Door Hinge Components: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for door hinge components

The global market for door hinge components presents a unique set of challenges for B2B buyers, particularly when it comes to sourcing high-quality products that meet specific application needs. As industries across Africa, South America, the Middle East, and Europe increasingly demand reliable and durable door hinge solutions, understanding the intricacies of hinge design and functionality becomes essential. This comprehensive guide delves into various types of door hinge components, including their applications, materials, and design considerations, helping buyers navigate the complexities of international sourcing.

From heavy-duty hinges that withstand high traffic in commercial environments to aesthetically pleasing options for residential properties, this guide equips buyers with the knowledge needed to make informed purchasing decisions. We will also explore critical aspects of supplier vetting, cost analysis, and the importance of compliance with regional standards, ensuring that businesses can effectively assess their options.

By arming international B2B buyers with actionable insights and expert guidance, this resource aims to facilitate successful partnerships with suppliers while optimizing procurement strategies. Whether you are based in Brazil, Germany, or beyond, understanding the nuances of door hinge components will empower your business to achieve operational excellence and maintain competitive advantage in your respective market.

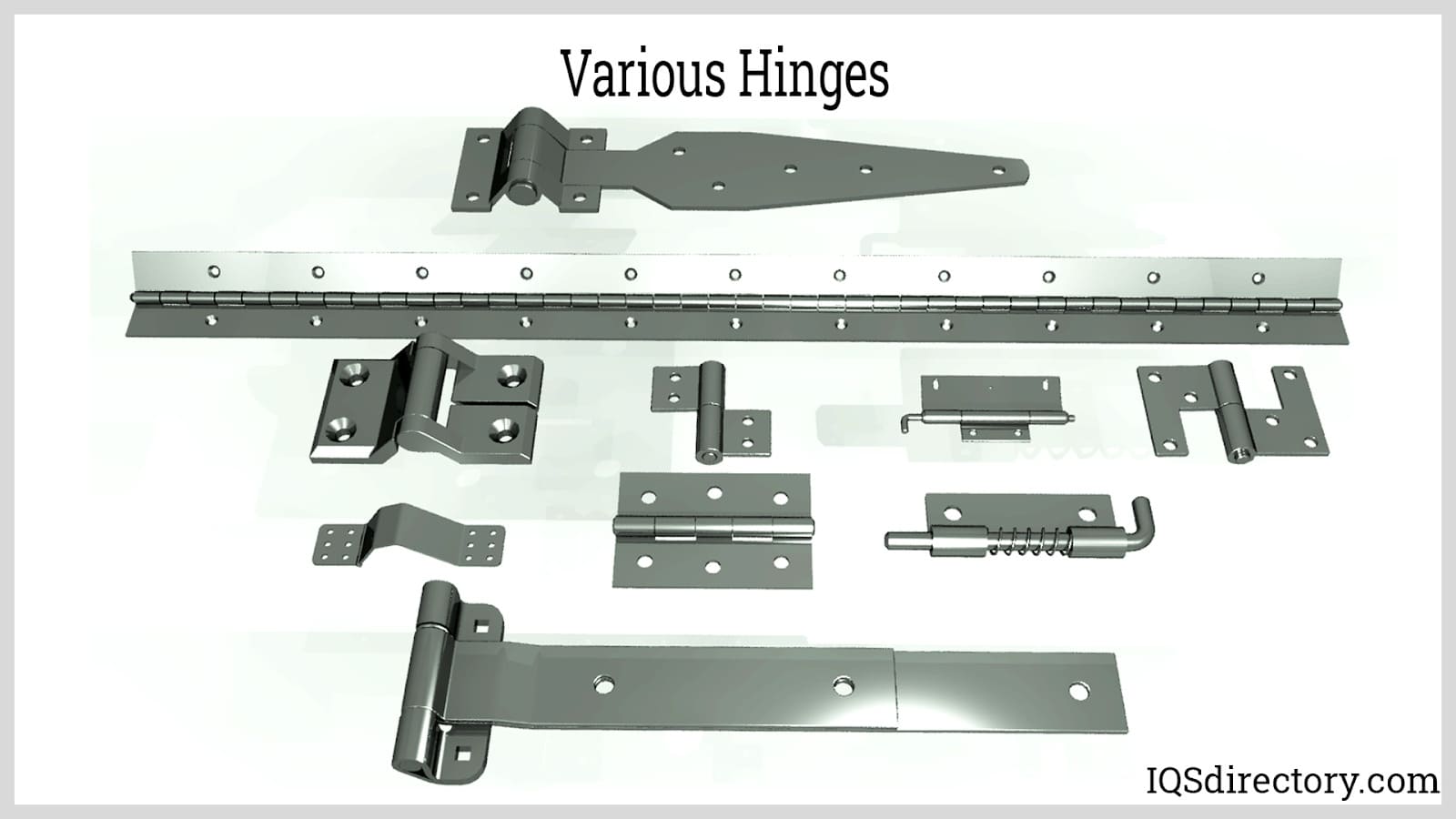

Understanding door hinge components Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Butt Hinge | Simple design with two leaves and a central pin | Interior doors, cabinets, and furniture | Pros: Easy installation; Cons: Limited weight capacity. |

| Continuous (Piano) Hinge | Long, continuous design with multiple knuckles | Heavy doors, gates, and industrial applications | Pros: Even weight distribution; Cons: More expensive. |

| Ball Bearing Hinge | Incorporates ball bearings for smooth operation | High-traffic areas, commercial doors | Pros: Durable and low friction; Cons: Requires more maintenance. |

| Spring Hinge | Contains a spring mechanism for automatic closing | Commercial doors, public buildings | Pros: Self-closing feature; Cons: Limited lifespan under heavy use. |

| Offset Hinge | Allows doors to open wider than standard hinges | Hospitals, kitchens, and commercial spaces | Pros: Maximizes doorway space; Cons: Complex installation. |

What are the Characteristics of Butt Hinges and Their Suitability for B2B Buyers?

Butt hinges are among the most commonly used hinge types, characterized by their straightforward design consisting of two leaves connected by a pin. They are ideal for applications such as interior doors and cabinetry where moderate weight support is needed. For B2B buyers, the ease of installation and cost-effectiveness make butt hinges a popular choice, although they may not be suitable for heavier doors due to their limited weight capacity.

How Do Continuous (Piano) Hinges Offer Advantages in Heavy-Duty Applications?

Continuous hinges, also known as piano hinges, feature a long, continuous design that provides consistent support along the entire length of the door. This makes them ideal for heavy-duty applications such as industrial doors and gates, where even weight distribution is crucial. B2B buyers should consider the initial investment, as continuous hinges tend to be more expensive than standard options; however, their durability can lead to lower long-term costs.

Why Are Ball Bearing Hinges Preferred in High-Traffic Areas?

Ball bearing hinges are engineered with internal ball bearings, allowing for smooth and effortless operation, making them an excellent choice for high-traffic environments like commercial buildings. Their design minimizes friction, enhancing longevity and reducing wear over time. B2B buyers should weigh the benefits of durability and low maintenance against the potential need for periodic lubrication and higher upfront costs.

What Benefits Do Spring Hinges Provide for Commercial Spaces?

Spring hinges are unique in that they incorporate a spring mechanism, enabling doors to close automatically. This feature is particularly advantageous in commercial settings, such as restaurants and public buildings, where maintaining door closure is essential for energy efficiency and security. While they offer convenience, B2B buyers should be aware that the lifespan of spring hinges may be limited under heavy usage, necessitating careful consideration of their application.

How Do Offset Hinges Maximize Space in Various Environments?

Offset hinges are designed to allow doors to swing wider than conventional hinges, making them particularly useful in environments like hospitals and commercial kitchens where space is at a premium. Their ability to create unobstructed pathways enhances accessibility and functionality. Buyers should consider the complexity of installation and the specific space requirements of their application when selecting offset hinges, as they may not be suitable for all door types.

Key Industrial Applications of door hinge components

| Industry/Sector | Specific Application of door hinge components | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Heavy-duty doors in commercial buildings | Enhanced durability and safety for high-traffic areas | Material strength, corrosion resistance, and compliance with local building codes |

| Automotive | Vehicle doors and compartments | Improved safety and functionality in vehicle operation | Weight tolerance, environmental resistance, and ease of installation |

| Healthcare | Hospital doors with automatic closing mechanisms | Ensures patient safety and accessibility | Compliance with health regulations, durability, and ease of maintenance |

| Retail & Hospitality | Entrance and interior doors in hotels and stores | Aesthetic appeal and functional reliability | Design compatibility, security features, and traffic endurance |

| Industrial Manufacturing | Machinery access panels and maintenance doors | Facilitates efficient operations and maintenance | Load capacity, resistance to wear, and adaptability to machinery specifications |

In the construction and architecture sector, door hinge components are critical for heavy-duty doors in commercial buildings. These hinges must withstand frequent use, ensuring safety and durability in high-traffic areas. Buyers should prioritize materials that offer strength and corrosion resistance, as well as compliance with local building codes to avoid costly delays during construction.

In the automotive industry, door hinges are essential for vehicle doors and compartments. They must provide reliable functionality while supporting the weight of the door. International buyers should consider the hinge’s weight tolerance and environmental resistance, especially in regions with extreme weather conditions. Efficient installation is also a key factor, as it impacts the overall assembly line process.

The healthcare sector requires specialized door hinge components for hospital doors, particularly those with automatic closing mechanisms. These hinges play a vital role in ensuring patient safety and easy access. Buyers in this industry must focus on compliance with health regulations, durability to withstand constant use, and ease of maintenance, as these factors contribute to operational efficiency.

In the retail and hospitality industry, door hinges are used in both entrance and interior doors of hotels and stores. These hinges not only need to be functional but also aesthetically pleasing to enhance the overall customer experience. Buyers should look for design compatibility and security features while ensuring that the hinges can endure high traffic, as this will minimize maintenance costs and enhance customer satisfaction.

Lastly, in industrial manufacturing, door hinge components are vital for access panels on machinery and maintenance doors. These hinges facilitate efficient operations and maintenance processes, which are crucial for productivity. Buyers should prioritize load capacity and resistance to wear, ensuring that the hinges can adapt to specific machinery specifications for optimal performance.

3 Common User Pain Points for ‘door hinge components’ & Their Solutions

Scenario 1: The Challenge of Heavy Doors and Insufficient Support

The Problem: In high-traffic environments, such as commercial buildings or warehouses, B2B buyers often face issues with heavy doors that are inadequately supported by standard hinge components. This can lead to frequent malfunctioning, including misalignment, difficulty in opening and closing, and ultimately, a risk of door failure. Such failures not only compromise safety but can also incur additional costs due to repairs and replacements. Buyers need to ensure that their chosen hinges can withstand the weight and usage of the doors they are intended for.

The Solution: To address this challenge, it is crucial to select heavy-duty hinges specifically designed for the weight and usage requirements of the doors. Buyers should assess the weight of the doors and choose hinges that have a higher load-bearing capacity, such as ball bearing hinges or continuous piano hinges. These types of hinges distribute the weight more evenly and reduce wear and tear. Additionally, it is advisable to install multiple hinges along the height of the door to further enhance support and stability. Regular maintenance checks to lubricate the hinges can also prolong their lifespan, ensuring smooth operation and reducing the risk of failure.

Scenario 2: Corrosion and Wear in Humid Environments

The Problem: In regions with high humidity or exposure to moisture, such as coastal areas or tropical climates, standard door hinge materials can suffer from corrosion and wear. B2B buyers may find that their hinges degrade faster than expected, leading to operational disruptions and potential safety hazards. This issue not only affects the functionality of the doors but can also result in costly replacements and repairs.

The Solution: To combat corrosion and wear, buyers should opt for hinges made from corrosion-resistant materials such as stainless steel or specialized coatings like zinc plating. It is essential to verify the material specifications with suppliers, ensuring that they are suitable for the environmental conditions. Furthermore, incorporating protective measures like applying anti-corrosive sprays or regular maintenance schedules can significantly enhance the longevity of the hinges. Buyers should also consider the installation of rubber or silicone seals around the hinges to minimize moisture exposure and protect the internal components from the elements.

Scenario 3: Aesthetic Compatibility with Design Requirements

The Problem: Many B2B buyers, particularly those in the construction and interior design sectors, encounter challenges in finding door hinge components that match the aesthetic requirements of their projects. Standard hinges may not align with the desired design features, leading to a mismatch that can affect the overall appeal of the finished product. This can be particularly frustrating when working on high-end residential or commercial projects where aesthetics are as critical as functionality.

The Solution: To resolve this issue, buyers should explore a wide range of hinge styles, finishes, and designs that align with their project specifications. Many manufacturers offer customizable options, allowing buyers to specify finishes such as brushed nickel, oil-rubbed bronze, or even painted colors that blend seamlessly with the door and surrounding decor. Engaging with suppliers who specialize in aesthetic hinges can provide insights into trending designs and innovative solutions. Additionally, considering the use of concealed hinges can enhance the overall look by hiding the hinge mechanism, providing a clean and modern appearance without compromising functionality. Prioritizing both aesthetic and functional requirements during the selection process will ensure a cohesive and visually appealing final product.

Strategic Material Selection Guide for door hinge components

When selecting materials for door hinge components, it is crucial to consider their properties, advantages, and limitations in relation to specific applications. This analysis focuses on four common materials: stainless steel, brass, plastic, and aluminum. Each material offers unique characteristics that impact performance, durability, and cost, making them suitable for different environments and requirements.

What Are the Key Properties of Stainless Steel for Door Hinges?

Stainless steel is renowned for its exceptional corrosion resistance, strength, and durability. It can withstand high temperatures and pressures, making it ideal for heavy-duty applications. The most common grades used in hinges, such as 304 and 316, provide excellent resistance to rust and tarnishing, which is essential for outdoor or humid environments.

Pros: Stainless steel hinges are highly durable, offer a long lifespan, and require minimal maintenance. They are suitable for high-traffic areas due to their strength and ability to handle significant weight.

Illustrative image related to door hinge components

Cons: The initial cost of stainless steel can be higher compared to other materials. Manufacturing processes can also be more complex, requiring specialized equipment.

Impact on Application: Stainless steel hinges are particularly effective in environments exposed to moisture, such as coastal regions or industrial settings. They comply with international standards like ASTM and DIN, making them a reliable choice for B2B buyers.

Why Choose Brass for Door Hinge Components?

Brass is a popular choice for decorative hinges due to its aesthetic appeal and good corrosion resistance. It is a copper-zinc alloy that provides moderate strength and is often used in residential applications.

Pros: Brass hinges are visually appealing and can enhance the overall design of a door. They also resist corrosion, making them suitable for indoor use.

Cons: Brass is softer than stainless steel, making it less durable in high-traffic areas. It can also be more expensive than alternatives like plastic or aluminum.

Impact on Application: Ideal for residential or low-traffic environments, brass hinges are often preferred for their design flexibility. Buyers should ensure compliance with local standards for quality assurance.

How Does Plastic Perform as a Material for Door Hinges?

Plastic hinges are lightweight, cost-effective, and resistant to corrosion and moisture. They are often made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC), which can withstand moderate loads.

Pros: The primary advantage of plastic hinges is their low cost and ease of manufacturing. They are also resistant to rust and can be designed in various colors.

Cons: Plastic hinges may not support heavy doors and can degrade under extreme temperatures or UV exposure. Their lifespan is generally shorter compared to metal options.

Impact on Application: Plastic hinges are suitable for lightweight doors in environments where aesthetics are less critical. They are often used in applications such as cabinets or lightweight partitions.

What Are the Benefits of Using Aluminum for Door Hinges?

Aluminum is a lightweight, corrosion-resistant metal that offers good strength-to-weight ratios. It is often used in commercial settings where weight reduction is essential.

Pros: Aluminum hinges are lightweight, making them easy to install and handle. They also resist corrosion, especially when anodized, and are cost-effective for large-scale applications.

Cons: While aluminum is durable, it is softer than stainless steel and may not withstand heavy loads as effectively. It can also be prone to scratching.

Impact on Application: Aluminum hinges are commonly used in commercial buildings and environments with moderate traffic. Compliance with standards like JIS is crucial for international buyers to ensure quality.

Summary Table of Material Selection for Door Hinge Components

| Material | Typical Use Case for door hinge components | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty doors in industrial settings | Exceptional durability and corrosion resistance | Higher initial cost and complex manufacturing | High |

| Brass | Decorative hinges for residential doors | Aesthetic appeal and moderate corrosion resistance | Less durable in high-traffic areas | Medium |

| Plastic | Lightweight doors and cabinets | Low cost and corrosion resistance | Limited load capacity and shorter lifespan | Low |

| Aluminum | Commercial buildings with moderate traffic | Lightweight and cost-effective | Softer than stainless steel, prone to scratches | Medium |

This guide provides a comprehensive overview of material selection for door hinge components, helping international B2B buyers make informed decisions based on their specific needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for door hinge components

What Are the Main Stages in the Manufacturing Process of Door Hinge Components?

The manufacturing of door hinge components involves several critical stages, each designed to ensure the final product meets the necessary standards for functionality and durability. Here’s a breakdown of the main stages involved:

How is Material Prepared for Door Hinge Manufacturing?

Material preparation is the foundational step in the hinge manufacturing process. Common materials include stainless steel, brass, and various alloys due to their strength and corrosion resistance. The preparation phase typically involves:

- Material Selection: Choosing the right material based on the application (e.g., heavy-duty doors may require thicker steel).

- Cutting: Raw materials are cut into appropriate sizes using laser cutting or shearing techniques. Precision is crucial to ensure uniformity across all components.

- Surface Treatment: This may include cleaning, de-greasing, and applying protective coatings to prevent corrosion during subsequent manufacturing stages.

What Forming Techniques Are Used in Door Hinge Production?

Once the materials are prepared, they undergo forming processes to achieve the desired shapes. Key techniques include:

- Stamping: This method is used to create the leaves and knuckles of the hinge. High-speed presses stamp the material into specific shapes, ensuring high precision.

- Bending: Components may need to be bent to form the knuckles or specific leaf designs. This is often done using hydraulic or mechanical presses.

- Machining: For parts that require tighter tolerances, CNC (Computer Numerical Control) machining is employed to achieve precise dimensions.

How Are Door Hinge Components Assembled?

After forming, the assembly stage brings together the different parts of the hinge. This stage often involves:

Illustrative image related to door hinge components

- Pin Insertion: The pin, which connects the leaves, is inserted into the knuckles. It is crucial that this pin fits snugly to ensure smooth operation.

- Welding or Riveting: In some hinge designs, parts may be welded or riveted together for added strength.

- Quality Checks: Assembly lines typically include checkpoints to verify that components fit correctly before proceeding.

What Finishing Processes Are Applied to Door Hinges?

Finishing processes enhance both the aesthetic and functional qualities of door hinges. Common techniques include:

- Coating: Hinge components may be coated with paint, powder, or galvanization to improve corrosion resistance and appearance.

- Polishing: For aesthetic hinges, polishing provides a smooth, shiny surface that complements architectural designs.

- Final Inspection: Before shipping, finished hinges undergo a final inspection to ensure they meet quality standards and specifications.

What Quality Assurance Practices Are Essential for Door Hinge Components?

Quality assurance (QA) is integral to the manufacturing process, particularly for door hinge components that must perform reliably under various conditions. Here are key practices involved:

Which International Standards Should B2B Buyers Be Aware Of?

International standards play a crucial role in ensuring product quality and safety. Notable standards include:

- ISO 9001: This standard focuses on quality management systems and is widely recognized across industries. Manufacturers certified under ISO 9001 demonstrate a commitment to quality in their processes.

- CE Marking: In Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For hinges used in specialized applications, such as oil and gas, API standards may apply.

What Are the Key Quality Control Checkpoints in Hinge Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that products meet specified standards. Common checkpoints include:

Illustrative image related to door hinge components

- Incoming Quality Control (IQC): Materials are inspected upon arrival to verify they meet specifications before being used in production.

- In-Process Quality Control (IPQC): During manufacturing, random samples may be tested to ensure adherence to design specifications and tolerances.

- Final Quality Control (FQC): The finished hinges undergo rigorous testing for functionality, durability, and aesthetic quality before packaging.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, ensuring the quality of door hinge components is paramount. Here are effective methods to verify supplier QC:

What Audits and Reports Should Buyers Request?

Conducting audits and requesting detailed reports can provide insights into a supplier’s quality assurance processes:

- Supplier Audits: Buyers should consider conducting on-site audits of potential suppliers to evaluate their manufacturing processes and quality control measures.

- Quality Reports: Requesting documentation on quality tests and certifications can help buyers understand the supplier’s compliance with international standards.

How Do Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection agencies can add an extra layer of assurance:

- Independent Verification: Third-party inspectors can provide unbiased evaluations of the manufacturing process and product quality.

- Certification: Many third-party agencies offer certification services that can further validate a supplier’s adherence to industry standards.

What Are the Unique Quality Control Considerations for International Buyers?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and market expectations is crucial. Here are some nuances to consider:

- Regional Compliance: Different regions may have specific regulations regarding materials and product safety. Buyers should be aware of these regulations to ensure compliance.

- Supply Chain Transparency: International buyers should seek suppliers that provide transparency in their supply chain, including sourcing practices and material certifications.

- Cultural Considerations: Understanding cultural differences in business practices can help build stronger relationships with suppliers and ensure smoother transactions.

Conclusion

Understanding the manufacturing processes and quality assurance practices for door hinge components is vital for B2B buyers. By knowing the main stages of production, relevant international standards, and effective verification methods, buyers can make informed decisions and select suppliers that meet their quality expectations. This diligence not only enhances product reliability but also strengthens business partnerships across global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door hinge components’

In the competitive landscape of B2B procurement, sourcing door hinge components requires a strategic approach to ensure quality, compatibility, and cost-effectiveness. This checklist serves as a practical guide for international buyers, particularly those in Africa, South America, the Middle East, and Europe, to streamline their sourcing process.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your project is vital. Define the dimensions, load capacity, and materials needed for the door hinges. Consider the environment where the hinges will be used, such as exposure to moisture or heavy traffic, which may necessitate specific materials like stainless steel or brass.

Step 2: Research Different Types of Hinges

Familiarize yourself with the various types of door hinges available in the market. Options such as ball bearing hinges, continuous hinges, and spring-loaded hinges each have unique properties suited for different applications. Knowing the types will help you select hinges that not only meet functional requirements but also align with aesthetic preferences.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Look for suppliers with a solid reputation and experience in providing door hinge components. Request company profiles, product catalogs, and customer testimonials to gauge their reliability and product quality. It’s also beneficial to check if they have experience serving clients in your specific industry or region.

Illustrative image related to door hinge components

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers have the necessary certifications that align with international standards. Certifications such as ISO 9001 for quality management systems or CE marking for compliance with European regulations are indicators of a supplier’s commitment to quality and safety. This step is crucial to mitigate risks associated with subpar products.

Step 5: Request Samples and Prototypes

Before making a bulk purchase, request samples or prototypes of the hinges. This allows you to assess the quality, fit, and functionality of the components firsthand. Testing samples can help identify any potential issues early in the process, ensuring that the final product meets your standards and requirements.

Step 6: Negotiate Pricing and Terms

Once you have identified potential suppliers and evaluated their products, it’s time to negotiate pricing and terms. Discuss bulk purchase discounts, payment terms, and delivery schedules. Establishing clear agreements can help prevent misunderstandings and ensure a smooth procurement process.

Step 7: Plan for Logistics and Supply Chain Management

Consider the logistics involved in importing door hinge components, especially when dealing with international suppliers. Assess shipping options, customs regulations, and potential lead times. A well-planned logistics strategy will ensure timely delivery and help you avoid disruptions in your project timeline.

By following this checklist, B2B buyers can make informed decisions when sourcing door hinge components, ensuring they meet both operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for door hinge components Sourcing

Understanding the cost structure and pricing of door hinge components is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis covers the key cost components, price influencers, and provides valuable buyer tips to enhance purchasing decisions.

What Are the Key Cost Components of Door Hinge Components?

The cost structure for door hinge components typically includes several critical elements:

-

Materials: The choice of material significantly impacts the cost. Common materials include stainless steel, zinc alloy, and plastic. Stainless steel offers durability but comes at a higher price point compared to plastic. The choice of material can also affect the hinge’s weight capacity and longevity.

-

Labor: Labor costs vary based on the manufacturing location and complexity of the hinge design. Regions with lower labor costs may provide a cost advantage, but it is essential to consider the trade-off between labor expense and quality.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Overhead can vary significantly by region and production volume.

-

Tooling: Tooling costs are associated with the creation of molds and dies necessary for production. Custom designs may incur higher tooling costs, but these can be amortized over larger production runs.

-

Quality Control (QC): Investing in quality control processes ensures that products meet safety and performance standards. While this adds to the overall cost, it can prevent costly recalls and enhance customer satisfaction.

-

Logistics: Shipping and handling costs are influenced by the distance from the supplier to the buyer, as well as the chosen transportation method. Import duties and customs fees should also be considered in the total logistics cost.

-

Margin: The supplier’s profit margin will also affect the final price. Suppliers may have varying pricing strategies based on their market positioning and competition.

What Influences Pricing for Door Hinge Components?

Several factors can influence the pricing of door hinge components:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower per-unit prices. Understanding the MOQ requirements of suppliers can help buyers negotiate better pricing.

-

Specifications and Customization: Customized hinges tailored to specific applications or aesthetics typically come at a premium. Clear communication of requirements can help avoid unexpected costs.

-

Quality and Certifications: Higher quality hinges with certifications (e.g., ISO, CE) may cost more but often provide better performance and longevity, reducing total cost of ownership.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can impact pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is crucial as they define the responsibilities of buyers and sellers in shipping costs and risks. Incoterms like CIF (Cost, Insurance, and Freight) can affect overall pricing.

What Buyer Tips Can Enhance Cost Efficiency?

For B2B buyers, particularly in international markets, there are several strategies to enhance cost efficiency:

-

Negotiate Effectively: Leverage volume purchases and long-term partnerships to negotiate better pricing and terms. Building a strong relationship with suppliers can lead to additional discounts and favorable payment terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also the long-term costs associated with maintenance, replacement, and potential downtime. Investing in higher-quality hinges may yield savings in the long run.

-

Research Local Market Conditions: Understanding local market dynamics can provide insights into competitive pricing and sourcing options. Buyers should be aware of regional trends that may affect costs.

-

Stay Informed on Global Supply Chain Trends: Fluctuations in material costs, labor availability, and geopolitical factors can impact pricing. Staying informed can help buyers make timely decisions and mitigate risks.

Conclusion

The landscape of sourcing door hinge components is influenced by a myriad of factors, from raw materials to logistics. By understanding the cost components and price influencers, international B2B buyers can make informed purchasing decisions that align with their operational needs and budget constraints. It is essential to approach the sourcing process strategically, considering not only immediate costs but also the long-term implications of their choices.

Disclaimer: Prices and costs mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific requirements.

Alternatives Analysis: Comparing door hinge components With Other Solutions

Understanding Alternative Solutions to Door Hinge Components

In the realm of door mechanisms, door hinge components are a traditional yet effective solution for ensuring smooth operation and stability. However, various alternative technologies and methods exist that can also achieve similar goals. This analysis explores how door hinge components stack up against two viable alternatives: pivot hinges and sliding door systems. By examining their performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Door Hinge Components | Pivot Hinges | Sliding Door Systems |

|---|---|---|---|

| Performance | High durability and smooth operation for swinging doors | Excellent for space-saving and allowing wider openings | Ideal for maximizing space, especially in small areas |

| Cost | Generally low to moderate, depending on materials used | Moderate; often more expensive than standard hinges | Higher initial cost due to hardware and installation complexity |

| Ease of Implementation | Simple installation with standard tools | Requires precise installation for optimal function | More complex installation, often needing professional help |

| Maintenance | Minimal; occasional lubrication required | Low; infrequent maintenance needed | Moderate; may require track cleaning and roller replacement |

| Best Use Case | Residential and commercial doors with regular traffic | Office partitions, closets, and specialty applications | Areas with limited space, such as small apartments or commercial spaces |

Analyzing Alternatives: What Are Their Pros and Cons?

Pivot Hinges

Pivot hinges provide a unique solution for door functionality by allowing the door to rotate around a pivot point rather than relying on the traditional hinge mechanism. This design allows for a wider opening and can be aesthetically pleasing in modern architectural designs. However, the installation requires more precision and expertise, which can increase labor costs. Additionally, pivot hinges may not be as robust as traditional door hinges in high-traffic environments, potentially leading to quicker wear if not properly maintained.

Sliding Door Systems

Sliding door systems offer a practical alternative, particularly in environments where space is at a premium. These systems glide along a track, allowing for easy access without the need for swing space, making them ideal for apartments, offices, and retail environments. However, they typically come with higher upfront costs and require more complex installation, potentially necessitating professional services. Maintenance can also be moderate, as the tracks may need cleaning and rollers may need replacement over time to ensure smooth operation.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating door hinge components against alternatives like pivot hinges and sliding door systems, B2B buyers should consider the specific requirements of their applications. Factors such as space availability, budget constraints, and the expected volume of use will significantly influence the decision-making process. For traditional settings with regular traffic, door hinge components may remain the best choice due to their durability and ease of installation. Conversely, for modern spaces requiring aesthetic appeal and efficient use of space, pivot hinges or sliding systems may offer superior functionality. Ultimately, understanding the unique benefits and drawbacks of each option will empower buyers to select the most suitable solution for their operational needs.

Essential Technical Properties and Trade Terminology for door hinge components

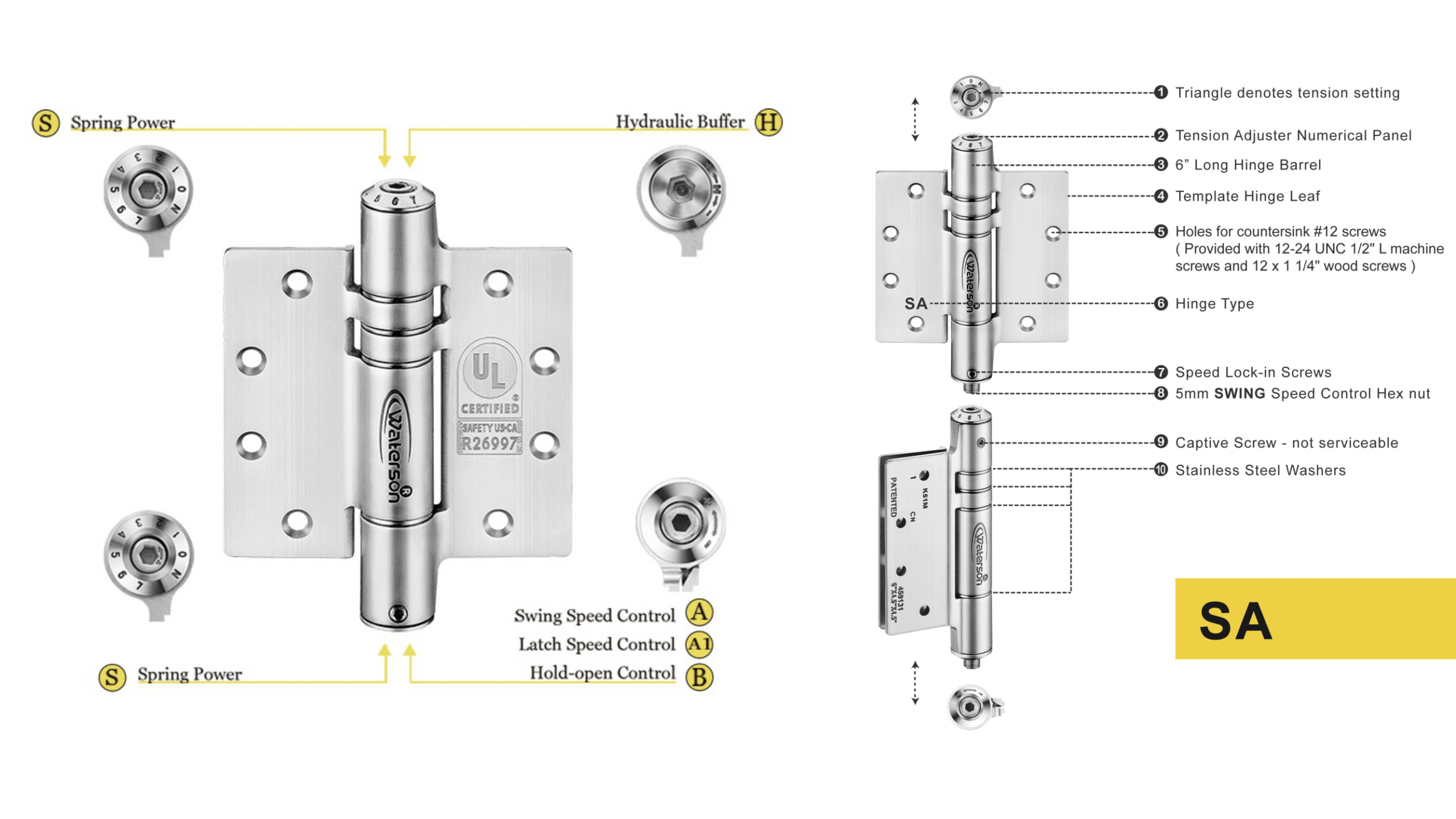

What Are the Key Technical Properties of Door Hinge Components?

Understanding the essential technical properties of door hinge components is crucial for B2B buyers. These properties ensure that the hinges will meet the demands of specific applications, particularly in various climates and usage scenarios across regions such as Africa, South America, the Middle East, and Europe. Here are some critical specifications to consider:

1. Material Grade

The material grade of a hinge significantly impacts its strength, durability, and resistance to environmental factors. Common materials include stainless steel, brass, and zinc alloys. For instance, stainless steel is often preferred for its corrosion resistance, making it ideal for outdoor applications or humid environments. Buyers must assess the material’s compatibility with the intended installation environment to ensure longevity.

2. Load Capacity

Load capacity refers to the maximum weight a hinge can support without failing. This specification is critical, especially for heavy doors or high-traffic areas. Manufacturers usually provide load ratings based on standard testing, allowing buyers to select hinges that can handle the expected load. Understanding load capacity helps prevent premature wear and potential safety hazards.

3. Tolerance

Tolerance defines the allowable deviation in the hinge dimensions and is vital for ensuring proper alignment and function. Tight tolerances are essential in precision applications, such as in machinery or high-end architectural designs, where even minor misalignments can cause operational issues. Buyers should inquire about tolerance specifications to ensure the hinges will fit correctly in their intended applications.

4. Finish and Coating

The finish or coating of a hinge affects its aesthetic appeal and resistance to wear and corrosion. Options include painted, anodized, or electroplated finishes, each offering different levels of protection and visual appeal. Selecting the right finish can enhance the overall look of a door while ensuring that the hinge remains functional over time, especially in harsh environments.

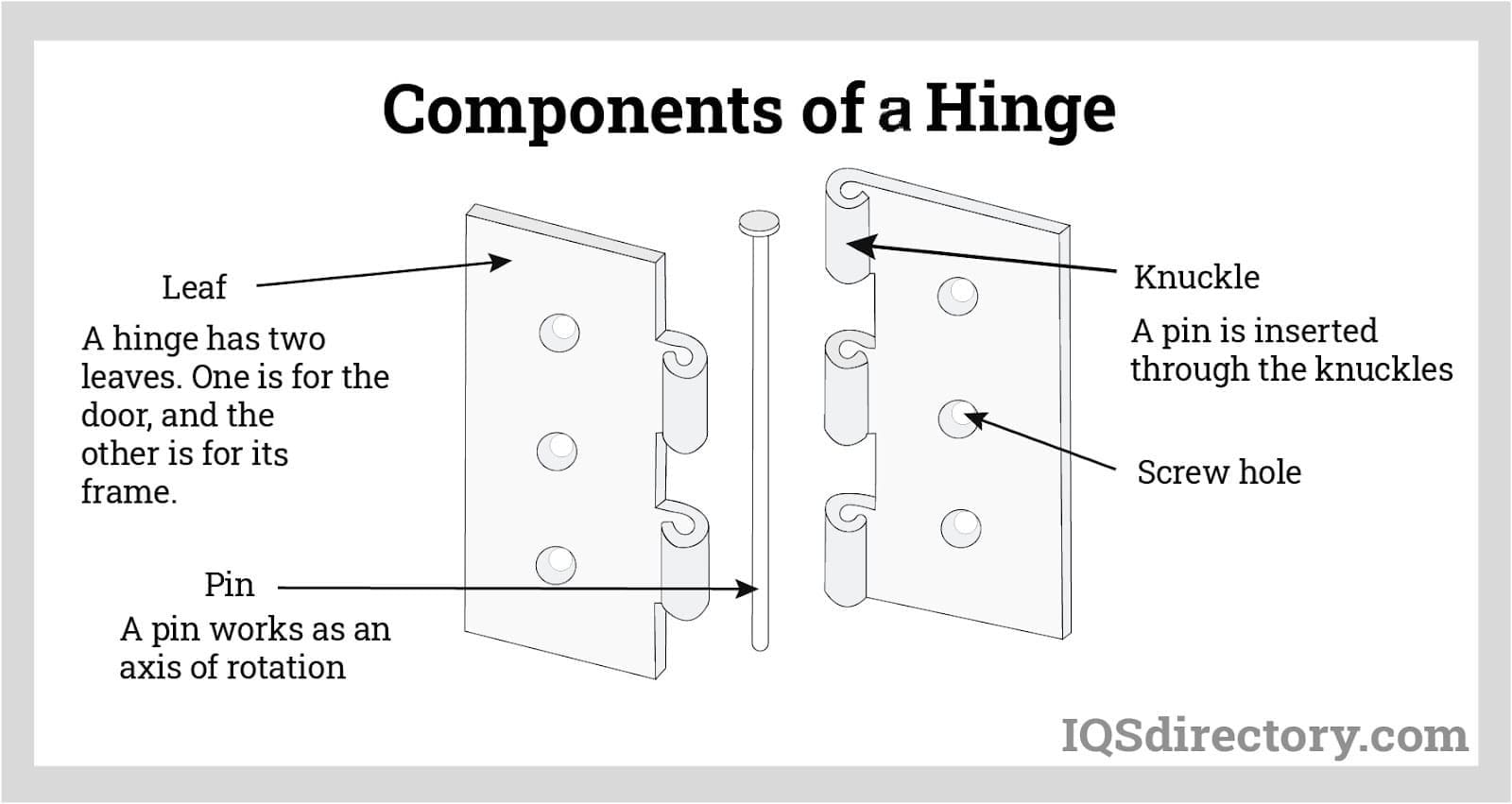

5. Pivot Point Design

The design of the pivot point, which often includes the pin and knuckles, influences the hinge’s smooth operation and lifespan. High-quality designs minimize friction and wear, allowing for smoother door movement. Buyers should consider hinges with well-engineered pivot points to ensure reliability, especially in high-use environments.

What Are Common Trade Terms Used in the Door Hinge Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to door hinge components:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are sold under another company’s brand name. In the hinge industry, OEMs may supply hinges to door manufacturers, who then integrate these components into their products. Understanding OEM relationships can help buyers identify reliable suppliers and ensure quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cost. Buyers should negotiate MOQ terms to align with their purchasing capabilities and inventory strategies, especially when sourcing from international suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. It is crucial for obtaining competitive pricing and understanding the terms of sale. An effective RFQ can streamline the purchasing process and ensure that buyers receive comprehensive information to make informed decisions.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers involved in global sourcing, as they clarify shipping responsibilities and costs, minimizing potential disputes.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. For door hinge components, lead time can vary based on manufacturing processes and shipping logistics. Buyers should account for lead times in their project timelines to ensure timely availability of materials for installation or production.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing door hinge components, ensuring that they meet both functional and aesthetic requirements for their applications.

Navigating Market Dynamics and Sourcing Trends in the door hinge components Sector

What Are the Key Market Dynamics Affecting Door Hinge Components for B2B Buyers?

The door hinge components market is currently experiencing significant growth driven by various global factors. Increased construction activities, particularly in emerging economies in Africa and South America, have led to a rising demand for durable and efficient door hardware. Additionally, the renovation and refurbishment of existing structures in Europe and the Middle East are contributing to an upward trend in hinge component sales.

Technological advancements also play a crucial role in this sector, with the introduction of smart hinges that incorporate sensors and automation. These innovations cater to the growing demand for smart home integration, appealing to both residential and commercial buyers. Moreover, as manufacturers adopt advanced manufacturing techniques, such as 3D printing, the customization of hinge components becomes more feasible, allowing buyers to meet specific requirements for unique applications.

International buyers must navigate several sourcing trends, including the shift towards direct sourcing from manufacturers to enhance supply chain efficiency and cost-effectiveness. This trend is particularly relevant for B2B buyers from regions like Brazil and Germany, where local manufacturers may offer competitive pricing and shorter lead times. Furthermore, understanding regional compliance and standards is crucial, as variations in regulations across different markets can impact sourcing decisions.

How Does Sustainability Influence Sourcing Decisions for Door Hinge Components?

Sustainability has emerged as a pivotal consideration in the sourcing of door hinge components. International buyers are increasingly aware of the environmental impact of their purchasing decisions, leading to a demand for eco-friendly products. This trend is particularly pronounced in Europe, where stringent regulations and consumer preferences favor sustainable practices.

Ethical sourcing is also gaining traction, with businesses prioritizing suppliers that demonstrate a commitment to social responsibility. This includes fair labor practices and transparency in supply chains. B2B buyers should look for manufacturers who hold certifications such as ISO 14001, which denotes a commitment to environmental management, or those who utilize recycled materials in their hinge components.

The use of ‘green’ materials, such as biodegradable plastics or sustainably sourced metals, is becoming more prevalent. Buyers should inquire about the environmental certifications of their suppliers and consider the lifecycle impact of the products they source. By aligning their sourcing strategies with sustainability goals, businesses can enhance their brand reputation while contributing positively to the environment.

What Is the Historical Context of Door Hinge Components in the B2B Sector?

The evolution of door hinge components dates back centuries, with early designs primarily focused on functionality and durability. Initially made from wood, hinges transitioned to metal as industrialization advanced, allowing for greater strength and longevity.

In the mid-20th century, the introduction of standardized hinge designs facilitated mass production, reducing costs and making them more accessible for both residential and commercial applications. The late 20th and early 21st centuries saw innovations such as the development of ball-bearing hinges, which provided smoother operation and extended lifespan, catering to the increasing demand for performance in high-traffic environments.

Today, as the industry embraces digital technologies and sustainable practices, the door hinge components market continues to evolve. This historical context underscores the importance of innovation and adaptability in meeting the changing needs of B2B buyers across various global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of door hinge components

-

How do I choose the right door hinge for my project?

Choosing the right door hinge involves considering several factors, including the weight and size of the door, the frequency of use, and the environment in which the hinge will be installed. For heavy doors, opt for heavy-duty hinges like ball bearing or continuous hinges, which can withstand greater stress. Additionally, consider the aesthetic aspects if the hinge will be visible. Consult with suppliers to understand the specifications and load ratings of various hinge types to ensure optimal performance and longevity. -

What is the best material for door hinges in humid environments?

For humid environments, stainless steel hinges are highly recommended due to their corrosion resistance and durability. They are ideal for areas like coastal regions or places with high moisture levels. If aesthetics are a consideration, look for hinges with protective coatings that enhance their resistance to rust while complementing the design of your doors. Always confirm with suppliers about the specific grades of stainless steel used, as this can affect performance in challenging conditions. -

What are the minimum order quantities (MOQs) for door hinge components?

Minimum order quantities (MOQs) for door hinge components vary by supplier and are influenced by the hinge type and material. Typically, MOQs can range from 50 to 1,000 units, depending on the manufacturer’s production capabilities and inventory levels. It’s advisable to negotiate MOQs with your supplier, especially if you’re a smaller business or looking to test a new product line. Always clarify the implications of lower MOQs on pricing and lead times. -

How can I ensure the quality of door hinge components when sourcing internationally?

To ensure quality when sourcing door hinge components internationally, consider implementing a robust supplier vetting process. This includes reviewing certifications, requesting product samples, and checking customer references. Additionally, consider conducting factory audits or using third-party inspection services to verify manufacturing processes and standards. Establish clear quality assurance protocols in your purchase agreements to address any discrepancies that may arise post-delivery. -

What payment terms should I expect when sourcing door hinges from international suppliers?

Payment terms for international suppliers typically range from 30% upfront and 70% upon delivery to full payment in advance. Some suppliers may offer letters of credit or payment through escrow services to mitigate risks. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Ensure that all payment terms are clearly outlined in the contract, including currency, payment methods, and any penalties for late payments. -

What customization options are available for door hinge components?

Many suppliers offer customization options for door hinge components, including size, finish, and material specifications. Depending on your needs, you can request specific dimensions, load ratings, or even unique designs to fit your application. Discuss your requirements with potential suppliers early in the negotiation process to ensure they can meet your specifications. Be aware that customization may affect lead times and pricing, so factor this into your planning. -

What logistics considerations should I keep in mind when importing door hinges?

When importing door hinges, logistics considerations include shipping methods, customs regulations, and delivery timelines. Determine whether air or sea freight is more suitable based on urgency and cost. Familiarize yourself with the import regulations of your country to avoid delays at customs. It may also be beneficial to work with a freight forwarder who can manage shipping logistics and provide guidance on documentation required for smooth clearance. -

How can I assess the reliability of a door hinge supplier?

Assessing the reliability of a door hinge supplier involves evaluating their track record, industry reputation, and customer feedback. Look for suppliers with established experience in the hinge market and verify their compliance with international quality standards. Request case studies or references from previous clients to gauge their performance. Engaging in initial smaller orders can also serve as a trial to evaluate their service, product quality, and responsiveness before committing to larger contracts.

Top 6 Door Hinge Components Manufacturers & Suppliers List

1. TPH Supply – Hinges and Hinge Parts

Domain: tphsupply.com

Registered: 2008 (17 years)

Introduction: Hinges and Hinge Parts include various types of door hinges that fasten partition doors to pilasters, allowing doors to swing open while keeping the pilaster in place. Key components include cams and pintles for door movement and self-closing mechanisms. The product range features items from manufacturers such as Accurate, All American, Flush Metal, Hadrian, Knickerbocker, and Sanymetal. Notable p…

2. IQS Directory – Hinges

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Hinges are mechanical devices that join two elements, allowing them to pivot around a fixed axis. They are used in various applications such as doors, enclosures, containers, furniture, jewelry, construction, and electronic devices. Types of hinges include: 1. Ball-bearing Hinges: Reduce friction using ball bearings, ideal for high-traffic commercial doors. 2. Block Hinges: Heavy-duty hinges made …

3. Reddit – Pintle Gate Hinges

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The male part of the hinge is called a Pintle, and the female part is called a Gudgeon. This type of hinge is referred to as a lift-off hinge or a pintle gate hinge, commonly found in farm supply stores. It allows for the gate to be lifted off when both pintles are facing up, and can be secured by installing the upper pintle facing down to require tools for removal.

4. Maxave Group – Key Parts of a Door Hinge

Domain: maxavegroup.com

Registered: 2021 (4 years)

Introduction: Key Parts of a Door Hinge: 1. Leaf: Two flat metal plates with screw holes for attachment to door and frame. 2. Knuckle: Cylindrical segments that interlock, determining hinge strength. 3. Pin: Cylindrical connector allowing rotational movement, acting as the pivot point. 4. Screw Hole: Pre-drilled holes for secure attachment to door and frame.

5. True – Top Door Hinge Kit

Domain: restaurant-equipment-parts.com

Registered: 2007 (18 years)

Introduction: Product Name: True 205684 Top Door Hinge Kit, MSRP: $150.48, Now: $100.99; Product Name: True 220168 – Left Hinge Spring, MSRP: $199.85, Now: $114.99; Product Name: True 945483 Door Hinge (Replaces 879294), MSRP: $168.66, Now: $94.99; Product Name: True 905244 – Plastic Shim, Now: $0.25; Product Name: True 823089 – Cam Hinge (formerly 832136), MSRP: $199.85, Now: $114.99; Product Name: Component H…

6. Beasts of Bermuda – Door Hinges

Domain: wiki.beastsofbermuda.com

Registered: 2017 (8 years)

Introduction: Door hinges are mechanical devices essential for the functioning of doors and gates, allowing smooth swinging motion. Key components include: Hinge Leaf (flat plates connecting door and frame), Pin (cylindrical part holding leaves together), Knuckle (surrounds pin for rotation), Bushing (reduces friction), and Screw Hole (for securing hinge). Types of door hinges include Butt Hinges, Continuous Hi…

Strategic Sourcing Conclusion and Outlook for door hinge components

As the demand for door hinge components continues to grow globally, understanding the intricacies of these essential elements is crucial for B2B buyers. Key takeaways include recognizing the importance of hinge anatomy—specifically the leaf, knuckle, and pin—as they directly influence durability and functionality. Strategic sourcing is vital; it enables companies to select high-quality materials that align with their operational needs while considering factors such as aesthetics, load-bearing capacity, and environmental conditions.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should prioritize partnerships with reliable suppliers who can provide tailored solutions. By leveraging insights on various hinge types and their applications, companies can make informed decisions that enhance their product offerings and customer satisfaction.

Looking ahead, the door hinge market is poised for innovation, with advancements in materials and design paving the way for more efficient and stylish options. Engage with leading manufacturers and explore new possibilities to ensure your projects are supported by the best hinge components available. The future of door hinges is bright—seize the opportunity to lead in this evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.