Different Kinds Of Mixers: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for different kinds of mixers

In the dynamic landscape of global trade, sourcing the right mixers can pose a significant challenge for B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe. With a wide array of mixer types—ranging from high shear mixers to industrial blenders—understanding the unique applications and benefits of each can be overwhelming. This guide aims to demystify the complexities of the mixer market by providing an in-depth look at various mixer types, their specific applications, and essential considerations for supplier vetting and cost analysis.

By exploring the nuances of different mixers, this comprehensive resource empowers international buyers to make informed purchasing decisions that align with their operational needs. Whether you’re in Nigeria seeking efficient dough mixers for a burgeoning bakery or in Germany looking for robust emulsifiers for food production, this guide is tailored to address your specific requirements. It will equip you with actionable insights into the latest innovations and industry trends, ensuring you choose the right equipment for your business.

Investing in the right mixer not only enhances operational efficiency but also contributes to product quality and customer satisfaction. As you navigate through this guide, you will gain the knowledge necessary to confidently select the best mixers that meet your business objectives and elevate your competitive edge in the global market.

Understanding different kinds of mixers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dough Mixers | Spiral agitator design for efficient dough mixing | Bakeries, pizzerias, and catering services | Pros: Efficient dough handling; ideal for large batches. Cons: Limited to dough applications. |

| Planetary Mixers | Offset shaft design with multiple attachments | Restaurants, catering, and food production | Pros: Versatile for various tasks; multiple attachments available. Cons: May require additional investment for attachments. |

| High Shear Mixers | Rotor-stator design for emulsifying and homogenizing | Pharmaceutical, cosmetic, and food industries | Pros: Fast mixing; effective for complex mixtures. Cons: Higher initial cost; may require specialized training. |

| Vertical Cutter Mixers | High horsepower motor and versatile attachment options | High-volume food production and processing | Pros: Multi-functional; suitable for bulk preparation. Cons: Larger footprint; may need dedicated space. |

| Tank Mixers | Designed to mix multiple ingredients in a single tank | Chemical, agricultural, and food industries | Pros: Efficient blending; suitable for various materials. Cons: May require specific tank design for certain applications. |

What Are Dough Mixers and Their Key B2B Benefits?

Dough mixers, often referred to as spiral mixers, are specialized for efficiently mixing and kneading dough. Their spiral agitator design allows for the gentle folding of dough, which is essential for developing gluten without overworking the mixture. Ideal for bakeries and pizzerias, these mixers can handle large quantities, making them indispensable for high-demand food production. When considering a dough mixer, buyers should evaluate the mixer’s capacity, ease of cleaning, and durability to ensure it meets their operational needs.

How Do Planetary Mixers Stand Out in the Market?

Planetary mixers are characterized by their unique design where the mixing bowl remains stationary while the agitator moves around it. This allows for thorough mixing without leaving unmixed areas. They are suitable for a variety of applications, including whipping, kneading, and mixing, making them ideal for restaurants and catering services. Buyers should consider the mixer’s versatility, attachment options, and size to ensure it fits their specific food preparation needs.

What Advantages Do High Shear Mixers Offer to Industries?

High shear mixers are engineered for emulsifying, homogenizing, and dispersing mixtures, making them vital in industries such as pharmaceuticals, cosmetics, and food processing. Their rotor-stator design creates high shear forces that rapidly break down particles, leading to uniform mixtures. While they offer significant efficiency and speed, buyers should consider the investment required and whether their staff is trained to operate such specialized equipment effectively.

Why Choose Vertical Cutter Mixers for High-Volume Production?

Vertical cutter mixers are designed for high-volume food processing, featuring a powerful motor and an assortment of attachments for various tasks like chopping and mixing. They are particularly beneficial in settings like cafeterias and large-scale food production facilities. When purchasing, businesses should assess the mixer’s capacity, operational versatility, and the space required for installation to ensure it aligns with their production goals.

What Are the Benefits of Using Tank Mixers in Various Industries?

Tank mixers are designed to blend multiple ingredients in a single tank, making them a go-to solution in chemical, agricultural, and food industries. Their ability to mix liquids, powders, and emulsions efficiently is a significant advantage. Buyers should evaluate the mixer’s compatibility with different materials, ease of maintenance, and overall design to ensure it meets the specific requirements of their operations.

Key Industrial Applications of different kinds of mixers

| Industry/Sector | Specific Application of different kinds of mixers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Dough Mixers for large-scale bakery production | Ensures consistent dough quality, reducing waste | Capacity, power requirements, and ease of cleaning |

| Chemical Manufacturing | High Shear Mixers for emulsifying chemicals | Improves product consistency and reduces processing time | Material compatibility, energy efficiency, and safety features |

| Pharmaceuticals | Homogenizers for drug formulation | Achieves uniformity in drug compounds, enhancing efficacy | Compliance with industry standards and certifications |

| Cosmetics and Personal Care | Emulsifiers for creating stable creams and lotions | Enhances product texture and shelf life | Versatility, maintenance, and ease of operation |

| Agriculture | Tank Mixers for blending fertilizers and pesticides | Ensures uniform application, improving crop yields | Chemical compatibility, tank size, and operational efficiency |

How Are Dough Mixers Used in the Food and Beverage Industry?

Dough mixers play a pivotal role in the food and beverage sector, particularly in bakeries and pizzerias. These mixers are designed to handle large batches of dough, ensuring uniform consistency and optimal gluten development without overworking the mixture. This capability is crucial for businesses aiming to deliver high-quality baked goods consistently. For international buyers, especially from regions like Nigeria and Germany, sourcing mixers with appropriate capacities and energy efficiency is essential to meet local demand and operational costs.

What Role Do High Shear Mixers Play in Chemical Manufacturing?

In the chemical manufacturing industry, high shear mixers are essential for emulsifying various substances, ensuring that products maintain consistent quality and performance. These mixers facilitate the rapid blending of immiscible liquids, reducing processing times and enhancing product stability. Buyers from South America and the Middle East should prioritize equipment that meets specific material compatibility and energy efficiency standards to optimize production processes and comply with local regulations.

Why Are Homogenizers Critical in Pharmaceuticals?

Homogenizers are vital in the pharmaceutical sector for creating uniform drug formulations. By breaking down particles to a consistent size, these mixers enhance the efficacy and bioavailability of medications. For B2B buyers in Europe, understanding regulatory compliance and certification requirements is crucial when sourcing homogenizers to ensure that they meet stringent industry standards and deliver reliable performance in drug manufacturing.

How Are Emulsifiers Beneficial in Cosmetics and Personal Care?

Emulsifiers are widely used in the cosmetics industry to create stable creams and lotions. They help blend oil and water phases, resulting in products with a desirable texture and extended shelf life. For international buyers, especially from Africa and the Middle East, it is vital to consider the versatility and maintenance requirements of emulsifiers, ensuring they can handle various formulations and comply with cosmetic regulations.

What Is the Importance of Tank Mixers in Agriculture?

Tank mixers are commonly employed in agriculture for blending fertilizers and pesticides, ensuring that these substances are uniformly mixed for effective application. This uniformity is critical for maximizing crop yields and minimizing waste. Buyers from regions like South America should focus on sourcing tank mixers that are compatible with the specific chemicals used in their operations, as well as those that offer efficient mixing capabilities to enhance productivity.

3 Common User Pain Points for ‘different kinds of mixers’ & Their Solutions

Scenario 1: Ensuring Consistency in Product Quality with Mixers

The Problem: A food manufacturing company in Nigeria struggles with maintaining the consistency and quality of their products due to variations in mixing processes. Different batches yield different textures and flavors, leading to customer complaints and wasted resources. This inconsistency is often traced back to the type of mixer used and the specific settings employed during production, making it a critical issue for B2B buyers who must uphold brand integrity and customer satisfaction.

The Solution: To address this issue, it is vital for companies to invest in high-quality, specialized mixers tailored to their specific production needs. For instance, a high shear mixer can effectively emulsify and homogenize ingredients, ensuring a consistent mixture every time. Additionally, implementing a standard operating procedure (SOP) that details the mixing process—including speed, duration, and mixer type—can help maintain consistency across batches. B2B buyers should also consider mixers with digital controls that allow for precise adjustments and monitoring, which can help in replicating successful batches and minimizing variations.

Scenario 2: Overcoming Production Bottlenecks with Efficient Mixing Equipment

The Problem: A beverage company in Brazil faces significant production bottlenecks due to inefficient mixing processes. Their current mixers are slow and unable to handle the volume required for their growing production demands. This not only delays product launches but also increases operational costs, as employees spend more time mixing than on other essential tasks.

The Solution: To overcome these bottlenecks, it is essential to evaluate and upgrade to more efficient mixing equipment. B2B buyers should consider investing in industrial blenders or high-capacity drum mixers that are designed for faster processing times and higher volumes. Additionally, exploring options for automated mixers can enhance efficiency by reducing manual labor and speeding up the mixing process. Implementing a thorough assessment of production needs, including volume and product type, will help in selecting the right mixer. Training staff on the new equipment will also ensure that the transition is smooth and the potential of the new mixers is fully realized.

Scenario 3: Addressing Maintenance Challenges with Mixing Equipment

The Problem: A cosmetics manufacturer in Germany encounters frequent downtime due to maintenance issues with their mixers. The mixers often require repairs that can take days, leading to delays in production and increased operational costs. This issue is particularly detrimental in a fast-paced industry where timely product launches are crucial for competitiveness.

The Solution: To mitigate maintenance challenges, B2B buyers should prioritize purchasing mixers known for their durability and ease of maintenance. Investing in mixers with a gear-driven system rather than a belt-driven system may offer better longevity and require less frequent servicing. Additionally, establishing a preventive maintenance schedule can help identify potential issues before they escalate, ensuring mixers remain in optimal working condition. This should include regular inspections, cleaning, and parts replacement as necessary. Collaborating with suppliers for training on proper use and maintenance can also empower staff to handle minor issues, thus reducing downtime and ensuring smoother operations.

Strategic Material Selection Guide for different kinds of mixers

What Are the Key Properties of Stainless Steel for Mixers?

Stainless steel is a popular choice for various types of mixers due to its excellent corrosion resistance and durability. It typically withstands temperatures up to 500°F (260°C) and pressures exceeding 150 psi, making it suitable for high-performance applications. The alloy’s non-reactive nature ensures that it does not contaminate the materials being mixed, which is crucial in industries such as food processing and pharmaceuticals. Additionally, stainless steel is easy to clean, a significant advantage in maintaining hygiene standards.

Pros & Cons: The primary advantage of stainless steel mixers is their longevity and resistance to rust and corrosion. However, they can be more expensive than alternatives like plastic or carbon steel. Manufacturing complexity is also higher, as stainless steel requires specialized welding techniques and equipment.

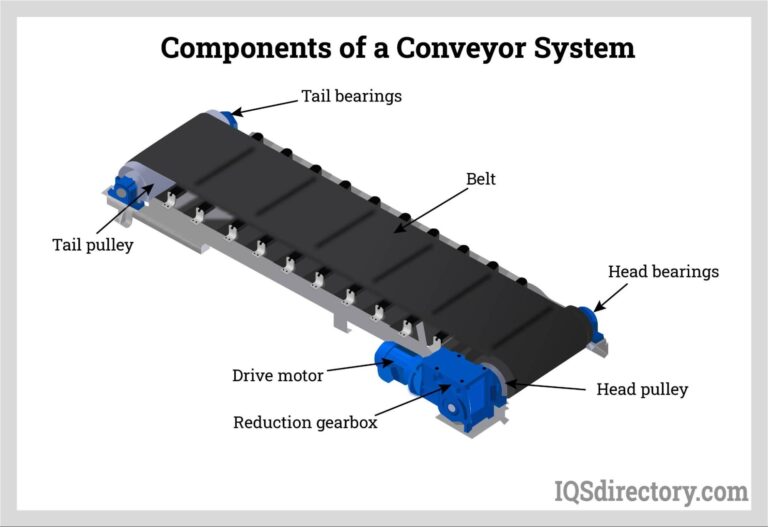

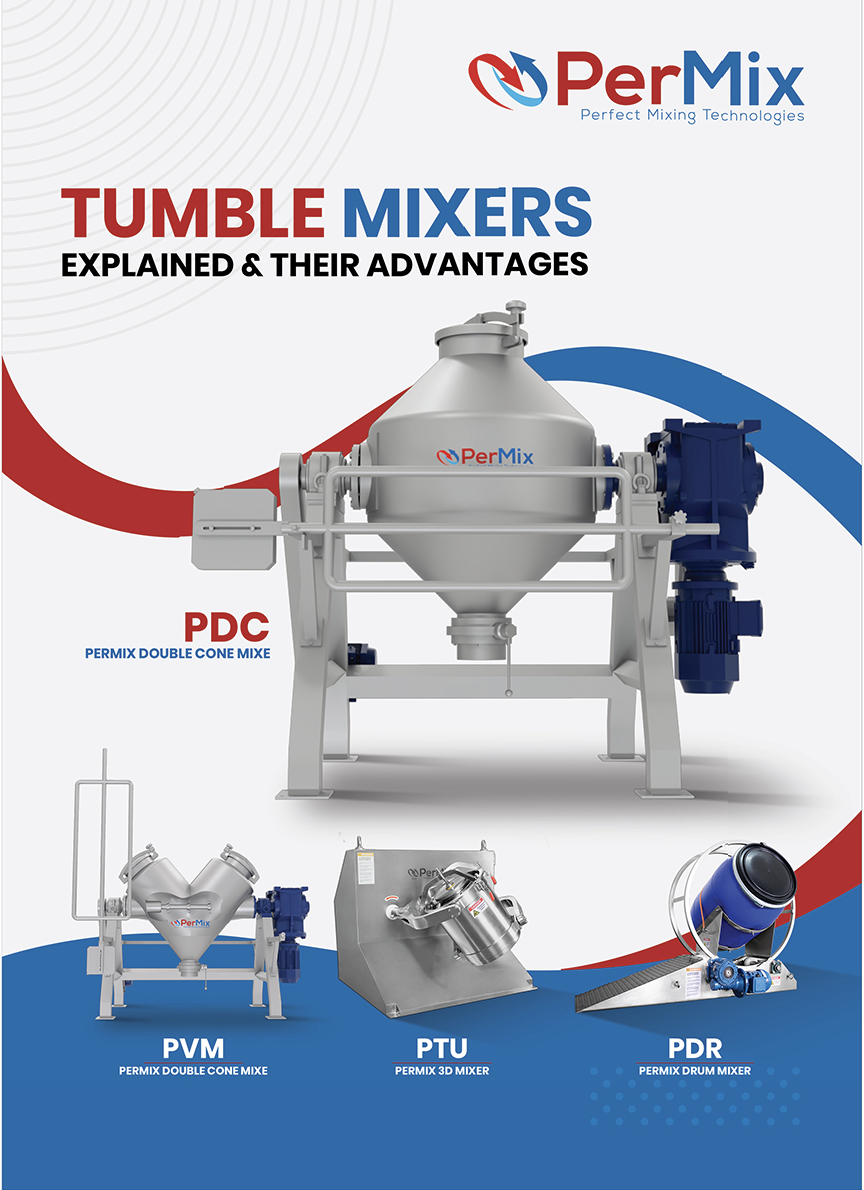

Illustrative image related to different kinds of mixers

Impact on Application: Stainless steel is compatible with a wide range of media, including acidic and alkaline substances, making it versatile for various industries. However, it may not be the best choice for highly abrasive materials, which can wear down the surface over time.

Considerations for International Buyers: Buyers from regions such as Europe and the Middle East should ensure compliance with standards like ASTM and DIN, which govern material quality and safety. In countries like Nigeria, where local sourcing may be preferred, verifying the origin and certification of stainless steel is essential.

How Does Carbon Steel Perform in Mixer Applications?

Carbon steel is another common material used in mixer construction, particularly for industrial applications. It can handle high temperatures and pressures, typically up to 400°F (204°C) and 150 psi. While it offers good strength and durability, it is less resistant to corrosion compared to stainless steel, making it less suitable for harsh environments.

Pros & Cons: The main advantage of carbon steel is its cost-effectiveness, as it is generally less expensive than stainless steel. However, its susceptibility to rust and corrosion can lead to increased maintenance costs over time. The manufacturing process for carbon steel is also less complex, allowing for quicker production times.

Impact on Application: Carbon steel is suitable for mixing applications involving dry materials or non-corrosive liquids. However, it is not recommended for food or pharmaceutical applications due to its tendency to rust and contaminate products.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of carbon steel in food-grade applications, especially in regions like South America, where food safety standards may vary significantly.

Illustrative image related to different kinds of mixers

What Benefits Do Plastic Materials Offer for Mixers?

Plastic materials, such as polyethylene and polypropylene, are often used in mixers designed for specific applications, particularly in the agricultural and chemical sectors. These materials can withstand temperatures up to 200°F (93°C) and pressures around 50 psi, depending on the type of plastic used.

Pros & Cons: The key advantage of plastic mixers is their lightweight nature and resistance to corrosion. They are also less expensive to manufacture and can be produced in various colors and shapes. However, plastic materials are generally less durable than metal options and may not be suitable for high-temperature applications.

Impact on Application: Plastic mixers are ideal for handling non-abrasive and non-corrosive materials, making them suitable for agricultural products and certain chemicals. However, they are not recommended for heavy-duty industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding plastic materials, particularly in food-related applications. In regions like Africa, where environmental concerns are paramount, selecting recyclable plastics can enhance sustainability.

How Does Glass Reinforced Polymer (GRP) Enhance Mixer Performance?

Glass Reinforced Polymer (GRP) is increasingly being used in mixer construction due to its exceptional strength-to-weight ratio and corrosion resistance. GRP can withstand temperatures up to 250°F (121°C) and pressures around 100 psi, making it suitable for various mixing applications.

Pros & Cons: The primary advantage of GRP is its lightweight nature combined with high strength, allowing for easier handling and installation. However, the initial cost can be higher than traditional materials, and the manufacturing process is more complex.

Impact on Application: GRP is particularly effective in mixing applications involving corrosive chemicals, making it suitable for the chemical and wastewater treatment industries. Its non-reactive properties ensure that it does not contaminate the mixture.

Considerations for International Buyers: Buyers should verify compliance with international standards such as ASTM and JIS, especially in regions like Europe, where stringent regulations govern material use in industrial applications.

Summary Table of Material Selection for Mixers

| Material | Typical Use Case for different kinds of mixers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Industrial applications, dry materials | Cost-effective | Susceptible to rust and corrosion | Low |

| Plastic | Agricultural products, non-corrosive chemicals | Lightweight and corrosion-resistant | Less durable, not for high temps | Med |

| Glass Reinforced Polymer (GRP) | Chemical and wastewater treatment | High strength-to-weight ratio | Higher initial cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for different kinds of mixers

What Are the Main Stages of Manufacturing Different Types of Mixers?

The manufacturing process for various types of mixers involves several critical stages that ensure both functionality and quality. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used in Mixer Manufacturing?

The first step in manufacturing mixers is the preparation of materials. Common materials include stainless steel for the mixer body due to its durability and resistance to corrosion, particularly in food processing applications. Plastics may be used for non-critical components to reduce weight and costs.

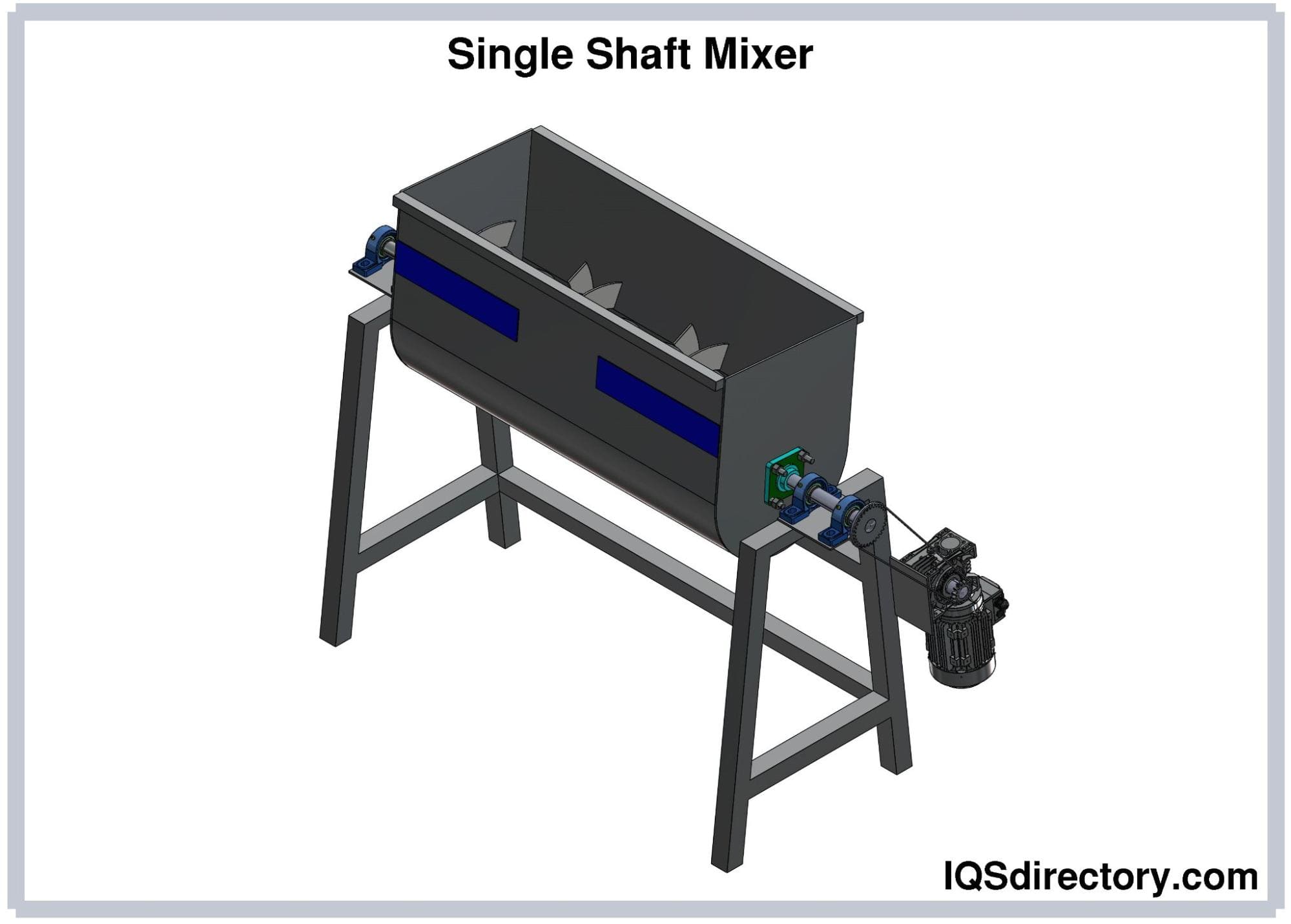

Illustrative image related to different kinds of mixers

The choice of materials directly influences the mixer’s performance and longevity. For example, high-shear mixers often require specialized alloys to handle abrasive materials. Suppliers should provide material certifications to ensure compliance with international standards.

What Forming Techniques Are Commonly Used in Mixer Production?

Once materials are prepared, the forming process begins. This may include techniques such as:

- Casting: Used primarily for heavier components where complex shapes are required. This is common for mixer bases and housings.

- Machining: Precision machining is essential for components like rotor-stator assemblies in high shear mixers. This process ensures tight tolerances for optimal performance.

- Welding: For stainless steel mixers, welding is a critical step in assembling the body and ensuring structural integrity.

These techniques can affect the mixer’s performance, particularly in high-stress applications. B2B buyers should inquire about the forming techniques used by suppliers to ensure they align with their operational requirements.

How Are Mixers Assembled, and What Quality Checks Are Conducted?

The assembly stage involves fitting together various components, including motors, impellers, and control systems. This stage may include:

- Manual Assembly: Skilled technicians typically assemble smaller mixers, ensuring that each part is fitted correctly.

- Automated Assembly Lines: Larger manufacturers may utilize robotics for efficiency and consistency, particularly in high-volume production.

During assembly, several quality checks are conducted, including:

- Incoming Quality Control (IQC): Verification of materials and components before they are used.

- In-Process Quality Control (IPQC): Ongoing inspections during the assembly process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets specifications.

What Finishing Techniques Are Employed for Mixers?

Finishing processes enhance the aesthetic and functional properties of mixers. Common techniques include:

- Surface Treatment: Techniques such as polishing or coating improve resistance to corrosion and wear.

- Painting or Powder Coating: This not only provides an aesthetic finish but also protects against environmental factors.

Finishing quality can impact the longevity of the mixer and its suitability for various applications, especially in food processing where hygiene is paramount.

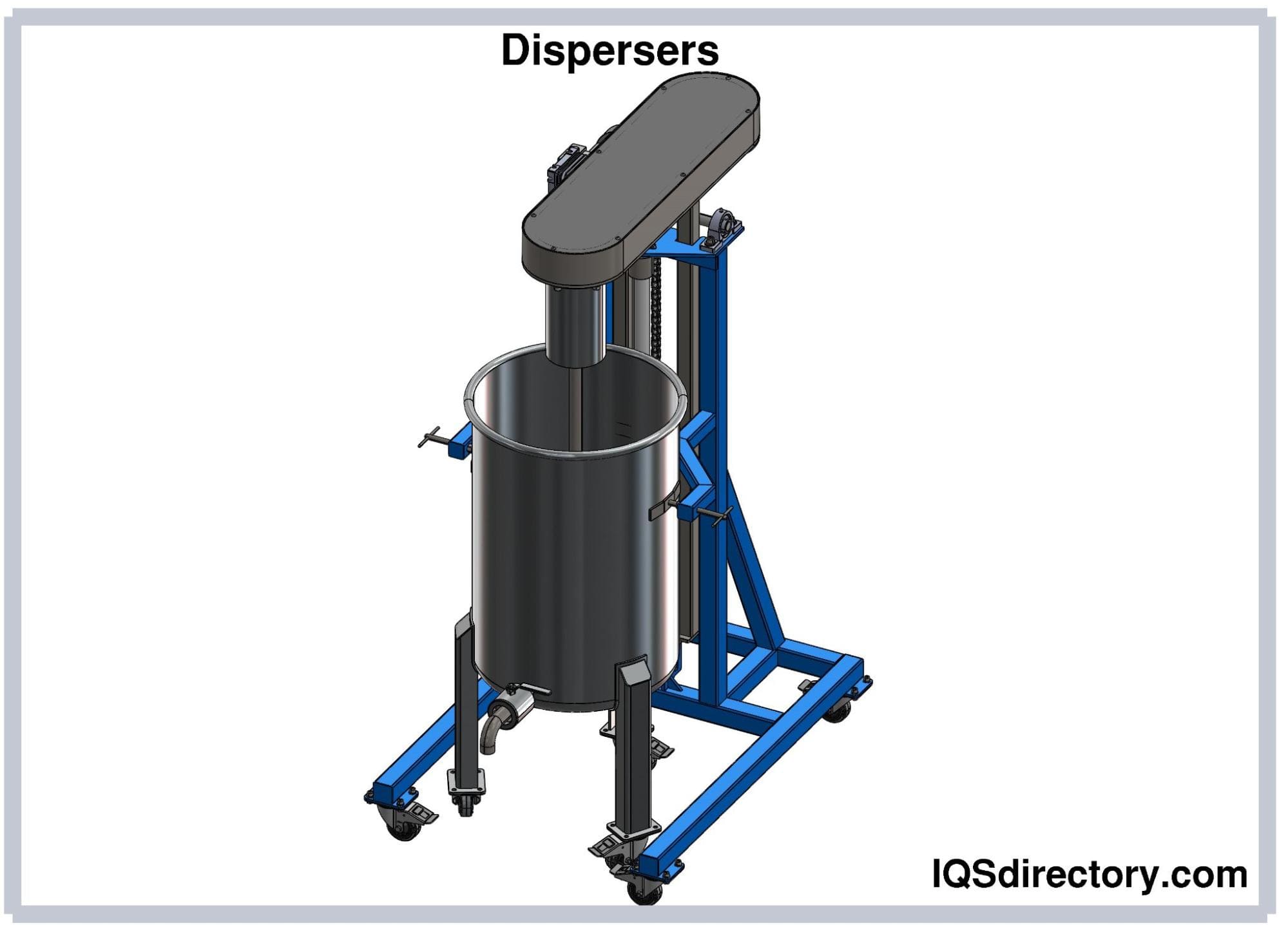

Illustrative image related to different kinds of mixers

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is crucial for ensuring that mixers perform reliably and meet safety standards. For international B2B buyers, understanding relevant quality standards is essential.

Which International Standards Are Relevant for Mixer Manufacturing?

ISO 9001 is the most recognized international standard for quality management systems. Compliance with ISO 9001 ensures that suppliers have robust processes in place for managing quality throughout the manufacturing cycle.

Additionally, industry-specific certifications may include:

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for mixers used in the oil and gas sector.

Buyers should verify that their suppliers hold these certifications, as they serve as indicators of quality and reliability.

Illustrative image related to different kinds of mixers

What Are the Key Quality Control Checkpoints in Mixer Manufacturing?

Quality control checkpoints are integral to the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Evaluating raw materials and components before they enter the production line.

- In-Process Quality Control (IPQC): Regular inspections during assembly to ensure adherence to specifications.

- Final Quality Control (FQC): Comprehensive testing of the finished product, including functionality tests and performance evaluations.

Each checkpoint serves to identify and rectify issues early, reducing the risk of defective products reaching the market.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying the quality control processes of suppliers is crucial for mitigating risk in purchasing decisions. B2B buyers can adopt several strategies:

What Auditing Practices Should Buyers Implement?

Conducting audits is a proactive way to assess supplier quality. Buyers can perform:

- On-Site Audits: Visiting the manufacturing facility allows buyers to observe processes firsthand and evaluate quality management systems.

- Third-Party Inspections: Engaging independent auditors can provide an unbiased assessment of a supplier’s quality practices.

These audits should focus on compliance with international standards and the effectiveness of quality control measures.

How Can Buyers Request Quality Assurance Documentation?

Buyers should request relevant documentation from suppliers, including:

- Quality Management System (QMS) Manuals: These documents outline the supplier’s quality policies and procedures.

- Inspection and Test Reports: Providing evidence of FQC and other quality checks performed during manufacturing.

Having access to these documents can provide reassurance about the supplier’s commitment to quality.

What Are the Challenges and Considerations for International B2B Buyers?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, several challenges may arise:

- Regulatory Compliance: Different regions may have varying regulations that must be adhered to. Understanding local laws and standards is essential.

- Cultural Differences: Communication barriers and differing business practices can complicate supplier relationships. Establishing clear expectations and open lines of communication is vital.

- Logistical Challenges: Shipping and customs clearance can delay the procurement process. Buyers should plan for these potential delays in their timelines.

By being aware of these challenges and actively addressing them, B2B buyers can enhance their procurement strategies and ensure they partner with reliable suppliers.

In conclusion, a comprehensive understanding of manufacturing processes and quality assurance in mixer production is crucial for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and quality assurance standards, buyers can make informed decisions and select suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different kinds of mixers’

Introduction

Navigating the procurement of mixers for your business can be a complex process, especially when considering the variety of types and applications available. This guide is designed to provide international B2B buyers with a clear, step-by-step checklist to ensure you make informed decisions when sourcing different kinds of mixers. By following these steps, you can align your mixer selection with your specific operational needs and market conditions.

Step 1: Define Your Mixing Requirements

Start by clearly outlining the specific mixing tasks your business needs to accomplish. Consider factors such as the type of materials you will be mixing, the required consistency, and the volume of production.

– Material Types: Are you mixing dry powders, liquids, or a combination? Different mixers are designed for different materials.

– Production Volume: Assess the scale of your operations to determine the capacity and power requirements of the mixer.

Step 2: Research Mixer Types and Applications

Familiarize yourself with the various types of mixers available and their specific applications. This understanding will help you identify which mixer type aligns with your requirements.

– Types to Consider: Agitators, high shear mixers, and planetary mixers each serve different purposes. For example, high shear mixers are ideal for emulsifying and homogenizing, while dough mixers are specialized for bakery applications.

– Applications: Understand the typical industries that utilize each mixer type, as this can provide insights into their effectiveness for your needs.

Step 3: Evaluate Supplier Certifications

Before making a purchase, it’s crucial to verify that potential suppliers hold relevant certifications and adhere to industry standards. This step ensures that you are dealing with reputable manufacturers.

– Quality Assurance: Check for ISO certifications or industry-specific certifications that indicate compliance with quality standards.

– Safety Standards: Ensure that mixers meet safety regulations pertinent to your industry, particularly if you are in food or pharmaceutical sectors.

Step 4: Request Product Demonstrations

Whenever possible, request demonstrations of the mixers you are considering. Seeing the equipment in action can provide valuable insights into its performance and suitability for your needs.

– Hands-On Experience: A demonstration allows you to assess the ease of use, maintenance requirements, and the mixer’s operational efficiency.

– Test Mixing: If feasible, conduct test runs with your materials to evaluate how well the mixer handles your specific mixing needs.

Step 5: Compare Warranty and Support Options

Review the warranty terms and post-purchase support options provided by suppliers. A robust warranty and support system can save you time and money in the long run.

– Warranty Coverage: Look for comprehensive warranties that cover parts and labor, as well as the duration of coverage.

– Technical Support: Ensure that the supplier offers accessible technical support for troubleshooting and maintenance issues.

Step 6: Consider Logistics and Delivery Times

Evaluate the logistics of procuring the mixer, including lead times and shipping costs. Understanding these factors can help you plan your production schedules effectively.

– Shipping Options: Inquire about shipping methods and costs, especially if you’re importing equipment from different regions.

– Delivery Timelines: Confirm estimated delivery dates to ensure that the mixer will arrive when needed to meet production demands.

Step 7: Finalize Your Purchase and Negotiate Terms

Once you have evaluated your options, finalize your decision and negotiate terms with your chosen supplier.

– Pricing and Payment Terms: Discuss pricing structures and payment options, looking for flexibility that can benefit your cash flow.

– Contract Review: Carefully review the purchase agreement to ensure all terms are clearly outlined and protect your interests.

Illustrative image related to different kinds of mixers

By following these steps, you can streamline the sourcing process and select the right mixer for your business, ensuring optimal performance and reliability in your operations.

Comprehensive Cost and Pricing Analysis for different kinds of mixers Sourcing

When sourcing mixers for industrial applications, understanding the cost structure and pricing dynamics is critical for B2B buyers. This analysis will provide insights into the various cost components, price influencers, and practical buyer tips tailored for international markets, including Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Mixer Manufacturing?

The cost structure of mixers involves several key components:

-

Materials: The choice of materials significantly impacts costs. For instance, stainless steel mixers are often more expensive due to their durability and resistance to corrosion, essential for industries like food processing and pharmaceuticals. In contrast, plastic mixers might be cheaper but may not offer the same longevity.

-

Labor: Labor costs vary by region and influence overall pricing. In countries with higher labor costs, such as Germany, manufacturers may need to price their mixers higher to maintain profitability. Conversely, sourcing from regions with lower labor costs can reduce expenses.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom designs or specialized tooling can increase upfront costs. Buyers should assess whether the investment in custom tooling is justified by their specific needs.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. While these processes add to the cost, they are crucial for minimizing defects and ensuring customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely based on the location of the supplier and the destination market. Buyers should consider both freight costs and potential tariffs when evaluating total expenses.

-

Margin: Suppliers will factor in their desired profit margins, which can vary based on market competition and the supplier’s positioning.

What Influences Pricing for Mixers in International Markets?

Several factors can influence mixer pricing:

-

Volume/MOQ: Minimum order quantities (MOQ) often affect pricing structures. Bulk purchases typically lead to lower unit costs, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom features, such as enhanced mixing speeds or specialized attachments, can increase the price. Buyers should balance the need for customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, CE) can elevate prices but are often necessary for compliance in regulated industries. Buyers should weigh the importance of certifications against the potential cost savings of lower-quality options.

-

Supplier Factors: The supplier’s reputation, reliability, and customer service capabilities can also affect pricing. Established suppliers with a track record may charge a premium but offer greater assurance of quality and support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for cost management. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears transportation costs and risks, impacting the total landed cost.

What Are Effective Buyer Tips for Negotiating Mixer Prices?

-

Negotiation: Engaging in open discussions with suppliers can yield favorable terms. Consider negotiating not only on price but also on payment terms and delivery schedules to improve overall cost efficiency.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), including maintenance, energy consumption, and potential downtime. A lower initial purchase price may not be advantageous if the mixer incurs high operating costs.

-

Pricing Nuances for International Buyers: Understand local market dynamics, currency fluctuations, and economic conditions that can affect pricing. Buyers from Africa, South America, and the Middle East should also consider potential import tariffs and taxes.

Conclusion

While indicative prices can provide a starting point for negotiations, it is essential to conduct thorough research and engage with multiple suppliers to ensure the best value. By understanding the cost components and pricing influencers, B2B buyers can make informed decisions when sourcing mixers for their operations.

Alternatives Analysis: Comparing different kinds of mixers With Other Solutions

When evaluating the best solutions for mixing applications in various industrial sectors, it is crucial to consider alternatives to traditional mixers. Different types of mixers, such as agitators, emulsifiers, and high shear mixers, serve specific needs, but other technologies and methods may also fulfill these requirements effectively. In this analysis, we will compare various mixers against two alternative solutions: inline mixers and batch processing systems.

Comparison Table

| Comparison Aspect | Different Kinds of Mixers | Inline Mixers | Batch Processing Systems |

|---|---|---|---|

| Performance | High efficiency for specific tasks; ideal for continuous mixing | Excellent for continuous flow applications; consistent output | Suitable for large volume production; flexibility in formulations |

| Cost | Moderate to high initial investment; long-term savings through efficiency | Generally lower initial cost; cost-effective for high volume | High operational costs due to labor and equipment requirements |

| Ease of Implementation | Can be complex to install; requires skilled personnel for operation | Easy to integrate into existing production lines | Simple setup, but may require additional equipment for large batches |

| Maintenance | Regular maintenance required; parts can be costly | Low maintenance; fewer moving parts | High maintenance due to extensive equipment and potential downtime |

| Best Use Case | Ideal for food, pharmaceutical, and chemical industries requiring specific mixing | Best for continuous production in food, chemicals, and pharmaceuticals | Suitable for industries needing flexibility in production, such as food processing and cosmetics |

Understanding Inline Mixers as an Alternative

Inline mixers are designed to blend materials as they flow through a pipeline. They are particularly advantageous for continuous mixing applications, offering consistent performance and efficiency. The primary advantage of inline mixers is their lower initial cost compared to traditional mixers, making them an attractive option for businesses aiming to optimize production without significant upfront investment. However, they may not be as effective for applications requiring precise control over the mixing process, which can limit their versatility in specialized industries.

Evaluating Batch Processing Systems

Batch processing systems allow for the mixing of large quantities of materials at once, providing flexibility in formulations and product variations. This method is particularly beneficial for companies that produce a wide range of products or need to make quick adjustments to their recipes. The simplicity of setup and operation makes batch systems appealing; however, they come with higher operational costs, including labor and potential downtime during changeovers. This can impact overall productivity, especially in high-demand scenarios.

Conclusion: How to Choose the Right Mixing Solution

When selecting the appropriate mixing solution, B2B buyers should carefully assess their specific operational needs, including production volume, product variability, and budget constraints. Different kinds of mixers may offer specialized performance for certain applications, while alternatives like inline mixers and batch processing systems can provide flexibility and cost savings. Ultimately, the decision should align with the business’s production goals, ensuring that the chosen solution enhances efficiency and meets industry standards.

Essential Technical Properties and Trade Terminology for different kinds of mixers

What are the Key Technical Properties of Different Types of Mixers?

Understanding the technical specifications of mixers is crucial for B2B buyers, especially when making decisions that affect production efficiency and product quality. Here are several essential technical properties to consider:

-

Material Grade

The material used in the construction of mixers significantly impacts their durability and performance. Common materials include stainless steel, which offers corrosion resistance and is ideal for food applications, and carbon steel, which is often used in industrial settings for its strength. Selecting the appropriate material grade ensures compliance with industry standards and enhances the longevity of the equipment. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions during manufacturing. In mixers, tight tolerances are essential for maintaining consistent mixing quality and preventing leaks in high-pressure applications. Understanding tolerance levels helps buyers assess whether a mixer will meet their specific operational requirements, which can minimize downtime and maintenance costs. -

Power Rating (Horsepower)

The power rating of a mixer, usually measured in horsepower (HP), indicates its capacity to handle different mixing tasks. Higher horsepower ratings are necessary for heavy-duty mixing applications, while lower ratings may suffice for lighter tasks. Buyers should consider their production volume and the types of materials being mixed when evaluating horsepower requirements. -

Speed Variability

Mixers often come with adjustable speed settings, which allow operators to customize mixing intensity based on the material being processed. This feature is particularly important for applications requiring delicate mixing or emulsification. Understanding the range of speeds available can guide buyers in selecting a mixer that meets their specific processing needs. -

Tank Capacity

The tank capacity defines the maximum volume of material a mixer can handle at one time. This specification is vital for businesses aiming to scale production or maintain efficiency in batch processing. Buyers should align tank capacity with their production goals to optimize workflow and resource allocation.

What are Common Trade Terms in the Mixer Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can provide insights into the quality and reliability of the equipment being purchased, as well as potential for customization. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory effectively and ensure they are not over-committing to purchases that exceed their immediate needs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This process helps buyers compare pricing and terms from different manufacturers, ensuring they get the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined international trade terms that clarify the responsibilities of buyers and sellers in shipping and logistics. Understanding these terms can help buyers navigate delivery processes and manage risks associated with transportation and customs. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. For buyers, understanding lead times is critical for planning production schedules and ensuring timely delivery of materials.

By grasping these technical properties and trade terminology, B2B buyers can make informed decisions that enhance operational efficiency, maintain product quality, and foster strong supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the different kinds of mixers Sector

What Are the Current Market Dynamics and Key Trends in the Mixers Sector?

The global market for different types of mixers is witnessing robust growth, driven by the increasing demand for efficient mixing solutions across diverse industries such as food and beverage, pharmaceuticals, and chemicals. As economies in Africa, South America, the Middle East, and Europe continue to industrialize, the need for high-performance mixers is becoming more pronounced. For instance, the rise of the food processing sector in Nigeria and Brazil has led to an uptick in the adoption of specialized mixers like high shear and emulsifiers, which cater to the unique requirements of local cuisines and production methods.

Emerging B2B technologies are reshaping the sourcing landscape, with automation and smart technologies becoming integral to mixer design and functionality. Buyers are increasingly looking for mixers equipped with IoT capabilities for real-time monitoring and data analytics, which enhance operational efficiency and reduce downtime. Additionally, the trend towards modular mixers allows businesses to customize their equipment based on specific production needs, fostering flexibility in manufacturing processes.

Market dynamics are also influenced by the ongoing shift towards sustainability. Manufacturers are responding to consumer demand for environmentally friendly products by incorporating energy-efficient designs and recyclable materials into their mixers. As international buyers seek reliable suppliers, understanding these market trends will be crucial for making informed purchasing decisions.

How Important Is Sustainability and Ethical Sourcing in the Mixers Sector?

Sustainability is a significant consideration for B2B buyers in the mixers sector, particularly in regions where environmental regulations are tightening. The production and operation of mixers can have substantial environmental impacts, including energy consumption and waste generation. As such, buyers are increasingly favoring suppliers who prioritize sustainability in their manufacturing processes.

Ethical sourcing practices are also gaining traction, with businesses looking to ensure that their supply chains are transparent and responsible. This includes the sourcing of raw materials that are certified as environmentally friendly, such as recycled metals for stainless steel tanks or biodegradable components for smaller mixers. Certifications like ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers aiming to attract conscientious buyers.

Furthermore, incorporating green technologies, such as energy-efficient motors and low-emission designs, is not just a trend but a necessity. Buyers who prioritize these features can enhance their corporate social responsibility (CSR) profiles while often benefiting from lower operational costs over time.

What Is the Historical Evolution of Mixers and Its Relevance to Today’s B2B Buyers?

The evolution of mixers can be traced back to the early 20th century when manual mixing methods were gradually replaced by mechanical solutions. Initially, simple agitators and drum mixers dominated the market, but as industries grew, the demand for more sophisticated equipment increased. This led to the development of high shear mixers and homogenizers, which revolutionized the way various materials were processed.

In the latter half of the century, the introduction of electronic controls and automation transformed the mixers landscape, allowing for precise mixing and reduced labor costs. Today, the integration of smart technology and IoT capabilities represents the next frontier in mixer evolution, enabling real-time monitoring and enhanced operational efficiency.

For B2B buyers, understanding the historical context of mixers is crucial for recognizing the technological advancements that have shaped the current market. This knowledge can guide purchasing decisions, ensuring that businesses invest in equipment that not only meets their current needs but is also adaptable to future industry shifts.

Illustrative image related to different kinds of mixers

Frequently Asked Questions (FAQs) for B2B Buyers of different kinds of mixers

-

How do I choose the right mixer for my business needs?

When selecting a mixer, consider the specific applications you require, such as emulsifying, blending, or kneading. Evaluate the type of materials you’ll be mixing, the volume of production, and the mixer’s capacity. Different mixer types, like planetary or high shear mixers, serve distinct purposes. Also, assess the available space in your facility and whether a countertop, stand, or floor model is most appropriate. Prioritize mixers with features that enhance efficiency, such as variable speed controls and easy maintenance options. -

What is the best type of mixer for food production?

For food production, planetary mixers are versatile and suitable for a variety of tasks, including mixing dough and whipping ingredients. Dough mixers are specifically designed for bread and pastry applications, providing gentle handling to preserve dough quality. If you require high-volume mixing, vertical cutter mixers can perform multiple tasks, from chopping to blending. Assess your production scale and the specific food items you plan to prepare to determine the most effective mixer type. -

What are the typical payment terms in international mixer purchases?

Payment terms for international purchases often include options such as letters of credit, telegraphic transfers, or payment upon delivery. Negotiating terms that suit both parties is crucial; common practices include a 30% deposit with the order and the remaining balance before shipment. Familiarize yourself with the supplier’s payment policies and consider using escrow services for added security. Ensure that terms are clearly outlined in the contract to avoid any misunderstandings. -

How can I vet suppliers for industrial mixers?

To vet suppliers, start by checking their credentials, including certifications and industry experience. Request references from previous clients and investigate their reputation through online reviews or industry forums. Verify their capacity to meet your specific needs, such as customization and quality assurance processes. It’s beneficial to visit their manufacturing facility if possible, to assess production capabilities and quality control measures firsthand. -

What is the minimum order quantity (MOQ) for industrial mixers?

Minimum order quantities (MOQ) can vary significantly based on the supplier and the type of mixer. Generally, larger suppliers may have higher MOQs due to manufacturing efficiencies, while smaller manufacturers might accommodate lower orders. Discuss your needs with potential suppliers and inquire about flexibility in MOQs. Some suppliers may offer sample mixers or allow trial orders to help you assess their products before committing to larger quantities. -

How can I ensure quality assurance for mixers sourced internationally?

To ensure quality assurance, request detailed specifications and compliance certifications from your supplier. Implement a rigorous inspection process, including pre-shipment inspections and third-party quality checks, to verify that products meet your standards. Establish clear communication channels with the supplier regarding quality expectations and any corrective actions needed for defects. Consider including quality clauses in your contract to protect your interests. -

What logistics considerations should I keep in mind when importing mixers?

When importing mixers, consider shipping methods (air vs. sea), customs clearance, and potential tariffs or duties applicable to your region. Evaluate the lead time for manufacturing and shipping to ensure timely delivery for your operations. Work with a reliable logistics partner who understands international shipping regulations and can facilitate smooth transportation. Also, ensure that your mixers are adequately packaged to prevent damage during transit. -

Can I customize mixers to meet specific production requirements?

Yes, many manufacturers offer customization options for mixers, allowing you to tailor features such as size, power, and attachments based on your production needs. Discuss your specific requirements with potential suppliers, including any special materials or configurations you may need. Customization may involve additional costs and longer lead times, so factor these into your planning. Always request detailed specifications and prototype designs to ensure the final product meets your expectations.

Top 5 Different Kinds Of Mixers Manufacturers & Suppliers List

1. IQS Directory – Types of Mixers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Types of Mixers: Paddle Mixer (for viscous semi-solid substances), Horizontal Ribbon Mixer (for food, chemicals, powders), Tumbler Mixer (for bakery ingredients), Drum Mixer (for low and medium viscosity materials like slurry or cement), Emulsifier (for immiscible liquids like oils), Static Mixer (for gasses and liquids). Key factors in selecting a mixer include material characteristics (shape, de…

2. Webstaurant Store – Types of Mixers

Domain: webstaurantstore.com

Registered: 2003 (22 years)

Introduction: Types of Mixers: 1. Dough Mixers (Spiral Mixers) – Ideal for mixing large quantities of dough for pizza and bread. Applications: Mixing, kneading, mashing, whipping, and churning. Best for: Bakeries, pizzerias, and caterers. 2. Planetary Mixers – Designed with an offset shaft for thorough mixing. Applications: Mix, knead, mash, and whip. Best for: Caterers, restaurants, and bakeries. 3. Vertical C…

3. DoughTech – Horizontal and Spiral Mixers

Domain: doughtech.com

Registered: 2002 (23 years)

Introduction: 1. Horizontal Mixer: Produces the largest volume of dough quickly; continuously feeds next batch; easy dough exit into trough; drawback: raises dough temperature due to friction.

2. Spiral Mixer: Popular and flexible; mixes dough efficiently with little friction; available in various sizes; energy-efficient compared to horizontal mixers.

3. Planetary Mixer: Common in home kitchens; central mixing …

4. Reddit – Kitchen Appliances

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Hand mixer, Stand mixer, KitchenAid stand mixer, Hamilton Beach hand mixer, KitchenAid 600 Pro

5. Equippers – Industrial Kitchen Mixers

Domain: equippers.com

Registered: 1999 (26 years)

Introduction: Industrial & Commercial Kitchen Mixers and Accessories available at Restaurant Equippers. The product range includes various types of mixers and accessories such as beaters, bowls, dough hooks, and wire whip attachments. The store offers a wide selection of food prep equipment and smallwares, including bakery equipment, cookware, cutlery, and utensils. Additional categories include food storage so…

Strategic Sourcing Conclusion and Outlook for different kinds of mixers

In navigating the diverse landscape of mixers, international B2B buyers must prioritize strategic sourcing to maximize efficiency and productivity. Understanding the unique applications and advantages of various mixer types—such as agitators, dough mixers, and high shear mixers—enables companies to make informed purchasing decisions that align with their operational needs. This insight is particularly crucial for businesses operating in dynamic markets across Africa, South America, the Middle East, and Europe, where the right equipment can significantly enhance production capabilities and product quality.

Investing in the appropriate mixing technology not only streamlines processes but also ensures compliance with industry standards, particularly in sectors such as food and beverage, pharmaceuticals, and chemicals. As buyers evaluate their options, they should consider factors such as mixer capacity, drive systems, and safety features to select equipment that meets both current and future demands.

Looking ahead, the global mixer market is poised for innovation, driven by advancements in technology and an increasing focus on sustainability. By staying informed and proactive, B2B buyers can leverage these trends to enhance their sourcing strategies. Take the next step in optimizing your operations—explore your mixer options today to secure a competitive edge in your industry.

Illustrative image related to different kinds of mixers

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.