Testing: Subjecting products to stress or environmental conditions to assess their longevity.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are several methods to confirm supplier QC:

Supplier Audits: What Should Buyers Expect?

Conducting supplier audits can provide insight into a manufacturer’s quality control practices. Buyers should look for:

Illustrative image related to door lock parts names diagram

- Documentation of QC Procedures: Suppliers should have clear, documented processes that outline their quality assurance measures.

- Records of Past Audits: A history of successful audits by third parties can indicate a commitment to maintaining high standards.

Requesting Quality Reports: What Information Should Be Included?

Buyers can request quality reports that detail the outcomes of various tests conducted on products. These reports should include:

- Test Results: Documenting the performance of products against established benchmarks.

- Non-Conformance Reports: Outlining any defects found during inspections and how they were addressed.

Third-Party Inspection: How Does It Enhance Confidence?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These services typically offer:

- Random Sampling: Ensuring that products are tested from various production batches.

- Comprehensive Reports: Providing detailed insights into the quality of the products and the effectiveness of the supplier’s QC measures.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when sourcing door lock parts. Variations in regulations, standards, and market expectations can impact the quality assurance process.

Regional Standards: How Do They Affect Sourcing Decisions?

Different regions may have varying standards and regulations that impact product certification. Buyers should familiarize themselves with local regulations to ensure compliance. For example, locks sold in Europe must meet CE marking requirements, while those in the U.S. may need to adhere to ANSI/BHMA standards.

Understanding Supply Chain Dynamics: What Challenges Exist?

Buyers should also consider the complexities of international supply chains, which may include shipping delays, customs regulations, and local sourcing practices. Establishing clear communication with suppliers and understanding their production capabilities can mitigate potential risks.

Conclusion: Ensuring Quality in Door Lock Parts Manufacturing

For B2B buyers, understanding the manufacturing processes and quality assurance measures for door lock parts is essential. By focusing on material preparation, forming techniques, assembly, and finishing, along with robust quality control practices, buyers can make informed sourcing decisions that enhance security and reliability in their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door lock parts names diagram’

When sourcing door lock parts, understanding the specific components involved is essential for ensuring quality and functionality. This guide provides a practical checklist to aid B2B buyers in procuring the right parts, tailored to their needs.

1. Identify Your Requirements

Begin by defining what specific door lock parts you need. Consider the type of locks (e.g., deadbolts, knob locks, smart locks) and the components involved, such as cylinders, bolts, and strike plates. This clarity will help you communicate effectively with suppliers and avoid unnecessary purchases.

2. Research Supplier Credentials

Conduct thorough background checks on potential suppliers. Look for certifications, industry experience, and customer reviews. Reliable suppliers often have ISO certifications or relevant local certifications that attest to their quality management systems.

- Check References: Ask for testimonials from businesses in your industry or region.

- Review Case Studies: Look for documented success stories that highlight their capabilities.

3. Evaluate Product Quality

Assess the quality of the door lock parts offered by suppliers. Request samples to inspect materials, finishes, and overall craftsmanship. High-quality materials such as stainless steel or brass enhance durability and security.

- Inquire About Standards: Ensure that products meet relevant safety and security standards applicable in your market.

- Look for Warranty Options: A robust warranty can indicate confidence in product quality.

4. Understand Pricing Structures

Request detailed quotations from multiple suppliers to compare pricing. Pay attention to the total cost, including shipping and taxes, as well as any volume discounts. Understanding the pricing structure helps in budgeting and can provide leverage in negotiations.

- Clarify Payment Terms: Discuss payment options and terms to avoid cash flow issues later.

- Assess Value vs. Cost: Consider the long-term benefits of investing in higher-quality parts even if they come at a premium price.

5. Check Lead Times and Availability

Confirm the lead times for delivery of the door lock parts. Ensure that suppliers can meet your project timelines to avoid delays. Reliable suppliers should provide a clear timeline for manufacturing and shipping.

- Ask About Stock Levels: Regularly stocked items can expedite the procurement process.

- Plan for Contingencies: Discuss options for expedited shipping if needed.

6. Inquire About After-Sales Support

Evaluate the level of after-sales support offered by suppliers. Good suppliers provide installation guidance, maintenance tips, and responsive customer service. This support can be crucial for troubleshooting any issues post-purchase.

- Request Technical Documentation: Ensure you receive manuals or diagrams for proper installation and maintenance.

- Check for Training Opportunities: Some suppliers may offer training for your team on how to install or maintain the locks.

7. Negotiate Terms and Finalize Contracts

Once you have selected a supplier, engage in negotiations to finalize terms. Discuss pricing, delivery schedules, and any additional services they may offer. A written contract should clearly outline all agreed-upon details to avoid misunderstandings.

- Include Performance Metrics: If applicable, set measurable expectations for product performance and delivery.

- Review Cancellation Policies: Understand the terms regarding order cancellations or changes.

By following this checklist, B2B buyers can ensure they are well-prepared to source door lock parts effectively, leading to improved security solutions and operational efficiency.

Comprehensive Cost and Pricing Analysis for door lock parts names diagram Sourcing

What Are the Key Cost Components for Door Lock Parts Sourcing?

When sourcing door lock parts, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The choice of materials significantly influences the cost of door lock parts. High-quality metals such as stainless steel or brass may incur higher initial costs but can lead to lower maintenance and replacement costs over time. Additionally, smart lock components may require specialized materials and electronic components, increasing overall material costs.

-

Labor: Labor costs vary depending on the region and the complexity of manufacturing. In countries with higher labor costs, such as those in Europe, expect higher pricing. Conversely, regions in Africa or South America may offer competitive labor rates, impacting the overall cost structure favorably.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can minimize these costs, allowing for more competitive pricing.

-

Tooling: The initial investment in tooling and machinery can be substantial, especially for customized or specialized parts. Buyers should consider whether the supplier has the necessary tooling capabilities to meet their specifications.

-

Quality Control (QC): Ensuring that parts meet quality standards is essential for safety and functionality. Robust QC processes can add to the cost, but they also reduce the risk of defects and returns, ultimately affecting total costs positively.

-

Logistics: Shipping costs can vary significantly based on distance, mode of transport, and Incoterms. International shipping may involve additional tariffs and duties, which should be factored into the total cost.

-

Margin: Suppliers typically include a margin in their pricing to cover risks and ensure profitability. Understanding the market rates for similar products can help buyers negotiate better deals.

How Do Price Influencers Affect Door Lock Parts Sourcing?

Several factors influence pricing, which is essential for B2B buyers to consider.

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often lead to discounts, making it more cost-effective for businesses that can manage inventory effectively.

-

Specifications/Customization: Custom parts or specific technical requirements can lead to higher costs due to the additional resources needed for production. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials: The choice of materials impacts not only the cost but also the durability and security features of the locks. Buyers should balance cost with the required level of security.

-

Quality/Certifications: Certifications (such as ISO or ANSI) can add to the cost but are crucial for ensuring quality and compliance with safety regulations. Buyers in regulated markets must prioritize suppliers who meet these standards.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can influence pricing. Established suppliers may charge a premium for their experience and reputation, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the terms of delivery (e.g., FOB, CIF) can help buyers manage logistics costs more effectively, as these terms dictate who bears the risk and cost at various stages of transport.

What Tips Can Help Buyers Optimize Their Door Lock Parts Procurement?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance procurement efficiency:

-

Negotiation: Engage suppliers in discussions about pricing and terms. Suppliers may be willing to adjust prices based on order size or long-term partnership potential.

-

Cost-Efficiency: Analyze the total cost of ownership, which includes not just the purchase price but also maintenance, installation, and potential replacement costs. Opting for slightly higher-priced but more durable locks may lead to long-term savings.

-

Pricing Nuances: Be aware of currency fluctuations and their impact on pricing. Additionally, consider the potential for hidden costs in international transactions, such as tariffs or import duties.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Regular communication can also help address potential issues before they escalate.

-

Market Research: Stay informed about market trends and competitor pricing to ensure that your procurement strategy remains competitive.

Disclaimer

The prices and insights provided in this analysis are indicative and may vary based on specific circumstances, market conditions, and supplier negotiations. Always conduct thorough research and engage with multiple suppliers to obtain the best possible pricing and terms for your needs.

Alternatives Analysis: Comparing door lock parts names diagram With Other Solutions

Introduction to Alternative Solutions in Door Lock Technology

In the realm of door security, understanding the components of a door lock is crucial for effective decision-making. While a ‘door lock parts names diagram’ provides a foundational understanding of lock mechanisms, it is essential to explore alternative solutions that can enhance security and functionality. This analysis compares the door lock parts names diagram against two viable alternatives: a digital lock system and a smart lock technology. Each option presents unique advantages and considerations for B2B buyers looking to optimize their security solutions.

Comparison Table

| Comparison Aspect | Door Lock Parts Names Diagram | Digital Lock System | Smart Lock Technology |

|---|---|---|---|

| Performance | Basic understanding of components | Provides enhanced security features | Advanced security with remote access |

| Cost | Low (educational tool) | Moderate (installation & maintenance) | Higher (initial investment + subscription fees) |

| Ease of Implementation | Simple to understand and create | Requires professional installation | User-friendly installation, often DIY |

| Maintenance | Low (static diagram) | Moderate (software updates) | High (battery changes, software updates) |

| Best Use Case | Educational purposes, training | High-security environments | Residential and commercial applications with tech integration |

Detailed Breakdown of Alternatives

Digital Lock System

Digital lock systems utilize electronic mechanisms to secure doors, often requiring a code or a keycard for access. The primary advantage of digital locks is their enhanced security features, which can include audit trails and the ability to change access codes regularly. This technology is particularly suitable for high-security environments such as offices, schools, and banks, where traditional keys may pose a risk of unauthorized access.

However, the cost of installation and ongoing maintenance can be moderate, requiring periodic updates to software and hardware. Additionally, users need to ensure they are trained to manage the digital access systems effectively, which can pose a challenge for some organizations.

Smart Lock Technology

Smart lock technology takes security a step further by integrating with smartphones and home automation systems. Users can lock and unlock doors remotely, monitor access in real time, and receive alerts about unauthorized entry attempts. This solution is highly adaptable, making it ideal for both residential and commercial environments that prioritize convenience and modern technology.

On the downside, smart locks typically have a higher initial investment and may require subscription fees for premium features. Maintenance can also be demanding, with regular battery changes and software updates needed to ensure optimal performance. Nevertheless, the benefits of enhanced security and remote access often justify the investment for many businesses.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right solution for door security, B2B buyers should consider their specific needs, including security requirements, budget constraints, and technological capabilities. While a door lock parts names diagram serves as a valuable educational tool, it may not suffice for organizations seeking advanced security solutions. Digital lock systems offer reliable security features, while smart locks provide convenience and integration with modern technology. Evaluating these options will help buyers make informed decisions that align with their operational goals and security needs.

Essential Technical Properties and Trade Terminology for door lock parts names diagram

What Are the Key Technical Properties of Door Lock Parts?

Understanding the essential technical properties of door lock components is crucial for B2B buyers, especially when sourcing or manufacturing these products. Here are some critical specifications to consider:

-

Material Grade

– Definition: The classification of materials based on their properties, such as steel, brass, or zinc alloy.

– Importance: Higher-grade materials enhance durability and resistance to wear and corrosion, which is vital for locks used in various environments. Buyers must ensure that the material grade aligns with the intended application, whether it be residential or commercial. -

Tolerance Levels

– Definition: The permissible limit of variation in a physical dimension, often expressed in millimeters or inches.

– Importance: Precise tolerances ensure that components fit together correctly, which is essential for the functionality and security of the lock. Inaccurate tolerances can lead to operational issues, increasing the risk of lock failure. -

Locking Mechanism Type

– Definition: The specific design or method by which a lock secures a door, such as deadbolts, knob locks, or smart locks.

– Importance: Different mechanisms offer varying levels of security. For instance, deadbolts are more secure than knob locks, making it crucial for buyers to understand the security needs of their customers to make informed purchasing decisions. -

Finish and Coating

– Definition: The surface treatment applied to lock components, which can include electroplating, powder coating, or anodizing.

– Importance: The finish not only affects the aesthetic appeal but also impacts corrosion resistance and longevity. Buyers should prioritize finishes that meet their market’s environmental conditions, especially in regions with high humidity or salinity. -

Weight Rating

– Definition: The maximum weight that the lock can support without compromising its integrity.

– Importance: Understanding the weight rating is essential for ensuring the lock is suitable for the intended door type. This is particularly important in commercial applications where heavier doors are common. -

Security Rating

– Definition: A classification indicating the level of security a lock provides, often based on industry standards or certifications (e.g., ANSI/BHMA ratings).

– Importance: Security ratings help buyers assess the effectiveness of a lock against forced entry. Higher-rated locks are generally recommended for external doors or sensitive areas, influencing procurement decisions.

What Are the Common Trade Terms Used in Door Lock Parts?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B market. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify reliable suppliers for high-quality lock components that meet their specifications. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is critical for buyers, particularly in budgeting and inventory management. It affects the cost-effectiveness of purchasing decisions. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a quote for specific products or services.

– Relevance: An RFQ is a valuable tool for buyers to compare pricing and terms from multiple suppliers, ensuring they make the most informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities and costs, which is vital for international trade, especially in diverse markets like Africa and South America. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the goods.

– Relevance: Understanding lead times helps buyers plan their inventory and project timelines effectively, ensuring they meet customer demands without delays. -

Certification Standards

– Definition: Industry benchmarks that products must meet to ensure quality and safety.

– Relevance: Familiarity with relevant certification standards (like UL or CE) helps buyers ensure that the locks they purchase comply with safety and quality regulations, particularly when entering new markets.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions in sourcing door lock parts, ensuring quality and security in their offerings.

Navigating Market Dynamics and Sourcing Trends in the door lock parts names diagram Sector

What Are the Current Market Dynamics and Key Trends in the Door Lock Parts Sector?

The global market for door lock parts is witnessing significant transformations driven by various factors, including technological advancements and heightened security concerns. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly looking for innovative solutions that combine functionality with enhanced security features. The rise of smart locks, equipped with IoT technology, is a notable trend, enabling remote access and real-time monitoring, which caters to a growing demand for home automation and security integration.

Moreover, sustainability is becoming a crucial consideration in sourcing decisions. Buyers are now prioritizing suppliers who offer eco-friendly materials and manufacturing processes. The need for compliance with international standards is also influencing purchasing behavior, as businesses aim to meet local regulations and consumer expectations.

Furthermore, the competitive landscape is shifting towards customization, with manufacturers offering bespoke solutions tailored to specific security needs. This trend is particularly relevant in markets such as Nigeria and Brazil, where varying security challenges necessitate adaptable locking mechanisms. Overall, understanding these dynamics is essential for B2B buyers to make informed sourcing decisions that align with both current trends and future market directions.

How Is Sustainability Influencing Sourcing Decisions in the Door Lock Parts Industry?

Sustainability has become a cornerstone of modern B2B sourcing strategies, particularly in the door lock parts sector. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to seek suppliers who demonstrate a commitment to sustainable practices. This includes the use of recyclable materials and the adoption of energy-efficient manufacturing techniques.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for manufacturers that adhere to fair labor practices and responsible sourcing. Certifications such as ISO 14001 for environmental management and FSC certification for wood products are becoming essential for suppliers aiming to establish credibility and trust with international buyers.

Incorporating ‘green’ materials into door lock components, such as using recycled metals for cylinders and latches, not only reduces environmental impact but also appeals to the growing consumer base that values sustainability. By prioritizing these factors, B2B buyers can enhance their brand reputation while contributing to a more sustainable future.

What Is the Evolution of Door Lock Parts and Their Importance in the B2B Market?

The evolution of door lock parts has been marked by advancements in technology and design aimed at improving security and functionality. Historically, door locks were primarily mechanical, relying on simple key-and-cylinder mechanisms. However, as security threats evolved, so too did the locking solutions. The introduction of deadbolts significantly increased security by providing a more robust locking mechanism compared to traditional knob locks.

The advent of smart locks has revolutionized the industry, integrating digital technology with traditional locking mechanisms. This shift not only enhances security but also offers convenience and flexibility for users. The evolution of materials used in manufacturing, from basic metals to advanced composites, has also played a crucial role in improving the durability and aesthetic appeal of door locks.

For B2B buyers, understanding this evolution is vital for making informed purchasing decisions that align with current security needs and technological advancements. By recognizing the historical context of door lock parts, buyers can better appreciate the innovations available in today’s market and select products that best meet their operational requirements.

Frequently Asked Questions (FAQs) for B2B Buyers of door lock parts names diagram

-

1. How do I choose the right door lock parts for my business needs?

Choosing the right door lock parts involves understanding the specific security requirements of your facilities. Consider factors such as the type of doors you have (wood, metal, etc.), the level of security needed (basic vs. high-security locks), and whether you need smart technology integration. Additionally, assess the compatibility of parts with existing systems, and think about future scalability. Consulting with a knowledgeable supplier can provide insights into the best options tailored to your operational needs. -

2. What are the essential components to look for in a door lock parts diagram?

A comprehensive door lock parts diagram should include key components such as the cylinder, latch assembly, strike plate, and handle or knob. Understanding these parts helps in troubleshooting and maintenance. Look for details on the lock’s operation mechanism, security features, and materials used. This information is critical for ensuring that the parts will function effectively in your specific application and meet your security standards. -

3. How can I verify the quality of door lock parts from international suppliers?

To verify the quality of door lock parts, request certifications and product samples from potential suppliers. Look for compliance with international standards such as ISO or ANSI. It’s also beneficial to check for customer reviews and testimonials. Establishing a quality assurance protocol, including inspections during production and before shipment, can help ensure that the products meet your specifications and standards. -

4. What are the typical minimum order quantities (MOQs) for door lock parts?

Minimum order quantities (MOQs) for door lock parts can vary significantly depending on the supplier and the type of product. Generally, MOQs may range from 100 to 1,000 units. It is advisable to discuss MOQs upfront with your supplier to negotiate terms that align with your business needs. Some suppliers may offer flexibility in MOQs for first-time buyers or larger orders, so exploring options can be beneficial. -

5. How do I ensure proper logistics for sourcing door lock parts internationally?

Ensuring proper logistics involves selecting a reliable freight forwarder familiar with international shipping regulations. Discuss shipping methods, delivery timelines, and customs clearance procedures with your supplier. It’s crucial to understand the incoterms used in your agreement to clarify responsibilities for shipping and insurance. Additionally, consider the location of your supplier and potential tariffs or duties that may apply to your order. -

6. What payment terms should I negotiate when sourcing door lock parts?

When sourcing door lock parts, negotiate payment terms that balance risk and cash flow. Common arrangements include a deposit upfront (usually 30-50%) with the balance paid upon delivery or after inspection. Consider using secure payment methods such as letters of credit or escrow services for larger orders. It’s also wise to establish a clear understanding of the currency used and any potential fluctuations that may affect the final cost. -

7. Can I customize door lock parts to meet specific security needs?

Yes, many suppliers offer customization options for door lock parts, allowing you to tailor features such as size, finish, and security specifications to meet your unique requirements. When discussing customization, provide detailed specifications and any relevant standards your products must meet. Ensure the supplier has the capability and experience to deliver customized solutions that adhere to your security protocols. -

8. What are the common issues to look out for in door lock parts during quality checks?

Common issues to look out for during quality checks include misalignment of components, poor finishing (like rough edges), and defects in the locking mechanism. Ensure that all parts fit together smoothly and operate without excessive force. Check for compliance with specified materials and standards. Implementing a thorough inspection process at various stages of production can help identify and mitigate potential problems before the parts are shipped.

Top 8 Door Lock Parts Names Diagram Manufacturers & Suppliers List

1. Pinterest – Door Knob & Lock Parts Guide

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Complete guide on 12 key Door Knob/lock Parts: Names & Diagram, covers names, functions, and diagrams to improve house safety & security.

2. Doornmore – Key Product

Domain: doornmore.com

Registered: 2010 (15 years)

Introduction: Key product details include various types of doors such as Custom Entry Doors, Steel Entry Doors, Fiberglass Entry Doors, Wooden Entry Doors, French/Patio Doors, and Interior Doors. The terminology section covers components like Brick Molding, Casing, Rough Opening, Transom, Sidelite, Jamb, and various parts of the door assembly including Rails, Stiles, Panels, and Bore Holes. It also mentions fea…

3. All About Doors – Multipoint Lock Glossary

Domain: allaboutdoors.com

Registered: 1997 (28 years)

Introduction: This company, All About Doors – Multipoint Lock Glossary, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Homestead Hardware – Door Hardware Glossary

Domain: homesteadhardware.com

Registered: 2005 (20 years)

Introduction: Door Hardware Glossary of Terms includes definitions for various door hardware components such as Door Knobs, Door Levers, Entry Door Handle Sets, Deadbolt Door Locks, Hinges, and various Door Accessories. Key terms include: Active Door, Backset, Bore, Center-to-Center Hole Spacing, Custom Keying, Cylinder, Deadbolt, Door Handle Plate, Door Swing, Door Thickness, Double Cylinder, Dummy (pair and s…

5. Chicago Locksmiths – Door Lock Parts

Domain: chicagolocksmiths.net

Registered: 2012 (13 years)

Introduction: Door Lock Parts: Cylinder (where the key is inserted), Bolt (holds the door closed), Box (holds the bolt in place). Deadbolt Parts: Bolt (locks inside the frame), Thumb Latch (allows deactivation from inside), Turnpiece (connects to the thumb latch for locking/unlocking), Keyhole (where the key is inserted). Strike Plate (keeps the bolt in place), Rosette (holds the doorknob in place and adds secu…

6. GoAsher – Anatomy of a Door

Domain: goasher.com

Registered: 2008 (17 years)

Introduction: Anatomy Of A Door: 24 Parts Of A Door You Should Know. Key components include: Door Frame (head, jambs, sill), Door Jamb (vertical components), Door Head (horizontal piece at the top), Threshold (strip at the bottom), Sill (base of the door frame), Brickmold (exterior trim), Casing (interior trim), Stile (vertical sections), Rail (horizontal sections), Door Panel (main body), Mullion (divider), Gl…

7. Olivari – Door Hardware & FritsJurgens – Pivot Hinge Systems

Domain: bellevuearch.com.au

Introduction: Key product details include: 1. Door Hardware by Olivari of Italy: – Door Handles (Entry Pull Handles, Large Fixed Sliding Handles, 3 Point Turn Handles, Door Knobs, Snibs & Escutcheons, Back Plates) – Door Stops – Olivari Finishes 2. Pivot Hinge Systems by FritsJurgens: – System FX (New 40 & 70mm Top Pivots, Reversed Top Pivot, Top Pivot 70mm, Top Pivot 40mm) – System M+ (90° & 180° Pivot Doors) …

8. Hunker – Doorknob Components

Domain: hunker.com

Registered: 2001 (24 years)

Introduction: Doorknobs consist of several components: 1. Handle: Two handles (one on each side), can be locking or non-locking. 2. Hardware: Includes screws and metal pieces for installation, varies by manufacturer and style. 3. Bolting Mechanism: Extends into the door frame’s latch hole to keep the door closed, retracts when a handle is twisted. 4. Lock: Operated by a lever or push button on the interior hand…

Strategic Sourcing Conclusion and Outlook for door lock parts names diagram

In conclusion, understanding the various components of door locks is critical for B2B buyers looking to enhance security solutions for their businesses. Each part, from the cylinder to the strike plate, plays a vital role in ensuring the integrity and functionality of door locking systems. By strategically sourcing high-quality door lock parts, businesses can not only improve security but also reduce maintenance issues and enhance customer satisfaction.

As international buyers from regions such as Africa, South America, the Middle East, and Europe evaluate their options, it is essential to consider suppliers who offer innovative solutions, like smart locks and robust deadbolts, that align with modern security needs. By prioritizing quality and reliability in sourcing decisions, companies can safeguard their assets and foster trust with clients and partners.

Looking ahead, the demand for advanced door lock systems is expected to grow, driven by increasing security concerns and technological advancements. Engage with reliable manufacturers and distributors to stay ahead of the curve and ensure that your business is equipped with the best locking solutions available. Take the next step in securing your operations today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.