Door Latches Hardware: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for door latches hardware

In the ever-evolving landscape of global commerce, sourcing high-quality door latches hardware presents a unique set of challenges for international B2B buyers. From navigating diverse manufacturing standards to ensuring compatibility with local regulations, the process can be daunting. This guide aims to equip decision-makers, particularly those in regions such as Africa, South America, the Middle East, and Europe—specifically markets like Saudi Arabia and Nigeria—with the knowledge they need to successfully navigate this intricate market.

Within these pages, we will explore the various types of door latches, including roller latches, touch latches, and surface bolts, each with its specific applications and benefits. We will also provide insights into supplier vetting processes, enabling buyers to identify reliable manufacturers that meet their quality and compliance standards. Additionally, the guide will cover cost considerations, ensuring that you can balance quality with budgetary constraints effectively.

By leveraging the information presented in this comprehensive resource, B2B buyers will be empowered to make informed purchasing decisions, minimizing risks and enhancing the overall efficiency of their procurement processes. Whether you are looking to secure residential properties or commercial spaces, understanding the nuances of door latches hardware will be crucial in meeting your operational needs.

Understanding door latches hardware Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Roller Latches | Utilizes a spring-loaded roller to engage a strike plate. | High-traffic interior doors, offices. | Pros: Quiet operation, adjustable tension. Cons: Not suitable for heavy doors. |

| Touch Latches | Allows doors to open with a gentle push; invisible mechanism. | Cabinetry, furniture, light doors. | Pros: Seamless design, easy to use. Cons: Limited load capacity. |

| Deadbolts | Mechanically secure; requires a key or thumb turn to operate. | External doors, commercial properties. | Pros: High security, durable materials. Cons: More complex installation. |

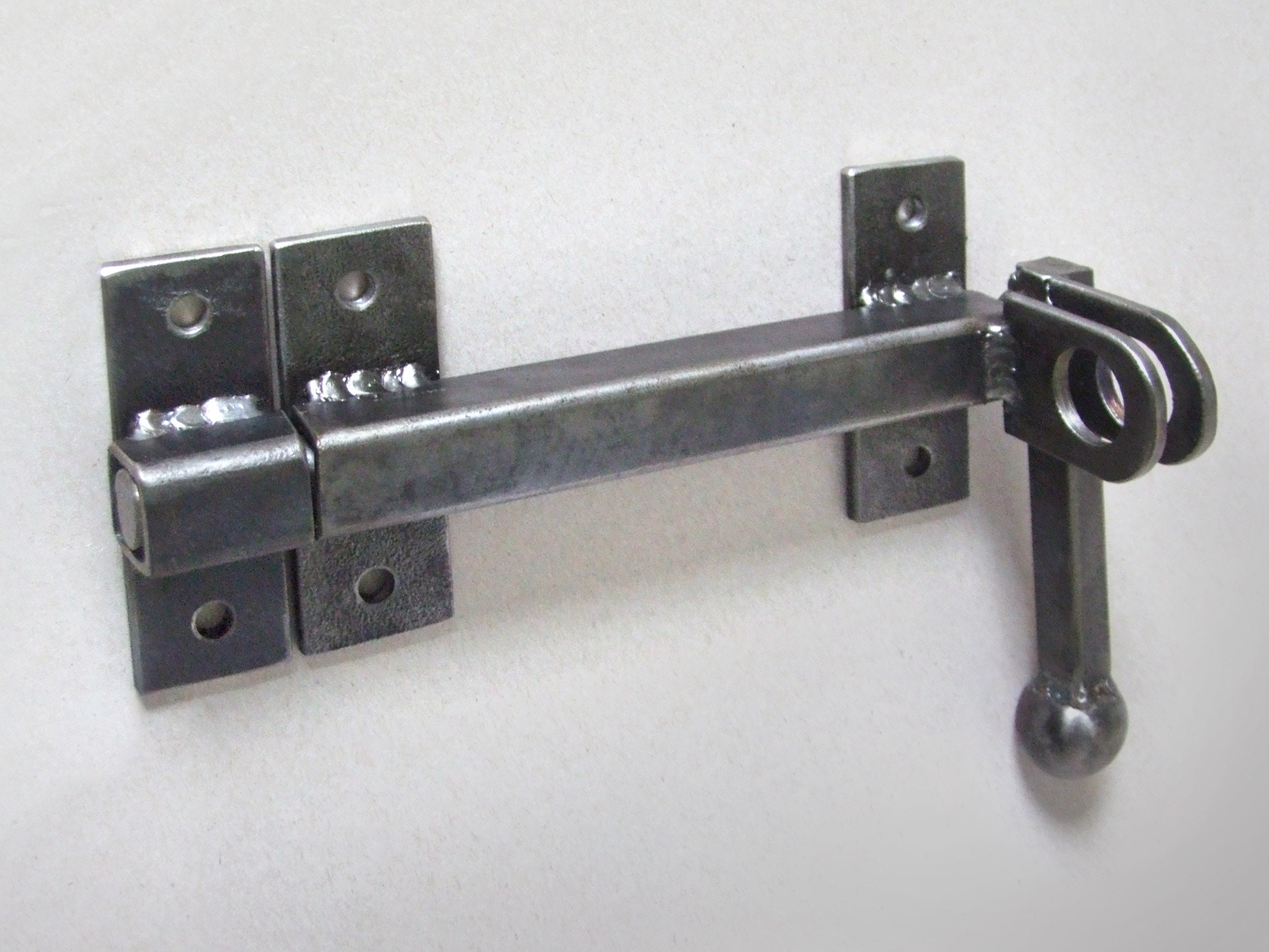

| Surface Bolts | Mounted on the surface of the door; provides extra security. | Double doors, gates, high-security areas. | Pros: Easy installation, versatile. Cons: Can be less aesthetically pleasing. |

| Mortise Latches | Installed within the door; offers a flush appearance. | High-end residential, commercial doors. | Pros: Enhanced security, sleek design. Cons: Requires precise installation. |

What Are the Key Characteristics of Roller Latches and Their B2B Applications?

Roller latches are designed for high-traffic interior doors, employing a spring-loaded roller that engages with a strike plate. This mechanism allows for quiet operation, making it ideal for office environments or residential spaces where noise reduction is important. When purchasing roller latches, B2B buyers should consider the latch’s adjustability and compatibility with existing door hardware, ensuring it meets the specific needs of their application.

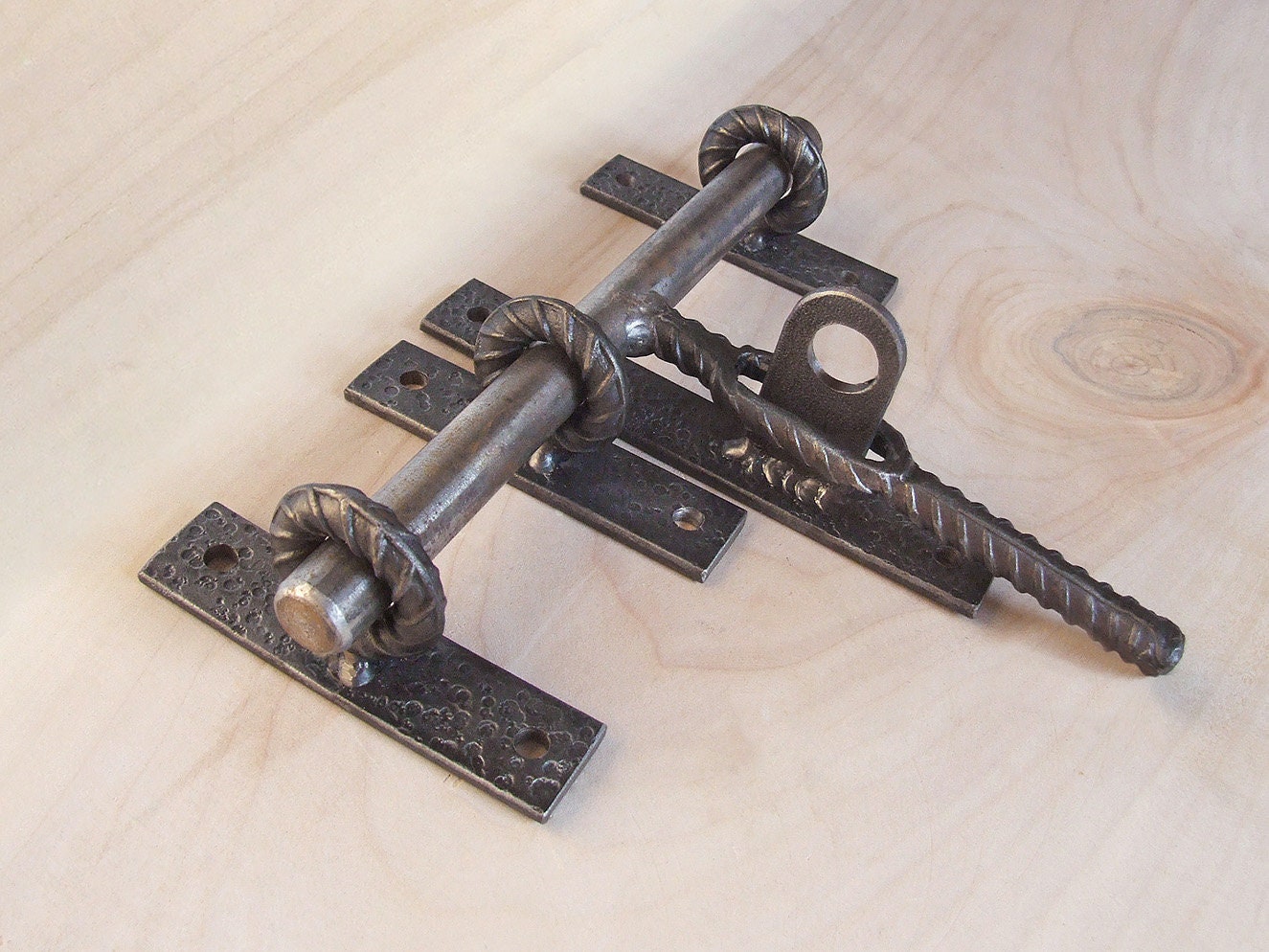

Illustrative image related to door latches hardware

How Do Touch Latches Enhance Door Functionality in B2B Settings?

Touch latches provide a modern solution for cabinetry and light doors, allowing for a simple push to open. Their invisible design offers an aesthetically pleasing finish, making them popular in furniture and cabinetry applications. For B2B buyers, the choice between regular and heavy-duty options is crucial, especially in environments where durability and ease of use are paramount. Consideration of door weight and frequency of use will guide the appropriate selection.

Why Are Deadbolts Essential for Security in Commercial Properties?

Deadbolts are synonymous with security, requiring a key or thumb turn for operation. They are widely used in external doors of commercial properties and high-security residential areas. Buyers should focus on the deadbolt’s material quality and security grade, as these factors directly impact its effectiveness against forced entry. Installation complexity is another consideration, as professional installation may be necessary for optimal performance.

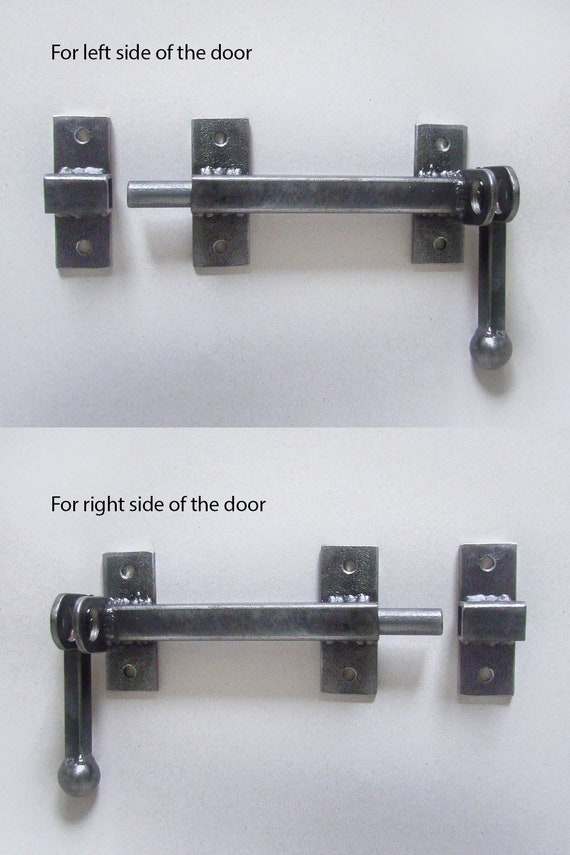

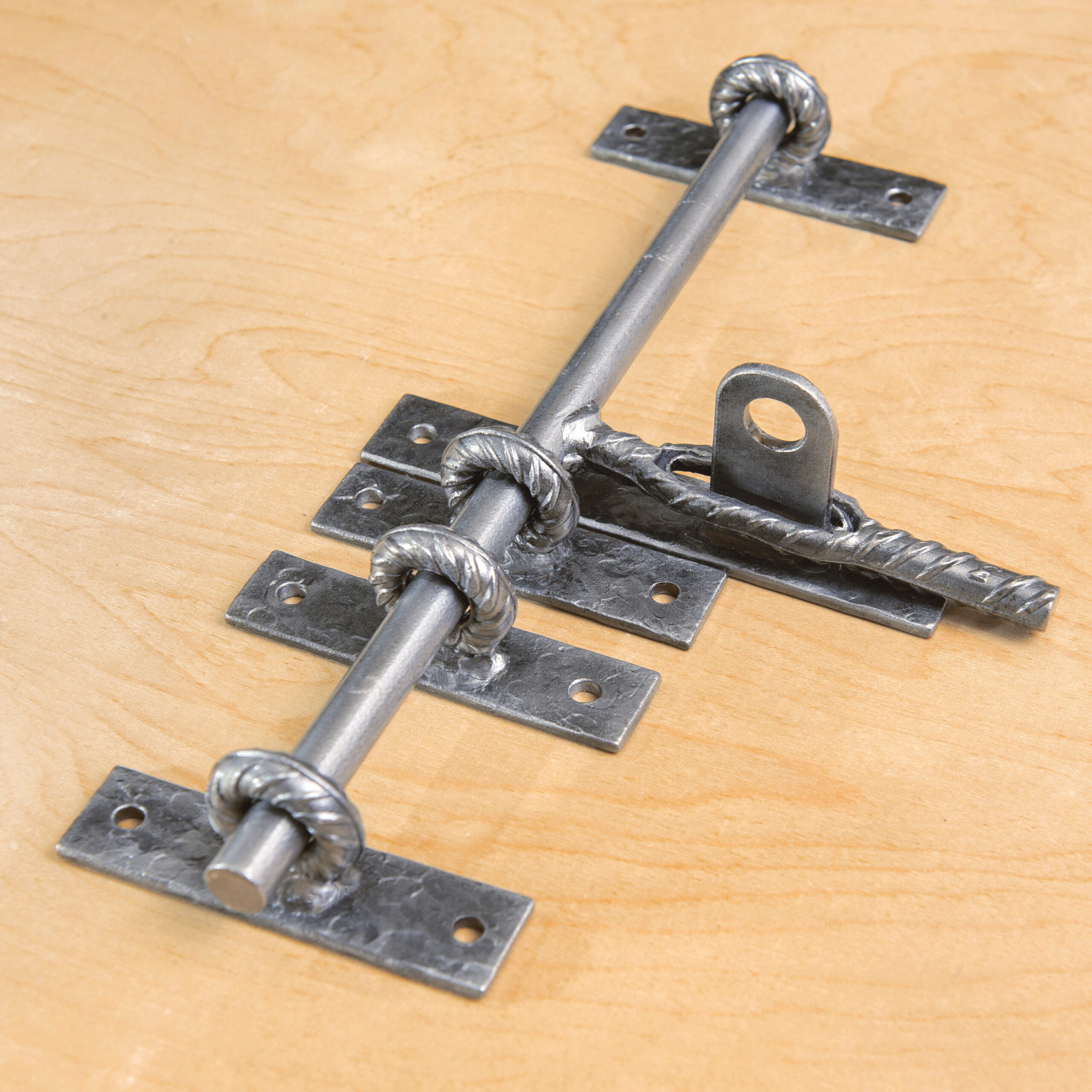

What Are the Advantages of Surface Bolts in High-Security Applications?

Surface bolts are mounted on the door’s surface, providing an additional layer of security, particularly for double doors and gates. They are easy to install and can be used in various applications, from residential to high-security environments. However, B2B buyers should weigh the aesthetic implications, as surface-mounted options may not blend seamlessly with all door designs. The versatility and ease of use make them a practical choice for many organizations.

How Do Mortise Latches Contribute to a Sleek Design in Commercial Settings?

Mortise latches are embedded within the door, offering a flush appearance that is often sought after in high-end residential and commercial applications. These latches provide enhanced security due to their robust installation method. When considering mortise latches, B2B buyers must account for precise installation requirements and compatibility with the door structure, as these factors are critical to ensuring optimal functionality and security.

Key Industrial Applications of door latches hardware

| Industry/Sector | Specific Application of door latches hardware | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Securing factory entrance and interior doors | Enhances security, prevents unauthorized access, and ensures safety for personnel and equipment. | Durability and resistance to wear and tear in high-traffic areas. |

| Hospitality | Access control for guest rooms and service areas | Improves guest experience through ease of access while maintaining security and privacy. | Aesthetic design to match decor, compliance with safety standards. |

| Construction | Installation in residential and commercial buildings | Facilitates compliance with building codes and enhances the overall security of structures. | Variety of finishes and types (e.g., mortise, surface-mounted) to suit different projects. |

| Retail | Locking display cases and storage rooms | Protects valuable merchandise and ensures inventory control. | Reliability and ease of operation, especially for high-frequency access areas. |

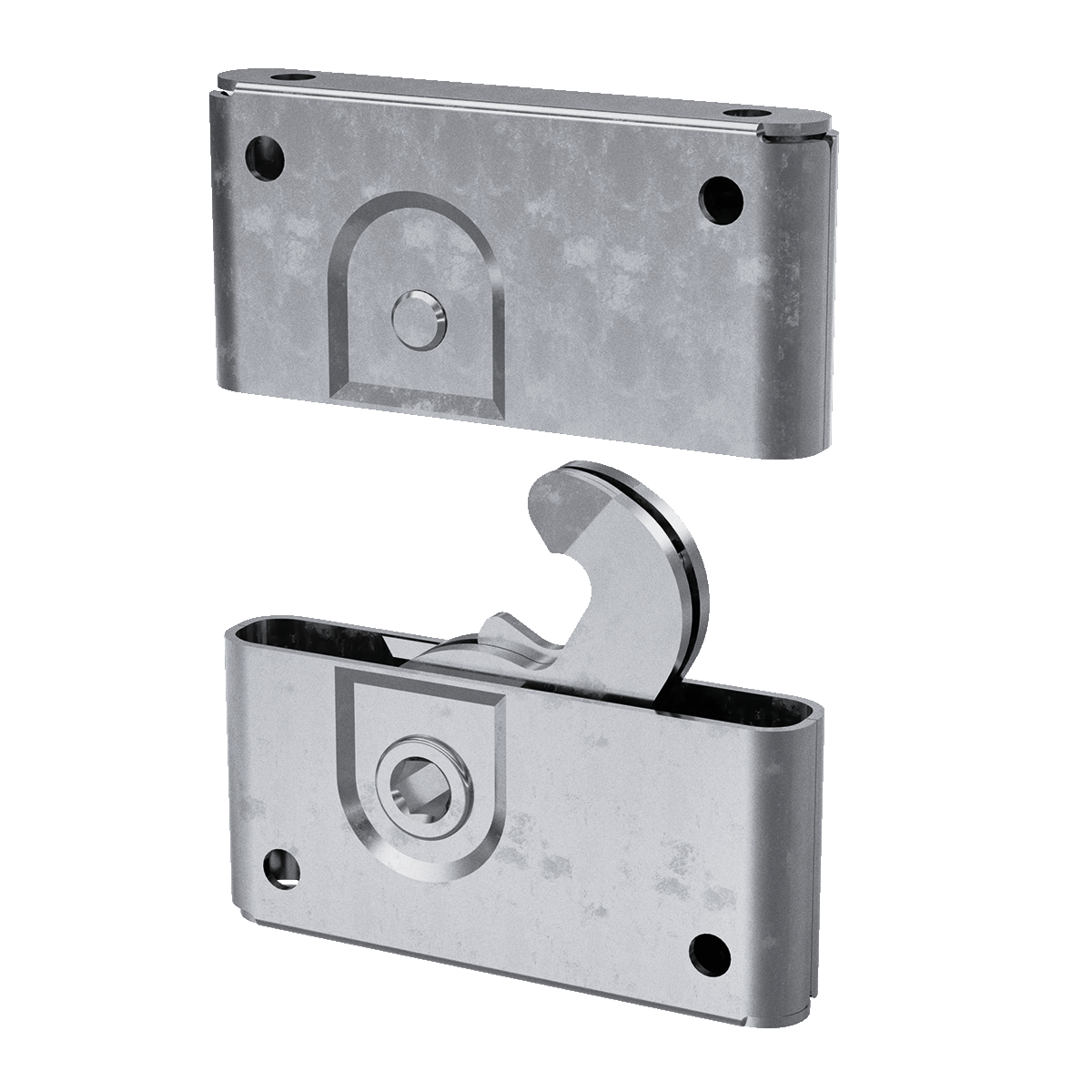

| Transportation | Securing cargo doors on trucks and shipping containers | Safeguards goods during transit, reducing theft and damage risks. | Weather resistance and compatibility with various locking mechanisms. |

How Are Door Latches Used in Manufacturing Settings?

In the manufacturing sector, door latches hardware is crucial for securing factory entrances and internal access points. These latches help prevent unauthorized entry, thereby protecting sensitive equipment and ensuring the safety of personnel. Buyers from regions like Africa and South America must consider the durability of these products, especially in high-traffic areas where wear and tear are common. Additionally, sourcing latches that meet local safety and security regulations is essential to avoid compliance issues.

What Role Do Door Latches Play in the Hospitality Industry?

In the hospitality sector, door latches are vital for managing access to guest rooms and service areas. They enhance the guest experience by providing ease of access while maintaining privacy and security. International B2B buyers, particularly from the Middle East and Europe, should focus on latches that not only function well but also complement the aesthetic of the hotel environment. Compliance with fire safety and accessibility standards is also a critical consideration.

Why Are Door Latches Important in Construction Projects?

During construction, door latches are integral to both residential and commercial buildings. They ensure compliance with various building codes while enhancing security features. Buyers in this sector need to consider a wide range of latch types, including mortise and surface-mounted options, to meet project specifications. Additionally, sourcing durable materials that withstand environmental conditions can help prolong the lifecycle of the hardware.

How Do Retail Businesses Benefit from Door Latches?

In retail environments, door latches are essential for securing display cases and storage areas. This hardware protects valuable merchandise from theft and helps maintain inventory control. B2B buyers in this industry must prioritize reliability and ease of operation, particularly in high-traffic areas where quick access is necessary. Additionally, selecting aesthetically pleasing designs that align with the store’s branding can enhance the overall customer experience.

Illustrative image related to door latches hardware

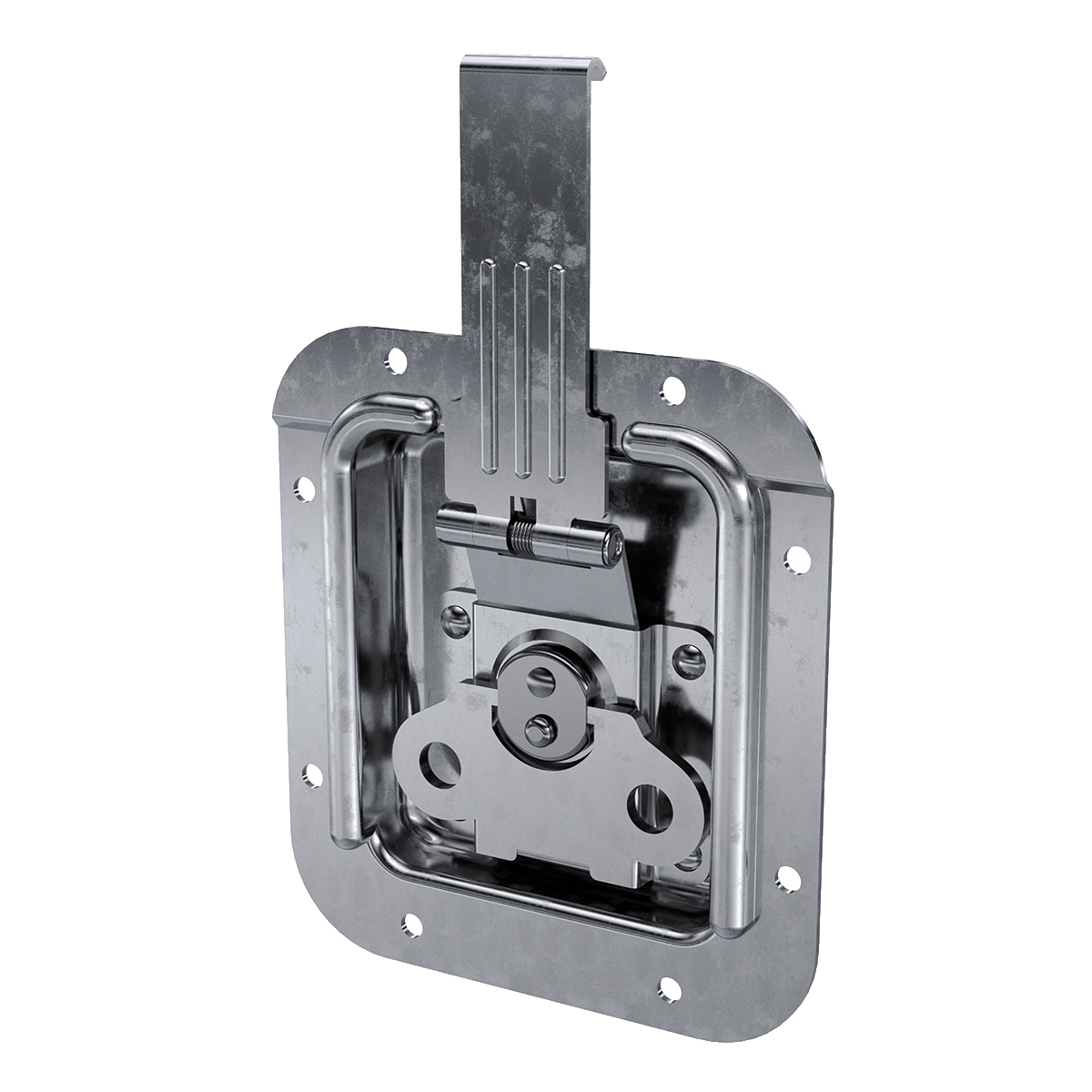

What Is the Significance of Door Latches in Transportation?

In the transportation industry, door latches secure cargo doors on trucks and shipping containers. This hardware is vital for safeguarding goods during transit, reducing the risk of theft and damage. Buyers from diverse regions, including Africa and South America, should consider latches that are weather-resistant and compatible with various locking mechanisms. Ensuring that the latches can withstand harsh environmental conditions is crucial for maintaining the integrity of transported goods.

3 Common User Pain Points for ‘door latches hardware’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Door Latch for Diverse Applications

The Problem: B2B buyers often face challenges in choosing the appropriate door latch for various applications, whether for residential, commercial, or industrial settings. With numerous options available, including roller latches, touch latches, and deadbolts, the selection process can become overwhelming. Buyers may struggle to identify which latch type meets the specific security and operational needs of their projects, leading to potential inefficiencies and increased costs.

The Solution: To effectively navigate the selection process, it is essential for buyers to conduct a thorough needs assessment before sourcing door latches. Start by analyzing the specific requirements of each application, such as the type of door (interior vs. exterior), the frequency of use, and security needs. Create a checklist that includes factors such as latch type, material durability, and finish options. Collaborating with suppliers who offer a comprehensive range of products can also facilitate informed decision-making. Additionally, requesting samples for testing can help verify that the latch performs as expected in real-world conditions, ensuring that the selected hardware enhances both functionality and security.

Scenario 2: Ensuring Consistent Quality Across Different Suppliers

The Problem: A common pain point for B2B buyers is the inconsistency in quality when procuring door latches from various suppliers. Discrepancies in manufacturing standards can lead to unreliable products that affect installation and overall project integrity. This inconsistency not only delays project timelines but can also result in increased labor costs due to the need for replacements or adjustments after installation.

The Solution: Establishing strong relationships with reputable suppliers is crucial for ensuring consistent quality. Buyers should prioritize suppliers who provide detailed specifications, certifications, and warranties for their products. Conducting site visits or audits of the supplier’s manufacturing facilities can offer insights into their quality control processes. Additionally, maintaining open lines of communication regarding quality expectations and performance standards can help align both parties on product requirements. Utilizing a standardized evaluation process for all potential suppliers can also streamline procurement and reduce the likelihood of quality issues.

Scenario 3: Addressing Installation Challenges and Technical Support

The Problem: Buyers may encounter installation challenges with door latches, particularly when dealing with complex systems or unique door configurations. Inadequate installation can lead to malfunctioning hardware, which not only compromises security but may also require costly remedial work. Additionally, a lack of technical support during the installation process can leave buyers feeling frustrated and unsupported.

The Solution: To mitigate installation challenges, buyers should prioritize sourcing door latches from manufacturers that offer comprehensive technical support and installation resources. This includes providing detailed installation guides, videos, and customer service assistance. Before committing to a purchase, buyers should inquire about training opportunities or support services that the supplier can offer, such as on-site installation assistance or consultations. Furthermore, investing in high-quality, user-friendly latch systems can simplify installation processes. Engaging with suppliers that offer modular or adjustable latching systems can also provide flexibility, accommodating various door types and configurations. By ensuring access to robust support and resources, buyers can enhance their installation experience and reduce the likelihood of complications.

Strategic Material Selection Guide for door latches hardware

What Are the Key Properties of Common Materials Used in Door Latches Hardware?

When selecting materials for door latches hardware, several options are prevalent in the market, each with unique properties that influence performance, durability, and cost. Understanding these materials is crucial for B2B buyers seeking reliable and effective solutions for their projects.

Steel: The Backbone of Strength and Durability

Steel is a widely used material in door latches due to its high strength and durability. It typically boasts excellent tensile strength, making it suitable for high-traffic areas. Steel latches can withstand significant pressure and impact, ensuring long-lasting performance. However, without proper treatment, steel can be prone to rust and corrosion, especially in humid or coastal environments.

Illustrative image related to door latches hardware

Pros:

– High strength and durability

– Cost-effective for mass production

– Easily machined and fabricated

Cons:

– Susceptible to corrosion without protective coatings

– Heavier than alternative materials, which may affect installation

Impact on Application:

Steel is ideal for applications requiring robust security, such as commercial buildings. However, buyers must consider the local climate and potential corrosion risks.

Considerations for International Buyers:

Buyers from regions like Saudi Arabia and Nigeria should ensure compliance with local standards such as ASTM for corrosion resistance. Coated or stainless steel options may be preferred in humid climates.

Stainless Steel: Corrosion Resistance Meets Aesthetic Appeal

Stainless steel is an alloy known for its excellent corrosion resistance, making it a popular choice for both interior and exterior door latches. It maintains its appearance over time and requires minimal maintenance, which is advantageous for B2B buyers looking for long-term solutions.

Pros:

– Exceptional corrosion resistance

– Aesthetic appeal with various finishes available

– Durable and low maintenance

Cons:

– Higher cost compared to standard steel

– More complex manufacturing processes can increase lead times

Impact on Application:

Stainless steel is well-suited for environments exposed to moisture, such as coastal areas or regions with high humidity. Its aesthetic versatility makes it suitable for both residential and commercial applications.

Considerations for International Buyers:

In Europe and the Middle East, adherence to DIN standards for stainless steel quality is crucial. Buyers should also consider the specific finish that aligns with regional aesthetic preferences.

Illustrative image related to door latches hardware

Brass: A Blend of Tradition and Functionality

Brass is another common material for door latches, known for its resistance to corrosion and attractive golden hue. It is often used in residential applications due to its classic appearance and ease of machining. Brass latches are generally durable but may not be ideal for high-traffic commercial environments.

Pros:

– Attractive appearance and traditional appeal

– Good corrosion resistance

– Easy to machine and customize

Cons:

– Softer than steel, making it less suitable for heavy-duty applications

– Can tarnish over time, requiring regular maintenance

Impact on Application:

Brass is often used in residential settings, where aesthetics are important, but it may not hold up under heavy use in commercial applications.

Considerations for International Buyers:

In regions like South America, where humidity can be high, buyers should consider lacquered finishes to maintain brass’s appearance and prevent tarnishing.

Plastic: Lightweight and Cost-Effective

Plastic latches are becoming increasingly popular due to their lightweight nature and cost-effectiveness. They are often used in applications where aesthetics are less critical, such as in temporary structures or lightweight doors.

Pros:

– Lightweight and easy to install

– Cost-effective for bulk purchases

– Resistant to corrosion and rust

Illustrative image related to door latches hardware

Cons:

– Limited strength compared to metal options

– May not be suitable for high-security applications

Impact on Application:

Plastic latches are best suited for low-security environments or temporary installations where weight and cost are primary concerns.

Considerations for International Buyers:

Buyers should verify that plastic latches meet relevant safety and quality standards in their region, particularly in Europe where compliance with EU regulations is essential.

Summary Table of Material Selection for Door Latches Hardware

| Material | Typical Use Case for Door Latches Hardware | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-traffic commercial buildings | High strength and durability | Susceptible to corrosion | Medium |

| Stainless Steel | Coastal and humid environments | Exceptional corrosion resistance | Higher cost | High |

| Brass | Residential applications | Attractive appearance | Softer than steel | Medium |

| Plastic | Temporary or low-security installations | Lightweight and cost-effective | Limited strength | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for door latches hardware

What Are the Main Stages in the Manufacturing Process of Door Latches Hardware?

The manufacturing process of door latches hardware involves several critical stages, each designed to ensure the final product meets the required specifications for functionality and durability. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Door Latches?

The process begins with the selection of high-quality materials, typically metals such as stainless steel, brass, or zinc alloys, known for their strength and resistance to corrosion. After selection, the raw materials undergo cutting and shaping to achieve the desired dimensions. This may involve techniques such as stamping or laser cutting, which provide precision and minimize waste.

Illustrative image related to door latches hardware

What Forming Techniques Are Commonly Used?

Once the materials are prepared, they are subjected to forming processes. This can include methods like forging, where metal is shaped by applying compressive forces, or machining, which removes material to create specific features such as holes or grooves. For more complex designs, die casting may be employed, allowing for intricate shapes and fine details that are essential for functionality and aesthetic appeal.

How Are Door Latches Assembled?

After forming, the components of door latches are assembled. This stage may involve manual assembly or the use of automated machinery, depending on the scale of production. Key components, such as springs, pins, and bodies, are combined to create the latch mechanism. Quality control checks during assembly ensure that parts fit correctly and function as intended.

What Finishing Processes Enhance Durability and Aesthetics?

The final stage in manufacturing is finishing, which enhances both the durability and appearance of the door latches. Techniques such as plating, powder coating, or anodizing are commonly used to provide a protective layer against corrosion and wear. This stage also includes surface treatments that improve aesthetics, offering various color and texture options to meet market demands.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is paramount in the manufacturing of door latches hardware, particularly for B2B buyers seeking reliability and compliance with international standards.

Which International Standards Are Relevant?

One of the most recognized standards is ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with this standard indicates that the manufacturer has established processes to ensure consistent quality. Additionally, industry-specific certifications such as CE marking (for European markets) and API (for oil and gas applications) may be required depending on the application of the door latches.

How Are Quality Control Checkpoints Implemented?

Quality control in door latch manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials received. It ensures that materials meet specifications and are free from defects.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspections are carried out at various stages to identify and rectify any defects early on. This may include monitoring forming processes and assembly operations.

-

Final Quality Control (FQC): Once the door latches are fully assembled, they undergo final inspection and testing. This includes functional tests, durability assessments, and visual inspections to ensure compliance with specifications.

What Common Testing Methods Are Used in Quality Assurance?

Several testing methods are employed to ensure that door latches meet quality standards:

-

Functional Testing: This involves checking the latch mechanism to ensure it operates smoothly and securely.

-

Durability Testing: Latches are subjected to stress tests simulating years of use, which helps identify potential failures.

-

Corrosion Resistance Testing: This is critical for latches exposed to harsh environments. Manufacturers may use salt spray tests to evaluate the effectiveness of protective coatings.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability.

What Steps Can Be Taken to Verify QC?

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This includes reviewing their QMS and compliance with relevant standards.

-

Requesting Quality Reports: Buyers can ask for documentation that details the supplier’s quality assurance processes, including IQC, IPQC, and FQC results.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality practices. This is particularly beneficial for international transactions where buyers may not be able to visit the manufacturing facility.

What Are the Quality Control Nuances for International Buyers?

When sourcing door latches from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers must be aware of additional nuances in quality control.

How Do Regional Standards Affect Quality Assurance?

Different regions may have specific quality standards and regulations that must be adhered to. For instance, CE marking is mandatory for products sold in the European Union, while other regions may have different certifications. Understanding these requirements is critical for compliance and market access.

What Challenges Might International Buyers Face?

Language barriers, cultural differences, and varying levels of manufacturing capabilities can pose challenges in ensuring quality. Building strong relationships with suppliers and maintaining clear communication can mitigate these risks. Additionally, being aware of local manufacturing practices can provide insights into potential quality issues.

Conclusion

In conclusion, understanding the manufacturing processes and quality assurance measures for door latches hardware is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control standards, buyers can make informed decisions that ensure they receive reliable and high-quality products. Verifying supplier quality control through audits, reports, and third-party inspections is essential, especially for international transactions where standards may vary significantly.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door latches hardware’

To assist international B2B buyers in efficiently sourcing door latches hardware, this guide provides a structured checklist that outlines key steps to ensure a successful procurement process. From defining technical requirements to verifying supplier capabilities, each step is designed to help buyers make informed decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to clearly outline your technical requirements. This includes determining the types of door latches needed (e.g., roller latches, touch latches, or surface bolts) and the specific applications they will serve, whether for commercial or residential use. Additionally, consider factors such as material (stainless steel, brass, etc.), finish (polished, matte), and security ratings.

Step 2: Research Market Trends and Standards

Understanding current market trends and industry standards is vital for making informed purchasing decisions. Investigate the latest advancements in door latch technology and consider compliance with regional standards, such as ANSI or ISO certifications. This knowledge not only informs your specifications but also enhances negotiation power with suppliers.

Illustrative image related to door latches hardware

Step 3: Evaluate Potential Suppliers

Vetting suppliers is a critical step in ensuring quality and reliability. Request detailed company profiles, product catalogs, and references from other buyers, especially those in similar industries or geographic regions. Assess their track record for on-time delivery and quality assurance, as these factors directly impact your supply chain efficiency.

- Key Considerations:

- Look for suppliers with a solid reputation in your target markets (e.g., Africa, South America).

- Verify any certifications relevant to your industry, such as quality management systems (ISO 9001).

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the door latches you are interested in. This step allows you to evaluate the quality, functionality, and compatibility of the products with your specific needs. Testing samples also provides insight into the supplier’s responsiveness and willingness to accommodate your requirements.

Step 5: Negotiate Terms and Conditions

Effective negotiation is key to establishing a mutually beneficial relationship with suppliers. Discuss pricing, payment terms, lead times, and warranty policies upfront to avoid misunderstandings later. Ensure that all terms are documented clearly in the contract, including any service level agreements (SLAs) regarding delivery and quality.

Step 6: Implement Quality Control Procedures

Before finalizing orders, establish quality control measures to ensure that the products meet your specifications. This may involve setting up inspections at the supplier’s facility or upon receipt of the goods. Consistent quality checks help mitigate risks associated with defective products and maintain operational efficiency.

Step 7: Build Long-Term Relationships

Lastly, focus on fostering long-term relationships with your suppliers. Open communication and regular feedback can lead to improved service and product quality over time. Consider collaborating on future product developments or joint marketing initiatives, especially as you expand into new markets.

By following this checklist, B2B buyers can streamline their sourcing process for door latches hardware, ensuring they select the right products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for door latches hardware Sourcing

What Are the Key Cost Components in Door Latch Hardware Sourcing?

When considering the procurement of door latch hardware, understanding the cost structure is crucial. The primary components influencing the cost include:

-

Materials: The choice of materials—such as stainless steel, brass, or plastic—affects the durability and performance of the latches. Higher-quality materials may incur a higher upfront cost but can lead to lower replacement rates and maintenance expenses.

-

Labor: Labor costs vary by region and can significantly impact the pricing structure. In countries with higher labor costs, such as those in Europe, manufacturers may charge more, while lower-cost regions, like parts of Africa and South America, might offer more competitive rates.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead, positively affecting pricing.

-

Tooling: The initial investment in tools and dies for producing specific latch designs can be substantial. Custom tooling for unique specifications may lead to increased costs, particularly if the order volume is low.

-

Quality Control (QC): Ensuring the reliability and safety of door latches requires stringent QC processes. Higher QC standards can lead to increased costs, but they are essential for maintaining product integrity and customer satisfaction.

-

Logistics: Transportation and shipping costs are particularly relevant for international buyers. Factors such as distance, mode of transport, and local tariffs can significantly influence the final price.

-

Margin: Finally, manufacturers and suppliers will incorporate profit margins into their pricing, which can vary widely based on market conditions and competition.

What Influences Pricing for Door Latch Hardware?

Several factors can influence the pricing of door latches beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better rates, especially for bulk purchases.

-

Specifications and Customization: Custom designs or specific features (like tamper resistance) may lead to higher costs. Buyers should clearly outline their needs to receive accurate pricing.

-

Materials and Quality Certifications: The use of premium materials and compliance with international quality standards (like ISO certifications) can drive up costs. Buyers should weigh the benefits of higher quality against budget constraints.

-

Supplier Factors: The reputation, reliability, and location of suppliers can affect pricing. Established suppliers may offer better quality assurance but might charge a premium.

-

Incoterms: Understanding international shipping terms (like FOB, CIF) is vital. Incoterms dictate responsibilities for shipping costs and risk, affecting the overall cost structure.

How Can International B2B Buyers Optimize Costs When Sourcing Door Latches?

To navigate the complexities of sourcing door latches, particularly for buyers from regions like Africa, South America, the Middle East, and Europe, consider these strategies:

-

Negotiate Effectively: Leverage your purchasing volume and long-term relationships to negotiate better pricing. Be prepared to discuss your needs and expectations clearly.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like maintenance, longevity, and potential replacements. A higher upfront cost might lead to long-term savings.

-

Understand Pricing Nuances: Pricing can vary significantly based on regional economic conditions and material availability. Stay informed about market trends to make better purchasing decisions.

-

Evaluate Local Suppliers: In some cases, local suppliers may offer more competitive pricing due to reduced shipping costs and tariffs. Investigate regional suppliers as part of your sourcing strategy.

-

Consider Payment Terms: Flexible payment terms can improve cash flow and facilitate larger orders. Discuss options with suppliers to find a mutually beneficial arrangement.

Disclaimer on Indicative Prices

Prices for door latch hardware can vary widely based on the factors discussed above. Always seek current quotes from multiple suppliers to ensure you are receiving a competitive rate tailored to your specific requirements.

Alternatives Analysis: Comparing door latches hardware With Other Solutions

Understanding Alternatives to Door Latches Hardware

In the realm of securing doors, door latches hardware is a popular choice, but it is essential for B2B buyers to explore various alternatives that may better fit their specific needs. Each solution has unique attributes that can influence performance, cost, and overall efficiency. Here, we compare door latches hardware with two viable alternatives: electronic door locks and magnetic locks.

Comparison Table

| Comparison Aspect | Door Latches Hardware | Electronic Door Locks | Magnetic Locks |

|---|---|---|---|

| Performance | Reliable for standard use; varying security levels based on type | High security with advanced features like access logs and integration with security systems | Offers quick access; can be less reliable in extreme conditions |

| Cost | Generally low-cost, ranging from $3 to $100 | Higher initial investment, typically $100 to $300+ | Moderate cost, usually $50 to $200 depending on features |

| Ease of Implementation | Straightforward installation; requires basic tools | May require professional installation for complex systems | Simple installation, but may need electrical access |

| Maintenance | Minimal; occasional lubrication needed | Moderate; software updates and battery replacements necessary | Low; typically requires minimal upkeep |

| Best Use Case | Residential and commercial doors needing basic security | High-security environments like offices, data centers | Areas needing quick access, such as emergency exits or restricted access zones |

In-Depth Analysis of Alternatives

Electronic Door Locks

Electronic door locks utilize keypads, cards, or biometrics to provide access, making them a modern alternative to traditional door latches. The primary advantage of electronic locks is their enhanced security features, which often include audit trails and remote management capabilities. However, the initial investment is higher, and these systems may require professional installation and regular maintenance, including battery changes. They are ideal for environments where security is paramount, such as corporate offices or facilities that handle sensitive information.

Magnetic Locks

Magnetic locks operate using electromagnetic force to secure doors. They offer a unique advantage in terms of quick access, as they can be released with a simple swipe of a card or a button. Their installation is relatively straightforward; however, they require access to electrical power, which may not be feasible in all locations. While magnetic locks provide a good level of security, their performance can be compromised in extreme temperatures or in cases of power failure. They are best suited for high-traffic areas needing easy access, such as emergency exits or commercial buildings.

Making the Right Choice for Your Business

When selecting the appropriate door security solution, B2B buyers should consider their unique requirements, including the level of security needed, budget constraints, and the specific environment where the solution will be implemented. Door latches hardware remains a cost-effective and reliable choice for many situations, particularly for standard residential and commercial applications. However, for businesses prioritizing advanced security measures or needing rapid access, electronic locks or magnetic locks may offer significant advantages. Evaluating these factors will help ensure that the chosen solution aligns with operational needs and enhances overall security.

Essential Technical Properties and Trade Terminology for door latches hardware

What Are the Key Technical Properties of Door Latches Hardware?

When sourcing door latches hardware, understanding specific technical properties is crucial for ensuring product quality, compliance, and functionality. Here are some essential specifications to consider:

1. Material Grade

The material used in door latches can significantly affect their durability and performance. Common materials include stainless steel, brass, and zinc alloys. Stainless steel, for instance, is favored for its corrosion resistance and strength, making it suitable for both interior and exterior applications. B2B buyers should ensure that the material grade meets the specific environmental conditions of their target market, particularly in regions with high humidity or saline exposure.

Illustrative image related to door latches hardware

2. Security/ANSI Grade

The American National Standards Institute (ANSI) grades door latches based on their security features. Grades range from 1 (highest security) to 3 (basic security). For commercial applications, ANSI Grade 1 or 2 latches are recommended due to their superior resistance to forced entry. Understanding these ratings helps buyers select appropriate hardware for varying security needs, especially in high-risk areas.

3. Latch Type

Door latches come in several types, including deadbolts, roller latches, and touch latches. Each type has unique operational mechanisms and suitability for specific door applications. For instance, roller latches are ideal for high-traffic interior doors, while deadbolts provide enhanced security for external doors. Knowing the right latch type ensures that buyers meet both functional and aesthetic requirements.

4. Finish Family

The finish of a latch not only impacts its appearance but also its resistance to wear and corrosion. Common finishes include satin nickel, oil-rubbed bronze, and polished brass. Buyers should consider the finish in relation to the environment where the latch will be installed, as some finishes may be more suitable for outdoor use than others. A well-chosen finish can enhance the longevity and appeal of the hardware.

5. Door Handing

Door handing refers to the orientation of the door and its hardware installation (left-hand, right-hand, or universal). Proper handing is essential for ensuring that the latch functions correctly and fits seamlessly with the door design. Misunderstanding door handing can lead to installation issues and increased costs for adjustments or replacements.

What Are Common Trade Terms Used in Door Latches Hardware?

In the door latches industry, certain jargon is frequently used that can impact purchasing decisions. Familiarity with these terms is essential for effective communication and negotiation.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. Understanding OEM relationships helps buyers identify the quality and reliability of the hardware, as reputable manufacturers often ensure stringent quality control and compliance with industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers to understand as it can affect inventory levels and cash flow. Knowing the MOQ helps businesses plan their purchasing strategy and budget more effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. For B2B buyers, submitting an RFQ allows them to compare offers from multiple vendors, ensuring they secure the best possible deal based on quality and price.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They specify who pays for shipping, insurance, and tariffs, which can significantly influence overall costs. Understanding Incoterms is crucial for buyers engaged in international trade, ensuring they avoid unexpected expenses.

5. Lead Time

Lead time is the period between placing an order and receiving the product. For door latches hardware, lead time can vary based on production schedules and shipping methods. Buyers must consider lead time in their project timelines to ensure timely completion.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing door latches hardware, ultimately enhancing their purchasing strategy and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the door latches hardware Sector

What Are the Key Trends Shaping the Global Door Latches Hardware Market?

The door latches hardware sector is experiencing significant growth driven by various global factors. Increased urbanization, particularly in regions like Africa and South America, is leading to a surge in construction activities, thereby amplifying the demand for door hardware. As businesses and households prioritize security, the trend towards enhanced locking mechanisms, including smart locks and tamper-resistant latches, is on the rise. Additionally, the expansion of e-commerce platforms facilitates easier access for international B2B buyers, enabling them to source a diverse range of products from various suppliers globally.

Current technological advancements are shaping sourcing trends, particularly with the integration of IoT (Internet of Things) in security hardware. Smart door latches that can be controlled remotely are becoming increasingly popular, especially in markets like the Middle East and Europe, where consumers are keen on smart home solutions. Moreover, the emphasis on customization is growing, as businesses seek tailored solutions to meet specific security needs. This shift is prompting manufacturers to innovate and expand their product lines to accommodate diverse customer preferences.

How Does Sustainability Impact Sourcing in the Door Latches Hardware Sector?

Sustainability is becoming a pivotal consideration in the sourcing of door latches hardware. The environmental impact of manufacturing processes and materials used in production is under scrutiny, prompting buyers to seek suppliers that prioritize eco-friendly practices. This includes the use of sustainable materials, such as recycled metals and biodegradable components, which help minimize the ecological footprint of products.

Ethical sourcing is equally important, as businesses are increasingly held accountable for their supply chain practices. Companies are expected to provide transparency regarding their sourcing methods and labor practices, ensuring that they do not contribute to environmental degradation or exploit workers. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can signal a supplier’s commitment to sustainability and ethical practices, making them more appealing to conscientious B2B buyers.

What Is the Historical Context of Door Latches Hardware Development?

The evolution of door latches hardware can be traced back to ancient civilizations, where rudimentary locking mechanisms were crafted from wood and metal. Over the centuries, these devices have significantly advanced, transitioning from simple wooden latches to complex mechanical systems incorporating advanced materials and technologies. The introduction of standardized manufacturing processes in the 19th century revolutionized the industry, leading to the mass production of door hardware.

In the modern era, the focus has shifted toward integrating technology with traditional hardware, resulting in the development of smart locks and latches that enhance security and convenience. This historical progression underscores the importance of innovation in meeting contemporary security needs and adapting to the changing landscape of the global market.

Conclusion

Understanding the dynamics and sourcing trends in the door latches hardware sector is crucial for international B2B buyers. By staying informed about market trends, sustainability practices, and the historical context of the industry, businesses can make strategic decisions that align with their security needs while also embracing ethical and sustainable practices. As the market continues to evolve, adapting to these changes will be essential for staying competitive and meeting the demands of a diverse clientele.

Frequently Asked Questions (FAQs) for B2B Buyers of door latches hardware

-

How do I select the right door latch for my business needs?

Choosing the appropriate door latch involves evaluating the type of doors you have (interior or exterior), the level of security required, and the traffic those doors experience. For high-traffic areas, consider heavy-duty latches or roller latches for quiet operation. Additionally, think about the finish and style that aligns with your brand aesthetic. Consulting with a hardware expert can help narrow down options based on specific use cases and durability requirements. -

What types of door latches are most suitable for commercial applications?

For commercial applications, heavy-duty latches such as mortise latches, deadbolts, and surface-mounted latches are recommended due to their strength and reliability. Roller latches are also suitable for interior doors that require frequent use. It’s essential to choose latches that meet industry standards for security (like ANSI grades) and consider the specific access control needs of your facility to enhance safety. -

What are the common customization options for door latches?

Customization options for door latches often include different sizes, finishes, and locking mechanisms. Many suppliers also offer the ability to customize latches with your brand logo or specific color requirements. When placing an order, discuss your needs with the manufacturer to explore available options and ensure the latch meets your specifications for functionality and aesthetics. -

What are the minimum order quantities (MOQs) for door latches?

MOQs for door latches can vary significantly between manufacturers and product lines. Typically, MOQs can range from 50 to 500 units for standard models. Custom orders may have higher MOQs due to the additional production processes involved. It’s advisable to inquire with potential suppliers about their MOQs and negotiate terms that align with your purchasing capacity and project timelines. -

What payment terms should I expect when sourcing door latches internationally?

Payment terms for international orders of door latches usually vary by supplier and can include options such as advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Establishing clear payment terms upfront is essential for cash flow management. Additionally, consider the impact of currency fluctuations and transaction fees when negotiating terms with suppliers from different regions. -

How do I verify the quality of door latches from suppliers?

To ensure the quality of door latches, request samples from potential suppliers before placing a bulk order. Look for certifications that indicate compliance with international standards (e.g., ISO, ANSI). Additionally, check for customer reviews and ratings, and consider conducting factory audits if feasible. Building a long-term relationship with reliable suppliers can also facilitate better quality assurance practices over time. -

What logistics considerations should I keep in mind when importing door latches?

When importing door latches, consider shipping methods, lead times, and potential customs duties. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but may take longer. Be aware of any import regulations specific to your country, including product standards and labeling requirements. Partnering with a logistics provider experienced in international trade can streamline the import process and mitigate potential challenges. -

What are the best practices for maintaining door latches to ensure longevity?

To ensure the longevity of door latches, regular maintenance is key. Clean the latches periodically to remove dust and debris, and lubricate moving parts with silicone-based or graphite lubricants to prevent sticking. Inspect latches for wear and tear, particularly in high-traffic areas, and replace any components that show signs of damage. Educating your staff on proper usage can also help prevent unnecessary wear and extend the life of your door hardware.

Top 6 Door Latches Hardware Manufacturers & Suppliers List

1. Hardwaresource – Door Latches and Bolts

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Door Latches and Bolts include various types such as Invisible Touch Latch, Concealed Magnetic Door Catches (Regular and Heavy Duty), Auxiliary Pusher for Touch Latch, Push-To-Open Door Latch, Chain Bolt, Modern Surface Bolt, Surface Mounted Sliding Gate Lock, Ball Catch, Heavy Duty Roller Latch, Heavy Duty Surface Bolt, Baldwin Dutch Door Bolt, Transom Bolt for Double Doors, Baldwin Residential F…

2. Acorn MFG – Thumb Latch Sets

Domain: acornmfg.com

Registered: 1996 (29 years)

Introduction: Thumb Latch Sets – Door Hardware

1. Rough Heart Thumb Latch Set – SKU#: RSCBR – Price: $43.00

2. Bean Thumb Latch Set – SKU#: RTHBR – Price: $43.00

3. Forged Bean Thumb Latch Set – SKU#: ATXBI – Price: $182.00

4. Smooth Spade Thumb Latch Set – SKU#: AT7BR – Price: $43.00

5. Smooth Heart Thumb Latch Set – SKU#: AT8BR – Price: $43.00

6. Smooth Bean Thumb Latch Set – SKU#: AT9BR – Price: $43.00

7. F…

3. Harney Hardware – Discounted Door Hardware

Domain: harneyhardware.com

Registered: 2004 (21 years)

Introduction: This company, Harney Hardware – Discounted Door Hardware, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. TCH – Heavy Duty Latches

Domain: us.tchweb.com

Registered: 1998 (27 years)

Introduction: TCH offers high quality and heavy duty latches for industrial and case hardware applications. The collection includes various styles and materials for safe locking solutions, such as cam latches, draw-latches, roto-locks, and spring latches. A wide selection of strike and keepers is also available to suit most latch styles. Specific products include: 1. Large Keeper Plate – $0.89 USD (SKU: 501-541…

5. Lowes – Trending Door Hardware

Domain: lowes.com

Registered: 1995 (30 years)

Introduction: Trending Door Hardware for Sale at Lowes.com includes a variety of products such as Electronic Door Locks, Smart Locks, Door Knobs, Door Handles, Handlesets, Keyed Entry Door Knobs, Keyed Entry Door Handles, Barn Door Hardware, Hinges, Deadbolts, and Combo Packs. The selection also features Ball Catches, Bathtub & Shower Door Hardware, Closet Door Hardware, Door Accessories, Door Closers, Door Exi…

6. Custom Service Hardware – Door Latches & Guards

Domain: cshardware.com

Registered: 1996 (29 years)

Introduction: Door Latches, Door Guards and Bolts from Custom Service Hardware include a variety of door hardware such as swing locks, chain door guards, door viewers, slide bolts, barrel bolts, and night latches. These products come in various styles and finishes to match different home aesthetics. Featured product: First Watch® Latch Guard 2.5″ x 6″ for Out Swing Doors in Polished Brass.

Strategic Sourcing Conclusion and Outlook for door latches hardware

In navigating the complexities of the door latches hardware market, strategic sourcing emerges as a vital process for international B2B buyers. Understanding the diverse range of products—such as roller latches, touch latches, and heavy-duty surface bolts—enables companies to select solutions that meet both functional and aesthetic requirements. By leveraging supplier relationships and market intelligence, businesses can optimize procurement strategies, ensuring competitive pricing and quality assurance.

Illustrative image related to door latches hardware

Additionally, incorporating sustainable practices in sourcing not only aligns with global standards but also enhances brand reputation, particularly in regions like Africa and South America, where sustainability is increasingly prioritized.

Looking ahead, the door latches hardware market is poised for innovation, with advancements in smart technology and enhanced security features. International buyers, especially those from regions such as the Middle East and Europe, are encouraged to stay informed and proactive in their sourcing strategies. This is an opportune moment to explore partnerships with reliable suppliers who can provide tailored solutions to meet the evolving demands of the industry. Embrace the future of door latches hardware—strategize, source wisely, and position your business for success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to door latches hardware

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.