Do Clocks Have Springs: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for do clocks have springs

In today’s global market, understanding the intricacies of whether clocks have springs is essential for B2B buyers looking to make informed purchasing decisions. The challenge often lies in sourcing reliable mechanical clocks that utilize mainsprings—components critical for the timekeeping accuracy and longevity of these devices. This guide delves into the various types of clock springs, their applications across different clock models, and the nuances of supplier vetting.

We will explore the key factors influencing the selection of mainsprings, including strength, length, and compatibility with various clock types. Additionally, we will provide insights into cost considerations and maintenance practices that can affect the overall value of your investment.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly countries like Germany and Brazil—this comprehensive guide serves as an invaluable resource. It empowers you to navigate the complexities of sourcing quality clock springs, ensuring that you can confidently choose suppliers that meet your unique business needs. By understanding the critical elements of clock mechanics and supplier evaluation, you can enhance your purchasing strategy and support your operational success in the competitive clock market.

Understanding do clocks have springs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mainspring Clocks | Utilizes a coiled metal spring for power | Antique restoration, clock repair | Pros: Reliable, long-running; Cons: Requires skilled maintenance. |

| Spring-Driven Clocks | Employs multiple springs for complex functions | High-end timepieces, luxury brands | Pros: Precision, intricate designs; Cons: Higher cost, complexity in repair. |

| Quartz Clocks | Battery-operated with minimal mechanical parts | Mass production, consumer markets | Pros: Low maintenance, accurate; Cons: Less traditional appeal. |

| Pendulum Clocks | Uses a swinging pendulum for time regulation | Collectors, educational purposes | Pros: Aesthetic appeal, historical value; Cons: Sensitive to environmental changes. |

| Clockwork Mechanisms | Combines gears and springs for movement | Custom clock manufacturing | Pros: Versatile design options; Cons: Requires specialized knowledge for repairs. |

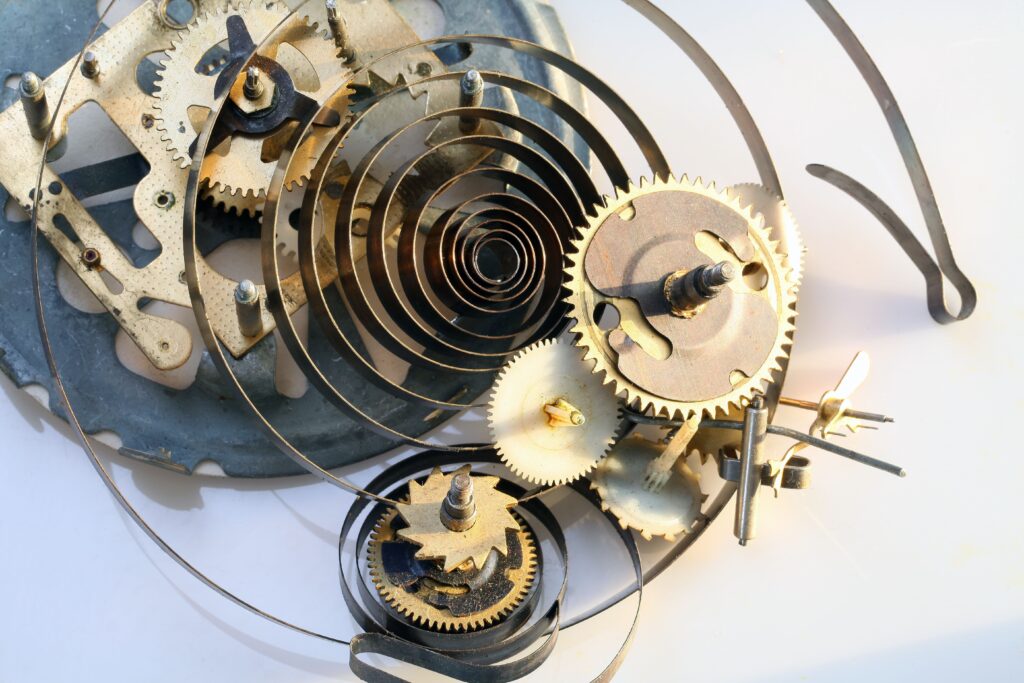

What are Mainspring Clocks and Their Applications in B2B?

Mainspring clocks are the quintessential mechanical timepieces, relying on a coiled metal spring to drive their movements. This type of clock is particularly popular in antique restoration and clock repair sectors, where the emphasis is on maintaining traditional craftsmanship. B2B buyers should consider the quality of the mainspring, as it significantly influences the clock’s performance and longevity. Regular maintenance is crucial, requiring skilled technicians who understand the intricacies of these mechanisms.

How Do Spring-Driven Clocks Differ from Other Types?

Spring-driven clocks utilize multiple springs to enable complex functionalities, making them ideal for high-end timepieces and luxury brands. Their intricate designs often appeal to discerning customers who value craftsmanship and precision. B2B buyers should be aware that while these clocks offer exceptional accuracy and aesthetic appeal, they come with a higher price point and may require specialized maintenance. Understanding the specific needs of your clientele can help guide purchasing decisions.

Why Choose Quartz Clocks for Mass Production?

Quartz clocks are battery-operated, relying on minimal mechanical components, which makes them suitable for mass production and consumer markets. They are favored for their low maintenance requirements and high accuracy, appealing to businesses looking for reliable timekeeping solutions. However, B2B buyers should note that quartz clocks may lack the traditional charm of mechanical clocks, which could be a consideration for specific market segments focused on heritage and craftsmanship.

What Are the Benefits of Pendulum Clocks in Collecting and Education?

Pendulum clocks are characterized by their swinging pendulum, which regulates timekeeping. They are often sought after by collectors and used in educational contexts to demonstrate the principles of time measurement and mechanics. B2B buyers interested in this category should consider the clock’s aesthetic and historical significance, as these factors can influence market value. However, they should also be mindful of the sensitivity of pendulum clocks to environmental factors, which can affect their performance.

How Do Clockwork Mechanisms Offer Versatility in Custom Manufacturing?

Clockwork mechanisms combine gears and springs, allowing for versatile designs tailored to specific requirements in custom clock manufacturing. This type is particularly relevant for businesses that specialize in creating unique timepieces. When purchasing, B2B buyers should evaluate the technical specifications and compatibility with existing designs, as well as the expertise required for repairs. The ability to customize can be a strong selling point, but it also necessitates a thorough understanding of the mechanics involved.

Key Industrial Applications of do clocks have springs

| Industry/Sector | Specific Application of do clocks have springs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Production of Mechanical Clocks | Ensures reliable timekeeping for manufacturing processes | Quality of mainspring, compatibility with clock movements |

| Restoration & Repair Services | Repairing Antique and Vintage Clocks | Preserves historical value and functionality | Availability of specific mainspring sizes and materials |

| Automotive | Timing Mechanisms in Mechanical Watches | Enhances precision in timekeeping for vehicle systems | Durability and strength of the mainspring for automotive use |

| Electronics | Integration in Hybrid Timekeeping Devices | Combines traditional and modern technology | Compatibility with electronic components and design specifications |

| Education | Teaching Tools in Horology Classes | Provides hands-on experience in mechanical engineering | Sourcing of educational kits and components for practical learning |

How Are Mainsprings Used in Mechanical Clock Manufacturing?

In the manufacturing sector, mainsprings are crucial components in the production of mechanical clocks. These springs store energy that powers the clock’s movement, ensuring precise timekeeping essential for various manufacturing processes. For businesses in this sector, sourcing high-quality mainsprings that match specific clock designs is vital. Buyers must consider the material, strength, and length of the mainspring to maintain the integrity and functionality of their timepieces.

Why Are Mainsprings Important for Clock Restoration and Repair?

Restoration and repair services for antique and vintage clocks heavily rely on the availability of quality mainsprings. These components are essential for maintaining the clock’s historical value and operational functionality. Buyers in this industry need to source mainsprings that fit specific antique models, which often requires a deep understanding of the clock’s design and mechanics. Ensuring compatibility with old mechanisms is crucial to successfully restoring these timepieces to their original state.

How Do Mainsprings Contribute to Automotive Timing Mechanisms?

In the automotive industry, mechanical watches equipped with mainsprings are used in timing mechanisms for various vehicle systems. These springs provide the necessary energy to ensure accurate timekeeping, which is essential for functionalities like navigation and performance tracking. Buyers must focus on the durability and strength of the mainspring to withstand the demands of automotive environments, ensuring reliability and precision in performance.

In What Ways Are Mainsprings Integrated into Hybrid Timekeeping Devices?

The electronics sector is increasingly integrating mainsprings into hybrid timekeeping devices that combine traditional mechanical elements with modern technology. This integration enhances the appeal of such devices, allowing for a unique user experience. Buyers should prioritize sourcing mainsprings that meet specific design specifications and compatibility with electronic components, ensuring that the device functions seamlessly while maintaining aesthetic value.

What Role Do Mainsprings Play in Educational Horology Tools?

In educational settings, mainsprings are essential for teaching horology and mechanical engineering principles. They provide students with hands-on experience in understanding clock mechanics and the principles of energy storage and release. Educational institutions must source mainsprings that are suitable for practical learning kits, ensuring they are safe and easy to handle while being durable enough for repeated use.

3 Common User Pain Points for ‘do clocks have springs’ & Their Solutions

Scenario 1: Understanding Mainspring Functionality in Mechanical Clocks

The Problem: B2B buyers, particularly those involved in clock manufacturing or repair, often struggle with understanding the intricate functionality of mainsprings. Many may not fully grasp how the quality and specifications of a mainspring affect the overall performance of mechanical clocks. This lack of knowledge can lead to improper sourcing of components, resulting in clocks that fail to keep accurate time or operate inefficiently. Additionally, the complexity of various clock mechanisms can deter buyers from making informed decisions, leading to increased costs and time delays in production or repair.

The Solution: To overcome this challenge, B2B buyers should invest time in training and education about mainspring mechanics. Manufacturers and suppliers should provide detailed specifications on mainsprings, including their length, strength, and width, along with comprehensive guides on how these factors influence clock performance. Establishing partnerships with knowledgeable suppliers who can offer expert advice and high-quality components is crucial. Engaging in webinars or workshops focused on clock mechanics can also empower buyers to make informed decisions when sourcing mainsprings, ensuring that they select the right product for their specific clock models.

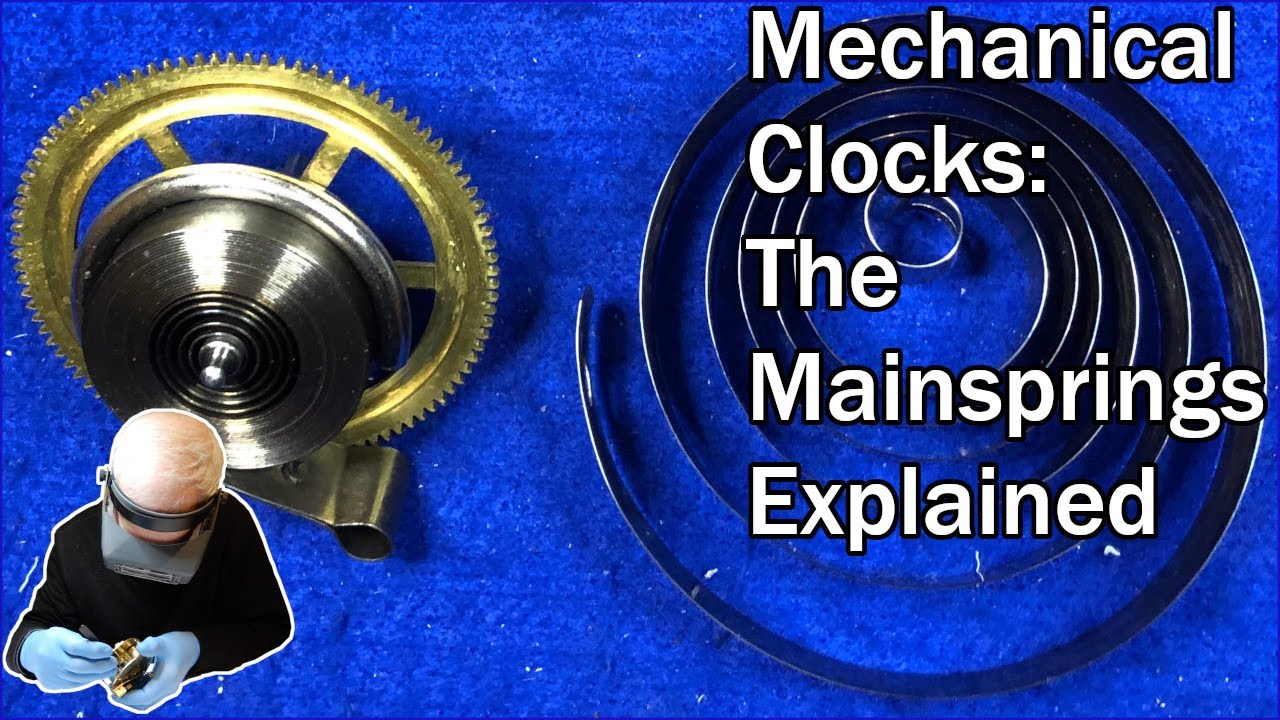

Illustrative image related to do clocks have springs

Scenario 2: Identifying Faulty Mainsprings and Their Symptoms

The Problem: Another significant pain point for B2B buyers is identifying faulty mainsprings in mechanical clocks. A broken or weakened mainspring can manifest in various ways, such as inaccurate timekeeping or the clock stopping altogether. Buyers often lack the expertise to diagnose these issues effectively, which can lead to prolonged downtime and decreased customer satisfaction. This situation is particularly challenging for businesses that rely on timely clock repairs or manufacturing, as it directly impacts their operational efficiency and profitability.

The Solution: Implementing a systematic approach to maintenance and inspection is essential for identifying faulty mainsprings. B2B buyers should establish a checklist that outlines the common signs of mainspring failure, such as changes in winding resistance or irregular timekeeping. Additionally, investing in diagnostic tools, such as timegrapher devices, can help businesses pinpoint issues more accurately. Creating a network of skilled technicians who are trained in mainspring assessment can further enhance the repair process. Buyers should also consider sourcing high-quality replacement mainsprings that come with warranties, ensuring that they can provide reliable services without incurring additional costs from frequent replacements.

Scenario 3: The Challenge of Sourcing the Right Mainspring

The Problem: Sourcing the correct mainspring for specific clock models can be a daunting task for B2B buyers. Many suppliers offer a wide range of mainsprings, but without proper guidance, buyers may end up purchasing components that are incompatible with their clock mechanisms. This not only leads to wasted resources but can also result in delays in production or repair timelines, affecting customer satisfaction and business reputation. Additionally, buyers in different regions may face challenges in accessing high-quality components, impacting their ability to serve their markets effectively.

Illustrative image related to do clocks have springs

The Solution: To streamline the sourcing process, B2B buyers should develop strong relationships with reputable suppliers who specialize in clock components. Creating a detailed inventory of clock models and their corresponding mainspring specifications can serve as a valuable reference when placing orders. Suppliers can also be encouraged to offer customization options or assistance in selecting the right mainspring based on specific clock designs. Utilizing online platforms that provide comprehensive catalogs and comparison tools can further enhance the sourcing experience. Lastly, establishing a feedback loop with suppliers regarding the performance of sourced mainsprings can help refine future purchasing decisions and ensure that businesses consistently obtain quality components.

Strategic Material Selection Guide for do clocks have springs

What Materials Are Commonly Used for Clock Springs?

When considering the materials used for clock springs, particularly mainsprings, it is essential to evaluate their properties, advantages, disadvantages, and suitability for specific applications. This analysis will focus on four common materials: high-grade steel, brass, composite materials, and stainless steel. Each material has unique characteristics that influence performance, durability, and overall cost-effectiveness.

High-Grade Steel: The Traditional Choice for Mainsprings

High-grade steel is the most widely used material for clock mainsprings due to its excellent elasticity and strength. This material can withstand significant stress and has a high fatigue resistance, making it ideal for mechanical clocks that require consistent performance over time.

Pros: High-grade steel is relatively inexpensive and readily available, making it a cost-effective choice for manufacturers. Its durability ensures long-lasting performance, reducing the frequency of replacements.

Cons: However, high-grade steel is susceptible to corrosion if not properly treated or maintained. Additionally, the manufacturing process can be complex, requiring precise tempering to achieve the desired spring characteristics.

Impact on Application: High-grade steel is compatible with various clock types, including antique and modern designs. However, buyers must consider the climate and environmental conditions in their region, as humidity can affect the longevity of steel springs.

Brass: A Classic Alternative with Aesthetic Appeal

Brass, an alloy of copper and zinc, is another common material used in clock springs, particularly in decorative timepieces. Its attractive appearance adds aesthetic value, making it a popular choice for high-end clocks.

Pros: Brass is highly corrosion-resistant and can withstand environmental changes, making it suitable for various applications. It is also easier to work with during manufacturing, allowing for intricate designs.

Cons: The primary drawback of brass is its lower tensile strength compared to high-grade steel, which can lead to quicker wear in high-stress applications. Additionally, brass can be more expensive due to the cost of raw materials.

Illustrative image related to do clocks have springs

Impact on Application: Brass springs are often used in luxury clocks and decorative pieces, appealing to markets in Europe and the Middle East where craftsmanship is highly valued. Buyers should be aware of the potential for tarnishing, which may require regular maintenance.

Composite Materials: Innovation in Clock Spring Design

Composite materials, including carbon fiber and polymer blends, are gaining traction in the clock industry due to their lightweight and high-strength properties. These materials can be engineered to provide specific performance characteristics.

Pros: Composites offer excellent resistance to corrosion and environmental factors, making them suitable for various applications. They are also lighter than traditional materials, which can enhance the overall design and functionality of the clock.

Illustrative image related to do clocks have springs

Cons: The primary disadvantage is the higher manufacturing complexity and cost associated with producing composite springs. Additionally, not all clock designs can accommodate the unique properties of composite materials.

Impact on Application: Composite materials are particularly appealing to innovative clock manufacturers looking to differentiate their products in competitive markets. However, international buyers should ensure compliance with relevant material standards in their regions.

Stainless Steel: The Corrosion-Resistant Option

Stainless steel is another viable alternative for clock springs, known for its exceptional corrosion resistance and durability. This material is often used in environments where moisture and humidity are prevalent.

Pros: Stainless steel offers a longer lifespan due to its resistance to rust and corrosion, making it suitable for clocks in tropical or humid regions. It also maintains its strength and elasticity over time.

Cons: The main drawback is the higher cost compared to high-grade steel and brass. The manufacturing process can also be more complex, requiring specialized techniques to achieve the desired properties.

Impact on Application: Stainless steel is ideal for clocks intended for outdoor use or in humid environments, making it a suitable choice for buyers in Africa and South America. Compliance with international standards is crucial for ensuring product quality and performance.

Summary Table of Material Selection for Clock Springs

| Material | Typical Use Case for do clocks have springs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Grade Steel | Mechanical clocks | Excellent elasticity and strength | Susceptible to corrosion | Low |

| Brass | Decorative and luxury clocks | Aesthetic appeal and corrosion resistance | Lower tensile strength | Med |

| Composite | Innovative clock designs | Lightweight and customizable | Higher manufacturing complexity | High |

| Stainless Steel | Outdoor and humid environment clocks | Exceptional corrosion resistance | Higher cost and complex manufacturing | High |

This analysis provides B2B buyers with a comprehensive overview of the materials used in clock springs, enabling informed decisions based on performance requirements, cost considerations, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for do clocks have springs

What Are the Key Stages in the Manufacturing Process of Clock Springs?

The manufacturing process of clock springs involves several critical stages that ensure the final product meets the high standards of quality and reliability required in the clock industry. Understanding these stages can help B2B buyers select suppliers who adhere to best practices in production.

Material Preparation: What Materials Are Used for Clock Springs?

The first step in manufacturing clock springs is the selection of high-quality materials. Typically, manufacturers use high-grade steel, which offers the necessary tensile strength and durability. Advanced alloys may also be used to enhance corrosion resistance and elasticity. Suppliers often procure materials that comply with international standards, ensuring that the raw materials are suitable for the precision required in clock mechanisms.

How Are Clock Springs Formed?

Once the materials are prepared, they undergo a forming process that shapes them into mainsprings. This usually involves:

- Coiling: The metal strip is wound into a coil, which is the fundamental shape of the mainspring. Precision coiling is essential, as the coil’s dimensions directly affect the clock’s performance.

- Heat Treatment: After coiling, the springs are subjected to heat treatment to improve their hardness and elasticity. This step is crucial for ensuring that the spring can withstand repeated winding and unwinding without losing its functional properties.

- Stress Relief: To prevent future issues like warping or brittleness, manufacturers often perform a stress relief process. This ensures that any internal tensions within the metal are alleviated, which is vital for long-term durability.

What Does the Assembly Process Involve?

The assembly of clock springs typically follows the forming stage. This involves:

- Inspection of Coils: Each coil undergoes a thorough inspection to check for defects or inconsistencies that could affect performance.

- Integration with Gear Mechanisms: The springs are then integrated into the clock’s gear mechanism. This is a delicate process that requires precision to ensure that the energy transfer between the mainspring and the gears is efficient.

- Final Adjustments: Once assembled, the clock undergoes final adjustments to ensure accuracy in timekeeping. This includes calibrating the tension of the mainspring to match the clock’s design specifications.

What Are the Finishing Techniques Applied to Clock Springs?

Finishing techniques are essential to enhance the aesthetic and functional qualities of clock springs. Common techniques include:

- Surface Treatment: This may involve polishing or coating to reduce friction and improve the longevity of the spring.

- Lubrication: Applying a specialized lubricant minimizes wear and tear, enhancing the clock’s overall performance.

These finishing touches not only improve the functionality of the springs but also contribute to the visual appeal of the final product.

What International Standards Guide Quality Assurance for Clock Springs?

For B2B buyers, understanding the quality assurance process is crucial. Manufacturers of clock springs typically adhere to international standards such as ISO 9001, which sets out criteria for a quality management system. This ensures that the manufacturer consistently meets customer requirements and enhances customer satisfaction.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure that the clock springs meet the required specifications. These include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet predefined standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor the production quality. This might include measuring the dimensions of the coiled springs or checking the effectiveness of heat treatments.

- Final Quality Control (FQC): Once the springs are completed, they undergo a final inspection to verify their functionality, accuracy, and aesthetic quality.

What Testing Methods Are Commonly Used for Clock Springs?

Several testing methods are employed to ensure the reliability and performance of clock springs:

- Tensile Testing: This assesses the strength of the material and its ability to withstand forces without breaking.

- Fatigue Testing: Clock springs are subjected to repeated winding and unwinding to simulate real-world use and to determine their durability over time.

- Timekeeping Accuracy Tests: These tests evaluate how well the clock maintains accurate time, a crucial factor for buyers.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some ways to do this:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand.

- Quality Assurance Reports: Requesting detailed reports on quality control practices, testing results, and compliance with international standards can provide valuable insights into the supplier’s reliability.

- Third-Party Inspections: Engaging independent third-party organizations to inspect the manufacturing facility and processes can offer an unbiased view of the supplier’s quality assurance measures.

What Are the Nuances of Quality Control Certification for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control certifications. Different regions may have varying requirements or standards that suppliers must meet. For instance:

Illustrative image related to do clocks have springs

- CE Marking in Europe: Suppliers exporting to Europe need to comply with CE marking requirements, indicating that products meet EU safety, health, and environmental protection standards.

- Local Certifications: In Africa and South America, there may be specific local standards that need to be adhered to, which can differ significantly from international norms.

Understanding these nuances can help buyers make informed decisions and mitigate risks associated with quality assurance in the procurement process.

Conclusion

In conclusion, the manufacturing processes and quality assurance for clock springs are intricate and vital for ensuring the reliability of mechanical clocks. By understanding the key stages of manufacturing, quality control measures, and testing methods, B2B buyers can make informed decisions when sourcing clock springs. Ensuring that suppliers adhere to international standards and maintaining a robust verification process will enhance the quality and performance of the clocks they offer, ultimately benefiting their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘do clocks have springs’

Introduction

This guide provides a comprehensive checklist for B2B buyers seeking to procure clocks that utilize springs, specifically focusing on the mainspring, which is essential for the operation of mechanical clocks. Understanding the procurement process ensures that you source high-quality components that meet your technical specifications and operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes the type of clock (e.g., mantel, wall, grandfather) and the specific characteristics of the springs you need, such as length, strength, and material.

- Length: Determines how long the clock will run on a single wind.

- Strength: Affects the force driving the clock’s gears, influencing accuracy and performance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers specializing in clock springs. Look for suppliers with a strong reputation in the market, particularly those that have experience serving your specific region.

- Customer Reviews: Check testimonials and ratings from other B2B buyers.

- Industry Experience: Prioritize suppliers with a proven track record in mechanical clock components.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that demonstrate their commitment to quality and safety standards. Certifications can include ISO 9001 for quality management systems or specific certifications for materials used in clock springs.

- Quality Assurance: Certifications indicate adherence to industry standards, ensuring consistent product quality.

- Regulatory Compliance: Confirm that suppliers meet local and international regulations applicable to your market.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the mainsprings you are considering. This allows you to assess the quality, durability, and compatibility of the products with your clock mechanisms.

- Testing: Evaluate the samples under actual working conditions to ensure they meet your performance expectations.

- Feedback Loop: Utilize insights from your testing phase to refine your final order specifications.

Step 5: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations to establish favorable terms, including pricing, payment terms, and delivery schedules.

- Bulk Discounts: Inquire about pricing structures for larger orders, which can significantly reduce costs.

- Lead Times: Clarify the expected delivery timeframes to ensure they align with your project timelines.

Step 6: Finalize Contracts and Agreements

After negotiating terms, ensure that all agreements are documented in a formal contract. This should include specifications, pricing, delivery terms, and any warranties offered by the supplier.

- Legal Review: Consider having legal counsel review the contract to safeguard your interests.

- Clarity: Ensure that all terms are clear and unambiguous to prevent misunderstandings later.

Step 7: Establish a Maintenance Plan

After procurement, develop a maintenance plan for the springs and clocks. Regular maintenance ensures longevity and optimal performance of the timepieces.

- Scheduled Maintenance: Outline intervals for checking and servicing the springs to avoid wear and tear.

- Lubrication Practices: Identify suitable lubricants that can enhance the performance and lifespan of the springs.

By following this checklist, B2B buyers can confidently navigate the sourcing process for clocks that utilize springs, ensuring they procure high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for do clocks have springs Sourcing

What Are the Key Cost Components in Sourcing Clock Springs?

When evaluating the costs associated with sourcing clock springs, several components contribute to the overall expense. The primary cost components include:

-

Materials: High-grade steel is commonly used for mainsprings due to its durability and ability to store energy effectively. The quality and type of steel can significantly impact the price. Additionally, any specialized coatings or treatments to enhance performance can further increase costs.

-

Labor: Skilled labor is required for manufacturing mainsprings, as the process involves precision engineering. Labor costs can vary by region, with countries that have higher wage standards generally reflecting increased production costs.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, factory rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs, leading to better pricing for buyers.

-

Tooling: The initial investment in tooling for creating molds and dies used in the production of clock springs can be significant. Buyers should consider how these costs are amortized over production volume, as larger orders can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring the reliability and performance of clock springs necessitates a robust QC process. This includes testing and inspection, which adds to the overall cost but is crucial for maintaining product quality.

-

Logistics: Shipping and handling costs can vary significantly based on the origin of the product and destination. International shipping may involve tariffs and customs duties, further influencing the total cost.

-

Margin: Suppliers typically add a margin to cover their costs and profit, which can vary based on market demand, competition, and the supplier’s reputation.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of clock springs, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better pricing and manage inventory effectively.

-

Specifications and Customization: Custom designs or specific performance characteristics can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses later in the process.

-

Materials: The choice of materials not only affects performance but also impacts cost. High-performance alloys may be more expensive but offer longer service life, which can be more cost-effective in the long run.

-

Quality and Certifications: Products that come with quality certifications (e.g., ISO) may command higher prices. However, these certifications can provide assurance of reliability, which is crucial for maintaining customer satisfaction.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is essential for international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost.

What Buyer Tips Can Help Optimize Cost-Efficiency?

For B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe, understanding the nuances of clock spring sourcing is vital:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may have flexibility that can benefit both parties.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance and replacement costs over the lifecycle of the product. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

-

Research Local Suppliers: Depending on the region, sourcing from local manufacturers can reduce shipping costs and lead times. This can be particularly beneficial in regions with developing supply chains.

-

Stay Informed on Market Trends: Awareness of market trends and fluctuations in material costs can empower buyers to make timely purchasing decisions, potentially at lower prices.

-

Request Samples: Before committing to large orders, request samples to assess quality and performance. This can prevent costly mistakes and ensure that the springs meet your specifications.

By understanding these cost components and influencers, B2B buyers can make informed decisions that optimize their sourcing strategies for clock springs, ensuring both quality and cost-effectiveness.

Alternatives Analysis: Comparing do clocks have springs With Other Solutions

Exploring Alternative Solutions to Mechanical Clocks with Springs

When it comes to timekeeping technology, mechanical clocks with mainsprings have long been the standard. However, various alternatives have emerged, each with unique features and benefits. This section examines the comparison between traditional spring-driven clocks and alternative technologies, providing B2B buyers with essential insights to make informed decisions.

Comparison Table

| Comparison Aspect | Do Clocks Have Springs | Quartz Clocks | Digital Clocks |

|---|---|---|---|

| Performance | High accuracy, but requires regular maintenance | Very accurate, minimal maintenance | Extremely accurate, no maintenance needed |

| Cost | Generally higher due to craftsmanship | Lower cost, widely available | Lowest cost, high volume production |

| Ease of Implementation | Requires skilled labor for setup and maintenance | Easy to set up, battery-operated | Simple installation, plug-and-play |

| Maintenance | Needs regular winding and occasional repairs | Low maintenance; battery replacement needed | Minimal; typically just requires power |

| Best Use Case | Antiques, luxury markets, and collectors | Everyday use, educational settings | Modern homes and offices, tech-savvy users |

Understanding the Alternatives in Detail

What Are Quartz Clocks and Their Advantages?

Quartz clocks utilize a battery-powered quartz crystal to keep time. They are known for their high accuracy and reliability, often deviating only a few seconds per year. The primary advantage of quartz technology lies in its low maintenance needs; users only need to replace the battery periodically. This makes quartz clocks an excellent choice for B2B buyers looking for cost-effective, reliable timekeeping solutions for commercial applications. However, they lack the craftsmanship appeal and longevity of traditional spring-driven clocks, which may be a downside for markets focused on heritage and luxury.

How Do Digital Clocks Compare?

Digital clocks operate using electronic components and can display time in various formats. They offer the highest accuracy and require virtually no maintenance beyond ensuring they are powered. Digital clocks are often the most economical option, appealing to budget-conscious businesses and environments like offices and schools. Their straightforward installation process makes them highly accessible. Nevertheless, they may lack the aesthetic appeal and charm of mechanical clocks, which could be a critical factor for businesses aiming to create a specific ambiance or brand identity.

Conclusion: Choosing the Right Timekeeping Solution

Selecting the appropriate timekeeping solution depends on various factors, including the intended use, budget constraints, and aesthetic preferences. For B2B buyers in sectors that value craftsmanship and historical significance, traditional clocks with mainsprings may offer the best return on investment. Conversely, for those prioritizing cost-efficiency and reliability, quartz or digital clocks present practical alternatives. Each option has its merits, and understanding the specific needs of your business will guide you toward making the right choice.

Essential Technical Properties and Trade Terminology for do clocks have springs

What Are the Key Technical Properties of Clock Springs?

Understanding the technical specifications of clock springs is essential for B2B buyers in the clock manufacturing and repair industry. Here are some critical properties to consider:

1. Material Grade

Clock springs are primarily made from high-grade steel, which offers durability and flexibility. The choice of material affects the spring’s ability to withstand tension and its overall lifespan. B2B buyers should prioritize suppliers who provide detailed information on material grades to ensure the springs meet industry standards and can endure daily use without failing.

2. Strength and Thickness

The strength of a mainspring is determined by its thickness, which influences the amount of energy it can store and release. A thicker mainspring provides more power but requires more force to wind. Buyers should assess the strength requirements based on the clock design to ensure optimal functionality. Inappropriate thickness can lead to operational issues, such as the clock running too fast or too slow.

Illustrative image related to do clocks have springs

3. Length

The length of the mainspring dictates how long the clock will run on a single wind. A longer mainspring generally allows for extended running times, which is crucial for consumer satisfaction in both mechanical and antique clocks. When sourcing mainsprings, it is vital to match the length specifications to the clock model to prevent malfunction.

4. Width

The width of the mainspring must align with the barrel in which it is housed. A proper fit is essential for efficient energy transfer and smooth operation. Buyers should be aware that incorrect width can lead to friction and wear, resulting in decreased accuracy over time.

5. Tolerance

Tolerance refers to the allowable deviation in the dimensions of the mainspring. High tolerance standards are essential for ensuring that the spring fits perfectly within the clock’s mechanism. B2B buyers should seek manufacturers that adhere to strict tolerance guidelines to minimize issues during assembly and operation.

6. Lubrication Compatibility

Clock springs often require lubrication to function smoothly and extend their lifespan. It is essential to consider the compatibility of the spring material with various lubricants. Buyers should inquire about recommended lubricants to ensure that they do not compromise the integrity of the spring.

What Are Common Trade Terminologies in Clock Manufacturing?

Familiarity with industry jargon can enhance communication and decision-making in B2B transactions. Here are some common terms relevant to clock springs:

Illustrative image related to do clocks have springs

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the clock industry, understanding OEM relationships is crucial for buyers looking to source high-quality clock springs that meet specific design requirements.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For clock springs, this figure can impact inventory management and cost considerations. B2B buyers must be aware of MOQs to plan their purchases effectively and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. Buyers should prepare RFQs that include detailed specifications for clock springs to ensure accurate quotes, facilitating better budgeting and negotiation.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers involved in importing clock springs, as they clarify who is responsible for shipping, insurance, and tariffs.

5. Lead Time

Lead time refers to the period from placing an order to its delivery. In clock manufacturing, knowing the lead time for mainspring orders can help businesses manage production schedules and customer expectations effectively.

6. Quality Assurance

Quality assurance involves the processes that ensure products meet specified requirements and standards. For clock springs, a robust quality assurance program can minimize defects and enhance product reliability, which is crucial for maintaining customer satisfaction and brand reputation.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing clock springs, ultimately leading to better product performance and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the do clocks have springs Sector

What Are the Global Market Dynamics Influencing the Do Clocks Have Springs Sector?

The market for mechanical clocks, particularly those utilizing mainsprings, is shaped by several global drivers. A notable trend is the resurgence of interest in mechanical timepieces, driven by consumers’ desire for craftsmanship and nostalgia. This trend is particularly pronounced in regions like Europe, where tradition and heritage in horology are highly valued. In Africa and South America, the growing middle class is increasingly interested in luxury and decorative items, including mechanical clocks, enhancing demand in these markets.

Illustrative image related to do clocks have springs

In terms of technology, advancements in materials science have led to the development of high-grade steel and synthetic materials that enhance the durability and performance of mainsprings. International B2B buyers must stay abreast of these innovations, as they can significantly influence sourcing decisions. Moreover, the ongoing digital transformation within the supply chain is allowing for more efficient inventory management and real-time tracking, which can benefit buyers looking to optimize their procurement processes.

Emerging markets are also seeing a shift toward e-commerce platforms, which provide easier access to a broader range of suppliers and products. This trend is particularly relevant for buyers in regions such as the Middle East, where online purchasing is rapidly gaining traction. Additionally, the focus on customization is growing, as consumers seek personalized timepieces, prompting manufacturers to adapt their offerings accordingly.

How Is Sustainability and Ethical Sourcing Shaping the Do Clocks Have Springs Market?

Sustainability is becoming a critical concern in the manufacturing of mechanical clocks and their components, including mainsprings. The environmental impact of production processes, particularly in terms of material sourcing and waste management, is under scrutiny. International B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, which includes using recycled materials and minimizing energy consumption during manufacturing.

Ethical sourcing is also gaining importance, as consumers demand transparency within supply chains. Buyers should seek manufacturers that adhere to ethical labor practices and have certifications such as Fair Trade or ISO 14001, which signify a commitment to environmental management. This focus on ethical sourcing not only aligns with consumer values but can also enhance brand reputation and customer loyalty.

Illustrative image related to do clocks have springs

Furthermore, the adoption of green certifications and sustainable materials is becoming a differentiator in the market. Buyers are encouraged to collaborate with suppliers who utilize eco-friendly lubricants and coatings for mainsprings, which can reduce the environmental footprint of their products. By prioritizing sustainability and ethical sourcing, B2B buyers can contribute positively to their brand image while meeting the growing consumer demand for responsible products.

What Is the Historical Context of Mainsprings and Their Evolution in the Clock Industry?

The evolution of mainsprings is a testament to the innovation and craftsmanship that has characterized the clock-making industry over centuries. Originating in the 15th century, the mainspring revolutionized timekeeping by allowing for more compact and portable clock designs, transitioning from large, weight-driven mechanisms to smaller, more efficient models.

By the 18th century, advancements in metallurgy and spring design improved the reliability and accuracy of clocks, making them essential household items. As mechanical clocks gained popularity, so did the demand for high-quality mainsprings, leading to the establishment of specialized manufacturers.

Today, while digital timekeeping devices dominate the market, mechanical clocks with mainsprings are experiencing a renaissance. This resurgence is fueled by a renewed appreciation for traditional craftsmanship and a growing market for luxury and collectible timepieces. Understanding this historical context helps B2B buyers appreciate the value of sourcing high-quality mainsprings and clock components that embody both tradition and modern innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of do clocks have springs

-

How do I solve issues with clock mainsprings?

To address problems with clock mainsprings, first identify symptoms such as inconsistent timekeeping or difficulty in winding. A faulty mainspring may require replacement, which involves disassembling the clock and carefully removing the old spring. Ensure you select a replacement that matches the length, strength, and width specifications of the original. For B2B buyers, sourcing high-quality mainsprings from reputable suppliers is essential to guarantee reliability and performance. Additionally, consider investing in maintenance tools and lubricants to prolong the lifespan of your clock mechanisms. -

What is the best type of mainspring for mechanical clocks?

The best type of mainspring for mechanical clocks typically depends on the clock’s design and intended use. For precision timepieces, high-grade steel mainsprings are preferred due to their durability and ability to maintain tension. Customization may be necessary for unique or antique clocks, so working with a supplier that offers tailored solutions is beneficial. When sourcing, inquire about the specifications such as length, width, and strength to ensure optimal performance and longevity of your clock. -

What factors should I consider when sourcing clock springs internationally?

When sourcing clock springs internationally, consider factors such as the supplier’s reputation, product quality, and compliance with international standards. Verify their manufacturing capabilities and whether they can accommodate custom orders. Evaluate shipping costs, lead times, and payment terms to ensure they align with your business needs. Additionally, consider the supplier’s ability to provide after-sales support and warranty services, which are crucial for maintaining long-term relationships and ensuring product reliability. -

How can I verify the quality of clock springs from suppliers?

To verify the quality of clock springs from suppliers, request samples for testing before committing to a larger order. Assess the materials used, particularly for durability and resistance to wear. Review certifications that indicate compliance with industry standards, and ask for references or case studies from other B2B clients. Conducting a factory visit or third-party inspection can also provide insights into the manufacturing processes and quality control measures employed by the supplier. -

What are the typical minimum order quantities (MOQ) for clock springs?

Minimum order quantities (MOQ) for clock springs can vary significantly by supplier and product type. Generally, MOQs can range from a few dozen to several hundred units, depending on the complexity and customization of the springs. When negotiating with suppliers, discuss the possibility of lower MOQs for first-time orders or trial runs to assess product quality. Additionally, consider the potential for bulk discounts on larger orders, which can help optimize your procurement costs. -

What payment terms should I expect when sourcing clock springs?

Payment terms when sourcing clock springs can vary widely among suppliers. Common arrangements include upfront payment, partial payment before shipment, or net terms that allow payment after delivery. It’s essential to clarify these terms during negotiations, considering factors such as your cash flow needs and the supplier’s payment policies. Some suppliers may offer trade financing options or discounts for early payments, so exploring these possibilities can provide additional financial flexibility. -

How can I ensure timely logistics for my clock spring orders?

To ensure timely logistics for your clock spring orders, collaborate closely with suppliers to establish clear timelines for production and shipping. Discuss preferred shipping methods, and choose reliable logistics partners with experience in international freight. Tracking shipments and maintaining open communication with both suppliers and logistics providers can help mitigate delays. Additionally, consider seasonal factors that might impact shipping times, especially if sourcing from regions prone to logistical challenges. -

What quality assurance measures should I implement when importing clock springs?

Implementing quality assurance measures when importing clock springs is crucial to maintaining product standards. Establish clear specifications and quality benchmarks that suppliers must meet. Consider conducting pre-shipment inspections to verify that products align with agreed-upon standards. Additionally, implement a robust return policy for defective items and maintain documentation of all transactions for accountability. Collaborating with suppliers who prioritize quality control can significantly enhance the reliability of your clock springs.

Top 5 Do Clocks Have Springs Manufacturers & Suppliers List

1. Clockworks – Mainspring Essentials

Domain: clockworks.com

Registered: 1996 (29 years)

Introduction: A mainspring in a clock is a coiled strip of high-grade steel that serves as the powerhouse for mechanical clocks. It stores energy when wound and releases it gradually to power the gears and hands of the clock. Key factors for selecting a mainspring include length, strength, and width, which directly impact the clock’s operation. Clockworks.com offers a variety of mainsprings suitable for differe…

2. Reddit – Mechanical Watches and Clocks

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Mechanical watches and clocks maintain consistent speed through the use of a pendulum or a balance wheel. The pendulum’s swing period is determined solely by its length, not by the weight or initial push. In watches, the balance wheel acts like a pendulum, swinging back and forth at a regular rate. An escapement mechanism regulates the movement, allowing the watch to tick consistently even as the …

3. Junghans B11 – Mainspring Replacement Insights

Domain: antiquevintageclock.com

Registered: 2018 (7 years)

Introduction: The article discusses the replacement of mainsprings in antique and vintage clocks, particularly focusing on the Junghans B11 mantel clock. It emphasizes that the steel used in original mainsprings is of higher quality than many modern replacements. The author rarely replaces mainsprings unless they are broken or defective, arguing that many clocks can run properly with original springs if the res…

4. Gift of Time – Clocks Powered by Six Mechanisms

Domain: giftoftimeclocks.com

Registered: 2003 (22 years)

Introduction: Clocks are powered in six ways: weight-driven, spring-driven, atmospheric, battery-operated, or electric. Weight-driven clocks use gravitational pull from heavy weights and need to be rewound every seven days. They often produce chimes, with grandfather clocks typically having 12 hammers and rods for melodies like Westminster, Whittington, or St. Michael’s. Some models have 16 hammers for addition…

5. HowStuffWorks – Spring-Driven Clocks

Domain: electronics.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Spring-driven clocks use a wound spring to store energy, which unwinds into a gear train similar to that of weight-driven clocks. They can be more accurate with design improvements, and the moon phase dial on grandfather clocks moves at a rate of one revolution every 56 days.

Strategic Sourcing Conclusion and Outlook for do clocks have springs

As the heart of mechanical clocks, mainsprings play an essential role in their functionality and longevity. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the intricacies of mainsprings can significantly enhance procurement strategies. High-quality mainsprings ensure reliable performance, reduce maintenance costs, and extend the lifespan of timepieces, making strategic sourcing vital for businesses in the clock repair and manufacturing sectors.

When sourcing mainsprings, it is crucial to consider factors such as material quality, size, and compatibility with specific clock models. Establishing relationships with reputable suppliers can provide access to a diverse range of products, ensuring that your business remains competitive in an evolving marketplace.

Looking ahead, the demand for mechanical clocks is expected to grow, fueled by trends in vintage and artisanal craftsmanship. By investing in high-quality mainsprings and prioritizing effective sourcing strategies, businesses can position themselves for success. Engage with suppliers who offer expert guidance and comprehensive resources, and take proactive steps to secure your supply chain. The future of clockmaking is bright—seize the opportunity to enhance your offerings and meet the needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.