Diagram Of Shell And Tube Heat Exchanger: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for diagram of shell and tube heat exchanger

The global market for shell and tube heat exchangers presents a unique set of challenges for international B2B buyers, especially when it comes to sourcing reliable and efficient solutions. As industries worldwide strive for enhanced energy efficiency and reduced operational costs, understanding the intricacies of these essential components becomes paramount. This guide delves into the various types of shell and tube heat exchangers, their applications across diverse sectors—from petrochemicals to power generation—and the critical factors to consider when evaluating suppliers.

Navigating the complexities of heat exchanger design, including TEMA standards and geometric terminology, this comprehensive resource equips buyers with the knowledge needed to make informed decisions. It covers essential topics such as supplier vetting processes, cost considerations, and the latest technological advancements in the field. For B2B buyers from regions like Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany, this guide serves as a vital tool to streamline procurement and ensure compliance with industry standards.

With a focus on actionable insights and expert recommendations, this guide empowers businesses to enhance their operational efficiency and achieve their thermal management goals. By understanding the full spectrum of options available in the market, buyers can confidently invest in solutions that not only meet their current needs but also position them for future growth.

Understanding diagram of shell and tube heat exchanger Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Tubesheet Exchanger | Tubesheet welded to the shell; simple design | Petrochemical and power industries | Pros: Economical construction, easy maintenance. Cons: Limited access for cleaning; potential for thermal stress. |

| U-Tube Exchanger | U-shaped tubes allow for thermal expansion | Chemical processing and HVAC systems | Pros: Flexibility in thermal expansion, easy bundle removal. Cons: Difficult internal cleaning, not suitable for dirty fluids. |

| Floating Head Exchanger | Tubesheet allows for movement, accommodating expansion | High-pressure and temperature applications | Pros: Suitable for rigorous conditions, easy cleaning. Cons: Higher cost compared to fixed designs. |

| E-Type Shell | Most common shell type, versatile for various duties | General industrial applications | Pros: Broad applicability, effective heat transfer. Cons: Potential for higher pressure drops in some configurations. |

| J-Type Shell | Designed to minimize pressure drops and tube vibrations | Specialized applications in reboilers | Pros: Reduces tube vibration, effective for high flow rates. Cons: More complex design may increase costs. |

What Are the Key Characteristics of Fixed Tubesheet Exchangers?

Fixed Tubesheet Exchangers feature a tubesheet that is welded to the shell, creating a robust and simple design. This type is particularly suitable for applications within the petrochemical and power industries, where reliability is crucial. Buyers should consider that while these exchangers are cost-effective and easy to maintain, they offer limited access for cleaning, which can be a drawback in systems with fouling fluids.

How Do U-Tube Exchangers Operate and Where Are They Used?

U-Tube Exchangers utilize U-shaped tubes that permit significant thermal expansion, making them ideal for chemical processing and HVAC systems. The design allows for easy removal of the tube bundle for maintenance. However, buyers should note that internal cleaning can be challenging, and these exchangers are best suited for clean fluids, as fouling can complicate operations.

What Advantages Do Floating Head Exchangers Offer?

Floating Head Exchangers are designed with a tubesheet that can move, accommodating thermal expansion without stressing the system. This design is advantageous in high-pressure and high-temperature applications, making it suitable for industries requiring rigorous heat exchange. While they offer easy cleaning and maintenance, the increased complexity results in higher initial costs, which buyers should factor into their purchasing decisions.

Why Is the E-Type Shell the Most Common Choice?

The E-Type Shell is the most widely used shell type due to its versatility across various industrial applications. It effectively supports a range of operating conditions, making it a preferred choice for general industrial heat exchange. However, buyers should be aware that while it is generally efficient, certain configurations may experience higher pressure drops, which can affect overall system performance.

In What Scenarios Would a J-Type Shell Be Preferred?

J-Type Shells are specifically designed to minimize pressure drops and reduce tube vibrations, making them suitable for applications like reboilers where flow rates can be high. This design helps maintain efficient heat transfer while mitigating potential operational issues. Buyers considering this option should weigh the complexity of the design against the potential benefits in high-flow situations, as it may lead to increased costs but also enhanced performance.

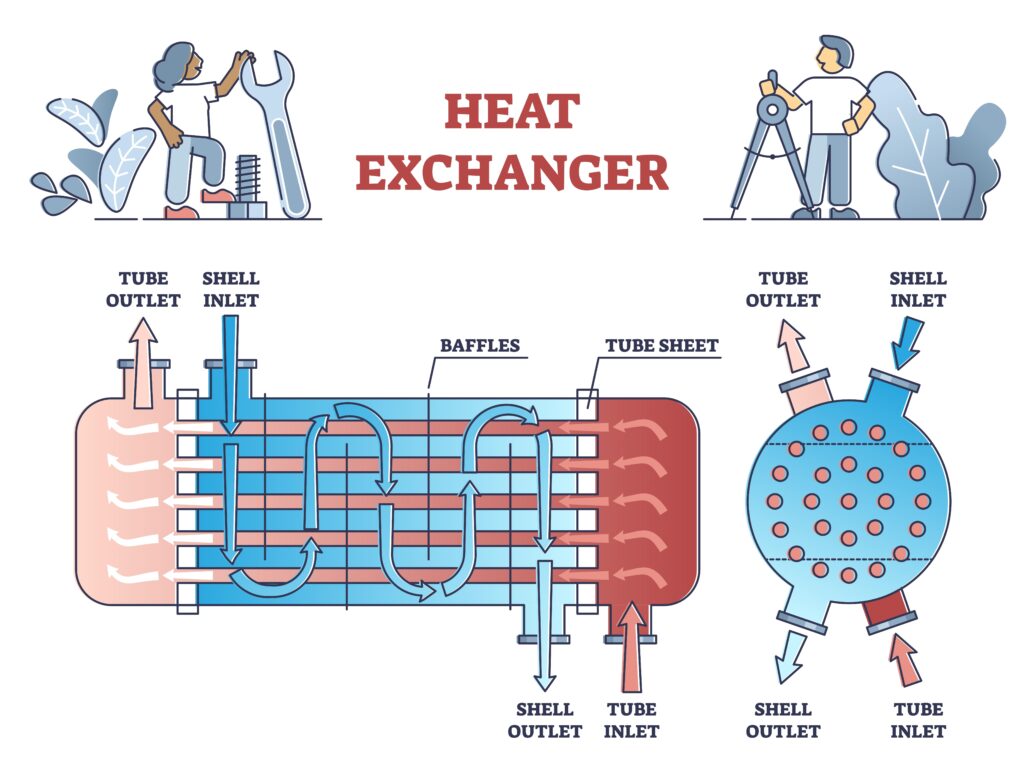

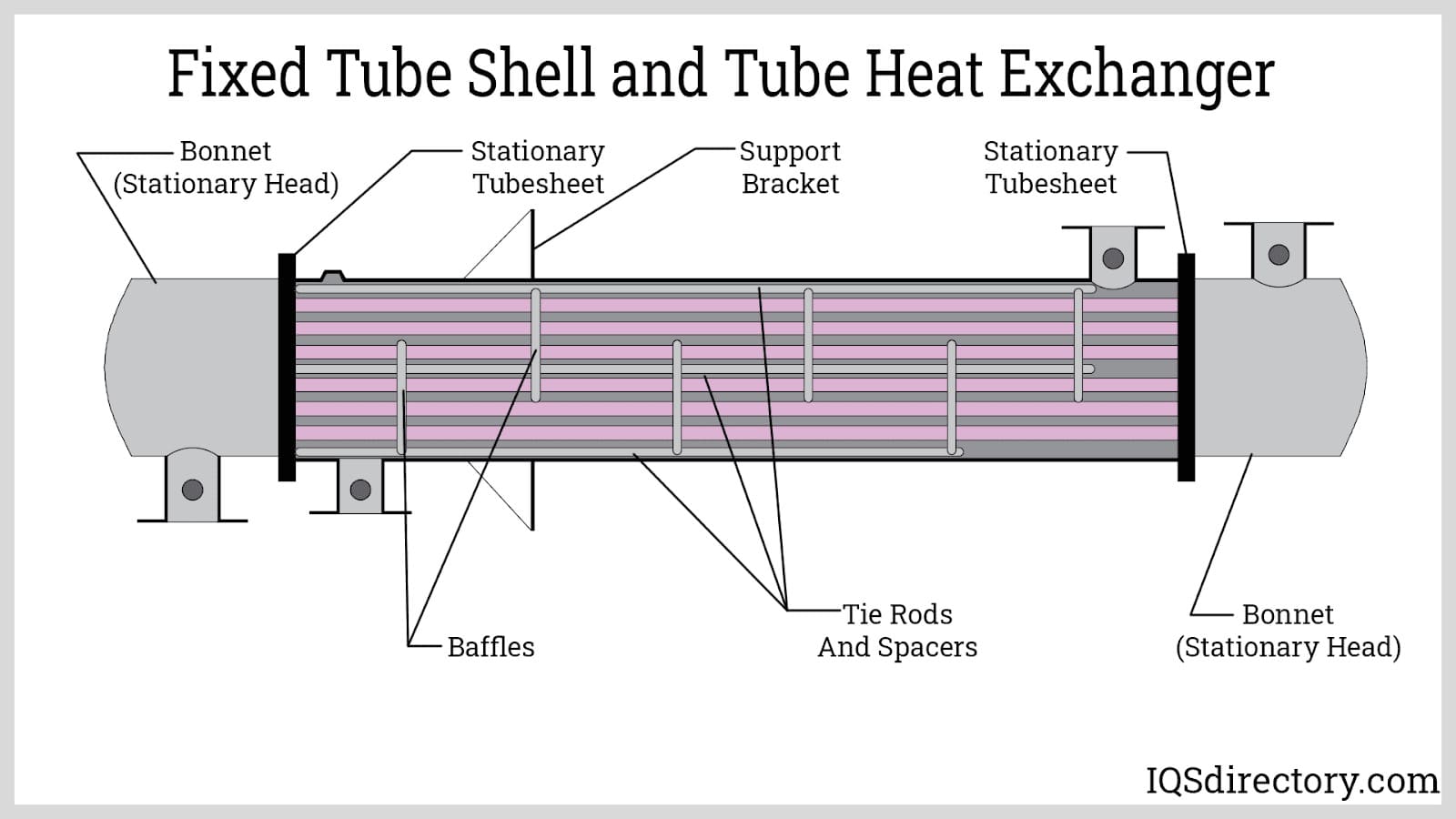

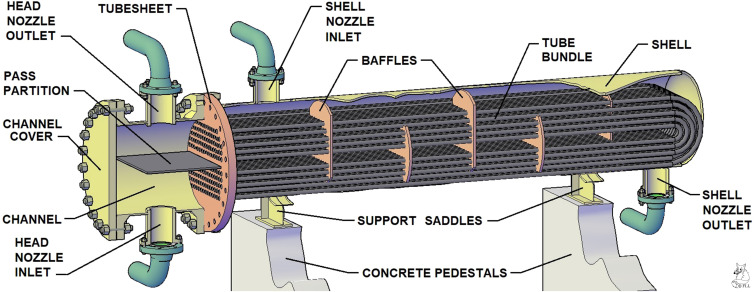

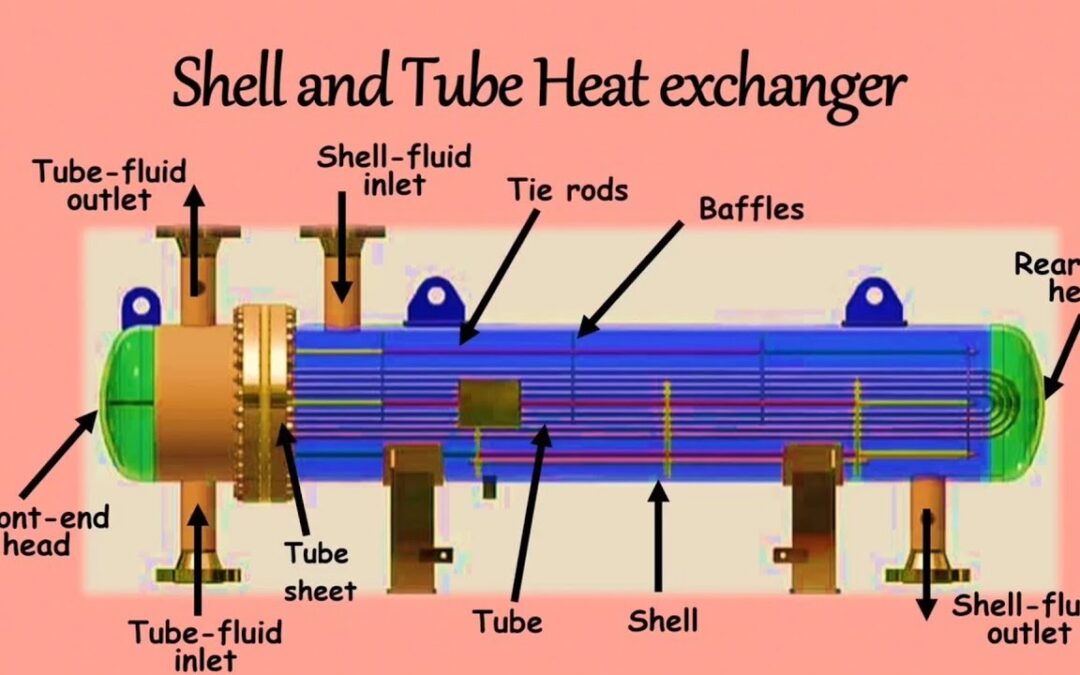

Illustrative image related to diagram of shell and tube heat exchanger

Key Industrial Applications of diagram of shell and tube heat exchanger

| Industry/Sector | Specific Application of diagram of shell and tube heat exchanger | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Petrochemical | Heat exchange in refining processes and chemical production | Enhances energy efficiency and reduces operational costs | Compliance with TEMA standards; material compatibility |

| Power Generation | Feedwater heating in steam power plants | Increases thermal efficiency and overall plant performance | High-pressure design options; maintenance and cleaning access |

| HVAC Systems | Chilled water systems for air conditioning | Improves cooling efficiency and reduces energy consumption | Size and capacity matching; custom designs for specific needs |

| Food and Beverage | Pasteurization and cooling processes in food production | Ensures product safety and quality while optimizing energy use | Sanitary design requirements; regulatory compliance |

| Pharmaceutical | Temperature control in drug manufacturing processes | Maintains product integrity and enhances production efficiency | Material certifications; precise temperature control capabilities |

How is the Shell and Tube Heat Exchanger Used in the Petrochemical Industry?

In the petrochemical sector, shell and tube heat exchangers are crucial for facilitating heat exchange in refining processes and chemical production. They enable the efficient transfer of heat between various process streams, significantly enhancing energy efficiency and lowering operational costs. International buyers must ensure that these exchangers comply with TEMA standards and are constructed from materials compatible with the specific chemicals being processed to prevent corrosion and ensure longevity.

What Role Do Shell and Tube Heat Exchangers Play in Power Generation?

In power generation, particularly in steam power plants, shell and tube heat exchangers are employed for feedwater heating. This process increases thermal efficiency, allowing plants to operate at higher performance levels. Buyers in this sector should focus on high-pressure design options, ensuring that the exchangers can withstand the operational demands while also considering ease of maintenance and access for cleaning to prolong equipment lifespan.

How Are Shell and Tube Heat Exchangers Utilized in HVAC Systems?

In HVAC applications, shell and tube heat exchangers are integral to chilled water systems used for air conditioning. They facilitate efficient heat transfer, improving cooling performance and reducing energy consumption. For B2B buyers, it is essential to match the size and capacity of the heat exchangers to the specific requirements of their HVAC systems, and consider custom designs to optimize efficiency and performance in varying climates.

What Applications Exist for Shell and Tube Heat Exchangers in the Food and Beverage Industry?

In the food and beverage industry, these heat exchangers are employed in pasteurization and cooling processes to ensure product safety and quality. They allow for the controlled transfer of heat, which is critical in maintaining the integrity of food products while optimizing energy use. Buyers must prioritize sanitary design requirements and ensure compliance with food safety regulations to avoid contamination and maintain product standards.

Illustrative image related to diagram of shell and tube heat exchanger

How Are Shell and Tube Heat Exchangers Used in Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, shell and tube heat exchangers are used for precise temperature control during drug production processes. This capability is vital for maintaining product integrity and enhancing overall production efficiency. Buyers should consider material certifications and the specific temperature control capabilities of the exchangers to meet stringent regulatory requirements and ensure the safety and efficacy of pharmaceutical products.

3 Common User Pain Points for ‘diagram of shell and tube heat exchanger’ & Their Solutions

Scenario 1: Understanding Complex Diagrams for Efficient Sourcing

The Problem: Many B2B buyers struggle with the intricate diagrams associated with shell and tube heat exchangers. The complexity of these diagrams can lead to misinterpretations that affect purchasing decisions. This is particularly challenging for teams that may lack specialized engineering knowledge, which can result in acquiring the wrong type of heat exchanger, subsequently causing delays and increased costs in the project lifecycle. Buyers often find themselves overwhelmed by the technical jargon and various design specifications, making it difficult to determine which type of heat exchanger is best suited for their specific needs.

The Solution: To effectively navigate the complexity of shell and tube heat exchanger diagrams, buyers should invest time in training sessions or workshops focused on understanding these technical specifications. Partnering with manufacturers who offer educational resources can be invaluable. When sourcing, request detailed product documentation that includes simplified diagrams and comprehensive explanations of each component’s function. Additionally, engaging with experienced engineers during the selection process can provide clarity on the best options tailored to specific applications. By ensuring that all team members are informed about the critical aspects of these diagrams, companies can minimize the risk of incorrect purchases and optimize their project timelines.

Scenario 2: Balancing Cost with Performance Requirements

The Problem: B2B buyers often face the challenge of balancing budget constraints with the performance requirements of shell and tube heat exchangers. The pressure to reduce costs while ensuring efficiency can lead to difficult decisions that might sacrifice quality for price. This is particularly common in industries where operational efficiency is paramount, such as petrochemical and power generation sectors. Buyers may feel trapped between selecting a lower-cost unit that may not meet performance criteria and a high-end model that exceeds their budget.

Illustrative image related to diagram of shell and tube heat exchanger

The Solution: To effectively balance cost with performance, it is crucial to conduct a thorough analysis of the specific application requirements before making a purchase. Buyers should define the parameters that are most critical, such as temperature ranges, pressure specifications, and fluid types. From there, they can create a shortlist of heat exchangers that meet these criteria across various price points. Engaging in direct discussions with multiple suppliers can also yield insights into cost-saving options, such as alternative materials or slightly different designs that maintain efficiency without overspending. Implementing a value engineering approach, where the total cost of ownership is considered rather than just the initial purchase price, can help buyers make more informed decisions that align with both their budget and operational needs.

Scenario 3: Navigating Compliance and Industry Standards

The Problem: Compliance with industry standards and regulations is a significant concern for B2B buyers of shell and tube heat exchangers. Different regions, such as Europe and the Middle East, have specific regulatory frameworks that dictate the design and operational requirements of heat exchangers. Failure to adhere to these standards can lead to legal repercussions, costly fines, and operational downtime. Buyers may find it challenging to decipher which standards apply to their projects and how to ensure their selected equipment meets all necessary compliance measures.

The Solution: To navigate compliance effectively, buyers should familiarize themselves with the relevant standards, such as those set by the Tubular Exchanger Manufacturers Association (TEMA) and local regulatory bodies. Consulting with compliance experts or legal advisors during the procurement process can provide essential guidance on which standards to prioritize. Additionally, buyers should prioritize manufacturers who are transparent about their compliance with industry regulations and can provide certification documentation. Conducting regular audits of equipment and maintaining open communication with suppliers about any changes in compliance requirements will further ensure that operations remain within legal parameters. By taking a proactive approach to compliance, buyers can mitigate risks and ensure their operations run smoothly and within the law.

Strategic Material Selection Guide for diagram of shell and tube heat exchanger

What Are the Key Materials Used in Shell and Tube Heat Exchangers?

When selecting materials for shell and tube heat exchangers, several factors must be considered, including the specific application, operating conditions, and environmental factors. Below is an analysis of four common materials used in the construction of these heat exchangers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability, with a temperature rating of up to 400°F (204°C) and good pressure ratings. It is not inherently corrosion-resistant, which can limit its application in certain environments.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for many applications. However, its susceptibility to corrosion can be a significant drawback, especially in industries dealing with aggressive media or in humid environments.

Impact on Application:

Carbon steel is suitable for applications involving water or other non-corrosive fluids. However, it may require additional protective coatings or treatments when used with corrosive substances.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM for the US or ABNT for Brazil. In Europe, adherence to EN standards is crucial. Carbon steel’s relatively low cost may make it appealing, but its limitations in corrosive environments should be carefully evaluated.

Illustrative image related to diagram of shell and tube heat exchanger

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and can withstand temperatures up to 1500°F (815°C). It is available in various grades, such as 304 and 316, which provide different levels of corrosion resistance.

Pros & Cons:

The key advantage of stainless steel is its durability and resistance to rust, making it ideal for a wide range of applications, including those involving corrosive fluids. However, it is more expensive than carbon steel and may require more complex manufacturing processes.

Impact on Application:

Stainless steel is highly compatible with a variety of media, including acidic and alkaline solutions, making it a preferred choice in the chemical and food processing industries.

Considerations for International Buyers:

Buyers should be aware of the specific grade of stainless steel required for their application and ensure compliance with international standards like DIN in Germany or JIS in Japan. The higher cost may be justified by the material’s longevity and performance in demanding environments.

3. Copper-Nickel Alloys

Key Properties:

Copper-nickel alloys exhibit excellent corrosion resistance, particularly in seawater and other saline environments, with temperature ratings up to 300°F (149°C).

Pros & Cons:

These alloys are highly durable and resistant to biofouling, making them suitable for marine applications. However, they are generally more expensive and may have limited availability in certain regions.

Impact on Application:

Copper-nickel alloys are particularly effective in applications involving seawater or brine, commonly used in marine heat exchangers. Their resistance to corrosion enhances the lifespan of the equipment.

Illustrative image related to diagram of shell and tube heat exchanger

Considerations for International Buyers:

For buyers in coastal regions or industries reliant on seawater, compliance with marine standards is essential. The higher cost and potential sourcing challenges should be factored into the purchasing decision.

4. Titanium

Key Properties:

Titanium is renowned for its exceptional corrosion resistance and strength-to-weight ratio, with a temperature rating of up to 1000°F (538°C).

Pros & Cons:

The primary advantage of titanium is its ability to withstand aggressive environments without corroding, making it ideal for chemical processing and seawater applications. However, it is one of the most expensive materials and can be challenging to fabricate.

Illustrative image related to diagram of shell and tube heat exchanger

Impact on Application:

Titanium is suitable for applications involving highly corrosive fluids, such as acids and chlorides, where other materials would fail.

Considerations for International Buyers:

Due to its high cost, titanium is often reserved for specialized applications. Buyers should ensure compliance with relevant international standards and consider the long-term cost benefits of reduced maintenance and replacement.

Summary Table

| Material | Typical Use Case for diagram of shell and tube heat exchanger | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Water and non-corrosive fluids | Cost-effective | Susceptible to corrosion | Low |

| Stainless Steel | Chemical and food processing | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Copper-Nickel Alloys | Marine and seawater applications | Durable and resistant to biofouling | Expensive and limited availability | Med |

| Titanium | Chemical processing and aggressive environments | Exceptional corrosion resistance | Very high cost and difficult to fabricate | High |

In-depth Look: Manufacturing Processes and Quality Assurance for diagram of shell and tube heat exchanger

What Are the Main Stages of Manufacturing a Shell and Tube Heat Exchanger?

The manufacturing process of a shell and tube heat exchanger involves several critical stages, each of which ensures that the final product meets the required specifications for efficiency, durability, and safety. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Shell and Tube Heat Exchanger Manufacturing?

Material preparation is the first step in the manufacturing process. High-quality materials such as stainless steel, carbon steel, or specialized alloys are selected based on the application and operational conditions. The materials undergo inspection to ensure they meet the required mechanical properties and chemical compositions. This often involves reviewing mill test reports and certificates of compliance.

Once the materials are verified, they are cut to size. This process may involve shearing plates for the shell and cutting tubes to the desired length. The edges of these components are deburred to prevent any sharp edges that could interfere with assembly or cause safety issues later on.

Illustrative image related to diagram of shell and tube heat exchanger

What Techniques Are Used in the Forming Stage?

The forming stage is where the individual components take shape. For the shell, processes such as rolling and welding are employed. The plates are rolled into cylindrical shapes and subsequently welded to create a seamless shell. For the tubes, techniques like extrusion or seamless tube manufacturing are utilized, ensuring a uniform wall thickness and high strength.

During this stage, attention to detail is paramount. Any distortion or misalignment can affect the heat exchanger’s performance. Therefore, manufacturers often use jigs and fixtures to maintain precise geometries throughout the forming process.

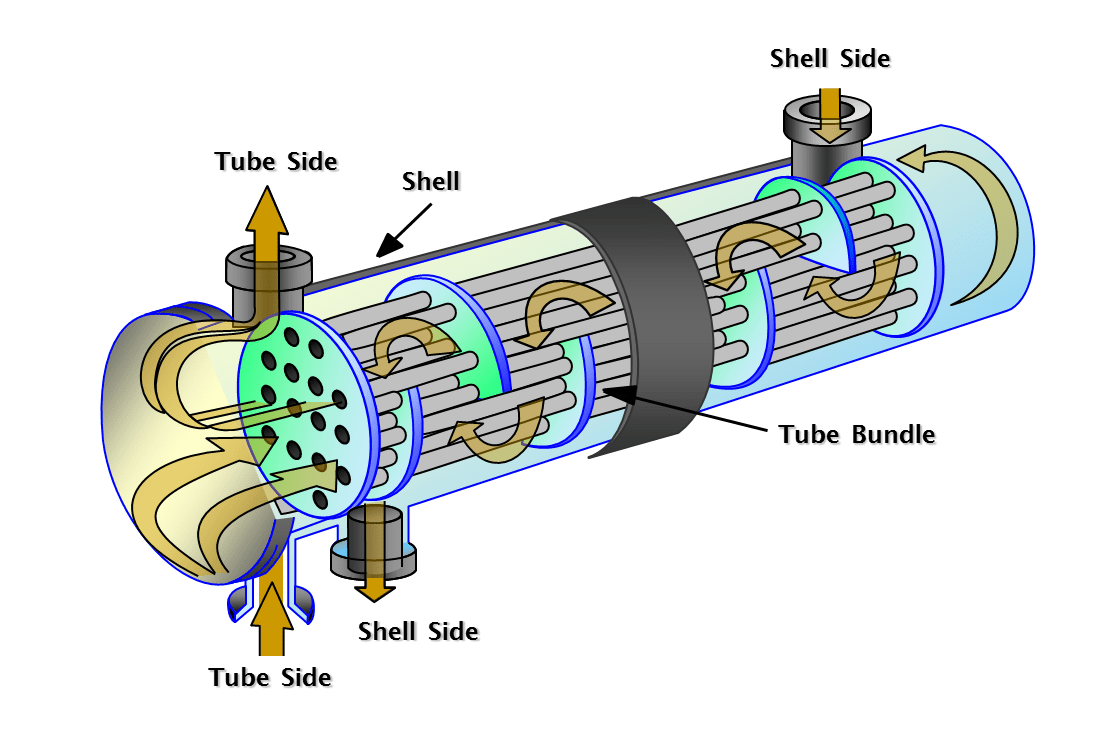

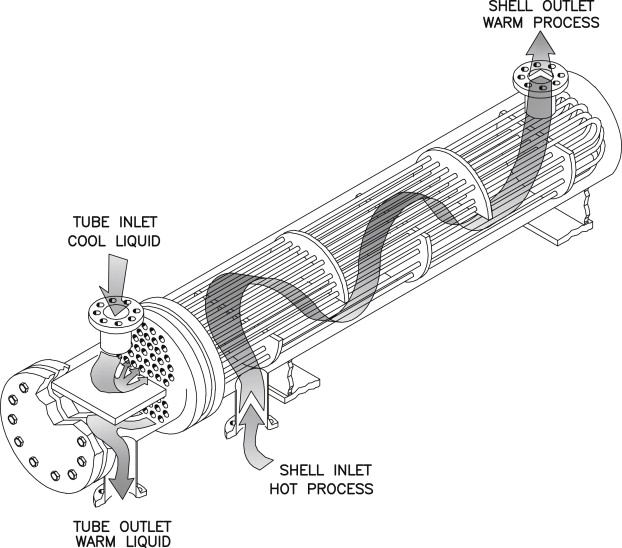

How Is the Assembly of Shell and Tube Heat Exchangers Carried Out?

After forming, the assembly stage begins. The tube bundle, consisting of the tubes and tube sheets, is carefully assembled. Tubes are inserted into the tube sheets, which are typically welded or mechanically expanded to ensure a tight fit. This process is crucial because it dictates the efficiency of heat transfer between the shell and tube sides.

Illustrative image related to diagram of shell and tube heat exchanger

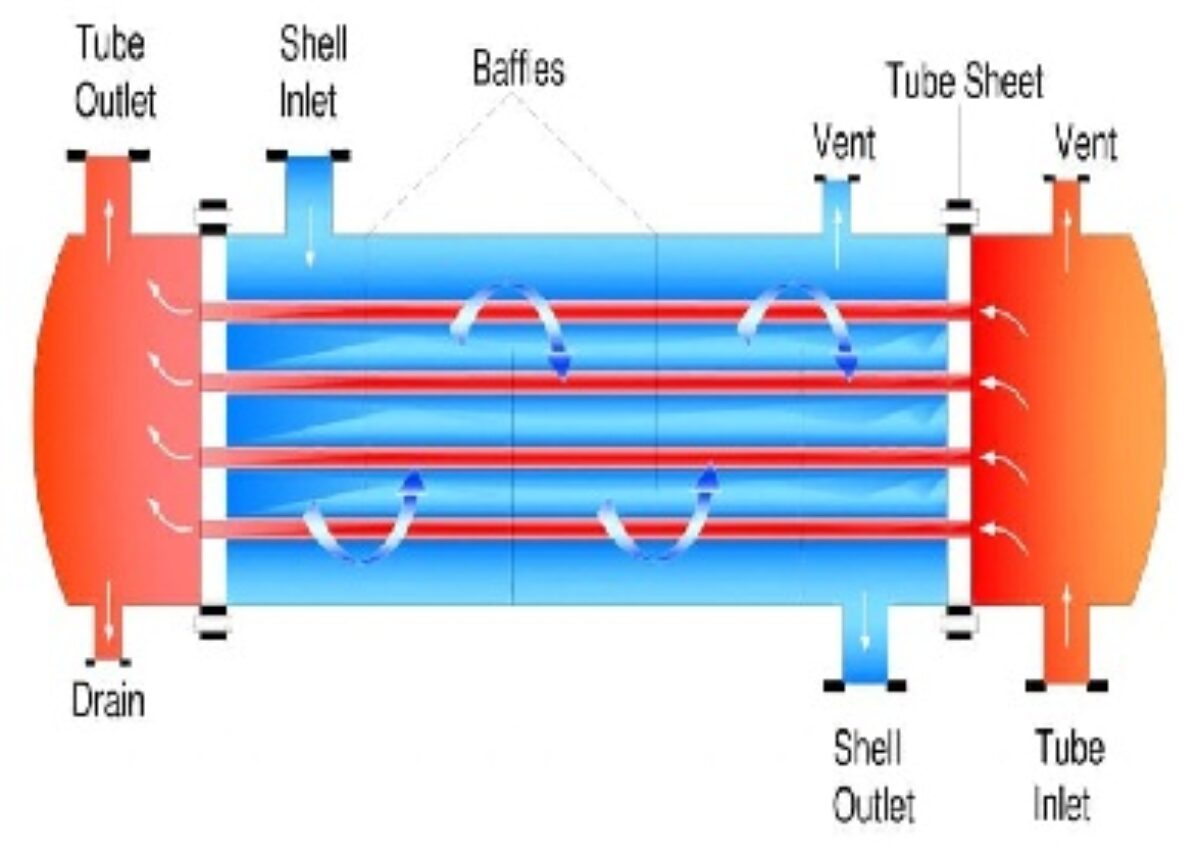

Baffles are also installed during assembly. These components guide the flow of the shell-side fluid, enhancing heat transfer efficiency while minimizing pressure drop. The entire assembly process must be conducted with precision to avoid any potential leaks or inefficiencies.

What Finishing Processes Are Essential for Quality Heat Exchangers?

Once assembled, the heat exchanger undergoes finishing processes. This often includes surface treatment, such as passivation or coating, to enhance corrosion resistance and longevity. Additionally, the unit may undergo hydrostatic testing to verify that there are no leaks and that it can withstand the specified operating pressures.

Finishing also involves cleaning the unit to remove any contaminants that may have been introduced during manufacturing. This step is vital, especially for applications in the petrochemical or food industries, where cleanliness is paramount.

What Quality Assurance Measures Are Implemented in Shell and Tube Heat Exchanger Production?

Quality assurance (QA) is integral to the manufacturing of shell and tube heat exchangers. A robust QA process ensures that every unit meets international standards and customer expectations.

Which International Standards Are Relevant for Quality Assurance?

Manufacturers often adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system. This certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications such as CE marking, which indicates compliance with European health, safety, and environmental protection standards, and API (American Petroleum Institute) standards for petroleum and petrochemical applications are crucial.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the forming, assembly, and finishing stages. This includes dimensional checks and visual inspections for welding quality.

-

Final Quality Control (FQC): After assembly, the completed unit undergoes comprehensive testing, including pressure testing and performance evaluation, to ensure it meets all operational specifications.

What Common Testing Methods Are Used for Quality Verification?

Several testing methods are commonly employed to verify the quality of shell and tube heat exchangers:

- Hydrostatic Testing: This is performed to check for leaks and ensure the unit can withstand the specified pressure.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or radiographic testing are utilized to detect internal flaws without damaging the unit.

- Performance Testing: This assesses the heat exchanger’s efficiency in transferring heat under specified conditions, ensuring it meets performance benchmarks.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to ensure the quality of their suppliers can take several proactive steps.

What Should Buyers Look for in Supplier Audits and Reports?

Prospective buyers should request detailed quality assurance reports from manufacturers. This includes documentation of certifications, testing results, and compliance with relevant standards. Furthermore, conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures.

Buyers should also inquire about the manufacturer’s history with previous clients and any third-party inspections that have been conducted.

What Are the QC Certification Nuances for International Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification is essential. Different regions may have varying requirements for certifications and compliance.

Illustrative image related to diagram of shell and tube heat exchanger

For instance, European buyers may prioritize CE marking, while buyers in South America might focus on local compliance standards. Understanding these requirements can help buyers select suppliers who not only meet international standards but also local regulations, ensuring a smooth procurement process.

Conclusion

Investing in a shell and tube heat exchanger requires a thorough understanding of the manufacturing processes and quality assurance measures involved. By focusing on material preparation, forming, assembly, and finishing, and by ensuring that suppliers adhere to recognized international standards, B2B buyers can make informed decisions that will lead to successful procurement and operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diagram of shell and tube heat exchanger’

Introduction

This guide serves as a practical sourcing checklist for B2B buyers seeking to procure diagrams of shell and tube heat exchangers. Understanding the critical components and specifications of these systems is essential for ensuring optimal performance, compliance with industry standards, and overall project success.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of your procurement process. Consider factors such as the intended application, operating temperatures, pressures, and fluid types. This step is crucial as it will guide you in selecting a heat exchanger that meets your operational needs while ensuring efficiency and safety.

Step 2: Research Applicable Standards and Regulations

Familiarize yourself with the relevant standards that govern shell and tube heat exchangers, such as TEMA (Tubular Exchanger Manufacturers Association) guidelines. Compliance with these standards ensures that the equipment will perform reliably and safely in your specific industrial context. Be aware of regional variations in standards, especially if sourcing from international suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, certifications, and case studies to assess their expertise in manufacturing shell and tube heat exchangers. It’s also beneficial to seek references from clients in similar industries or geographical regions to gauge their reliability and service quality.

Illustrative image related to diagram of shell and tube heat exchanger

Step 4: Review Supplier Capabilities and Technologies

Investigate the technological capabilities of potential suppliers, including their design software, manufacturing processes, and quality control measures. Look for suppliers who utilize advanced technologies that ensure precise manufacturing and the ability to customize designs to meet your specifications. This will enhance the reliability and performance of the heat exchangers.

Step 5: Request Detailed Proposals and Diagrams

Solicit detailed proposals from shortlisted suppliers, including comprehensive diagrams of their heat exchanger designs. These diagrams should illustrate key components such as tube bundles, headers, and baffles. Analyzing these diagrams will help you understand the supplier’s design approach and identify any potential issues before procurement.

Step 6: Conduct Cost-Benefit Analysis

Once you have received proposals, perform a cost-benefit analysis to compare the pricing structures against the value offered by each supplier. Consider not only the initial costs but also long-term factors such as maintenance, energy efficiency, and potential downtime. A lower upfront cost may not always equate to the best overall value.

Step 7: Verify Post-Sale Support and Warranty Terms

Before finalizing your purchase, confirm the supplier’s post-sale support and warranty terms. Ensure they provide adequate training, installation assistance, and ongoing maintenance options. A robust support structure is vital for minimizing operational disruptions and ensuring the longevity of your heat exchanger investment.

Following this checklist will equip you with the necessary insights to make informed decisions when sourcing diagrams of shell and tube heat exchangers, ultimately leading to successful project outcomes.

Illustrative image related to diagram of shell and tube heat exchanger

Comprehensive Cost and Pricing Analysis for diagram of shell and tube heat exchanger Sourcing

What Are the Key Cost Components in Sourcing Shell and Tube Heat Exchangers?

When sourcing a shell and tube heat exchanger, understanding the cost structure is crucial. The main cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials include carbon steel, stainless steel, and specialized alloys for high-temperature or corrosive environments. The type of fluid and operating conditions will dictate material selection, which can lead to price variances.

-

Labor: Labor costs encompass both manufacturing and assembly. Skilled labor is often required for the precision needed in constructing heat exchangers, especially for custom specifications. The location of production facilities can affect labor costs due to regional wage differences.

-

Manufacturing Overhead: This includes costs related to plant operations, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate these costs, but they can vary widely depending on the supplier’s capabilities.

-

Tooling: The initial costs for tooling can be significant, particularly for custom designs. These costs may be amortized over larger production runs, impacting the per-unit price.

-

Quality Control (QC): Given the critical role of heat exchangers in various industries, robust QC measures are essential. This includes testing, inspections, and certifications, which contribute to overall costs but ensure reliability and performance.

-

Logistics: Transportation and handling costs can vary based on the distance from the manufacturing site to the buyer. International shipping, customs duties, and insurance should also be considered, especially for buyers in Africa, South America, and the Middle East.

-

Margin: Suppliers typically include a margin that reflects their business model and market position. This can vary based on competition and demand.

How Do Price Influencers Affect Shell and Tube Heat Exchanger Costs?

Several factors can influence pricing:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Suppliers may offer price breaks for larger orders, which can be a strategic advantage for international buyers.

-

Specifications and Customization: Custom designs or specifications may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Materials and Quality: The quality of materials can significantly affect price. Certifications (e.g., ASME, TEMA) that ensure compliance with industry standards can also lead to higher costs but are essential for safety and performance.

-

Supplier Factors: The supplier’s reputation, experience, and geographical location can impact pricing. Established suppliers may charge a premium for their expertise and reliability.

-

Incoterms: Understanding the terms of shipment is vital. Different Incoterms can influence the total cost by determining who is responsible for shipping, insurance, and customs duties.

What Tips Can Help International Buyers Optimize Their Sourcing Costs?

International buyers should consider the following strategies to enhance cost-efficiency:

-

Negotiation: Building a strong relationship with suppliers can open avenues for negotiation. Discussing long-term partnerships may lead to better pricing structures.

-

Total Cost of Ownership (TCO): Beyond initial purchase price, consider maintenance, operational efficiency, and lifespan when evaluating costs. A higher upfront investment in quality materials may yield lower long-term operational costs.

-

Pricing Nuances for International Markets: Buyers from regions like Africa, South America, and the Middle East should be aware of local market conditions, including currency fluctuations and import tariffs, which can affect pricing. Engaging local representatives may provide insights into market dynamics and help navigate these complexities.

What Should Buyers Remember About Pricing and Sourcing?

While indicative prices can serve as a guideline, actual costs will vary based on the aforementioned factors. It is essential to request detailed quotes that outline all components of the price. This clarity will aid in making informed decisions and optimizing sourcing strategies for shell and tube heat exchangers.

Alternatives Analysis: Comparing diagram of shell and tube heat exchanger With Other Solutions

Exploring Alternatives to Shell and Tube Heat Exchangers

In the realm of heat exchange systems, the shell and tube heat exchanger stands out due to its versatility and efficiency. However, various alternative solutions are available that may better suit specific industrial needs or constraints. Understanding these alternatives can empower B2B buyers to make informed decisions that align with their operational requirements.

| Comparison Aspect | Diagram of Shell and Tube Heat Exchanger | Plate Heat Exchanger | Air-Cooled Heat Exchanger |

|---|---|---|---|

| Performance | High efficiency in heat transfer; handles high pressures and temperatures | Excellent thermal efficiency, compact design; lower pressure handling | Ideal for cooling applications; no need for cooling water |

| Cost | Moderate initial investment; cost-effective for large-scale operations | Lower initial cost; more economical for small to medium applications | Generally lower operational costs; high initial investment |

| Ease of Implementation | Requires skilled labor for installation; complex piping | Simple installation; compact design allows for flexible placement | Installation is straightforward; minimal space requirements |

| Maintenance | Regular maintenance required; potential for fouling | Easier to clean and maintain; less prone to fouling | Low maintenance; periodic checks needed |

| Best Use Case | Petrochemical, power generation industries | Food processing, HVAC systems | Power plants, oil and gas industries |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Plate Heat Exchangers?

Plate heat exchangers are designed with a series of thin, corrugated plates that create channels for fluid flow. This design promotes excellent heat transfer efficiency, making them suitable for applications in the food processing and HVAC sectors. Their compact nature allows for installation in tight spaces, making them ideal for facilities with limited room. However, they typically have a lower pressure handling capacity compared to shell and tube exchangers, which may limit their use in high-pressure applications. Additionally, while they are easier to clean, they may require more frequent maintenance if the fluids involved are prone to fouling.

How Do Air-Cooled Heat Exchangers Compare?

Air-cooled heat exchangers utilize air as the cooling medium, eliminating the need for water. This makes them particularly advantageous in water-scarce regions, such as parts of Africa and the Middle East. They are often used in power plants and oil and gas industries, where their operational costs can be lower due to reduced water usage. However, air-cooled systems generally require a higher initial investment and can be less efficient than liquid-cooled alternatives in certain applications. Their maintenance is relatively low, but they still require periodic inspections to ensure optimal performance.

Conclusion: Which Heat Exchanger Solution Is Right for Your Business?

Choosing the right heat exchanger involves a careful assessment of your specific operational needs, including temperature and pressure requirements, space constraints, and budget considerations. While shell and tube heat exchangers offer significant advantages for heavy-duty applications, alternatives like plate and air-cooled heat exchangers may provide better value in certain contexts, such as lower pressure environments or water-limited areas. B2B buyers should evaluate these options based on their unique operational goals, ensuring that the selected solution not only meets their immediate needs but also aligns with their long-term strategic objectives.

Essential Technical Properties and Trade Terminology for diagram of shell and tube heat exchanger

What Are the Key Technical Properties of Shell and Tube Heat Exchangers?

When considering a shell and tube heat exchanger for your operations, understanding its critical specifications is vital for ensuring optimal performance and compatibility with your processes. Here are some essential properties to consider:

-

Material Grade

The material used for the shell and tubes significantly impacts durability, corrosion resistance, and thermal conductivity. Common materials include stainless steel (e.g., 304 or 316 grades) for their excellent corrosion resistance and carbon steel for cost-effectiveness in less corrosive environments. Selecting the right material is crucial for meeting industry standards and ensuring longevity, especially in harsh operating conditions prevalent in sectors like petrochemicals and power generation. -

Design Pressure and Temperature Ratings

Each heat exchanger is rated for specific pressure and temperature limits. This specification is critical as it dictates the operational envelope within which the heat exchanger can safely function. Exceeding these limits can lead to catastrophic failures. Understanding these ratings helps buyers ensure that the equipment can handle the thermal and pressure demands of their application, thus preventing costly downtimes. -

Tolerances and Clearances

Manufacturing tolerances for dimensions and clearances between components are crucial for ensuring proper fit and function. In shell and tube exchangers, the tolerances can affect heat transfer efficiency and fluid flow. Tight tolerances are essential for high-performance applications, while more relaxed tolerances may suffice in less critical scenarios. Buyers must assess these specifications to ensure compatibility with existing systems and to maintain operational efficiency. -

Heat Transfer Area

The total heat transfer area is a key specification that influences the exchanger’s capacity to transfer heat between fluids. It is determined by the number of tubes, their diameter, and the overall design. A larger heat transfer area allows for better efficiency but may also lead to higher costs and larger footprints. Buyers should evaluate the heat transfer area relative to their operational needs to optimize performance and cost. -

Flow Arrangement

Shell and tube heat exchangers can be designed with various flow arrangements, including counterflow, parallel flow, and crossflow. Each configuration affects the heat exchange efficiency and pressure drop across the system. Understanding these arrangements helps buyers select the most suitable design for their specific application, enhancing energy efficiency and reducing operational costs.

What Common Trade Terms Should B2B Buyers Know?

In addition to technical specifications, familiarizing yourself with industry jargon is essential for effective communication and negotiation. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand name. In the heat exchanger market, knowing the OEM can assure buyers of the quality and reliability of the equipment they are purchasing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ helps buyers gauge the feasibility of purchasing equipment based on their operational needs and budget constraints. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This process is crucial for B2B buyers to compare costs and ensure they are receiving competitive pricing for their heat exchanger needs. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding Incoterms is vital for B2B buyers, as they clarify shipping costs, insurance, and risk transfer, thus preventing misunderstandings in cross-border transactions. -

TEMA Standards

The Tubular Exchanger Manufacturers Association (TEMA) sets design and construction standards for shell and tube heat exchangers. Familiarity with these standards helps buyers ensure that their equipment meets industry best practices for safety and performance.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right shell and tube heat exchanger tailored to their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the diagram of shell and tube heat exchanger Sector

What Are the Key Market Trends Influencing the Shell and Tube Heat Exchanger Sector?

The shell and tube heat exchanger market is witnessing robust growth driven by increasing industrialization and energy efficiency demands. The petrochemical and power generation sectors are the primary consumers, with emerging markets in Africa, South America, and the Middle East showing significant potential. In regions like Brazil and Germany, a surge in manufacturing activities and a push towards energy-efficient technologies are further propelling market expansion.

Additionally, the adoption of advanced manufacturing technologies, such as 3D printing and automation, is streamlining production processes, enhancing design flexibility, and reducing lead times. B2B buyers are increasingly interested in suppliers who can offer customized solutions that meet specific thermal performance requirements and comply with international standards such as TEMA.

Another noteworthy trend is the shift towards predictive maintenance technologies. By leveraging IoT and data analytics, companies can monitor the performance of heat exchangers in real-time, facilitating timely interventions and reducing downtime. As a result, buyers are prioritizing suppliers who integrate smart technologies into their offerings to enhance operational reliability and efficiency.

How Is Sustainability Shaping Sourcing Practices in the Shell and Tube Heat Exchanger Market?

Sustainability is becoming a cornerstone of sourcing strategies in the shell and tube heat exchanger sector. As environmental regulations tighten globally, B2B buyers are increasingly focusing on the environmental impact of their supply chains. Heat exchangers, which often utilize materials like stainless steel and carbon steel, can have significant ecological footprints during production and disposal phases.

To address these concerns, buyers are seeking suppliers who prioritize ethical sourcing and sustainable practices. This includes the use of recycled materials, eco-friendly manufacturing processes, and certifications like ISO 14001, which reflects a commitment to effective environmental management systems. Furthermore, the demand for “green” certifications is rising, with buyers preferring products that minimize energy consumption and promote circular economy principles.

The emphasis on sustainability is not just about compliance; it also presents a competitive advantage. Companies that can demonstrate their commitment to sustainable practices often gain favor with environmentally conscious clients, enhancing brand reputation and customer loyalty.

What Historical Developments Have Influenced the Shell and Tube Heat Exchanger Market?

The shell and tube heat exchanger has a rich history that dates back to the early 19th century, initially gaining traction in the steam and power generation industries. Over the decades, advancements in materials science and engineering have significantly improved the efficiency and reliability of these systems. The introduction of TEMA standards in the mid-20th century established a common nomenclature and design criteria, facilitating international trade and standardization.

In recent years, the evolution of digital technologies has transformed the industry landscape, enabling enhanced design capabilities and operational efficiencies. As global energy demands continue to rise, the shell and tube heat exchanger remains a critical component across various sectors, adapting to meet the challenges of modern industrial applications while maintaining its foundational principles of thermal exchange efficiency.

In summary, understanding the current market dynamics, sustainability imperatives, and historical context is essential for B2B buyers looking to navigate the complexities of sourcing shell and tube heat exchangers effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of diagram of shell and tube heat exchanger

-

How do I select the right shell and tube heat exchanger for my application?

To choose the right shell and tube heat exchanger, assess your specific requirements such as the type of fluids, temperature and pressure ranges, and the desired heat transfer efficiency. Consider the configuration (fixed tubesheet, U-tube, or floating head) based on maintenance needs and thermal expansion allowances. Review industry standards like TEMA for guidance on design specifications that suit your operational conditions. Engaging with a knowledgeable supplier can also provide insights tailored to your unique application. -

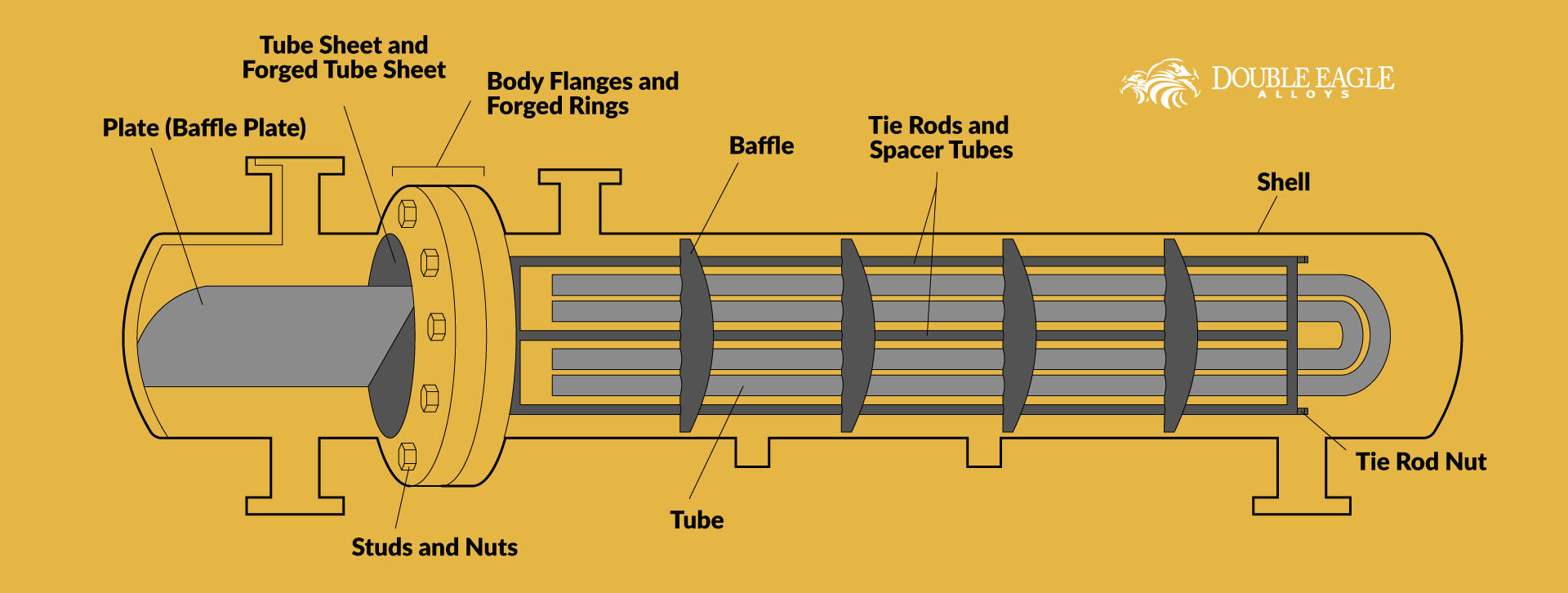

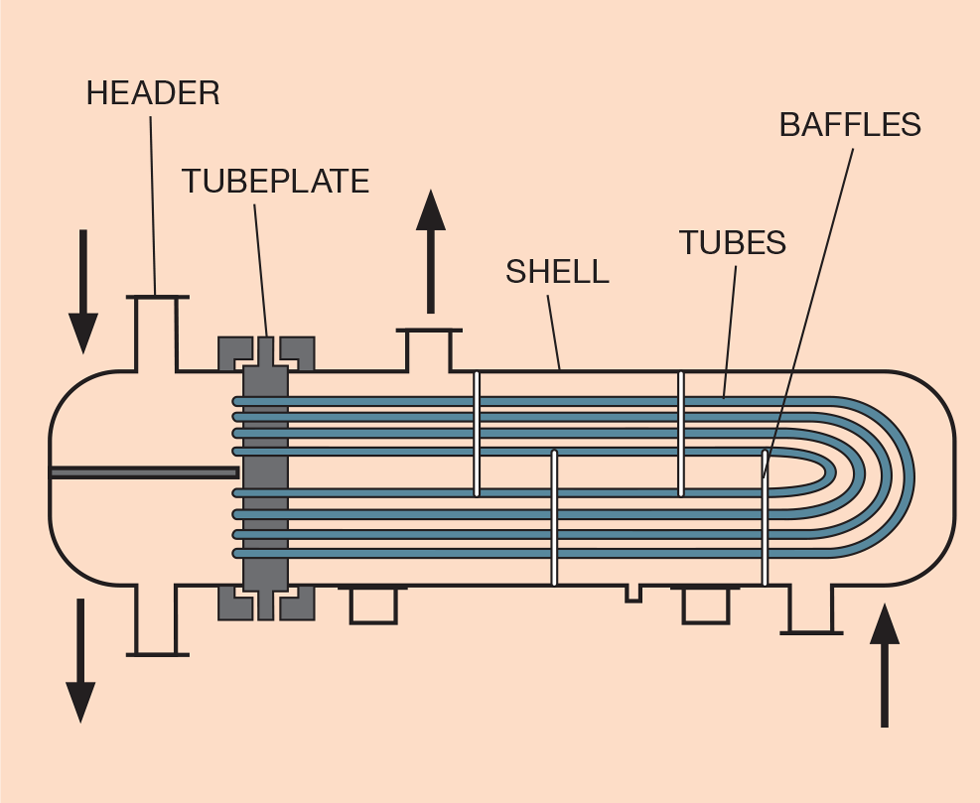

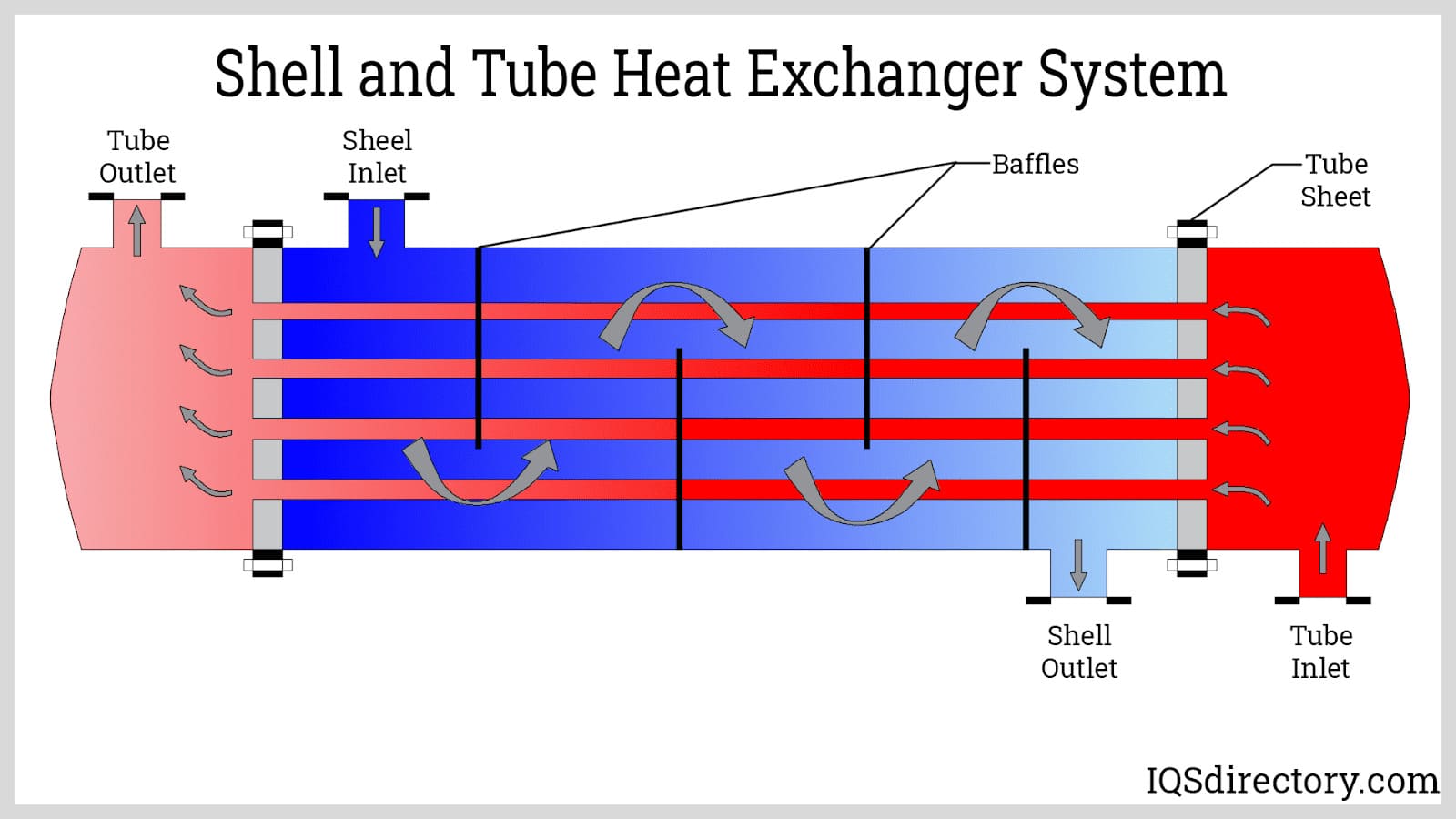

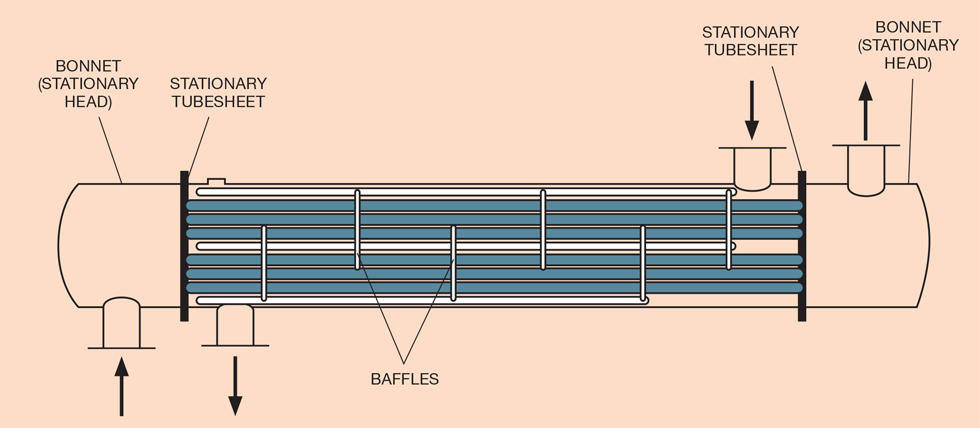

What are the key components to look for in a shell and tube heat exchanger diagram?

A comprehensive diagram should clearly depict the shell, tube bundle, front and rear headers, and any baffles or tie rods. Pay attention to the flow arrangement—parallel, counterflow, or crossflow—as this influences performance. Ensure the diagram includes labels for all parts, as understanding their function is crucial for maintenance and troubleshooting. A well-detailed diagram aids in comprehending how the heat exchanger operates within your system. -

What are the common standards for shell and tube heat exchangers?

Most shell and tube heat exchangers adhere to the Tubular Exchanger Manufacturers Association (TEMA) standards, which provide guidelines on design, materials, and testing methods. Additionally, industry-specific standards may apply, such as ASME for pressure vessels or API for the petroleum industry. Familiarizing yourself with these standards ensures compliance and reliability in your equipment selection. -

What customization options are available for shell and tube heat exchangers?

Customization options for shell and tube heat exchangers can include material selection (e.g., stainless steel, carbon steel), specific dimensions, and specialized configurations tailored to unique operational needs. Suppliers often provide options for additional features such as enhanced surface treatments for improved efficiency or customized baffle designs to optimize flow. Discussing your requirements with manufacturers can lead to tailored solutions that enhance performance and longevity. -

What minimum order quantities (MOQ) should I expect when sourcing shell and tube heat exchangers?

Minimum order quantities for shell and tube heat exchangers can vary significantly based on the manufacturer, the complexity of the design, and the materials used. Generally, MOQs may range from a single unit for standard designs to larger quantities for custom or specialized units. It’s advisable to communicate your needs clearly with suppliers to negotiate acceptable MOQs that align with your project timelines and budgets. -

What payment terms are typically offered by suppliers of shell and tube heat exchangers?

Payment terms for shell and tube heat exchangers typically vary by supplier and may include options such as upfront payment, partial payment upon order confirmation, and balance upon delivery. Some suppliers may offer financing or credit terms for larger orders. Always clarify payment terms during negotiations to ensure they meet your financial planning and cash flow needs. -

How can I ensure quality assurance when sourcing shell and tube heat exchangers?

To ensure quality assurance, select suppliers who adhere to recognized quality management systems, such as ISO 9001. Request documentation on testing procedures, certifications, and quality control processes used during manufacturing. Additionally, consider third-party inspections or audits to verify compliance with industry standards. Establishing clear communication with the supplier regarding your quality expectations is crucial for a successful partnership. -

What logistics considerations should I keep in mind when importing shell and tube heat exchangers?

When importing shell and tube heat exchangers, consider factors such as shipping methods, customs regulations, and delivery timelines. Engage with logistics providers experienced in handling industrial equipment to ensure safe and timely transport. Additionally, verify that the supplier can assist with necessary documentation for customs clearance. Planning for potential delays and understanding import duties or tariffs can help mitigate risks associated with international trade.

Top 6 Diagram Of Shell And Tube Heat Exchanger Manufacturers & Suppliers List

1. Thermopedia – Shell and Tube Heat Exchangers

Domain: thermopedia.com

Registered: 2007 (18 years)

Introduction: Shell and Tube Heat Exchangers are popular due to their flexibility for a wide range of pressures and temperatures. They are categorized into two main types: petrochemical industry exchangers (TEMA standards) and power industry exchangers (feedwater heaters, condensers). Key components include: Front Header (fluid entry), Rear Header (fluid exit), Tube Bundle (tubes, tube sheets, baffles), and She…

2. The Chemical Engineer – Shell and Tube Heat Exchangers

Domain: thechemicalengineer.com

Registered: 2014 (11 years)

Introduction: Shell and tube heat exchangers consist of tubes secured in tubeplates within a cylindrical shell. Key design considerations include: 1. Ensuring adequate convective coefficients by maintaining fluid velocities. 2. Allowing for differential thermal expansion between tubes and shell. 3. Accounting for fouling films that reduce heat transfer efficiency. Tube diameters are typically 3/4 inch or 1 inch…

3. IQS Directory – Shell and Tube Heat Exchangers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Shell and tube heat exchangers (STHE) are devices engineered for thermal energy exchange, consisting of a cylindrical shell housing numerous parallel tubes. Key components include the shell, tubes, channel, tube sheet, baffles, and nozzles. They are designed for efficiency and versatility, suitable for various applications in industries such as chemical processing, oil refineries, and power genera…

4. Heat Exchangers – Key Components Overview

Domain: slideshare.net

Registered: 2006 (19 years)

Introduction: This document provides a comprehensive overview of various components and design considerations in shell and tube heat exchangers, detailing the functions and specifications of the shell, baffles, tube sheets, and other parts. It highlights the importance of factors such as shell diameter, baffle types, tube sizes, and flow velocities in optimizing heat transfer efficiency while managing costs. Ad…

5. TubeTech – Shell and Tube Heat Exchangers

Domain: tubetech.com

Registered: 1997 (28 years)

Introduction: Shell and tube heat exchangers are devices where two working fluids exchange heat using tubes housed within a cylindrical shell. They are compact, simple in construction and maintenance, and effective for heat exchange across a wide temperature and pressure range. Types include: 1. Shell and Tube Heat Exchanger Bundle – removable tube bundles for maintenance. 2. Fixed Tube Heat Exchanger – tube sh…

6. Pinterest – Shell and Tube Heat Exchanger

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: The shell and tube heat exchanger is the most common industrial heat exchanger type. It transfers heat from one fluid to another without fluid contact, through the heat exchanger tube wall. The tube side fluid passes through the inside of the tubes, while the shell side fluid passes through the shell, outside of the tubes. The tubes are held in place in a tube bundle, with tube sheets that also se…

Strategic Sourcing Conclusion and Outlook for diagram of shell and tube heat exchanger

What Are the Key Takeaways for Strategic Sourcing of Shell and Tube Heat Exchangers?

In the competitive landscape of industrial operations, the strategic sourcing of shell and tube heat exchangers offers significant advantages. Understanding the diverse configurations—such as fixed tubesheet, U-tube, and floating head designs—enables buyers to select the most appropriate technology for their specific applications. This knowledge not only optimizes operational efficiency but also reduces long-term maintenance costs.

Moreover, adherence to recognized standards like TEMA ensures that the selected heat exchangers meet international quality benchmarks, crucial for organizations operating in regions like Africa, South America, the Middle East, and Europe. Investing in high-quality heat exchangers enhances reliability and performance, contributing to overall business sustainability.

How Can International Buyers Leverage This Knowledge?

As you consider your sourcing strategies, prioritize suppliers who demonstrate a thorough understanding of the technical specifications and regional regulations. Engage with manufacturers who offer customizable solutions tailored to your operational needs.

Looking ahead, the demand for efficient thermal management solutions will continue to rise globally. By strategically sourcing shell and tube heat exchangers, businesses can not only meet current operational challenges but also position themselves for future growth and innovation. Take action today—evaluate your suppliers and ensure your operations are equipped with the best technology available.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.