Diagram Push Button: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for diagram push button

Navigating the complexities of sourcing diagram push buttons can be a daunting task for international B2B buyers, especially when considering the varied applications and specifications across different industries. These essential components play a crucial role in controlling machinery, enhancing safety, and improving user interactions in diverse environments, from industrial settings in Brazil to automation systems in Saudi Arabia. Understanding the nuances of push button switches—including types, applications, and operational mechanisms—is vital for making informed purchasing decisions.

This comprehensive guide delves into the intricacies of diagram push buttons, offering insights into the various types available, their specific applications, and the critical factors to consider when vetting suppliers. From momentary to maintained switches, illuminated options to water-resistant variants, we cover the full spectrum of choices to meet your operational needs. Additionally, we address cost considerations and provide tips for ensuring quality and compliance with international standards.

Empowering B2B buyers from Africa, South America, the Middle East, and Europe, this guide serves as a crucial resource in navigating the global market for diagram push buttons. By arming you with the knowledge to assess your options critically, we help streamline your procurement process, ultimately leading to safer, more efficient operations within your organization.

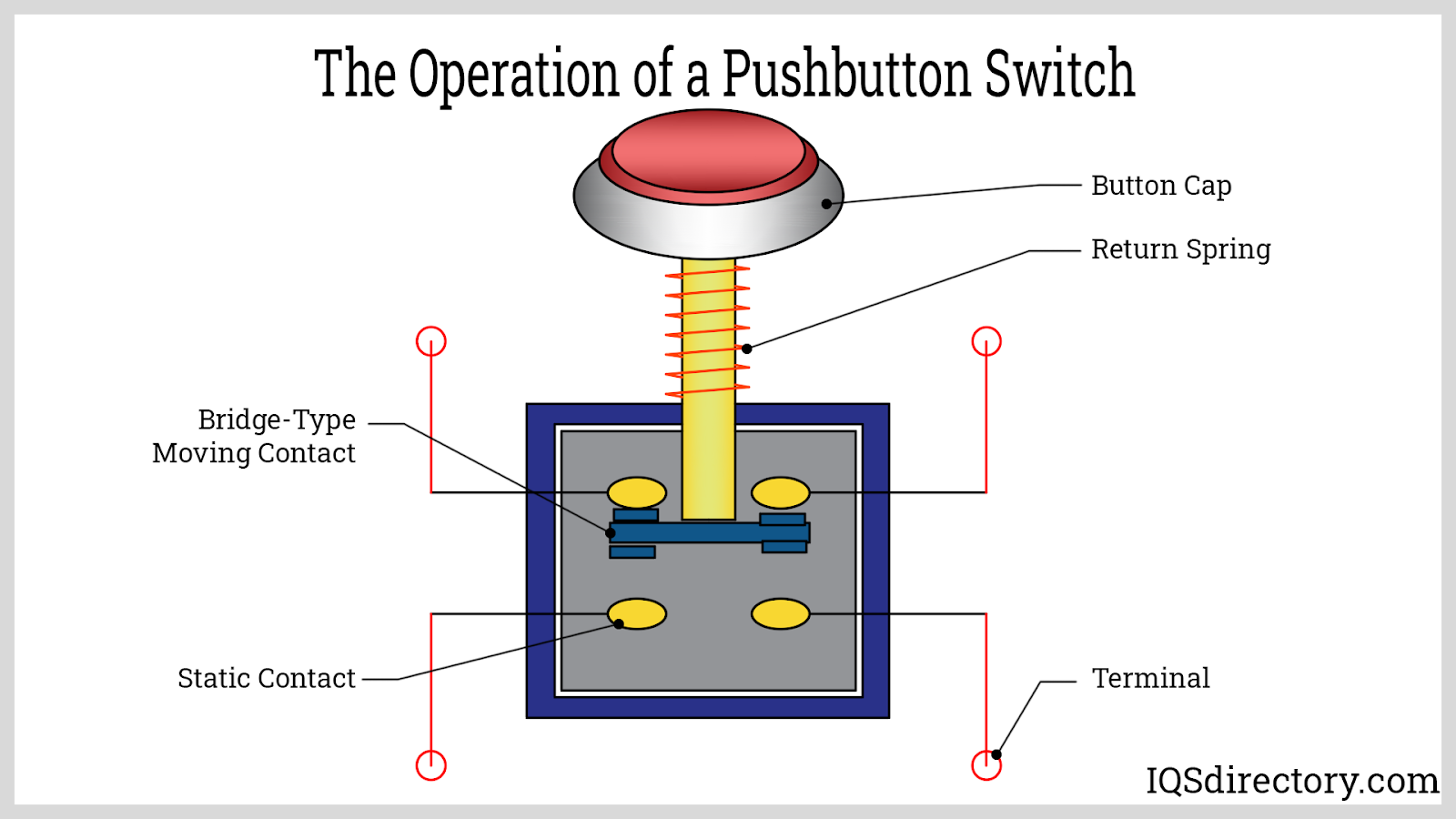

Understanding diagram push button Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Momentary Push Button | Requires continuous pressure to activate; returns to default state. | Control panels, doorbells, intercom systems | Pros: Simple operation, ideal for temporary actions. Cons: Not suitable for continuous operation. |

| Maintained Push Button | Latches in position until pressed again; stays in set state. | Machinery start/stop functions, lighting systems | Pros: Reliable for consistent operations. Cons: Can lead to accidental activation if not properly labeled. |

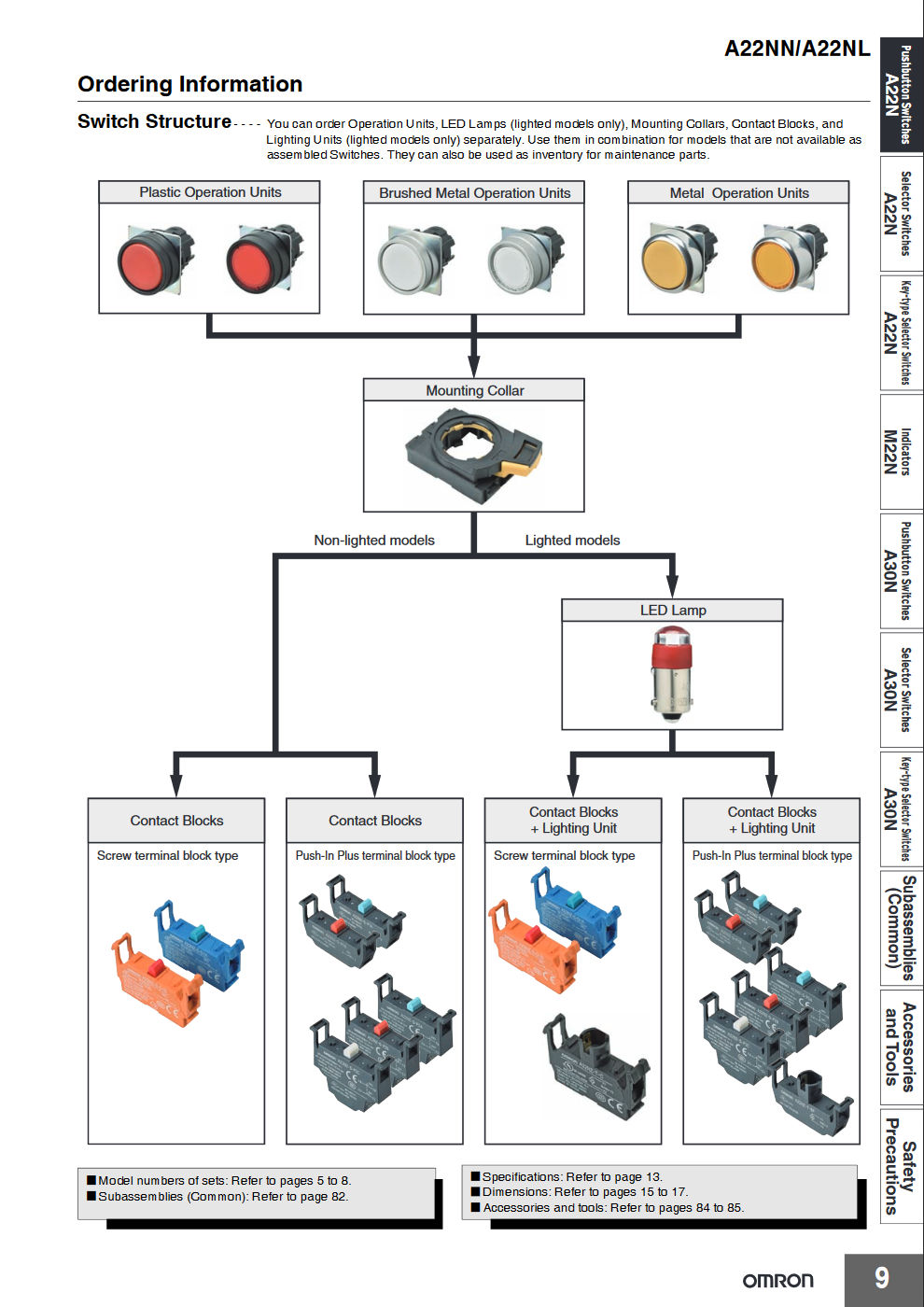

| Illuminated Push Button | Features built-in LED indicators for visibility. | Industrial machinery, control panels in dim environments | Pros: Enhances usability and safety. Cons: Slightly higher cost than non-illuminated variants. |

| Locking Push Button | Mechanical locking function prevents unintentional activation. | Safety equipment, emergency stop functions | Pros: Ensures safety and prevents accidental activation. Cons: Can be cumbersome for frequent use. |

| Panel Mounted Push Button | Designed for installation on sturdy surfaces; specific cut-out sizes. | Consumer electronics, automotive applications | Pros: Space-efficient, reliable for heavy-duty applications. Cons: Requires precise installation. |

What Are the Characteristics of Momentary Push Buttons?

Momentary push buttons are designed to operate only while being pressed, making them ideal for functions that require temporary activation, such as doorbells and intercom systems. Their simplicity allows for easy integration into various control panels. When considering a momentary push button, buyers should assess the required actuation force, as well as the button’s durability, especially in high-usage environments.

How Do Maintained Push Buttons Work in B2B Applications?

Maintained push buttons remain in their activated state until pressed again, making them suitable for applications like machinery start/stop controls and lighting systems. This latching functionality is advantageous for tasks that require sustained operation. Buyers should evaluate the button’s design to ensure it aligns with operational safety standards and consider the potential for accidental activation in busy settings.

Why Choose Illuminated Push Buttons?

Illuminated push buttons incorporate LED indicators, enhancing visibility and usability in low-light conditions, which is crucial for industrial machinery and control panels. These buttons help operators quickly identify the status of equipment. When purchasing, consider the power requirements for the LED and the overall robustness of the switch, as well as the potential for increased costs compared to standard buttons.

What Are the Benefits of Locking Push Buttons?

Locking push buttons feature a mechanical locking mechanism that prevents accidental activation, making them essential for safety equipment and emergency stop functions. This design ensures that the button remains in place until intentionally released, providing an added layer of safety. Buyers should assess the ease of use and the locking mechanism’s reliability, particularly in critical applications where safety is paramount.

How Do Panel Mounted Push Buttons Differ?

Panel mounted push buttons are specifically designed for installation on sturdy surfaces, with unique cut-out sizes for secure fitting. They are commonly used in consumer electronics and automotive applications, providing a space-efficient solution. Buyers should consider the installation requirements and the environmental conditions the button will face, as well as its compatibility with existing systems to ensure seamless integration.

Key Industrial Applications of diagram push button

| Industry/Sector | Specific Application of diagram push button | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Machine Start/Stop Control | Enhances operational efficiency and safety in production. | Look for durability, IP ratings, and compatibility with existing systems. |

| Transportation | Control Panels for Vehicles | Improves driver control and response time in critical situations. | Ensure compliance with safety standards and ergonomic design. |

| Oil & Gas | Emergency Shutdown Systems | Provides rapid response to hazardous situations, ensuring worker safety. | Focus on high ingress protection ratings and reliability under extreme conditions. |

| Automation & Robotics | Automated Control Systems | Increases precision and reduces manual labor costs. | Assess functionality, integration capabilities, and availability of custom designs. |

| Consumer Electronics | User Interfaces for Appliances | Enhances user experience and product appeal. | Prioritize tactile feedback, aesthetic design, and LED indicators for visibility. |

How is ‘diagram push button’ used in manufacturing applications?

In manufacturing, diagram push buttons are integral for machine start and stop controls. They enable operators to efficiently manage machinery, reducing downtime and enhancing safety protocols. For international B2B buyers, sourcing durable push buttons that meet specific IP ratings is crucial to ensure they withstand industrial environments. Additionally, understanding the compatibility of these switches with existing systems can streamline integration, thus preventing operational disruptions.

What role do diagram push buttons play in transportation control panels?

In the transportation sector, diagram push buttons are essential for control panels in vehicles. They allow drivers to execute commands rapidly, improving response times in critical situations. B2B buyers in this industry should consider sourcing buttons that comply with safety standards and offer ergonomic designs for ease of use. Moreover, ensuring these components are robust enough to handle vibrations and environmental factors is vital for long-term reliability.

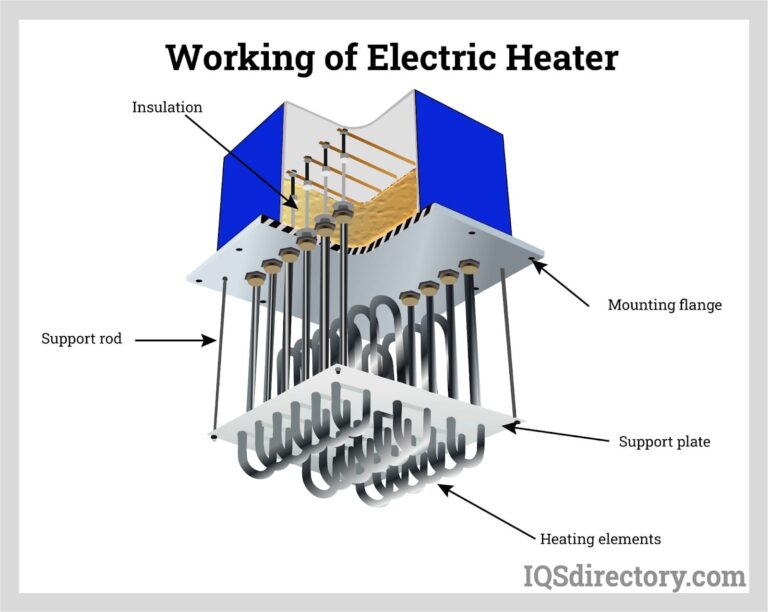

Illustrative image related to diagram push button

Why are diagram push buttons critical in oil and gas emergency systems?

In the oil and gas industry, diagram push buttons are often utilized in emergency shutdown systems. These buttons allow for immediate action in hazardous situations, significantly enhancing worker safety. Buyers should focus on sourcing push buttons with high ingress protection ratings to ensure they can withstand harsh conditions. Reliability is paramount, as any failure in these systems could lead to catastrophic consequences.

How do diagram push buttons enhance automation and robotics?

In automation and robotics, diagram push buttons serve as vital components of automated control systems. They facilitate precise operations, reducing the need for manual intervention and consequently lowering labor costs. B2B buyers should evaluate the functionality and integration capabilities of these switches to ensure they align with their specific automation needs. Custom designs may also be necessary to fit unique applications, emphasizing the importance of sourcing from adaptable suppliers.

What benefits do diagram push buttons provide in consumer electronics?

For consumer electronics, diagram push buttons are pivotal in user interfaces for various appliances. They enhance user experience by providing tactile feedback and visual indicators, making devices more appealing and intuitive to operate. Buyers in this sector should prioritize sourcing buttons that not only meet aesthetic requirements but also feature LED indicators for improved visibility. Additionally, ensuring these buttons are designed for longevity can enhance product quality and customer satisfaction.

3 Common User Pain Points for ‘diagram push button’ & Their Solutions

Scenario 1: The Challenge of Selecting the Right Push Button for Specific Applications

The Problem: B2B buyers often struggle with the vast array of push button options available in the market. Each application may require different specifications, such as momentary versus maintained action, normally open (N/O) versus normally closed (N/C) contacts, and varying voltage ratings. Without a clear understanding of their specific needs, buyers can easily select an inappropriate switch, leading to operational inefficiencies, equipment malfunctions, or safety hazards. The wrong choice can result in costly downtime, as well as the need for replacements or modifications later on.

The Solution: To overcome this issue, buyers should begin by thoroughly analyzing their application requirements. Create a detailed list of the operational context, including voltage requirements, the nature of the action (momentary or maintained), and the environmental conditions (such as moisture or dust exposure). Consulting with manufacturers or suppliers who offer expert guidance can also help clarify the specific needs of the application. Additionally, leveraging product selection tools or detailed comparison charts can provide insights into various push button types, enabling buyers to make informed decisions. For instance, if an application requires a push button that operates under wet conditions, sourcing options with a high ingress protection rating (e.g., IP67) would be crucial.

Scenario 2: Difficulty in Ensuring Compatibility with Existing Systems

The Problem: Another common pain point for B2B buyers is ensuring that new push buttons are compatible with existing electrical systems. Many facilities have legacy equipment or specific wiring configurations that can complicate the integration of new switches. Buyers may find themselves with push buttons that do not fit the existing panel cut-outs or that require different voltage ratings or wiring setups, leading to additional costs and installation challenges.

The Solution: To mitigate compatibility issues, buyers should conduct a comprehensive review of their current electrical systems before purchasing new push buttons. This includes checking existing wiring diagrams and panel specifications to ensure that the new switches can be integrated seamlessly. Buyers should prioritize sourcing push buttons from suppliers who provide comprehensive technical datasheets, which include dimensions, wiring configurations, and compatibility information. Additionally, engaging with a technical sales representative can help clarify any uncertainties and ensure that the chosen products align with existing systems. For instance, if a buyer needs to replace a push button in a control panel, they should measure the panel cut-out size and ensure the new button matches to avoid costly modifications.

Scenario 3: Managing Safety Regulations and Compliance Standards

The Problem: In industries such as manufacturing and construction, compliance with safety regulations is paramount. Buyers often face challenges in selecting push buttons that meet local and international safety standards, particularly in regions with stringent regulations. Failure to comply with these standards not only risks safety but can also lead to legal repercussions and financial penalties for businesses.

The Solution: To address safety and compliance concerns, B2B buyers should familiarize themselves with the relevant regulations governing their industry and region. This may include standards set by organizations such as the International Electrotechnical Commission (IEC) or local safety authorities. Buyers should seek push buttons that are certified for safety and compliance, which often have labels or markings indicating their adherence to specific standards. Additionally, it is advisable to work closely with suppliers who specialize in safety-rated components and can provide documentation to verify compliance. Conducting risk assessments and involving safety officers in the selection process can further ensure that the chosen push buttons not only meet regulatory requirements but also enhance overall workplace safety.

Strategic Material Selection Guide for diagram push button

What Are the Key Materials for Diagram Push Buttons?

When selecting materials for diagram push buttons, it is crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: plastic, metal, rubber, and silicone. Each material offers unique characteristics that can significantly impact performance and application suitability.

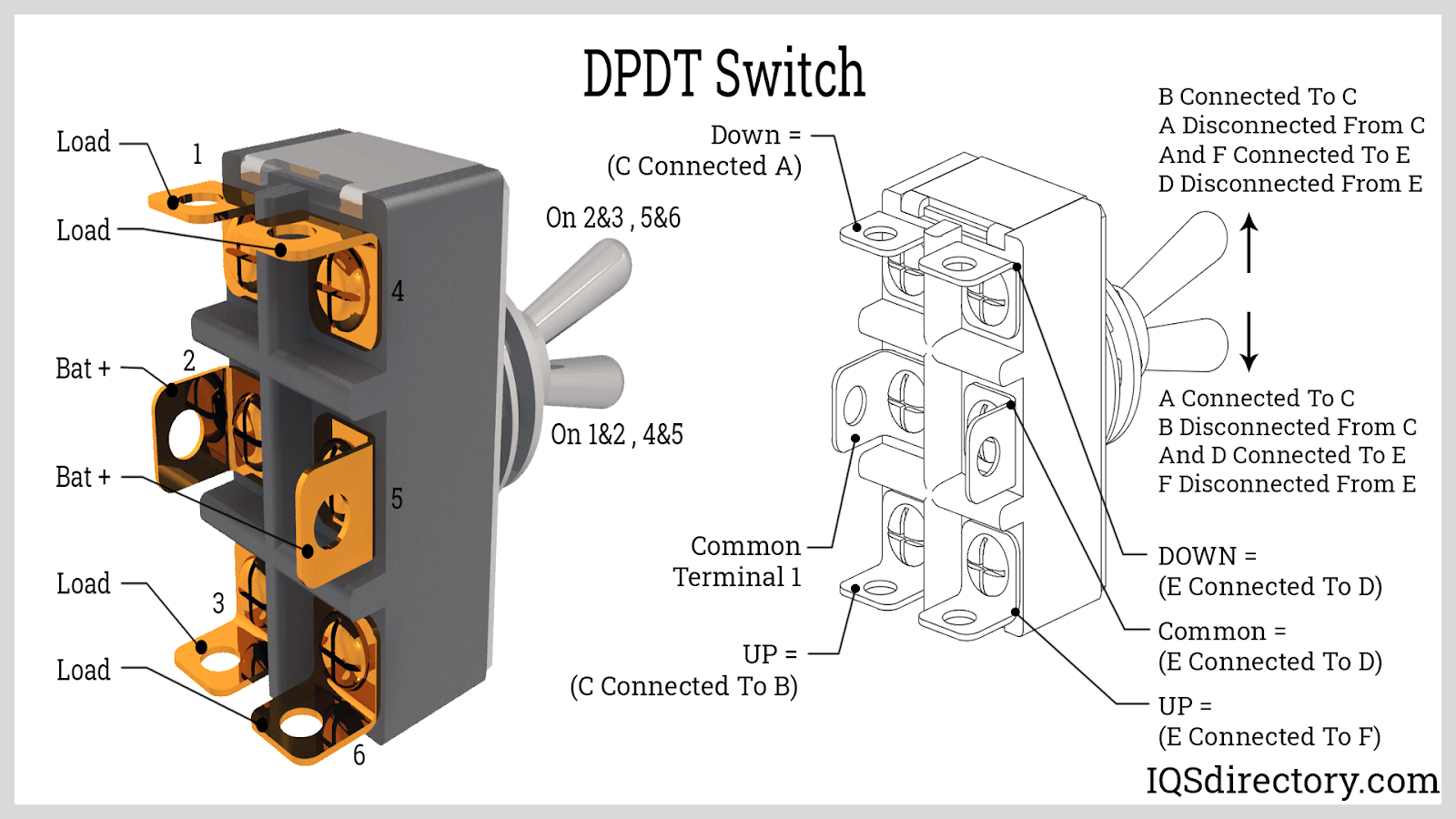

Illustrative image related to diagram push button

How Does Plastic Perform in Diagram Push Buttons?

Plastic is one of the most widely used materials for push buttons, particularly due to its versatility and cost-effectiveness. Common types of plastics used include polycarbonate and ABS (Acrylonitrile Butadiene Styrene). These materials typically have good temperature resistance (up to around 100°C) and are lightweight, making them suitable for various applications.

Pros: Plastic push buttons are generally durable and resistant to corrosion, making them ideal for environments that may involve exposure to moisture. They can be molded into various shapes and colors, enhancing design flexibility.

Cons: However, plastic can be less resistant to high temperatures and may degrade over time when exposed to UV light. Additionally, while they are cost-effective, they may not provide the same tactile feedback as metal buttons.

Impact on Application: Plastic push buttons are suitable for general applications, including consumer electronics and home appliances. However, they may not be ideal for heavy-duty industrial settings where higher durability is required.

What Advantages Do Metal Push Buttons Offer?

Metal push buttons, often made from stainless steel or aluminum, are known for their robustness and premium feel. These materials typically have excellent temperature and pressure ratings, often exceeding those of plastic counterparts.

Pros: Metal buttons are highly durable, resistant to corrosion, and can withstand harsh environmental conditions. They also provide superior tactile feedback, making them preferable in applications requiring precise control.

Cons: The main drawbacks include higher manufacturing costs and weight, which can be a consideration in portable applications. Additionally, metal buttons may require more complex installation due to their weight and electrical properties.

Impact on Application: Metal push buttons are ideal for industrial machinery, control panels, and outdoor applications where durability and reliability are paramount. Compliance with international standards such as ASTM and DIN is often easier with metal components.

How Do Rubber and Silicone Compare in Push Button Applications?

Rubber and silicone are often used for applications requiring flexibility and a soft touch. Rubber buttons can be molded into various shapes and sizes, while silicone offers enhanced durability and resistance to extreme temperatures.

Illustrative image related to diagram push button

Pros: Both materials provide excellent tactile feedback and are often resistant to moisture and dust. Silicone, in particular, is known for its high-temperature resistance (up to 200°C) and flexibility, making it suitable for various applications.

Cons: The primary disadvantage is that rubber can degrade over time, especially when exposed to UV light, while silicone tends to be more expensive. Additionally, both materials may not be as robust as metal in heavy-duty applications.

Impact on Application: Rubber and silicone push buttons are commonly found in consumer electronics, medical devices, and automotive controls. Buyers should consider compliance with relevant standards for these materials, particularly in regulated industries.

Summary Table of Material Selection for Diagram Push Buttons

| Material | Typical Use Case for Diagram Push Button | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Consumer electronics, home appliances | Cost-effective, versatile design | Less durable, temperature-sensitive | Low |

| Metal | Industrial machinery, control panels | Highly durable, excellent tactile feedback | Higher cost, heavier weight | High |

| Rubber | Automotive controls, medical devices | Good tactile feedback, moisture-resistant | Degrades over time, UV sensitivity | Medium |

| Silicone | Consumer electronics, flexible devices | High-temperature resistance, flexible | More expensive, less robust than metal | Medium |

This strategic material selection guide provides valuable insights for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the properties and applications of these materials can help in making informed decisions that align with industry standards and specific project requirements.

Illustrative image related to diagram push button

In-depth Look: Manufacturing Processes and Quality Assurance for diagram push button

What Are the Key Stages in the Manufacturing Process of Diagram Push Buttons?

The manufacturing process of diagram push buttons involves several critical stages, each ensuring the final product meets the required specifications for functionality, safety, and durability. Understanding these stages can help B2B buyers make informed decisions when sourcing these components.

1. Material Preparation

The initial stage of manufacturing diagram push buttons begins with the selection and preparation of materials. Common materials include high-grade plastics for the button casing and metal alloys for the internal contacts. Manufacturers often utilize injection molding for plastic components, ensuring consistent quality and precision. For metal parts, stamping or machining techniques are employed to create the necessary shapes and sizes.

Before production, materials undergo rigorous quality checks to verify their properties, such as tensile strength, chemical resistance, and electrical conductivity. This preparation is crucial in ensuring that the components can withstand operational stresses and environmental factors.

2. Forming Processes

Once the materials are prepared, the forming processes begin. This stage includes several techniques:

-

Injection Molding: Used primarily for the plastic housing of the push buttons, this technique allows for complex shapes and designs while maintaining tight tolerances.

-

Die-Casting: For metal components, die-casting is often utilized to create intricate shapes with a high degree of accuracy. This process is particularly important for ensuring that the internal contacts fit properly within the housing.

-

Stamping: Metal stamping is another common method for producing flat components, like the switch contacts. This technique allows for high-volume production while maintaining consistency.

Each of these forming processes plays a vital role in the functionality and durability of the final product.

3. Assembly of Components

The assembly stage is where the prepared components come together to form the complete push button switch. This step typically involves the following:

-

Component Insertion: Individual components, including the actuator, contacts, and housing, are assembled either manually or through automated machinery.

-

Soldering and Wiring: If the push button includes electrical connections, soldering is used to ensure secure and reliable connections. This step is critical for maintaining the electrical integrity of the switch.

-

Testing During Assembly: Many manufacturers incorporate in-line quality checks during assembly to ensure that each component functions as intended before the final product is completed.

4. Finishing Touches

The final stage of the manufacturing process involves finishing touches that enhance the aesthetics and functionality of the push buttons. This includes:

-

Surface Treatment: To improve durability and resistance to environmental factors, surfaces may undergo treatments such as painting, coating, or anodizing.

-

Labeling and Marking: Clear labeling is crucial for user safety and product identification. Manufacturers often use durable inks or engraving methods to ensure that labels remain intact over time.

-

Final Inspection: Before packaging, a comprehensive inspection is conducted to ensure that all specifications are met, including visual checks for defects and operational tests for functionality.

What Quality Assurance Measures Are Essential for Diagram Push Buttons?

Quality assurance is a critical aspect of manufacturing, particularly for components like diagram push buttons that are integral to electrical systems. The following standards and checkpoints are essential for ensuring product quality.

International Standards for Quality Control

B2B buyers should be aware of relevant international standards that manufacturers may adhere to:

-

ISO 9001: This is a widely recognized quality management standard that outlines requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer has consistent processes in place to meet customer and regulatory requirements.

-

CE Marking: In Europe, the CE mark signifies that a product meets EU safety, health, and environmental protection standards. For push buttons, this is particularly important for ensuring safety in electrical applications.

-

API Standards: For manufacturers targeting specific industries, adherence to API (American Petroleum Institute) standards may be necessary, particularly for products used in hazardous environments.

Quality Control Checkpoints in the Manufacturing Process

Quality control (QC) is performed at various stages of the manufacturing process to ensure that all components meet quality standards:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Materials are tested for compliance with specifications to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During production, manufacturers conduct regular checks to monitor processes and identify any deviations from the expected quality. This may include testing the electrical properties of the switches or verifying the dimensions of components.

-

Final Quality Control (FQC): After assembly, a final inspection is performed to ensure that each push button operates correctly and meets all safety and performance standards. This includes functional testing and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

Conduct Supplier Audits

B2B buyers should consider conducting on-site audits of potential suppliers. This allows buyers to assess the manufacturing facilities, quality control processes, and adherence to international standards firsthand.

Request Quality Assurance Reports

Buyers can ask suppliers for documentation that outlines their quality assurance processes, including results from IQC, IPQC, and FQC. Regular quality reports can provide insights into the supplier’s reliability over time.

Utilize Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services can conduct random checks during various stages of production to ensure compliance with specified standards.

What Are the Nuances of Quality Certification for International B2B Buyers?

B2B buyers from different regions may encounter specific nuances regarding quality certification. For instance:

-

Local Regulations: Understanding local regulations in countries like Brazil or Saudi Arabia is essential, as these may differ significantly from international standards. Manufacturers may need to obtain additional certifications specific to these markets.

-

Cultural Considerations: Cultural differences can influence quality perceptions and expectations. Buyers should communicate openly with suppliers to ensure that both parties have aligned expectations regarding quality standards.

-

Supply Chain Dynamics: In regions with developing supply chains, buyers should be vigilant about potential disruptions that may affect quality. Establishing strong relationships with suppliers can help mitigate these risks.

By understanding the manufacturing processes and quality assurance measures for diagram push buttons, B2B buyers can make more informed decisions, ensuring they select reliable suppliers capable of delivering high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diagram push button’

To assist B2B buyers in procuring diagram push buttons effectively, this guide provides a structured checklist to ensure that all necessary considerations are addressed. By following these steps, you will enhance your procurement process, ensuring that you select the right products from reliable suppliers.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s critical to establish clear technical specifications for the push buttons you require. This includes understanding the type of action (momentary vs. maintained), the required voltage ratings, and any specific features like illumination or water resistance. Clearly defined specifications help streamline supplier selection and reduce the risk of errors in your order.

- Consider the application: Will these buttons be used in industrial machinery, consumer electronics, or control panels?

- Evaluate environmental conditions: Will the buttons need to withstand moisture, dust, or extreme temperatures?

Step 2: Research Available Push Button Types

Familiarize yourself with the various types of push buttons available in the market. Understanding the differences between normally open (N/O) and normally closed (N/C) contacts, as well as the distinctions between momentary and maintained switches, is essential. This knowledge will guide you in selecting the right switch for your specific applications.

- Identify common types: Explore options like illuminated, tactile, and locking push button switches.

- Assess compatibility: Ensure the selected type aligns with your existing systems and components.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Look for suppliers with a strong reputation in the industry, and request their company profiles, case studies, and references from other businesses in similar markets. This vetting process will help you ensure that you are partnering with a reliable source.

- Check certifications: Verify that suppliers adhere to international quality standards relevant to your industry.

- Investigate customer reviews: Look for feedback regarding product quality, delivery times, and customer service.

Step 4: Request Samples for Testing

Once you have narrowed down potential suppliers, request samples of the push buttons you are considering. Testing samples allows you to assess the quality, functionality, and suitability of the buttons for your specific applications before making a larger commitment.

- Evaluate performance: Check for durability, ease of use, and responsiveness.

- Test compatibility: Ensure the buttons integrate seamlessly with your existing systems.

Step 5: Analyze Pricing and Payment Terms

Pricing is a crucial factor in the procurement process, but it should not be the only consideration. Analyze the pricing structure provided by each supplier, including any volume discounts or additional fees. Additionally, review payment terms to ensure they align with your budget and cash flow requirements.

- Consider total cost of ownership: Factor in shipping, handling, and potential import duties, especially for international purchases.

- Negotiate terms: Don’t hesitate to discuss payment terms and delivery timelines to secure the best deal.

Step 6: Confirm Logistics and Delivery Schedules

After finalizing your order, confirm the logistics and delivery schedules with your chosen supplier. Ensure that they can meet your timeline and that the shipping methods are reliable. This step is crucial to avoid any disruptions in your operations.

- Establish communication channels: Maintain open lines of communication for updates on shipping and handling.

- Plan for contingencies: Discuss what measures are in place in case of delays or issues during transit.

Step 7: Review Warranty and Support Options

Finally, before completing your purchase, review the warranty and support options available for the push buttons. A solid warranty can provide peace of mind, while responsive customer support can be invaluable in resolving any issues that arise post-purchase.

- Understand warranty coverage: Know what is included and for how long.

- Inquire about technical support: Ensure that assistance is readily available should any questions or concerns arise.

Comprehensive Cost and Pricing Analysis for diagram push button Sourcing

What Are the Key Cost Components in Sourcing Diagram Push Buttons?

When sourcing diagram push buttons, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Push buttons are commonly made from durable plastics or metals, with additional features such as LED illumination or IP-rated protection increasing material costs. The quality and sourcing of these materials can vary, influencing overall pricing.

-

Labor: Labor costs depend on the manufacturing location and the complexity of the push button design. Regions with higher labor costs may lead to increased prices, especially if skilled labor is required for assembly or customization.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and indirect labor. Efficient production processes can help mitigate these costs, but they will vary by manufacturer.

-

Tooling: Customization often necessitates specialized tooling, which can be a significant upfront investment. This cost should be factored into the overall pricing, especially for unique designs or large production runs.

-

Quality Control (QC): Ensuring that push buttons meet required safety and performance standards involves QC processes that add to the manufacturing cost. The rigor of these processes can influence both the price and the reliability of the product.

-

Logistics: Transportation and handling costs play a pivotal role in the final price. Factors such as shipping distance, mode of transport, and packaging requirements can all affect logistics expenses.

-

Margin: Suppliers typically include a margin to cover their operational costs and profit. This margin can vary based on market conditions and supplier relationships.

What Influences Pricing for Diagram Push Buttons?

Several factors influence the pricing of diagram push buttons, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs or specialized features can drive up costs. Understanding the necessary specifications will help buyers balance between custom requirements and budget constraints.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., IP ratings for water resistance) can increase the cost but may be necessary for specific applications. Buyers should assess the total cost of ownership against initial procurement costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more for their products due to perceived quality and service levels.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Buyers should consider how terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) impact the overall price and risk management.

What Are Effective Negotiation and Cost-Efficiency Strategies for B2B Buyers?

To optimize costs when sourcing diagram push buttons, consider these strategies:

-

Conduct Market Research: Understanding market prices and competitor offerings provides leverage during negotiations. This knowledge helps in setting realistic budget expectations.

-

Leverage Total Cost of Ownership (TCO): Focus on the long-term costs associated with the push buttons, including maintenance and replacement. This perspective can justify higher upfront costs if the product offers superior reliability and longevity.

-

Build Long-Term Relationships with Suppliers: Establishing strong partnerships can lead to better pricing, priority service, and collaborative problem-solving. Consider negotiating terms that benefit both parties.

-

Explore Alternative Suppliers: Don’t hesitate to evaluate multiple suppliers to compare pricing and quality. This can reveal opportunities for cost savings or better terms.

What Pricing Nuances Should International B2B Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of several pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly impact the final cost. Buyers should consider hedging strategies or agreements that mitigate these risks.

-

Import Duties and Taxes: Be aware of any tariffs or taxes that apply to imported goods, as these can add to the total procurement cost.

-

Cultural and Regional Factors: Understanding local market dynamics, including demand fluctuations and supplier capabilities, can influence negotiation strategies and pricing outcomes.

Conclusion

In conclusion, a comprehensive understanding of the cost components and pricing influencers for diagram push buttons is essential for international B2B buyers. By employing effective negotiation strategies and being mindful of regional pricing nuances, buyers can achieve cost-effective sourcing while ensuring product quality and reliability. Always remember that indicative prices may vary based on the factors discussed, and it’s advisable to conduct thorough due diligence before finalizing any procurement decision.

Alternatives Analysis: Comparing diagram push button With Other Solutions

When considering control mechanisms for various applications, it is essential to evaluate alternatives to the diagram push button. Each solution brings its own advantages and disadvantages, making it crucial for B2B buyers to understand their options thoroughly.

| Comparison Aspect | Diagram Push Button | Touch Screen Interface | Toggle Switch |

|---|---|---|---|

| Performance | Reliable and responsive for momentary or maintained use | Versatile with customizable interfaces, though responsiveness can vary based on technology | Simple mechanism with clear on/off states |

| Cost | Generally low-cost, depending on specifications | Can be higher due to screen technology and software | Typically low-cost and straightforward |

| Ease of Implementation | Easy to install with standard mounting options | Requires software integration and may need specialized setup | Simple to install, often just requires a mounting hole |

| Maintenance | Low maintenance, but may require replacement over time | Higher maintenance due to potential software updates and hardware issues | Minimal maintenance, but mechanical wear can occur |

| Best Use Case | Ideal for industrial applications and machinery control | Suitable for interactive applications needing customizable interfaces | Effective for simple on/off functions in home or industrial settings |

What Are the Advantages and Disadvantages of Using a Touch Screen Interface Instead of a Diagram Push Button?

Touch screen interfaces offer a modern alternative to traditional push buttons. They provide a versatile platform that can display multiple functions on a single screen, making it easy to customize user interactions. However, they can be less responsive in certain conditions, such as when used in environments with heavy machinery or where users wear gloves. Additionally, touch screens typically come at a higher cost due to their technology and potential need for software integration.

How Do Toggle Switches Compare with Diagram Push Buttons in Terms of Practical Applications?

Toggle switches are another viable alternative, particularly for straightforward on/off functions. They are known for their reliability and simplicity, making them easy to use. Their mechanical design allows for clear visual confirmation of their state, which is beneficial in applications where users need to quickly identify the switch position. However, toggle switches may not offer the same flexibility as diagram push buttons, especially in complex applications requiring multiple functions or configurations.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right control mechanism, B2B buyers should consider the specific requirements of their applications. Diagram push buttons are ideal for reliable, straightforward operations in industrial settings. In contrast, touch screen interfaces are better suited for environments that demand flexibility and customization, albeit at a higher cost and complexity. Toggle switches provide a simple solution for basic functions, making them an excellent choice for straightforward applications. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, buyers can make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for diagram push button

What Are the Essential Technical Properties of Diagram Push Buttons?

When selecting diagram push buttons, understanding their critical technical specifications is essential for ensuring optimal performance and compatibility within your applications. Here are several key properties to consider:

1. Material Grade

The material used in the construction of push buttons, typically plastic or metal, significantly impacts durability and functionality. High-grade plastics can offer resistance to chemicals and environmental conditions, while metal options provide robustness for high-traffic areas. For B2B buyers, selecting the right material is crucial for ensuring longevity and reducing maintenance costs.

2. Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. For push buttons, tight tolerance levels ensure a proper fit and reliable operation within assemblies. When purchasing, understanding tolerance is vital for ensuring compatibility with existing equipment and minimizing operational failures, which can lead to downtime.

3. Voltage and Current Ratings

Push buttons have specific voltage and current ratings that define their operational limits. These ratings determine the electrical load the switch can handle without failure. Buyers must match these ratings with their application’s requirements to prevent overheating or switch failure, ensuring safety and reliability.

4. Ingress Protection (IP) Rating

The IP rating indicates the level of protection against dust and water ingress. For instance, an IP67 rating means the button is dust-tight and can withstand immersion in water up to a certain depth. This property is particularly important for applications in harsh environments, as it directly affects the longevity and functionality of the switch.

5. Actuation Type

The actuation type determines how the push button operates. Common types include momentary (requiring continuous pressure) and maintained (staying in position until pressed again). Understanding the actuation type is essential for applications where user interaction is a factor, as it influences how the device will be used in practice.

6. Operating Temperature Range

This specification defines the temperature limits within which the push button can operate effectively. A broader temperature range is necessary for applications exposed to extreme conditions. Buyers should consider the operating environment to ensure the selected push button will perform reliably without compromising safety.

What Are Common Trade Terms Related to Diagram Push Buttons?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several commonly used terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the OEM relationship is critical for buyers looking to source components that align with specific branding or quality standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest order size a supplier is willing to accept. Knowing the MOQ is vital for budgeting and inventory management, as it can affect the total cost of procurement and the ability to meet production schedules.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit pricing and terms for specific products or services. It’s an essential step in the purchasing process, allowing buyers to compare offers and negotiate better terms based on their needs.

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers manage shipping costs and logistics effectively, ensuring clarity in delivery terms.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. This factor is crucial for project planning and inventory management, as longer lead times can affect production schedules and operational efficiency.

6. Certification Standards

Certification standards, such as CE or UL, indicate compliance with safety and quality regulations. For B2B buyers, ensuring that push buttons meet relevant certification standards is essential for regulatory compliance and minimizing risk in operations.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing diagram push buttons, ensuring compatibility and reliability in their applications.

Navigating Market Dynamics and Sourcing Trends in the diagram push button Sector

What Are the Current Market Dynamics and Key Trends in the Diagram Push Button Sector?

The global diagram push button market is experiencing significant transformation driven by advancements in technology and changing consumer demands. One of the primary drivers is the increasing automation in various industries, including manufacturing, automotive, and consumer electronics. As businesses seek to enhance operational efficiency, the demand for reliable and versatile push button switches continues to grow. Moreover, the rise of smart technologies is pushing manufacturers to innovate, leading to the development of advanced features such as illuminated buttons and enhanced ingress protection ratings.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of emerging sourcing trends. The shift towards digital procurement platforms is notable, allowing businesses to access a broader range of suppliers and products. Additionally, the importance of quick delivery times and after-sales support is rising as companies prioritize operational uptime. Sustainability is another critical factor influencing purchasing decisions, with more buyers seeking eco-friendly products and suppliers committed to responsible manufacturing practices.

In terms of market dynamics, competition is intensifying as new entrants emerge alongside established players. This competition fosters innovation and price competitiveness, benefiting buyers. Moreover, the ongoing global supply chain challenges necessitate agility and transparency from suppliers. Buyers are increasingly looking for partners that can provide reliable sourcing and can adapt to changing market conditions.

How Does Sustainability and Ethical Sourcing Impact the Diagram Push Button Sector?

Sustainability and ethical sourcing have become paramount in the diagram push button sector, reflecting a growing awareness of environmental impacts and corporate responsibility. The production and disposal of electronic components, including push buttons, can contribute to environmental degradation if not managed properly. As such, manufacturers are increasingly adopting sustainable practices, such as using recyclable materials and reducing waste during production processes.

For international B2B buyers, understanding the importance of ethical supply chains is crucial. Suppliers that demonstrate commitment to sustainability often gain a competitive edge, as buyers prefer to partner with companies that align with their values. Certifications like ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) can serve as indicators of a supplier’s commitment to sustainable practices.

Moreover, the demand for ‘green’ materials is on the rise. Buyers are looking for push buttons made from eco-friendly plastics or metals that minimize environmental impact. As legislation around electronic waste and environmental protection tightens globally, suppliers who prioritize sustainability are more likely to remain compliant and successful in the long term. This trend not only meets regulatory requirements but also appeals to environmentally conscious consumers.

What Is the Brief Evolution of the Diagram Push Button Sector?

The evolution of diagram push buttons dates back to the early 20th century when mechanical switches were the primary method for controlling electrical circuits. The introduction of electric push buttons revolutionized the industry, enabling more efficient and safer operation of electrical devices. Over the decades, technological advancements led to the development of various types of push buttons, including momentary and maintained switches, which catered to diverse applications across sectors.

As industries evolved, so did the design and functionality of push buttons. The advent of automation and smart technologies in the late 20th and early 21st centuries prompted manufacturers to innovate further, incorporating features such as LED indicators and enhanced durability. Today, the focus has shifted towards not only functionality but also aesthetics and user experience, with customizable designs becoming increasingly popular in the market.

In conclusion, the diagram push button sector is rapidly adapting to meet the demands of a globalized, technology-driven marketplace. For B2B buyers, staying informed about market dynamics, sustainability practices, and the historical context of push buttons can enhance sourcing strategies and facilitate successful partnerships.

Frequently Asked Questions (FAQs) for B2B Buyers of diagram push button

-

How do I choose the right diagram push button for my application?

When selecting a diagram push button, consider the specific requirements of your application, including the type of action (momentary vs. maintained), contact configuration (N/O vs. N/C), and environmental factors (such as water resistance and IP ratings). Assess the voltage ratings and ensure compatibility with your existing systems. Additionally, evaluate the button’s size, shape, and ergonomic design, as these factors can impact user interaction and safety. Consulting with suppliers who provide detailed technical specifications can also facilitate an informed decision. -

What are the key differences between momentary and maintained push buttons?

Momentary push buttons require continuous pressure to remain in an active state, making them ideal for temporary functions like doorbells or alarms. In contrast, maintained push buttons stay in their set state until pressed again, suitable for applications like machinery start/stop controls. Understanding these differences is crucial for selecting the right type for your operational needs. Consider your application requirements carefully, as using the wrong type can affect functionality and safety. -

What customization options are available for push buttons?

Many manufacturers offer customization options for push buttons, allowing you to tailor aspects such as color, shape, labeling, and functionality. You may also request specific materials for durability or enhanced aesthetic appeal. Some suppliers provide bespoke designs to fit unique operational requirements or branding. Always discuss your customization needs with potential suppliers to ensure they can meet your specifications and timelines. -

What is the minimum order quantity (MOQ) for push buttons?

The minimum order quantity for diagram push buttons can vary significantly between suppliers, often depending on the type of button and customization options. Generally, MOQs can range from a few dozen to several hundred units. It’s advisable to inquire about the MOQ during your supplier selection process, as this can impact your overall procurement strategy and budget. Suppliers may also offer flexibility for larger orders or repeat business. -

What payment terms should I expect when sourcing push buttons internationally?

Payment terms can vary widely among suppliers, but common options include advance payment, letter of credit, or partial payment upfront with the balance due upon delivery. When dealing with international transactions, it’s crucial to discuss and negotiate payment terms upfront to ensure clarity and avoid potential disputes. Additionally, consider factors like currency fluctuations and transaction fees, which can affect overall costs. -

How can I ensure quality assurance for push buttons from suppliers?

To ensure quality assurance when sourcing push buttons, request detailed product specifications and certifications from suppliers. Look for manufacturers with ISO certification or similar quality management systems. Additionally, consider conducting factory audits or third-party inspections to verify production standards. Establishing a clear quality control process, including testing samples before full-scale orders, can help mitigate risks associated with product quality. -

What logistics considerations should I keep in mind when importing push buttons?

When importing push buttons, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder experienced in handling electronic components to navigate international shipping complexities. Be aware of potential delays at customs and prepare necessary documentation to facilitate smooth clearance. Additionally, account for shipping costs in your overall budget, as these can vary significantly depending on the destination and shipping method. -

How do I vet suppliers for push buttons in different regions?

Vetting suppliers for push buttons involves assessing their reputation, experience, and compliance with industry standards. Start by researching potential suppliers online and reading reviews or testimonials from previous clients. Request references and visit their facilities if possible. Additionally, check for certifications relevant to your industry, and ensure they adhere to international quality standards. Engaging with local trade associations or chambers of commerce can also provide valuable insights into reputable suppliers in specific regions.

Top 6 Diagram Push Button Manufacturers & Suppliers List

1. RS Components – Push Button Switches

Domain: uk.rs-online.com

Registered: 2001 (24 years)

Introduction: A push button switch is a crucial component in electrical circuits that controls the flow of current to devices. They are commonly used in various applications including industrial machinery, home appliances, control panels, and security systems. Push button switches can be momentary (requiring continuous pressure to activate) or maintained (staying in the set state until pressure is reapplied). T…

2. Chinadaier – Push Button Switches

Domain: chinadaier.com

Registered: 2003 (22 years)

Introduction: Push Button Switches: Control electrical circuits with a single press. Types include: 1. Momentary Push Button Switch: Temporary action, closes circuit when pressed (e.g., doorbells). 2. Latching Push Button Switch: Toggles circuit between on/off states (e.g., light switches). 3. Illuminated Push Button Switch: Incorporates LED for visual indication (e.g., computer power buttons). 4. Safety Push B…

3. Pinterest – Electrical Switch Symbols

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Graphical symbols and descriptions of common electrical switches and push buttons per IEC and IEEE standards. Includes single-pole, multi-pos, passing, delayed action switches.

4. ShallowSky – Pushbutton Switch with Arduino Integration

Domain: shallowsky.com

Registered: 1998 (27 years)

Introduction: A pushbutton has four legs with two connections. When pressed, all legs connect; otherwise, the top and bottom legs connect separately. It can be wired to an LED using Arduino’s power and ground. One side connects to 5v and the other to pin 2. The button state can be read using digitalRead(2). A pull-down resistor (1 M\u03a9) is recommended to prevent floating pin states when the button is not pre…

5. SparkFun – Toggle Switches and Tactile Switches

Domain: learn.sparkfun.com

Registered: 2002 (23 years)

Introduction: Toggle Switch COM-09276: Heavy duty SPST toggle switch, rated for 2A at 250V or 4A at 125V, includes a face plate, price $2.25. SPDT Slide Switch COM-09609: Simple SPDT slide switch, great for ON/OFF control, price $0.95. 5-way Tactile Switch COM-10063: Allows for joystick-like interface, surface mount, price $3.95. Foot Pedal Switch COM-11192: Metal foot switch, similar to those used for power co…

6. Indicator Light – Push Button Switches

Domain: indicatorlight.com

Registered: 2004 (21 years)

Introduction: Push button switches are devices that can turn on or off a control circuit by pressing a button. They are durable and reliable, widely used in various applications, and can send control signals to other electrical appliances. Types of push button switches include: 1. Momentary Push Button Switch – Only turns on the circuit when pressed (e.g., doorbell, keyboard). 2. Latching Push Button Switch – S…

Strategic Sourcing Conclusion and Outlook for diagram push button

How Can Strategic Sourcing Enhance Your Push Button Procurement?

In conclusion, the strategic sourcing of push button switches is vital for optimizing operational efficiency and safety across various applications. By understanding the differences in switch types—such as momentary versus maintained, or normally open versus normally closed—businesses can select the most suitable options for their specific needs. Sourcing from reliable manufacturers ensures not only quality but also compliance with international standards, which is particularly important for buyers in diverse regions like Africa, South America, the Middle East, and Europe.

Investing in strategic sourcing allows companies to leverage supplier relationships, negotiate better terms, and ensure timely delivery, which is critical in today’s fast-paced market. Furthermore, as industries continue to evolve, the demand for innovative and robust push button solutions will grow, presenting opportunities for businesses to stay ahead of the curve.

As you consider your next procurement strategy, prioritize partnerships with suppliers that offer comprehensive support and a range of customizable options. Embrace the potential of push button technology to enhance your operations and drive success. The future of your business depends on making informed, strategic decisions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.